Page 1

V

V

ideo Recorder

RX180

User Manual

Issue 3 – 03/03 US1I-6228

Page 2

Issue 3 – 03/03 US1I-6228

Page 3

Copyright, Notices, and Trademarks

© Copyright 2000 by Honeywell Inc.

While this information is presented in good faith and believed to be

accurate, Honeywell disclaims the implied warranties of

merchantability and fitness for a particular purpose and makes no

express warranties except as may be stated in its written agreement

with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or

consequential damages. The information and specifications in this

document are subject to change without notice.

This document was prepared using Information Mapping

methodologies and formatting principles.

Information Mapping is a trademark of Information Mapping Inc.

Windows is a registered trademark of Microsoft Inc.

Modbus is a registered trademark of MODICON, Inc.

The omission of a name from this list is not to be interpreted that the

name is not a trademark.

Video Recorder – User Manual i

Page 4

About This Document

Abstract

This manual describes the installation, configuration, operation, and maintenance of the Video

Recorder.

Warranty

The device described herein has been manufactured and tested for correct operation and is warranted

as follows: The Video Recorder carries an 18 month warranty. This warranty includes immediate

technical assistance and replacement of the defective part or instrument, if necessary.

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact your local sales office of warranty information. If warranted goods are returned to

Honeywell during the period of coverage, Honeywell will repair of replace without charge those items it

finds defective. The foregoing is Buyer’s sole remedy and is in lieu of all other warranties,

expressed or implied, including those of merchantability and fitness for a particular purpose.

Specifications may change without notice. The information we supply is believed to be accurate and

reliable as of printing. However, we assume no responsibility for its use. While we provide application

assistance personally, through our literature and the Honeywell website, it is up to the customer to

determine the suitability of the product in the application.

Contacts

If you encounter any problem with your video recorder, please contact your nearest Sales Office. (See

the address list at the end of this manual).

An engineer will discuss your problem with you. Please have your complete model

number, serial number, and software version available. Model number and serial

number are located on the chassis nameplate. Software version can be viewed under

Maintenance mode; see Section 8 of this manual.

If it is determined that a hardware problem exists, a replacement instrument or part will be shipped

with instructions for returning the defective unit. Do not return your instrument without authorization

from your Sales Office or until the replacement has been received.

ii Video Recorder – User Manual

Page 5

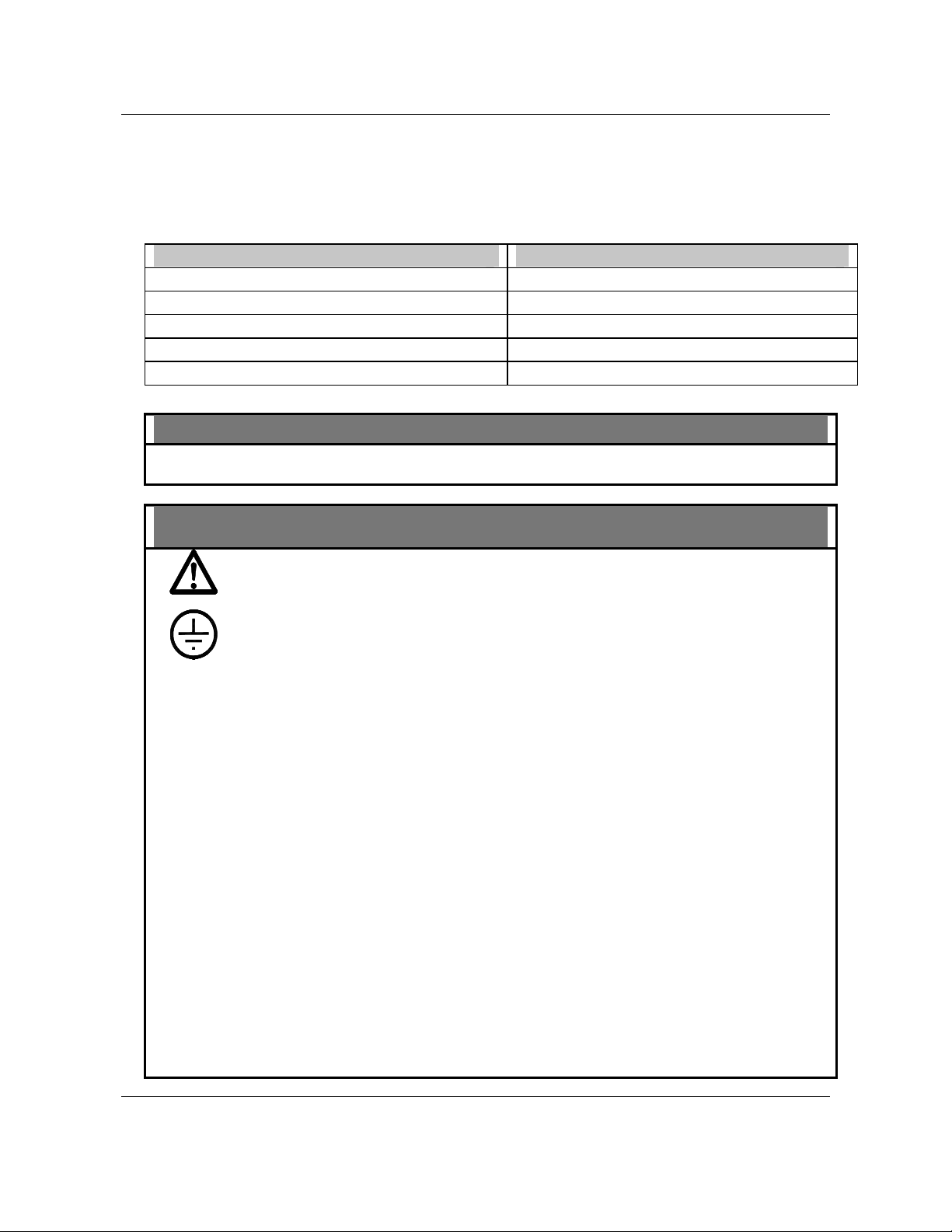

Symbol Meanings

Symbol What it means

Protective ground terminal. Provided for connection of the protective earth green (green

or green/yellow) supply system conductor.

Functional ground terminal. Used for non-safety purposes such as noise immunity

improvement.

WARNING. Risk of electric shock. This symbol warns the user of a potential shock

hazard where voltages greater than 30 Vrms, 42.4 Vpeak, or 60 Vdc may be accessible.

Failure to comply with these instructions could result in death or serious injury

CAUTION. When this symbol appears on the product, see the user manual for more

information. This symbol appears next to the required information in the manual.

Failure to comply with these instructions may result in product damage.

CE conformity

This product conforms with the protection requirements of the following European Council

Directives: 89/336/EEC, the EMC directive, and 73/23/EEC, the low voltage directive. Do not

assume this product conforms with any other “CE Mark” Directive(s).

Attention

The emission limits of EN 50081-2 are designed to provide reasonable protection against harmful

interference when this equipment is operated in an industrial environment. Operation of this

equipment in a residential area may cause harmful interference. This equipment generates, uses, and

can radiate radio frequency energy and may cause interference to radio and television reception when

the equipment is used closer than 30 meters to the antenna(e). In special cases, when highly

susceptible apparatus is used in close proximity, the user may have to employ additional mitigating

measures to further reduce the electromagnetic emissions of this equipment.

Video Recorder – User Manual iii

Page 6

iv Video Recorder – User Manual

Page 7

Contents

1. INTRODUCTION................................................................................................................ 1

1.1 Video Recorder Overview ...............................................................................................................1

1.2 Specifications..................................................................................................................................2

1.3 Model Selection Guide..................................................................................................................12

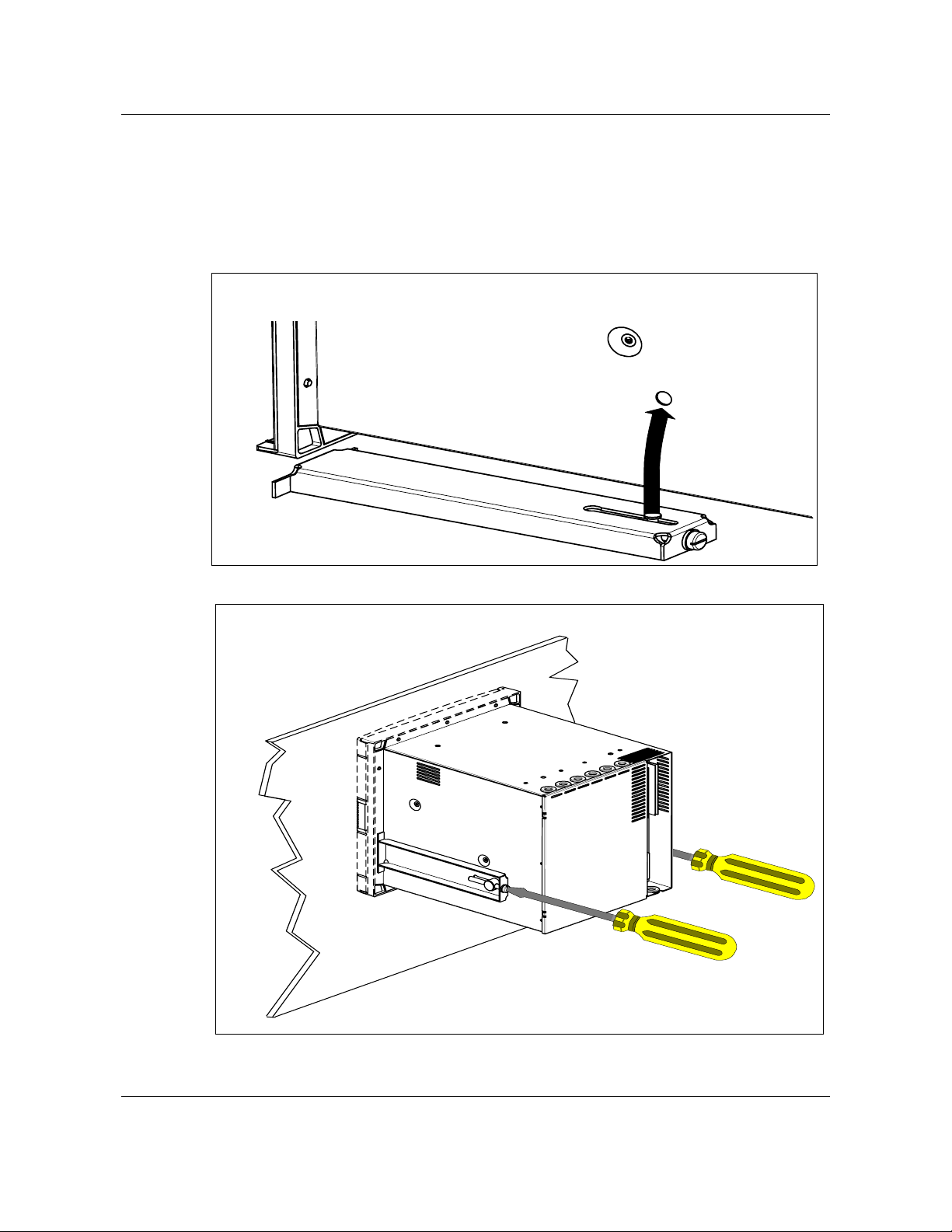

2 INSTALLATION.................................................................................................................13

2.1 Warning.........................................................................................................................................13

2.2 Unpacking .....................................................................................................................................14

2.3 Panel mounting the video recorder...............................................................................................15

2.4 Wiring the video recorder..............................................................................................................17

2.5 Terminal connections....................................................................................................................19

3. PROGRAMMING AND OPERATING CONCEPTS AND PROCEDURES........................ 35

3.1 Overview .......................................................................................................................................35

3.2 Quick Start Programming..............................................................................................................35

3.3 Modes of Operation.......................................................................................................................35

3.4 Menu Navigation...........................................................................................................................36

3.5 Button functions ............................................................................................................................41

3.6 Text Entry From External Sources................................................................................................45

3.7 Connecting a keyboard or a barcode reader ................................................................................47

3.8 Installing and removing a floppy disk............................................................................................48

3.9 Definition of Function Blocks.........................................................................................................49

3.10 Components of function blocks.....................................................................................................51

3.11 How to program input parameters ................................................................................................55

3.12 How to program function block parameters..................................................................................58

3.13 How to program a simple configuration ........................................................................................58

3.14 How to program common configurations......................................................................................60

3.15 Data Storage.................................................................................................................................74

4. HOW TO PROGRAM FUNCTION BLOCKS AND FEATURES........................................ 79

4.1 Overview .......................................................................................................................................79

4.2 Programming tips..........................................................................................................................80

4.3 The Program mode menu.............................................................................................................81

4.4 Frequently used programming prompts........................................................................................82

4.5 Set Mode.......................................................................................................................................83

Video Recorder – User Manual v

Page 8

4. HOW TO PROGRAM FUNCTION BLOCKS AND FEATURES..........CONT………………….

4.6 Enter Labels..................................................................................................................................84

4.7 Program Analog Inputs .................................................................................................................87

4.8 Program Control Loops.................................................................................................................90

4.9 Program Analog Outputs ............................................................................................................101

4.10 Program Discrete Inputs .............................................................................................................104

4.11 Program Discrete Outputs ..........................................................................................................105

4.12 Program Calculated Values ........................................................................................................105

4.13 Program Alarms..........................................................................................................................143

4.14 Program Totalizers......................................................................................................................144

4.15 Program Profiles .........................................................................................................................146

4.16 Program Constants.....................................................................................................................147

4.17 Copy Block..................................................................................................................................149

4.18 Program Displays........................................................................................................................150

4.19 Enable Features..........................................................................................................................159

4.20 Program Security ........................................................................................................................160

4.21 Serial Communications ...............................................................................................................161

4.22 Set Clock.....................................................................................................................................162

4.23 Load/Store Configuration............................................................................................................163

4.24 Scan Rate ...................................................................................................................................164

4.25 Select Language .........................................................................................................................165

4.26 Data Storage...............................................................................................................................166

5. SETPOINT PROFILER................................................................................................... 175

5.1 Overview of the Setpoint Profiler ................................................................................................175

5.2 Components of a profile..............................................................................................................178

5.3 Parameters that control a profile’s execution..............................................................................185

5.4 How to set up a profiler ...............................................................................................................189

5.5 How to load and run a profiler.....................................................................................................197

6. ONLINE OPERATIONS USING PRIMARY DISPLAYS.................................................. 209

6.1 Overview .....................................................................................................................................209

6.2 Interacting With Primary Displays...............................................................................................210

6.3 Display Messages and Symbols.................................................................................................217

vi Video Recorder – User Manual

Page 9

7. ONLINE OPERATION USING MENU S.......................................................................... 221

7.1 Overview .....................................................................................................................................221

7.2 Data Storage...............................................................................................................................222

7.3 Access Summaries .....................................................................................................................228

7.4 Data Entry...................................................................................................................................232

7.5 Setpoint Profiles..........................................................................................................................234

7.6 Tune Loop...................................................................................................................................235

7.7 Set Mode.....................................................................................................................................242

7.8 Review Programming..................................................................................................................242

8. MAINTENANCE............................................................................................................. 243

8.1 Overview .....................................................................................................................................243

8.2 Routine Maintenance..................................................................................................................245

8.3 Set Mode.....................................................................................................................................245

8.4 Calibrate Analog Inputs...............................................................................................................245

8.5 AO MODULE calibration .............................................................................................................246

8.6 Off-line Diagnostics.....................................................................................................................247

8.7 Database Services......................................................................................................................248

8.8 Reset Unit ...................................................................................................................................248

8.9 Product Information.....................................................................................................................248

8.10 Mains Frequency.........................................................................................................................248

8.11 Warm Start Time.........................................................................................................................249

8.12 Demo...........................................................................................................................................250

9. DIAGNOSTIC AND ERROR MESSAGES...................................................................... 251

9.1 Diagnostic Messages..................................................................................................................251

9.2 Loop Error Indicators...................................................................................................................254

9.3 Error Messages...........................................................................................................................255

10. PARTS ........................................................................................................................... 259

APPENDIX A........................................................................................................................ 263

SAFETY................................................................................................................................ 265

INDEX................................................................................................................................... 277

SALES AND SERVICE

Video Recorder – User Manual vii

Page 10

TABLES

Table 1-1 Specifications........................................................................................................................................ 2

Table 1-2 Analog Input Accuracy--Linear types .................................................................................................. 7

Table 1-3 Analog Input --Non-linear types........................................................................................................... 8

Table 1-4 Standards ............................................................................................................................................... 9

Table 2-1 Universal Analog Input Board Specifications..................................................................................... 22

Table 3-1 Button Functions................................................................................................................................. 41

Table 3-2 QWERTY Key Equivalents................................................................................................................ 45

Table 3-3 Function Block Types........................................................................................................................... 50

Table 3-4 Function Block Parameter Designators .............................................................................................. 53

Table 3-5 Output Code Connection Procedure................................................................................... ................ 55

Table 3-6 Example Number Selection Procedure Using Front Panel Buttons..................................................... 57

Table 3-7 Example Programming Discrete Input Parameter with a Number....................................................... 57

Table 3-8 Example Function Block Parameter Selection Procedure ................................................................... 58

Table 3-9 Function Block Configuration Procedure........................................................................................... 58

Table 3-10 Example Configuration Procedure..................................................................................................... 59

Table 3-11 Data Storage File Extensions............................................................................................................. 75

Table 4-1 Program Mode Menu........................................................................................................................... 81

Table 4-2 Frequently Used Programming Prompts............................................................................................. 82

Table 4-3 Labels for Function Blocks................................................................................................................. 85

Table 4-4 Other Labels ....................................................................................................................................... 86

Table 4-5 Analog Input Algorithm Selection...................................................................................................... 87

Table 4-6 Standard Algorithm Prompts.............................................................................................................. 87

Table 4-7 Custom Algorithm Prompts................................................................................................................ 89

Table 4-8 Loop Characteristics........................................................................................................................... 90

Table 4-9 Control Loop Type Menu Selections.................................................................................................. 92

Table 4-10 Loop Prompts.................................................................................................................................... 94

Table 4-11 Analog Output Types....................................................................................................................... 101

Table 4-12 Prompts For Analog Output Types.................................................................................................. 101

Table 4-13 Analog Output Prompts.................................................................................................................. 102

Table 4-14 Discrete Input Prompts................................................................................................................... 104

Table 4-15 Discrete Output Prompts................................................................................................................. 105

Table 4-16 CV Types......................................................................................................................................... 106

Table 4-17 Peak Picking Prompts..................................................................................................................... 107

Table 4-18 Signal Select Prompts..................................................................................................................... 108

Table 4-19 Compare Prompts............................................................................................................................ 109

Table 4-20 Compare’s Condition Type and Condition Time Prompts ............................................................. 111

Table 4-21 Counter Prompts............................................................................................................................. 113

Table 4-22 Math Prompts..................................................................................................................................114

Table 4-23 Free Form Math Prompts................................................................................................................ 115

Table 4-24 Free Form Math Functions ............................................................................................................. 116

Table 4-25 Logic Prompts................................................................................................................................. 117

Table 4-26 Logic Operators.............................................................................................................................. 118

Table 4-27 Free Form Logic Prompts ............................................................................................................... 119

Table 4-28 (A OR B) AND C............................................................................................................................ 120

Table 4-29 Results of Logic Equation Using Iteration....................................................................................... 120

Table 4-30 Inverter Prompts............................................................................................................................. 120

Table 4-31 BCD Prompts.................................................................................................................................. 121

Table 4-32 How Profiles Are Saved In Memory .............................................................................................. 122

Table 4-33 Function Generator Prompts........................................................................................................... 123

Table 4-34 Interval Timer Prompts.................................................................................................................... 125

Table 4-35 Periodic Timer Prompts.................................................................................................................. 127

viii Video Recorder – User Manual

Page 11

Table 4-36 Set Up Timer Prompts..................................................................................................................... 127

Table 4-37 Mass Flow Prompts........................................................................................................................ 128

Table 4-38 Carbon Prompts.............................................................................................................................. 129

Table 4-39 Relative Humidity Prompts ........................................................................................................... 131

Table 4-40 F

Sterilization Prompts.................................................................................................................. 132

0

Table 4-41 Advanced Splitter Prompts............................................................................................................... 134

Table 4-42 Standard Splitter Prompts................................................................................................................. 135

Table 4-43 Scaling Prompts.............................................................................................................................. 136

Table 4-44 Signal Clamp Prompts.................................................................................................................... 137

Table 4-45 1 Point Block Average Prompts...................................................................................................... 138

Table 4-46 Rolling Average Prompts................................................................................................................ 139

Table 4-47 Multiple Average Prompts.............................................................................................................. 140

Table 4-48 CEMS Block Average Prompts...................................................................................................... 141

Table 4-49 CEMS Rolling Average Prompts.................................................................................................... 142

Table 4-50 Alarm Prompts................................................................................................................................ 143

Table 4-51 Totalizer Prompts.............................................................................................................................. 145

Table 4-52 Constant Prompts............................................................................................................................ 147

Table 4-53 Copy Block Prompts........................................................................................................................ 149

Table 4-54 Display Setup Procedure................................................................................................................. 152

Table 4-55 Set Up Trend 1 Prompts ................................................................................................................. 152

Table 4-56 Paper Chart Speed Equivalents to Time Base Selections ............................................................... 153

Table 4-57 1 trend group live buffer size............................................................................................................ 154

Table 4-58 2 trend group live buffer size........................................................................................................... 154

Table 4-59 4 trend group live buffer size........................................................................................................... 155

Table 4-60 Set Up Bar Graph 1 Prompts.......................................................................................................... 156

Table 4-61 Set Up Panel Display Prompts........................................................................................................ 156

Table 4-62 Set Up Unit Data Display Prompts................................................................................................. 156

Table 4-63 Set Up Profile Display Prompts...................................................................................................... 156

Table 4-64 Assign Displays To Keys Prompts................................................................................................. 157

Table 4-65 Enable Features Prompts ................................................................................................................ 159

Table 4-66 Security Prompts.............................................................................................................................. 160

Table 4-67 Serial Communications Prompts ...................................................................................................... 161

Table 4-68 Set Clock Prompts.......................................................................................................................... 162

Table 4-69 Load/Store Config Files Prompts....................................................................................................163

Table 4-70 Suggested Scan Rates ...................................................................................................................... 164

Table 4-71 Data Storage Setup Procedure........................................................................................................ 166

Table 4-72 Prompts For Storage Setup Of Trends, Alarms, Events, Diagnostics............................................. 168

Table 4-73 Stored Events.................................................................................................................................. 169

Table 4-74 Unit Data Prompts.......................................................................................................................... 170

Table 4-75 Disk capacity Prompts.................................................................................................................... 172

Table 4-76 Disk Storage Capacity of LS120 or ZIP disk.................................................................................. 173

Table 4-77 Disk Storage Capacity for the 1.44 Mbyte Floppy Disk................................................................... 174

Table 5-1 Example of Segment Events............................................................................................................. 183

Table 5-2 Parameters That Control Profiler Execution..................................................................................... 185

Table 5-3 Program Profiler Prompts................................................................................................................. 190

Table 5-4 Setpoint Profiles Prompts................................................................................................................... 191

Table 5-5 Edit Profile Prompts ......................................................................................................................... 193

Table 5-6 Edit Segments Prompts..................................................................................................................... 196

Table 5-7 How Profiles Are Stored In Memory................................................................................................ 198

Table 5-8 Procedure To Load A Program From Memory Using Online Menu................................................. 199

Table 5-9 Procedure To Load A Program From Memory Using Point/Detail Menu......................................... 199

Table 5-10 How Profiles Are Stored On Disk.................................................................................................. 200

Table 5-11 Disk Program Capacity................................................................................................................... 200

Table 5-12 Procedure To Load A Program From Disk..................................................................................... 201

Video Recorder – User Manual ix

Page 12

Table 5-13 Profiler Starting Procedure............................................................................................................. 202

Table 5-14 Profiler Hold Procedure.................................................................................................................. 203

Table 5-15 Profiler Reset Procedure................................................................................................................. 203

Table 5-16 Profiler Advance Procedure............................................................................................................ 204

Table 5-17 Profiler Shutdown Procedure.......................................................................................................... 204

Table 5-18 Event Viewing Procedure............................................................................................................... 205

Table 5-19 Details Viewing Procedure............................................................................................................. 205

Table 5-20 Summary Viewing Procedure......................................................................................................... 206

Table 5-21 Segment Editing Procedure ............................................................................................................ 207

Table 6-1 Displays Accessed With Display Button.......................................................................................... 209

Table 6-2 Point/Detail Menu Prompts .............................................................................................................. 211

Table 6-3 Stop Panel_4 Display Rotation Procedure........................................................................................ 214

Table 6-4 Resume Panel_4 Display Rotation Procedure.................................................................................. 214

Table 6-5 Interacting With Loop Displays........................................................................................................ 216

Table 6-6 Messages and Symbols at Bottom of Display................................................................................... 218

Table 6-7 Messages and Symbols Elsewhere on Display.................................................................................. 219

Table 7-1 Online Main Menu............................................................................................................................. 221

Table 7-2 Floppy Disk Insertion/Removal Procedure....................................................................................... 222

Table 7-3 Disk Status......................................................................................................................................... 223

Table 7-4 Storage Start/Stop Controls .............................................................................................................. 225

Table 7-5 Data Storage Replay Procedure........................................................................................................ 226

Table 7-6 Alarm Acknowledgment Procedure................................................................................................... 229

Table 7-7 Diagnostic Acknowledgment Procedure............................................................................................ 230

Table 7-8 Delete All Diagnostics Procedure..................................................................................................... 231

Table 7-9 Tune Loop Prompts........................................................................................................................... 235

Table 7-10 Stages Of Pretune ............................................................................................................................ 238

Table 7-11 Pretune STOPPED Prompts............................................................................................................. 238

Table 7-12 Pretune IDENTIFYING & CALCULATING Prompts.................................................................. 239

Table 7-13 Pretune COMPLETE Prompts......................................................................................................... 240

Table 7-14 Pretune Abort Messages .................................................................................................................. 241

Table 8-1 Maintenance Mode Menu................................................................................................................. 243

Table 8-2 Calibrate Analog Output Procedure................................................................................................... 247

Table 8-3 Offline Diagnostic Prompts............................................................................................................... 247

Table 8-4 Database Services Prompts............................................................................................................... 248

Table 9-1 Diagnostic Error Messages................................................................................................................ 251

Table 9-2 Internal Error Messages.................................................................................................................... 252

Table 9-3 Abnormal Loop Conditions And Indicators...................................................................................... 254

Table 9-4 Error Messages................................................................................................................................. 255

Table 10-1 Parts................................................................................................................................................ 259

Table A-1 Security Bypass Procedure ...............................................................................................................263

x Video Recorder – User Manual

Page 13

Figures

Figure 1-1 Video Recorder .............................................................................................................................. 1

Figure 1-2 Video Recorder Model Number................................................................................................. 10

Figure 2-1 AI Board Terminal Block Connections...................................................................................... 22

Figure 2-2 10 ohm Copper Connections ..................................................................................................... 22

Figure 2-3 DI Board Terminal Block Connections...................................................................................... 23

Figure 2-4 AO Board Terminal Block Connections.................................................................................... 24

Figure 2-5 DO Board Terminal Block Connections.................................................................................... 25

Figure 2-6 DO Board Relay Contact Setting............................................................................................... 26

Figure 2-7 RS232 wiring configur at ion......................................................................................................... 29

Figure 2-8 RS422 wiring configuration ........................................................................................................ 30

Figure 2-9 RS422 Interface Connections.................................................................................................... 30

Figure 2-10 RS485 wiring configurat ion ........................................................................................................ 32

Figure 2-11 Interface connector ..................................................................................................................... 32

Figure 3-1 Video Recorder Front Door Buttons.......................................................................................... 36

Figure 3-2 Menu Navigation Guide Through ON LINE, PROGRAM, and MAINTENANCE mode

MAIN MENUs............................................................................................................................... 37

Figure 3-3 ON LINE mode MAIN MENU ...................................................................................................... 38

Figure 3-4 PROGRAM mode MAIN MENU.................................................................................................. 39

Figure 3-5 MAINTENANCE mode MAIN MENU ......................................................................................... 40

Figure 3-6 Connection of a keyboard or a barcode reader........................................................................ 47

Figure 3-7 Alarm 1 Function Block Components......................................................................................... 51

Figure 3-8 Example Input Parameter Connection....................................................................................... 55

Figure 3-9 Function Block Connection Format............................................................................................ 56

Figure 3-10 Example Configuration................................................................................................................ 59

Figure 3-11 Control Of Furnace Zone Temperature With 4-20 mA (CAT) Control Signal ..................... 60

Figure 3-12 Basic Function Blocks Required For Control Configuration Of Figure 3-11........................ 61

Figure 3-13 Labeling Each Function Block’s Name And Major Inputs And Outputs............................... 62

Figure 3-14 Labels For Internal Function Bl oc k Parameters...................................................................... 63

Figure 3-15 Interconnections Between Function Blocks............................................................................. 62

Figure 3-16 Complete Function Block Diagram Of Figure 3-11................................................................. 64

Figure 3-17 Control Of Wastewater pH Using A Time Proportioning (DAT) Control Signal .................. 65

Figure 3-18 Function Block Diagram Of Figure 3-17................................................................................... 65

Figure 3-19 Temperature Control Of Water Using Split Output Or Duplex Control ................................ 66

Figure 3-20 Function Block Diagram Of Figure 3-19................................................................................... 67

Figure 3-21 Temperature Control Of An Oil Heated Chemical Reaction Chamber ................................ 68

Figure 3-22 Function Block Diagram Of The Cascade Control Strategy.................................................. 69

Figure 3-23 Example Set Point Prof ile........................................................................................................... 70

Figure 3-24 Function Block Diagram Of Set Point Profile Control Of Figure 3-16 .................................. 71

Figure 3-25 Discrete Inputs Controlling Execution Of Set Point Profiler Function Block ....................... 71

Figure 3-26 Up To 16 Discrete Events May Be Programmed Per Step Of A Set Point Profile............. 72

Figure 3-27 Tying A Profile Function Block’s Discrete Events With Discrete Output Hardware ........... 73

Figure 3-28 Categories of Stored Data.......................................................................................................... 74

Figure 4-1 Function Block Configuration of a Typical Ratio Control Loop ....................................... 100

Figure 4-2 Compare Signal Flow...................................................................................................... 109

Figure 4-3 Compare’s Greater Than Result, With Hysteresis.......................................................... 110

Figure 4-4 Math CV Feedback Programming................................................................................... 114

Figure 4-5 Logic Signal Flow............................................................................................................ 116

Figure 4-6 Free Form Logic Signal Flow.......................................................................................... 119

Figure 4-7 Function Generator Curve .............................................................................................. 123

Video Recorder – User Manual xi

Page 14

Figure 4-8 Function Generator Configuration For Valve Characterization....................................... 124

Figure 4-9 Function Generator Configuration For Input Signal Characterization............................. 124

Figure 4-10 Periodic Timer................................................................................................................. 126

Figure 4-11 Typical Carbon Potential Control Configuration.............................................................. 130

Figure 4-12 Advanced Splitter (Default Outputs) .............................................................................. 133

Figure 4-13 Heat/Cool Configuration................................................................................................. 133

Figure 4-14 Standard Split Output Function...................................................................................... 135

Figure 4-15 CEMS Rolling Average .................................................................................................. 142

Figure 4-16 Example of Constant Destination................................................................................... 148

Figure 4-17 Displays Accessible by the Display Buttons (continued)............................................... 150

Figure 5-1 Setpoint Profiler Schematic..................................................................................................... 176

Figure 5-2 Single and Multi-phase Profiles.............................................................................................. 177

Figure 5-3 Value/Duration Ramp Type..................................................................................................... 178

Figure 5-4 Time Ramp Type ...................................................................................................................... 179

Figure 5-5 Rate Ramp Type....................................................................................................................... 180

Figure 5-6 External Ramp Type................................................................................................................. 181

Figure 5-7 Guaranteed Soak and Hysteresis ........................................................................................... 182

Figure 5-8 Activating Events In Mid-Segment .......................................................................................... 183

Figure 5-9 Example Of A Segment Loop .................................................................................................. 184

Figure 5-10 Hot Start...................................................................................................................................... 186

Figure 5-11 Fast Forward............................................................................................................................... 187

Figure 5-12 Shutdown .................................................................................................................................... 188

Figure 5-13 Allowable and Non-All o wable Pro gram Storage................................................................... 192

Figure 5-14 Buttons ........................................................................................................................................ 197

Figure 6-1 Changing Profile Batch Tag ..................................................................................................... 210

Figure 6-2 Horizontal and Vertical Trend Displays .................................................................................. 211

Figure 6-3 Vertical Trend at 2X Zoom........................................................................................................ 213

Figure 6-4 Panel Display.............................................................................................................................. 214

Figure 6-5 Loop Displays............................................................................................................................. 215

Figure 6-6 Example of Primary Display..................................................................................................... 217

Figure 7-1 Data Storage Status Display.................................................................................................... 226

Figure 7-2 Control Loop Tuning Display.................................................................................................... 237

Figure 8-1 AO Module Jumper ST1 ............................................................................................................ 246

xii Video Recorder – User Manual

Page 15

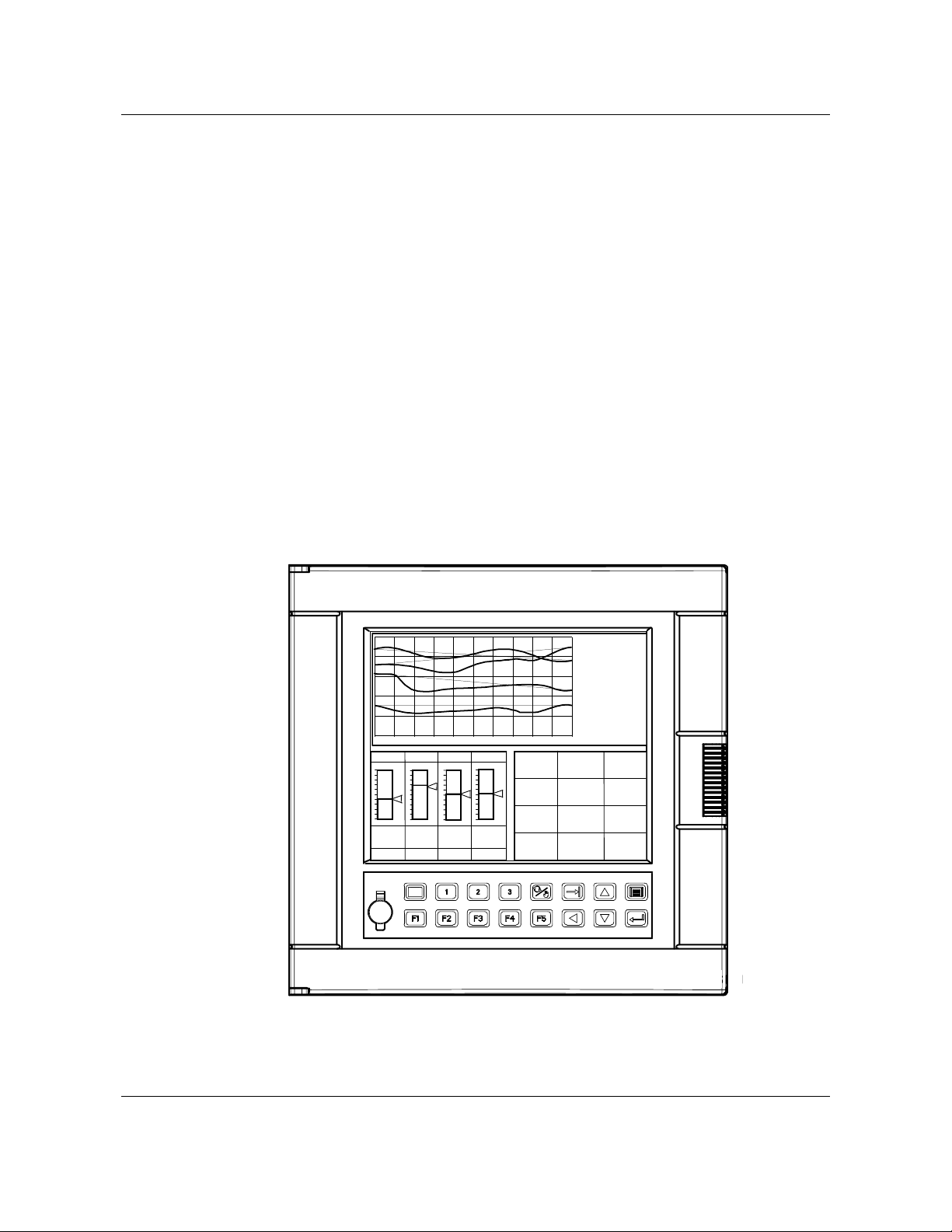

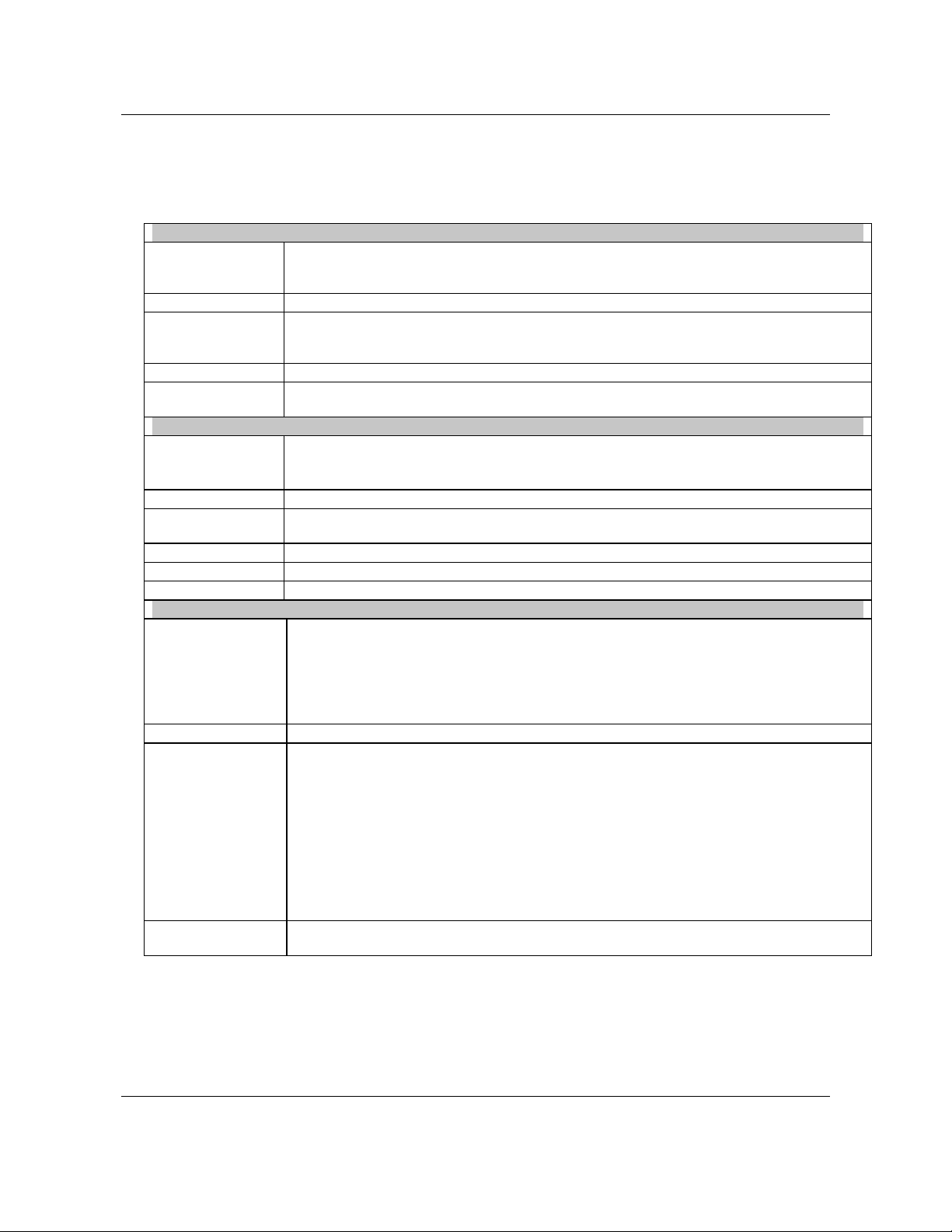

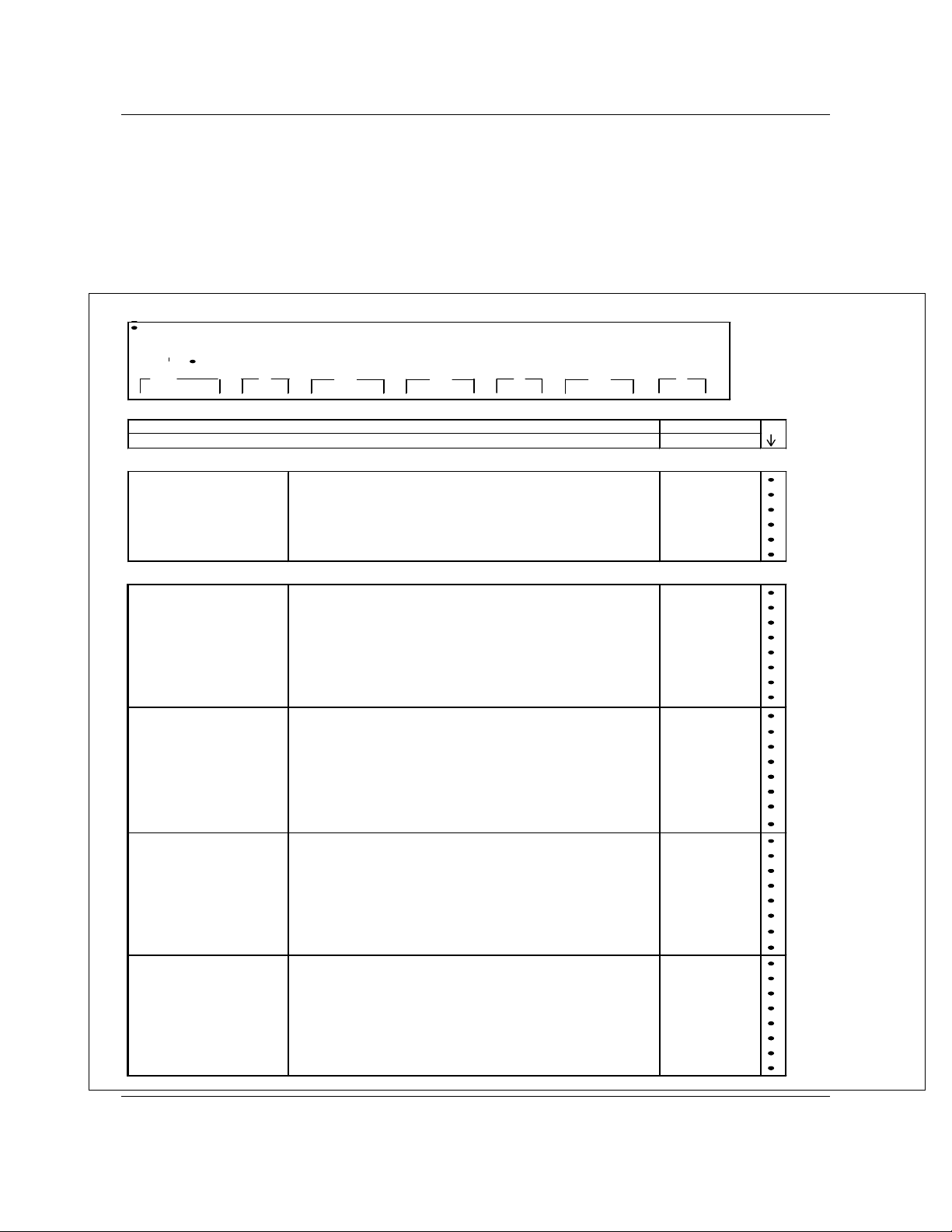

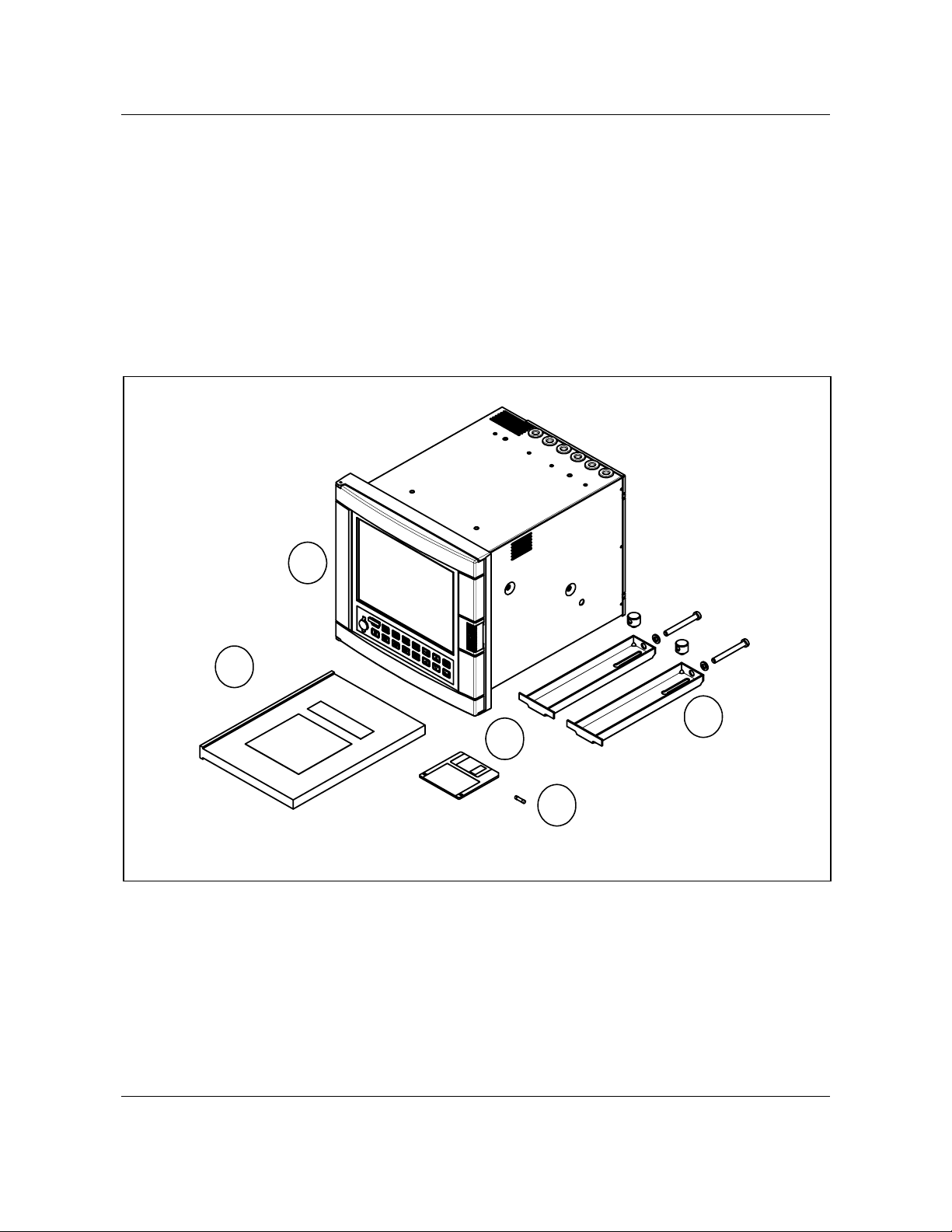

1.1 Video Recorder Overview

The Video Recorder (Figure 1-1) is part of the family of multi-point, multi-function video products. The

instrument offers display versatility, flexible data storage, up to 8 control loops, each one can run its own

profile, and advanced math functions. This integration of several functions eliminates the need for

multiple devices and reduces installation costs.

The instrument features a high resolution LCD display which is capable of displaying up to 16 different

colors simultaneously. The front door opens to allow access to a 100MB ZIP disk drive. A mini DIN

connector can be used on the front door for connecting a PC keyboard or barcode reader for easy

labeling of parameters. Barcode reader also stores Event Records to disk.

Sixteen panel keys control all functions of the instrument, including configuration.

The instrument will accept thermocouple, RTD, pyrometer, milliamp, millivolt and volt inputs. Up to eight

analog outputs are available for retransmission or control. Data can be directed to various display

formats, stored on floppy disk, or read from an optional serial communications link. Analog and discrete

data can be displayed in trend or tabular format. Viewed data can be either “live” (real time inputs) or

historical (retrieved from disk).

Flexible modular design and several options make this instrument adaptable to nearly any industrial

application.

Introduction

1. Introduction

TAG1

TAG7

VALUE1

VALUE7

TAG2

TAG8

VALUE2

VALUE8

TAG3

TAG9

VALUE3

VALUE9

TAG4

TAG10

VALUE4

VALUE10

TAG5

TAG11

VALUE5

VALUE11

TAG6

TAG12

VALUE6

VALUE12

LP1

1000.00

0.00

PV 405.00

SP 405.00

OUT 15 .0

A S1

LP2

1500.00

1054.00

1040.00

10.0

M S2

0.00

LP3

1200.00

623.00

622.00

5.0

M S1

LP4

ZONE1

ZONE2

2400.00

123.45

DEG F

ZONE4

123.45

DEG F

ZONE7

0.00

0.00

1266.00

1244.00

5.0

A S1

123.45

DEG F

ZONEA

123.45

DEG F

123.45

DEG C

ZONE5

123.45

DEG F

ZONE8

123.45

DEG C

ZONEB

123.45

DEG

ZONE3

123.45

DEG F

ZONE6

123.45

DEG C

ZONE9

123.45

DEG F

ZONEC

123.45

DEG F

Figure 1-1 Video Recorder

Video Recorder - User Manual 1

Page 16

Introduction

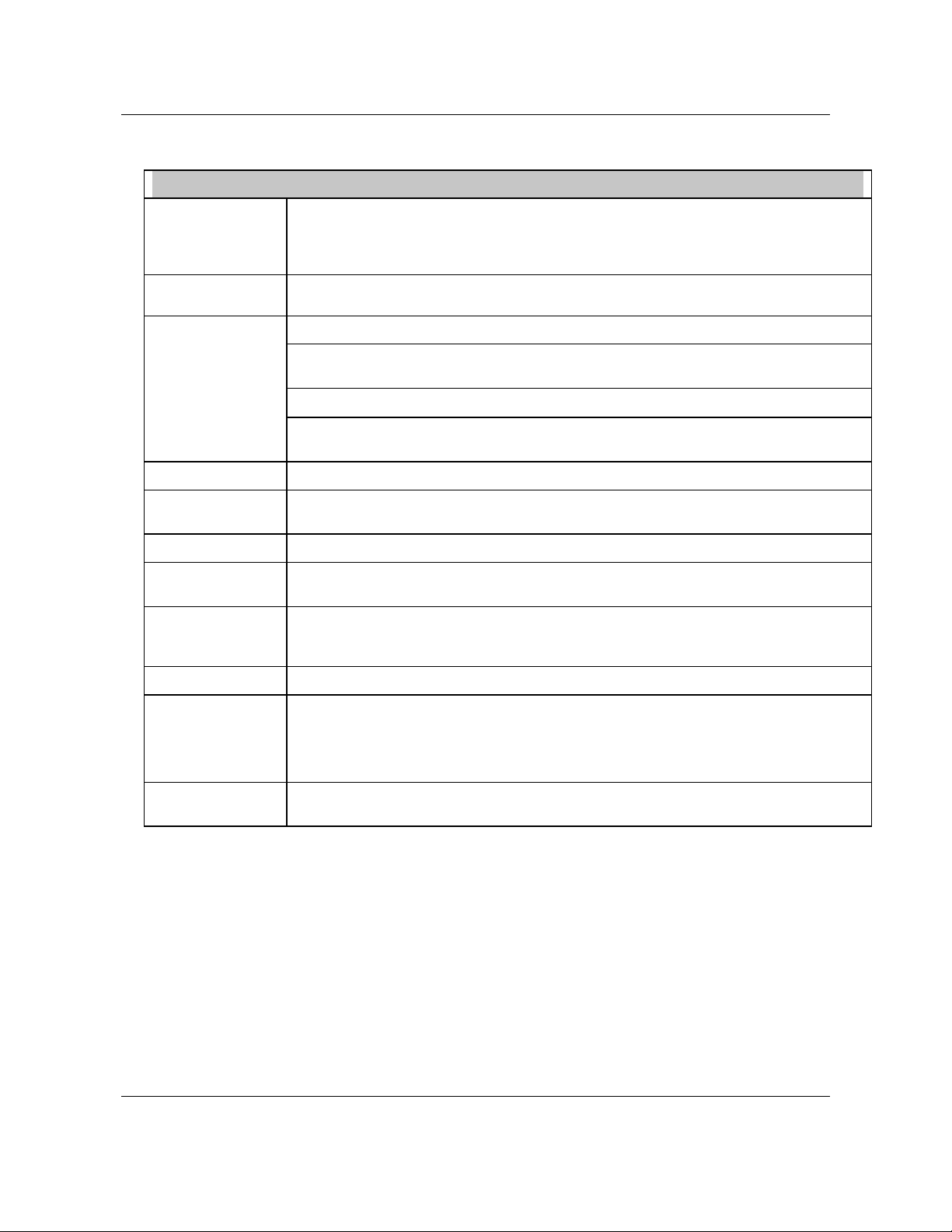

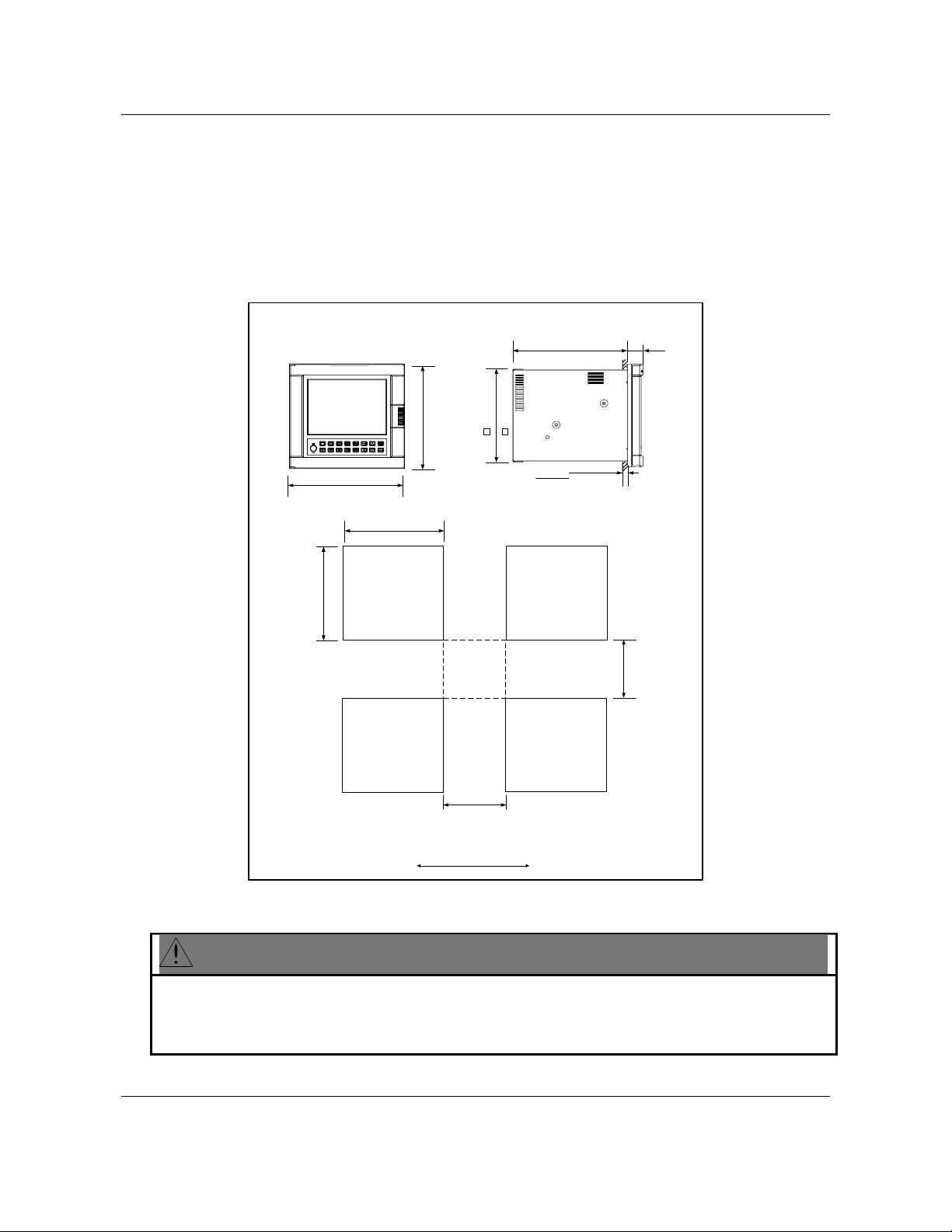

1.2 Specifications

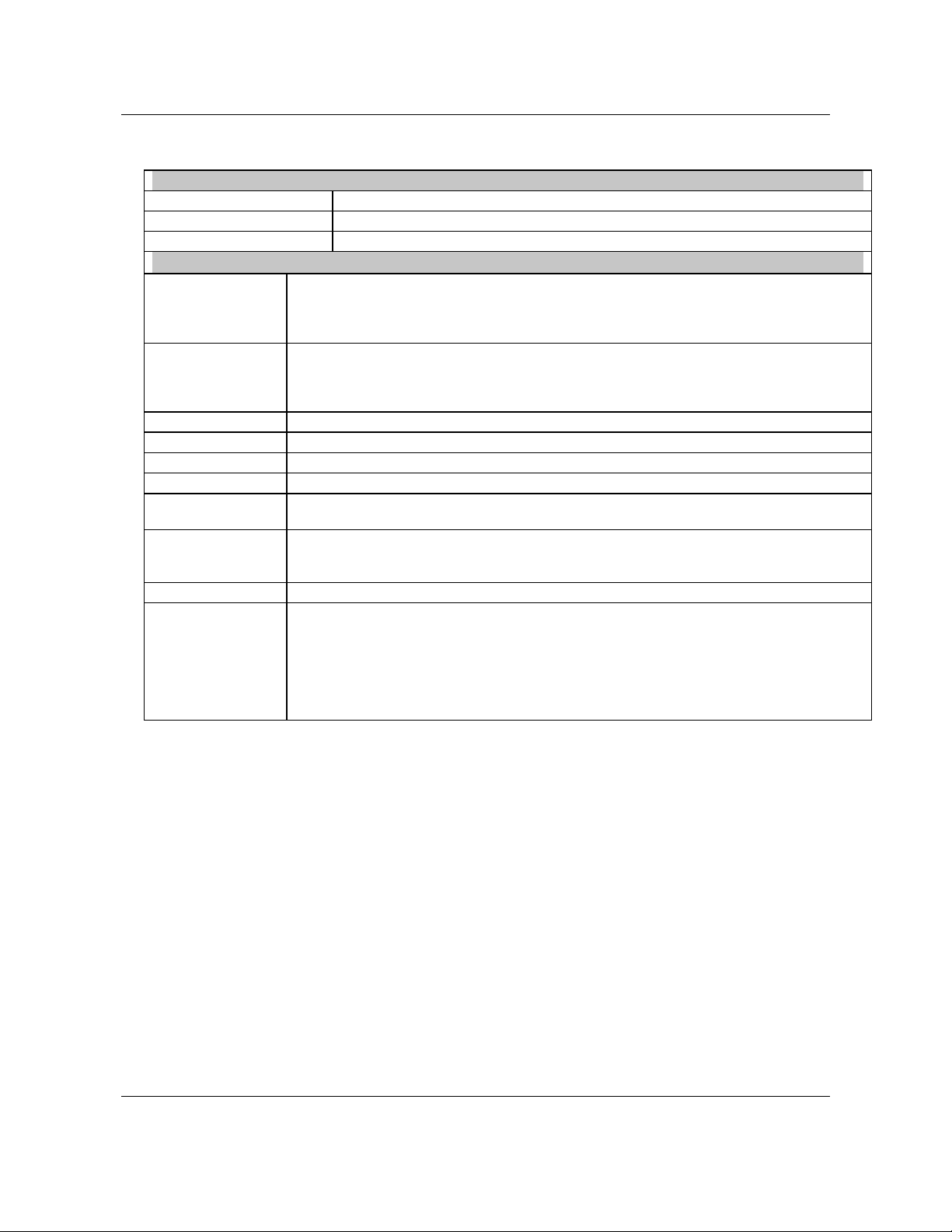

Table 1-1 Specifications

Physical

Enclosure Metal case and rugged die cast aluminium door and frame. High impact resistant

polycarbonate keypad and glass or polycarbonate window. IP55 rating (NEMA 3) from front

panel.

Mounting (Panel) 40 mm thickness (max.) (1,57")

Dimensions Compact size: 320 mm (12.60") depth

310 mm front face height x 317 mm width (12.21" x 12.48")

278 mm x 278 mm (10.95" x 10.95") cutout

Weight 14 kg, depending on configuration (30 lbs)

I/O Ports Standard PC keyboard Connector (6 pin mini DIN type) - on front panel. May be used to connect to a

QWERTY keyboard or to an ASCII Barcode Reader.

Environmental

Temperature

Altitude < 2000 meters

Installation

Category

Pollution Degree 2

Power Universal power supply, 100 to 240 Vac/dc, 100 VA max.

Fuse Rating 3.15 Amps, 250 Vac slow blow

Display

Keys 16 membrane switches.

Data Archiving

Setpoint

programmers

Operating: 5 to 40°C (41 to104°F).

Storage: -20 to 60°C (-4 to 158°F).

Relative Humidity: 10 to 90%, non-condensing at 40°C.

II

Attributes

Type: Color LCD active matrix.

Screen Size: 10.4" diagonal.

Resolution: 640 x 480 pixels.

Update Rate: 1 second.

Trend Timebase: 5 min. to 24 hrs/screen; 0.5 cm/hr to 154 cm/hr vertical (0.2"/hr to 61"/hr

vertical), 0.8 cm/hr to 250 cm/hr horizontal (0.3"/hr to 100"/hr horizontal).

Media: 100MB ZIP disk drive.

Data Types: Analog points, calculations, discrete status, alarms, diagnostics.

Trends: 4 max. (up to 12 points max. per trend)

Unit Data: 1 (up to 12 points, 10,000 records)

Alarm History: Up to 1600 records

Event History: Up to 1600 records

Diagnostic History: Up to 1600 records

Setpoint Programs: 224 maximum on LS120 floppy disk.

Storage Rate Range: 0.25 to 3600 sec.

Capacity: Automatically calculates storage time based on storage rate.

Up to 4

Video recorder – User Manual 2

Page 17

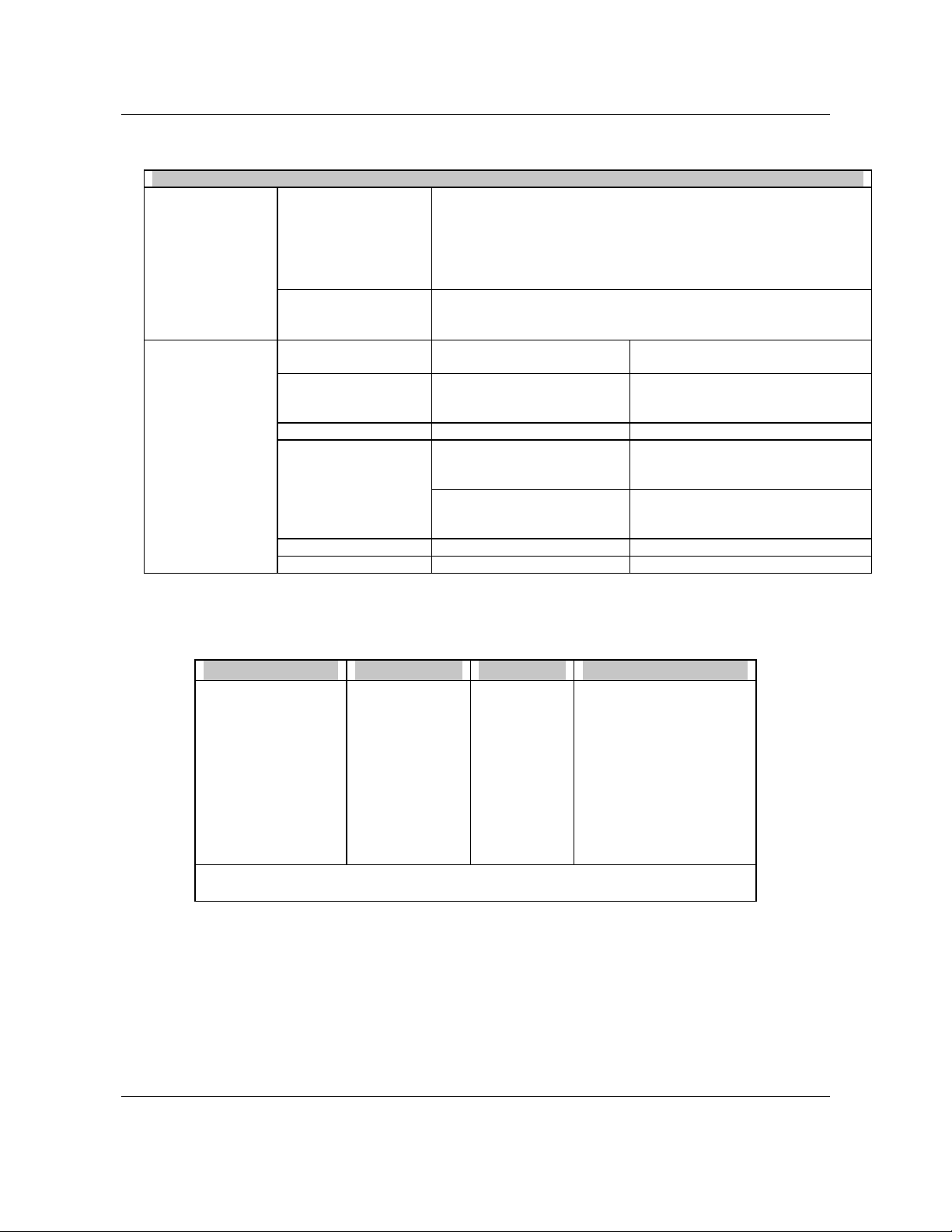

Table 1-1 Specifications (continued)

Program Capability

Introduction

Number of

Programs

Number of

Segments

Ramping Capability

Ramp Time Range

Soak

Soak time range

Program Cycling

Startup/Shutdown

Memory can store 96 programs for a single channel programmer, 48 programs for a dual

channel programmer, 32 programs for a three channel programmer, and 24 for a four

channel programmer. Programs can also be stored to floppy disk. Programmer has ability

to start a program at a predetermined time.

63 segments per profile

Ramp X - Ramp rate is set by specifying x degrees per second, per minute, or per hour.

Ramp T - Ramp rate is set by selecting the time to go from previous setpoint to next

setpoint in t time.

Ramp E - Ramp rate is set to increment by ∆SP for every pulse of a digital input.

Value Duration Ramp - Ramp rate is based on the start value of the ramp and the time

specified to reach the next soak start value.

0-9,999,999 hours, minutes, or seconds.

Guaranteed or non-guaranteed. Can be applied to ramp or soak segment or across entire

profile/program.

0-9,999,999 hours, minutes, or seconds.

Entire programs or portions of a program can be cycled up to 99 times. Loops can be

nested up to 4 deep.

Can be set up to use a predefined startup profile separate from the normal processing

programs. Shutdown profile can be attached to the end of a profile and can be jumped to

for emergency shutdown.

PV Hot Start

Batch Programming

Profile Events

Can start the profile at the point where the present PV value first intersects the profile.

1 to 255 Batch numbers. Batch number is assigned by the programmer and is incremented

automatically when batch is started.

Using a keyboard or bar code reader and the front keyboard connector, a batch can be

labeled with a name of up to 8 characters.

Up to 16 events can be defined in each segment of a profile. Each event’s state is

activated at the beginning of the segment and is held throughout the segment.

Video Recorder - User Manual 3

Page 18

Introduction

Table 1-1 Specifications (continued)

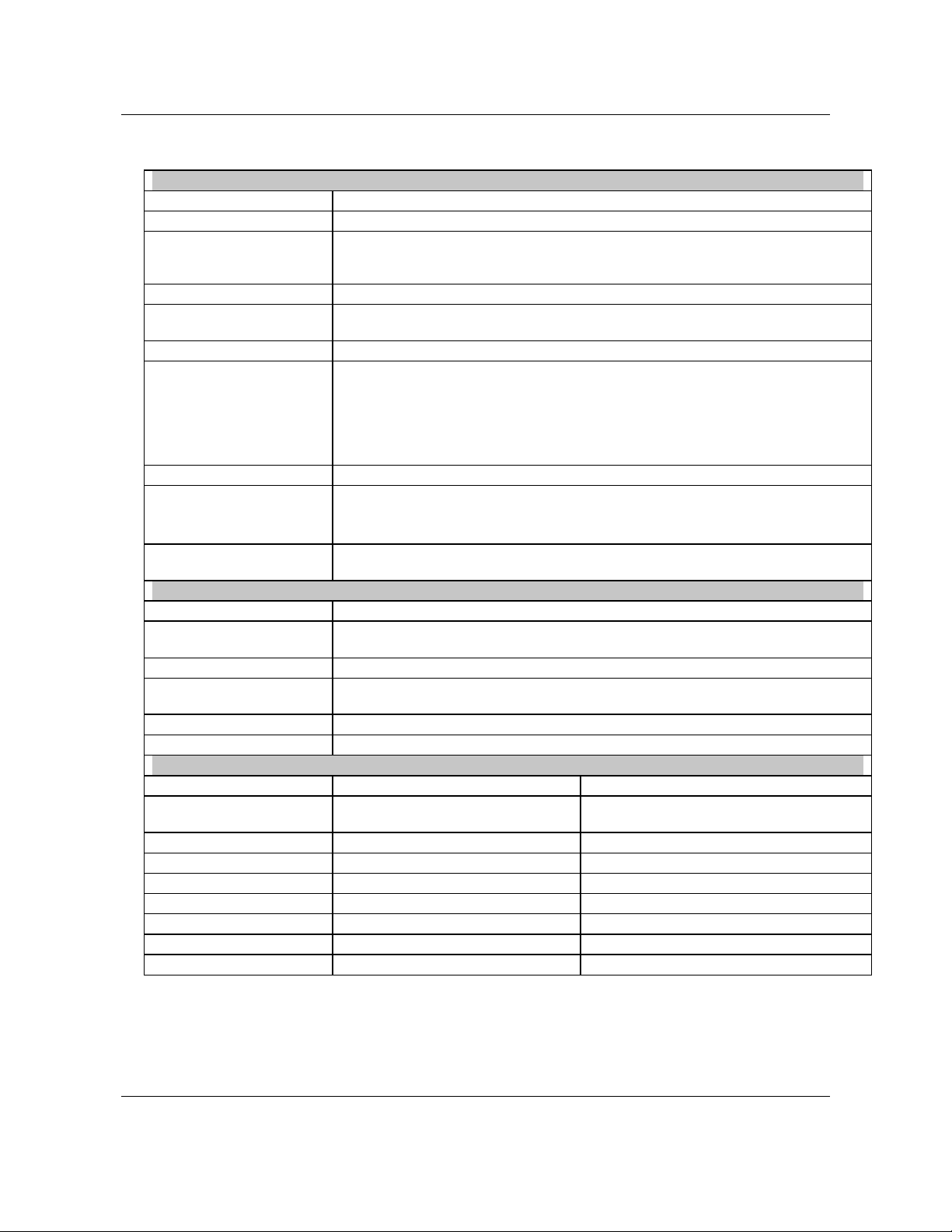

Universal Analog Inputs

Number 4 per module, up to 12 modules per video recorder

Input Types mV, V, mA, T/C, RTD, pyrometers

Signal source Thermocouple with cold junction compensation

Line resistance up to 1000 ohms, T/C, mV, mA, V

RTD, 3-wire connections, 40 ohms balanced maximum

Input Impedance 10 megohms for T/C and mV inputs; >1 megohm for volt inputs

Input Isolation 400 Vdc point-to-point

1350 Vac RMS A/D converter to logic

Stray rejection Series mode >60 dB. Common mode at 120 Vac >130 dB.

Burnout T/C, Pyrometry configurable to upscale, downscale or none.

Linear types: none except following ranges:

Volt: -500 to 500 mV; -1 to 1V; -2 to 2V; -5 to 5V; 0 to 10V; -10 to 10V; inherent to

zero volt

RTD: Inherent upscale

mA: Inherent downscale

T/C Break Detection Via current pulse

Scan rate Fastest rate:

250 ms up to 4 inputs, 500 ms up to 12 inputs, 750 ms up to 16 inputs,

1s up to 24 inputs,1,5 s up to 28 inputs, 2 s up to 44 inputs, 3 s up to 48 inputs.

A/D Converter Resolution Better than 1 part in 50,000 at 50 Hz.

Better than 1 part in 41,667 at 60 Hz.

Analog Outputs

Number 4 per module (non-isolated), up to 2 modules per video recorder (8 outputs)

Type Current output configurable within 0 to 20 mA. Maximum load 400 ohms per output.

Voltage output configurable 0 to 5 V.

Isolation from ground 350 Vac

Accuracy Factory configured accuracy = 0.1% at reference conditions

Field calibration accuracy = 0.05%

Temperature Effects 0.1% per 10°C in the rated limits

D/A Resolution 16 bits

Digital Inputs

Number 6 per module, up to 6 modules per

video recorder

Input Voltage Range 80 to 264 Vac 10.2 to 26.4 Vdc

Peak Voltage 264 Vac 26.4 Vdc

AC Frequency 47 to 63 Hz N/A

Isolation from ground 2300 Vac/1 min. 1100 Vac/1 min.

Isolation between inputs 350 Vac 30 Vac

ON Voltage Level 75 Vac minimum 9.5 Vdc minimum

OFF Voltage Level 20 Vac maximum 3.5 Vdc maximum

AC Inputs DC Inputs

6 (sink/source) per module, up to 6 modules

per video recorder

Video recorder – User Manual 4

Page 19

Introduction

Table 1-1 Specifications (continued)

Input Impedance 51K 5.6K

Input Current 0.9 mA @ 100 Vac 1.1 mA @ 12 Vdc

3.2 mA @ 24 Vdc

Minimum ON Current 0.3 mA 0.3 mA

Maximum OFF Current 0.15 mA 0.2 mA

Base Power Required* 50 mA maximum 50 mA maximum

OFF to ON Response 5 to 30 ms 1 to 8 ms

ON to OFF Response 10 to 50 ms 1 to 8 ms

Logic Inputs

Number 6 (dry contact) per module, up to 6 modules per video recorder

Isolation from ground 2300 Vac/1 min.

Switching Voltage 5 Vdc

Switching Current 5 mA

Digital Outputs

Number 6 per module, up to 6 modules per video

recorder. Only 1-5 on each module can

be configured as DAT outputs.

Operating Voltage 15 to 264 Vac 10.2 to 26.4 Vdc

Output Type SSR (Triac) NPN open collector

Peak Voltage 264 Vac 40 Vdc

AC Frequency 47 to 63 Hz N/A

Isolation from ground 2300 Vac/1 min. 1100 Vac/1 min.

Isolation between outputs 350 Vac 30 Vac

ON Voltage Drop <1.5 Vac (>0.1A)

<3.0 Vac (<0.1A)

Maximum Load Current 0.5A per point 0.3A per point

Maximum Leakage Current 4 mA (264 Vac, 60 Hz)

1.2 mA (100 Vac, 60 Hz)

0.9 mA (100 Vac, 50 Hz)

Maximum Inrush Current 10A for 10 ms 1A for 10 ms

Minimum Load 10 mA 0.5 mA

Base Power required* 20 mA/ ON pt. 250 mA

maximum

OFF to ON Response 1 ms 1 ms

ON to OFF Response 1 ms +1/2 cycle 1 ms

Fuses (European type 5 x

20mm)

Number 6 per module, up to 6 modules per video recorder. Only 1-5 on each module can be

Contact Rating 2A, 250 Vac on resistive load

Isolation from ground 2300 Vac/1 min.

Isolation between outputs 2300 Vac/1 min.

Contact Type SPST normally open (NO), individually configurable to normally closed (NC) via

* Base Power Required is the power required to provided module operation within specifications.

1 per output, 1.0A slow blow 1 per output

configured as DAT outputs.

jumper

AC Outputs DC Outputs

6 (current sinking) per module, up to 6

modules per video recorder. Only 1-5

on each module can be configured as

DAT outputs.

1.5 Vdc maximum

0.1 mA @ 40 Vdc

120 mA maximum

5V

1A fast blow

Relay (Alarm) Outputs

Video Recorder - User Manual 5

Page 20

Introduction

Table 1-1 Specifications (continued)

Time Proportional Outputs (TPO) on digital output

Time Resolution Equals the Scan Cycle time of the recorder.

Module Only Digital outputs 1 to 5 can be configured as DAT outputs.

Synchronization Individual TPOs are not synchronized with others.

Performance/Capacities

Math Calculations Standard Math package includes: 24 Calculated Values along with the following Math

functions: Free Form Math, Math Operators (+, -, x, ÷, Absolute Value, Square Root, Std.

Deviation), Free Form Logic, Logic Operators (AND, OR, XOR, Inverter, Flip Flop, OneShot), Inverter algorithms.

Constants 32

Alarms 96

Totalizers 0, 4 or 48

Control Loops Up to 8 (PID, ON/OFF, Cascade, Split, Ratio).

Auto Tune Each loop can be pre-tuned automatically to establish acceptable tuning parameters. On-

Primary Displays Up to 10 displays may be assigned from the 32 formats selected among trend screens,

Support Displays 13 (menu access).

Communications

(optional)

Advanced Math package includes: 64 Calculated Values with the functions from Standard

Math along with the following types of pre-packaged algorithms: Signal Select, Compare,

Signal Clamp, Periodic Timer, Interval Timer, Counter, Relative Humidity, Standard Splitter,

Scaling.

line fuzzy overshoot suppression.

Bargraph screens, Panel screens, Summary screens, loop screens, Setpoint profiler

screens.

Type: RS-422/485, Modbus RTU protocol

Connection: 2 or 4 wire RS485.

Distance: 600 meters, (2000 feet).

Number of links: Up to 30

Baud Rate: 1200, 2400, 4800, 9600, 19.2K, 38.4K.

Parity: Selectable; odd, even, none.

Video recorder – User Manual 6

Page 21

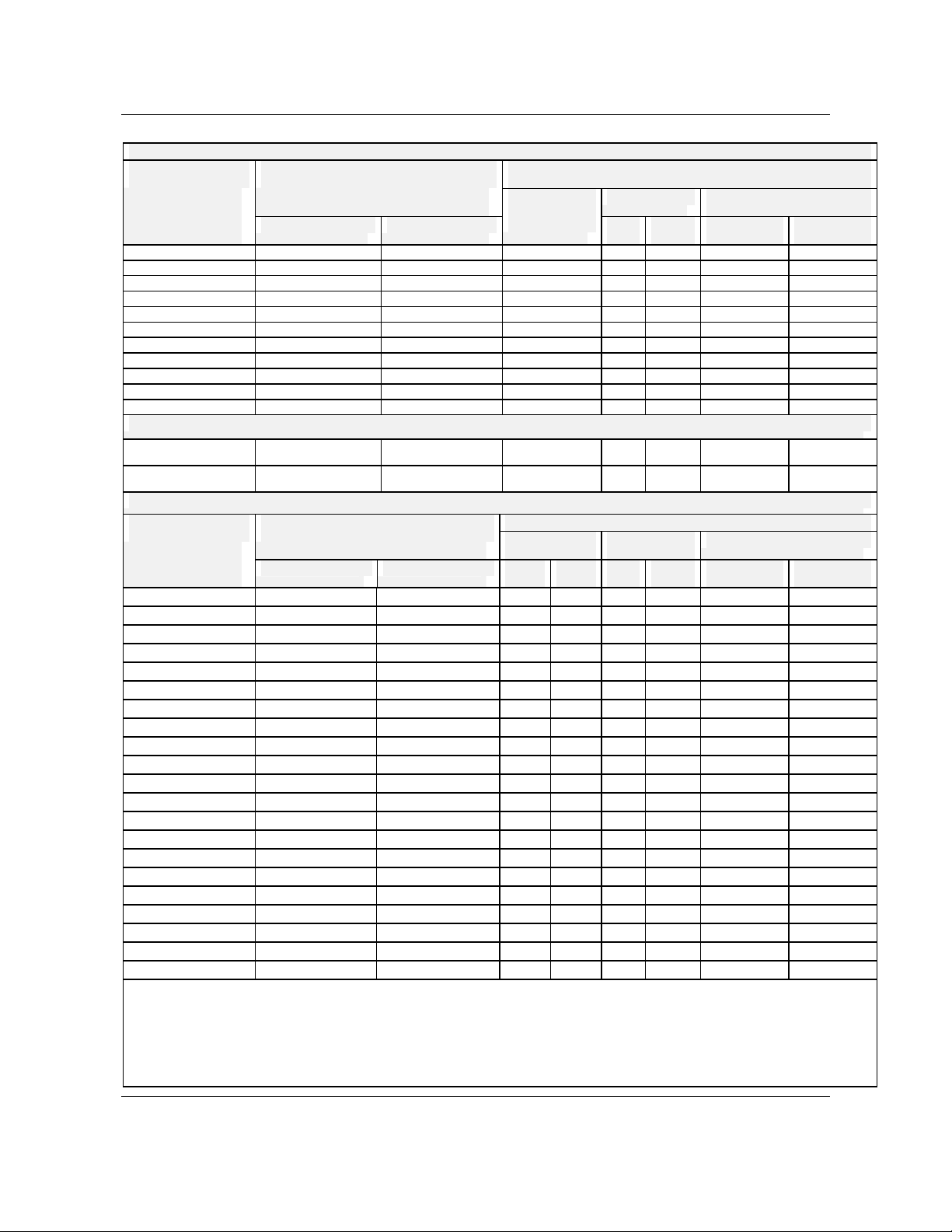

Accuracy

Accuracy

Rated limits and

associated drifts

Reference conditions

Parameters Rated limits Influence on accuracy

Temperature

Supply voltage

Source resistance

RTD 0.1°C per Ohm in each wire

Humidity

Long-term stability

Table 1-2 Analog Input Accuracy--Linear types

Millivolts Volts Current Ohms

0 to 10 mV

-10, +10 mV

0 to 20 mV

-20, 0, +20 mV

0, 50 mV

-50, 0, +50 mV

10 to 50 mV

0 to 100 mV

-100, 0, +100 mV

0 to 500 mV

-500, 0, +500 mV

NOTE:

- The mA inputs must be connected to a 250 ohms resistor across the input terminals.

Table 1-1 Specifications (continued)

Analog input accuracy and rated limits

Temperature = 23°C ± 2°C (73°F ± 3°F)

Humidity = 65% RH ± 5%

Line voltage = Nominal ± 1%

Source resistance = 0 ohm

Series mode and common mode = 0 V

Frequency = Nominal ± 1%

Field calibration accuracy 0.05% of the selected range (IEC 873)

Factory calibration: 0.1%

Cold junction accuracy: ± 0.5°C

0 to 50°C (32 to 120 °F) 0.15% per 10°C of change (See

85 to 250 V No influence

T/C, mV 6 µV per 400 Ohms of line

10 to 90% RH at 25°C 0.1% max.

0.1% per year

0 to 1 V

-1, 0, 1 V

0 to 2 V

-2, 0, +2 V

0 to 5 V

-5, 0, +5 V

1 to 5 V

0 to 10 V

-10, 0, +10 V

0, 20 mA

4, 20 mA

Introduction

Note A)

Cold junction 0.3°C/10°C

resistance max. = 1000 Ohms

balanced leads

40 Ohms max. (from 0 to 400°C)

0 to 200

0 to 2000

Video Recorder - User Manual 7

Page 22

Introduction

Table 1-3 Analog Input --Non-linear types

Thermocouples -ITS-90 except where noted

Type

% Range

°F °C

J 0 to 2190 -18 to 1199 0.1 0.4 0.2

K 0 to 2500 -18 to 1371 0.1 0.4 0.2

E -450 to 1830 -268 to 999 0.1 0.4 0.2

T -300 to 752 -184 to 400 0.1 0.4 0.2

N 0 to 2372 -18 to 1300 0.1 0.6 0.3

B 110 to 3300 43 to 1816 0.1 2.5 1.4 752 to 3300 400 to 1816

R 0 to 3210 -18 to 1766 0.1 1.5 0.8

S 0 to 3210 -18 to 1766 0.1 1.6 0.9

W5/W26 (3)

PLAT II (3)

NI-NIMO 32 to 2502 0 to 1372 0.1 0.4 0.2

0 to 4200 -18 to 2316 0.1 0.9 0.5 32 to 3272 0 to 1800

-100 to 2500 -73 to 1371 0.1 0.4 0.2

RTD (4)

CU10 -100 to 310 -73 to 154

PT100 IEC -300 to 1570 -184 to 854 0.1 0.5 0.3

0.5 2.5 1.4

Pyrometry (Rayotube & Spectray) Types

Type

Operating span

Max value Min value

°F °C

18890-0035 1200 to 2600 649 to 1426 4 2 1 0.6

18890-0073 800 to 1800 427 to 982 12.5 7 1 0.6

18890-0074 1100 to 2300 594 to 1260 3 1.7 1 0.6

18890-0075 1500 to 3300 816 to 1815 6 3 1.8 1

18890-0163 200 to 1000 94 to 537 11 6 1.5 0.8

18890-0216 2110 to 4600 1155 to 2537 8 4.4 1.8 1

18890-0412 1375 to 3000 747 to 1648 10 5.6 1.3 0.7

18890-00643 1850 to 4000 1010 to 2204 8 4.4 1 0.6

18890-1729 1650 to 3600 899 to 1982 5 3 1.5 0.8

18890-3302 750 to 1600 399 to 871 6 3 1 0.6

18890-5423 2210 to 5000 1210 to 2760 18 10 2 1.1

18894-0579 752 to 2552 400 to 1400 33 18 3.6 2

18899-8814 340 to 1800 172 to 982 11 6 2 1.1

18894-9014 752 to 2552 400 to 1400 20 11 2.6 1.4

Spectray 18885 1832 to 3452 1000 to 1900 30 17 0.6 0.3

Spectray 18885-1 1292 to 2912 700 to 1600 60 33 0.6 0.3

Spectray 18885-2 806 to 1400 430 to 760 38 21 0.2 0.1

Spectray 18886 1833 to 3452 1001 to 1900 20 11 0.6 0.3

Spectray 18886-1 1292 to 2912 700 to 1600 80 44 0.6 0.3

18874-0578 752 to 2552 400 to 1400 3.6 2 1.8 1

18875-0579 752 to 2552 400 to 1400 3.6 2 1.8 1

°F °C °F °C

NOTES:

1: The accuracy will be the larger value between Min Value and %range of the selected limits

2: Reference range = operating range when blank

3: IPTS-68

4: T° influence: 0.5% per 10°C on Cu 10 ohms, 0.3% per 10°C on Pt 100 ≤ 200°C

5: For Pyrometry, the worst accuracy (Max value) is at the low range limit , the best (Min value) is at the high limit.

- For non linear temperature transmitter, the transmitter range MUST be identical to the input range of the recorder.

Accuracy (1) Operating span

Min value

Reference range (2)

°F °C °F °C

Accuracy ( 5 )

Video recorder – User Manual 8

Page 23

Introduction

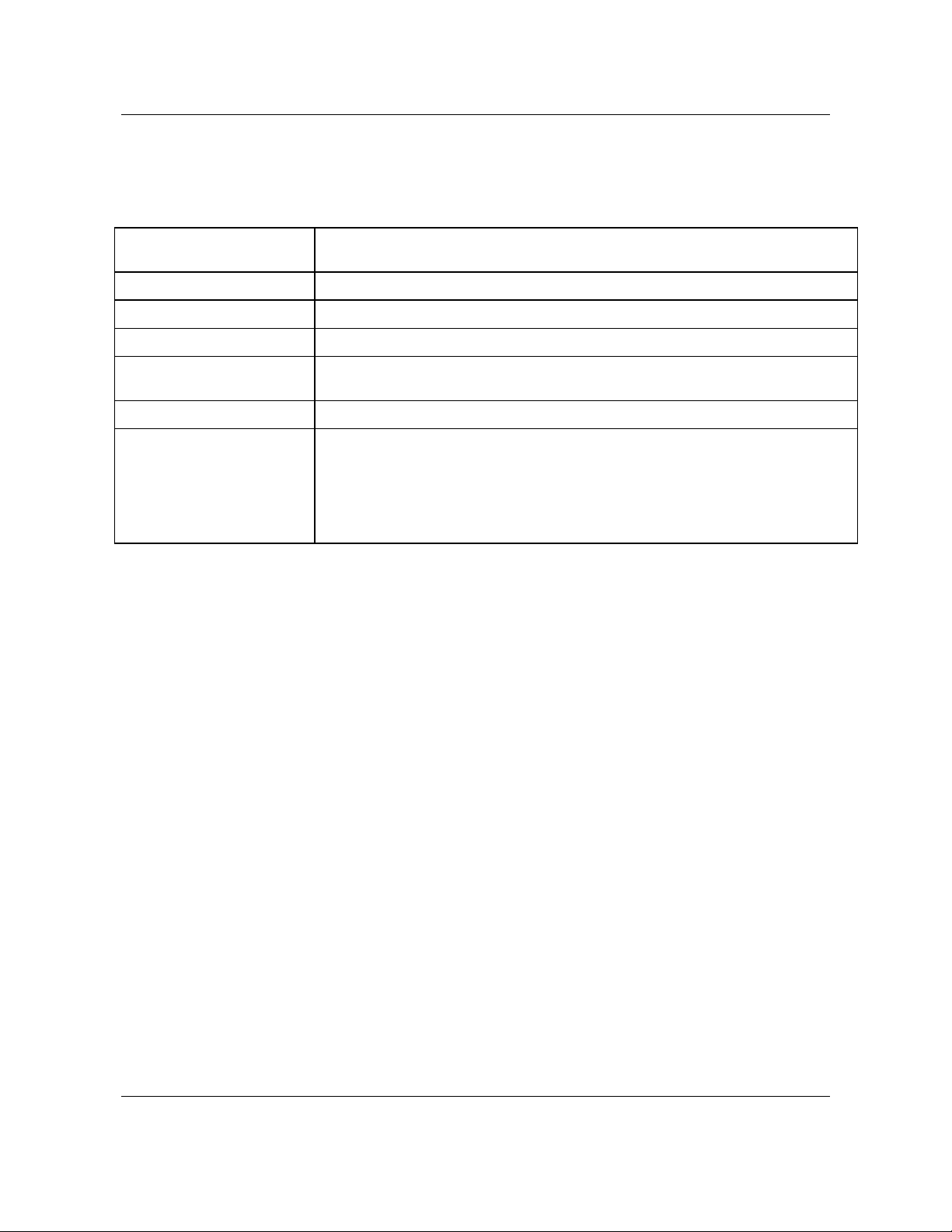

Table 1-4 Standards

This product is designed and manufactured to be in conformity with applicable U.S., Canadian, and International

(IEC/CENELEC/CE) standards for intended instrument locations. The following Standards and Specifications are

met or exceeded.

Case Protection IP55 on front door only, when the instrument is panel mounted and the front door

securely closed.

Rear of Panel EN 60529, IP 20

Flammability Rating UL 94 - V2

Vibration Level 10 to 40 Hz, 0.07 mm displacement; 40 to 60 Hz, 0.2g acceleration

Electromagnetic

Compatibility

Safety IEC1010 Installation Category II for personal protection

Intended Instrument

Locations

CE EMC Directive 89/336/EEC

Rack or panel mounting in control room or industrial environments (operator

accessibility front of panel only)

Installation Category II with grounded mains supply from isolation transformer or GFI

(ground fault interrupter)

Pollution Degree 2 with rear of panel enclosed, in industrial environment

Video Recorder - User Manual 9

Page 24

Introduction

g

g

g

g

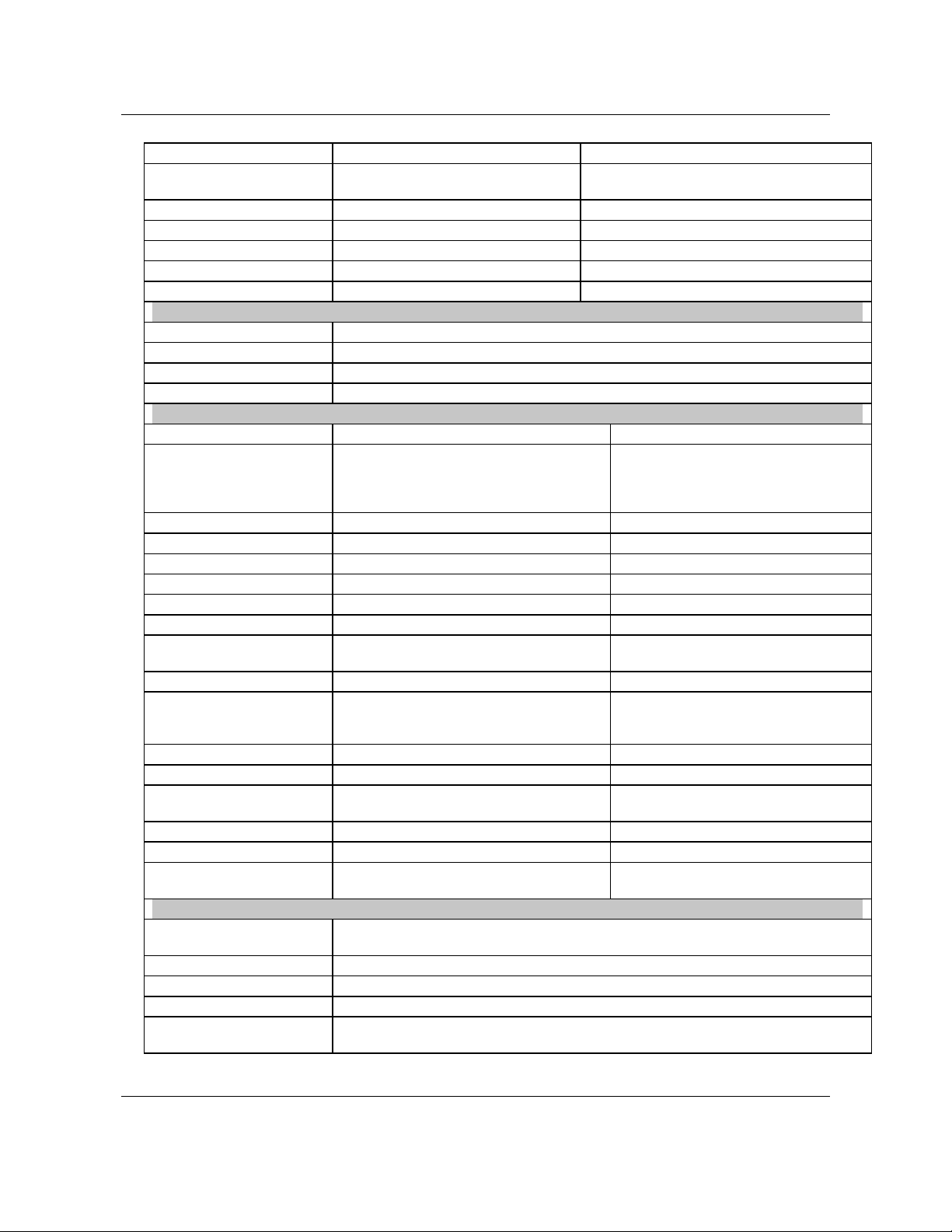

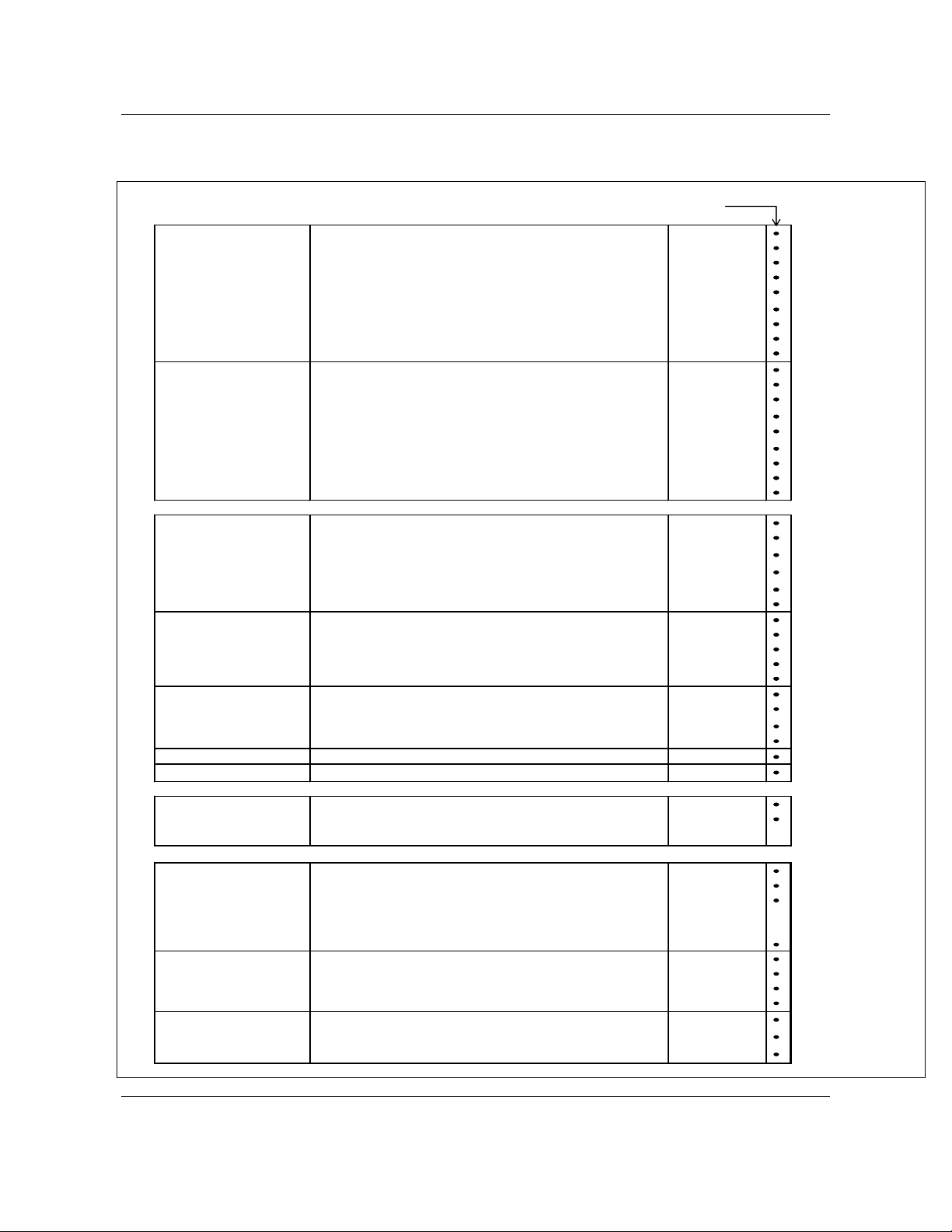

1.3 Model Selection Guide

This table helps you to identify correctly the unit in front of you. Please refer to the product label and

verify that you have the right unit.

Select the desired key number. The mark to the right shows the selection available. A complete model

number has the requested number of digits from each table as follows.

Video Recorder Model Number Figure 1-2 Video Recorder Model Number

Instructions

Key Number I II III IV V VI

KEY NUMBER Selection Availability

Description

Video Recorder VRX180

TABLE I - ANALOG INPUTS

Analog Universal Inputs 4 Universal Analog Inputs 04

TABLE II - ADDITION AL INPUTS AND OUTPUTS

Make the desired selection from Tables I to VI .

The arrow to the right marks the selection available.

A dot ( ) denotes unrestricted availability.

VRX180 - _ _ - _ _ _ _ _ _ - _ _ _ _ _ - _

-

_ _ _ _ _ _

-_ _

( slot A to F ) 8 Universal Analog Inputs 08

12 Universal Analog Inputs 12

16 Universal Analog Inputs 16

20 Universal Analog Inputs 20

24 Universal Analog Inputs 24

Slot J 4 Universal Analog Inputs A _ _ _ _ _

Slot K 4 Universal Analog Inputs _A _ _ _ _

Slot L 4 Universal Analog Inputs _ _ A _ _ _

Slot M 4 Universal Analog Inputs _ _ _ A _ _

None 0 _ _ _ _ _

6 Digital Inputs ( contact closure) B _ _ _ _ _

6 Di

ita l Inputs 24 Vdc C _ _ _ _ _

6 Digital Inputs 120 / 240 Vac E _ _ _ _ _

6 Relays Outputs R _ _ _ _ _

6 Digital O utputs 24 Vdc ( open collector) G _ _ _ _ _

6 Digital O utputs 120 / 240 Vac ( triac ) H _ _ _ _ _

None _0 _ _ _ _

6 Digital Inputs ( contact closure) _B_ _ _ _

ita l Inputs 24 Vdc _C_ _ _ _

6 Di

6 Digital Inputs 120 / 240 Vac _E _ _ _ _

6 Relays Outputs _R_ _ _ _

6 Digital O utputs 24 Vdc ( open collector) _G_ _ _ _

6 Digital O utputs 120 / 240 Vac ( triac )

None _ _ 0 _ _ _

6 Digital Inputs ( contact closure) _ _ B _ _ _

6 Di

ita l Inputs 24 Vdc _ _ C _ _ _

6 Digital Inputs 120 / 240 Vac _ _ E _ _ _

6 Relays Outputs _ _ R _ _ _

6 Digital O utputs 24 Vdc ( open collector) _ _ G _ _ _

6 Digital O utputs 120 / 240 Vac ( triac )

None _ _ _ 0 _ _

6 Digital Inputs ( contact closure) _ _ _ B _ _

6 Di

ita l Inputs 24 Vdc _ _ _ C _ _

6 Digital Inputs 120 / 240 Vac _ _ _ E _ _

6 Relays Outputs _ _ _ R _ _

6 Digital O utputs 24 Vdc ( open collector) _ _ _ G _ _

6 Digital O utputs 120 / 240 Vac ( triac )

_H_ _ _ _

_ _ H _ _ _

_ _ _ H _ _

Video recorder – User Manual 10

Page 25

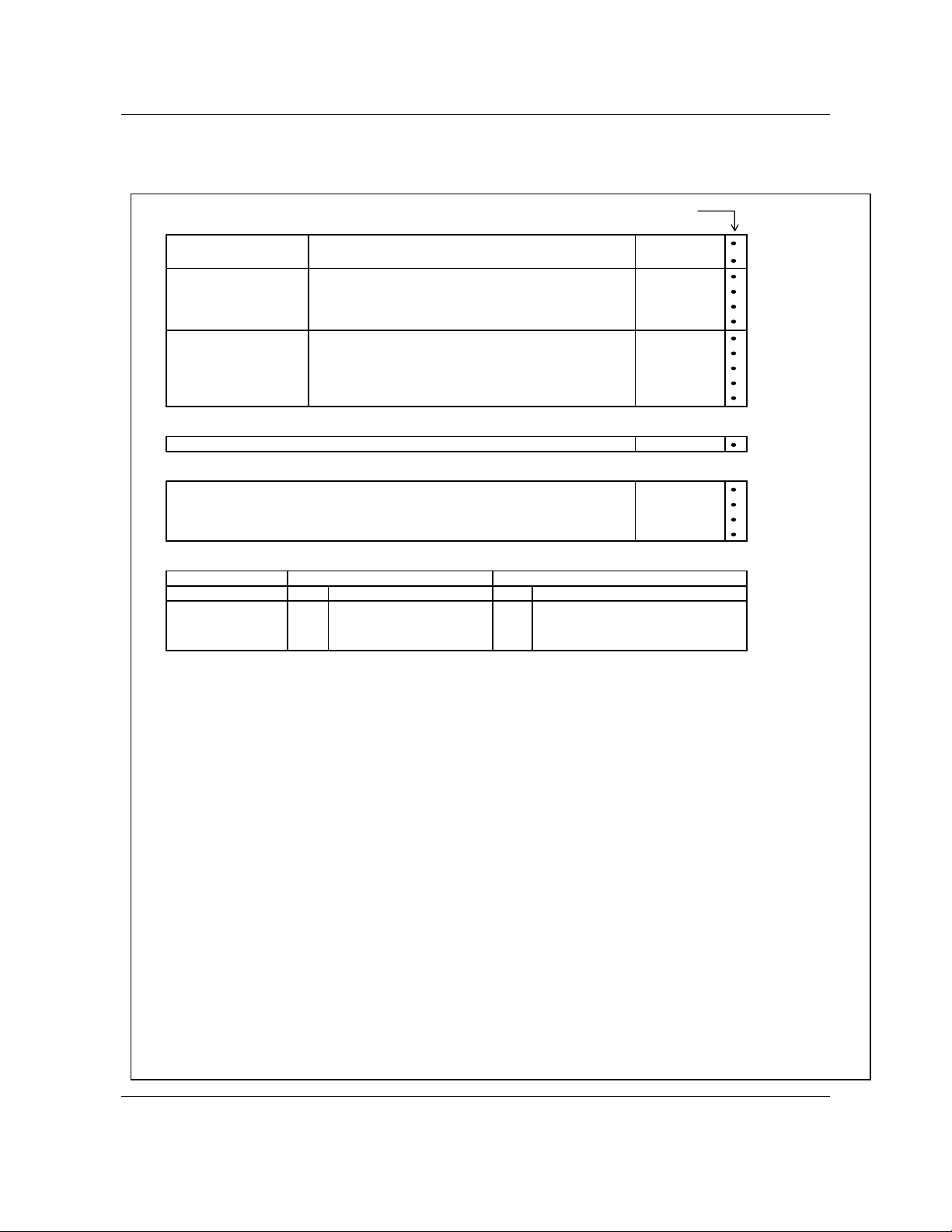

Model Selection Guide (cont.)

g

g

g

)

Introduction

TABLE II - ADDITIONAL INPUTS AND OUTPUTS (continued)

Slot N 4 Universal Analog Inputs _ _ _ _ A _

Slot P 4 Universal Analo g Inputs _ _ _ _ _ A

TABLE III - FIRMWARE - DATA STORAGE

Control Lo ops 1 Control Loop 1 _ _ _ _

(Notes 1, 5) 2 Control Loops 2 _ _ _ _

Set Point Programs 1 Set Point Program _ 1 _ _ _

(Note 4) 2 Set Point Programs _ 2 _ _ _

Math Standard Math _ _ 0 _ _

(Note 2) Advance Math _ _ 1 _ _

Da ta s tora

Other None

TABLE IV - COMMUNICATION

Comm unication None 0

e (Note 6

TABLE V - OPTIONS

Docum entatio n English E _ _ _ _ _

(prompts langua ge, F rench F _ _ _ _ _

manual) German G _ _ _ _ _

English - (U.S. form at) U _ _ _ _ _

Certificates None _ 0 _ _ _ _

Tagging Non e _ _ 0 _ _ _

None _ _ _ _ 0 _

6 Digital Inputs ( contact closure) _ _ _ _ B _

6 Di

ital Inputs 24 Vdc _ _ _ _ C _

6 D ig ital In p u ts 1 2 0 / 24 0 V a c _ _ _ _ E _

6 Relays Outputs _ _ _ _ R _

6 Digital Outputs 24 Vdc ( open collector) _ _ _ _ G _

6 Digital Outputs 120 / 24 0 Vac ( triac ) _ _ _ _ H _

4 C u rre nt Ou tp u ts

None _ _ _ _ _ 0

6 Digital Inputs ( contact closure) _ _ _ _ _ B

ital Inputs 24 Vdc _ _ _ _ _ C

6 Di

6 Digital Inputs 120 / 240 Vac _ _ _ _ _ E

6 Relays Outputs _ _ _ _ _ R

6 Digital Outputs 24 Vdc ( open collector) _ _ _ _ _ G

6 Digital Outputs 120 / 24 0 Vac ( triac ) _ _ _ _ _ H

4 C u rre n t O u tp u ts

None 0 _ _ _ _

4 Control Loops 4 _ _ _ _

6 Control Loops 6 _ _ _ _

8 Control Lo ops

None _ 0 _ _ _

3 Set Point Programs _ 3 _ _ _

4 Set Point Programs

Advance Math and 4 Totalizers _ _ 2 _ _

Advance Math and 48 Totalizers

100 Mb Z IP Drive

RS485 - Modbus RTU C

Eth ern e t In te rfa c e E c

Ita lian I _ _ _ _ _

Spanish S _ _ _ _ _

Certificate of C onformance _ B _ _ _ _

C a libr a tio n C ert ificate

Calibration and Conformance Certificates

Linen _ _ L _ _ _

Stainless steel

(No te 7 )

(No te 3 )

(No te 3 )

VRX180

Sele c tion

_ _ _ _ M _

_ _ _ _ _ M

8 _ _ _ _

_ 4 _ _ _

_ _ 3 _ _

_ _ _ 2 _

_ _ _ _ 0

_ C _ _ _ _

_ E _ _ _ _

_ _ S _ _ _

Video Recorder - User Manual 11

Page 26

Introduction

(

)

p

g

p

y

g

Model Selection Guide (cont.)

TABLE V - OPTIONS (continued)

Approvals CE Mark Compliant _ _ _ 0 _ _

Software None _ _ _ _ 0 _

Case Galvanized Case, Grey Door, Glass Window, Latch _ _ _ _ _ 0

TABLE VI

Factory Use Only 00

SOFTWARES AND SUPPORT PARTS Part #

SDA Data Analysis Software (can be ordered separately if not selected in Table V) 045501

SCF Configuration Software (can be ordered separately if not selected in Table V) 045502

SDI Di sk In itia liza tio n S o ftw a re

Kit of 4 resistors 250 Ohms for 4-20 mA in

RESTRICTIONS

Restriction Letter Available With Not Available With

c

Notes:

1. The available algorithms include: P ID (standard and advance), Cascade, Split O utput and On/Off.

The appropriate outputs from Table I must be specified - Current or Relays.

If Split (Duplex) output Control is required, adv ance math must be selected ( Table III ).

2. Standard Math includes 24 Calculated Values and the following pre-packaged algorithms

Free Form Math Logic Operators Flip-Flop/One Shot Periodic Tim er

Free Form Logic Math Operators Invertor

Advance Math includes 64 Calculated Values and the followin

Signal Select Interval Timer Counter

Compare R elative Humidity Scaling

Signal Clamp Mass Flow Advanced Splitter

Peak Picking Fo Calculation Continuous Emissions Monitoring

Function Generator Multi

Carbon Potential Single Point Average - CEM Rolling Average

Rolling Average Standard Splitter