Page 1

VRN Pressure Independent Control

Valves and Actuators

PRODUCT DATA

FEATURES

• Sizes from 1/2 to 3 in. with internal (female) NPT

connections.

• Controls hot or chilled water with up to 50% glycol.

• Regulated flow rates available from 1 to 95 gpm.

• Differential pressure regulator for constant pressure

drop across valve seat.

• Positive pressure, rolling diaphragm regulator design

for flow control accuracy of ±5%.

• Equal percentage flow characteristic using patented

flow control ball insert.

• Multiple maximum flow rates available per valve size.

• Patented ball seals for low operating torque.

• Nickel-chrome plated brass or stainless steel trim.

• Choice of factory-installed actuation using

Honeywell MVN or MN/MS series direct coupled

actuators: Floating, Modulating (2-10 V), Non-Spring

APPLICATION

The VRN2 two-way dynamic pressure-regulating control

valves maintain constant flow of hot or chilled water with

glycol solutions up to 50% in closed-loop heating,

ventilating, and air conditioning systems, within the

specified pressure drop ranges of each model number.

These valve assemblies can be ordered with or without

factory-mounted actuators.

Return and Spring Return.

• Spring return actuators field-configurable for

normally open or normally closed fail-safe position.

• Removable, manual operating handle to control

valve during installation or in an event of power

failure.

• Upstream Test Port for venting or pressure gauge

attachment.

• Three actuator orientations on the valve for cramped

spaces.

• Integral snubber eliminates effect of system

pressure fluctuations and entrapped air while

improving flow performance.

Contents

Application ..................................................................................... 1

Features .......................................................................................... 1

Specifications ............................................................................... 2

Ordering Information ................................................................ 2

Typical Specifications ............................................................... 14

Installation .................................................................................... 15

Operation and Checkout .......................................................... 21

38-00032-03

Page 2

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

SPECIFICATIONS

Valve Type: Pressure Independent Control Valve

Body Style: Two-way ball valve, straight-through flow, full

port with patented flow control insert.

Pipe Size: 1/2 to 3 inches with female NPT pipe fittings.

Body Pressure Rating (maximum): 360 psi (2500 kPa) at

250°F (121 °C).

Controlled Medium: Water or Glycol solutions up to 50%.

Not suitable for combustible gases, oil or steam.

Medium Temperature Range: -22 to +250°F

(-30 to +121 °C).

Maximum Differential Pressure: See Table 1.

Close-off pressure: 100 psid

Flow Characteristics

Equal Percentage with flow control insert. See Fig. 40.

Materials

Body: Forged Brass (ASTM B283).

Flow Optimizer: laser-milled, glass-reinforced Noryl

Trim (ball and stem): Nickel-chrome plated brass, or

stainless steel.

™

Stem Seals: EPDM O-ring and Teflon

Ball Seals: Reinforced Teflon™ seals, with EPDM O-rings.

Regulator: Hydrogenated acrylonitrile-butadiene rubber

rolling diaphragm in stainless steel housing.

Compatible Actuators

Minimum Torque Required:

35 lb-in. (4 N m) up to 3 in. (≤DN80).

27 lb-in. (3 N m) up to 1-1/4 in. (≤DN32).

Fail Safe: MSXX05*

Non-Fail Safe: MVN & MNXX05*

* These actuators are available as factory-installed

assemblies.

See Table 1 for all available options.

Approvals Standards

Actuators: See literature for the given actuator.

bearings.

®

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number. If you have additional questions, need further

information, or would like to comment on our products or services, please write or phone:

1. Your local Honeywell Environmental and Combustion Controls Sales Office (check white pages of your phone

directory).

2. Honeywell Customer Care

1985 Douglas Drive North

Golden Valley, Minnesota 55422-4386

3. http://customer.honeywell.com or http://customer.honeywell.ca

International Sales and Service Offices in all principal cities of the world. Manufacturing in Belgium, Canada, China,

Czech Republic, Germany, Hungary, Italy, Mexico, Netherlands, United Kingdom, and United States.

38-00032—03 2

Page 3

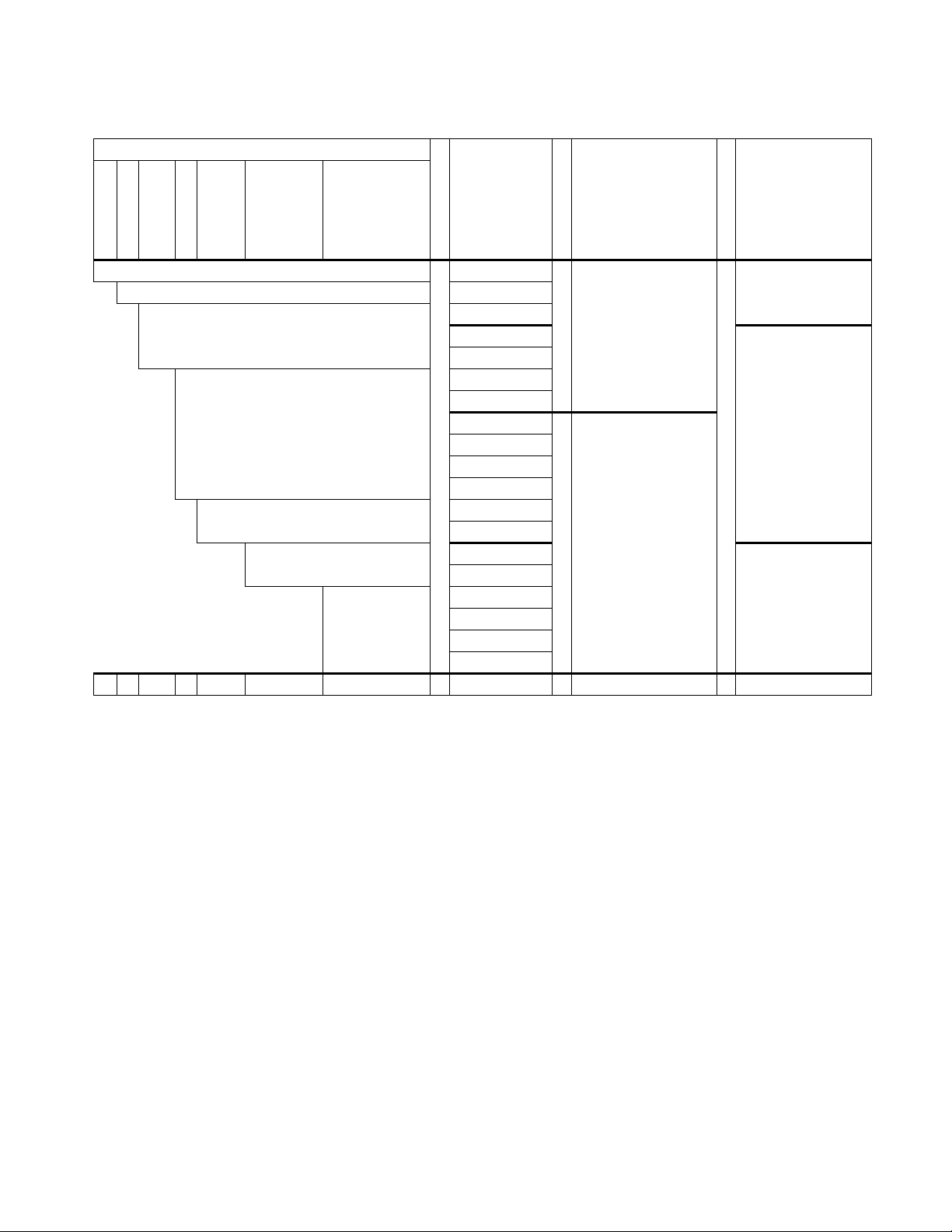

Table 1. VRN Model Selection.

Model Selection: Pressure Independent Control Valve

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

Valve

Fitting

Body/Flow Type

Size

Max flow rate

Trim

Actuator Adapter

Actuator Fail Position Accessories

VR - Pressure Independent Control Valve MVN613A0000*

N- Female NPT threaded MVN643A0000*

2- 2 way MVN713A0000*

MN6105A1011

(Leave blank)

= Fail in place

MN6105A1201

A - 1/2 (DN15)

B - 3/4 (DN20)

C - 1 (DN25)

D - 1-1/4 (DN32)

E - 1-1/2 (DN40)

F - 2 (DN50)

G - 2-1/2 (DN65)

H - 3 (DN80)

xxx.xx - Max flow rate designator

See Table 4.

P - Plated Brass

S - Stainless Steel

A - Standard Base

X - MN/MS DCA

Actuator Bracket

MN7505A2001

MN7505A2209

MS7505A2030

MS7505A2130

MS8105A1030

MS8105A1130

MS4105A1030

MS4105A1130

MS7103A2021*

MS7103A2221*

MS3103A1023*

MS3103A1223*

MS7503A2021*

FSO = Fail Safe Open

FSC = Fail Safe Closed

MS7503A2221*

VR N 2 A 001.00 P A + MVN613A0000 + + C1

Example part number: VRN2A001.00PA+MVN613A0000+C1

* Only compatible with valves 1-1/4” or smaller.

(Leave blank)

C1

- 1 meter cable

C3

- 3 meter cable

(Leave blank)

= No cable

= No

encolsure

3R - NEMA 3R Enclosure

(Leave blank)

= 3 ft cable

standard

3 38-00032—03

Page 4

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

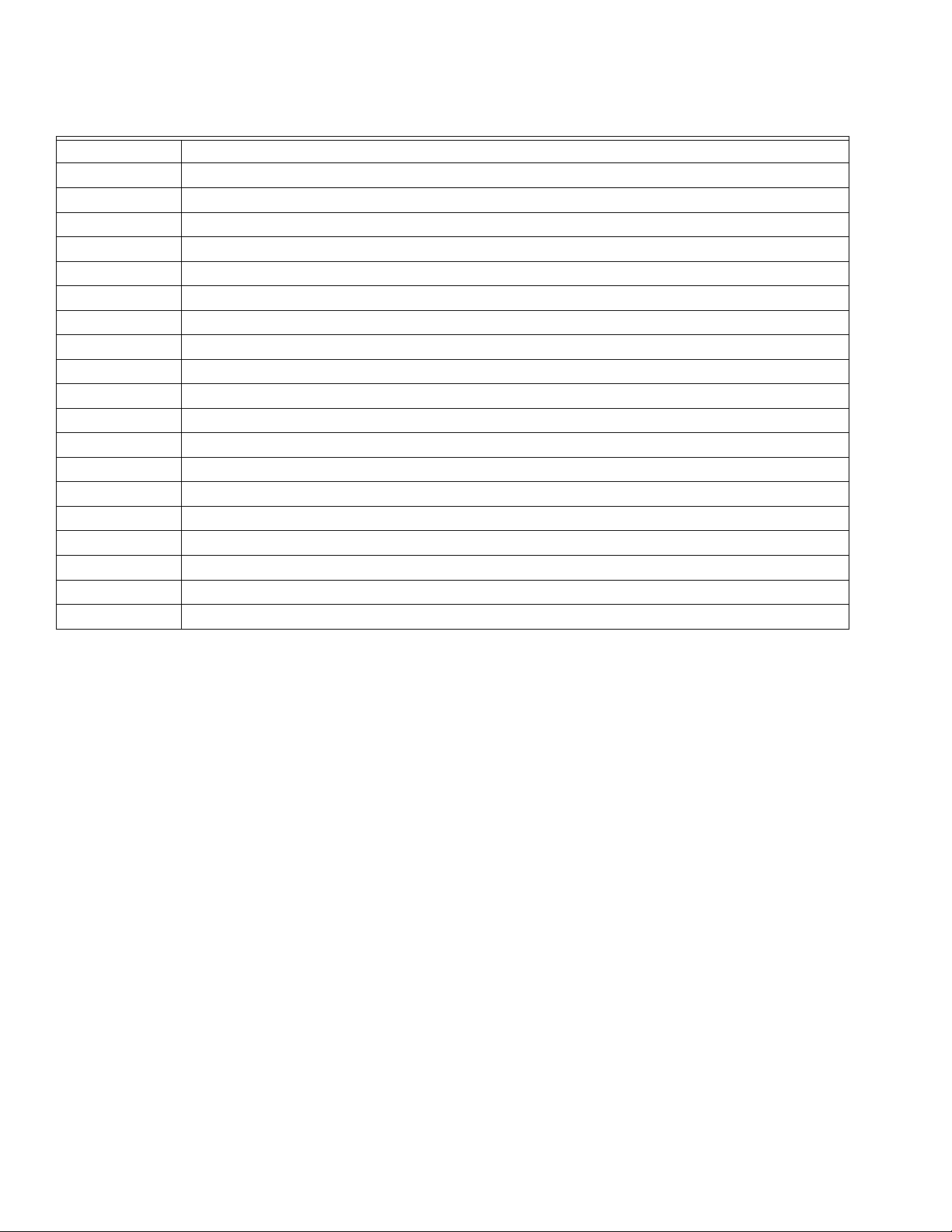

Table 2. Actuator Control Description.

Actuator Control

MVN613A0000

MVN643A0000

MVN713A0000

Floating, Two-position (SPDT) (90 sec. timing), 24 V, Fail in Place

Floating, Two-position (SPDT or SPST) Fast Acting (30 sec. timing), 24 V, Fail in Place

0(2)-10 Vdc Modulating, 24 V, Fail in Place

MN6105A1011 Floating, Two-position (SPDT), 24 V, Fail in Place

MN6105A1201 Floating, Two-Position (SPDT), 24 V, Fail in Place with end switches

MN7505A2001 0(2)-10 Vdc Modulating, 24 V, Fail in Place

MN7505A2209 0(2)-10 Vdc Modulating, 24 V, Fail in Place with end switches

MS7505A2030 Universal, 0(2)-10 Vdc Modulating, Floating, Two-position (SPDT), 24 V, Fail Safe

MS7505A2130 Universal, 0(2)-10 Vdc Modulating, Floating, Two-Position (SPDT), 24 V, Fail Safe with end switches

MS8105A1030 Two-Position (SPST), 24 V, Fail Safe

MS8105A1130 Two-Position (SPST), 24 V, Fail Safe with end switches

MS4105A1030 Two-Position (SPST), 120 V, Fail Safe

MS4105A1130 Two-Position (SPST), 120 V, Fail Safe with end switches

MS7103A2021 2-10 Vdc Modulating, 24 V, Fail Safe

MS7103A2221 2-10 Vdc Modulating, 24 V, Fail Safe with end switches

MS3103A1023 Sylk-enabled, 24 V, Fail Safe

MS3103A1223 Sylk-enabled, 24 V, Fail Safe with end switches

MS7503A2021 Universal, 0(2)-10 Vdc Modulating, Floating, Two-Position, 24 V, Fail Safe

MS7503A2221 Universal, 0(2)-10 Vdc Modulating, Floating, Two-Position, 24 V, Fail Safe with end switches

38-00032—03 4

Page 5

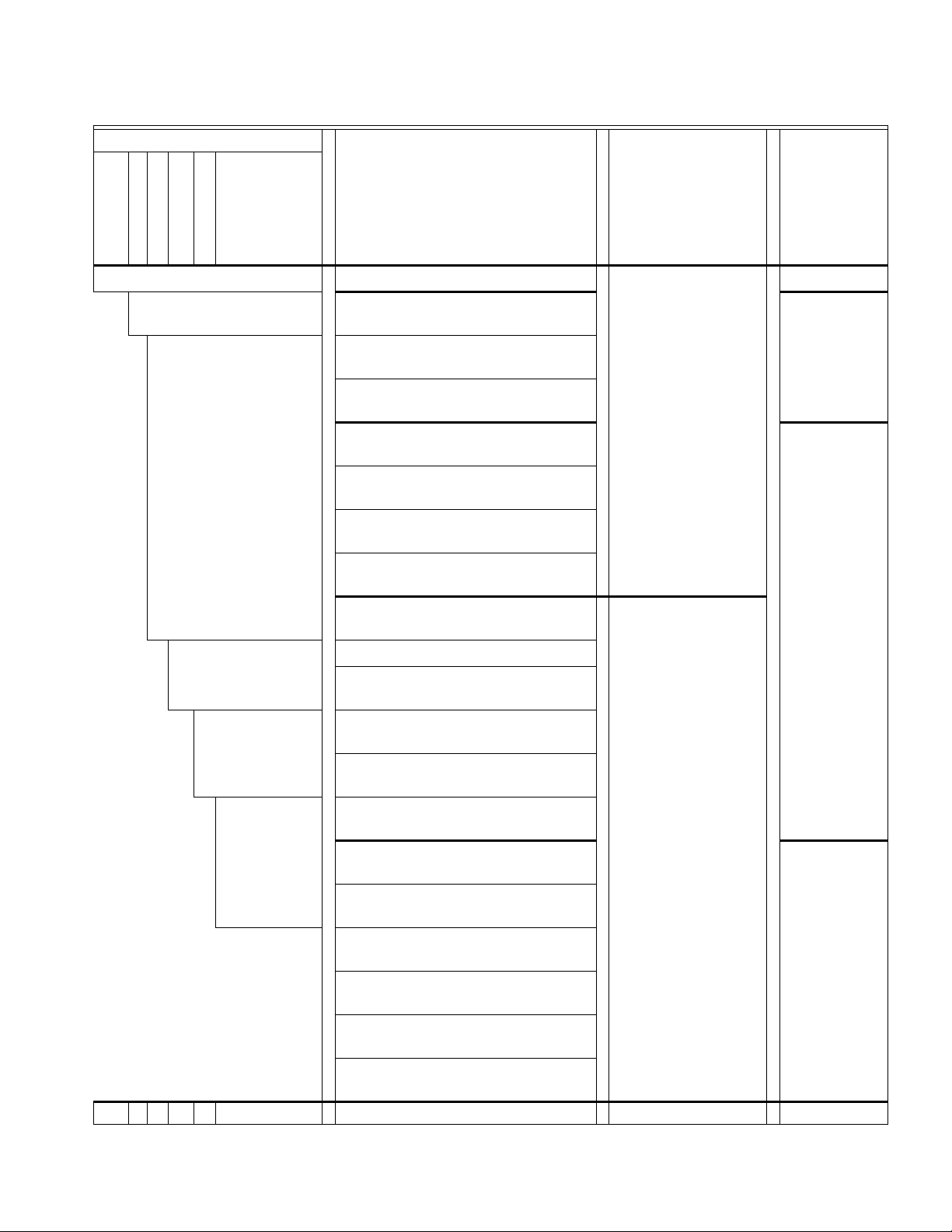

Table 3. Pressure Independent Valve Short Order Codes ½” – 3”.

Model Selection: Control Valve

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

Valve

Body Flow Type

Valve Size

Max Flow Rate

Trim

Adapter

Actuator

Actuator Fail Position Accessories

VRN - Pressure Independent Control Valve 0 - No Actuator (valve only)

2 - 2-way

A---1/2 (DN15)

B---3/4 (DN20)

C---1 (DN25)

D---1-1/4 (DN32)

E---1-1/2 (DN40)

F---2 (DN50)

G---2-1/2 (DN65)

H---3 (DN80)

1 - 24 Vac, Floating/2-Pos., 90 sec. (MVN613,

Fail in place)*

2 - 24 Vac, Floating/2-Pos., 30 sec. (MVN643,

Fail in place)*

3 - 24 Vac, Modulating 0(2)-10 Vdc (MVN713,

Fail in place)*

4 - 24 Vac, Floating/2-Position

(MN6105, Fail in place)

5 - 24 Vac, Mod. 0(2)-10 Vdc

(MN7505, Fail in place)

C - 24 Vac, Floating/2-Position w/ end switches

(MN 6105, Fail in place)

D - 24 Vac, Mod. 0(2)-10Vdc w/ end switches

(MN7505, Fail in place)

6 - 24 Vac, Mod. 0(2)-10 Vdc/Floating (MS7505,

Fail safe)

Flow Rate (GPM)

Options range from B-9.

See Table 4.

P - Nickel Chrome

Plated Brass

S - 316 Stainless Steel

7 - 24 Vac, 2-Position (MS8105, Fail safe)

8 - 100-250 Vac, 2-Position

(MS4105, Fail safe)

9 - 100-250 Vac, 2-Pos. w/ end switches

(MS4105, Fail safe)

A - 24 Vac, 2-Position w/ end switches

(MS8105, Fail safe)

B - 24 Vac, Mod 0(2)-10 Vdc/Floating w/ end

A - Standard Base

switches (MS7505, Fail safe)

E - 24Vac, Mod. 2-10 Vdc

X - MN/MS DCA

Actuator Bracket

(MS7103, Fail safe)*

F -24Vac, Mod. 2-10 Vdc w/ end switches

(MS7103, Fail safe)*

00 - None

00 - None

01 - 1 m Cable (C1)

03 - 3 m Cable (C3)

0 - No Actuator

or Fail in Place (FIP)

00 - None

02 - NEMA 3R

enclosure

1 - Fail Safe Open (FSO)

2 - Fail Safe Closed (FSC)

G - 24Vac, Sylk Enabled

(MS3103, Fail safe)*

H - 24Vac, Sylk Enabled w/ end switches

(MS3103, Fail safe)*

J - 24Vac, Universal 0(2)-10Vdc / Floating / 2-

Position (MS7503, Fail safe)*

K - 24Vac, Universal 0(2)-10Vdc / Floating / 2-

Position, w/ end switches (MS7503, Fail safe)*

VRN 2 A B P A 1 0 00

Example part number: VRN2ABPA1000

* Only compatible with valves 1-1/4” or smaller.

5 38-00032—03

01 - 3 ft Cable

Page 6

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

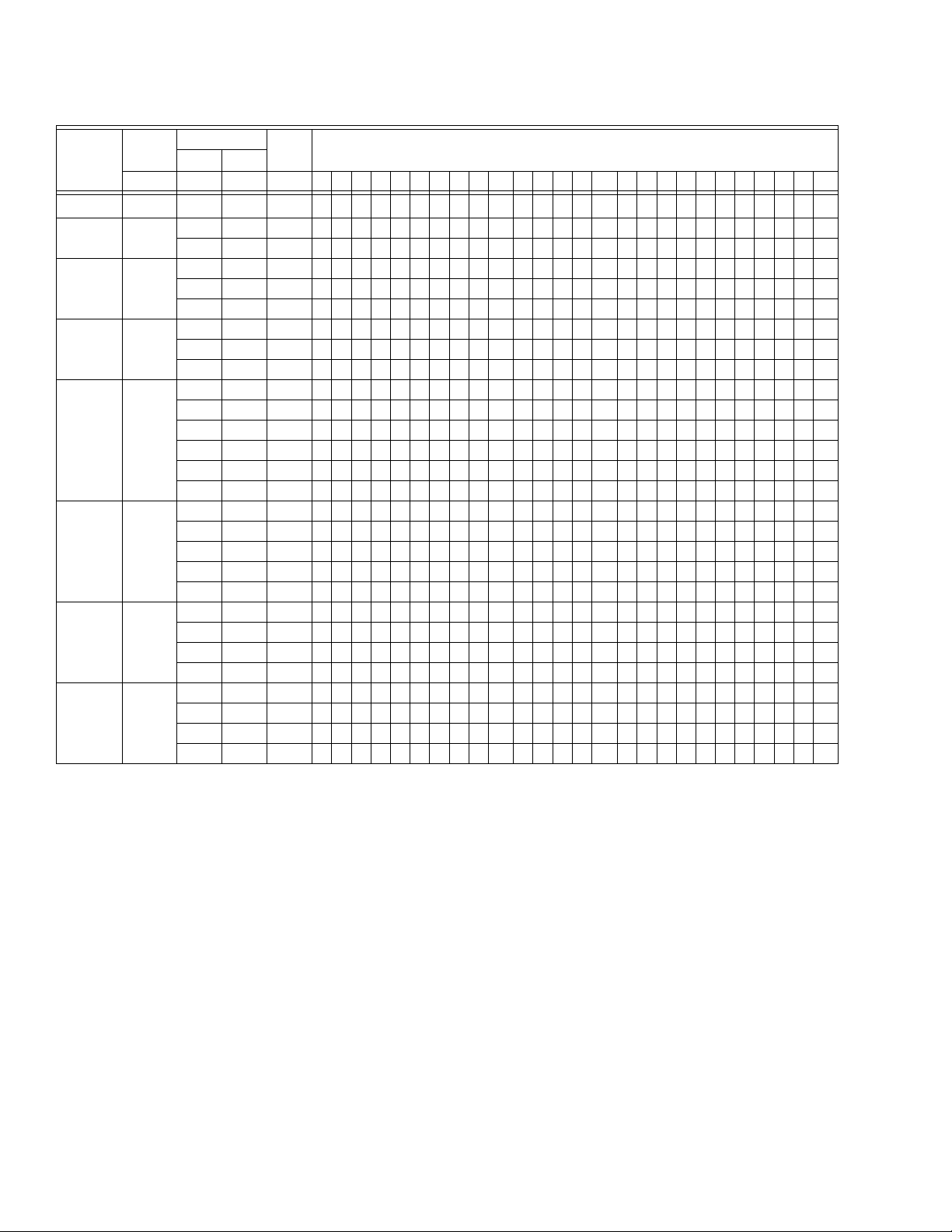

Table 4. VRN Flow Rate (GPM) and Differential Pressure with Short Order Code Indicator.

Model

Size

ΔP range

Min Max

Head

Loss

Short Order Code Indicator

(inch) (psi) (psi) (psi)BDEFGHJKLMNPQR S TU12345678 9

VRN2A 0.5

VRN2B 0.75

VRN2C 1

VRN2D 1.25

VRN2E 1.5

VRN2F 2

VRN2G 2.5

VRN2H 3

3 35 3 1234567

3 35 3 1234567

6356 8910*

3 35 3 1234567

6356 89

4 50 4 10 15 20

4 50 4 10 15 20

5505 2530

6.5586.5 35*

4 50 4 10 15 20

5505 2530

4584 35

6586 404550

7 58 7 55 60 65 70 75 80 85

11 58 11 95*

4 50 4 10 15 20

5505 2530

4584 35

6586 404550

7 58 7 55 60 65 70 75

4584 253035

6586 404550

7 58 7 55 60 65 70 75 80 85

11 58 11 95*

4584 253035

6586 404550

7 58 7 55 60 65 70 75 80 85

11 58 11 95*

* Valve does not have flow control insert.

Maximum GPM

38-00032—03 6

Page 7

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

G

CLEARANCE ABOVE ACTUATOR 3/4 (19)

E

F

D

A

B

C

M34967

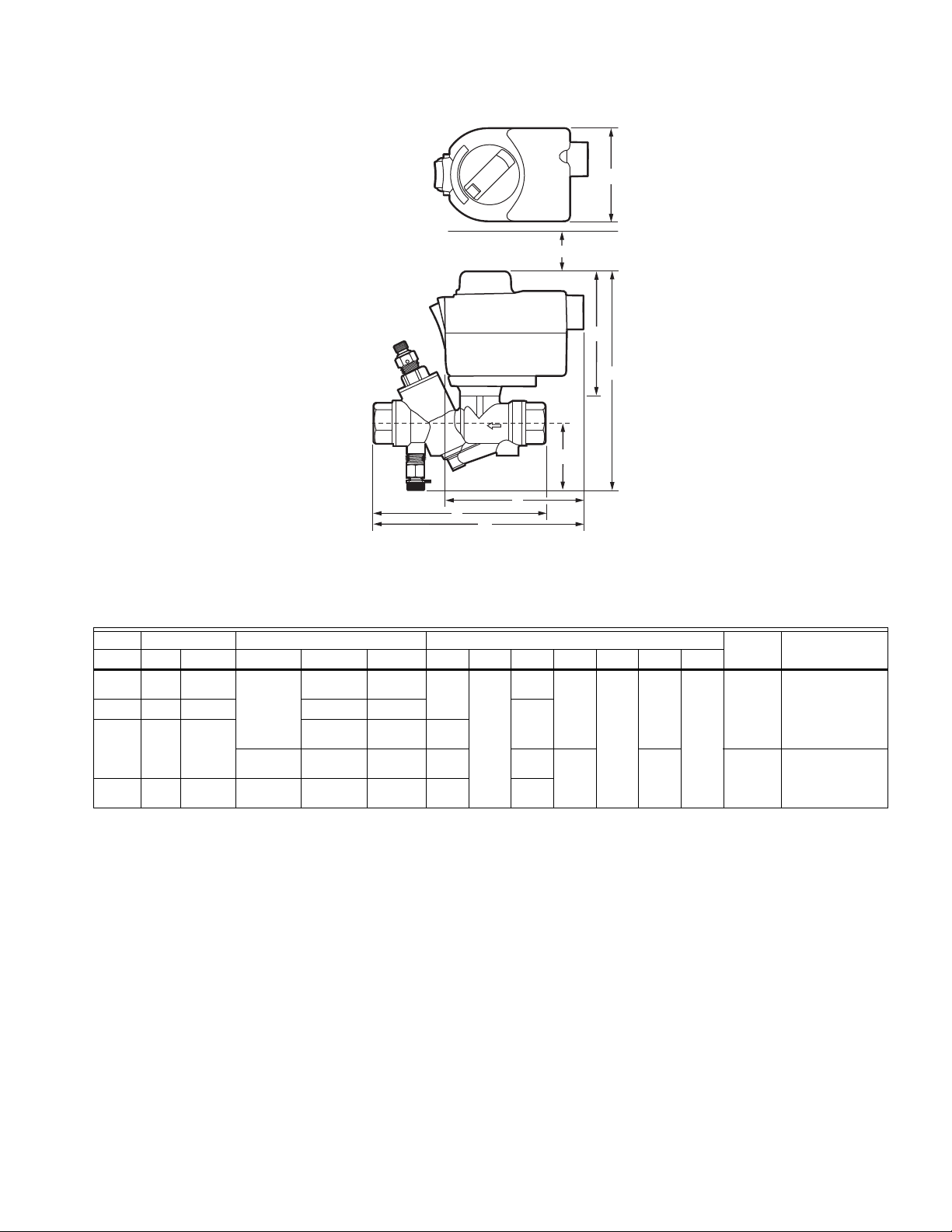

Fig. 1. Valve Dimensions with MVN Actuator; see Table 5.

Table 5. Valve Dimensions with MVN Actuator.

Model Pipe Size Flow, gpm (m3/h) Dimensions in in. (mm)

VRN2A 1/2 DN15 1.0 (0.23) 7.0 (1.6) 5.71

VRN2B 3/4 DN20 9.0 (2.0) 10 (2.3) 6.63

VRN2C 1 DN25 15.0 (3.4) 5.83

20 (4.5) 20 (4.5) 9.65

VRN2D 1–1/4 DN32 10 (2.3) 30 (6.8) 35 (7.9) 8.98

a

Do not use stainless steel replacement stem assemblies in valves with plated brass trim; galvanic reactions may occur.

(145)

(148)

(245)

(228)

4.56

(116)

6.57

(167)

(168)

9.13

(232)

8.79

(223)

2.32

(59)

2.41

(61)

3.87

(98)

7.36

2.8 (71) 2.5 (1.1) Stem: 5112-19

(187)

8.01

(203)

Weight

lb. (kg)

7.1 (3.2) Stem: 5112-20

Service Replacement

PartsNPT in. S.I. metric Min. Rating Max. Rating Full Port A B C D E F G

5112-22 (SS

Regulator:

8615-100 for 1-3 gpm;

8615-101 for 4-10 gpm

5112-23 (SS

Regulator:

8615-102

a

);

a

);

7 38-00032—03

Page 8

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

E

F

B

D

A

C

M35993

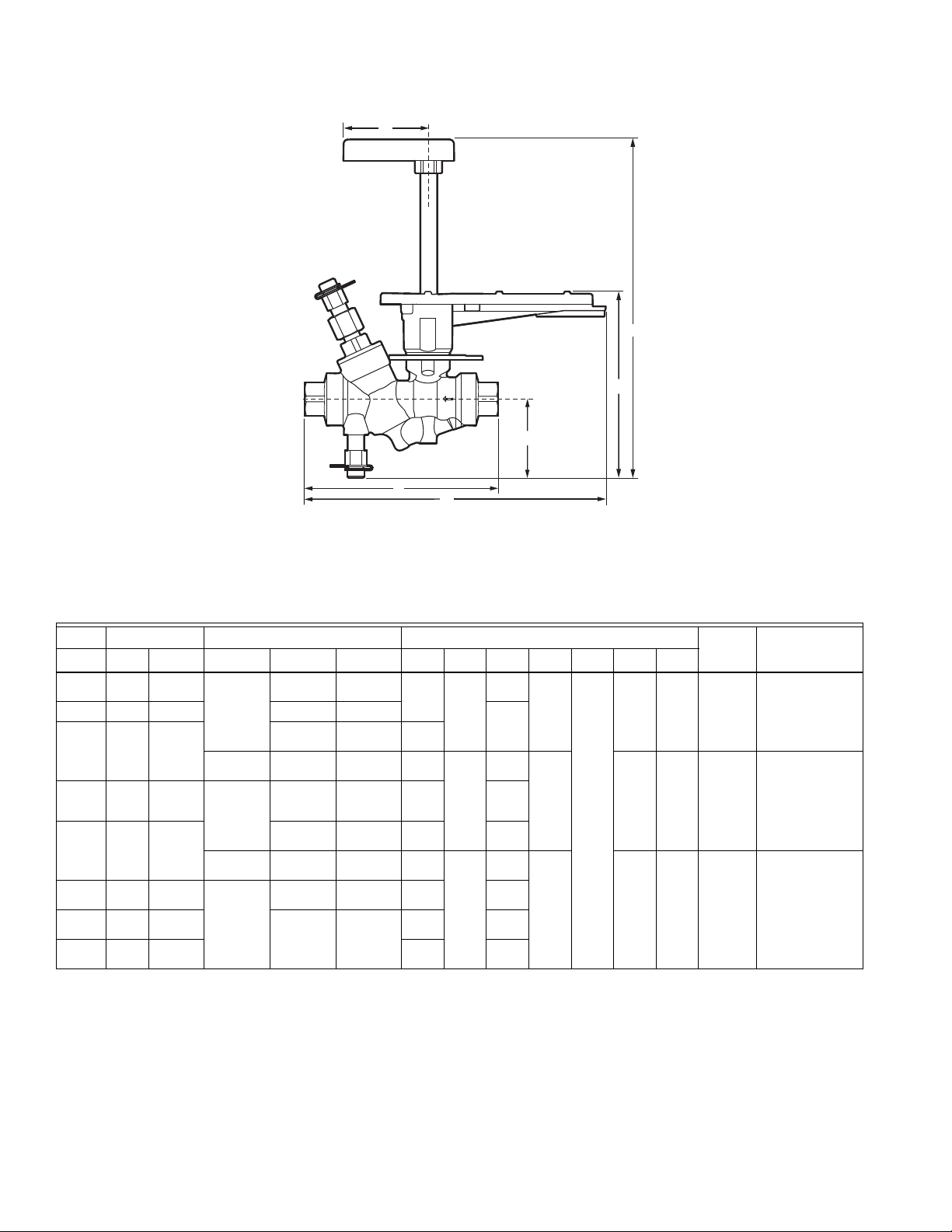

Fig. 2. Dimensions of valves used with MN/MS actuators; see Table 6.

Actuator not shown. See Figures 4 and 6 for MN/MS actuator dimensions.

Table 6. Dimensions of valves used with MN/MS actuators; see Fig. 2.

See Figures 4 and 6 for MN/MS actuator dimensions.

Model Pipe Size Flow, gpm (m3/h) Dimensionsc in in. (mm)

a

VRN2A

VRN2B

VRN2C

VRN2D

VRN2E

VRN2F

VRN2G

VRN2H

a

Long shaft supplied with “Zelix” direct coupled spring return actuators; short shaft supplied with MN series stay-in-place

1/2 DN15

3/4 DN20 9.0 (2.0) 10 (2.3)

1DN25

1–1/4 DN32

1–1/2 DN40

2DN50

2–1/2 DN65

3DN80

1.0 (0.23)

20 (4.5) 20 (4.5)

10 (2.3)

40 (9.1) 85 (19.3) 95 (21.6)

25 (5.7)

7.0 (1.6)

15.0 (3.4)

30 (6.8) 35 (7.9)

35 (7.9)

75 (17.0)

85 (19.3) 95 (21.6)

5.71

(145)

5.83

(148)

9.65

(245)

8.98

(228)

(213)

8.80

(224)

10.66

(271)

10.97

(279)

11.42

(290)

11.80

(300)

5.43

(138)

6.10

(155)

6.95

(177)

8.87

(225)

8.94

(227)

11.44

(291)

11.10

(282)

11.01

(280)

12.84

(326)

13.00

(330)

13.23

(336)

13.41

(341)

2.32

(59)

2.41

(61)

2.93

(74)

2.5 (64)

10.02

(255)

10.68

(271)

11.55

(293)

Fs

8.77

(223)

9.43

(240)

10.30

(262)

a

Weigh t

lb. (kg)

2.5 (1.1)

7.1 (3.2)

13.7 (6.2)

Service Replacement

PartsNPT in. S.I. metric Min. Rating Max. Rating Full Port A B C D E Fz

Stem: 5112-19

5112-22 (SS

Regulator :

8615-100 for 1-3 gpm;

8615-101 for 4-10 gpm

Stem: 5112-20

5112-23 (SS

Regulator :

8615-102

Stem: 5112-21

5112-24 (SS

Regulator :

8615-031

b

);

b

);

b

);

DCAs.

b

Do not use stainless steel replacement stem assemblies in valves with plated brass trim; galvanic reactions may occur.

c

Actuator dimensions fall within the envelope of the handle and mounting bracket. See actuator literature for detailed

dimensions.

38-00032—03 8

Page 9

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

MVN Actuator

APPLICATION

MVN 3Nm (27 lb-in.) Control Valve Actuator is used with

the VRN2 Pressure Independent Control Valves to control

hot and chilled water with glycol solutions up to 50% in

heating, ventilating, and air conditioning (HVAC) systems

to provide two-position or modulating functions.

FEATURES

• Non-spring Return

• Floating and modulating

• Space saving, click-on installation – no tool required

• Extendable position indicator for easy commissioning

• Available with or without cable (1 m or 3 m length)

• Compatible with control ball valves from 1/2 to 1-1/4

inches.

• Actuator can be mounted on the valve in any of four

positions.

SPECIFICATIONS

Actuator Type: Valve

Rotational Stroke: 90° ±3°.

Fail Safe Mode: Non-spring return, Fail in place

Torque: 27 lb-in. (3 N m).

External Auxiliary Switches Available: No

Supply Voltage: 24 Vac +20%, -15%, 24 Vdc

Power Consumption: 5 VA- Modulating, 1.5 VA - Floating,

6 VA - Fast Acting SPDT

Environmental Rating: NEMA2

Frequency: 50 Hz; 60 Hz

Mounting: Click-on installation – no tool required

Noise Rating at 1m (Maximum): 35 dB(A) max at 1 m

[50 dB(A) for MVN643].

Materials: Plenum rated plastic housing

Operating Humidity Range (% RH):

5 to 95% RH, non-condensing

Ambient Temperature Range:

-4°F to 131°F (-20°C to 55°C)

Storage Temperature Range:

-40°F to 176°F (-40°C to 80°C)

Weight: 0.6 lb. (0.27 kg)

Dimensions: See Fig. 1 and Table 5.

Timing: 90 sec. (+/-10%) for MVN613 and MVN713;

30 sec. (+/-10%) for MVN643

Electrical Connections: Field wiring 18 to 20 AWG to

screw terminals, located under the removable access

cover.

G

CLEARANCE ABOVE ACTUATOR 3/4 (19)

E

B

MVN WITH 2-WAY BALL VALVE

Fig. 3. Dimensions; see Table 5 on page 7.

M34969

Humidity Ratings: 5% to 95% RH non-condensing.

Design Life (at Rated Voltage):

60,000 cycles; 1 cycle = 0°…90°…0°

Cable Specification:

18 AWG, Plenum Rated, 300 V, 10 A, 1 m or 3 m length

available.

Environmental Protection Ratings: IP40.

Approvals:

UL/cUL

UL60730

Table 7. Actuators and Accessories

Actuator Description Accessory

MVN613A0000 Floating control ball valve actuator

MVN643A0000 Fast acting SPDT contol ball valve actuator

MVN713A0000 Modulating control ball valve actuator

To order actuator with accessories order actuator part

number + accessory. For example: MVN613A0000 + C1

9 38-00032—03

C1- 1 meter cable

C3 - 3 meter cable

Page 10

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

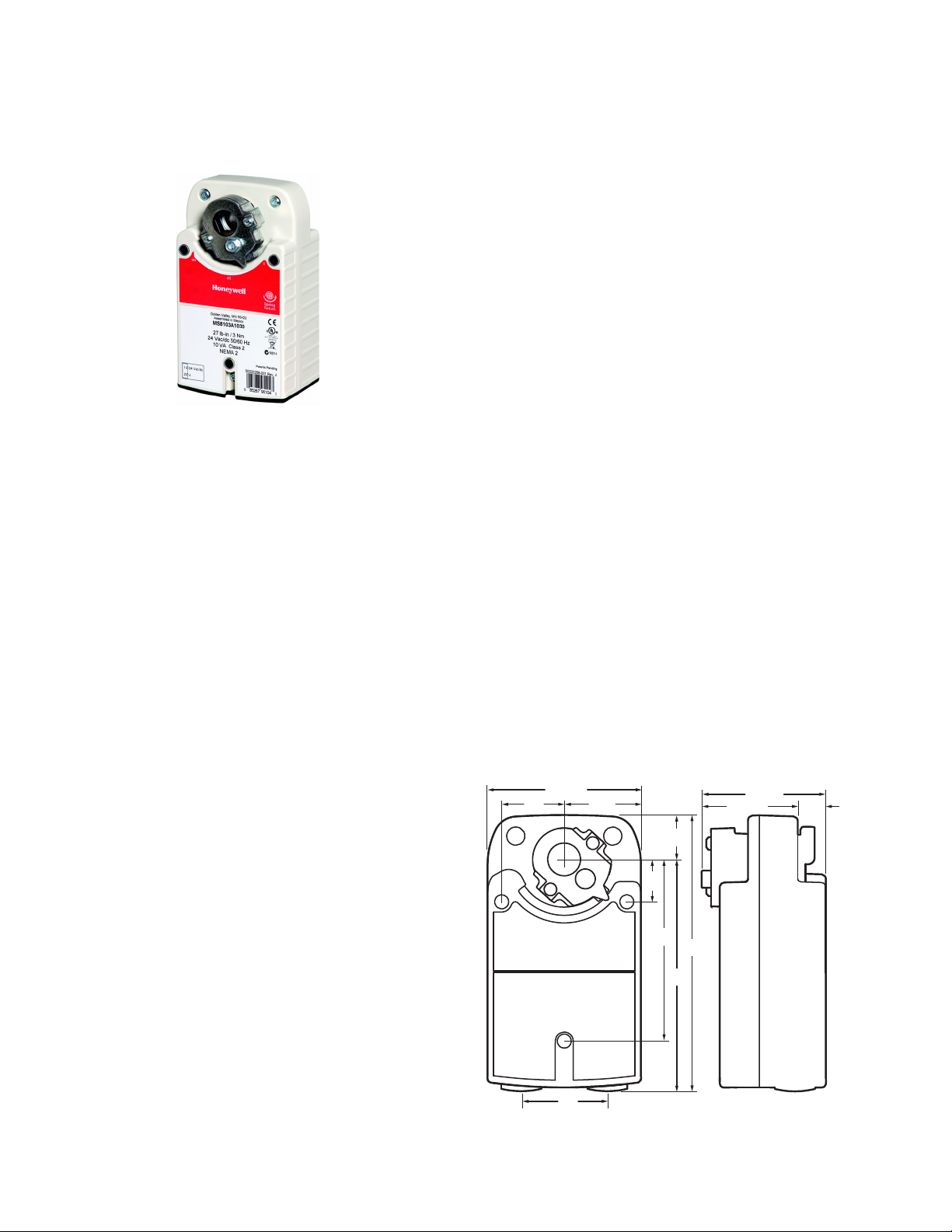

Non-Spring Return Direct Coupled Actuator

APPLICATION

This non-spring return direct-coupled damper actuator

provides modulating and floating/2-position control for:

air dampers, air handlers, ventilation flaps, louvers, and

reliable control for air damper applications with up to

10 sq. ft./ 44lb.-in. (5 N m) and 20 sq. ft./88 lb.-in. (10 N m)

(seal-less damper blades; air friction-dependent).

FEATURES:

Maximum Noise Rating, Driving (dBA @ 1m): 35

Rotation to Open: By switch

Rotational Stroke Adjustment: Dual Integral Adj. Stops

(3 degree increments)

Compatible Damper Shafts:

1/4 to 1/2 in. square or 3/8 to 5/8 in. round

(6 to 13 mm square or 8 to 16 mm round)

Shaft Adapter Type: U-bolt clamp

Supply Voltage: 24 Vac +20%, -15%, 24 Vdc

Power Consumption: 5 VA

Materials: Plenum rated plastic housing

Ingress Protection Rating: IP54

Operating Humidity Range (% RH):

5 to 95% RH, non-condensing

Ambient Temperature Range:

-5°F to +140°F (-20°C to +60° C)

Storage Temperature Range:

-22°F to +176°F (-30°C to +80°C)

Weight: 1 lb (0.45 kg)

Includes: Mounting bracket, screws, shaft adapter,

water-tight strain-relief cable fittings

Comments: Integral 1/2 in. NPSM conduit connection.

• Declutch for manual adjustment

• Adjustable mechanical end limits

• Access cover includes enclosed screw terminal strip

(22 to 14 AWG) for electrical connections

• Models available with 3 foot 18 AWG color-coded

cable

• Mountable in any orientation

• Function selection switch for selecting modulating or

floating/2-position control

SPECIFICATIONS

Actuator Type: Damper; Valve

Rotational Stroke: 95° ±3 degrees

Fail Safe Mode: Non-spring return

Tor que : 44 lb-in. (5 N m)

External Auxiliary Switches Available: No

Environmental Rating: NEMA2

Frequency: 50 Hz; 60 Hz

Manual operation: Declutch mechanism

Mounting: Direct coupled

Approvals:

CE: 89/336/ECC, 73/23/EEC

C-Tick: N314

Underwriters Laboratories, Inc.: UL873, Plenum Rated

Canadian Underwriters Laboratories, Inc.:

cUL C22.2 No. 24-93

1-5/8

(41)

3-11/32

(85)

5-9/32

(134)

2-7/16

(62)

2-19/32

(66)

Fig. 4. Non-spring return direct coupled actuator

dimensions in inches (mm).

M23103A

4-1/4

(108)

38-00032—03 10

Page 11

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

M37351

2-7/8 (73)

6-1/2

(165)

5-3/8

(137)

3-1/8 (79)

3-1/8 (79)

7

(178)

3-17/64 (83)

1-9/16

(40)

FOR 1/2 INCH SHAFT.

Spring Return 3 Nm Diamond

APPLICATION

MS7103 and MS3103 Spring Return Direct Coupled

Actuators (DCA) are used within heating, ventilating and

air-conditioning (HVAC) systems. They can drive a variety

of quarter-turn, final control elements requiring spring

return fail-safe operation.

FEATURES

• Brushless DC submotor with electronic stall

protection

• Self-centering shaft adaptor (shaft coupling) for wide

range of shaft sizes

•Fast test mode

• MS7103 models for use with 2-10 Vdc control

• MS3103 models for use with Sylk-enabled controllers

• Models available with two internal end switches

• Durable plastic housing with built-in mechanical end

limits

• Spring return direction field selectable

• Shaft position indicator and scale

• UL (cUL) listed and CE compliant

• Plenum rated actuator and control/power cable

Cable Specification:

Power Cable: Plenum Rated, 3 ft (0.914 m) length from end

of access cover, 18 AWG

Switch Cable: Appliance Rated, 3 ft (0.914 m) length from

end of access cover, 18 AWG

Ingress Protection Rating: IP54

Environmental Rating: NEMA 2

Frequency: 50 Hz; 60 Hz

Mounting: Direct Coupled

Maximum Noise Rating, Driving (dBA @ 1m): < 40

Maximum Noise Rating, Spring Return (dBA @ 1m): < 65

Rotational Stroke Adjustment: Mechanically limited

7.5 degree increments

Compatible Damper Shafts: 3/8 to 3/4 in. round or 1/4 to

1/2 in. square (9 to 19 mm round or 6 to 13 mm square)

Shaft Adapter Type: U-bolt

Materials: Plenum rated plastic housing

Operating Humidity Range (% RH): 5 to 95% RH, non-

condensing

Ambient Operating Temperature: -40 F to +150F (-40 C

to +65 C)

Shipping and Storage Temperature: -40 F to +150F (-40 C

to +65 C)

Weight: 1.7 lb (0.78 kg)

Approvals

UL60730

IEC 60730-1 and Part 2–4

UL1097 for Double Insulation

CE Certification Low Voltage Directive 2014/35/EU

CE EMC 2004/108/EC

Switch cables are UL certified only

SPECIFICATIONS

Actuator Type: Damper; Valve

Rotational Stroke: 95 ±3 degrees

Fail Safe Mode: Spring Return

Tor que : 27 lb-in. (3 Nm)

Spring Return Torque: 27 lb-in (3 Nm)

Spring Return Direction: By orientation

External Auxiliary Switches Available: No

Fig. 5. Dimensions in in. (mm).

11 38-00032—03

Page 12

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

M27712A

3-55/64 (98)

6-61/64

(177)

1-1/8

(29)

5-27/32

(148)

1-9/16

(40)

3-5/32 (80)

4-9/16

(116)

1-15/16

(49)

1-1/16

(27)

2-1/64

(55)

47/64

(19)

2-27/64 (61)

Spring Return Direct Coupled Actuator

APPLICATION

MS4105, MS7405, MS7505, and MS8105 Spring Return

Direct Coupled Actuators (DCA) are used within heating,

ventilating, and air-conditioning (HVAC) systems. They can

drive a variety of quarter-turn, final control elements

requiring spring return fail-safe operation.

FEATURES

• Brushless DC submotor with electronic stall

protection on all models

• Self-centering shaft adaptor (shaft coupling) for wide

range of shaft sizes

• Access cover includes enclosed screw terminal strip

(22 to 14 AWG) for electrical connections.

• Models available with 3 foot 18 AWG color-coded

cable

• Durable plastic housing with built-in mechanical end

limits

• Spring return direction field selectable

• Shaft position indicator and scale

• UL (cUL) listed and CE compliant

• All models are plenum rated per UL873

SPECIFICATIONS

Actuator Type: Damper; Valve

Frequency: 50 Hz; 60 Hz

Mounting: Direct Coupled

Maximum Noise Rating, Holding (dBA @ 1m):

20 (no audible noise)

Maximum Noise Rating, Driving (dBA @ 1m): 50

Rotation to Open: By switch

Rotational Stroke Adjustment:

Mechanically limited 5 degree increments

Compatible Damper Shafts:

1/4 to 1/2 in. square or 3/8 to 5/8 in. round

(6 to 13 mm square or 9 to 16 mm round)

Shaft Adapter Type: Self-centering clamping

Materials: Plenum rated plastic housing

Supply Voltage: 24 Vac +20%, -15%, 24 Vdc

Power Consumption: 5 VA

Operating Humidity Range (% RH):

5 to 95% RH, non-condensing

Ambient Temperature Range: -40°F to +149°F

(-40°C to +65°C) for two-position actuators only

Storage Temperature Range:

-40°F to +150°F (-40°C to +65°C)

Weight: 3.5 lb. (1.6 kg)

Includes: Mounting bracket, self-centering shaft adapter

Approvals:

CE: EMC 2004/108/EC; Certification Low Voltage

Directive 2006/95/EC; IEC 60730-1 and Part 2-14

C-Tick: N314

Underwriters Laboratories, Inc.: UL873

Canadian Underwriters Laboratories, Inc.:

cUL C22.2 No. 24-93

Rotational Stroke: 95 ±3 degrees

Fail Safe Mode: Spring Return

Torque: 44 lb-in. (5 N m)

Spring Return Torque: 44 lb-in. (5 N m)

Spring Return Direction: By orientation

External Auxiliary Switches Available: No

Environmental Rating: NEMA2

38-00032—03 12

Fig. 6. Spring return direct coupled actuator

dimensions in inches (mm).

Page 13

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

Table 8. Actuator Accessories and Replacement Parts.

MVN613A0000

MVN643A0000

MVN713A0000

Couple Actuators

MN Non-Fail-

Safe Direct

Part Number Description

5112-3R Weather Enclosure Assembly x x

MVNAAA Replacement Valve Adaptor x x x

MVNAAL Replacement Valve Adaptor, Low Profile

Direct Couple

MS Fail-Safe

Actuators

MVNAC7131 Replacement Cable with Terminal 1m, Modulation

x

(RED, BLACK, WHITE)

MVNAC6131 Replacement Cable with Terminal 1m, Floating

xx

(RED, BLACK, WHITE)

MVNAT3 Replacement Screw type Terminal Block, Pluggable x x x

5112-11 Replacement actuator bracket x x

205860 Minimum position Potentiometer x x

32006306-001 Resistor Kit (500 ohm); converts 4-20 mA signal to 2-10 Vdc x x

Q7002B1009 Universal Interface Module x x

STRN-SCSA Self-centering Shaft Adapter x

32000085-001 Strain Relief Fitting (10 pack) x

STRN-STRNRLF Stain Relief Fitting (10 pack) x

13 38-00032—03

Page 14

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

Application Notes

IMPORTANT

Valve sizing is important for correct system

operation. Undersized valves do not have sufficient

capacity at maximum load. Oversized valves do not

have sufficient authority over the load in

modulating applications.

Oversized valves can cause excessive cycling and

the seat and ball can be damaged because of the

restricted opening.

Proper Use

VRN valves are intended for use in chilled water and hot

water closed loop applications only, with a temperature

range of 35 to 250 °F, and pressures up to 360 psig.

Water should be properly filtered, treated and conditioned

for good operating performance, and according to

recommendations of the boiler or chiller manufacturers.

The installation of strainers and filters is recommended.

Do not use with manual balancing valves.

IMPORTANT

The presence of excessive iron oxide (red rust) in

the system voids the valve warranty.

Effective Flow Rate

The built-in differential pressure regulator makes fluid flow

through the valve independent of changes in supply

pressure, eliminating “hunting” by the control system, even

at low coil flow. The pressure regulator virtually eliminates

cavitation in the valve, and decouples the control valve

from the effects of piping components such as reducers

and elbows.

Pressure independent control valves are sized to match

design coil flow regardless of coil size. VRN2 valves

eliminate the need to balance the system for proper flow,

and allow chillers to be operated at design temperature

differential for maximum efficiency at every load condition.

When used in a system with variable speed pump drives,

3-way valves and coil bypass lines are not required. In new

construction, VRN2 valves perform better than reverse

return piping designs without the extra materials these

systems need. Pressure-independent control requires less

flow, enabling use of smaller piping, pumps, and chillers.

Flow Characteristics

The VRN2 two-way dynamic pressure-regulating control

valves have:

• an equal percentage flow characteristic with

characterized flow control insert.

Required Operating Torque

Both Honeywell non-spring return MVN and spring return

low torque direct coupled actuators can be utilized with the

VRN2 valves. VR valves use a patented seat design that

reduces the torque needed from the actuator.

Table 9. Close-off, Differential Pressure Ratings.

Close-off

Pressure Rating

Valve Type Valve Size

2 way 1/2 in., 3/4 in. 100

1 in., 1-1/4 in., 1-1/2 in. 100

(psi)

TYPICAL SPECIFICATIONS

Valve Actuator

Actuator shall accept analog modulating [(0)2-10 Vdc],

floating (tri-state), or two-position signal as indicated in

the control sequence. Actuators shall be manufactured by

Honeywell. Actuator shall provide minimum torque

required for full valve shutoff position. Wiring terminals

shall be provided for installation to control signal and

power wiring.

Actuator shall be available with housing suitable for

outdoor installation.

Accessories Identification tags shall be available for all

valves.

Pressure Independent Valve

Valve housing shall consist of forged brass rated at no less

than 360 psi at 250°F. Standard valve ball shall consist of

chemically nickel-plated brass. Manufacturer shall be able

to provide optional 316 stainless steel ball and stem. The

valve shall have an integral differential pressure regulator

to maintain constant pressure drop across valve seat to

decouple valve flow from system pressure changes. Flow

control accuracy shall be +/-5% or better. Regulator will be

constructed from 316 stainless steel with a rolling

diaphragm and operate under positive pressure. Regulator

shall be located above axis of pipe with ¼” ISO test port

fittings to allow pressure measurement and venting.

Valve stem assembly shall be of a pack-less design and be

field-replaceable without removing the valve body from the

piping. Teflon™ seals shall hold the stem in alignment, and

protect the O-ring from system temperature fluctuations.

Stem O-ring shall be made of peroxide-cured EPDM and

be isolated from system treatment chemicals by a reservoir

of silicon grease. Valve shall have a blow-out proof stem

with minimum 600 psi rating.

38-00032—03 14

Page 15

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

CAUTION

M34979

FLOW FLOW

2-WAY; CLOSED

2-WAY; OPEN

NOTES: FOR 2-WAY VALVES TO MOUNT ACTUATOR ON OPEN VALVE, TURN ACTUATOR

FULLY COUNTER CLOCKWISE AS SHOWN. FOR 2-WAY VALVES TO MOUNT

ACTUATOR ON CLOSED VALVE, TURN ACTUATOR FULLY CLOCKWISE AS SHOWN.

45

45

M33091

INSTALLATION

When installing this product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check ratings given in instructions and on the

product to ensure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Preparation

Equipment Damage Hazard

Foreign particles like dirt and metal chips can

damage the ball seals.

For trouble-free operation of the product, good

installation practice must include initial system

flushing, and chemical water treatment. Clean the

lines upstream of particles larger than 1/16 inch

diameter (welding slag, pipe scale, sand and other

suspended particulate). Use of a 50 micron (or

finer) system side stream filter is suggested.

Remove all filters before flushing.

3. Eliminate air from system.

4. Two-way valves are marked to show flow direction.

IMPORTANT

Flow arrows must point in the direction of the flow

for proper operation.

5. Stem rotation:

a. For two-way valves:

(1) Clockwise to close.

(2) Counterclockwise to open.

NOTE: After valves have been installed in the piping,

the installer can determine the ball

orientation within the valve from the notches

in the top of the valve stem. For two-way

valves, the lengthwise direction of the notch

indicates the flow through the ball (i.e. when

the notch is parallel to the axis of the valve

between A and B ports, the ball will allow flow

through the valve).

6. Valve must be mounted with the actuator/bracket

above the valve body. Do not install the valve with the

stem below horizontal or upside down.

(See Fig. 8 – 10.)

Do not use boiler additives, solder flux and wetted

materials which are petroleum based or contain

mineral oil, hydrocarbons, or ethylene glycol

acetate. Compounds which can be used, with

minimum 50% water dilution, are diethylene glycol,

ethylene glycol, and propylene glycol (antifreeze

solutions).

If installing these valves in an addition to, or

retrofitting an existing building, do not assume that

the fluid in the existing piping meets these criteria.

Mechanical Installation

IMPORTANT:

Hold valve with pipe wrench by hexagonal fitting

ONLY. Do NOT handle the valve body with the pipe

wrench; product damage may result.

The valves are tapped in NPT and should be sealed with an

approved pipe sealant. Torque should not exceed 75 lb-ft.

Refer to actuator literature for actuator dimensions.

1. Clean the lines upstream of particles larger than

1/16 in. diameter (welding slag, pipe scale and other

contaminants).

2. Proceed with installation once the system specifics

(expansion/contraction of the system and its

medium as well as operating pressures) are within

tolerances.

Fig. 7. Orientation of valve.

Fig. 8. Acceptable valve angle from vertical

for MVN actuators.

15 38-00032—03

Page 16

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

85 85

M29519A

M29526B

VALVE BODY

VALVE STEM

COUPLER**

WING NUT**

MOUNTING

PLATE**

STEM ASSEMBLY COVER**

SCREWS (2)**

HANDLE (REMOVABLE) FOR

MANUALLY ROTATING SHAFT**

STEM ASSEMBLY**

SCREWS (2)**

STEM RETAINER PLATE

BOLT**

ANTI-ROTATION

BRACKET**

**

INCLUDED IN REPLACEMENT KIT (PART NO. 5112-11).

Fig. 9. Acceptable valve angle from vertical

for MN and MS actuators.

Fig. 10. Vertical valve installation.

M34954

Fig. 11. Actuator mounting plate adjustment.

Mounting Plate Adjustment

NOTE: See Fig. 11 for valve exploded view.

The Actuator Mounting Plate can be rotated to a different

position for installation in confined spaces. This is

accomplished as follows:

1. Remove the handle from the shaft and set it aside.

2. Remove the two screws that hold the stem assembly

to the mounting plate and set them aside.

3. Remove and set aside the stem assembly.

4. Remove and set aside the two screws that attach the

mounting plate to the valve.

5. Remove and set aside hold-down ring from mounting

plate.

6. Rotate mounting plate around valve top to the

desired position.

NOTE: Take note of the screw hole positions on the valve.

They limit the mounting plate positions.

7. Lower ring down to valve body and engage it in the

new position relative to the mounting plate.

8. Tighten screws to valve body securing the mounting

plate.

9. Reattach the stem assembly to the mounting plate.

10. If desired, replace the handle on the shaft.

38-00032—03 16

Page 17

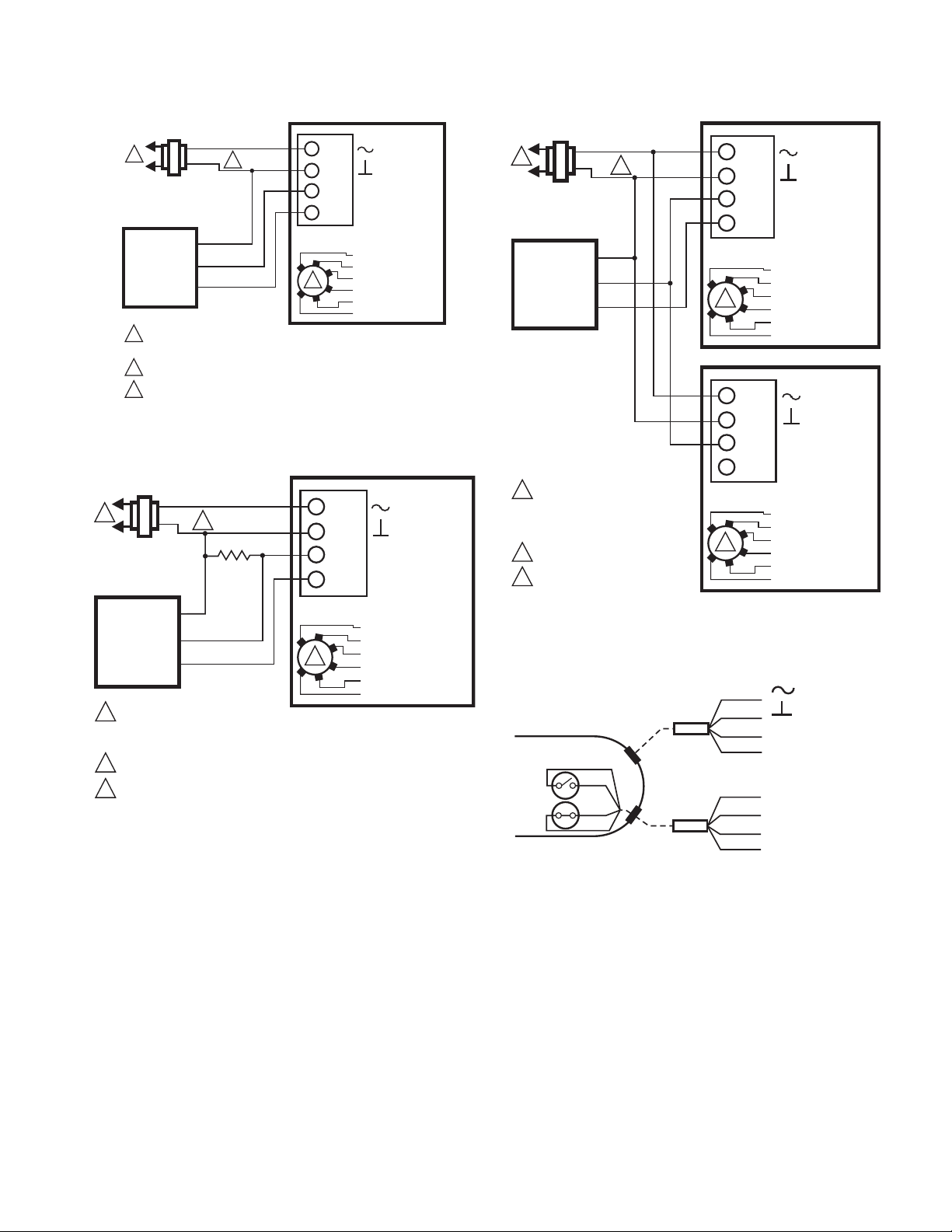

Electrical Installation

432

FLOATING ACTUATOR

24 VAC

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

CONNECTION REQUIRED FOR SPST CONTROL.

2

CONTROLLER

2

DIRECT

REVERSE

SERVICE/OFF

M34869A

3

4

3

2

FLOATING ACTUATOR

24 VAC

Direct

Reverse

Service/Off

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

FLOATING

CONTROLLER

M18946A

24 VAC

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

PROPORTIONAL

CONTROLLER

+

–

FEEDBACK

1

325

PROPORTIONAL ACTUATOR

FEEDBACK

+

0(2)-10 VDC OF 0(4)-20 mA CONTROL SIGNAL ACCEPTABLE.

SET CONTROL SIGNAL DIP SWITCH TO “OFF” FOR VOLTAGE.

SET TO “ON” FOR CURRENT.

2

2

2 -10 Vdc

2 -10 Vdc

0 -10 Vdc

0 -10 Vdc

M18947B

4

5°

85°

S1 S2

S3 S5 S6

M25214A

END SWITCHES (CLASS II-ONLY)

FLOATING ACTUATOR

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FLOATING

CONTROLLER

M33137D

2

3

4

1

BLACK

WHITE

BROWN

2

1. If necessary, remove actuator wiring cover.

2. Wire actuator using Figures 12 through 35 for the

application required.

3. Replace cover.

Wiring

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

Fig. 12. MN6105 with On/Off SPDT Control.

Fig. 13. MN6105 with Floating Control.

Fig. 14. MN7505 with 0(2)-10 Vdc Control.

Fig. 15. Wiring for MN6105 and MN7505 models with

aux./end switches.

Fig. 16. MVN613 with Floating Control.

17 38-00032—03

Page 18

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FLOATING ACTUATOR

24 VAC

1

FLOATING

CONTROLLER

2

3

4

1

M33138C

BLACK

WHITE

BROWN

2

M33557C

FLOATING ACTUATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

3

4

1

24 VAC

BLACK

BROWN

WHITE

SPST

PROPORTIONAL ACTUATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

4-20mA

CONTROLLER

M33141C

1

2

3

+

+

–

DIP SWITCH POSITION

1 2 MODE

OFF OFF 2-10V

OFF ON 0-10V

ON OFF 10-2V

ON ON 10-0V

PROPORTIONAL/MODULATING: 4-20mA CONTROLLER OUTPUT WITH

500Ω SERIES RESISTOR

TO OTHER

ACTUATORS

500 OHMS,

1/2 W

MINIMUM

24 VAC

RED

BLACK

WHITE

1

PROPORTIONAL ACTUATOR

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

0 (2)-10 VDC

CONTROLLER

M33140A

1

2

3

+

+

–

DIP SWITCH POSITION

1 2 MODE

OFF OFF 2-10V

OFF ON 0-10V

ON OFF 10-2V

ON ON 10-0V

PROPORTIONAL/MODULATING: 0(2)...10 VDC OR 10...0(2) VDC CONTROLLER OUTPUT

2

RED

BLACK

WHITE

2

1

SPDT

24 VAC

1

1

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SET SWITCH TO FLOATING.

ACTUATOR

V

0°-90°/MODULATING

90°-0°/FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING, FWD

FLOATING, REV

2

RED

BLACK

BROWN

WHITE

CLASS 2

24 VAC

1

1

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SET SWITCH TO FLOATING.

ACTUATOR

V

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING, FWD

FLOATING, REV

2

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

CLASS 2

Fig. 17. MVN613 or MVN643 with Two Position SPDT

Control.

Fig. 18. MVN643 with Two Position SPST Control.

Fig. 20. MVN713 with 0(2)-10 Vdc Control.

Fig. 21. MS7505 with Two Position SPDT Control.

38-00032—03 18

Fig. 19. MVN713 with 4-20mA Control.

Fig. 22. MS7505 with Floating Control.

Page 19

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

ACTUATOR

4 TO 20 mA

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

490 TO 510

OHMS,

1/2 W

MINIMUM

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING IF AVAILABLE.

V

–

+

FEEDBACK

4

3

1

2

M37321

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING, FWD

FLOATING, REV

3

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

CLASS 2

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION

AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING

IF AVAILABLE.

V

–

+

FEEDBACK

4

3

1

2

M37322

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING

, FWD

FLOATING

, REV

3

ACTUATOR

V

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING

, FWD

FLOATING

, REV

3

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

CLASS 2

ACTUATOR

SPST SWITCHES

MAIN

CABLE

M37303A

RED

BLACK

WHITE

BROWN

SWITCHES

CABLE

BLUE

BROWN

GRAY

BLACK

FEEDBACK OR 90˚−0˚

+ OR 0˚−90˚

CLASS 2

RED

1

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

FEEDBACK

1

2

3

24 VAC

2

–

+

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING IF AVAILABLE.

1

2

3

4

3

BLACK

WHITE

BROWN

ACTUATOR

V

0°-90°/MODULATING

90°-0°/FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING

, FWD

FLOATING

, REV

M37320

Fig. 23. MS7103 with 2-10 Vdc Control (MS7503 shown,

ignore selection switch).

Fig. 24. MS7103 with 4-20 mA Control (MS7503 shown,

ignore selection switch).

Fig. 25. MS7103 with 2-10 Vdc Control using two

actuators (MS7503 shown, ignore selection switch).

Fig. 26. Wiring for MS7103 and MS3103 Auxiliary

Switches. Gray/Black = Normally Open. Closed in range

80 degrees to Fully Open. Blue/Brown = Normally

Closed. Open in range 10 degrees to Fully Open.

19 38-00032—03

Page 20

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

ACTUATOR

SPST

24 VAC

1

1

2

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

V

1

2

M34973

3

ACTUATOR

SPST

1

1 LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

V

1

2

M34974

2

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19576A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPDT

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19577A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPST

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M34976

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

4 TO 20 mA

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

490 TO 510

OHMS,

1/2 W

MINIMUM

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M34977

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

Fig. 30. MS7505 with override to full closed.

Fig. 27. MS8105 with Two Position SPDT Control.

1

1

2

3

24 VAC

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

Fig. 28. MS7505 with Floating Control.

38-00032—03 20

Fig. 29. MS7505 with override to full open.

1

2

3

4

5

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M34975

Fig. 31. MS7505 with 0(2)-10 Vdc Controllers.

Fig. 32. MS7505 with 4-20mA Controllers.

Page 21

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

S1S3

S2

M35813

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M34978

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

24 VAC

1

24 VAC

1

2

24 VAC

1

HOT

COM

–

+

1

1 LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

Fig. 33. MS4105 with 120 Vac Two Position SPDT

Fig. 34. Wiring for MS4105, MS7505, and MS8105

Fig. 35. MS7505 with 0(2)-10 Vdc controller operating

SPST

1

2

ACTUATOR

control.

models with aux./end switches.

multiple actuators.

V

M29122

CLASS 2

24 VAC

CONTROLLER

HOT

COM

S-BUS

S-BUS

LINE VOLTAGE POWER SUPPLY.

1

PROVIDE DISCONNECT MEANS

AND OVERLOAD

PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

2

3

ADDRESS SELECTOR

RED

BLACK

BROWN

BROWN

ACTUATOR

S-BUS

S-BUS

ADDRESS 11

ADDRESS 12

ADDRESS 13

ADDRESS 14

ADDRESS 15

TEST

Fig. 36. MS3103 with Sylk Bus control.

NOTE: All identified parts except for the valve body and

aluminum valve stem coupler are included in

Replacement Kit (part no. 5112-11).

OPERATION AND CHECKOUT

Once both the mechanical and electrical installations are

complete:

1. Cycle the actuator to verify that the direction of rota-

tion suits the control sequence.

2. If the rotation direction is incorrect:

a. For 2-position and Sylk-enabled spring return

actuators: Remove, flip over, and replace actuator

on the bracket.

b. For floating control actuators: Reverse two control

signal wires (CW/CCW), or change position of

selector switch.

c. For analog control actuators either:

(1) Change setting of reverse/direct-acting

switch, or

(2) Remount actuator on the bracket.

3. If the control scheme requires fail-safe operation,

ensure that, upon removal of power, the fail position

coincides with the control sequence.

4. Spring return actuators are factory-configured for

normally-closed, fail-safe operation on power loss. To

change this action to normally-open, remove and

reinstall the actuator in the opposite orientation as

follows:

a. Loosen the shaft coupling bolt using a 10 mm

wrench.

b. Loosen all other mounting bolts connecting the

actuator to the mounting bracket, and set aside.

c. Remove the actuator from the valve shaft.

d. Move the Self-Centering Shaft Adaptor to the

opposite side of the actuator, as displayed in

Fig. 37.

21 38-00032—03

Page 22

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

M29908A

The pressure regulator takes a minimum pressure to

operate, and has a maximum differential regulation

capability. See Fig. 39. The high pressure drop across a

VRN2 Valve is comparable to the pressure drop across a

control valve and balancing valve in a conventional system

design.

M27714

Fig. 37. Change actuator to normally open.

(1) Remove the retainer clip from the

Self-Centering Shaft Adapter and set it aside

for later use.

(2) Remove SCSA from actuator.

(3) Reinstall SCSA on the opposite side of the

actuator, aligning it based on the stroke

labeling.

(4) Replace the retainer clip on the shaft coupling

using the groove of the coupling.

e. Reconnect the actuator to the valve mounting

bracket by replacing the screws previously

removed (step b).

f. Tighten the shaft coupling bolt using a 10 mm

wrench or socket.

Operation

PIN changes constantly in a multi-zone system as other

valves open and close, changing system flow and head

pressure according to the characteristics of the supply

pump curve. Reaction of the mechanical pressure

regulator is instantaneous, eliminating changes in room

temperature due to changes in fluid flow, and reducing the

need for the control system to constantly operate the

control portion of the valve to correct for the non-load

related temperature changes that occur in a system with

standard control valves.

12

8

16

DIFFERENTIAL PRESSURE (PSID)

100% OPEN

80% OPEN

60% OPEN

40% OPEN

20% OPEN

34 40

28

22

60

50

M29707A

FLOW

RATE

(GPM)

12

10

8

6

4

0

5.8

Fig. 39. Pressure regulation, large body models.

SETTINGS AND ADJUSTMENTS

At the full open position, VRN2 valves will maintain flow in

the loop. Flow rates are listed in the Specification Data

form 62-3115EFS. Under steady state operation, the

control system will only require the valve to open enough to

satisfy load conditions. During morning recovery from

night setback, the controller will usually command the

valve to 100%. For optimum performance, choose only the

next larger valve size needed to satisfy design load. Do not

oversize valves—reduced rangeability and may result in

less accurate temperature control.

Ball valves close between 10 and 15% of stroke, to ensure

full seal engagement. If desired, modulating actuators can

be set to 0-10 V response so that 2 V of a 2-10 V control

signal more closely corresponds to minimum flow. The

valve will still close with signal loss.

If desired, maximum flow may be trimmed to a lesser value

in one of two ways:

1. With modulating actuator, limit span of control

voltage issued by the building automation controller.

Valves with flow control inserts have an equal

percentage flow characteristic (See Fig. 40). Each

10% reduction in maximum control voltage will

result in a 10% reduction in flow.

Fig. 38. VRN2 cross section showing fitting, control ball,

and pressure regulator.

At full flow in a 2-position control application, a VRN2

behaves as a flow limiter.

38-00032—03 22

100%

80%

FULL PORT

BALL

60%

FLOW

40%

20%

0%

0° 30° 60° 90°

10°

20°

40° 50°

VALVE STEM STROKE

Fig. 40. Typical flow characteristics.

2-WAY

CHARACTERIZED

FLOW

80°

70°

M29551B

Page 23

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

CAUTION

STEM

ASSEMBLY

COUNTERSUNK

SCREWS

STEM RETAINER

PLATE

“T” SYMBOL

STEM

UPPER PACKING

GLAND

O-RING

LOWER PACKING

GLAND

M34994

2. To mechanically limit stroke, set DCA to full open

position. Loosen shaft coupling and rotate valve

shaft to desired maximum flow position, as

confirmed by pressure measurement across coil,

using coil manufacturer's data. Retighten shaft

coupling. Use Fig. 40 as a guide to setting actuator

stroke.

If using mechanical adjustment technique with

MN/MS7505 modulating actuators, the stroke

auto-adaption feature will automatically scale the

2–10 Vdc signal to the mechanical rotation of the

ball. See actuator literature for details.

Coil flow can be confirmed by reading pressures at the coil

inlet and coil outlet (not across control valve as with

conventional balancing—this pressure drop will be

constant), and using the manufacturer's data to calculate

flow.

Note that the pressure regulator in this valve guarantees

that the flow through the coil will not be affected by

upstream changes in pressure. Unlike conventional

balancing valves, it is not necessary to reconfirm coil flow

after adjusting other valves. Any overflow during morning

recovery due to oversized pressure regulated valves will not

affect other valves in the system, provided pumps are

capable of required flow.

Service and Repair

The valve stem can be replaced in-line, if necessary. See

Fig. 41.

Follow steps 1 to 6 of “Mounting Plate Adjustment” on

page 16, then:

1. If the lower packing gland is stuck, remove it with

gland removal tool or rubber-tipped dental tool.

Avoid scratching the inside of the valve neck.

This may cause a leak when re-assembled.

2. Carefully remove any fouling or corrosion from inside

of valve.

3. Align arrow with short leg of “T” symbol on new stem

assembly.

NOTE: “T” symbol will vary.

4. Insert the new stem assembly. Be sure to line up the

stem key with the ball slot.

5. Fasten stem retainer high pressure plate to the valve

using the new countersunk screws. Then fasten the

mounting plate to the valve.

6. Repressurize valve and confirm stem does not leak

before proceeding.

7. Slide the sub shaft over the stem with the tab

oriented as shown in Fig. 41.

8. Replace the thermal break, shaft, and shaft cover. If

shaft has come loose from thermal break, push firmly

on end of shaft until blade in shaft snaps into

thermal break.

9. Replace actuator and secure it to shaft and mounting

plate.

10. Snap handle onto top of shaft.

Any other service to valve such as seat seal replacement

requires removal of valve from piping.

Fig. 41. Replacing the valve stem in-line.

23 38-00032—03

Page 24

VRN PRESSURE INDEPENDENT CONTROL VALVES AND ACTUATORS

Honeywell Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

® U.S. Registered Trademark

© 2020 Honeywell International Inc.

38-00032—03 M.S. Rev. 12-20

Printed in United States

Loading...

Loading...