Honeywell VRN Dynamic Pressure-Regulating Control Valves and Actuators Installation Instructions

Page 1

38-00005EFS-04

VRN Dynamic Pressure-Regulating Control Valves and Actuators

INSTALLATION INSTRUCTIONS

Oversized valves can cause excessive cycling and the seat

and ball can be damaged because of the restricted

opening.

Proper Use

VRN valves are intended for use in chilled water and hot

water closed loop applications only, with a temperature

range of 35 to 250°F, and pressures up to 360psig.

Water should be properly filtered, treated and conditioned

for good operating performance, and according to

recommendations of the boiler or chiller manufacturers.

The installation of strainers and filters is recommended.

Do not use with manual balancing valves.

IMPORTANT

The presence of excessive iron oxide (red rust) in

the system voids the valve warranty.

APPLICATION

The VRN2 two-way dynamic pressure-regulating control

valves maintain constant flow of hot or chilled water with

glycol solutions up to 50% in closed-loop heating,

ventilating, and air conditioning systems, within the

specified pressure drop ranges of each model number.

These valve assemblies can be ordered with or without

factory-mounted actuators.

Application Notes

Valve sizing is important for correct system operation.

Undersized valves do not have sufficient capacity at

maximum load. Oversized valves do not have sufficient

authority over the load in modulating applications.

Effective Flow Rate

The built-in differential pressure regulator makes fluid

flow through the valve independent of changes in supply.

The pressure regulator virtually eliminates cavitation in

the valve, and decouples the control valve from the effects

of piping components such as reducers and elbows.

Pressure independent control valves are sized to match

design coil flow regardless of coil connection size. VRN2

valves eliminate the need to balance the system for proper

flow, and allow chillers to be operated at design

temperature differential for maximum efficiency at every

load condition. When used in a system with variable speed

pump drives, 3-way valves and coil bypass lines are not

required.

Required Operating Torque

Both Honeywell fail in place and fail-safe low torque direct

coupled actuators can be used with the VRN valves.

VRN valves use a patented seat design that reduces the

torque needed from the actuator.

Actuators with 27 lb-in torque, (for valves up to 1-1/4 in

size), and 35 lb-in torque (for 1-1/2 in size and above)

provide sufficient torque to operate the valve at rated

close-off. (See Table 1).

Maximum safe operating torque is 44 lb-in.

Page 2

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

CAUTION

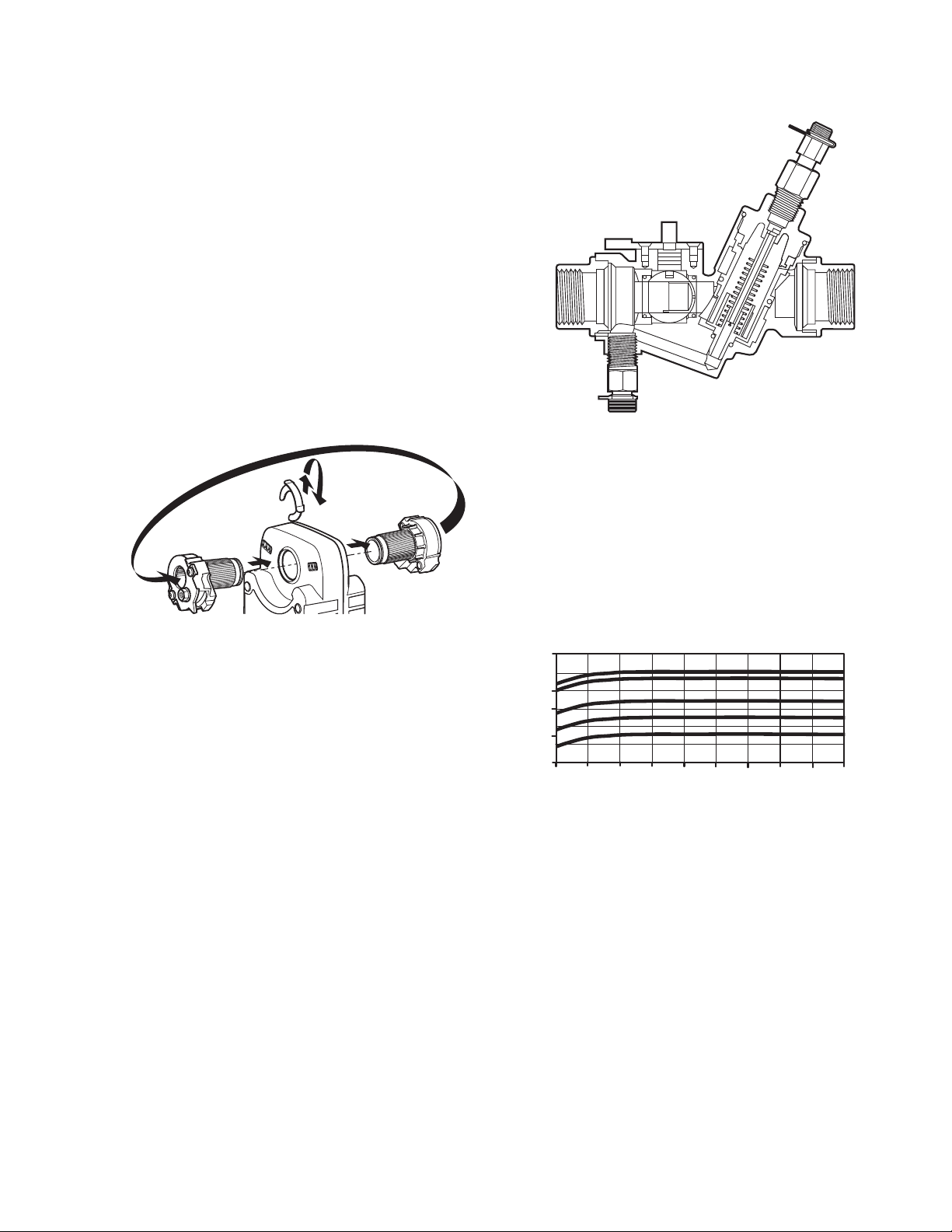

M34979A

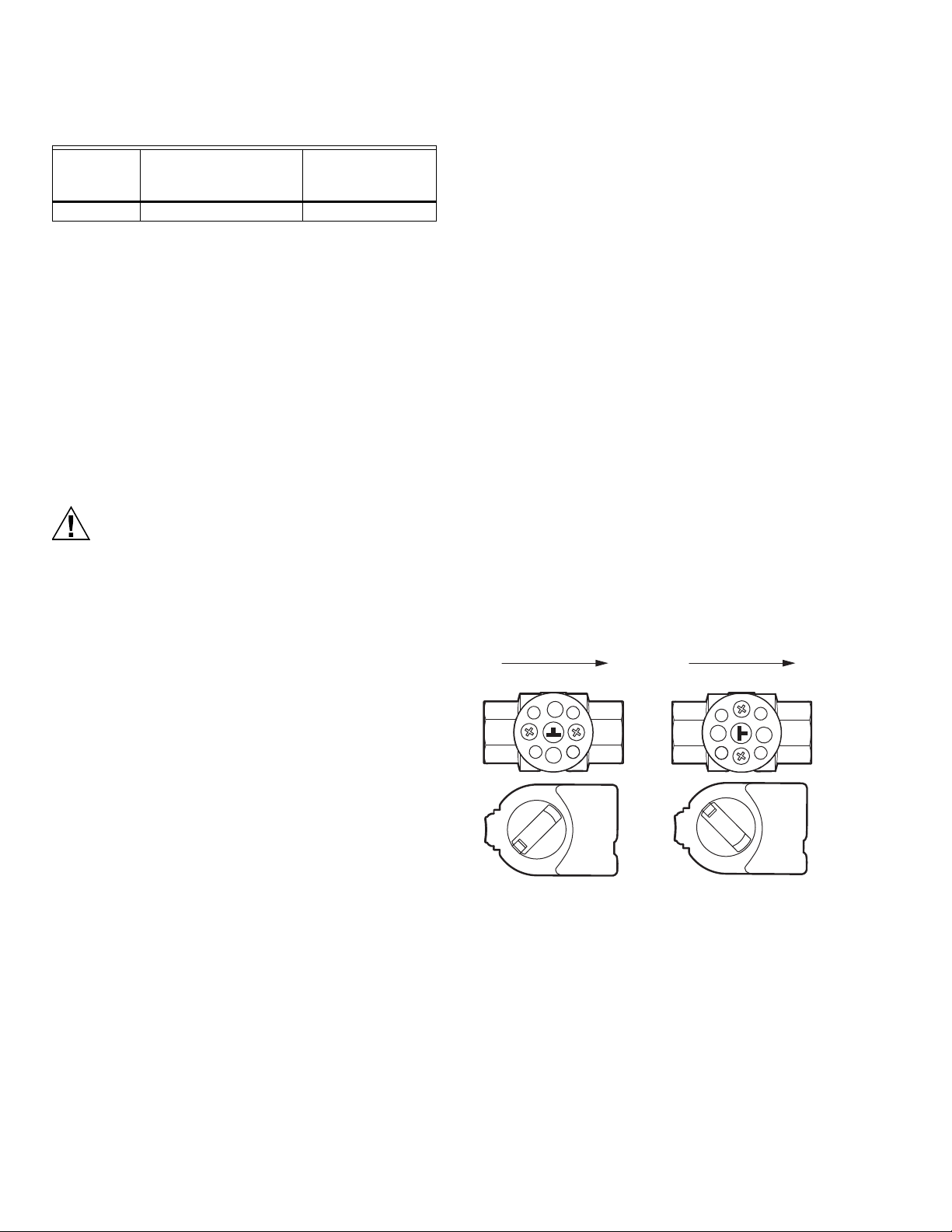

FLOW FLOW

CLOSED

OPEN

NOTES: TO MOUNT ACTUATOR ON OPEN VALVE, TURN ACTUATOR FULLY

COUNTER CLOCKWISE AS SHOWN. TO MOUNT ACTUATOR ON

CLOSED VALVE, TURN ACTUATOR FULLY CLOCKWISE AS SHOWN.

The valves are tapped in NPT and should be sealed with an

Table 1. Close-off, Differential Pressure Ratings.

Close-off

Pressure Rating

Valve Type Valve Size

2 way 1/2 in. to 3 in. 100

(psi)

INSTALLATION

When installing this product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check ratings given in instructions and on the prod-

uct to ensure the product is suitable for your application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

approved pipe sealant. Torque should not exceed 75 lb-ft.

Refer to actuator literature for actuator dimensions.

1. Clean the lines upstream of particles larger than

1/16 in. diameter (welding slag, pipe scale and other

contaminants).

2. Proceed with installation once the system specifics

(expansion/contraction of the system and its

medium as well as operating pressures) are within

tolerances.

3. Eliminate air from system.

4. Valves are marked to show flow direction.

IMPORTANT

Flow arrows must point in the direction of the flow

for proper operation.

5. Stem rotation:

a. Clockwise to close.

b. Counterclockwise to open.

NOTE: After valves have been installed in the pip-

Preparation

Equipment Damage Hazard

Foreign particles like dirt and metal chips can

damage the ball seals.

For trouble-free operation of the product, good

installation practice must include initial system

flushing, and chemical water treatment. Clean the

lines upstream of particles larger than 1/16 inch

diameter (welding slag, pipe scale, sand and other

suspended particulate). Use of a 50 micron (or

finer) system side stream filter is suggested.

Remove all filters before flushing.

Do not use boiler additives, solder flux and wetted

materials which are petroleum based or contain

mineral oil, hydrocarbons, or ethylene glycol

acetate. Compounds which can be used, with

minimum 50% water dilution, are diethylene

glycol, ethylene glycol, and propylene glycol

(antifreeze solutions).

If installing these valves in an addition to, or

retrofitting an existing building, do not assume

that the fluid in the existing piping meets these

criteria.

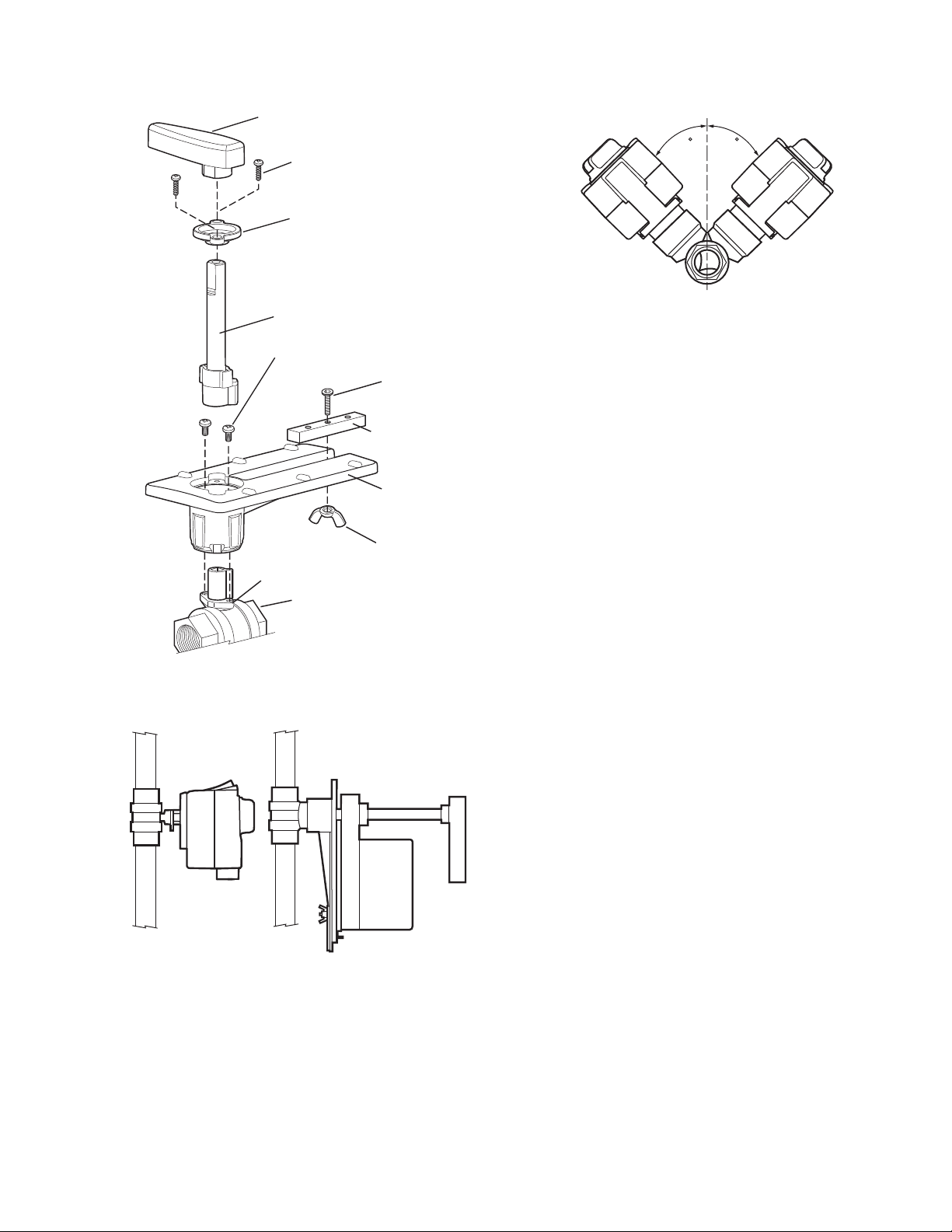

6. Valve must be mounted with the actuator/bracket

above the valve body. Do not install the valve with

the stem below horizontal or upside down. (See

Fig. 3 and 4.)

ing, the installer can determine the ball orientation within the valve from the notches

in the top of the valve stem. For VRN valves,

the lengthwise direction of the notch indicates the flow through the ball (i.e. when the

notch is parallel to the axis of the valve

between A and B ports, the ball will allow

flow through the valve).

Mechanical Installation

IMPORTANT:

38-00005EFS—04 2

Hold valve with pipe wrench by hexagonal fitting

ONLY. Do NOT handle the valve body with the pipe

wrench; product damage may result.

Fig. 1. Orientation of valve.

Page 3

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

M13738A

VALVE BODY

VALVE STEMCOUPLER

WING NUT**

MOUNTING

PLATE**

ANTI-ROTATION

BRACKET**

BOLT**

STEM ASSEMBLY COVER**

SCREWS (2)**

HANDLE (REMOVABLE) FOR

MANUALLY ROTATING SHAFT**

STEM ASSEMBLY**

**INCLUDED IN REPLACEMENT KIT (PART NO. 5112-11)

SCREWS (2)**

M34954

45

45

M33091

Fig. 4. Acceptable valve angle from vertical

Mounting Plate Adjustment

The Actuator Mounting Plate can be rotated to a different

position for installation in confined spaces. This is

accomplished as follows:

1. Remove the handle from the shaft and set it aside.

2. Remove the two screws that hold the stem assembly

to the mounting plate and set them aside.

3. Remove and set aside the stem assembly.

4. Remove and set aside the two screws that attach the

mounting plate to the valve.

5. Remove and set aside hold-down ring from mount-

ing plate.

6. Rotate mounting plate around valve top to the

desired position.

Fig. 2. Valve assembly exploded view.

Fig. 3. Vertical valve installation.

NOTE: Take note of the screw hole positions on the valve.

They limit the mounting plate positions.

7. Lower ring down to valve body and engage it in the

new position relative to the mounting plate.

8. Tighten screws to valve body securing the mounting

plate.

9. Reattach the stem assembly to the mounting plate.

10. If desired, replace the handle on the shaft.

NOTE: See Fig. 2 for valve exploded view.

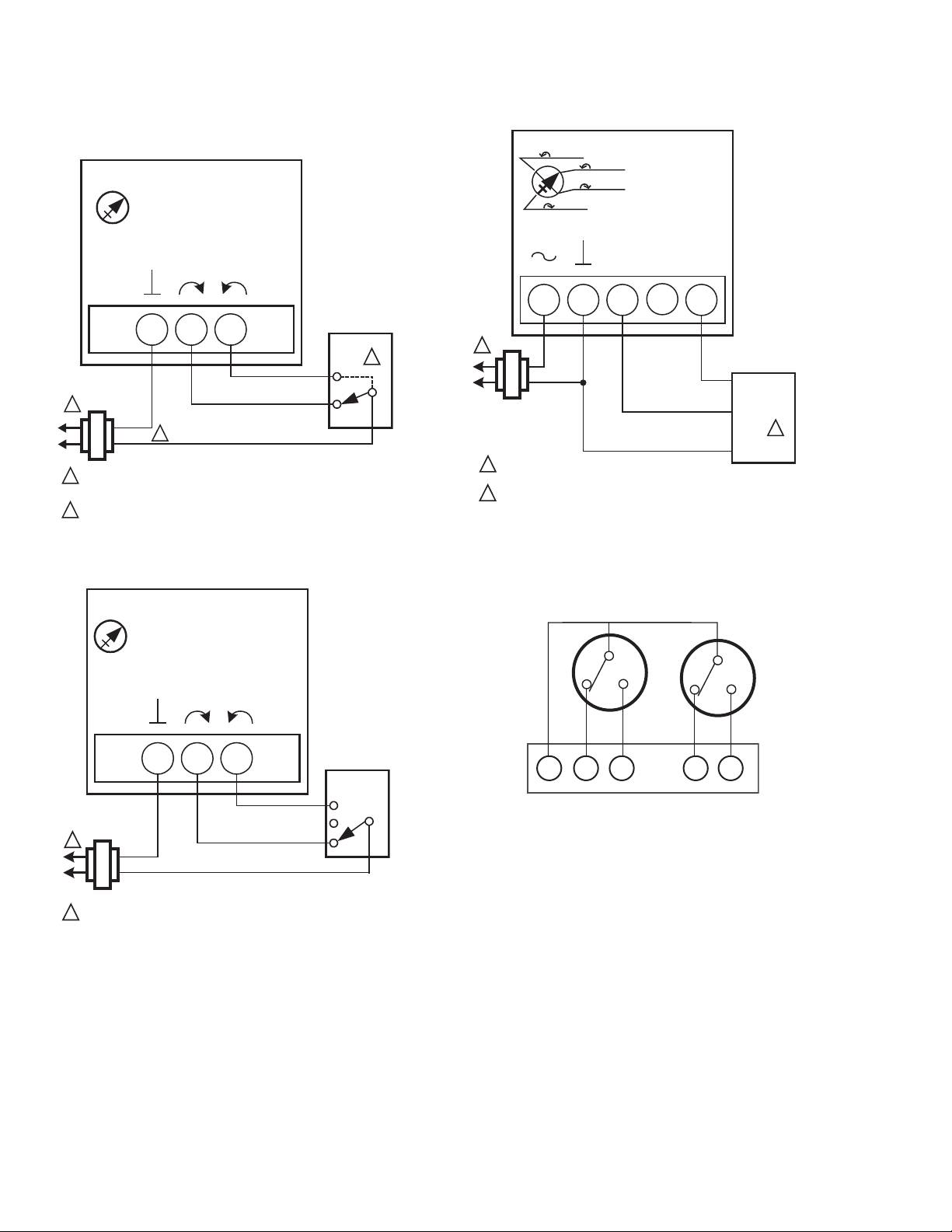

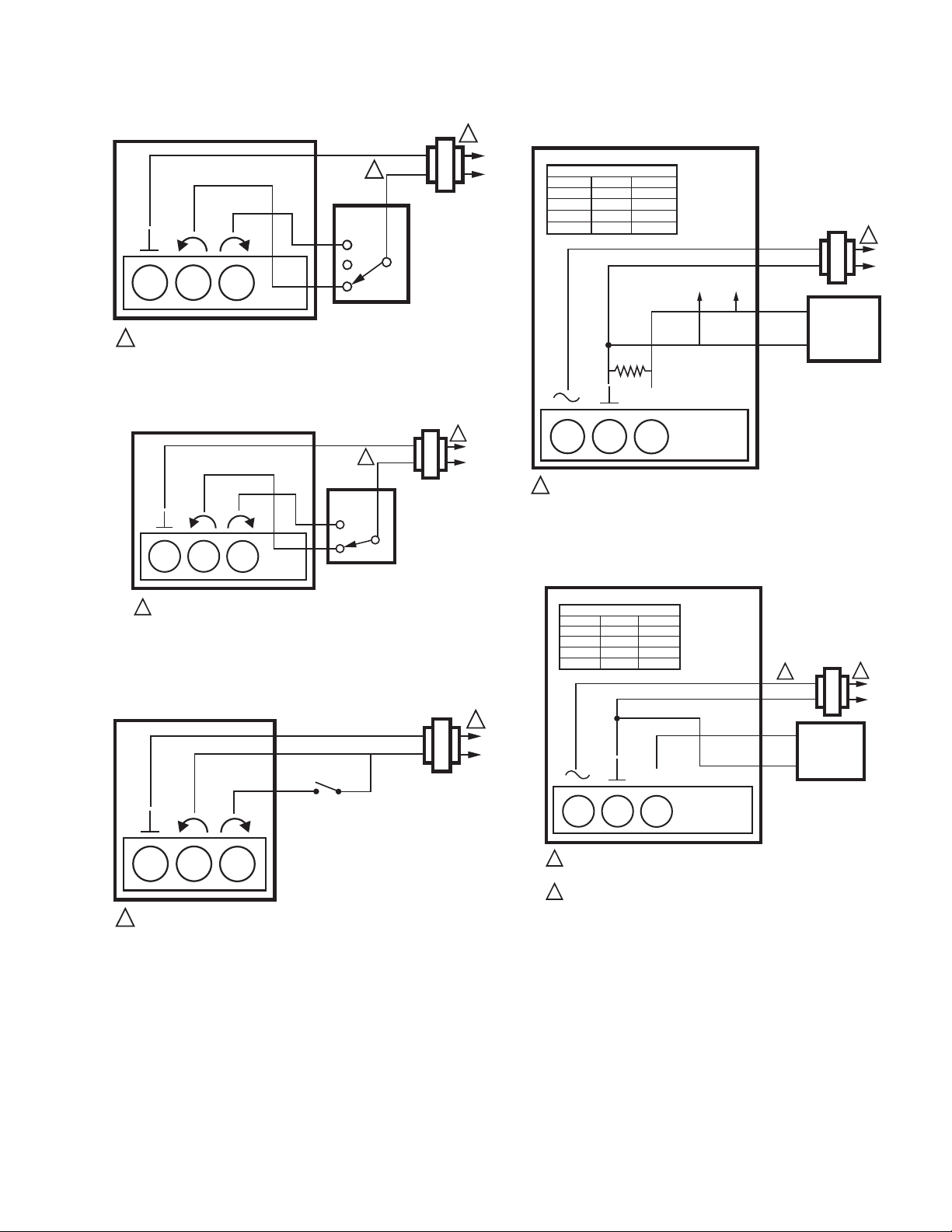

Electrical Installation

1. If necessary, remove actuator wiring cover.

2. Wire actuator using Figures 5 through 28 for the

application required.

3. Replace cover.

3 38-00005EFS—04

Page 4

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

4

3

2

FLOATING ACTUATOR

24 VAC

Direct

Reverse

Service/Off

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

FLOATING

CONTROLLER

M18946A

24 VAC

1

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

PROPORTIONAL

CONTROLLER

+

–

FEEDBACK

1

325

PROPORTIONAL ACTUATOR

FEEDBACK

+

0(2)-10 VDC OF 0(4)-20 mA CONTROL SIGNAL ACCEPTABLE.

SET CONTROL SIGNAL DIP SWITCH TO “OFF” FOR VOLTAGE.

SET TO “ON” FOR CURRENT.

2

2

2 -10 Vdc

2 -10 Vdc

0 -10 Vdc

0 -10 Vdc

M18947B

4

5°

85°

S1 S2

S3 S5 S6

M25214A

END SWITCHES (CLASS II-ONLY)

Wiring

FLOATING ACTUATOR

DIRECT

SERVICE/OFF

REVERSE

432

1

3

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

CONNECTION REQUIRED FOR SPST CONTROL.

CONTROLLER

Fig. 5. MN6105 with On/Off SPDT Control.

2

M34869A

Fig. 7. MN7505 with 0(2)-10 Vdc Control.

Fig. 6. MN6105 with Floating Control.

38-00005EFS—04 4

Fig. 8. Wiring for MN6105 and MN7505 models with

aux./end switches.

Page 5

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

FLOATING ACTUATOR

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FLOATING

CONTROLLER

M33137D

2

3

4

1

BLACK

WHITE

BROWN

2

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

FLOATING ACTUATOR

24 VAC

1

FLOATING

CONTROLLER

2

3

4

1

M33138C

BLACK

WHITE

BROWN

2

M33557C

FLOATING ACTUATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2

3

4

1

24 VAC

BLACK

BROWN

WHITE

SPST

PROPORTIONAL ACTUATOR

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

4-20mA

CONTROLLER

M33141C

1

2

3

+

+

–

DIP SWITCH POSITION

1 2 MODE

OFF OFF 2-10V

OFF ON 0-10V

ON OFF 10-2V

ON ON 10-0V

PROPORTIONAL/MODULATING: 4-20mA CONTROLLER OUTPUT WITH

500Ω SERIES RESISTOR

TO OTHER

ACTUATORS

500 OHMS,

1/2 W

MINIMUM

24 VAC

RED

BLACK

WHITE

1

PROPORTIONAL ACTUATOR

24 VAC

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

0 (2)-10 VDC

CONTROLLER

M33140A

1

2

3

+

+

–

DIP SWITCH POSITION

1 2 MODE

OFF OFF 2-10V

OFF ON 0-10V

ON OFF 10-2V

ON ON 10-0V

PROPORTIONAL/MODULATING: 0(2)...10 VDC OR 10...0(2) VDC CONTROLLER OUTPUT

2

RED

BLACK

WHITE

2

1

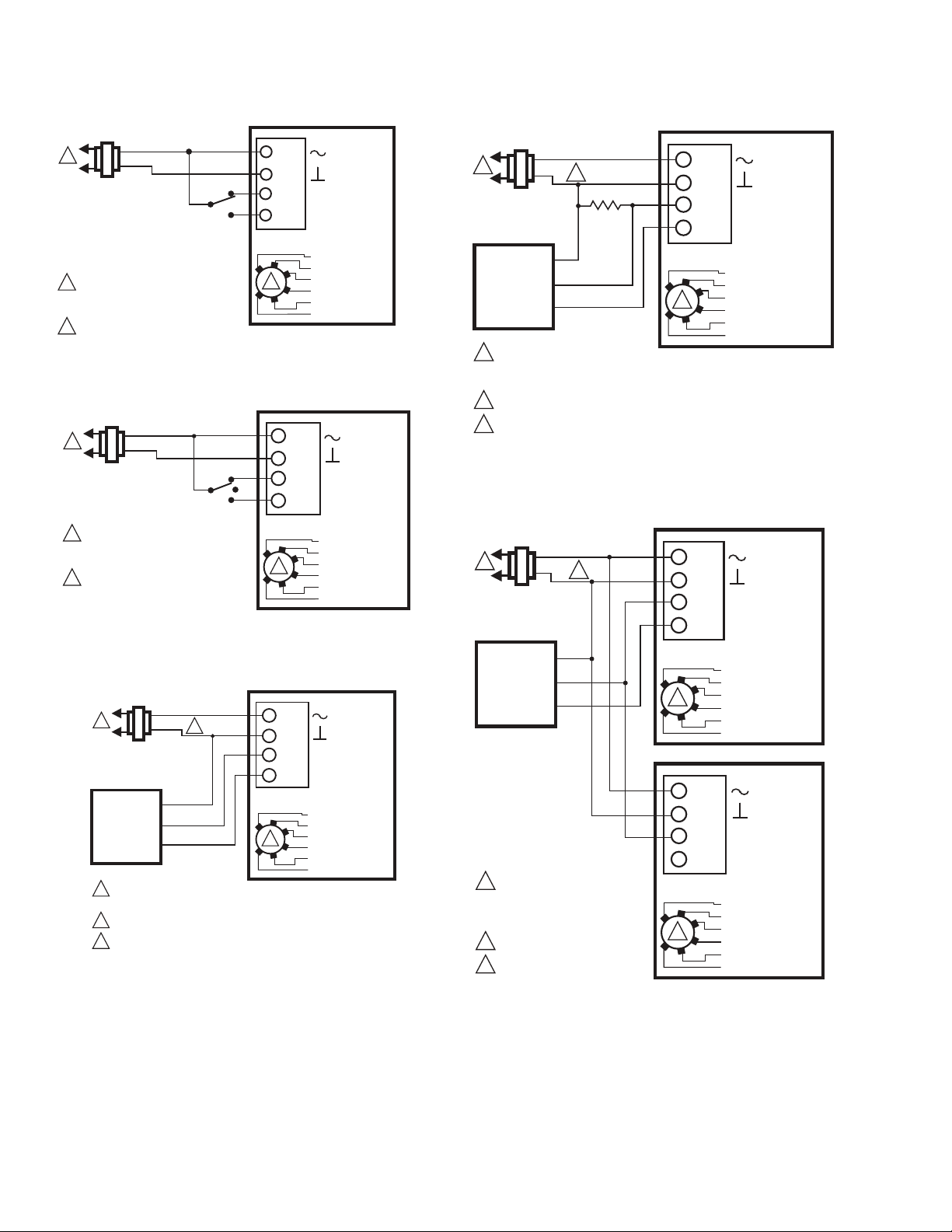

Fig. 9. MVN613 with Floating Control.

Fig. 10. MVN613 or MVN643 with Two Position SPDT

Control.

Fig. 11. MVN643 with Two Position SPST Control.

Fig. 12. MVN713 with 4-20mA Control.

Fig. 13. MVN713 with 0(2)-10 Vdc Control.

5 38-00005EFS—04

Page 6

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

SPDT

24 VAC

1

1

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SET SWITCH TO FLOATING.

M37304

ACTUATOR

V

0°-90°/MODULATING

90°-0°/FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING, FWD

FLOATING, REV

2

RED

BLACK

BROWN

WHITE

CLASS 2

24 VAC

1

1

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

SET SWITCH TO FLOATING.

M37319

ACTUATOR

V

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING, FWD

FLOATING, REV

2

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

CLASS 2

ACTUATOR

4 TO 20 mA

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

490 TO 510

OHMS,

1/2 W

MINIMUM

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING IF AVAILABLE.

V

–

+

FEEDBACK

4

3

1

2

M37321

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING, FWD

FLOATING, REV

3

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

CLASS 2

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION

AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING

IF AVAILABLE.

V

–

+

FEEDBACK

4

3

1

2

M37322

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING

, FWD

FLOATING

, REV

3

ACTUATOR

V

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING

, FWD

FLOATING

, REV

3

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

0°-90°/MODULATING

90°-0°/FEEDBACK

RED

BLACK

BROWN

WHITE

CLASS 2

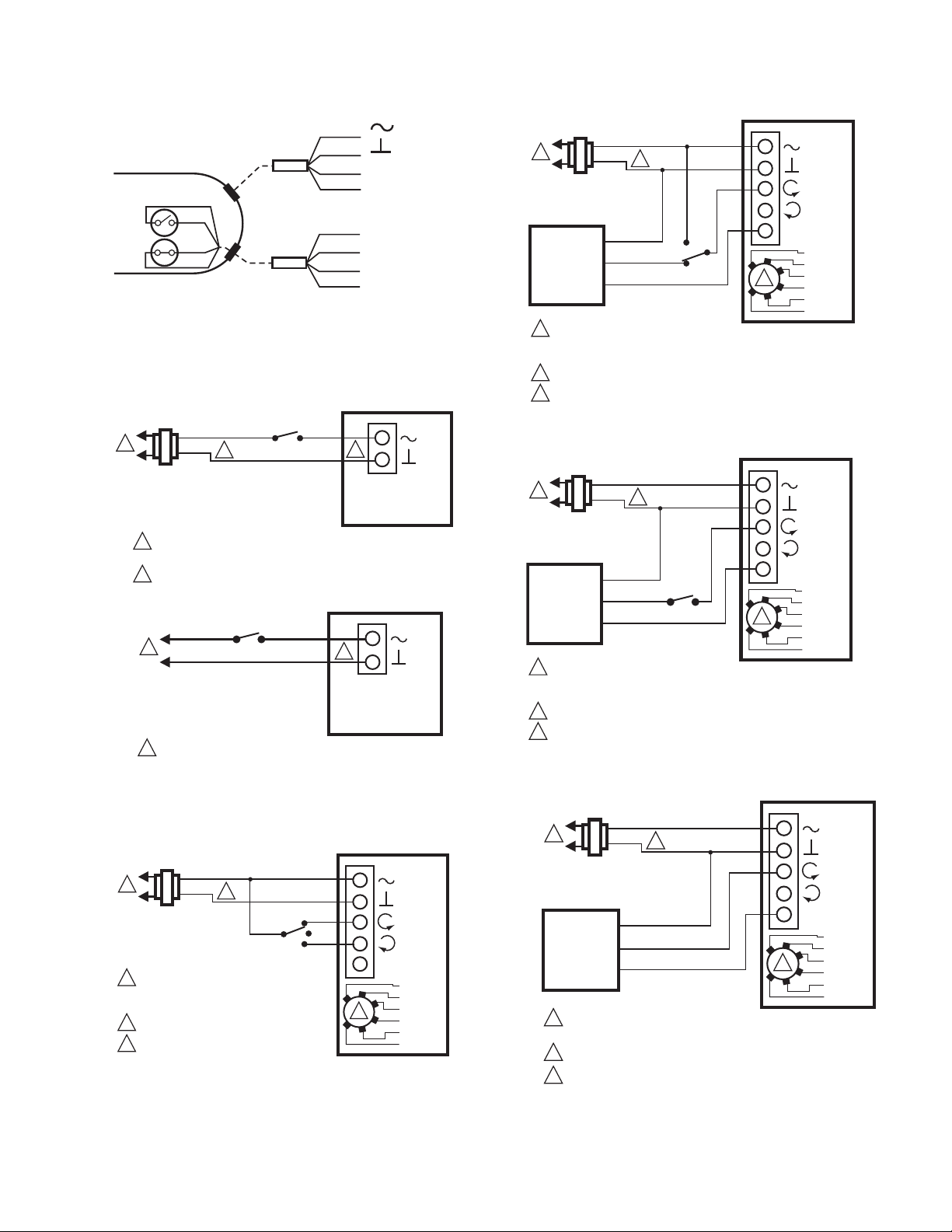

Fig. 14. MS7505 with Two Position SPDT Control.

Fig. 17. MS7103 with 4-20 mA Control (MS7503 shown,

ignore selection switch).

Fig. 15. MS7505 with Floating Control.

CLASS 2

1

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

FEEDBACK

1

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

2

3

SET SWITCH TO MODULATING IF AVAILABLE.

Fig. 16. MS7103 with 2-10 Vdc Control (MS7503 shown,

38-00005EFS—04 6

RED

24 VAC

–

+

2

1

2

BLACK

3

WHITE

4

BROWN

3

ignore selection switch).

ACTUATOR

0°-90°/MODULATING

90°-0°/FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

FLOATING

FLOATING

V

, FWD

, REV

M37320

Fig. 18. MS7103 with 2-10 Vdc Control using two

actuators (MS7503 shown, ignore selection switch).

Page 7

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

ACTUATOR

SPST

24 VAC

1

1

2

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

V

1

2

M34973

3

ACTUATOR

SPST

1

1 LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

V

1

2

M34974

2

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19576A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPDT

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19577A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPST

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M34976

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

RED

BLACK

ACTUATOR

SPST SWITCHES

MAIN

CABLE

WHITE

BROWN

+ OR 0˚−90˚

FEEDBACK OR 90˚−0˚

BLUE

BROWN

GRAY

SWITCHES

CABLE

BLACK

M37303A

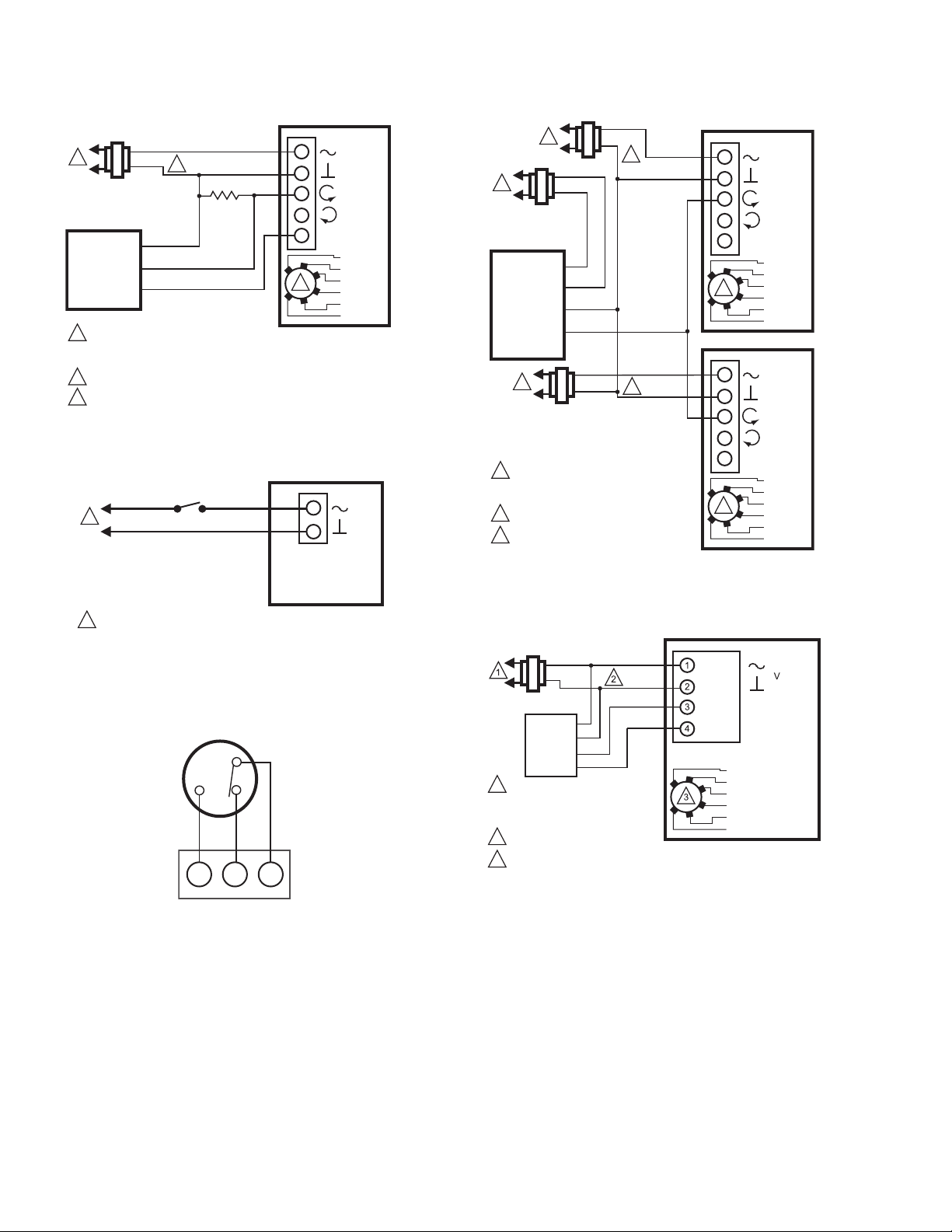

Fig. 19. Wiring for MS7103 and MS3103 Auxiliary

Switches. Gray/Black = Normally Open. Closed in range

80 degrees to Fully Open. Blue/Brown = Normally

Closed. Open in range 10 degrees to Fully Open.

Fig. 22. MS7505 with override to full open.

Fig. 20. MS8105 with Two Position SPDT Control.

1

1

2

3

24 VAC

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

Fig. 21. MS7505 with Floating Control.

1

2

3

4

5

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

Fig. 23. MS7505 with override to full closed.

M34975

Fig. 24. MS7505 with 0(2)-10 Vdc Controllers.

7 38-00005EFS—04

Page 8

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

ACTUATOR

4 TO 20 mA

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

490 TO 510

OHMS,

1/2 W

MINIMUM

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M34977

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

S1S3

S2

M35813

1

2

3

HOT

COM

CONTROLLER

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS

AND OVERLOAD

PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

ADDRESS SELECTOR

S-BUS

S-BUS

24 VAC

CLASS 2

S-BUS

S-BUS

RED

BLACK

BROWN

BROWN

ACTUATOR

ADDRESS 11

ADDRESS 12

ADDRESS 13

ADDRESS 14

ADDRESS 15

TEST

Fig. 25. MS7505 with 4-20mA Controllers.

1

1 LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

SPST

1

2

ACTUATOR

V

M29122

24 VAC

24 VAC

ACTUATOR

2

2

1

2

3

4

5

3

1

2

3

4

5

3

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M34978

1

1

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

1

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

2

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

3

24 VAC

HOT

COM

–

+

1

Fig. 28. MS7505 with 0(2)-10 Vdc controller operating

multiple actuators.

Fig. 26. MS4105 with 120 Vac Two Position SPDT

Fig. 27. Wiring for MS4105, MS7505, and MS8105

models with aux./end switches.

38-00005EFS—04 8

control.

Fig. 29. MS3103 with Sylk Bus control.

OPERATION AND CHECKOUT

Once both the mechanical and electrical installations are

complete:

1. Cycle the actuator to verify that the direction of rota-

tion suits the control sequence.

2. If the rotation direction is incorrect:

a. For 2-position and Sylk-enabled spring return

actuators: Remove, flip over, and replace actuator on the bracket.

b. For floating control actuators: Reverse two con-

trol signal wires (CW/CCW), or change position

of selector switch.

Page 9

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

M27714

A

0

FLOW

RATE

(GPM)

DIFFERENTIAL PRESSURE (PSID)

12

10

6

4

5.8

8

16

22

28

50

M29707A

8

12

34 40

60

100% OPEN

80% OPEN

60% OPEN

40% OPEN

20% OPEN

c. For analog control actuators either:

(1) Change setting of reverse/direct-acting

switch, or

(2) To change spring return direction: remove,

flip over, and replace actuator on bracket.

3. If the control scheme requires fail-safe operation,

ensure that, upon removal of power, the fail position

coincides with the control sequence.

4. Spring return actuators are factory-configured for

normally-closed, fail-safe operation on power loss.

To change this action to normally-open, remove and

reinstall the actuator in the opposite orientation as

follows:

a. Loosen the shaft coupling bolt using a 10 mm

wrench.

b. Loosen all other mounting bolts connecting the

actuator to the mounting bracket, and set aside.

c. Remove the actuator from the valve shaft.

d. Move the Self-Centering Shaft Adaptor to the

opposite side of the actuator, as displayed in

Fig. 30.

M29908

Fig. 31. VRN2 cross section showing fitting, control ball,

and pressure regulator.

At full flow in a 2-position control application, a VRN2

behaves as a flow limiter.

The pressure regulator takes a minimum pressure to

operate, and has a maximum differential regulation

capability. See Fig. 32. The high pressure drop across a

VRN2 Valve is comparable to the pressure drop across a

control valve and balancing valve in a conventional

system design.

Fig. 30. Change actuator to normally open.

(1) Remove the retainer clip from the Self-Cen-

tering Shaft Adapter and set it aside for later

use.

(2) Remove SCSA from actuator.

(3) Reinstall SCSA on the opposite side of the

actuator, aligning it based on the stroke label-

ing.

(4) Replace the retainer clip on the shaft cou-

pling using the groove of the coupling.

e. Reconnect the actuator to the valve mounting

bracket by replacing the screws previously

Fig. 32. Pressure regulation, large body models.

removed (step b).

f. Tighten the shaft coupling bolt using a 10 mm

wrench or socket using maximum 120 lb-in

torque.

Operation

PIN changes constantly in a multi-zone system as other

valves open and close, changing system flow and head

pressure according to the characteristics of the supply

pump curve. Reaction of the mechanical pressure

regulator is instantaneous, eliminating changes in room

temperature due to changes in fluid flow, and reducing the

need for the control system to constantly operate the

control portion of the valve to correct for the non-load

related temperature changes that occur in a system with

standard control valves.

SETTINGS AND ADJUSTMENTS

At the full open position, VRN2 valves will maintain flow in

the loop. Flow rates are listed in the Specification Data

form 62-3115EFS. Under steady state operation, the

control system will only require the valve to open enough

to satisfy load conditions. During morning recovery from

night setback, the controller will usually command the

valve to 100%. For optimum performance, choose only the

next larger valve size needed to satisfy design load. Do not

oversize valves—reduced rangeability and may result in

less accurate temperature control.

9 38-00005EFS—04

Page 10

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

CAUTION

0%

20%

40%

60%

80%

100%

0° 30° 60° 90°

VALVE STEM STROKE

FLOW

M29551A

10°

20°

40° 50°

70°

80°

FULL PORT

BALL

2-WAY

CHARACTERIZED

FLOW

STEM

ASSEMBLY

COUNTERSUNK

SCREWS

STEM RETAINER

PLATE

“T” SYMBOL

STEM

UPPER PACKING

GLAND

O-RING

LOWER PACKING

GLAND

M34994

Ball valves close between 10 and 15% of stroke, to ensure

full seal engagement. If desired, modulating actuators can

be set to 0-10 V response so that 2 V of a 2-10 V control

signal more closely corresponds to minimum flow. The

valve will still close with signal loss.

If desired, maximum flow may be trimmed to a lesser value

in one of two ways:

1. With modulating actuator, limit span of control volt-

age issued by the building automation controller.

Valves with flow control inserts have an equal percentage flow characteristic (See Fig. 33). Each 10%

reduction in maximum control voltage will result in a

10% reduction in flow.

Service and Repair

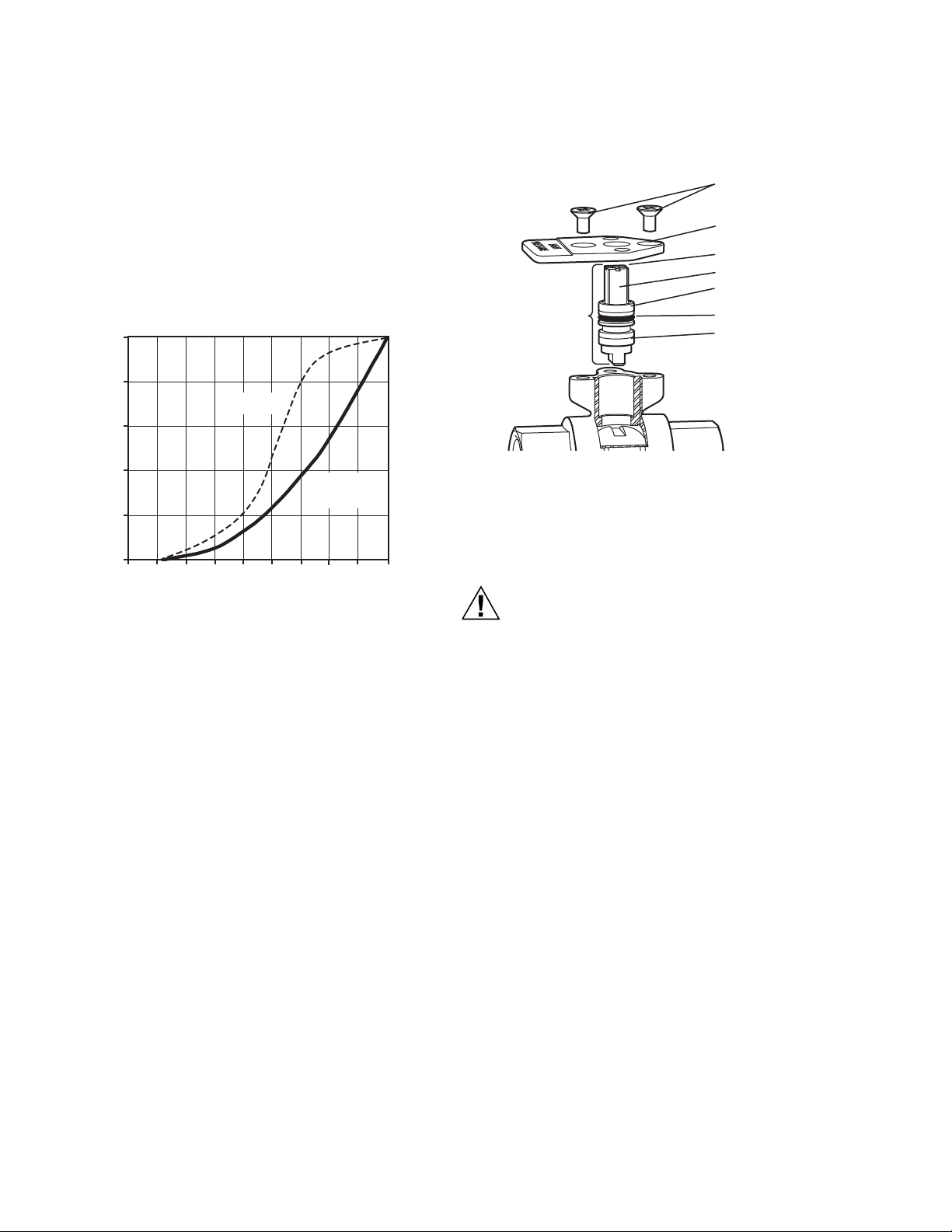

The valve stem can be replaced in-line, if necessary. See

Fig. 34.

Fig. 34. Replacing the valve stem in-line.

Follow steps 1 to 6 of “Mounting Plate Adjustment” on

page 3, then:

1. If the lower packing gland is stuck, remove it with

gland removal tool or rubber-tipped dental tool.

Fig. 33. Typical flow characteristics.

2. To mechanically limit stroke, set DCA to full open

position. Loosen shaft coupling and rotate valve

shaft to desired maximum flow position, as confirmed by pressure measurement across coil, using

coil manufacturer's data. Retighten shaft coupling.

Use Fig. 33 as a guide to setting actuator stroke.

If using mechanical adjustment technique with

MN/MS7505 modulating actuators, the stroke autoadaption feature will automatically scale the 2–

10 Vdc signal to the mechanical rotation of the ball.

See actuator literature for details.

Coil flow can be confirmed by reading pressures at the coil

inlet and coil outlet (not across control valve as with

conventional balancing—this pressure drop will be

constant), and using the manufacturer's data to calculate

flow.

Note that the pressure regulator in this valve guarantees

that the flow through the coil will not be affected by

upstream changes in pressure. Unlike conventional

balancing valves, it is not necessary to reconfirm coil flow

after adjusting other valves. Any overflow during morning

recovery due to oversized pressure regulated valves will

not affect other valves in the system, provided pumps are

capable of required flow.

Avoid scratching the inside of the valve neck.

This may cause a leak when re-assembled.

2. Carefully remove any fouling or corrosion from

inside of valve.

3. Align arrow with short leg of “T” symbol on new stem

assembly.

NOTE: “T” symbol will vary.

4. Insert the new stem assembly. Be sure to line up the

stem key with the ball slot.

5. Fasten stem retainer high pressure plate to the valve

using the new countersunk screws. Then fasten the

mounting plate to the valve.

6. Repressurize valve and confirm stem does not leak

before proceeding.

7. Slide the sub shaft over the stem with the tab ori-

ented as shown in Fig. 34.

8. Replace the thermal break, shaft, and shaft cover. If

shaft has come loose from thermal break, push

firmly on end of shaft until blade in shaft snaps into

thermal break.

9. Replace actuator and secure it to shaft and mount-

ing plate.

10. Snap handle onto top of shaft.

Any other service to valve such as seat seal replacement

requires removal of valve from piping.

38-00005EFS—04 10

Page 11

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

11 38-00005EFS—04

Page 12

VRN DYNAMIC PRESSURE-REGULATING CONTROL VALVES AND ACTUATORS

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or

modification to, the literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any

liability, cost, or damages, including attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

Honeywell Building Technologies

In the U.S.:

Honeywell

® U.S. Registered Trademark

© 2019 Honeywell International Inc.

38-00005EFS—04 M.S. Rev. 12-19

Printed in United States

Page 13

Clapets et actionneurs de régulation

de pression dynamique VRN

NOTICE D’INSTALLATION

Les clapets trop grands peuvent causer des cycles trop

fréquents, et le siège et la bille peuvent être endommagés

en raison de l'ouverture restreinte.

Utilisation correcte

Les clapets VRN sont uniquement conçus pour les circuits

à boucle fermée d’eau chaude ou refroidie dans une plage

de températures de 1,7 à 121 °C (35 à 250 °F) et à une

pression maximale de 2 482 kPa (360 lb/po²).

L’eau doit être correctement filtrée, traitée et conditionnée

pour fournir un bon rendement opérationnel,

conformément aux recommandations des fabricants de

chaudières et refroidisseurs.

Il est recommandé de poser des crépines et des filtres.

Ne pas utiliser avec des robinets d'équilibrage manuels.

APPLICATION

Les clapets de régulation dynamique à deux voies VRN2

permettent de maintenir un débit constant d'eau chaude

ou refroidie avec concentrations de glycol pouvant

atteindre 50 % dans les circuits de chauffage, de

ventilation et de climatisation (CVC) à boucle fermée, dans

les plages de chute de pression de chaque numéro de

modèle.

Ces clapets peuvent être commandés avec ou sans les

actionneurs montés en usine.

Notes d’application

Le dimensionnement des clapets est important pour que

le système fonctionne correctement. Les clapets trop

petits n'ont pas une capacité suffisante pour la charge

maximale. Les clapets trop grands n'ont pas une autorité

suffisante sur la charge dans les applications à

modulation.

IMPORTANT

La présence d’oxyde de fer (rouille rouge) en excès

dans le système annule la garantie du clapet.

Débit efficace

Le régulateur de pression différentielle intégré assure

l'écoulement du liquide dans le clapet sans égard aux

changements de l'alimentation. Le régulateur de pression

élimine virtuellement la cavitation dans le clapet, et libère

le régulateur des effets des organes de tuyauterie, tels que

les réducteurs et les coudes.

Les clapets indépendants de la pression sont

dimensionnés pour convenir au débit du serpentin, peu

importe son diamètre de raccordement. Les clapets VRN2

éliminent le besoin d’équilibrer le système pour assurer un

débit adéquat et permettent d’utiliser les refroidisseurs à

la température différentielle prévue lors de la conception

pour une efficacité maximale dans toutes les conditions

de charge. Lorsque le système est utilisé avec des

entraînements de pompe à vitesse variable, des clapets à

trois voies et des lignes de dérivation de serpentin ne sont

pas requis.

Couple de fonctionnement requis

Les actionneurs à accouplement direct à maintien de

position en cas de panne et à sécurité intégrée Honeywell

peuvent être utilisés avec les clapets VRN.

Les clapets VRN utilisent un siège de conception brevetée

qui réduit le couple requis de l'actionneur.

Page 14

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

MISE EN GARDE

Actionneurs fournissant un couple de 305 Ncm (27 lb-po)

(pour clapets jusqu’à 1,25 po de diamètre) et de 395 Ncm

(35 lb-po) (pour les clapets de 1,5 po de diamètre et plus)

qui suffit à fermer le clapet à son taux nominal. (Reportezvous au Table 1.)

Couple de fonctionnement maximal sécuritaire : 500 Ncm

(44 lb-po).

Tableau 1. Valeurs nominales de pression différentielle

pour la fermeture.

Type de

clapet Taille de clapet

2voies 1/2po à 3po 100

Pression de fermeture

nominale (psi)

INSTALLATION

Lors de l’installation de ce produit...

1. Lire attentivement ces instructions. Le non-respect

des instructions peut endommager le produit ou

provoquer une situation dangereuse.

2. Vérifier les caractéristiques nominales indiquées

dans les instructions et sur le produit, et s’assurer

que celui-ci correspond bien à l’application prévue.

3. L’installateur doit être un technicien expérimenté

ayant reçu la formation adéquate.

4. Une fois l’installation terminée, vérifier que le pro-

duit fonctionne comme indiqué dans ces instructions.

Préparation

Risque de dommages de l'équipement

Les particules étrangères telles que la poussière et

les copeaux métalliques peuvent endommager les

joints des billes.

Pour un fonctionnement sans problème du produit,

les bonnes pratiques d’installation doivent inclure

une vidange initiale du système et un traitement de

l’eau chimique. Nettoyer les conduits en amont des

particules d’un diamètre supérieur à 1/16 po

(scories de soudage, dépôts calcaires de conduits,

sable et autres particules en suspension). Il est

recommandé d’utiliser un filtre en dérivation de

50 microns ou plus fin. Retirer tous les filtres avant

de procéder à la vidange.

Ne pas utiliser d'additifs pour chaudières, de flux à

soudure, ou de matériaux humides à base de pétrole

ou qui contiennent des huiles minérales, des

hydrocarbures ou du monoacétate d'éthylène

glycol. Les composés qui peuvent être employés,

dilués avec au moins la moitié d'eau, sont le

diéthylène glycol, l'éthylène glycol et le propylène

glycol (solutions antigel).

Si ces clapets sont installés dans un

agrandissement ou pour la modernisation d’une

installation existante, envisager la possibilité que le

liquide présent dans la tuyauterie existante ne soit

pas conforme à ces critères.

Installation mécanique

IMPORTANT

Tenir le clapet avec une clé à tuyau par le raccord

hexagonal UNIQUEMENT. NE PAS tenir le clapet

par le corps avec une clé à tuyau; ceci pourrait

endommager le produit.

Les clapets ont un filetage NPT et doivent être

étanchéifiés avec un produit d’étanchéité pour tuyauterie

approuvé. Le couple ne doit pas dépasser 75 lb-pi.

Consulter la documentation de l’actionneur pour les

dimensions de l’actionneur.

1. Nettoyer les conduits en amont des particules d’un

diamètre supérieur à 1/16 po (scories de soudage,

dépôts calcaires de conduits et autre contaminants).

2. Procéder à l’installation une fois que les spécifica-

tions du système (expansion/contraction du système et du fluide, et pressions de fonctionnement)

sont dans les tolérances indiquées.

3. Éliminer l’air du système.

4. Les clapets à sont marqués pour montrer la direc-

tion du débit.

IMPORTANT

Les flèches de débit doivent pointer dans la direction du débit pour assurer un fonctionnement

adéquat.

5. Rotation de la tige :

a. Sens horaire pour fermer.

b. Sens antihoraire pour ouvrir.

REMARQUE : Une fois les clapets installés dans la

tuyauterie, l’installateur peut déterminer

l’orientation de la bille dans le clapet grâce

aux encoches en haut de la tige du clapet.

Pour les clapets VRN, la direction longitudinale de l'encoche indique un débit par la

bille (c'est-à-dire que lorsque l'encoche est

parallèle à l'axe du clapet entre les ports A et

B, la bille permet le débit par le clapet).

6. Le clapet doit être monté avec l’actionneur/support

au-dessus du corps du clapet. Ne pas installer le clapet avec la tige sous l’horizontale ou inversée. (Voir

les Fig. 3 et 4.)

38-00005EFS—04 2

Page 15

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

MF34979

DÉBIT DÉBIT

FERMÉ

OUVERT

REMARQUES :

POUR MONTER L'ACTIONNEUR SUR UN CLAPET OUVERT, TOURNER

COMPLÈTEMENT L’ACTIONNEUR DANS LE SENS ANTIHORAIRE COMME ILL

POUR MONTER L'ACTIONNEUR SUR UN CLAPET FERMÉ, TOURNER

COMPLÈTEMENT L’ACTIONNEUR DANS LE SENS HORAIRE COMME ILLUST

MF13738A

CORPS DU CLAPET

TIGE DU CLAPET COUPLEUR

ÉCROU À

AILETTES**

PLAQUE DE

MONTAGE**

COUVERCLE DE TIGE**

VIS (2)**

POIGNÉE (AMOVIBLE) POUR LA

ROTATION MANUELLE DE L’ARBRE**

TIGE**

**INCLUS DANS LE NÉCESSAIRE DE RECHANGE (RÉF. N° 5112-11)

VIS (2)**

SUPPORT

ANTIROTATION**

BOULON**

M34954

45

45

M33091

Fig. 1. Orientation du clapet.

Fig. 3. Installation verticale du clapet.

Fig. 2. Vue éclatée du clapet.

Fig. 4. Angle de clapet acceptable par rapport à la

verticale

Ajustement de la plaque de montage

La plaque de montage de l’actionneur peut être tournée à

une position différente pour les installations en espace

réduit. Ceci s’accomplit de la façon suivante :

1. Retirer la poignée de l'arbre et la mettre de côté.

2. Retirer les deux vis fixant la tige à la plaque de mon-

tage et les mettre de côté.

3. Retirer la tige et la mettre de côté.

4. Retirer les deux vis fixant la plaque de montage au

clapet et les mettre de côté.

5. Retirer la bague de retenue de la plaque de montage

et la mettre de côté.

6. Faire tourner la plaque de montage autour de la par-

tie supérieure du clapet à la position désirée.

REMARQUE : Noter la position des trous de vis sur le cla-

pet. Ils limitent les positions de la plaque de

montage.

7. Abaisser la bague sur le corps du clapet et l'engager

dans la nouvelle position par rapport à la plaque de

montage.

8. Serrer les vis du corps du clapet fixant la plaque de

montage.

9. Rattacher la tige à la plaque de montage.

10. Si cela est souhaité, replacer la poignée sur l'arbre.

REMARQUE : Voir la Fig. 2 pour la vue éclatée du clapet.

3 38-00005EFS—04

Page 16

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

432

ACTIONNEUR FLOTTANT

24 V c.a.

1

1 ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

CONNEXION REQUISE POUR COMMANDE UNIPOLAIRE

BIDIRECTIONNELLE.

2

RÉGULATEUR

2

DIRECT

SERVICE/ARRÊT

INVERSE

MF34869B

3

4

3

2

ACTIONNEUR FLOTTANT

24 V c.a.

1

1

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

RÉGULATEUR

FLOTTANT

MF18946

DIRECT

SERVICE/ARRÊT

INVERSE

24 V c.a.

1

1

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

CONTRÔLEUR

PROPORTIONNEL

+

–

RETOUR

1

325

ACTIONNEUR PROPORTIONNEL

RETOUR

+

SIGNAL DE COMMANDE 0(2)-10 V c.c. OU 0(4)-20 mA ACCEPTABLE.

RÉGLER LE COMMUTATEUR DIP DU SIGNAL DE COMMANDE SUR

ARRÊT POUR LA TENSION ET SUR MARCHE POUR LE COURANT.

2

2

2 -10 V c.c.

2 -10 V c.c.

0 -10 V c.c.

0 -10 V c.c.

MF18947B

4

5°

85°

S1 S2

S3 S5 S6

MF25214A

INTERRUPTEURS D'EXTRÉMITÉ (CLASSE II UNIQUEMENT)

Installation électrique

1. Si nécessaire, retirer le couvercle de câblage de

l'actionneur.

2. Câbler l’actionneur en consultant les Fig. 5 à 28 pour

l’application requise.

3. Replacer le couvercle.

Câblage

Fig. 5. MN6105 avec commande SPDT marche/arrêt.

38-00005EFS—04 4

Fig. 6. MN6105 avec commande flottante.

Fig. 7. MN7505 avec commande 0(2)-10 V CC.

Fig. 8. Câblage pour modèles MN6105 et MN7505 avec

contacteurs aux./de fin de course.

Page 17

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ACTIONNEUR FLOTTANT

24 V c.a.

1

2

3

4

1

MF33138C

NOIR

BLANC

MARRON

2

RÉGULATEUR

MF33557B

ACTIONNEUR FLOTTANT

1

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

2

3

4

1

24 V c.a.

NOIR

MARRON

BLANC

SPST

(UNIPOLAIRE

UNIDIRECTIONNEL)

É

ACTIONNEUR PROPORTIONNEL

24 V c.a.

1

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

CONTRÔLEUR

0 (2)-10 V c.c.

MF33140

1

2

3

+

+

–

POSITION DU COMMUTATEUR DIP

1 2 MODE

ARRÊT ARRÊT 2-10V

ARRÊT MARCHE 0-10V

MARCHE ARRÊT 10-2V

MARCHE MARCHE 10-0V

PROPORTIONNEL/MODULATION : SORTIE DE CONTRÔLEUR 0(2)...10 V c.c. OU 10...0(2) V c.c.

2

ROUGE

NOIR

BLANC

2

1

ACTIONNEUR FLOTTANT

NOIR

BLANC

MARRON

3

2

1

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

4

24 V c.a.

2

RÉGULATEUR

Fig. 9. MVN613 avec commande flottante

1

MF33137B

PROPORTIONNEL/MODULATION : SORTIE DE R

AVEC RÉSISTANCE 500

ACTIONNEUR PROPORTIONNEL

POSITION DU COMMUTATEUR DIP

1 2 MODE

ARRÊT ARRÊT 2-10V

ARRÊT MARCHE 0-10V

MARCHE ARRÊT 10-2V

MARCHE MARCHE 10-0V

ROUGE

NOIR

VERS D’AUTRES

ACTIONNEURS

BLANC

500 OHMS,

1/2 W

MINIMUM

+

2

1

1

ALIMENTATION. PLACER SI NÉCESSAIRE UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

3

GULATEUR 4-20mA

24 V c.a.

RÉGULATEUR

4-20 mA

Fig. 12. MVN713 avec régulateur 4-20mA.

1

+

–

MF33141D

Fig. 10. MVN613 ou MVN643 à commande SPDT à deux

positions.

Fig. 11. MVN643 avec commande unipolaire

unidirectionnelle à deux positions.

Fig. 13. MVN713 avec régulateur 0(2)-10 V c.c.

5 38-00005EFS—04

Page 18

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

SPDT

1

2

MF37304

ACTIONNEUR

V

4

3

1

2

2-10 V CC

10-2 V CC

0-10 V CC

10-0 V CC

FLOTTANT, MARCHE AVANT

FLOTTANT, MARCHE ARRIÈRE

0°-90°/MODULATION

90°-0°/RÉTROACTION

ROUGE

NOIR

BRUN

BLANC

CLASSE 2

24 V CA

1

2

TENSION D’ALIMENTATION.

AU BESOIN, PLACEZ UN DISPOSITIF

DE COUPURE ET UNE PROTECTION

CONTRE LES SURCHARGES.

RÉGLEZ LE COMMUTATEUR AU

MODE « FLOTTANT ».

ACTIONNEUR

0/2 À 10 V CC

RÉGULATEUR À

COMMANDE

PROPORTIONNELLE

24 V CA

1

1

2

3

2

490 À 510

OHMS,

1/2 W

MINIMUM

TENSION D’ALIMENTATION. AU

BESOIN, PLACEZ UN DISPOSITIF DE

COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V CC ACCEPTÉE.

RÉGLEZ LE COMMUTATEUR À MODULATION, SI POSSIBLE.

V

–

+

RÉTROACTION

4

3

1

2

MF37321

2-10 V CC

10-2 V CC

0-10 V CC

10-0 V CC

FLOTTANT, MARCHE AVANT

FLOTTANT, MARCHE ARRIÈRE

3

0°-90°/MODULATION

90°-0°/RÉTROACTION

ROUGE

NOIR

BRUN

BLANC

CLASSE 2

Fig. 14. MS7505 à commande SPDT à deux positions.

CLASSE 2

1

1

2

24 V CA

TENSION D’ALIMENTATION.

AU BESOIN, PLACEZ UN DISPOSITIF

DE COUPURE ET UNE PROTECTION

CONTRE LES SURCHARGES.

RÉGLEZ LE COMMUTATEUR AU

MODE « FLOTTANT ».

Fig. 15. MS7505 à commande à flotteur.

CLASSE 2

1

0/2 À 10 V CC

RÉGULATEUR À

COMMANDE

PROPORTIONNELLE

RÉTROACTION

1

2

3

Fig. 16. MS7103 avec commande 2-10 V CC (MS7503

38-00005EFS—04 6

24 V CA

2

–

+

TENSION D’ALIMENTATION. AU BESOIN, PLACEZ UN DISPOSITIF DE COUPURE

ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V CC ACCEPTÉE.

RÉGLEZ LE COMMUTATEUR À MODULATION, SI POSSIBLE.

montré, ignorez le sélecteur).

1

2

3

4

2

NOIR

BLANC

BRUN

V

0°-90°/MODULATION

90°-0°/RÉTROACTION

2-10 V CC

10-2 V CC

0-10 V CC

10-0 V CC

FLOTTANT, MARCHE AVANT

FLOTTANT, MARCHE ARRIÈRE

ACTIONNEUR

ROUGE

ACTIONNEUR

ROUGE

1

2

NOIR

3

BLANC

4

BRUN

3

V

0°-90°/MODULATION

90°-0°/RÉTROACTION

2-10 V CC

10-2 V CC

0-10 V CC

10-0 V CC

FLOTTANT, MARCHE AVANT

FLOTTANT, MARCHE ARRIÈRE

MF37319

MF37320

Fig. 17. MS7103 avec commande 4-20 mA (MS7503

montré, ignorez le sélecteur).

CLASSE 2

1

RÉGULATEUR À

COMMANDE

PROPORTIONNELLE

0/2 À 10 V CC

24 V CA

2

–

+

RÉTROACTION

TENSION D’ALIMENTATION.

1

AU BESOIN, PLACEZ UN

DISPOSITIF DE COUPURE ET

UNE PROTECTION CONTRE

LES SURCHARGES.

2

ALIMENTATION 24 V CC

ACCEPTÉE.

3

RÉGLEZ LE COMMUTATEUR À

MODULATION, SI POSSIBLE.

1

2

3

4

3

1

2

3

4

3

ACTIONNEUR

ROUGE

NOIR

BLANC

BRUN

V

0°-90°/MODULATION

90°-0°/RÉTROACTION

2-10 V CC

10-2 V CC

0-10 V CC

10-0 V CC

FLOTTANT, MARCHE AVANT

FLOTTANT, MARCHE ARRIÈRE

ACTIONNEUR

ROUGE

NOIR

BLANC

BRUN

V

0°-90°/MODULATION

90°-0°/RÉTROACTION

2-10 V CC

10-2 V CC

0-10 V CC

10-0 V CC

FLOTTANT, MARCHE AVANT

FLOTTANT, MARCHE ARRIÈRE

Fig. 18. MS7103 avec commande 2-10 V CC utilisant

deux actionneurs (MS7503 montré, ignorez le

sélecteur).

MF37322

Page 19

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

ACTIONNEUR

SPST

24 V c.a.

1

1

2

2

ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

V

1

2

MF34973

3

ACTIONNEUR

SPST

1

1 ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

V

1

2

MF34974

2

24 V c.a.

1

1

2

3

2

ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE

UN DISPOSITIF DE COUPURE ET UNE PROTECTION

CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

RÉGLER LE COMMUTATEUR SUR FLOTTANT.

MF34975

ACTIONNEUR

V

OR +

OR N/A

RETOUR

5

4

3

1

2

2-10 V c.c.

10-2 V c.c.

0-10 V c.c.

10-0 V c.c.

Fltg, fwd

Fltg, rev

3

ACTIONNEUR

RÉGULATEUR

PROPORTIONNEL

0/2 À 10 V C.C.

24 V c.a.

1

1

2

3

2

ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

RÉGLER LE COMMUTATEUR SUR MODULANT.

V

OR +

OR N/A

RETOUR

–

+

RETOUR

5

4

3

1

2

MF19576

2-10 V c.c.

10-2 V c.c.

0-10 V c.c.

10-0 V c.c.

Fltg, fwd

Fltg, rev

3

SPDT

ACTIONNEUR

RÉGULATEUR

PROPORTIONNEL

0/2 À 10 V C.C.

24 V c.a.

1

1

2

3

2

ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

RÉGLER LE COMMUTATEUR SUR MODULANT.

V

OR +

OR N/A

RETOUR

–

+

RETOUR

5

4

3

1

2

MF34976

2-10 V c.c.

10-2 V c.c.

0-10 V c.c.

10-0 V c.c.

Fltg, fwd

Fltg, rev

3

ROUGE

NOIR

ACTIONNEUR

INTERRUPTEURS SPST

CÂBLE

PRINCIPAL

BLANC

BRUN

+ OU 0°−90°

RÉTROACTION OU 90°-0°

BLEU

BRUN

CÂBLE DES

INTERRUPTEURS

GRIS

NOIR

MF37303A

Fig. 19. Câblage pour interrupteurs auxiliaires MS7103

et MS3103). Gray/Black = Normally Open. Closed in

range 80 degrees to Fully Open. Blue/Brown = Normally

Closed. Open in range 10 degrees to Fully Open.

Fig. 20. MS8105 à commande SPDT à deux positions.

Fig. 22. MS7505 avec dérivation pour ouverture

complète.

ACTIONNEUR

1

RÉGULATEUR

PROPORTIONNEL

0/2 À 10 V C.C.

1

ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

2

ALIMENTATION 24 V c.c. ACCEPTABLE.

3

RÉGLER LE COMMUTATEUR SUR MODULANT.

RETOUR

24 V c.a.

–

+

2

SPST

1

2

3

4

5

3

V

OR +

OR N/A

RETOUR

2-10 V c.c.

10-2 V c.c.

0-10 V c.c.

10-0 V c.c.

Fltg, fwd

Fltg, rev

MF19577

Fig. 23. MS7505 avec dérivation pour fermeture

complète.

Fig. 21. MS7505 pour action flottante.

Fig. 24. MS7505 avec régulateurs 0(2)-10 V CC.

7 38-00005EFS—04

Page 20

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

ACTIONNEUR

SPST

1

1 ALIMENTATION SECTEUR. FOURNIR AU BESOIN UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

V

1

2

MF29122A

S1S3

S2

M35813

ACTIONNEUR

RÉGULATEUR

PROPORTIONNEL

0/2 À 10 V C.C.

1

2

3

2

ALIMENTATION SECTEUR. PLACER SI

NÉCESSAIRE UN DISPOSITIF DE COUPURE ET

UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

RÉGLER LE COMMUTATEUR SUR MODULANT.

V

OR +

OR N/A

RETOUR

5

4

3

1

2

MF34978

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTIONNEUR

V

OR +

OR N/A

RETOUR

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

24 V c.a.

1

24 V c.a.

1

2

24 V c.a.

1

SOUS TENSION

COMMON

–

+

1

2

3

CHAUD

COM

CONTRÔLEUR

ALIMENTATION DE TENSION DE

LIGNE. FOURNIR DES MOYENS

DE DÉCONNEXION ET UNE

PROTECTION CONTRE LES

SURCHARGES, SI NÉCESSAIRE.

ALIMENTATION 24 V CC ACCEPTÉE.

SÉLECTEUR D'ADRESSE

S-BUS

S-BUS

24 V CA

CLASSE 2

S-BUS

S-BUS

ROUGE

NOIR

BRUN

BRUN

ACTIONNEUR

ADRESSE 11

ADRESSE 12

ADRESSE 13

ADRESSE 14

ADRESSE 15

TEST

ACTIONNEUR

1

RÉGULATEUR

PROPORTIONNEL

4 À 20 mA

1

2

3

24 V c.a.

2

490 À

510 OHMS,

1/2 W

–

+

RETOUR

ALIMENTATION SECTEUR. PLACER SI NÉCESSAIRE UN DISPOSITIF

DE COUPURE ET UNE PROTECTION CONTRE LES SURCHARGES.

ALIMENTATION 24 V c.c. ACCEPTABLE.

RÉGLER LE COMMUTATEUR SUR MODULANT.

MINIMUM

1

2

3

4

5

3

V

OR +

OR N/A

RETOUR

2-10 V c.c.

10-2 V c.c.

0-10 V c.c.

10-0 V c.c.

Fltg, fwd

Fltg, rev

MF34977

Fig. 25. MS7505 avec régulateurs 4-20 mA.

Fig. 26. MS4105 à commande SPDT 120 V CA à deux

positions.

d’extrémité/auxiliaire.

Fig. 27. Câblage pour les modèles avec interrupteurs

38-00005EFS—04 8

Fig. 28. MS7505 avec régulateur 0(2)-10 V CC

actionnant plusieurs actionneurs.

Fig. 29. MS3103 with Sylk Bus control.

Page 21

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

M27714

A

FONCTIONNEMENT ET VÉRIFICATION

Une fois les installations mécanique et électrique

terminées :

1. Actionner l’actionneur pour vérifier que le sens de

rotation correspond à la séquence de commande.

2. Si le sens de rotation est incorrect :

a. For 2-position and Sylk-enabled spring return

actuators : Retirer, inverser et replacer l’actionneur sur le support.

b. Pour les actionneurs de commande flottants :

Inverser les deux fils de signal de commande

(sens horaire/antihoraire) ou modifier la position

de la commande du sélecteur.

c. Pour les actionneurs analogiques :

(1) Modifier le réglage de l’interrupteur à action

directe/inverse, ou

(2) Pour changer le sens du ressort de rappel :

déposer, inverser et poser l’actionneur de

nouveau sur le support.

3. Si la configuration de commande nécessite un

fonctionnement avec sécurité intégrée, s’assurer

que la position de sécurité coïncide avec la

séquence de commande lors de l’interruption de

l’alimentation.

4. Les actionneurs à ressort de rappel sont configurés

en usine pour un fonctionnement normalement

fermé à sécurité intégrée lors des coupures d’alimentation. Pour changer cette action pour un

fonctionnement en position normalement ouvert,

retirer et réinstaller l’actionneur dans le sens opposé

de la façon suivante :

a. Desserrer le boulon d’accouplement de l’arbre

avec une clé de 10 mm.

b. Desserrer tous les autres boulons de montage

connectant l’actionneur au support de montage

et les mettre de côté.

c. Retirer l’actionneur de l’arbre du clapet.

d. Déplacer l’adaptateur d’arbre à centrage

automatique du côté opposé à l’actionneur,

comme illustré dans la Fig. 30.

(1) Retirer l’attache de fixation de l’adaptateur

d’arbre à centrage automatique et la mettre

de côté pour une utilisation ultérieure.

(2) Retirer l’adaptateur d’arbre à centrage

automatique de l’actionneur.

(3) Reposer l’adaptateur d’arbre à centrage

automatique du côté opposé de l’actionneur

en l’alignant conformément à l’étiquetage de

course.

(4) Replacer l’attache de fixation sur l’accouple-

ment de l’arbre en utilisant la rainure de

l’accouplement.

e. Reconnecter l’actionneur au support de montage

du clapet en remplaçant les vis précédemment

déposées (étape b).

f. À l’aide d’une clé ou d'une douille de 10 mm, ser-

rez fermement le boulon d'accouplement d'arbre

à un couple de 13,6 Nm (120 lb-po).

Fonctionnement

PIN change constamment dans un système multi-zones

lors de l’ouverture et de la fermeture d’autres clapets,

modifiant le débit et la pression de refoulement du

système conformément aux caractéristiques de la courbe

de la pompe d’alimentation. La réaction du régulateur de

pression mécanique est instantanée, éliminant les

modifications de température de la pièce dus aux

changements de débit de liquide, et réduisant la nécessité

d’un fonctionnement continu du système de commande

du clapet pour corriger les changements de température

non liés à la charge se produisant dans les systèmes avec

clapets de commande standard.

Fig. 30. Placer l’actionneur en position normalement

ouvert.

M29908

Fig. 31. VRN2 Vue en coupe du VRN2 illustrant le

raccord, la bille de contrôle et le régulateur de pression.

Pour une application à commande à deux positions à plein

débit, le VRN2 agit comme un limiteur de débit.

Le régulateur de débit ne nécessite qu’une pression

minimale pour fonctionner, et a une capacité de

régulation différentielle maximale. Consulter la Fig. 32. La

chute de pression élevée d’un clapet VRN2 est comparable

à la chute de pression d’un régulateur et d’un clapet

d’équilibrage d’un système conventionnel.

9 38-00005EFS—04

Page 22

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

MISE EN GARDE

0

DÉBIT

GAL./MIN)

PRESSION DIFFÉRENTIELLE (PSID)

12

10

6

4

5.8

8

16

22

28

50

MF29707

8

12

34 40

60

100 % OUVERT

80 % OUVERT

60 % OUVERT

40 % OUVERT

20 % OUVERT

TIGE

VIS À TÊTE

FRAISÉE

PLAQUE DE

FIXATION DE TIGE

SYMBOLE « T »

TIGE

FOULOIR

SUPÉRIEUR

JOINT TORIQUE

FOULOIR INFÉRIEUR

MF34994

2. Pour limiter mécaniquement la course, régler

l’actionneur à accouplement direct en position complètement ouverte. Desserrer l’accouplement de

l’arbre et faire tourner l’arbre du clapet à la position

de débit maximum désirée, telle que confirmée par

la mesure de pression du serpentin, en utilisant les

données du fabricant du serpentin. Resserrer

l’accouplement de l’arbre. Utiliser la Fig. 33 comme

guide de réglage de la course de l’actionneur.

Si une technique d’ajustement mécanique est util-

Fig. 32. Régulation de pression, modèles à grand corps.

isée avec les actionneurs modulants MN/MS7505,

la fonction d’auto-adaptation de la course règle

automatiquement le signal de 2-10 V c.c. en

RÉGLAGES ET AJUSTEMENTS

En position d'ouverture complète, les clapets VRN2

maintiennent le débit dans la boucle. Les débits sont

indiqués dans le document de spécifications

62-3115EFS. En fonctionnement stable, le système de

commande ne requiert qu'une ouverture du clapet

suffisante pour répondre aux conditions de charge. Lors

de la récupération matinale du décalage de nuit, le

contrôleur commande généralement le clapet à 100 %.

Pour une performance optimale, ne choisir que la taille de

clapet immédiatement supérieure pour satisfaire à la

charge de conception. Ne pas utiliser de clapets trop

grands : une gamme réduite pourrait entraîner une

régulation de température moins précise.

Les clapets à bille se ferment entre 10 et 15 % de leur

course pour assurer un engagement complet du dispositif

fonction de la rotation mécanique de la bille. Voir la

documentation de l’actionneur pour les détails.

Le débit du serpentin peut être confirmé en lisant les

pressions d’entrée et de sortie du serpentin (et non pas sur

le régulateur comme c’est le cas avec un équilibrage

traditionnel : cette chute de pression est constante) et en

utilisant les données du fabricant pour calculer le débit.

Noter que le régulateur de pression de ce clapet garantit

que le débit dans le serpentin ne sera pas affecté pas les

changements de pression en amont. Contrairement aux

clapets d’équilibrage traditionnels, il n’est pas nécessaire

de reconfirmer le débit du serpentin après le réglage

d’autres clapets. Tout débit excessif ayant lieu lors de la

récupération matinale dû à des régulateurs de pression

surdimensionnés n’affecte pas les autres clapets du

système, à condition que les pompes soient d’une

capacité suffisante pour le débit requis.

d’étanchéité. Le cas échéant, les actionneurs modulants

peuvent être réglés à une réponse de 0-10 V pour que les

2 V d’un signal de commande de 2-10 V assurent une

meilleure correspondance au débit minimum. Le clapet

continuera à se fermer en cas de perte de signal.

Réparations et entretien

La tige de clapet peut être remplacée dans le système, si

nécessaire. Voir la Fig. 34.

Le cas échéant, le débit maximum peut être ajusté à une

valeur moindre de l’une des deux façons suivantes :

1. Avec l’actionneur modulant, limiter la plage de ten-

sion de commande du contrôleur d’automatisation

de bâtiment. Les clapets avec inserts de commande

de débit ont des caractéristiques d’égal pourcentage

(voir la Fig. 33). Chaque réduction de 10 % de la tension de commande maximale entraîne une réduction de 10 % du débit.

100%

80%

60%

DÉBIT

40%

20%

0%

0° 30° 60° 90°

38-00005EFS—04 10

10°

Fig. 33. Caractéristiques de débit types.

BILLE À ORIFICE

INTÉGRAL

20°

40° 50°

COURSE DE TIGE DE CLAPET

DÉBIT

CARACTÉRISÉ

À DEUX VOIES

80°

70°

Fig. 34. Remplacement dans le système de la tige de

clapet.

Suivre les étapes 1 à 6 de la section «Ajustement de la

plaque de montage» à la page 3, puis :

1. Si le fouloir inférieur est coincé, le retirer avec un

outil d’extraction de fouloir ou un outil dentaire à

extrémité en caoutchouc.

MF29551

Éviter d’érafler l’intérieur du cou du clapet.

Ceci pourrait causer une fuite lors du remontage.

Page 23

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

2. Retirer avec précaution toute saleté ou corrosion à

l’intérieur du clapet.

3. Aligner la flèche avec la patte courte du symbole

« T » de la tige neuve.

REMARQUE : Le symbole « T » varie.

4. Insérer la tige neuve. Veiller à bien aligner la clavette

de la tige avec la fente de la bille.

5. Attacher la plaque haute pression de fixation de la

tige au clapet en utilisant les vis à tête fraisée

neuves. Attacher ensuite la plaque de montage sur

le clapet.

6. Remettre le clapet sous pression et vérifier que la

tige ne fuit pas avant de continuer.

7. Glisser le sous-arbre sur la tige avec la languette ori-

entée comme indiqué dans la Fig. 34.

8. Replacer le coupe-circuit thermique, l’arbre et le

couvercle de l’arbre. Si l’arbre s’est desserré du disjoncteur thermique, pousser fermement sur

l’extrémité de l’arbre jusqu’à ce que la lame dans

l’arbre s’enclenche sur le coupe-circuit thermique.

9. Remplacer l’actionneur et l’attacher à l’arbre et à la

plaque de montage.

10. Enclencher la poignée sur la partie supérieure de

l’arbre.

Tout autre entretien du clapet, tel que le remplacement du

joint de siège, nécessite le retrait du clapet de la

tuyauterie.

11 38-00005EFS—04

Page 24

CLAPETS ET ACTIONNEURS DE RÉGULATION DE PRESSION DYNAMIQUE VRN

Par l'utilisation de la présente documentation Honeywell, vous consentez à ce qu'Honeywell ne possède aucune responsabilité

pour tous dommages résultant de votre utilisation ou modification de ladite documentation. Vous défendrez et indemniserez

Honeywell, ses sociétés affiliées, filiales pour et contre toute responsabilité, frais ou dommages, y compris les honoraires

d'avocats, résultant de quelque manière, ou survenant en connexion avec toute modification à la documentation de votre part.

Honeywell Building Technologies

Aux États-Unis :

Honeywell

® Marque de commerce déposée aux États-Unis

© 2019 Honeywell International Inc.

38-00005EFS—04 M.S. Rev. 12-19

Imprimé aux États-Unis

Page 25

Válvulas de control y actuadores

VRN con regulación de presión

dinámica

INSTRUCCIONES PARA LA INSTALACIÓN

Las válvulas de mayor tamaño pueden ocasionar ciclos

excesivos y el asiento y la bola se pueden dañar debido a

la abertura restringida.

Uso correcto

Las válvulas VRN están diseñadas para usar solamente en

aplicaciones de circuito cerrado de agua fría y caliente,

con un rango de temperatura de 35 °F a 250 °F (2 °C a

120 °C) y presiones de 360 psig (25 kg/cm²).

El agua debe estar bien filtrada, tratada y acondicionada

para un buen rendimiento operativo, y de acuerdo con las

recomendaciones del fabricante de la caldera o del

enfriador.

Se recomienda la instalación de tamices y filtros.

No utilizar con válvulas de equilibrado manual.

APLICACIÓN

Las válvulas de control bidireccionales VRN2 con

regulación de presión dinámica mantienen el flujo

constante de agua caliente y fría con soluciones de glicol

de hasta el 50 % en sistemas de calefacción, ventilación y

aire acondicionado de circuito cerrado, dentro de los

rangos de variación de presión especificados de cada

número de modelo.

Estos ensambles de válvula se pueden pedir con o sin

actuadores de montaje en fábrica.

Notas sobre la aplicación

El tamaño de la válvula es importante para el

funcionamiento adecuado del sistema. Las válvulas de

menor tamaño no tienen suficiente capacidad a la carga

máxima. Las válvulas de mayor tamaño no tienen

suficiente control sobre la carga en aplicaciones

modulantes.

IMPORTANTE

La presencia de óxido de hierro (oxidación de color

rojo) en exceso en el sistema anula la garantía de

la válvula.

Caudal efectivo

El regulador de presión diferencial incorporado hace fluir

el líquido a través de la válvula, independientemente de

los cambios de presión de suministro. El regulador de

presión prácticamente elimina la cavitación en la válvula y

libera la válvula de control de los efectos de los

componentes de la tubería, como los reductores y los

codos.

Las válvulas de control independientes de presión están

diseñadas para adaptarse al flujo de diseño en el

serpentín, independientemente del tamaño del serpentín.

Con las válvulas VRN2 no es necesario compensar el

sistema para obtener un flujo adecuado, ya que permiten

hacer funcionar los enfriadores según el diferencial de

temperatura de diseño a fin de obtener una eficacia

máxima en cualquier condición de carga. Cuando las usa

en un sistema con impulsores de bomba de velocidad

variable, las válvulas de 3 vías y las líneas con derivación

de serpentín no son necesarias.

Par de torsión operativo necesario

Tanto los actuadores de acoplamiento directo de poco par

de torsión a prueba de fallas como de falla en la posición

de Honeywell se pueden utilizar con las válvulas VRN.

Page 26

VÁLVULAS DE CONTROL Y ACTUADORES VRN CON REGULACIÓN DE PRESIÓN DINÁMICA

PRECAUCIÓN

Las válvulas VRN utilizan un diseño de asiento patentado

que disminuye el par de torsión necesario del actuador.

Los actuadores con un par de torsión de 27 lb-in (3 Nm)

(para válvulas de hasta 1-1/4" [32 mm] de tamaño) y

35 lb-in (4 Nm) (para válvulas mayores de 1-1/2" [38 mm]

de tamaño) ofrecen par de torsión suficiente para operar

la válvula en el cierre nominal. (Consulte la Table 1).

El par de torsión máximo para una operación segura es

44 lb-in (5 Nm).

Tabla 1. Especificaciones de cierre-apagado, presión

diferencial.

Tipo de

válvula Tamaño de la válvula

2 vías 1/2 in. a 3 in. 100

Especificación de

presión de cierre-

apagado (psi)

INSTALACIÓN

Cuando instale este producto...

1. Lea detenidamente estas instrucciones. De no

seguirlas, se podría dañar el producto o provocar

una situación peligrosa.

2. Revise los valores nominales especificados en las

instrucciones y en el producto, para asegurarse que

el producto sea adecuado para la aplicación.

3. El instalador debe ser un técnico de servicio capacit-

ado y experimentado.

4. Después de terminar la instalación, compruebe el

funcionamiento del producto tal como se indica en

estas instrucciones.

Preparación

No emplee aditivos para calderas, fundente para

soldar ni materiales húmedos a base de petróleo o

que contengan aceites minerales, hidrocarburos o

acetato de etilenglicol. Los compuestos que se

pueden utilizar, con un mínimo de 50% de

disolución en agua, son: dietilenglicol, etilenglicol y

propilenglicol (soluciones anticongelantes).

Si instala estas válvulas en la ampliación o

modernización de un edificio existente, no dé por

hecho que el líquido en las tuberías existentes

cumple con estos requisitos.

Instalación mecánica

IMPORTANTE:

Sujete la válvula con una llave para tubería por el

conector hexagonal ÚNICAMENTE. NO manipule

el cuerpo de la válvula con la llave para tubería; el

producto se puede dañar.

Las válvulas se roscan en el conector NPT y se deben

sellar con un sellador aprobado para tuberías. La fuerza

de torsión no debe exceder 75 lb-pies.

Consulte los documentos del actuador para conocer las

dimensiones del actuador.

1. Limpie los conductos de manera ascendente para

quitar partículas de más de 1/16 in (1.6 mm) de

diámetro (escorias de soldadura, sarro en las

tuberías y otros agentes contaminantes).

2. Continúe con la instalación una vez que las condi-

ciones específicas del sistema (expansión/contrac-

ción del sistema y su medio, así como también las

presiones de funcionamiento) estén dentro de las

tolerancias.

3. Elimine el aire del sistema.

4. Las válvulas están marcadas para mostrar la direc-

ción del flujo.

Riesgo de daño en el equipo

Las partículas extrañas, como los restos de metal y

la suciedad, pueden dañar los sellos de la bola.

Para que el producto funcione sin complicaciones,

el proceso de instalación adecuado debe incluir el

drenado inicial del sistema y el tratamiento

químico del agua. Limpie los conductos de manera

ascendente para quitar partículas de más de

1/16 in (1.6 mm) de diámetro (escorias de

soldadura, sarro en las tuberías, arena y otras

partículas suspendidas). Se sugiere utilizar un

filtro de corriente lateral para el sistema de

50 micrones (o más fino). Retire todos los filtros

antes de realizar el drenaje.

38-00005EFS—04 2

IMPORTANTE

Las flechas del flujo deben estar orientadas en la

dirección del flujo para un funcionamiento

correcto.

5. Rotación del vástago:

a. En sentido horario para cerrar.

b. En sentido antihorario para abrir.

NOTA: Después de instalar las válvulas en las tuberías, el

instalador puede determinar la orientación de la

bola dentro de la válvula por las muescas que se

encuentran en la parte superior del vástago de la

válvula. Para las válvulas VRN, la dirección en

sentido longitudinal de la muesca indica el flujo a

través de la bola (es decir, cuando la muesca se

encuentra paralela al eje de la válvula entre los

puertos A y B, la bola permitirá el flujo a través de

la válvula).

6. La válvula se debe montar con el actuador/soporte

por encima del cuerpo de la válvula. No instale la

válvula con el vástago por debajo de la línea hori-

zontal o en forma invertida. (Consulte las Fig. 3 y 4).

Page 27

VÁLVULAS DE CONTROL Y ACTUADORES VRN CON REGULACIÓN DE PRESIÓN DINÁMICA

MS34979

FLUJO FLUJO

CERRADO

ABIERTO

NOTAS: PARA MONTAR EL ACTUADOR EN UNA VÁLVULA ABIERTA, GIRE EL

ACTUADOR COMPLETAMENTE EN SENTIDO ANTIHORARIO COMO SE MUESTRA.

PARA MONTAR EL ACTUADOR EN UNA VÁLVULA CERRADA, GIRE EL

ACTUADOR COMPLETAMENTE EN SENTIDO HORARIO COMO SE MUESTRA.

M34954

45

45

M33091

Fig. 1. Orientación de la válvula.

MANIJA (DESMONTABLE)

PARA ROTACIÓN MANUAL**

Fig. 3. Instalación vertical de la válvula.

** INCLUIDOS EN EL KIT DE REEMPLAZO (PIEZA 5112-11).

Fig. 2. Vista en despiece del ensamble de la válvula.

ACOPLADOR DEL VÁSTAGO DE LA VÁLVULA

TORNILLOS (2)**

CUBIERTA DEL ENSAMBLE

DE VÁSTAGO**

ENSAMBLE DE VÁSTAGO**

TORNILLOS (2)**

CUERPO DE LA VÁLVULA

PERNO**

SOPORTE

ANTIRROTACIÓN**

PLACA DE MONTAJE**

TUERCA MARIPOSA**

MS13738A

Fig. 4. Ángulo aceptable de la válvula desde la línea

vertical.

Ajuste de la placa de montaje

La placa de montaje del actuador se puede girar hacia una

posición diferente para la instalación en espacios

reducidos. Esto se realiza de la siguiente manera:

1. Quite la manija del eje y déjela a un lado.

2. Quite los dos tornillos que sujetan el ensamble del

vástago a la placa de montaje y déjelos a un lado.

3. Quite y deje a un lado el ensamble del vástago.

4. Quite y deje a un lado los dos tornillos que sujetan la

placa de montaje a la válvula.

5. Quite y aparte el aro de sujeción de la placa de mon-

taje.

6. Gire la placa de montaje alrededor de la parte supe-

rior de la válvula a la posición deseada.

NOTA: Tenga en cuenta las posiciones de los agujeros

para los tornillos en la válvula. Estos limitan las

posiciones de la placa de montaje.

7. Baje el aro hasta el cuerpo de la válvula y engánch-

elo en la nueva posición con relación a la placa de

montaje.

8. Apriete los tornillos al cuerpo de la válvula para fijar

la placa de montaje.

9. Vuelva a fijar el ensamble del vástago a la placa de

montaje.

10. Si lo desea, reemplace la manija en el eje.

NOTA: Consulte la Fig. 2 para ver la vista en despiece de

la válvula.

3 38-00005EFS—04

Page 28

VÁLVULAS DE CONTROL Y ACTUADORES VRN CON REGULACIÓN DE PRESIÓN DINÁMICA

24 V CA

1

1

SUMINISTRO ELÉCTRICO. PROPORCIONE LOS MEDIOS DE DESCONEXIÓN

Y DE PROTECCIÓN CONTRA SOBRECARGAS SEGÚN SE REQUIERA.

CONTROLADOR

PROPORCIONAL

+

–

RETROALIMENTACIÓN

1

325

ACTUADOR PROPORCIONAL

RETROALIMENTACIÓN

+

0(2)-10 V CC DE 0(4)-20 mA SEÑAL DE CONTROL ACEPTABLE. CONFIGURE

EL INTERRUPTOR DIP DE CONTROL DE SEÑAL EN “OFF” (APAGADO) PARA

VOLTAJE. CONFIGURE EN “ON” (ENCENDIDO) PARA CORRIENTE.

2

2

2 -10 V CC

2 -10 V CC

0 -10 V CC

0 -10 V CC