Page 1

TRADELINE

®

VR8345M Universal

Electronic Ignition Gas Contr ol

Application

These universal electronic ignition gas controls are used

in gas-fired appliances with capacities up to 300 cu ft/hour

at 1 inch wc pressure drop [8.5 cu m/hour at 0.25 kPa] for

natural gas. The VR8345M will operate with a direct spark

(DSI), hot surface (HSI) or intermittent pilot ignition. The

control includes a manual valve, two automatic operators, a

pressure regulator, pilot adjustment, pilot plug, conduit

cover and ignition adapter. Refer to the following list for

the VR8345M specifications.

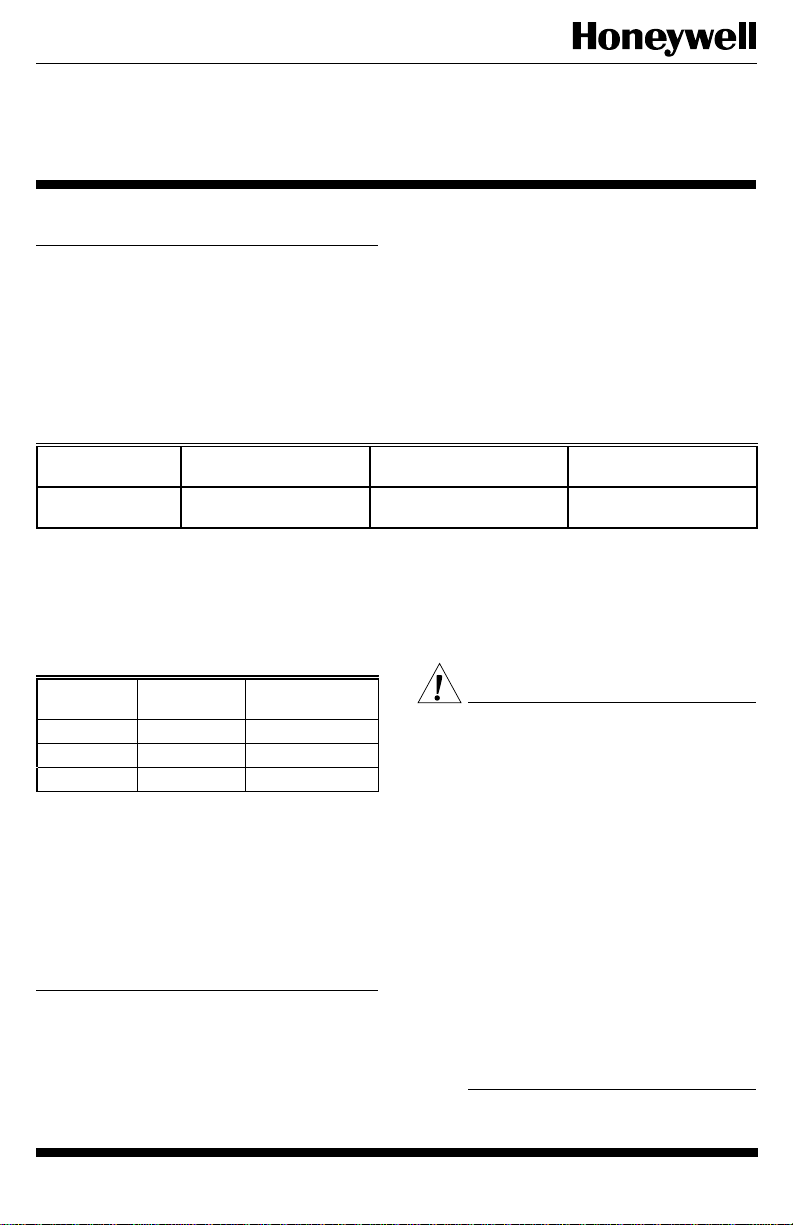

TABLE 1—GAS CAPACITY.

Size

(Inlet x Outlet)

3/4 x 3/4 300 cu ft/hour

a

Capacity based on 1000 Btu/cu ft, 0.64 specific gravity natural gas at 1 in. wc pressure drop [37.3 MJ/cu m, 0.64 specific

gravity natural gas at 0.25 kPa pressure drop].

Use conversion factors in Table 2 to convert capacities

for other gases.

TABLE 2—GAS CAPACITY

CONVERSION FACTORS.

Gas

Manufactured 0.60 0.516

Mixed 0.70 0.765

Propane 1.53

APPROVALS:

American Gas Association Design Certificate: L2025007.

Canadian Gas Association Design Certificate: L2025007.

PIPE ADAPTERS: Includes two 3/4 to 1/2 inch NPT bush-

ings and one 1/2 to 3/8 inch NPT bushing.

CROSS REFERENCE: See Table 3 for cross reference

information.

Capacity (at 1 in. wc

pressure drop)

[8.5 cu m/hour]

Specific

Gravity

a

Multiply Listed

Capacity By

Installation

WHEN INSTALLING THIS PRODUCT…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for your

application.

AMBIENT TEMPERATURE RANGE: -40° to +175° F

[-40° to +79° C].

BODY PATTERN: Straight-through.

REGULATOR TYPE: Standard opening.

INLET X OUTLET SIZE: 3/4 x 3/4 inch.

IGNITION ADAPTER: Configures VR8345M to operate

with direct spark or hot surface ignition.

ELECTRICAL RATINGS:

Voltage and Frequency: 24 Vac, 60 Hz.

Current Draw: 0.7A.

CAPACITY: See Table 1.

Minimum

Regulated Capacity

30 cu ft/hour

0.8 cu m/hour]

3. The installer must be a trained, experienced service

technician.

4. After installation is complete, use these instructions to

check out product operation.

Maximum

Regulated Capacity

415 cu ft/hour

[11.8 cu m/hour]

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Follow these warnings exactly:

1. Disconnect power supply before wiring to prevent electrical shock or equipment damage.

2. To avoid dangerous accumulation of fuel gas,

turn off gas supply at the appliance service

valve before starting installation, and perform

Gas Leak Test after completion of installation.

3. When working with a system using intermittent

pilot ignition, do not bend pilot tubing at gas

control or pilot burner after compression fitting

has been tightened because gas leakage at the

connection can result.

4. Always install sediment trap in gas supply line

to prevent contamination of gas control.

5. Do not force the gas control knob. Use only your

hand to turn the gas control knob. Never use any

tools. If the gas control knob will not operate by

hand, call a qualified service technician to replace the gas control. Force or attempted repair

can result in fire or explosion.

J.H. • Rev. 10-94 • ©Honeywell Inc. 1994 • Form Number 69-0844—1

1 69-0844—1

Page 2

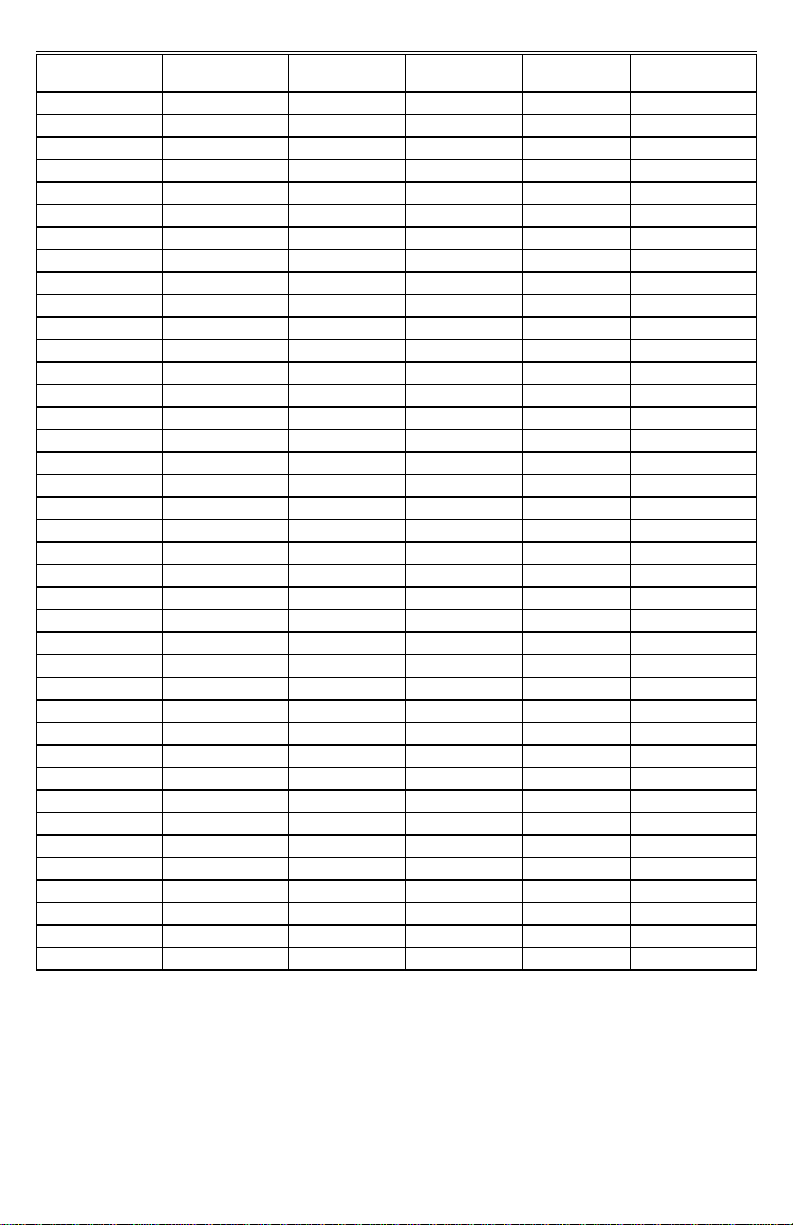

TABLE 3—VR8345 REPLACES THESE IGNITION CONTROLS.

Old Model No. Manufacturer VR8200 VR8300 VR800

36E36-304 DSI/HSI WHITE RODGERS VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

36E36-304 IP WHITE RODGERS VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

720-050 ROBERTSHAW VR8205A2024 VR8305M3506 — VR8345M4302

720-051 ROBERTSHAW VR8205A2024 VR8305M3506 — VR8345M4302

720-070 ROBERTSHAW VR8204A2076 VR8304A3509 — VR8345M4302

V4185A1000 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M3402

V4185A1010 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4185B1008 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4185B1016 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4185B1024 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225A1002 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225A1028 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225A1044 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225A1051 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225A1077 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225B1000 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225B1018 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4225B1026 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4227A1000 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4227A1018 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4227B1008 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4227B1016 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4249A1004 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4249A1012 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4249A1020 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4297A1005 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4297A1013 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4297A1021 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4297A1039 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4297A1047 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4297A1054 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4298A1004 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V4298A1012 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V445A1009 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

V445A1017 HONEYWELL VR8205A2024 VR8305M3506bVR8450A4113bVR8345M4302

V8185A1001 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

V8185A1019 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

V8185A1035 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

V8185B1009 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

a

Direct ignition application.

b

Requires Honeywell AT40 or AT72 transformer.

c

Regulator setting on replacement valve differs from original. Adjust to rated pressure as necessary for optimum performance.

d

Shipped by Honeywell as LP gas only, may have been converted to natural gas by OEM.

e

Use with 1/8 in. compression fitting, part no. 3934014-1.

f

Use with 3/4 in. angle flange, part no. 393690-15 .

g

Requires 1/2 in. straight flange (part no. 393690—16) or an angle flange (part no. 393690—13).

Universal

Replacement

a

a

a

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a,b

a

a

a

a

(Continued)

69-0844—1 2

Page 3

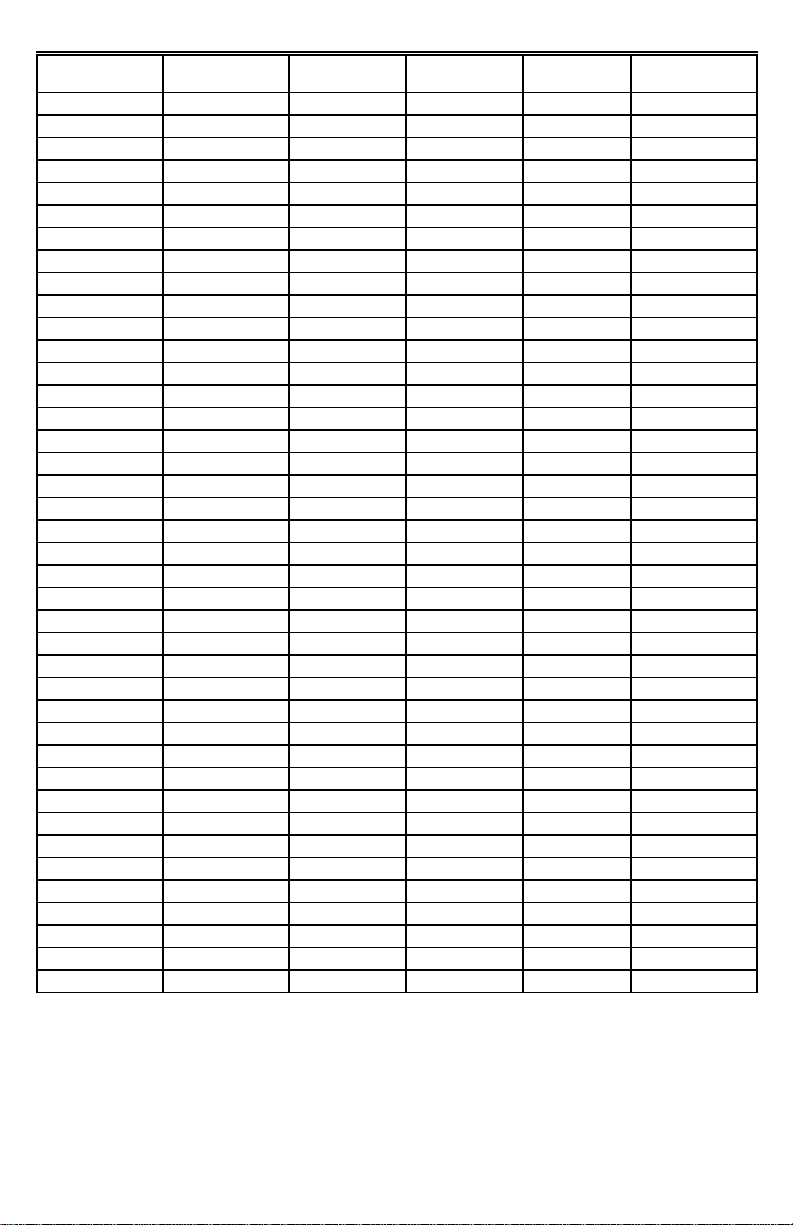

TABLE 3—VR8345 REPLACES THESE IGNITION CONTROLS (Continued).

b,c

VR8345M4302

Universal

Replacement

Old Model No. Manufacturer VR8200 VR8300 VR800

V8185B1017 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

V8247A1000 HONEYWELL VR8205A2024 VR8305A3506 VR8450A4113 VR8345M4302

V8247B1005 HONEYWELL VR8205A2024 VR8305A3506 VR8450A4113 VR8345M4302

V845A1018 HONEYWELL VR8205A2024 VR8305A3506 VR8450A4113 VR8345M4302

V845A1026 HONEYWELL VR8205A2024cVR8305A3506 VR8450A4113cVR8345M4302

V845A1034

V845A1133

d

HONEYWELL VR8205A2024 VR8305A3506 VR8450A4113 VR8345M4302

d

HONEYWELL VR8205A2024 VR8305A3506 VR8450A4113 VR8345M4302

VR4450M2035 HONEYWELL VR8205A2024bVR8305A3506bVR8450A4113bVR8345M4302

VR4450M2126 HONEYWELL VR8205A2024bVR8305A3506bVR8450A4113bVR8345M4302

VR4450M2159

d

HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

VR445M1009 HONEYWELL VR8205A2024bVR8305M3506bVR8450A4113bVR8345M4302

VR445M1017

d

HONEYWELL VR8205A2024

b,c

VR8305M3506

b,c

VR8450A4113

VR8204A2032 HONEYWELL — — — VR8345M4302

VR8204A2001 HONEYWELL VR8204A2076 — — VR8345M4302

VR8204A2027 HONEYWELL VR8204A2076c— — VR8345M4302

VR8204A2035 HONEYWELL VR8204A2076c— — VR8345M4302

VR8204A2043

d

HONEYWELL VR8204A2076c— — VR8345M4302

VR8204A2050 HONEYWELL VR8204A2076 — — VR8345M4302

VR8204A2068

d

HONEYWELL VR8204A2076 — — VR8345M4302

VR8204A2076 HONEYWELL VR8204A2076 — — VR8345M4302

VR8204A2092

d

HONEYWELL VR8204A2076c— — VR8345M4302

VR8204A2100 HONEYWELL VR8204A2076e— — VR8345M4302

VR8204A2118 HONEYWELL VR8204A2076

e,f

— — VR8345M4302

VR8204A2126 HONEYWELL VR8204A2076 — — VR8345M4302

VR8204A2134 HONEYWELL VR8204A2076c— — VR8345M4302

VR8204A2142 HONEYWELL VR8204A2076 — — VR8345M4302

VR8204A2167

d

HONEYWELL VR8204A2076c— — VR8345M4302

VR8204A2175 HONEYWELL VR8204A2076c— — VR8345M4302

VR8205A2008 HONEYWELL VR8205A2024 — — VR8345M4302

VR8205A2016

d

HONEYWELL VR8205A2024c— — VR8345M4302

VR8205A2024 HONEYWELL VR8205A2024 — — VR8345M4302

VR8205A2073 HONEYWELL VR8205A2024e— — VR8345M4302

VR8440A2001 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440A2019

d

HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440A2050 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440A2076 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440A2084 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440A2092 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440A2100 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440A2118 HONEYWELL VR8204A2076eVR8304M3509 VR8440A3025eVR8345M4302

a

Direct ignition application.

b

Requires Honeywell AT40 or AT72 transformer.

c

Regulator setting on replacement valve differs from original. Adjust to rated pressure as necessary for optimum performance.

d

Shipped by Honeywell as LP gas only, may have been converted to natural gas by OEM.

e

Use with 1/8 in. compression fitting, part no. 3934014-1.

f

Use with 3/4 in. angle flange, part no. 393690-15 .

g

Requires 1/2 in. straight flange (part no. 393690—16) or an angle flange (part no. 393690—13).

a

a

a

a

a,c

a

a

a,b

a,b

a,b

a,b

a,b,c

c

c

c

c

e

e,f

c

c

c

a

a,c

a

a,c

c

c

c

e

(Continued)

3 69-0844—1

Page 4

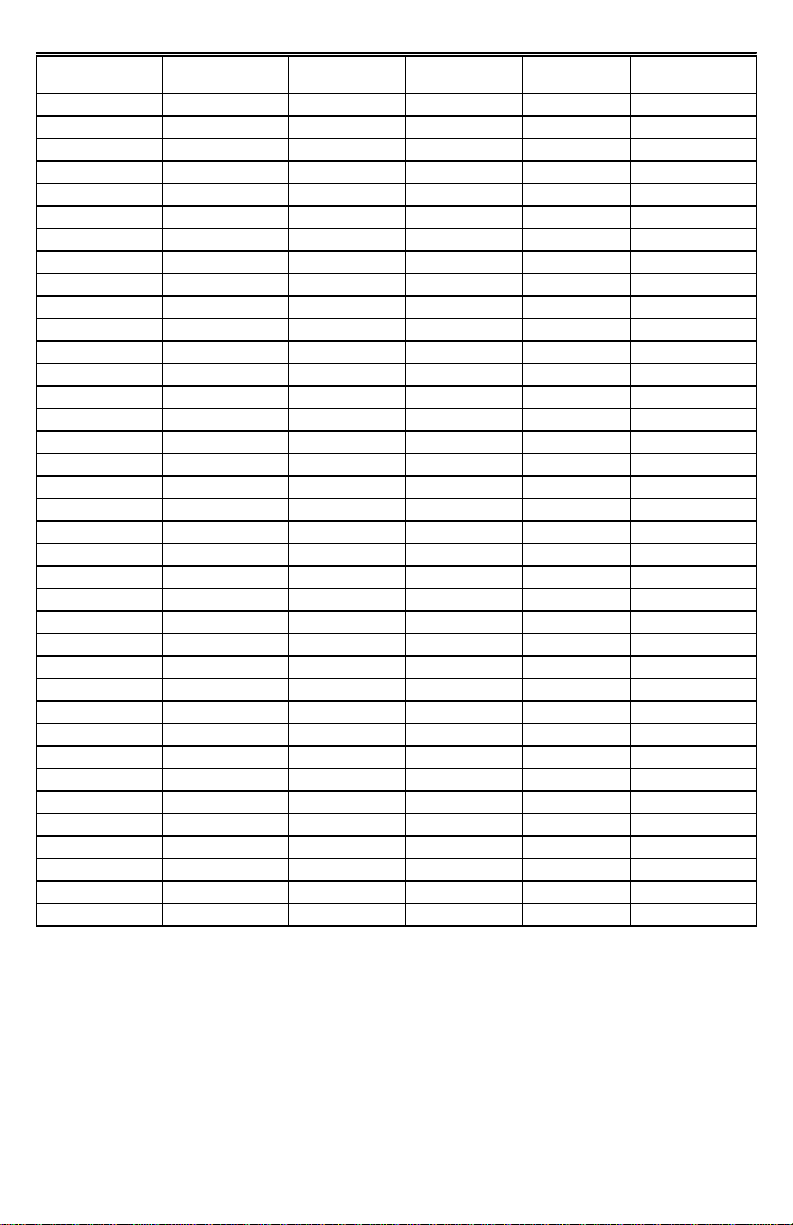

TABLE 3—VR8345 REPLACES THESE IGNITION CONTROLS (Continued).

Old Model No. Manufacturer VR8200 VR8300 VR800

VR8440A2134 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440A2142 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440M1000 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440M2008 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440M2016 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440M2024 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440M2032

VR8440M2040

d

HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440M2057 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440M2065 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440M2073 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR8440M2081

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8440M2099 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR844A1002 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844A1028

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR844A1051 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844A1085 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1006 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1014 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1063 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1162 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1170 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1188

VR844M1196

VR844M1220

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

d

HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1246 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844M1287

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR844M1295 HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR844N1003 HONEYWELL VR8204A2076 VR8304M3509 VR8440A3025 VR8345M4302

VR844R1005

d

HONEYWELL VR8204A2076cVR8304M3509 VR8440A3025cVR8345M4302

VR8450A2000 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

VR8450A2109 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

VR8450A2117

d

HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

VR8450M2023 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

VR8450M2064 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

VR8450R6003 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

VR845M1013 HONEYWELL VR8205A2024 VR8305M3506 VR8450A4113 VR8345M4302

a

Direct ignition application.

b

Requires Honeywell AT40 or AT72 transformer.

c

Regulator setting on replacement valve differs from original. Adjust to rated pressure as necessary for optimum performance.

d

Shipped by Honeywell as LP gas only, may have been converted to natural gas by OEM.

e

Use with 1/8 in. compression fitting, part no. 3934014-1.

f

Use with 3/4 in. angle flange, part no. 393690-15 .

g

Requires 1/2 in. straight flange (part no. 393690—16) or an angle flange (part no. 393690—13).

Universal

Replacement

c

c

c

c

c

c

c

c

c

c

c

c

a

a

a

a

a

a

69-0844—1 4

Page 5

CAUTION

Never apply a jumper across or short the valve coil

terminals. This can burn out the heat anticipator in

the thermostat or damage the electronic intermittent pilot (IP) module.

Fig. 1—Use moderate amount of pipe compound.

TWO IMPERFECT

THREADS

GAS CONTROL

PIPE

IMPORTANT: These gas controls are shipped with pro-

tective seals over inlet and outlet tappings. Do not

remove seals until ready to connect piping.

Follow the appliance manufacturer instructions if avail-

able; otherwise, use the following instructions.

CONVERTING BETWEEN NATURAL AND LP

GAS

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Do not attempt to use a gas control set for natural

gas on LP gas or a gas control set for LP gas on

natural gas.

Convert standard-opening gas controls from natural gas

to LP gas with the conversion kit included with this

TRADELINE® gas control. Part number 393691 will convert from natural to LP gas. Part number 394588 will convert

from LP to natural gas.

USE PIPE ADAPTER TO SOLVE SWING RADIUS

PROBLEMS

In some field service applications, space limitations make

it difficult or impossible to thread the gas control onto the gas

supply pipe. This problem can be resolved for many installations by using a pipe adapter. Install the pipe adapter on the

end of the supply pipe in place of the gas control by following

the same precautions and instructions that are used for

installing the gas control. After the pipe adapter is installed,

attach the gas control to the adapter as outlined in the Install

Pipe Adapters to Gas Control section.

NOTE: Using a pipe adapter increases the overall length of

the gas control.

INSTALL PIPE ADAPTER TO GAS CONTROL

Install adapter to gas control as follows:

Bushings

1. Remove seal over gas control inlet or outlet.

2. Apply moderate amount of good quality pipe com-

pound to bushing, leaving two end threads bare. See Fig. 1.

3. Insert bushing in gas control and carefully thread pipe

into the bushing until tight.

THREAD PIPE THE AMOUNT

SHOWN IN TABLE 4 FOR

INSERTION INTO GAS CONTROL

APPLY A MODERATE AMOUNT OF

PIPE COMPOUND TO PIPE ONLY

(LEAVE TWO END THREADS BARE).

M3075A

LOCATION

Locate the combination gas control in the appliance

vestibule on the gas manifold. In replacement applications,

locate the gas control in the same location as the old control.

Do not locate the gas control where it can be affected by

steam cleaning, high humidity, dripping water, corrosive

chemicals, dust or grease accumulation, or excessive heat.

For proper operation, follow these guidelines:

• Locate gas control in a well-ventilated area.

• Mount gas control high enough above the cabinet bottom to avoid exposure to flooding or splashing water.

• Make sure the ambient temperature does not exceed

the ambient temperature ratings for each component.

• Cover gas control when the appliance is cleaned with

water, steam, or chemicals or to avoid dust and grease

accumulation.

• Avoid locating gas control where exposure to corrosive chemical fumes or dripping water is possible.

INSTALL PIPING TO GAS CONTROL

All piping must comply with applicable codes and ordinances or with the National Fuel Gas Code (ANSI Z223.1

NFPA No. 54), whichever applies. Tubing installation must

comply with approved standards and practices.

1. Use new, properly reamed pipe free from chips. If

tubing is used, make sure the ends are square, deburred and

clean. Make sure all tubing bends are smooth and without

deformation.

2. Run pipe or tubing to the gas control. If tubing is used,

obtain a tube-to-pipe coupling to connect the tubing to the

gas control.

3. Install sediment trap in the supply line to the gas

control. See Fig. 2.

INSTALL GAS CONTROL

1. This gas control can be mounted from 0 to 90 degrees

in any direction from the vertical position of the gas control

knob.

2. Mount the gas control so gas flow is in the direction of

the arrow on the bottom of the gas control.

3. Thread pipe the amount shown in Table 4 for insertion

into the gas control.

IMPORTANT: Do not thread pipe too far. Valve distortion

or malfunction can result when the pipe is inserted

too deeply into the gas control.

5 69-0844—1

Page 6

Fig. 2—Install sediment trap.

DROP

HORIZONTAL

3 INCHES

[76]

MINIMUM

HORIZONTAL

PIPED

GAS

SUPPLY

GAS

CONTROL

2

DROP

TUBING

1

GAS

SUPPLY

Fig. 3—Top view of gas control.

GAS

CONTROL

RISER

PIPED

GAS

SUPPLY

3 INCHES

[76]

MINIMUM

2

PRESSURE REGULATOR

ADJUSTMENT (UNDER

CAP SCREW)

INLET

PRESSURE TAP

INLET

GAS CONTROL KNOB

1

MUST USE WIRE ADAPTER (NOT SHOWN) ON HSI OR DSI SYSTEM.

2

MUST USE PILOT PLUG (NOT SHOWN) ON HSI OR DSI SYSTEM.

CONVENIENCE

TERMINALS (2)

(OPTIONAL)

1

WIRING

TERMINALS (2)

OUTLET

PRESSURE

TAP

OUTLET

PILOT OUTLET

PILOT ADJUSTMENT

(UNDER CAP SCREW)

M8436

2

GAS

RISER

3 INCHES

[76]

MINIMUM

ALL BENDS IN METALLIC TUBING SHOULD BE SMOOTH.

1

2

CAUTION: SHUT OFF THE MAIN GAS SUPPLY

BEFORE REMOVING END CAP TO PREVENT

GAS FROM FILLING THE WORK AREA. TEST

FOR GAS LEAKAGE WHEN INSTALLATION

IS COMPLETE.

CONTROL

2

M8435

4. Apply a moderate amount of good quality pipe compound (do not use Teflon tape) to pipe only, leaving two end

threads bare. See Fig. 1. On LP installations, use compound

resistant to LP gas.

5. Remove seals over gas control inlet and outlet if

necessary.

6. Connect pipe to gas control inlet and outlet. Use

wrench on the square ends of the gas control. See Figs. 3

and 4.

TABLE 4—NPT PIPE THREAD LENGTH IN INCHES.

Maximum Depth

Pipe Can Be

Pipe

Size

Thread Pipe

This Amount

Inserted Into

Control

3/8 9/16 3/8

1/2 3/4 1/2

3/4 13/16 3/4

When working with an intermittent pilot ignition system, go to Connect Pilot Gas Tubing section next. When

installing on a hot surface or direct spark ignition system,

go to the Wiring section.

Fig. 4—Proper use of wrench on gas control.

APPLY WRENCH

FROM TOP OR

BOTTOM OF GAS

CONTROL TO

EITHER SHADED AREA

M8562

CONNECT PILOT GAS TUBING (INTERMITTENT

PILOT IGNITION ONLY)

1. Remove the pilot gas seal (plug).

2. Cut tubing to desired length and bend as necessary for

routing to pilot burner.

CAUTION

1. Do not make sharp bends or deform the tubing.

2. Do not bend tubing at the gas control or pilot

burner after compression fitting has been tightened because this can result in gas leakage at

the connection.

69-0844—1 6

Page 7

3. Square off and remove burrs from end of tubing.

4. Use the compression fitting supplied with this gas

control. Slip the fitting over the tubing and slide out of the

way.

NOTE: When replacing a gas control, cut off old compres-

sion fitting and replace with the new compression fitting

provided on the gas control. Never use the old compression fitting because it may not provide a gas-tight seal.

5. Push tubing into the pilot gas tapping on the outlet end

of the control until it bottoms. While holding tubing all the

way in, slide compression fitting into place, engage threads

and turn until finger tight. Then tighten one more turn with

wrench. Do not overtighten. Refer to Figs. 5 and 6.

6. Connect other end of tubing to pilot burner according

to pilot burner manufacturer instructions.

Fig. 5—Always use new compression fitting.

GAS CONTROL

TIGHTEN NUT ONE TURN

BEYOND FINGER TIGHT

FITTING BREAKS OFF AND CLINCHES

TUBING AS NUT IS TIGHTENED

TO

BURNER

M3076A

Fig. 6—Remove pilot gas seal (plug) and

install pilot gas tube for intermittent pilot

application on VR8345.

O

N

O

F

F

PV

PV

MV

MV

PILOT GAS

TUBE

M8441

WIRING

All wiring, including insulated quick connect terminals,

must comply with applicable electrical codes and ordinances.

1. Check the power supply rating on the gas control and

CAUTION

Disconnect power supply before making wiring

connections to prevent electrical shock or equipment damage.

make sure it matches the available supply. Install thermostat

and other controls as required.

2. When the gas control is installed on a hot surface or

direct spark ignition system, attach the wire adapter provided

to the wiring terminals. See Fig. 7 for the wire terminal

location.

Follow the wiring instructions furnished by the appliance

manufacturer, if available, or use the following general instructions. Where these instructions differ from the appliance

manufacturer, follow the appliance manufacturer instructions.

Fig. 7—Install wire adapter for hot surface or direct spark ignition systems. Pilot plug must be in the

valve pilot opening.

O

N

O

FF

3. Connect control circuit to gas control terminals. See

Figs. 3 and 8, 9, or 10.

4. Adjust the thermostat heat anticipator to 0.7, the rating

stamped on the valve operator.

WIRE

ADAPTER

V

P

V

P

V

M

V

M

PILOT GAS SEAL

(PLUG)

M8440

7 69-0844—1

Page 8

Fig. 8—VR8345 wiring connections in intermittent ignition system.

GND

MV/PV

PV

(BURNER)

MV

24V

GND

S8610U

5

VENT

TH-W

DAMPER

PLUG

24V

SENSE

SPARK

1

L1

(HOT)

AIR

PROVING

SWITCH

COMBUSTION

AIR BLOWER

RELAY

L2

COMBUSTION

AIR BLOWER

MOTOR

CONTROLLER

1

MV/PV

MV

MV

VR8345

DUAL VALVE COMBINATION

GAS CONTROL

SENSOR

IGNITER

PILOT

BURNER

PILOT GAS

SUPPLY

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

ALTERNATE LIMIT CONTROLLER LOCATION.

2

MAXIMUM CABLE LENGTH 3 ft [0.9 m].

3

CONTROLS IN 24V CIRCUIT MUST NOT BE GROUND LEG TO TRANSFORMER.

4

LEAVE VENT DAMPER PLUG CONNECTED.

5

REMOVE JUMPER AND CONNECT SENSE TERMINAL ON TWO ROD APPLICATION ONLY.

6

GROUND

Fig. 9—VR8345 wiring connections in hot surface ignition system.

S8910U HOT SURFACE IGNITER CONTROL

M

P

L

S

., M

N

5

5

4

2

6

S

8910U

5

rd

. C

a

n

c

ry

o

r d

e

a

m

a

lfu

n

c

e

r try

to

u

n

w

e

t -- re

E

V

)

D

L

N

A

V

(G

0

0

A

0

a

u

s

e

7

5

th

.

STATUS LED:

tio

n

if

1. Flash-Ignition Lockout

2 Flash-Weak Flame Signal

s

e

a

3 Flash-Internal Error-Replace Control

p

la

c

e

it.

Pulsing "Heartbeat"-Normal Operation

T

R

I

A

L

N

U

M

.

O

F

C

O

N

F

I

G

U

D

V

P

L

E

L

24

IN

V

A

L

V

E

=

2

4

T

I

M

E

,

T

R

I

A

L

S

R

A

T

I

O

N

U

G

!

W

ARNING

E

x

p

lo

s

io

n

h

a

z

a

s

e

rio

u

s

in

ju

T

h

is

d

e

v

ic

e

c

a

n

it g

e

ts

w

e

t. N

e

v

d

e

v

ic

e

th

a

t h

a

s

b

e

e

)

R

E

)

N

D

D

R

N

N

U

B

24V

(G

G

(

2

H

O

T S

U

R

FA

C

E IG

P

U

T

V

O

L

T

A

G

E

S

=

1

2

0

&

2

H

S

I =

1

2

0

V

, 6

.5

A

A

M

A

X

T

O

1

N

E

M

T

A

L

2

4

V

L

O

Prepurge Time = 30 Sec

Igniter Warmup Time = 34 sec

2

0

V

A

C

U

T

R

A

L

I

S

2

L

H

V

, 1

E

V

L

A

V

L2

N

ITIO

4

V

A

A

X

A

D

=

0

1

2

0

H

I

S

H

THERMOSTAT

2

4

LIMIT

CONTROLLER

L1

(HOT)

N

C

, 6

0

H

Z

.2

+

V

A

L

V

V

A

C

O

T

I

N

S

T

F

O

R

S

E

N

1

A

P

P

L

6

3

M8564

A

U

T

O

IG

N

IT

IO

N

S

Y

S

T

E

M

S

A

N

S

I Z

2

1

.2

0

E

L

O

A

D

S

E

E

R

U

C

T

I

O

N

S

E

R

E

M

O

T

E

S

S

E

/

D

U

A

L

N

R

O

D

E

L

I

C

A

T

I

O

N

S

S

TRIAL

TIME: 7 SEC

NUM OF

TRIALS: 1

THERMOSTAT OR

CONTROLLER

VR8345M

COMBINATION

GAS CONTROL

BURNER

GROUND

QUICK

CONNECTS

MV

MV

HSI WIRE

ADAPTER

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

MAKE SURE L1 AND L2 ARE NOT REVERSED. THIS WOULD PREVENT FLAME DETECTION.

2

ALTERNATE LIMIT CONTROLLER LOCATION

3

SENSE TERMINAL AND Q354 FLAME SENSOR ON D MODELS ONLY.

69-0844—1 8

3

Q354 FLAME

SENSOR

HOT SURFACE

IGNITER/SENSOR

LIMIT

CONTROLLER

2

L1

(HOT)

L2

1

3

M8563

Page 9

Fig. 10—VR8345 wiring connections in direct spark ignition system (single rod application).

L1

BURNER

(HOT)

L2

1

MV

MV

QUICK

CONNECTS

M8438

DSI WIRE

ADAPTER

VR8345

COMBINATION

GAS CONTROL

2

S87 CONTROL MODULE

5

ALARM

24V (GND)

VALVE

VALVE

24V

4

TEMPERATURE

CONTROLLER

3

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

2

3

MAXIMUM IGNITER-SENSOR CABLE LENGTH: 3 ft [.9 m] OR LESS.

4

3A REPLACEABLE FUSE.

ALARM TERMINAL PROVIDED ON SOME MODELS.

5

GND

IGNITER-SENSOR AND

BURNER GROUND

ALARM, IF USED

Q347 IGNITER-SENSOR

Startup and Checkout

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

1. Do not force the gas control knob. Use only your

hand to turn the gas knob. Never use any tools.

2. If the gas control knob will not operate by hand,

call a qualified service technician to replace the

gas control.

GAS CONTROL KNOB SETTINGS

The gas control knob operates differently in intermittent

pilot, hot surface and direct spark ignition systems.

The gas control knob settings for an intermittent pilot

system are as follows:

OFF: Prevents pilot and main burner gas flow.

ON: Permits gas to flow into the control body. Under

control of the thermostat and intermittent pilot module, gas can flow to the pilot and main burner.

The gas control knob settings for hot surface or direct

spark ignition systems are as follows:

OFF: Prevents main burner gas flow.

ON: Permits main burner gas flow. Under control of the

thermostat and ignition module, gas can flow to the

main burner.

NOTE: Gas controls are shipped with the gas control knob in

the ON position.

PERFORM GAS LEAK TEST

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Check for gas leaks with a rich soap and water

solution anytime work is done on a gas control.

9 69-0844—1

Page 10

GAS LEAK TEST

1. Paint all pipe connections upstream of the gas control

with a rich soap and water solution. Bubbles indicate a gas

leak.

2. If a gas leak is detected, tighten the pipe connection.

CAUTION

Stand clear while lighting main burner to prevent

injury caused from hidden gas leaks that could

cause flashback in the appliance vestibule.

3. Turn on the system by rotating the gas control knob

counterclockwise to ON.

4. Light the main burner by following the appliance

manufacturer instructions or turning up the thermostat to call

for heat.

5. With the main burner in operation, paint all pipe joints

and gas control inlet and outlet with a rich soap and water

solution.

6. If another gas leak is detected, tighten joints and pipe

connections.

7. If gas leak cannot be stopped, turn the gas control knob

clockwise to OFF.

8. Replace the leaking part.

9. Perform the gas leak test.

ADJUST THE PILOT BURNER FLAME (INTERMITTENT PILOT IGNITION ONLY)

The pilot flame should envelop 3/8 to 1/2 in. [10 to

13 mm] of the igniter-sensor tip. See Fig. 11. To adjust the

pilot flame:

1. Remove the pilot adjustment cover screw. Refer to

Fig. 3.

2. Turn the inner adjustment screw clockwise t o

decrease or counterclockwise to increase pilot flame.

3. To prevent gas leakage, always replace the cover

screw after adjustment.

Fig. 11—Proper flame adjustment.

PROPER FLAME

3/8 TO 1/2 INCH

[10 TO 13 mm]

IGNITERSENSOR

M3080A

ADJUSTMENT

CHECK AND ADJUST GAS INPUT TO MAIN

BURNER

CAUTION

1. Do not exceed the input rating stamped on the

appliance nameplate, or manufacturer recommended burner orifice pressure for the size

orifice(s) used. Make certain the primary air

supply to the main burner is properly adjusted

for complete combustion (refer to the appliance manufacturer instructions).

2. WHEN CHECKING GAS INPUT BY

CLOCKING THE GAS METER:

• Make sure that the only gas flow through the

meter is that of the appliance being checked.

• Make certain that other appliances are turned

off with pilot burners extinguished (or deduct that gas consumption from the meter

reading).

• Convert the flow rate to Btuh as described in

Gas Controls Handbook, form 70-2602, and

compare to the Btuh input rating on the

appliance nameplate.

3. WHEN CHECKING GAS INPUT WITH A

MANOMETER (PRESSURE GAUGE):

• To connect the manometer, be sure the gas

control knob is in the OFF position before

removing the outlet pressure tap plug.

• When removing the manometer, turn the gas

control knob back to OFF and replace the

outlet pressure tap plug.

• Shut off the gas supply at the appliance

service valve, or at the gas tank for LP gas,

before removing the outlet pressure tap plug

and before disconnecting the manometer and

replacing the outlet pressure tap plug.

• Perform the Gas Leak Test at the outlet

pressure tap plug.

Standard-Opening Pressure Regulator

1. The gas control outlet pressure should match the

manifold pressure listed on the appliance nameplate.

2. With the main burner operating, check the gas control

flow rate by using the meter clocking method or check the

gas pressure using a manometer connected to the gas control

outlet pressure tap. See Fig. 3.

3. If necessary, adjust the pressure regulator to match the

appliance rating. Refer to Table5 for the factory set nominal

outlet pressures and adjustment setting ranges.

a. Remove the pressure regulator adjustment cap screw.

b. Using a screwdriver, turn the inner adjustment screw

clockwise to increase or counterclockwise to

decrease the main burner gas pressure.

c. Always replace the cap screw and tighten firmly to

safeguard proper operation.

4. If the desired outlet gas pressure or gas flow rate

cannot be achieved by adjusting the gas control, check the

gas control inlet pressure by using a manometer at the inlet

pressure tap. If the inlet pressure is in the normal range (refer

to Table 5), replace the gas control. Otherwise, take the

necessary steps to provide proper gas pressure to the gas

control.

69-0844—1 10

Page 11

TABLE 5—PRESSURE REGULATOR

SPECIFICATION PRESSURES FOR STANDARD-

Unit

Measure

CHECK SAFETY SHUTDOWN PERFORMANCE

OPENING NATURAL GAS.

Outlet Pressure

(Full Rate)

Nominal

of

in. wc 5.0 - 7.0 3.5 3.0 - 5.0

kPa 1.2 - 1.7 0.9 0.7 - 1.2

Inlet

Pressure

Range

Nominal

Factory

Outlet

Setting

Adjustment

Setting

Range

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Perform the safety shutdown test any time work is

done on a gas system.

NOTE: Read steps 1 through 7 below before starting and

compare to the safety shutdown or safety lockout tests

recommended for the intermittent pilot (IP), hot surface

(HSI) or direct spark (DSI) module. When different, use

the procedure recommended for the module.

1. Turn off gas supply.

2. Set the thermostat or controller above room tempera-

ture to call for heat.

3. • Intermittent Pilot Ignition—Watch for an ignition

spark at pilot burner either immediately or following prepurge. See ignition module specifications.

• Hot Surface or Direct Spark Ignition—Watch for

an ignition spark or glow at hot surface igniter

either immediately or following prepurge. See ignition module specifications.

4. If module has timed ignition, time the length of the

igniter operation. See ignition module specifications.

5. • Intermittent Pilot Ignition—After the module locks

out, turn on gas supply and make sure there is no

gas flow to the pilot or main burner.

NOTE: With modules that continue spark until pilot lights or

system is shut down manually, pilot should light when

gas supply is turned on.

• Hot Surface or Direct Spark Ignition—After the

module locks out, turn on gas supply and assure

there is no gas flow to main burner.

6. Set the thermostat below room temperature and wait

at least 45 seconds to reset system.

7. Operate system through one complete cycle to make

sure all controls operate properly.

Maintenance

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Improper cleaning or reassembly can cause gas

leakage. When cleaning, be sure that the control is

reassembled properly and perform gas leak test.

Regular preventive maintenance is important in applications such as commercial cooking, agricultural and industrial

operations that place a heavy load on system controls because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000 to 200,000

cycles per year. Such heavy cycling can wear out the

gas control in one to two years.

• Exposure to water, dirt, chemicals and heat can damage the gas control and shut down the control system.

The maintenance program should include regular checkout of the gas control; see Startup and Checkout section. To

check out the control system, see the appliance manufacturer

literature. Maintenance frequency must be determined individually for each application. Some considerations are:

• Cycling frequency. Appliances that may cycle 100,000

times annually should be checked monthly.

• Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before

the next use.

• Consequence of unexpected shutdown. Where the cost

of an unexpected shutdown would be high, the system

should be checked more often.

• Dusty, wet, or corrosive environment. Since these

environments can cause the gas control to deteriorate

more rapidly, the system should be checked more

often.

NOTE: If the gas control will be exposed to high ammonia

conditions, e.g., those used in greenhouses or animal barns,

contact your Honeywell sales representative to request a

gas control with corrosion resistant construction.

The gas control should be replaced if:

• It does not perform properly during checkout or

troubleshooting.

• The gas control knob is hard to turn or push down.

• The gas control is likely to have operated for more than

200,000 cycles.

Service

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY OR DEATH

Do not disassemble the gas control; it contains no

replaceable components. Attempted disassembly

or repair can damage the gas control.

11 69-0844—1

Page 12

CAUTION

Do not apply a jumper across or short the valve coil

terminals. Doing so can burn out the heat anticipator

in the thermostat or damage the ignition module.

IF MAIN BURNER WILL NOT COME ON WITH

CALL FOR HEAT

1. Make sure the gas control knob is in the ON position.

2. Adjust thermostat several degrees above room temperature.

3. Using an ac voltmeter, check for voltage at gas control.

• Intermittent Pilot Igntion—If pilot lights, measure

voltage across MV/PV and MV. If pilot does not light,

measure across MV/PV and PV before safety lockout

occurs.

• Hot Surface or Direct Spark Ignition—Measure volt-

age across MV terminals at gas control.

4. If voltage is not present, check control circuit for pro-

per operation.

5. If proper control circuit voltage is present, replace

gas control.

INSTRUCTIONS TO THE HOMEOWNER (FOR

YOUR SAFETY, READ BEFORE OPERATING)

W ARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH

Follow these warnings exactly:

1. Pilot/main burner flame is lit automatically. Do

not light the pilot/main burner flame manually.

2. Before lighting appliance, smell around the appliance for gas. Be sure to smell next to the floor

because LP gas is heavier than air.

3. IF YOU SMELL GAS:

• Turn off the gas supply at the appliance ser-

vice valve. On LP gas systems, turn off gas

supply at the gas tank.

• Do not light any appliances in the house.

• Do not touch electrical switches or use phone.

• Leave the building and use a neighbor’s

phone to call your gas supplier.

• If you cannot reach your gas supplier, call the

fire department.

4. Do not force the gas control knob. Use only your

hand to push down or turn the gas control knob.

Never use any tools. If the gas control knob will

not operate by hand, call a qualified service

technician to replace the gas control. Force or

attempted repair can result in a fire or explosion.

5. Call a qualified service technician to replace the

gas control if it has been flooded with water.

6. Replace the gas control in the event of any

physical damage, tampering, bent terminals,

missing or broken parts, stripped threads, or

evidence of exposure to heat.

IMPORTANT: Follow the operating instructions provided

by the manufacturer of your heating appliance. The

information below will be of assistance in a typical gas

control application, but the specific controls used and

the procedures outlined by the manufacturer or your

appliance may differ and require special instructions.

To Turn On The Applicance

Stop: Read the warnings on page 9.

The pilot/main burner flame is lit automatically. Do not

attempt to manually light the pilot. If the appliance does not

turn on when the thermostat is set several degrees above

room temperature, follow these instructions:

1. Set the thermostat to its lowest setting to reset the

safety control.

2. Disconnect all electric power to the appliance.

3. Remove the gas control access panel.

4. Push in the gas control knob slightly and turn clock-

wise to OFF.

5. Wait five minutes to clear out any unburned gas. If you

then smell gas, STOP! Follow step 3 of the Warning in the

Instructions To The Homeowner section. If you do not smell

gas, continue with the next step.

6. Turn the gas control knob counterclockwise to

ON.

7. Replace the gas control access panel.

8. Reconnect all electric power to the appliance.

9. Set the thermostat to the desired setting.

10. If the appliance does not turn on, set the gas control

knob to OFF and contact a qualified service technician for

assistance.

Turning Off The Appliance

VACATION SHUTDOWN—Set the thermostat to the de-

sired room temperature while you are away.

COMPLETE SHUTDOWN—Push in the gas control knob

slightly and turn clockwise to OFF. Do not force.

Appliance will completely shut off. Follow the Instructions

to the Homeowner above to resume normal operation.

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

69-0844—1 12

Printed in U.S.A.

M1P 2V9

QUALITY IS KEY

Loading...

Loading...