APPLICATION

TheVR6200H ContinuousPilot CombinationGasControl

is used in gas-fired appliances from 20 to 200 cfh natural

gas capacity. It includes safety shutoff a manual valve, two

automatic operators, a pressure regulator, a pilot filter, l/4

in. quick-connect convenience terminals, and an EC0

connector with two 114 in. quickconnect convenience terminals.

The VR6200H operates at 24V/60 Hz and has an

ambient temperature range of O0 F to 175” F [-I 6” C to 78’

C]. The thermostat heat anticipator setting is 0.5A.

Angle and straight adapters are available for 316. 112,

and 3/4 in. pipe. Refer to Table 1 for adapter part numbers.

Flange kits include one flange with attached O-ring, four

mounting screws, a 9164 in. hex wrench, and instruction

sheet.

The VR6200H is factory-set for natural gas. Do not

attempt to use VR6200H on LP gas. To convert VR6200H

from naturalgasto LPgas,followinstructionsinLPgasconversion kit.

TABLE l-FLANGE PART NUMBERS.

INLET/ LESS

OUTLET FLANGE

PIPE SIZE TYPE WRENCH WRENCH

310 in. NPT Straight 393690-I

l/2 in. NPT Straight 393690.6

314 in. NPT Straight 393690-4

a Elbow (angle) flanges cannot provide right hand inlet

when the EC0 connector is used.

NOTE: Flange Kits include one flange with attached

O-ring and four mounting screws.

AMERICAN GAS ASSOCIATION DESIGN CERTIFICATE:

P-70-42A.

CANADIAN GAS ASSOCIATION DESIGN CERTIFICATE:

1029~CC-6395 series.

AUSTRALIAN GAS ASSOCIATION CERTIFICATE: 4214.

Elbow” 393690-2 393690-I 2

Elbow 393690-3 393690-13

Elbow’ 393690-5 393690-15

PART NO. PART NO.

HEX

WITH

HEX

393690-I 1

393690-I 6

393690-14

INSTALLATION

WHEN INSTALLING THIS PRODUCT...

I, Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service technician.

4. After installation is complete, check out product operation as provided in these instructions,

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE, SEVERE

INJURY OR DEATH.

Follow these warnings exactly.

1. Disconnect oower SUDDIV before Wirha to

prevent electrical shot% or equipment iamage.

2. To avold dangerousaccumulatlon of fuel gas,

turn off gas supply at the appliance service

valve before starting installation, and perform

Gas LeakTest after completion of Installation.

3. Do not attempt to use a control set for natural

(manufactured) gason LP gas, or a control set

for LP on natural gas.

4. Do not bend pilot tubing at gas control or pilot

burner after compresslon nut has been tightened, or gas leakage at the connection may

result.

5. Always Install sediment trap in gas supply line

to prevent contamination of gas control.

6. Do not force the gas control knob. Use only

your hand to push down the reset button or

turn the gascontrol knob. Never use any tools.

If the knob or reset button will not operate by

hand, the control should be replaced by a

qualifledservketechnlclan.Forceorattempted

reoalr mav result In fire or explosion.

Never apply a jumper across or short the valve coil

terminals, This may burn out the heat anticipator in

the thermostat.

These gas controls are shipped with protective seals

over inlet and outlet tappings. Do not remove seals

until ready to connect piping.

Followthe appliance manufacturer’s instructions if avail-

able; otherwise, use the instructions provided below.

INSTALL ADAPTERS TO CONTROL

tf adapters are installed on the gas control, mount them

as follows:

Flanges:

I, Choose the appropriate flange for your application.

NOTE: A right angle inlet flange cannot be used with EC0

connected.

2. Remove seal over control inlet or outlet.

3. Check to ensure that the O-ring is fitted in the groove

of flange. ff the O-ring is not attached or is missing, do not

use the flange.

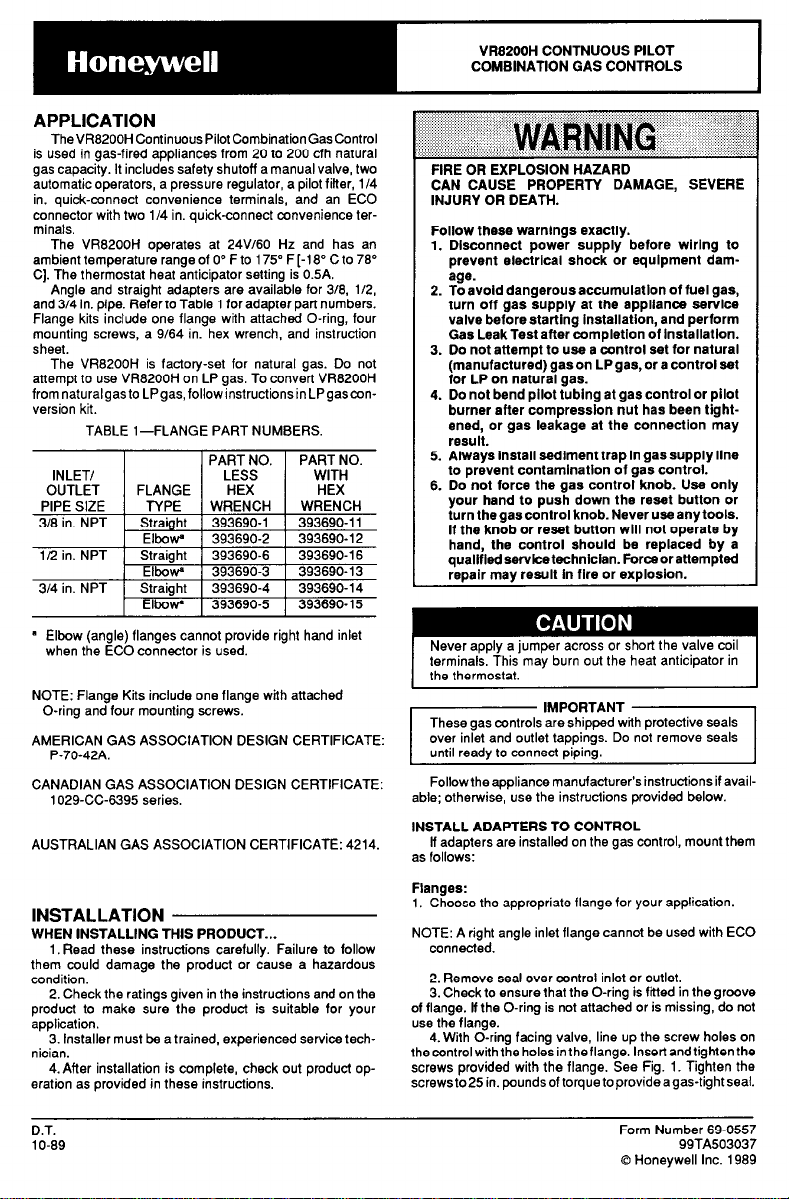

4. With O-ring facing valve, line up the screw holes on

thecontrolwiththe holesintheflange. lnsertandtightenthe

screws provided with the flange. See Fig. I. Tighten the

screwsto in. poundsof torque toprovideagas-tight seal.

IMPORTANT I

D.T.

1 O-89

Form Number 69-0557

99TA503037

0 Honeywell Inc. 1989

Bushings:

1. Remove seal over control inlet or outlet.

2. Apply moderate amount of good quality pipe compound to bushing, leaving two end threads bare. On LP

installation, usecompound resistantto LPgas. DoNOTuse

Teflon tape.

3. Insert bushing in control and thread pipe carefully into

bushing until tight.

Complete instructions below for piping, installing control, connecting pilottubing, thermocouple and wiring. Make

certain the leak test you perform on the control after

completing the installation includes leak testing the adapters and screws. ff you use a wrench on the valve after

flanges are installed, usethe wrench onlyon theflange, not

the control.

I I ,..I*

lg. l-Fasten flange to valve firmly, but do not over-

tighten ecrews.

LOCATfON

Do not locate the combination gas control where it may

be affected by steam cleaning, high humidity, or dripping

water, corrosive chemicals, dust or grease accumulation,

or excessive heat. To ensure proper operation, follow

these guidelines.

. Locate in a well ventilated area.

* Mount high enough above the cabinet bottom to

avoid exposure to flooding or splashing water.

- Ensure the ambient temperature does not exceed

the ambient temperature ratings for each component.

* Cover gas control if appliance is cleaned with water,

steam, or chemicals or to avoid dust and grease

accumulation.

* Avoid locating where exposure to corrosive chemi-

cal fumes or dripping water are likely.

Mount the combination gas control in the appliance

vestibule on the gas manifold. ff this is a replacement application, mount the new control in the same location as

the old control.

Install Piping to Control

All piping must comply with local codes and ordinances

or with the National Fuel Gas Code (ANSI 2223.1 NFPA

No. 54) whichever applies. Tubing installation must comply with approved standards and practices.

1. Use new, properly reamed pipe free from chips. ff

tubing is used, make sure the ends are square, deburred

and clean. All tubing bends must be smooth and without

deformation.

2. Run pipe or tubing to the control. ff tubing is used,

obtain a tube-to-pipe coupling to connect the tubing to the

control.

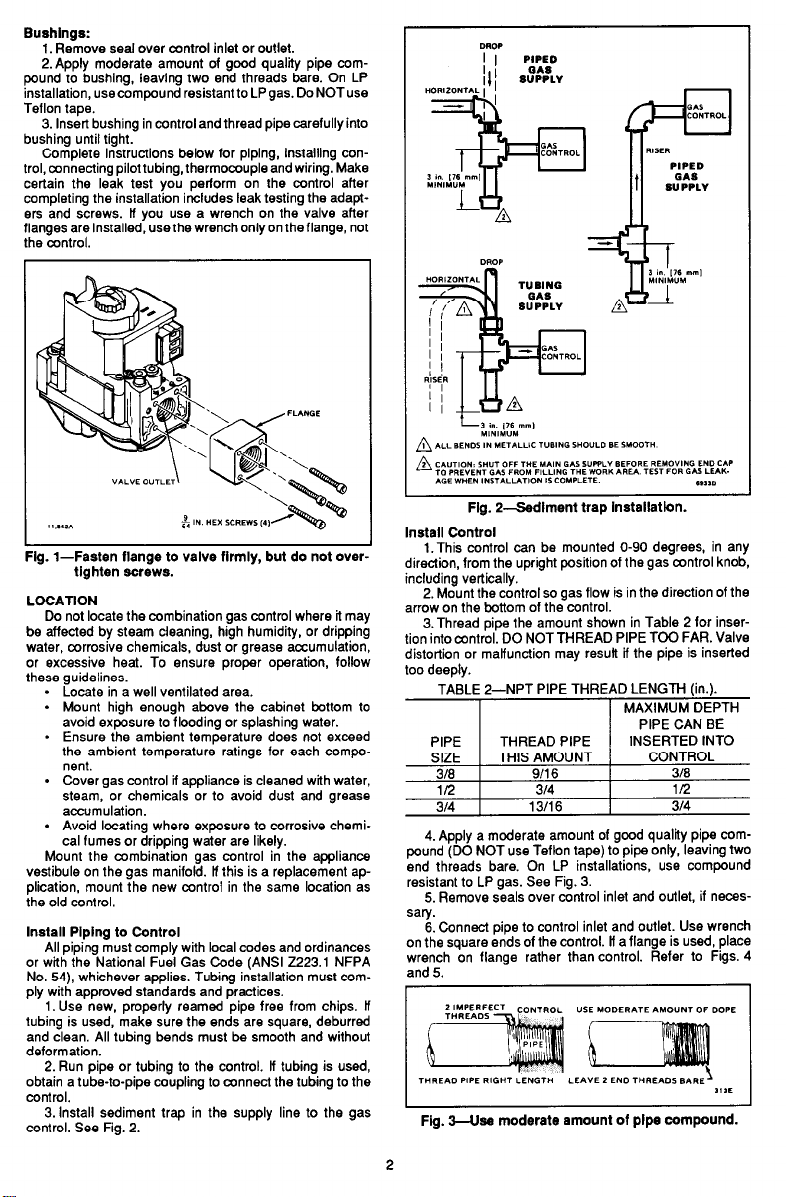

3.lnstall sediment trap in the supply line to the gas

control. See Fig. 2.

Flg. Zadlment trap installatfon.

Install Control

I

l.This control can be mounted O-90 degrees, in any

direction, from the upright position of the gas control knob,

including vertically.

2. Mount the control so gas flow is in the direction of the

arrow on the bottom of the control.

3.Thread pipe the amount shown in Table 2 for insertion into control. DO NOT THREAD PIPE TOO FAR. Valve

distortion or malfunction may result if the pipe is inserted

too deeply.

TABLE 2-NPT PIPE THREAD LENGTH (in.).

I

I

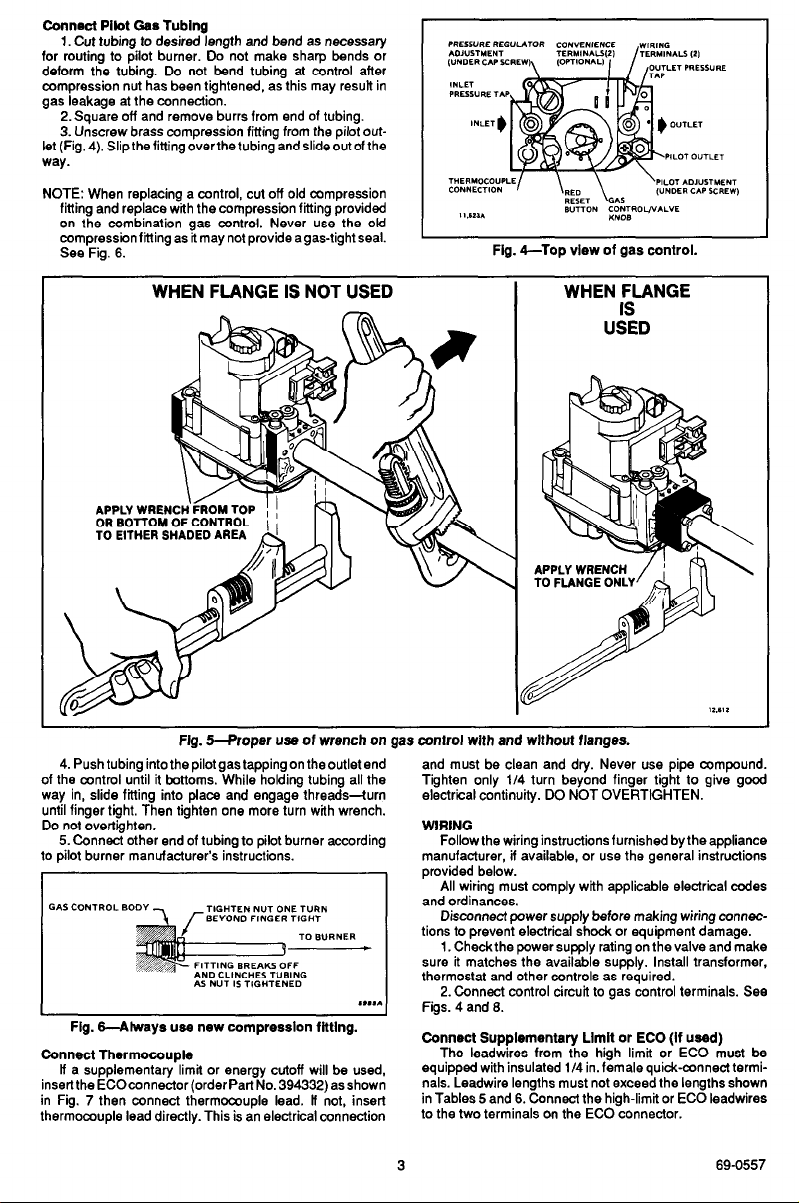

4. Apply a moderate amount of good quality pipe com-

pound (DO NOT use Teflon tape) to pipe only, leaving two

end threads bare. On LP installations, use compound

resistant to LP gas. See Fig. 3.

5. Remove seals over control inlet and outlet, if neces-

sary.

6. Connect pipe to control inlet and outlet. Use wrench

on the square ends of the control. ff a flange is used, place

wrench on flange rather than control. Refer to Figs. 4

and 5.

1 MAXIMUM DEPTH

1 PIPE CAN BE

I

Fig. 3-Use moderate amount of plpe compound.

2

Connect Pilot Gas Tubing

1. Cut tubing to desired length and bend as necessary

for routing to pilot burner. Do not make sharp bends or

deform the tubing. Do not bend tubing at control after

compression nut has been tightened, as this may result in

gas leakage at the connection.

2. Square off and remove burrs from end of tubing.

3. Unscrew brass compression fitting from the pilot out-

let (Fig.4). Slipthefittingoverthetubing andslideoutofthe

way.

NOTE: When replacing a control, cut off old compression

fitting and replace with the compression fitting provided

on the combination gas control. Never use the ofd

compression fitting as it may not provide a gas-tight seal.

See Fig. 6.

11.1211

Fig. ~-TOP view of gas control.

B”TTDN mTBRow*L”E

WHEN FLANGE IS NOT USED

APPLY WRENC

OR BOTTOM 0

TO EITHER SHADED AREA

Fig. S-F’roper usa of wrench on gas control with and without flanges.

4. Push tubing into the pilot gas tapping on the outlet end

of the control until it bottoms. While holding tubing all the

way in, slide fitting into place and engage threads--turn

until finger tight. Then tighten one more turn with wrench.

Do not overtlghten.

5. Connect other end of tubing to pilot burner according

to pilot burner manufacturer’s instructions.

,**,*

Fig. GAlways use new compression fitting.

Connect Thermocouple

ff a supplementary limit or energy cutoff will be used,

inserttheECOconnector(orderPartNo.394332)asshown

in Fig. 7 then connect thermocouple lead. ff not, insert

thermocouple lead directly. This is an electrical connection

WHEN FLANGE

“k:D

and must be clean and dry. Never use pipe compound.

Tighten only 114 turn beyond finger tight to give good

electriial continuity. DO NOT OVERTIGHTEN.

WRING

Follow the wiring instructions furnished by the appliance

manufacturer, if available, or use the general instructions

provided below.

All wiring must comply with applicable electrical codes

and ordinances.

Disconnect power supply before making wiring wnnec-

tions to prevent electrical shock or equipment damage.

1. Check the power supply rating on the valve and make

sure it matches the available supply. Install transformer,

thermostat and other controls as required.

2. Connect control circuit to gas control terminals. See

Figs. 4 and 6.

Connect Supplementary Limit or EC0 (If used)

The leadwires from the high limit or EC0 must be

equipped with insulated l/4 in. female quick-connect termi-

nals. Leadwire lengths must not exceed the lengths shown

in Tables 5 and 6. Connect the high-limit or EC0 leadwires

to the two terminals on the EC0 connector.

3 69-0557

Loading...

Loading...