Honeywell VQ400, VQ420, VQ440, VQ425, VQ450 Product Handbook

UNIVERSAL GAS VALVES

VQ400 Series

CLASS “A” COMBINATIONVALVES

PRODUCT HANDBOOK

APPLICATION

The VQ400 Series class “A” safety combination valves are

used for control and regulationofgaseous fluids in gas power

burners, atmospheric gas boilers, melting furnaces,

incinerators and othergasconsuming appliances.

These combination valves are available intwoversions:

model VQ420/25 (pipe sizes3/4” and 1”)

and model VQ440/50(pipesizes 1 1/2” and 2”).

The 1 1/4” connection is obtained by using a DN32 flange kit

on a VQ440 body.

The features and specificationsofboth models are identical

(unless specified otherwise).

model VQ440/50

model VQ420/25

Contents

General

Description 2.......................................

Features 3.........................................

Technical

Specifications 4 -- 5.................................

Performance characteristics 6........................

Capacity curves 7...................................

Dimensional drawings 8 -- 9.........................

Installation and Operation

Installation 10......................................

Adjustments and finalcheckout 11 -- 12...............

Construction and workingprinciples 13................

Various

Standards and approvals 14..........................

Ordering information 15 -- 16.........................

Standard configurations 17 -- 26......................

Replacement parts and accessories 27................

Subject to change withoutnotice. Printed in the Netherlands.

EN2R--9018 9704R1--NE

DESCRIPTION

The VQ400 Series combination valves are suitable for the

controlof gaseous fluidsin gas consuming appliances

according to international standards.

The VQ400 Series combination valves meet the class “A”

specification according EN161.

The VQ400 Series combination valves have straight flanged

pipe connection from 3/4” up to 2”.

The VQ400 Series combination valves are standard equipped

with two main valves V1 and V2. Safety valve V1 is always

fast opening/closing. The second valve (V2) can be either fast

(= with flow regulation) or slow (= with flow regulation and

adjustable opening).

At the main body (4) flange connections are provided to

mount either an:

• internalby--pass valve to achieve high--low flame control

• internalor external pilot valve

• vent valve

• pressure switch (Min. or Max.)

• Valve Proving System (VPS) + pressure switch.

These accessories can be mounted on various positions of

the main body of the VQ400.

2

EN2R--9018 9704R1- -NE

FEATURES

• Class “A” safety combination valve for control of

gaseous fluids in gas consuming appliances in

accordance with international standards.

• Main body with two gas valves with single seat.

• Internalby--pass valve to achieve high--low flame

control.

• internalor external pilot valve.

• Ventvalve.

• Options for mounting flanged minimum and maximum

pressure switches.

• ValveProving System (VPS).

• Closing time: < 1 second.

• Coils field replaceable.

• Coils suitable for permanent energization.

• Fine mesh screen between inlet flange and main body.

• Various pressure tap points at main body available,

when no additional valves or pressure switches are

used.

• Second main valve, either with adjustable flow

regulator(fast), or characterizedopening mechanism

(slow) with adjustable maximum flow rate and step

pressure.

• Rectifier board with LEDs (VQ440/50 only) to indicate

energization of coil

• Rectifier boards field replaceable.

• Plug connector according to DIN 43650: standard for

VQ440/50, optional for VQ420/25.

• PG11 cable strain relief standard at VQ420/25.

• Optional mounting of Closed Position Indication

switch (CPI) at bottom of safety valve V1.

3

EN2R--9018 9704R1- -NE

SPECIFICATIONS

The specifications described in this chapter are related to the

main gas valve, by--pass valve and pilot valve (see also

Performancecharacteristics on page 6.).

Models

VQ420/25 (DN20 and DN25)

VQ440/50 (DN40 and DN50)

NOTE: DN32 connection is obtained with a flange kit on

The main gas volume is adjustable at 2

The startflow is adjustable at slow open 2

Dimensions

See dimensionaldrawings and table on page 8 and 9.

Pipe sizes

Main body

1 1/4”,1 1 /2” and 2”.

Pilot valve and vent valve

(all internal pipe thread according to ISO 7--1)

Capacity

Main body

VQ440 body.

:Inletand outletstraight flange connection 3/4”, 1”,

: outlet 3/4” thread.

: see capacity curves on page 7.

Pilot valve and vent valve on VQ400 DN20 ... 50

By--pass on VQ400 DN20 ... 40

By--pass on VQ400 DN50:

(see capacity curves VE4000 Series product handbook)

Maximum operating pressure

200 or 360 mbar, depending on the model

Connections

• Pressure taps at inlet and outlet flanges.

•

Optional:

Indication switch (CPI) at bottom of safety valve V1.

At the main body (4) flange connections are provided to

mount either an:

• internalby--pass valve to achieve high--low flame control

• internalor external pilot valve

• vent valve

• pressure switches (Min. or Max.)

• Valve Proving System (VPS).

By--pass valve/high--low valve

Twostage valve 3/4” is used at VQ420/425/440 series valves.

Twostage valve 1” is used at VQ450 series valves.

Torsion and bendingstress

Pipe connections meet group 2 according to EN161

requirements.

Supplyvoltages

Line voltage: 220 ...240 Vac,50/60 Hz

Other voltages on request.

Electricalequipment

DC current coils with separated rectifierinside the cover.

1/4” plug connection for Closed Position

200 Vac, 50/60 Hz

100/110 Vac, 50/60 Hz

24 ...28 Vdc

: as VE4020

as VE4025

nd

main valve.

nd

main valve.

: as VE4020

Electricalconnections

VQ420/25: standard plug connection according PG11 on main

gas valves and additional valves.

Optional:

valves and additional valves.

VQ440/450: standard three pin plug connector (”DIN plug”) on

main gas valves.

Optional:

valves.

Ambienttemperaturerange

--15 ... 60 °C

Coilinsulation solenoid valves

Insulation material according class F.

Enclosure

IP 54

IP65 (optional, only for VQ420/25)

Bodymaterial

aluminium alloy die cast

Strainer

AISI 303 steel

Closingspring

AISI 302 steel

Valve plunger

Chrome plated Fe 360B steel sliding on anti--friction bearing.

Sealsand gaskets

Hydrocarbon resistant NBR rubber type.

Flangekits

There are two different series of kits available:

The firstseries of kits consist of: 1 flange with sealing plug,

1 O--rings and 4 screws.

The second series of kits consist of: 1 flange with sealing plug

or cast pressure tap, 1 strainer, 1 O--rings and 4 screws.

three pin plug connector (”DIN plug”) on main gas

three pin plug connector (”DIN plug”) on additional

O.S. number

KTCOMB20 3/4” with plug

KTCOMB25 1” with plug

KTCOMB32 11/4” intended for 440

KTCOMB40 11/2” with tap

KTCOMB50 2” with tap

O.S. number

KTCOMS20 3/4” with plug

KTCOMS25 1” with plug

KTCOMS32 11/4” intended for 440

KTCOMS40 11/2” with tap

KTCOMS50 2” with tap

Size (Rp) Remarks

body, with tap

Size (Rp) Remarks

body, with tap

4

EN2R--9018 9704R1- -NE

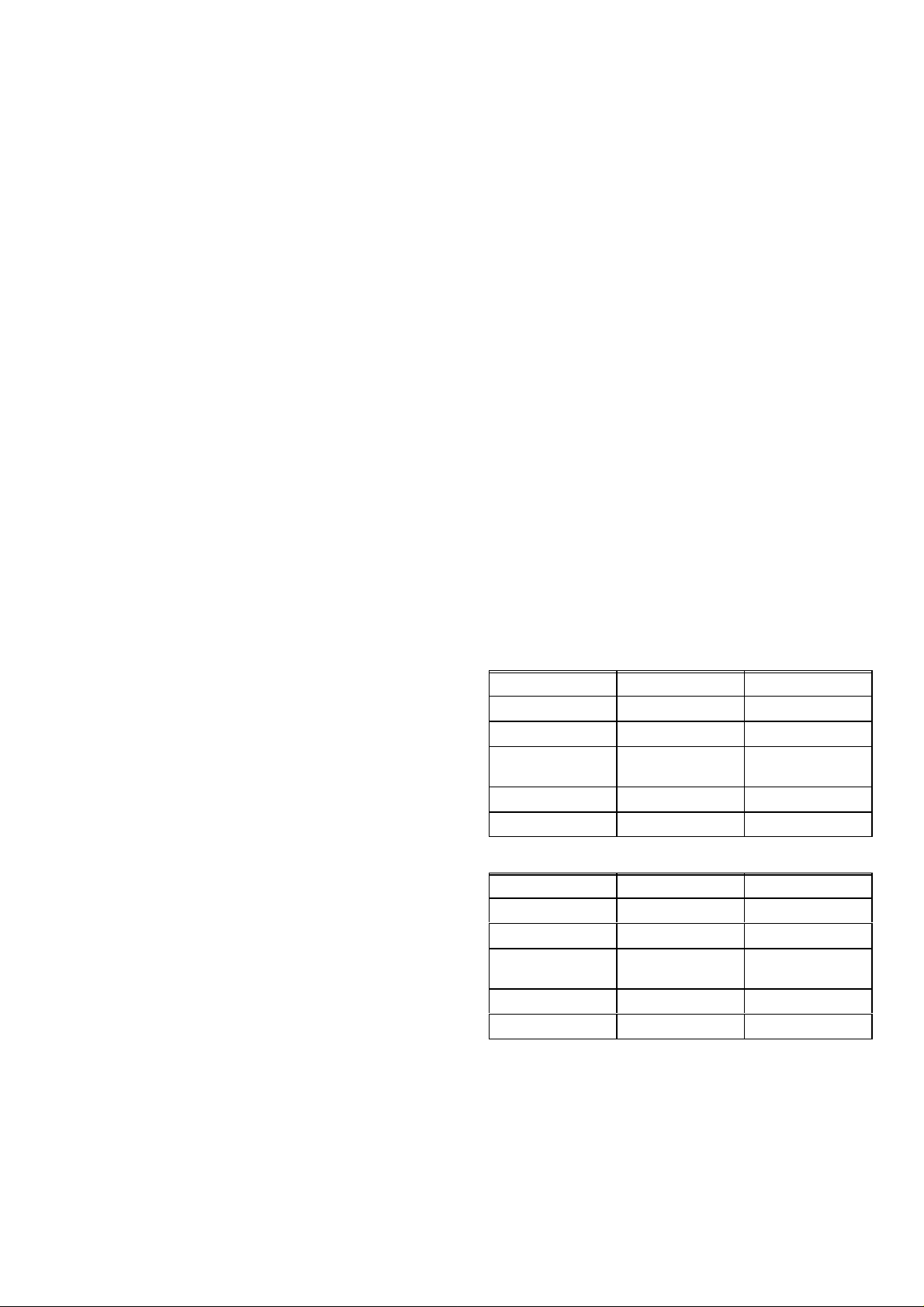

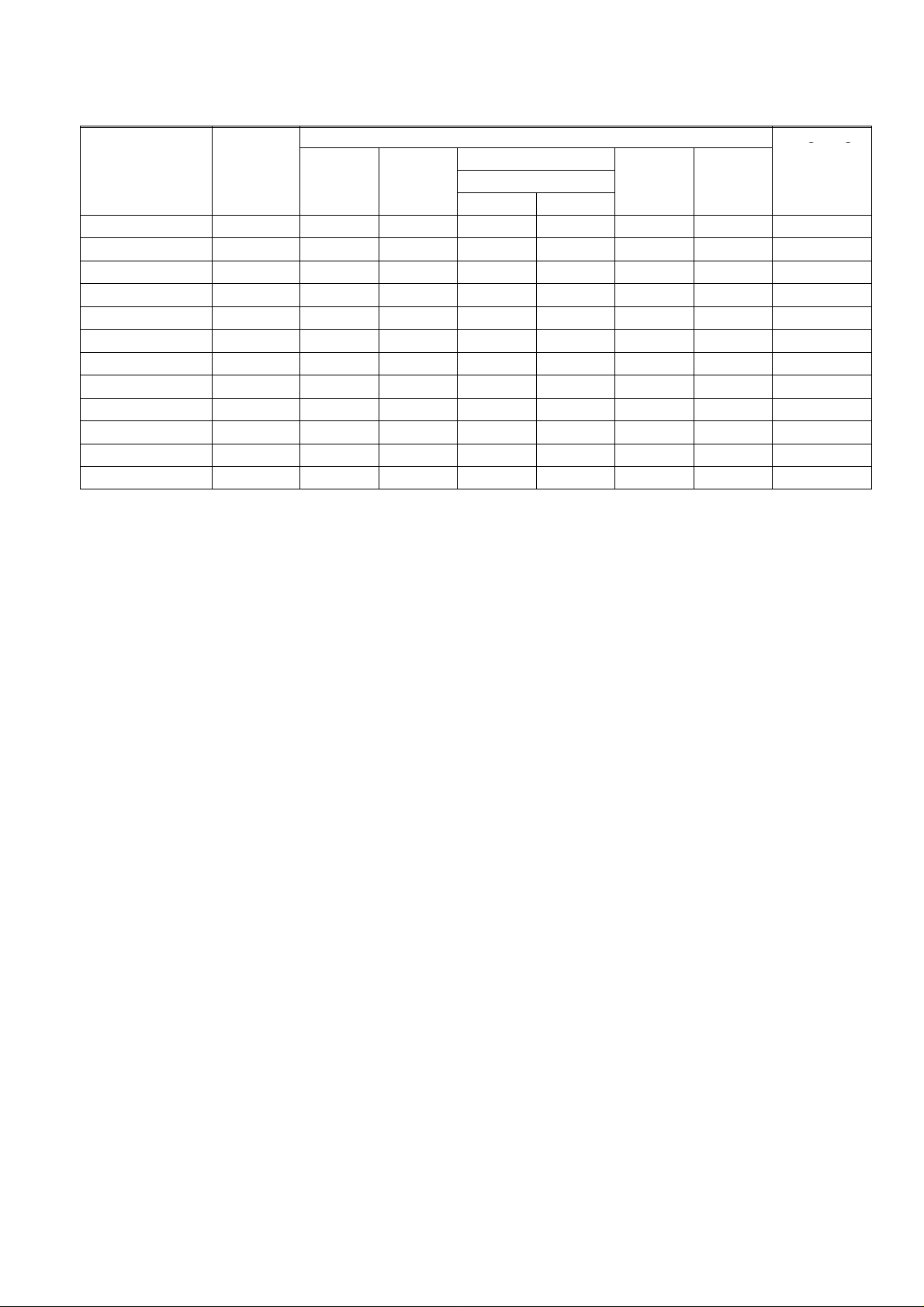

Table 1. Power consumption (W) main valve VQ400 Series

360 mbar 200 mbar

Model

220 ... 240 Vac 100/110Vac 24 ... 28 Vdc 220 ... 240 Vac 100/110 Vac 24 ... 28 Vdc

V1 V2 V1 V2 V1 V2 V1 V2 V1 V2 V1 V2

F S F S F S F S F S F S

VQ420Ax 14 14 14 14 14 14 17 17 17 14 14 14 14 14 14 17 17 17

VQ425Ax 20 20 20 18 18 18 24 24 24 20 20 20 18 18 18 24 24 24

VQ440Ax 41 41 41 48 48 48 64 64 64 40 40 40 47 47 47 67 67 67

VQ450Ax 60 60 60 65 65 65 67 67 67 41 41 41 48 48 48 64 64 64

Table 2. Power consumption (W) additional valves

Additional

valve

220 ... 240 Vac 100/110 Vac 24 ... 28 Vdc 220 ... 240 Vac 100/110 Vac 24 ... 28 Vac

360 mbar 200 mbar

3/4” 1” 3/4” 1” 3/4” 1” 3/4” 1” 3/4” 1” 3/4” 1”

by--pass valve 14 20 14 18 17 24 14 20 14 18 17 24

pilot valve 14 -- 14 -- 17 -- 14 -- 14 -- 17 --

vent valve 14 -- 14 -- 17 -- 14 -- 14 -- 17 --

5

EN2R--9018 9704R1- -NE

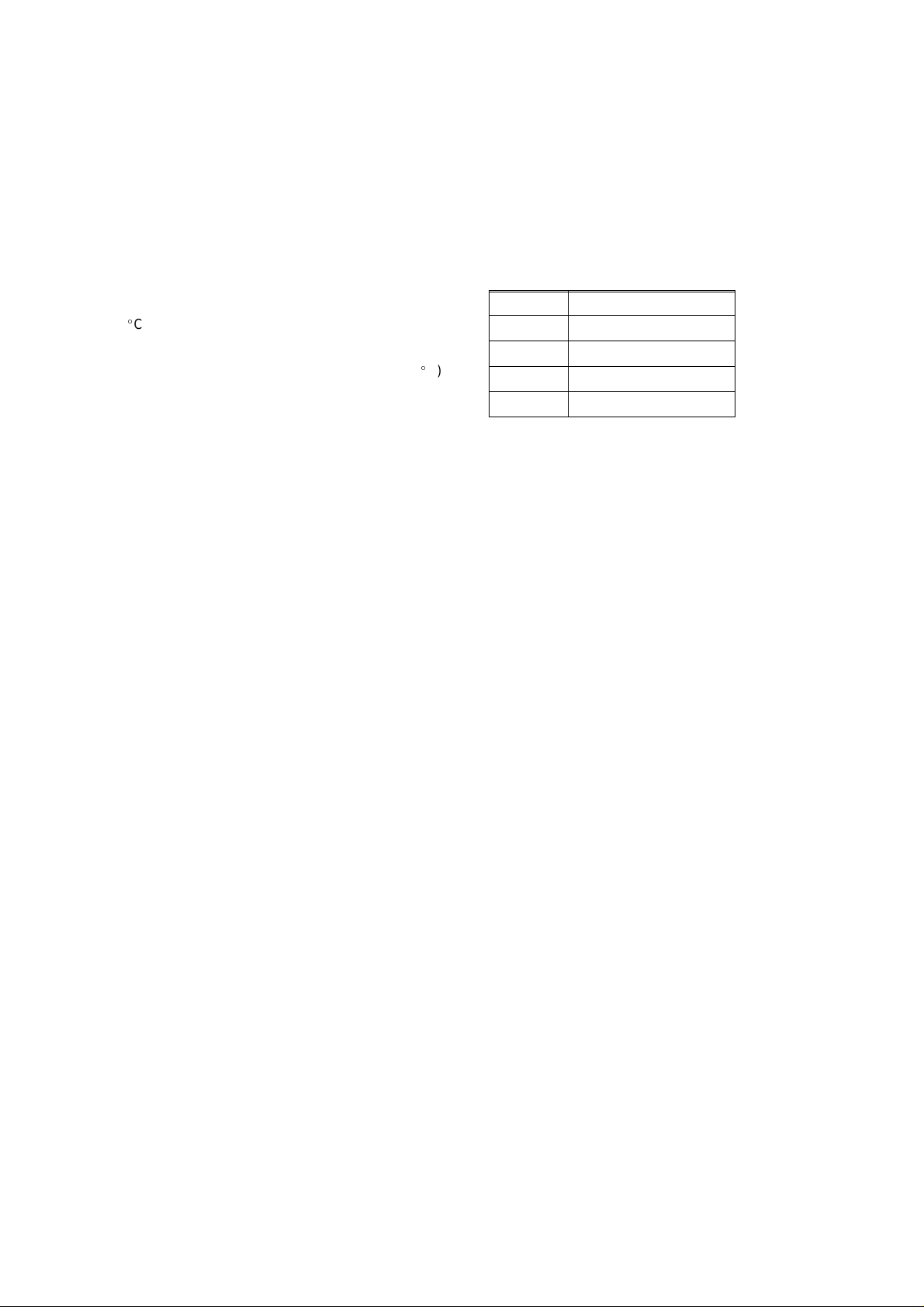

PERFORMANCE CHARACTERISTICS

Opening time

The firstvalve (V1) opens in less than 1 second.

The second valve (V2), by--pass valve (Vb) and pilot valve

(Vp) can be either a fast opening valve which opens in less

than 1 second or a characterized opening valve which is

adjustable from 1 up to 30 seconds, at rated capacity.

The opening characteristicis factory set at approximately 6

seconds at the following conditions:

− measured at 80 % of rated capacity

− 30mbar supply pressure

− nominal voltage

− 20

− 2,5 mbar pressure drop

− nostep pressure

Due to the influence of ambient temperature (--15 ... 60

the adjusted opening time of 6 seconds measured at 80% of

adjusted flow rate can vary

Closing time (V1, V2 , Vb and Vp)

Less than 1 second for all four valves.

E

C

E

C)

+

/--4 seconds.

Maximum workingfrequency

1 cycle per minute

Duty cycle

Coil suitable for permanent energization

Operational voltage range

The combinationgas valve willfunction satisfactorybetween

85% and 110% of the rated voltage.

Design life

Model

VQ420AA 600,000

VQ425AA 600,000

VQ440AA 300,000

VQ450AA 300,000

Number of Cycles

6

EN2R--9018 9704R1- -NE

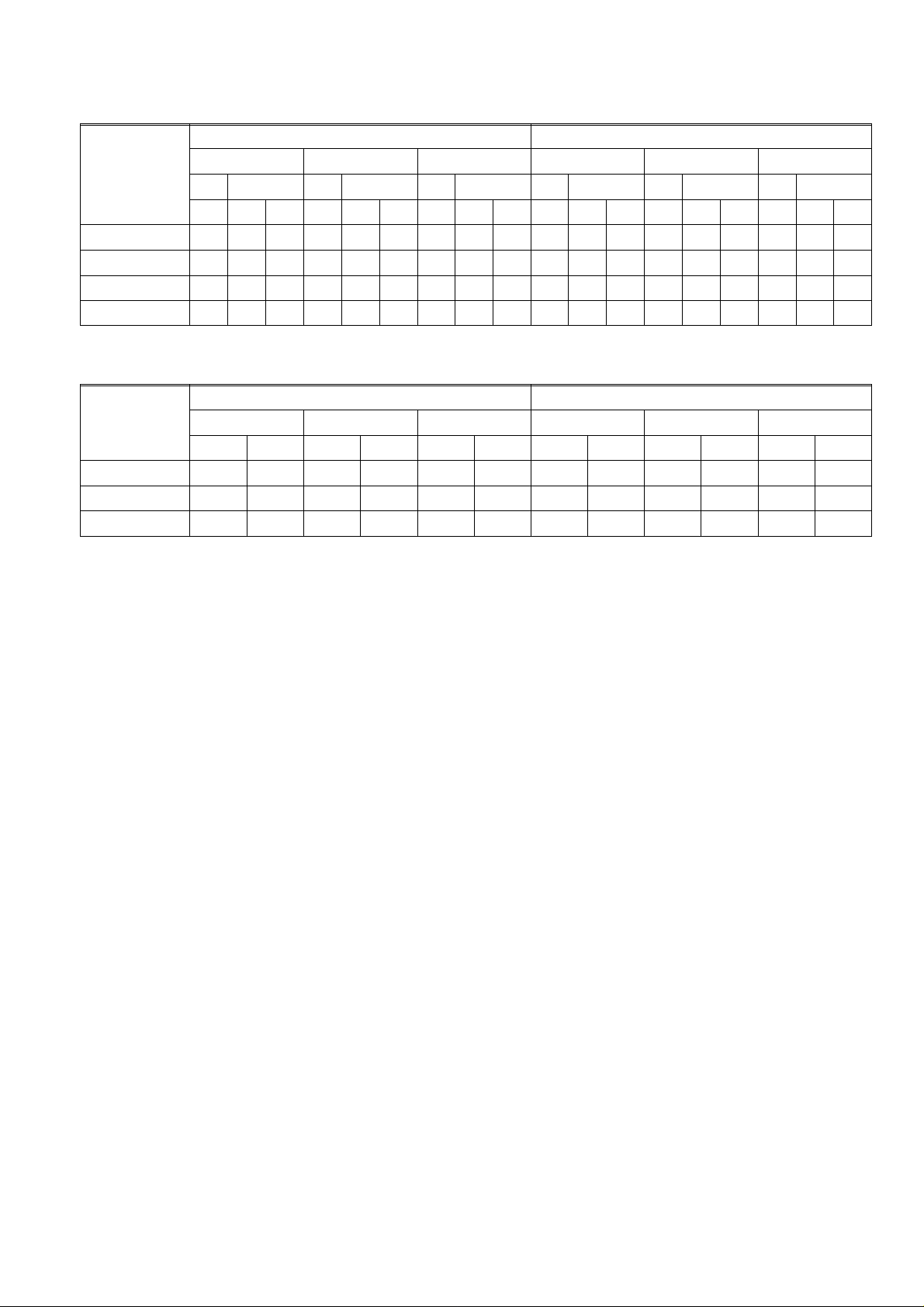

CAPACITY CURVES

Capacity curve combination gas valves

Table 1. Capacity in m3/hair atap=2,5mbar

3/4” DN20

8 11 25 31 40

6

60

5

50

40

4

30

3

20

2

10

1

p(kPa)

a

0.8

p (mbar)

a

0.6

0.5

0.4

0.3

8

6

5

4

3

1” DN25 1 1/4” DN32 1 1/2” DN40 2” DN50

DN20

DN25

DN50

DN40

DN32

Vn (m3/h)

Air dv=1

Methane dv 0.64

0.2

0.1

2

1

1234568

10 20 30 40 50 60 80 200 300

10865432

Fig. 1. Capacity curves for VQ400 Series class “A” combination valves

100

100 300200806050403020

7

EN2R--9018 9704R1- -NE

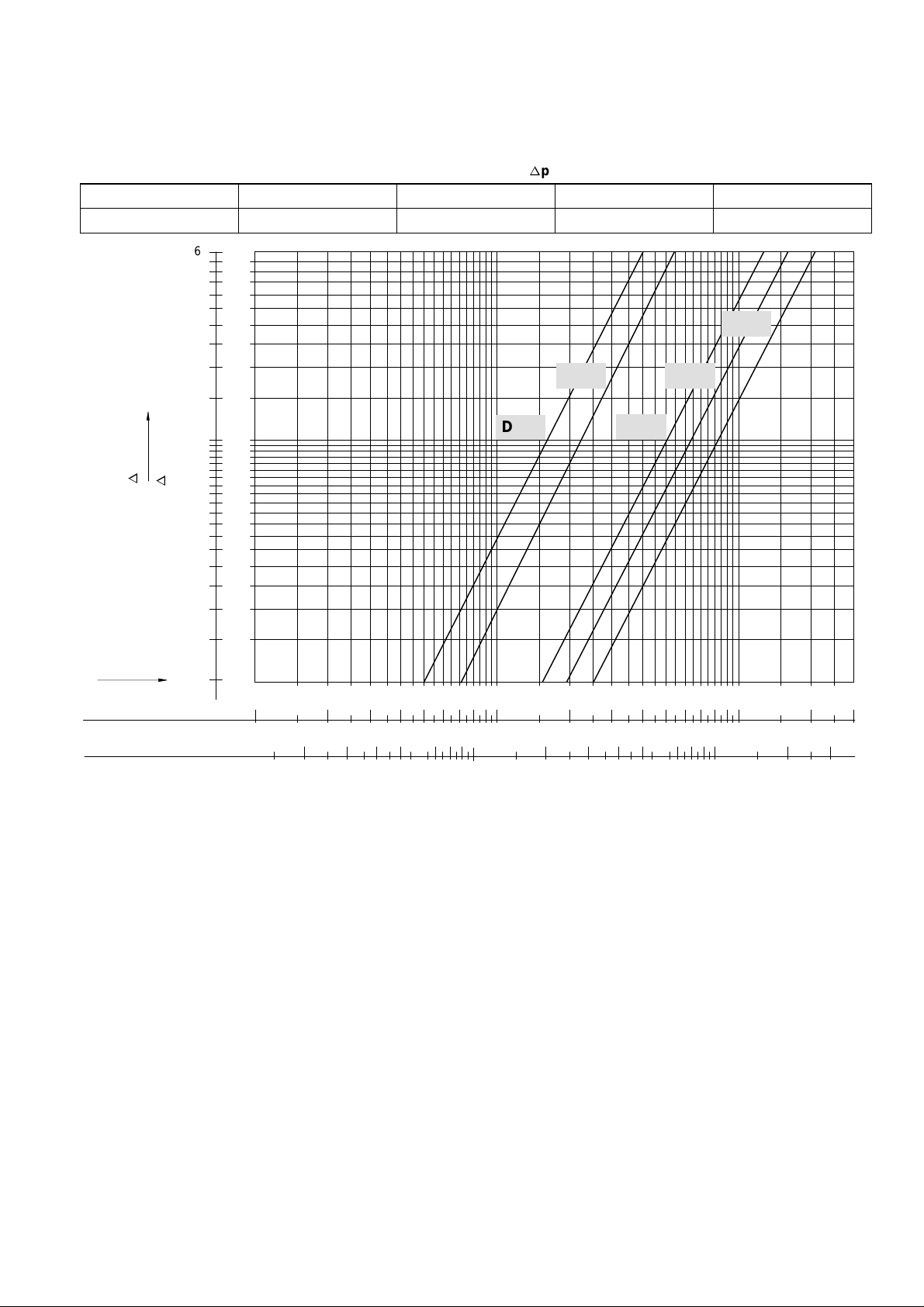

DIMENSIONAL DRAWINGS

C

HONEYWELL

A

BC

B

A

3/4”

D

H

H

D

62

188

151

E

Fig. 2. Overall dimensions VQ400 Series (shown 2ndvalve slow)

8

EN2R--9018 9704R1- -NE

Table 2. Dimensions VQ400 Series (see also installation drawing).

g(g

)

Model Connect.

(inch)

A B

Overall Dimensions (mm)

C

D E

Weight (kg)

2ndmain valve

fast slow

VQ420Ax 3/4 204 42.5 111.5 157.5 60 108 3.5

VQ420Bx--Cx--Ex 3/4 204 42.5 112 157 60 177 4.8

VQ420Dx--Fx 3/4 204 42.5 112 157 60 247 6.1

VQ425Ax 1 204 42.5 135.5 181.5 64.5 108 5.0

VQ425Bx--Cx--Ex 1 204 42.5 136 181 64.5 177 6.3

VQ425Dx--Fx 1 204 42.5 136 181 64.5 247 7.6

VQ440Ax 11/2 297 62 174 228 63.5 119 10.7

VQ440Bx--Cx--Ex 11/2 297 62 174 228 63.5 209 11.9

VQ440Dx--Fx 11/2 297 62 174 174 63.5 300 13.5

VQ450Ax 2 297 62 174 (184) 228 (238) 63.5 119 12.1

VQ450Bx--Cx--Ex 2 297 62 174 (184) 228 (238) 63.5 209 14.1

VQ450Dx--Fx 2 297 62 174 (184) 228 (238) 63.5 300 16.4

(..)360 mbar versions

9

EN2R--9018 9704R1- -NE

Loading...

Loading...