Honeywell VPX Installation Instructions Manual

Installation Instructions for the

MICRO SWITCH VPX Series

Valve Position Indicator for Hazardous Locations

Issue F

32312068

Multiple language versions of installation instructions and

other documents are available on Honeywell’s website. To

access:

1. Go to http://sensing.honeywell.com/hazardousareaswitches

2. Select the product’s instructions from the installation instruction section.

Installationsanweisungen und andere Dokumente stehen in

mehreren Sprachen auf der HoneywellWebsite zur Verfügung. So greifen Sie darauf zu:

1. Gehen Sie auf die Webseite http://sensing.honeywell.de/

hazardousareaswitches

2. Wählen Sie im Bereich “Installationsanweisungen” die zum

entsprechenden Produkt gehörenden Anweisungen aus.

Versiones de las instrucciones de instalación y otros documentos se encuentran disponibles en el sitio de internet de

Honeywell en múltiples idiomas. Para acceder:

1. Vaya a http://sensing.honeywell.com/hazardousareaswitches

2. Seleccione las instrucciones del producto en la sección de

instruccions de instalación.

Les instructions d’installation et d’autres documents

sont disponibles dans plusieurs langues sur le site Web

d’Honeywell. Procédure d’accès :

1. Accédez à la page http://sensing.honeywell.com/hazardousareaswitches

2. Sélectionnez les instructions relatives au produit qui vous

intéresse dans la section « Installation Instructions

mWARNING

PERSONAL INJURY

DO NOT USE these products as safety or emergency stop

devices or in any other application where failure of the

product could result in personal injury.

Failure to comply with these instructions could result in

death or serious injury.

mWARNING

IMPROPER CONDUIT THREAD USE

DO NOT USE any other conduit thread than the one

identified on the product. Verify that the mating threaded

fitting is identical with the conduit thread marked near the

conduit opening (see Figure 6).

Failure to comply with these instructions could result in

death or serious injury.

mWARNING

To maintain ATEX/IECEx protection methods, an Ex cable

gland or Ex conduit sealing device, rated Ex db IIC Gb

IP66, Ex tb IIIC Db IP66 shall be installed. For Intrinsically

Safe models, cable glands must have a minimum service

temperature of 80oC.

mWARNING

Enclosure contains aluminum. Care must be taken to avoid

hazard due to impact or friction

mWARNING

To reduce the risk of ignition in hazardous atmospheres,

conduit runs must have a sealing fitting connected within

18 inches of enclosure.

Sul sito Web di Honeywell sono disponibili istruzioni per

l’installazione in più lingue e altra documentazione. Per accedere:

1. Andare a http://sensing.honeywell.com/hazardousareaswitches

2. Selezionare le istruzioni per il prodotto nella sezione istruzioni

per l’installazione.

As versões em diversos idiomas das instruções de instalação

e outros documentos estão disponíveis no site da Honeywell.

Para acessar:

1. Vá para http://sensing.honeywell.com/hazardousareaswitches

2. Selecione as instruções do produto na seção de instruções de

instalação.

多语种安装指南和其他文档均可从霍尼韦尔的网站上获取。访问

网站:

1.前往 http://sensing.honeywell.com/hazardousareaswitches

2.从安装指南部分选择具体的产品指南。

На веб-сайте Honeywell имеются инструкции по установке

и другие документы на различных языках. Для доступа

к ним выполните следующие действия.

1. Перейдите по адресу http://sensing.honeywell.com/

hazardousareaswitches

2. Выберите инструкции для изделия в разделе инструкций

по установке.

mWARNING

Substitution of components may impair intrinsic safety.

mWARNING

OPENING PRODUCTS HAZARD

DO NOT OPEN these products when energized or in a

flammable gas atmosphere.

Failure to comply with these instructions could result in

death or serious injury.

mWARNING

RISK TO LIFE OR PROPERTY

Never use this product for an application involving serious

risk to life or property without ensuring that the system as

a whole has been designed to address these risks, and that

this product is properly rated and installed for the intended

use within the overall system.

Failure to comply with these instructions could result in

death or serious injury.

mWARNING

This equipment has a non-conducting coating and may

generate an ignition-capable level of electrostatic charges

under certain extreme conditions. The user should ensure

that the equipment is not installed in a location where it may

be subjected to external conditions (such as high pressure

steam) which might cause a build up of electrostatic

charges on non-conducting surfaces. Additionally, cleaning

of the equipment should be done with a damp cloth.

Sensing and Internet of Things

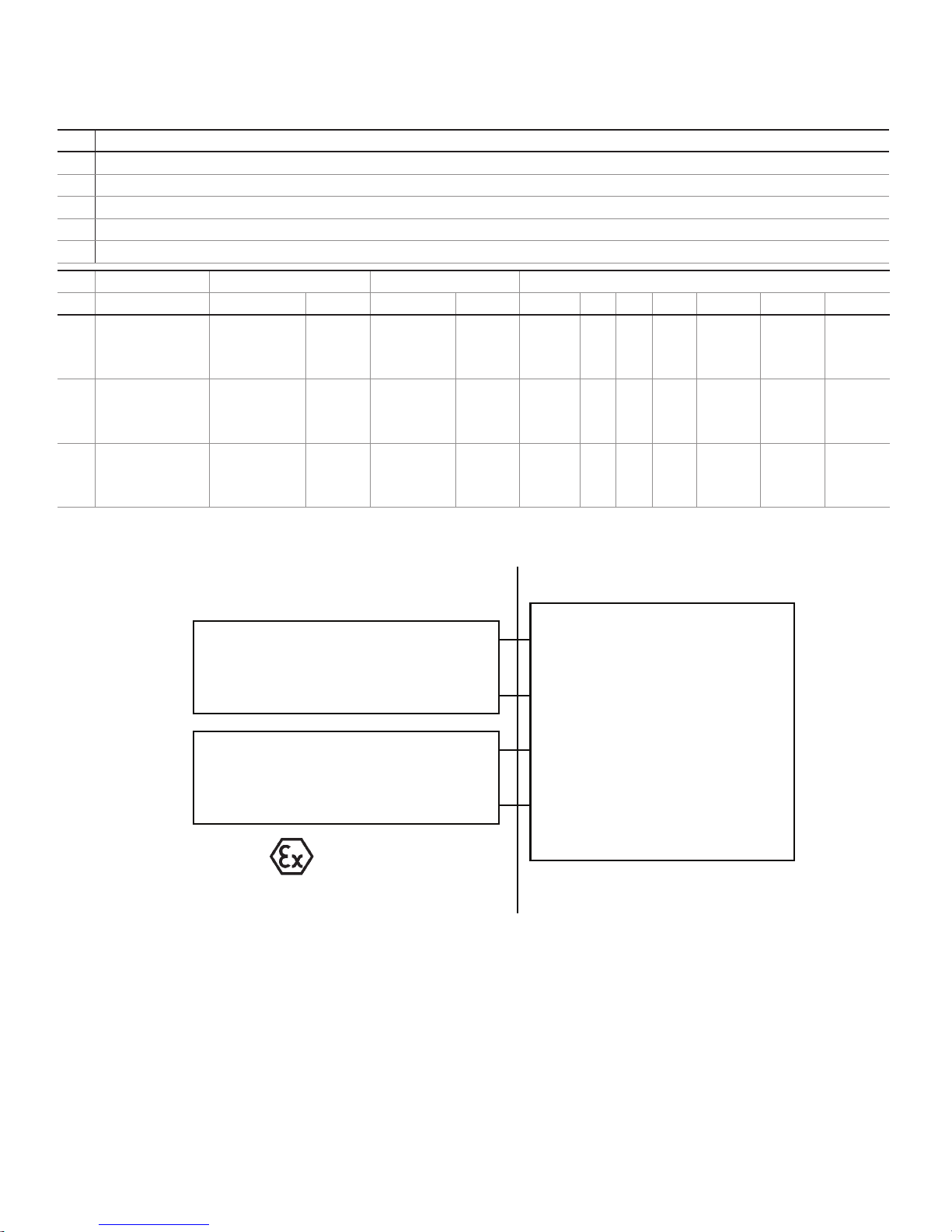

MICRO SWITCH VPX Series

Flange flame paths

Shaft

flame

paths

0518

ISSUE F 32312068

GENERAL INFORMATION

The VPX Valve Position Indicator is designed specifically for

use in potentially hazardous locations where explosive gases or

dusts may be present. To comply with explosion proof requirements the VPX has flame paths within the housing, which cool

any explosion below the ignition temperature before it reach

explosive gases or dusts in the surrounding atmosphere. Flame

paths on the VPX are 1) an extended shaft between the switch

cavity and head and 2) the cover-housing flange joint.

The equipment has a non-conducting coating and may generate an ignition-capable level of electrostatic charges under certain conditions. The user should ensure that the equipment is

not installed in a location where it may be subjected to external

conditions (such as high pressure steam) that might cause a

build up of electrostatic charges on non-conducting surfaces.

Additionally, cleaning of the equipment should be done with a

damp cloth.

Figure 1. VPX Valve Position Indicator

Figure 2. Flame Paths

2 sensing.honeywell.com

ENVIRONMENTAL PROTECTION

The VPX Valve Position Indicator is often ideal for outdoor use

or in potentially adverse environments. The enclosure is sealed

for protection against corrosion, water, dust and oil as defined

in UL 50E to enclosure types 4, 4X, 6, and 13 as well as to IP66

and IP67 as defined in IEC 60529. An ingress protection rating

of IP66 was confirmed according to IEC 600790 along with

the hazardous location approvals. A rating of IP67 was confirmed by Honeywell according to IEC 60529.

HAZARDOUS LOCATION RATINGS

IECEx UL 16.0102X

DEMKO 16 ATEX 1733X

Compliance with the Essential Health and Safety Requirements

has been assured by compliance with:

• CENELEC EN 600790 EXPLOSIVE ATMOSPHERES -

PART 0: EQUIPMENT - GENERAL REQUIREMENTS - Issue

Date 2012/08/01 - Revision Date 2013/01/01

• CENELEC EN 600791 EXPLOSIVE ATMOSPHERES -

PART 1: EQUIPMENT PROTECTION BY ENCLOSURES “d”

Issue Date 2014/10/01 Revision Date 2014/10/23

• CENELEC EN 6007911 EXPLOSIVE ATMOSPHERES

- PART 11: EQUIPMENT PROTECTION BY INTRINSIC

SAFETY “I” - Issue Date 2012/01/01

• CENELEC EN 6007931 EXPLOSIVE ATMOSPHERES -

PART 31: EQUIPMENT DUST IGNITION PROTECTION BY

ENCLOSURE “T” - Issue Date 2014/07/01 Revision Date

2014/07/22

• IEC 600790 EXPLOSIVE ATMOSPHERES. PART 0: EQUIP

MENT GENERAL REQUIREMENTS - Edition 6 - Issue Date

2011/06/01 - Revision Date 2014/10/01

• IEC 600791 EXPLOSIVE ATMOSPHERES. PART 1: EQUIP

MENT PROTECTION BY ENCLOSURES “d” - Edition 7 - Issue Date 2014/06/01 - Revision Date 2014/06/01

• IEC 6007911 EXPLOSIVE ATMOSPHERES – PART

11: EQUIPMENT PROTECTION BY INTRINSIC SAFETY

“I” - Edition 6 - Issue Date 2011/06/01 - Revision Date

2014/10/01

• IEC 6007931 EXPLOSIVE ATMOSPHERES. PART 31:

EQUIPMENT DUST IGNITION PROTECTION BY ENCLO

SURE “T” - Edition 2 - Issue Date 2013/11/01 - Revision

Date 2013/11/01

• EUROPEAN DIRECTIVE ON EQUIPMENT AND PROTEC

TIVE SYSTEMS INTENDED FOR USE IN POTENTIALLY

EXPLOSIVE ATMOSPHERES (2014/34/EU) commonly

referred to as the ATEX Directive.

• UL 1203 ExplosionProof and DustIgnitionProof Electri-

cal Equipment for Use in Hazardous (Classified) Locations,

5th Edition, Revision 20131122

• CSA C22.2 No. 30 Explosion-proof enclosures for use in

class I hazardous locations, 3rd Edition, Reaffirmed 2012

• CSA C22.2 No. 25 Enclosures for Use in Class II Groups E,

F, and G Hazardous Locations, Reaffirmed 2014

MICRO SWITCH VPX Series

ISSUE F 32312068

The explosion-proof ratings per these standards are:

II 2 G, II 2 D CL 1 DIV 1

Groups B, C, D

Ex db IIC T6 Gb

Ex tb IIIC T85°C Db

Ta 40 °C to +50 °C (Switch Code 4A or 4B)

Ta 40 °C to +60 °C (Switch Code 2A or 2B)

CL II DIV 1

Groups E, F, G

In addition, versions of the VPX with proximity switches carry an

intrinsically safe rating:

II 1 G, II 1 D

Ex ia IIC T4 Ga

Ex ia IIIC 135°C Da

Ta 40 °C to 80 °C (Switch Code 2C)

Honeywell ensures all the elements, requirements and provisions adopted comply with the product’s Ex certificate and

technical documentation. As detailed in section 5.1 of EN/IEC

600791 the requirements of the flamepath joints are met as

follows:

Table 1. Flame Path Measurements

Flame Path Comments

Shaft & bearing Cylindrical spigot joint

0,06 mm maximum gap

Cover to base Flanged joint, 9,5 mm min. surface mate

at any location within the joint, 0,038 mm

max. clearance between cover and base

North America Hazardous location ratings per UL 1203:2013

and CSA C22.2 No. 30:2003 and CSA C22.2 No. 25:1966 are:

• Division 1, Class I, Groups B, C, D

• Division 1, Class II, Groups E, F, G

NEPSI RATING

一、 防爆等级

1. 切换开关:

Ex d ⅡC T6 Gb,Ex tD A21 IP66 T85℃

Ta -40 ℃ to +50 ℃ (Switch Code 4A or 4B)

Ta -40 ℃ to +60 ℃ (Switch Code 2A or 2B)

2. NAMUR接近开关:

Ex ia ⅡC T4 Ga,Ex iaD 20 T135

Ta -40 ℃ to +80 ℃ (Switch Code 2C)

二、 产品的安全使用特殊条件

1. 产品外壳材质为铝合金,安装方式必须具有防止由于冲击或摩

擦引起点燃危险的安全措施。

2. 产品内部装配德国P+F公司生产的NCB2–V3–N0矩型接近开关已

由国家级仪器仪表防爆安全监督检验站依据GB3836.1–2010

和GB3836.4–2010防爆标准规定的要求予以认可,防爆合格证

号为GYJ16.1394X;接近开关的内部等效参数、最高使用环境温度

之间的对应关系详见GYJGYJ16.1394X防爆合格证附件。

同时,阀位回讯器的使用环境温度必须同时满足接近开关和阀

位回讯器在同一温度组别条件下对环境温度的要求。

3. 涉及到隔爆接合面尺寸的确认请参见安装说明书(文件编

号:32312068);外壳紧固件的最小屈服强度为205MPa。

三、 产品使用注意事项

1. 额定电气参数:

NAMUR开关:8.2V,接通电流<1mA,切断电流>3mA

切换开关:150VAC/15A,250VAC/10A,250VDC/0.5A

2. 本安参数:

当产品防爆标志为Ex ia ⅡC T4 Ga或Ex iaD 20 T135时,

产品的本安电气参数和内部等效参数详见GYJGYJ16.1394X

防爆合格证附件。

3. 除非防爆标志为Ex ia ⅡC T4 Ga,否则产品不得在爆炸性环

境开盖。

4. 应当保持产品外壳表面清洁,以防粉尘堆积,但严禁用压缩空

气吹扫。

5. 用户不得自行更换该产品的零部件,应会同产品制造商共同解

决运行中出现的故障,以杜绝损坏现象的发生。

6. 产品的安装、使用和维护应同时遵守产品说明书、

GB3836.13–2013“爆炸性环境第13部分:设备的修理、检修、

修复和改造”、GB3836.15–2000“爆炸性气体环境用电气设备

第15部分:危险场所电气安装(煤矿除外)”、

GB3836.16–2006“爆炸性气体环境用电气设备 第16部分:电气

装置的检查和维护(煤矿除外)”、GB15577–2007“粉尘防爆安

全规程”、GB12476.2–2010“可燃性粉尘环境用电气设备 第2

部分:选型和安装”和GB50257–2014“电气装置安装工程爆炸

和火灾危险环境 电气装置施工及验收规范”的有关规定。

SAFETY INTEGRITY LEVEL (SIL)

SIL 3 per IEC 615082 as evaluated by Sira Certification Service.

SAFETY FUNCTION

The safety function of the certified equipment is:

‘To provide indication of a monitored valve position upon rotation of the shaft via switches or proximity sensors and a visual

indicator.’

UNDETECTABLE DANGEROUS FAILURE

‘If an undetected dangerous failure of the VPX Valve Position

Indicator were to occur it would fail to respond and would give

an incorrect indication of valve position. However this would

only ever occur if both the switches or sensors and visual indicator were to have failed’.

PROOF TEST REQUIREMENTS

A maximum proof test interval of 1 year is recommended for the

VPX products. The proof test procedure must be carried out by

a competent person who is trained in safety operations and is

familiar with the VPX product. A generic proof test procedure

can be found in Table 2, however depending on application may

vary.

MATERIALS OF CONSTRUCTION

The following materials are used in the VPX Valve Position Indicator: aluminum housing, bunaN seals, polycarbonate indicator and indicator cover and stainless steel shaft and fasteners.

The suitability of these materials for the application environment is solely up to the customer.

ELECTROMECHANICAL SNAP ACTION

SWITCHES

The electrical ratings of the VPX with snap-action switches are

• 15 A @ 150 Vac, 10 A @ 250 Vac, 0.5 A @ 250 Vdc

Sensing and Internet of Things 3

MICRO SWITCH VPX Series

A certied associated apparatus with

VPX VALVE POSITION INDICATOR

SWITCHING AMPLIFIER

Table 2. Proof Test Procedure

Step Action

1

Bypass safety PLC and/or take alternative actions to avoid false trip.

2

Visually inspect the VPX Valve Position Indicator for signs of wear or damage.

3

Perform the proof test by manually operating the valve being monitored and perform a full stroke.

4

Monitor the visual indication and switch outputs and record test results as per local procedure.

5

Remove the safety PLC bypass and restore the safety system for normal operation.

MCTF Mechanical Life(Cycles) MCTF Electrical Life(Cycles) Highest SIL

S.NO Catalog Value Reference Value Reference SIL Level HF T1SC2PTI

VPX Series - Electro-

mechanical snap-

1

action switches loaded

at 16 A, 250 Vac

VPX Series - Electro-

mechanical snap-

2

action switches loaded

at 0.5 A, 250 Vdc

VPX Series - Intrensi-

3

cally safe proximity

switches

Notes: 1 HFT: Hardware Fault Tolerance; 2 SC: Systematic Capability; 3 PTI: Proof Test Interval; 4 PT: Product Type

> 500,000 with

Single Sided

Confidence Limit

of 100%.

> 500,000 with

Single Sided

Confidence Limit

of 100%.

> 500,000 with

Single Sided

Confidence Limit

of 100%.

SIRA TA

16002/01

SIRA TA

16002/01

SIRA TA

16004/01

> 25,000 with

Single Sided

Confidence

Limit of 50%

> 10,000 with

Single Sided

Confidence

Limit of 100%.

> 50,000 with

Single Sided

Confidence

Limit of 100%.

SIRA TA

16001/01

SIRA TA

16001/01

SIRA TA

16003/01

SIL 3 0 SC 3 1 year Type A

SIL 3 0 SC 3 1 year Type A

SIL 3

SC 3

0

ISSUE F 32312068

3

1 year Type A

PT

4

Staandard Reference

IEC

615082:

2010

IEC

615082:

2010

IEC

615082:

2010

SIRA FSP

16005/00

SIRA FSP

16005/00

SIRA FSP

16005/00

Figure 3. Intrinsically Safe Zone Diagram

Ui = 16V

Proximity

Switch #1

Proximity

Switch #2

Ii = 25 mA

Pi = 34 mW

Ci = 100 nF

Li = 100 µH

Ui = 16V Io ≤ Ii

Ii = 25 mA

Pi = 34 mW

Ci = 100 nF Lo ≥ Li + Lcable

Li = 100 µH

Zone 0, 1, 2

HAZARDOUS (CLASSIFIED) LOCATION NON-HAZARDOUS LOCATION

INTRINSICALLY SAFE PROXIMITY SWITCHES

A VPX equipped with proximity switches is considered intrinsically safe when used with an appropriate switching amplifier,

also referred to as an associated apparatus, which complies

with EN 6094756:2000 or IEC 6094756:1999. The amplifier contains a dc source to supply the control circuit and is

controlled by the variable internal resistance of the proximity

switch. This amplifier is placed outside of the hazardous area. A

diagram of the typical installation is shown in Figure 3.

Cable capacitance, Ccable, plus intrinsically safe equipment

capacitance, Ci, must be less than the marked capacitance, CO,

shown on any associated apparatus used. The same applies for

4 sensing.honeywell.com

Switch 1 L+

Switch 1 L-

Switch 2 L+

Switch 2 L-

zone and group approval and

with entity pa rameters:

Uo ≤ Ui

Po ≤ Pi

Co ≥ Ci + Ccable

inductance (Lcable, Li and Lo, respectively). Where the cable

capacitance and inductance per foot are not known, the following values shall be used: Ccable = 200 pF/m., Lcable = 1 μH/m.

The associated apparatus output current must be limited by a

resistor such that the output voltage-current plot is a straight

line drawn between open-circuit voltage and short-circuit current. The associated apparatus must be installed in accordance

with its manufacturer’s control drawing. When required by the

manufacturer’s control drawing, the associated apparatus must

be connected to a suitable ground electrode per local installation codes, as applicable. The resistance of the ground path

must be less than 1 Ohm. Associated apparatus must not be

Loading...

Loading...