Page 1

Alwa-Kombi-4 with internal threads

Construction

The Alwa-Kombi-4 valve consists of:

• Valve housing in straight pattern with internal threads to ISO 7

(DIN 2999) or external threads according to DIN ISO 228

•Valve insert

• Handwheel with digital display of pre-setting

• Thermal actuator (accessory)

• Pipe connections (accessory)

Materials

• Valve housing made of red bronze

•Valve insert made of red bronze and brass

•EPDM O-rings

• PTFE seat sealing

• Handwheel, pre-setting dial and display made of plastic,

orange

V1810

Alwa-Kombi-4

Circulation throttle valve

Product specification sheet

Application

The Alwa-Kombi-4 is used as throttle valve for hydronic balancing

of warm potable water circulation systems.

To achieve a hydronic balance the flow in the circulation pipe is

throttled by manually pre-setting the valve. The valve can also be

equipped with a thermal actuator which allows a regulation of the

water temperature in the circulation system to the exact degree.

The thermal actuator can be installed without interruption of the

warm water supply.

When the thermal actuator 50 - 60 °C (122 - 140 °F) is used, a

thermal disinfection according to DVGW worksheet W551 and

W553 is supported. Hydronic balance is also retained during the

thermal disinfection process to ensure disinfection of all pipelines

and risers.

Special Features

• Meets KTW requirements

• For regulation according to DVGW worksheets W551 and

W553

• Valve housing and all parts with flow-contact made of corrosion-resistant red bronze

• Retrofittable automatic temperature-control with support of

thermal disinfection

• Draining option with retrofittable and removable draining

adapter

• No additional side connections to valve housing

• Cavity-free cartridge with maintenance-free spindle sealing

• Spindle thread is isolated from the flow

• Seat sealing made of PTFE

• Visible, digital pre-setting dial with concealed pre-setting

handwheel

• High accuracy due to factory calibration to every single valve

Technical Data

Medium Water

Operating temperature max. 130 °C

Operating pressure max. 16 bar

k

-value DN 15

vs

DN 20

DN 25

DN 32 und DN 40

2.7

6.4

6.8

16.0

EN0H-1805GE23 R0307 • Subject to change

www.honeywell.com 1

Page 2

V1810 Alwa-Kombi-4

Method of Operation

As throttle valve the Alwa-Kombi-4 limits the flow through the

circulation pipe. This is achieved either by manually closing the

valve to a certain position or automatically, when the valve is

equipped with a thermal actuator.

Manual pre-setting: the valve is pre-set according to a calculated

value and stays in that position. The flow of the water is limited

by the narrowed valve opening.

Automatic regulation: the valve is equipped with a thermal

actuator and pre-set to the desired water temperature. The

thermal actuator holds the water temperature at the valve to the

exact degree.

When the water temperature falls the valve opens and the flow of

warm water increases. When the water temperature rises, the

valve closes and shuts-off when the pre-set water temperature is

reached (except for a leakage rate).

With manual pre-setting the valve can only be set for optimal

operation under „full load“. The automatic regulation process

allows a permanent regulation and by that an optimal supply of

all pipelines under most economical energy use.

As part of Honeywell´s "Kombi“ family of valves, additional

functions can also be fitted and used after the valve has been

installed. The functions are carried out by installing adapters into

the cartridge spindle:

• The thermal actuator (preferably 50 - 60 °C [122 - 140 °F])

can be installed at any time without interrupting the supply of

warm water. The actuator is simply screwed into the spindle

and allows permanent hydronic balancing based on the

water temperature in the circulation pipe.

• The draining adapter is fitted to drain a pipe or riser and can

be removed when the draining process is finished. It can be

used with any Alwa-Kombi-4 potable water balancing valve

and also with any Honeywell Kombi-3-plus heating/cooling

balancing valve.

• The current temperature in the circulation line can be read on

the thermometer at any time. The thermometer can be used

for variants both with and without a temperature-controlled

actuator.

• The sampling valve is used in conjunction with the drain

adapter and is used to determine chemical and microbiological parameters.

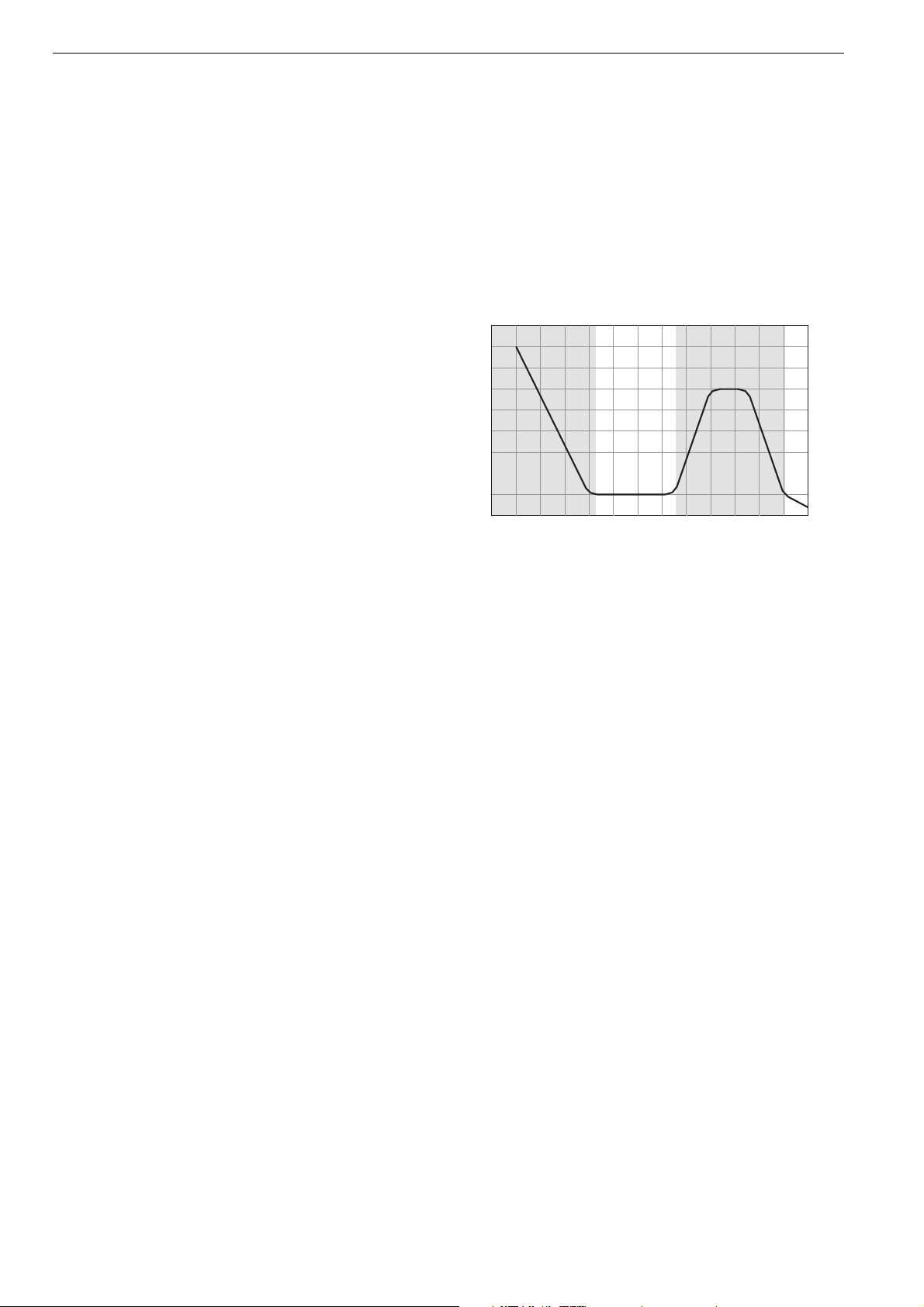

Thermal disinfection at temperatures over 70 °C (158 °F)

Supported by Alwa-Kombi-4 with fitted thermal actuator

50 - 60 °C (122 - 140 °F)

Starting from the leakage rate the valve opens at a water temperature of 63 °C (145 °F) and the flow rate increases.

When the water reaches a temperature of 72 °C (162 °F) the flow

of the water is throttled to a flow rate below the leakage rate. This

has the advantage that the hydronic balance is retained and the

hot water is repily distributed in all risers and pipelines.

When the thermal disinfection process is finished and the water

temperature drops again, Alwa-Kombi-4 returns to the standard

control position..

Desinfection

range

72°C

(162°F)

Flow rate

Control

range

63°C (145°F)

Water temperature

Fig.1 Relation of flow rate and water temperature

Note: The thermal disinfection id only supported by the thermal

actuator 50 - 60 °C (122 - 140 °F), OS-No. VA2400A002.

The thermal actuator has to be set to 55 °C (131 °F) =

pre-setting 1.5.

2 www.honeywell.com

EN0H-1805GE23 R0307 • Subject to change

Page 3

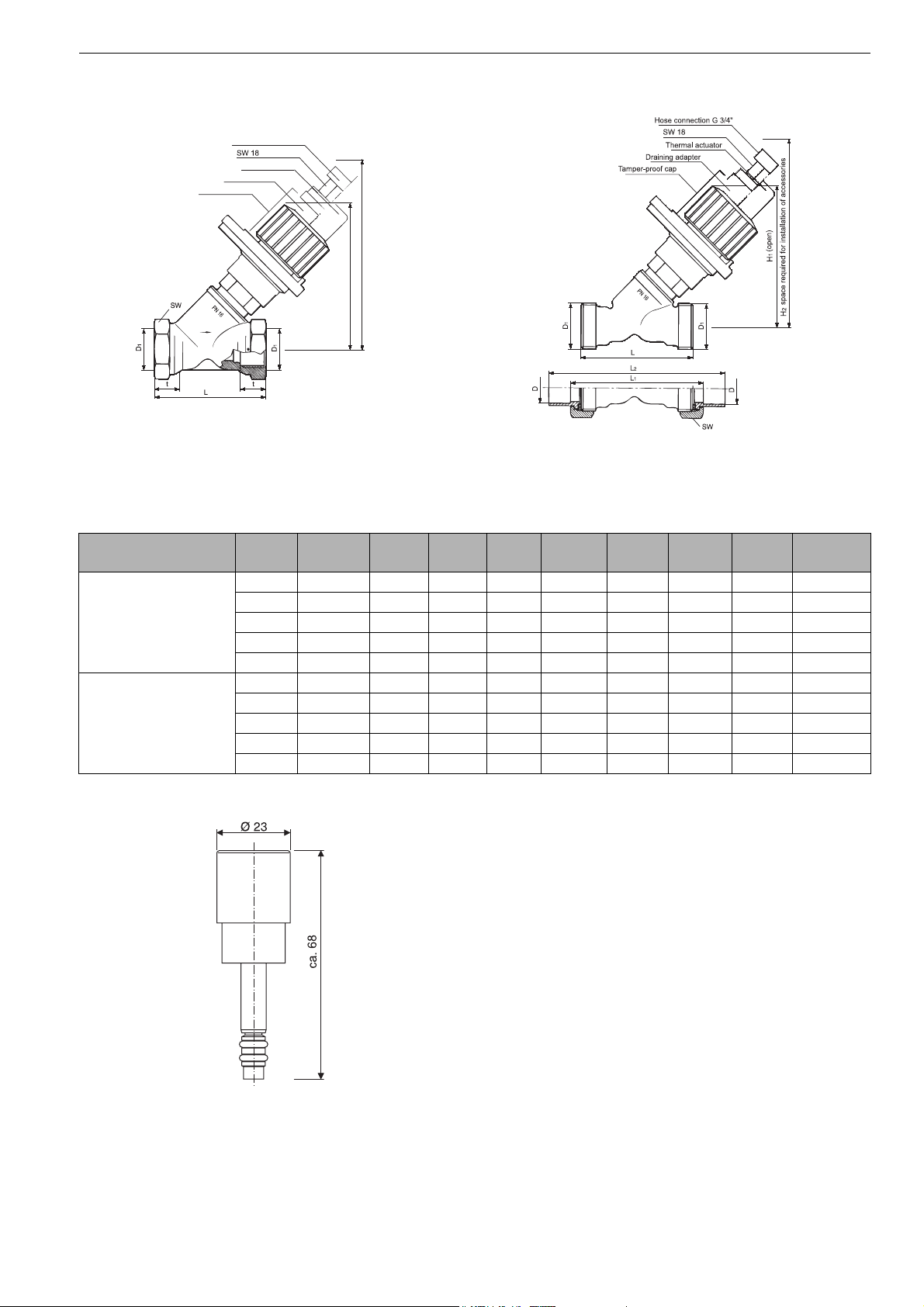

Dimensions

Hose connection G3/4"

Thernal actuator

Draining adapter

Tamper-proof cap

H1 (open)

2 space required for installation of accessories

H

Fig.2 Alwa-Kombi-4 with internal threads Fig.3 Alwa-Kombi-4 with external threads

Note: Draining adapter and thermal actuator available, see accessories.

V1810 Alwa-Kombi-4

Table 1. Alwa-Kombi-4

Version DN D1 kvs (cv)-

value

Alwa-Kombi-4 with

internal threads (Fig. 2)

15 Rp 1/2" 2.7 - 65 - - 85 135 27

20 Rp 3/4" 6.4 - 75 - - 100 150 32

25 Rp 1" 6.8 - 90 - - 100 150 41

32 Rp 1 1/4" 16.0 - 110 - - 137 210 50

40 Rp 1 1/2" 16.0 - 120 - - 137 210 55

Alwa-Kombi-4 with

external threads (Fig. 3)

15 G 3/4" A 2.7 15/18 65 81 105 85 135 30

20 G 1" A 6.4 22 75 91 125 100 150 37

25 G 1 1/4" A 6.8 28 90 108 148 100 150 47

32 G 1 1/2" A 16.0 35 110 128 178 137 210 52

40 G 1 3/4" A 16.0 42 120 140 198 137 210 60

Note: All dimensions in mm unless stated otherwise.

D2 L L1 L2 H1 H2 SW

EN0H-1805GE23 R0307 • Subject to change

Fig.4 Thermal actuator for Alwa-Kombi-4

www.honeywell.com 3

Page 4

V1810 Alwa-Kombi-4

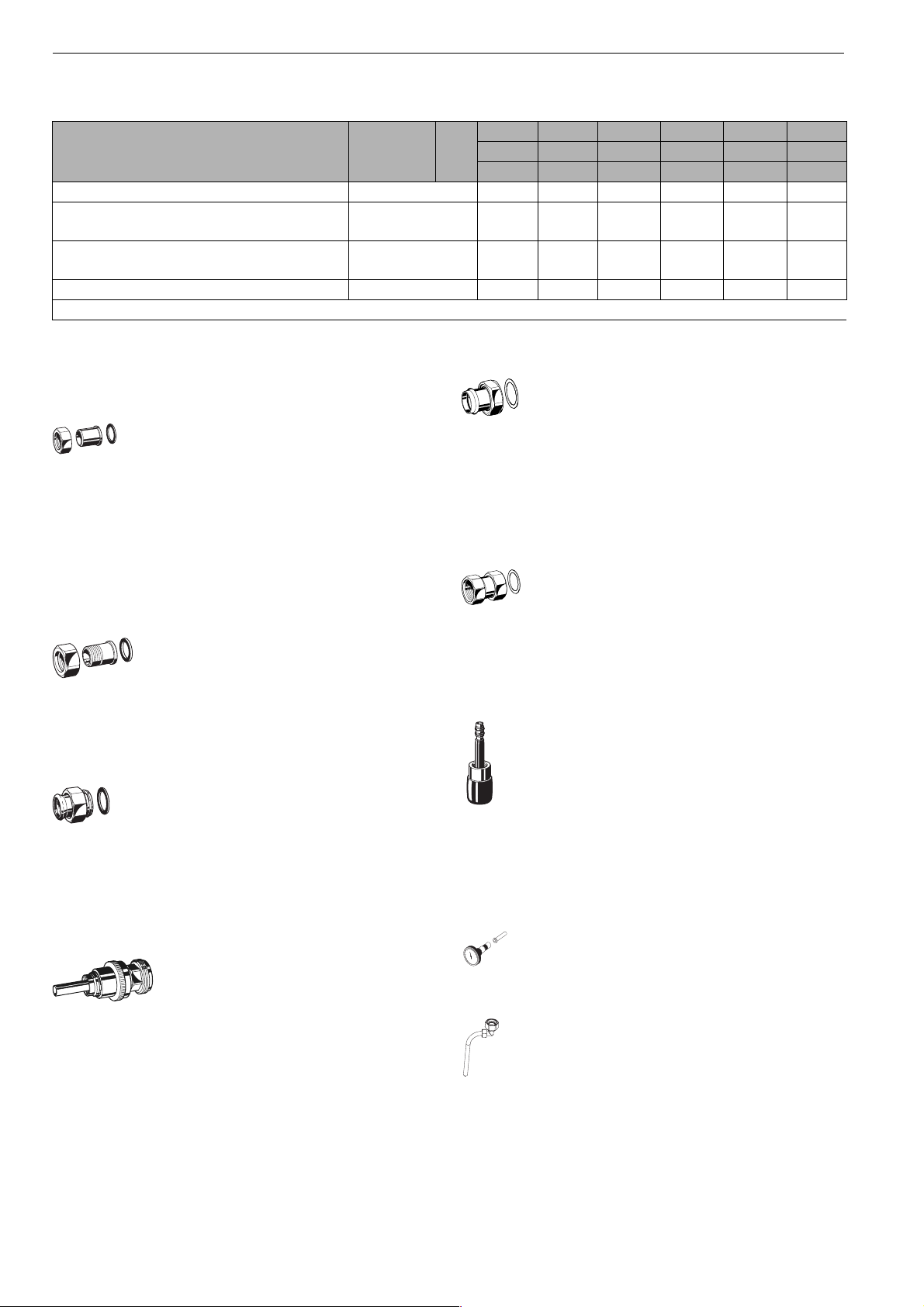

Order information

Table 2. Ordering text and OS-Nos. (OS = Ordering System).

Version OS.-No. DN 15 15 20 25 32 40

mm 15 18 22 28 35 42

R 1/2" 1/2" 3/4" 1" 1 1/4" 1 1/2"

Alwa-Kombi-4 throttle valve with internal threads V1810Y0 015 - 020 025 032 040

Alwa-Kombi-4 throttle valve with internal threads

and fitted ‘Mapress‘ press-fittings

Alwa-Kombi-4 throttle valve with internal threads

and fitted ‘Sanpress‘ press-fittings

Alwa-Kombi-4 throttle valve with external threads V1810X0 015 - 020 025 032 040

Note: Add desired size to OS-No.: V1810X0 in DN15 = V1810X0015

Accessories

Connections for external threads

Union nut, sealing and red bronze soldering tailpiece for

external threads

DN 15, for 15 mm pipe-∅˜ VA7400A015

DN 15, for 16 mm pipe-∅ VA7400A016

DN 20, for 18 mm pipe-∅˜ VA7400A018

DN 20, for 22 mm pipe-∅ VA7400A020

DN 25, for 28 mm pipe-∅ VA7400A025

DN 32, for 35 mm pipe-∅ VA7400A032

DN 40, for 42 mm pipe-∅˜ VA7400A040

Union nut, sealing and externally threaded red bronze tailpiece for external threads

DN 15 VA7401A015

DN 20 VA7401A020

DN 25 VA7401A025

DN 32 VA7401A032

DN 40 VA7401A040

Union nut with MAPRESS-fitting for external threads

DN 15, für 15 mm Rohr-∅ VA7403A015

DN 15, für 18 mm Rohr-∅ VA7403A018

DN 20, für 22 mm Rohr-∅ VA7403A020

DN 25, für 28 mm Rohr-∅ VA7403A025

DN 32, für 35 mm Rohr-∅ VA7403A032

DN 40, für 42 mm Rohr-∅ VA7403A040

Draining adapter

for all types and sizes VA3400A001

V1816Y0 015 018 020 025 032 040

V1817Y0 015 018 020 025 032 040

Sanpress/Profipress System connection set (red bronze)

DN 15, for 15 mm pipe-∅ VA7404A015

DN 15, for 18 mm pipe-∅ VA7404A018

DN 20, for 22 mm pipe-∅ VA7404A020

DN 25, for 28 mm pipe-∅ VA7404A025

DN 32, for 35 mm pipe-∅ VA7404A032

DN 40, for 42 mm pipe-∅ VA7404A040

Union nut, sealing and internally threades red bronze teilpiece for external threads

DN 15 VA7405A015

DN 20 VA7405A020

DN 25 VA7405A055

DN 32 VA7405A032

DN 40 VA7405A040

Thermal actuator

for all sizes, temperature

VA2400A002

setting range 50 - 60°C

(122-140°F)

for all sizes, temperature

VA2400B002

setting range 40 - 65°C

(104-149°F)

Note: Thermal disinfection is supported by thermal actuator

50 - 60°C (OS-No. VA2400A001) with pre-setting

between 1.5 and 2.0.

Thermometer

for all sizes 0 - 120 °C TH07K

60

80

40

100

120

20

0

4 www.honeywell.com

Sampling valve

for all sizes

only in conjunction with drain

adapter VA3400A001

VA3400C001

EN0H-1805GE23 R0307 • Subject to change

Page 5

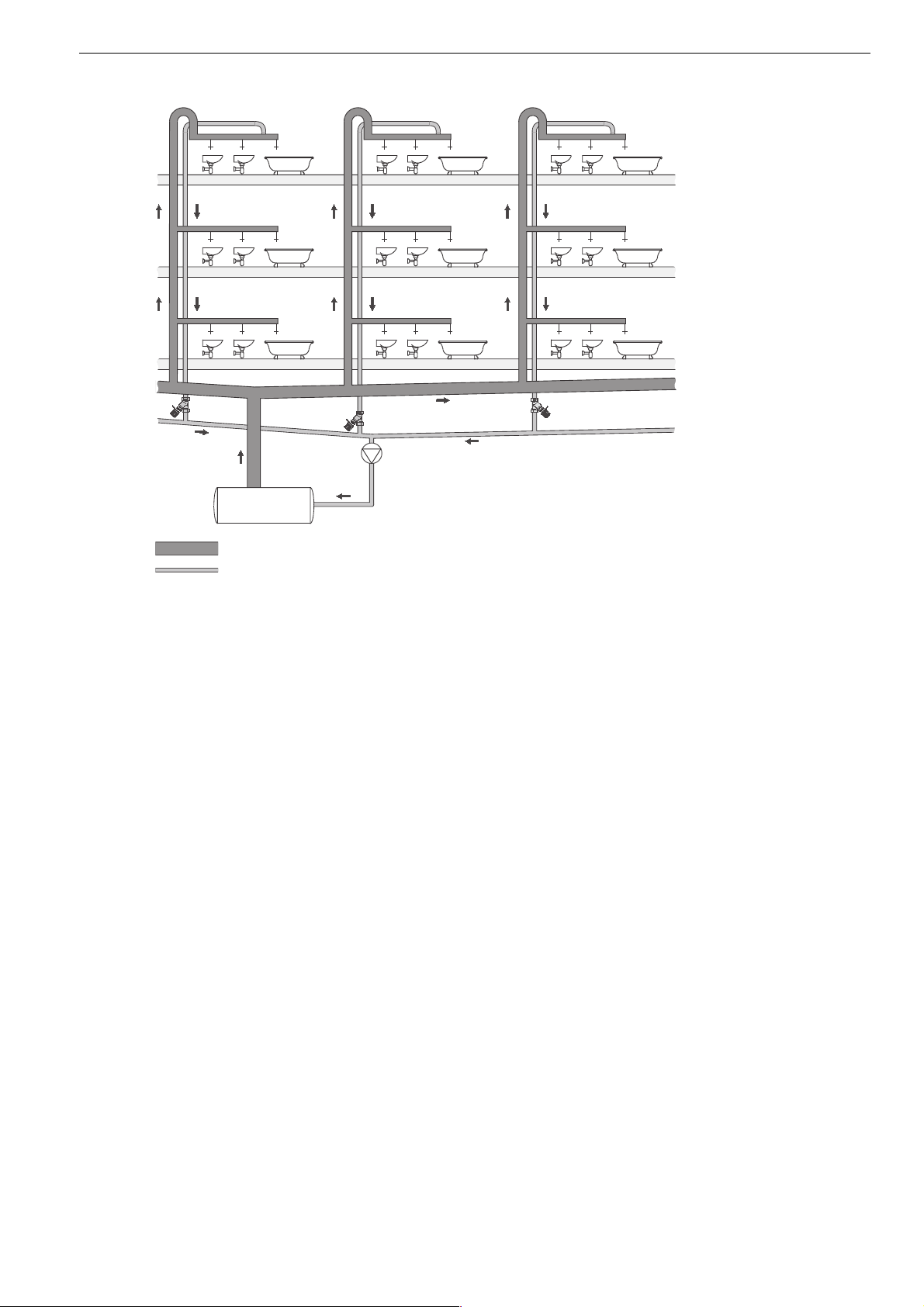

Installation Example

V1810 Alwa-Kombi-4

Warm water pipe

Circulation system

EN0H-1805GE23 R0307 • Subject to change

www.honeywell.com 5

Page 6

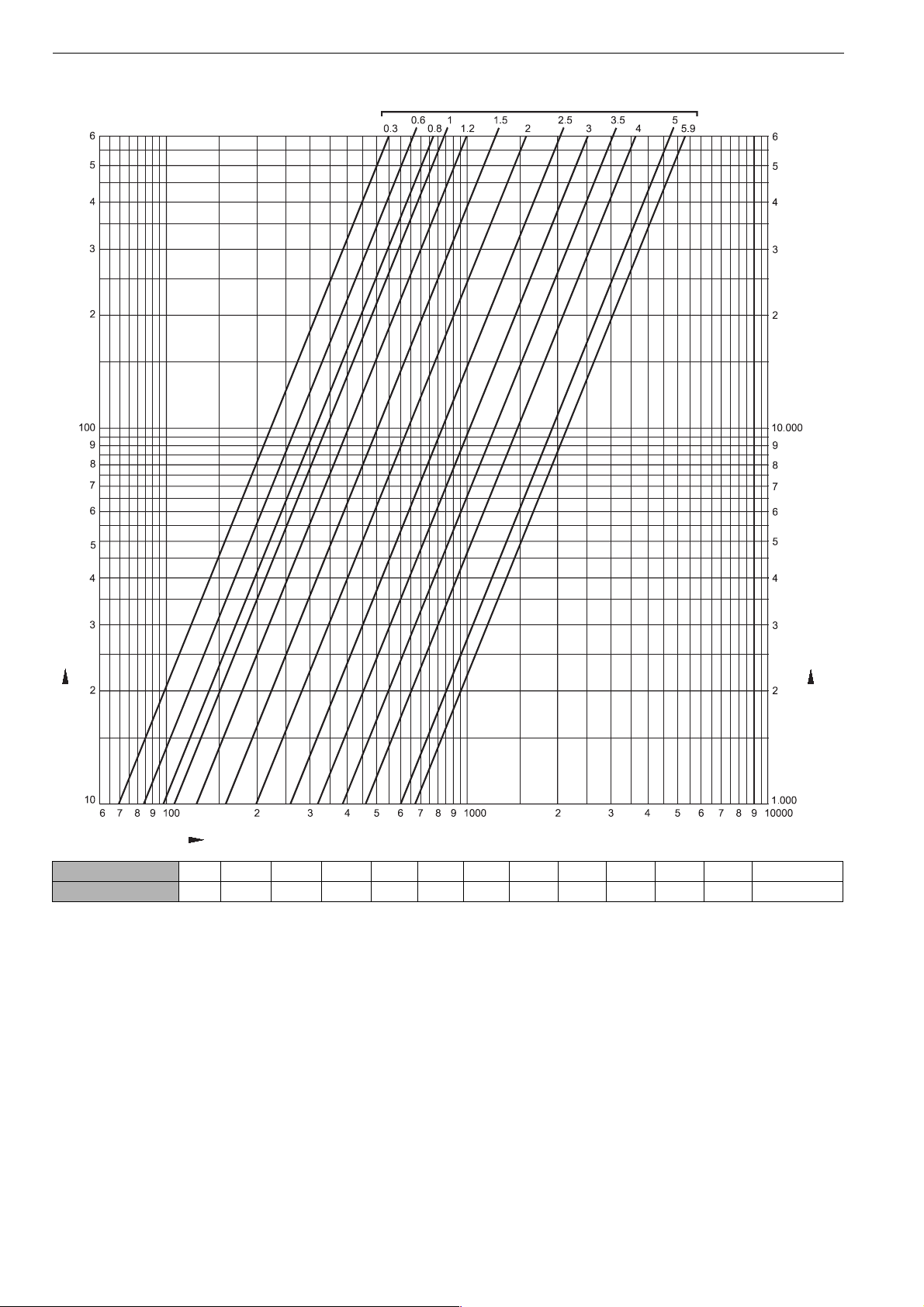

V1810 Alwa-Kombi-4

Flow Diagram for DN 15

Pre-setting

Pressure loss in mbar

Pressure loss in Pa

Flow in kg/h

Pre-setting 0.3 0.6 0.8 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.9 = open

kvs-value 0.37 0.49 0.57 0.65 0.85 1.00 1.13 1.32 1.66 2.12 kvs = 2.70

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

6 www.honeywell.com

Page 7

Flow Diagram for DN 20

V1810 Alwa-Kombi-4

Pre-setting

Pressure loss in mbar

Flow in kg/h

Pre-setting 0.3 0.6 0.8 1.0 1.2 1.5 2.0 2.5 3.0 3.5 4.0 5.0 5.9 = open

kvs-value 0.68 0.84 0.97 1.10 1.30 1.60 2.10 2.60 3.12 3.73 4.40 5.84 kvs = 6.40

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

Pressure loss in Pa

www.honeywell.com 7

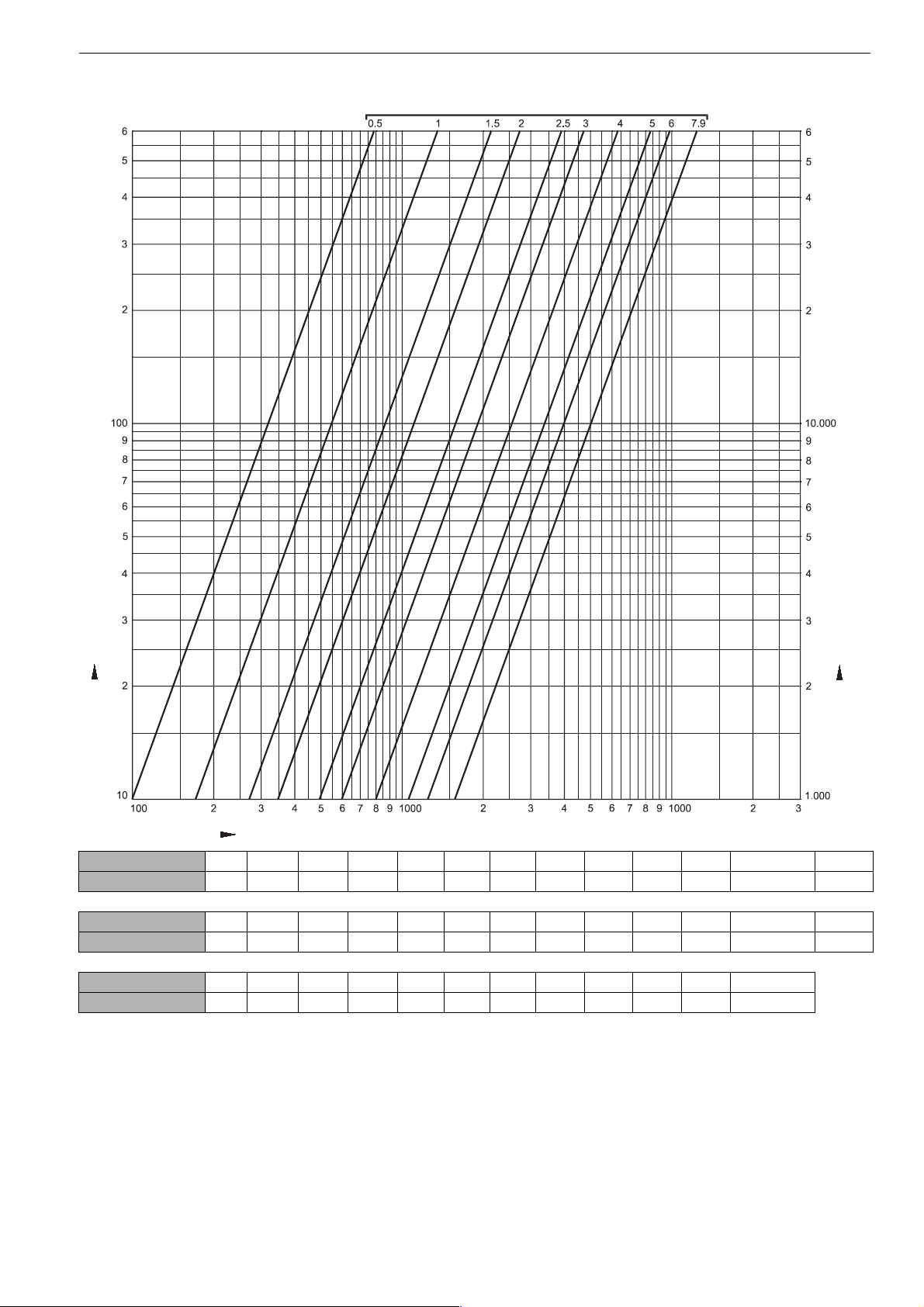

Page 8

V1810 Alwa-Kombi-4

Flow Diagram for DN 25

Pre-setting

Pressure loss in mbar

Flow in kg/h

Pre-setting 0.3 0.6 0.8 1.0 1.2 1.5 2.0 2.5 3.0 3.5 4.0 5.0 5,9 = open

kvs-value 0.68 0.84 0.97 1.10 1.30 1.60 2.10 2.60 3.20 3.90 4.64 6.06 kvs = 6.80

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

Pressure loss in Pa

EN0H-1805GE23 R0307 • Subject to change

8 www.honeywell.com

Page 9

Flow Diagram for DN 32 and DN 40

V1810 Alwa-Kombi-4

Pre-setting

Pressure loss in mbar

Flow in kg/h

Pre-setting 0.5 0.6 0.7 0.8 1.0 1.4 1.6 1.8 2.0 2.2 2.4 2.6 2.8

kvs-value 1.02 1.13 1.42 1.48 1.70 2.16 2.44 2.96 3.54 4.12 4.71 5.28 5.77

Pre-setting 3.0 3.2 3.4 3.6 3.8 4.0 4.2 4.4 4.6 4.8 5.0 5.2 5.4

kvs-value 6.13 6.44 6.91 7.77 8.19 8.74 9.20 9.36 9.62 10.1 10.5 11.0 11.5

Pre-setting 5.8 6.0 6.2 6.4 6.6 6.8 7.0 7.2 7.4 7.6 7.8 7.9 =open

kvs-value 12.0 12.5 12.8 13.3 13.7 14.1 14.5 14.8 15.0 15.3 15.6 kvs = 16.0

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

Pressure loss in Pa

www.honeywell.com 9

Page 10

V1810 Alwa-Kombi-4

Alwa-Kombi-4 with installed thermal actuator

k

-value of Alwa-Kombi-4 with installed thermal actuator

vs

50 - 60 °C (122 - 140 °F) in relation to water temperature at

pre-setting 1.5

kv-value

Water temperature

DN 20 and DN 25

kv-value

Pre-setting values for thermal actuators

We recommend:

Pre-setting value =desired minimal temperature

(standard setting)

Desired minimal temperature

55 °C (131 °F) = Pre-setting 1.5

If the required throttle position according to DVGW worksheet

W553 is to the right of the 2K-line (tempreature in pipe is below

53°C [127°F] at pre-setting 1.5) the pre-setting has to be

increased by 2K:

Desired minimal temperature

55 °C (131 °F) + 2K = Pre-setting 1.7

If the required throttle position according to W553 is to the right

of the 5K-line (temperature in pipe is below 53 °C [127 °F] at presetting 1.7) the following possibilities are left:

• Manually pre-set thermal actuator and valve with values

calculated according to DVGW worksheet W553.

• Use valve of larger dimension.

• Increase pre-setting by 5K:

55 °C (131 °F) + 5K = pre-setting 2.0

The increased pressure loss over the valve must be taken into

account when the pump is specified!

When installation is set according to above recommendations

the hydronic balance is also retained at 70 °C (158 °F) - during

the thermal disinfection process.

Water temperature

DN 32 and DN 40

kv-value

Water temperature

10 www.honeywell.com

EN0H-1805GE23 R0307 • Subject to change

Page 11

Flow Diagram for DN 15 with thermal actuator 50 - 60 °C

V1810 Alwa-Kombi-4

Control deviation

Pressure loss in mbar

Flow in kg/h

Throttle position according to calculation example 3 of DVGW worksheet W553 (multi storey building with 48 flats)

v = 0,5 m/s with pipe-ø 15 x 1 mm

Pre-setting 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

Temperature °C 50 51 52 53 54 55 56 57 58 59 60

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

Pressure loss in Pa

www.honeywell.com 11

Page 12

V1810 Alwa-Kombi-4

Flow Diagram for DN 20 and DN 25 with thermal actuator 50 - 60 °C

Control deviation

Pressure loss in mbar

Flow in kg/h

Throttle position according to calculation example 3 of DVGW worksheet W553 (multi storey building with 48 flats)

v = 0,5m/s with pipe-ø 22 x 1 mm

v = 0,5m/s with pipe-ø 28 x 1 mm

Pressure loss in Pa

Pre-setting 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.0

Temperature °C 50 51 52 53 54 55 56 57 58 59 60

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

12 www.honeywell.com

Page 13

Flow Diagram for DN 32 and DN 40 with thermal actuator 50 - 60 °C

V1810 Alwa-Kombi-4

Control deviation

Pressure loss in mbar

Flow in kg/h

Throttle position according to calculation example 3 of DVGW worksheet W553 (multi storey building with 48 flats)

v = 0,5m/s with pipe-ø 35 x 1 mm

Pre-setting 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2,0

Temperature °C 50 51 52 53 54 55 56 57 58 59 60

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

Pressure loss in Pa

www.honeywell.com 13

Page 14

V1810 Alwa-Kombi-4

Flow Diagram for DN 15 with thermal actuator 40 - 65 °C

Control deviation

Pressure loss in mbar

Flow in kg/h

Throttle position according to calculation example 3 of DVGW worksheet W553 (multi storey building with 48 flats)

v = 0,5m/s with pipe-ø 15 x 1 mm

Pre-setting 0.5 0.7 1.0 1.2 1.5 2,0

Temperature °C 40 45 50 55 60 65

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

Pressure loss in Pa

EN0H-1805GE23 R0307 • Subject to change

14 www.honeywell.com

Page 15

Flow Diagram for DN 20 and DN 25 with thermal actuator 40 - 65 °C

V1810 Alwa-Kombi-4

Control deviation

Pressure loss in mbar

Flow in kg/h

Throttle position according to calculation example 3 of DVGW worksheet W553 (multi storey building with 48 flats)

v = 0,5m/s with pipe-ø 22 x 1 mm

v = 0,5m/s with pipe-ø 28 x 1 mm

Pre-setting 0.5 0.7 1.0 1.2 1.5 2,0

Temperature °C 40 45 50 55 60 65

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

EN0H-1805GE23 R0307 • Subject to change

Pressure loss in Pa

www.honeywell.com 15

Page 16

V1810 Alwa-Kombi-4

Flow Diagram for DN 32 and DN 40 with thermal actuator 40 - 65 °C

Control deviation

Pressure loss in mbar

Flow in kg/h

v = 0,5m/s with pipe-ø 35 x 1 mm

Throttle position according to calculation example 3 of DVGW worksheet W553 (multi storey building with 48 flats)

Pre-setting 0.5 0.7 1.0 1.2 1.5 2,0

Temperature °C 40 45 50 55 60 65

Note: Due to manufacturing reasons the closes position (shutoff) is already reached between pre-setting 0.2 and 0.4.

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division

of Honeywell Technologies Sàrl, Ecublens, Route

du Bois 37, Switzerland by its Authorised Representative Honeywell GmbH

EN0H-1805GE23 R0307

Subject to change without notice

© 2007 Honeywell GmbH

www.honeywell.com

Pressure loss in Pa

EN0H-1805GE23 R0307 • Subject to change

Loading...

Loading...