Page 1

Operating Instructions

Unipoint Flammable and Toxic

Gas Detection Controller

Page 2

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

1 Safety

Ensure that this manual is read and understood BEFORE installing / operating / maintaining the

equipment.

WARNINGS

Unipoint is designed for installation and use in indoor safe area

non-explosive atmospheres. Installation must be in accordance

with the recognized standards of the appropriate authority in the

country concerned.

Unipoint should be installed inside a lockable enclosure or in a

secure location to prevent unauthorized access.

Before carrying out any work ensure local regulations and site

procedures are followed. Work must only be conducted by trained

personnel. Take any necessary precautions to prevent false alarms.

The detectors/sensors that the controller connects to may be used

for gas detection in hazardous atmospheres. Refer to the individual

detector/sensor instructions for their details.

The fault and alarm relay outputs may be used to switch voltages

in excess of 50Vac. Ensure circuits have DOUBLE or REINFORCED

insulation and are segregated in accordance with the voltage being

switched and access is restricted to authorized personnel only.

Unipoint must be zero and span calibrated with the

detector before operation.

Disposal should be according to local waste management

requirements and environmental legislation. Alternatively contact

your local Honeywell Analytics representative.

Honeywell Analytics can take no responsibility for installation and/or use of its equipment if

this is not done in accordance with the appropriate issue and/or amendment of the manual.

The reader of this manual should ensure that it is appropriate in all details for the exact

equipment to be installed and/or operated. If in doubt, contact Honeywell Analytics for advice.

Every effort has been made to ensure the accuracy of our documents; however,

Honeywell Analytics can assume no responsibility for any errors or omissions in our documents

or their consequences.

Honeywell Analytics greatly appreciates being informed of any errors or omissions that

may be found in the contents of any of our documents. For information not covered in this

document, or if there is a requirement to send comments/ corrections about this document,

please contact Honeywell Analytics.

Honeywell Analytics reserve the right to change or revise the information supplied in this

document without notice and without obligation to notify any person or organization of such

revision or change. If information is required that does not appear in this document, contact

the local distributor/agent or Honeywell Analytics.

2

Page 3

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

2 Table of Contents

1 Safety...................................................................................................................................... 2

2 Table of Contents.................................................................................................................... 3

3 Introduction............................................................................................................................. 4

4 Installation............................................................................................................................... 4

4.1 Mechanical Installation......................................................................................................... 4

4.2 Electrical Installation............................................................................................................ 6

4.2.1 Unipoint Controller Selection............................................................................................ 6

4.2.2 Power Connection............................................................................................................ 6

4.2.3 Terminal Detail................................................................................................................... 7

4.2.4 Detector Types.................................................................................................................. 7

4.2.5 Generic Detector Wiring Schematics................................................................................ 8

4.3 Maximum Cable Lengths..................................................................................................... 9

4.3.1 mA Detectors.................................................................................................................... 9

4.3.2 mV Detectors.................................................................................................................... 9

5 Default Conguration.............................................................................................................. 10

5.1 Unipoint mV Input Version................................................................................................... 10

5.2 Unipoint 4-20mA Input Version............................................................................................ 10

6 Switch On................................................................................................................................ 11

7 Initial Conguration................................................................................................................. 11

7.1 Setting Detector type (mA version only)............................................................................... 12

8 Normal Operation.................................................................................................................... 13

8.1 Display and Pushbutton Layout........................................................................................... 13

8.2 Normal Operation LCD Event Codes.................................................................................... 14

8.3 Display, Sounder and Relay Operation................................................................................. 14

8.4 Accept/Resetting Alarms...................................................................................................... 14

8.5 Fault Codes........................................................................................................................... 15

8.6 Inhibit.................................................................................................................................... 15

8.7 Overrange............................................................................................................................. 15

8.8 Self Test................................................................................................................................ 15

9 Conguration........................................................................................................................... 16

10 Ranges and Units.................................................................................................................. 17

11 Alarm Relay On/Off Delay...................................................................................................... 17

11.1 Alarm Relay On Delay......................................................................................................... 17

11.2 Alarm Relay Off Delay......................................................................................................... 18

12 Maintenance.......................................................................................................................... 18

13 Ordering Information.............................................................................................................. 19

14 Warranty Statement............................................................................................................... 19

15 Appendix A- Specication..................................................................................................... 20

16 Approvals............................................................................................................................... 21

17 EC Declaration of Conformity................................................................................................ 22

18 Notes...................................................................................................................................... 23

3

Page 4

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

3 Introduction

Unipoint is a self-contained single channel gas detection controller for use in indoor safe areas.

It is designed for use with any mV ammable gas detector as well as any 2 wire or 3 wire

4-20mA source gas detector*. Unipoint is DIN rail mounted and displays gas concentration,

alarm, fault and status information via its backlit LCD and LEDs, as well as providing a built

in audible alarm. A keypad located below the display provides the facility to make changes

to the system conguration. Unipoint is powered from 24VDC via the DIN rail. The detectors

are connected to the controller via terminals on the side of the controller where terminals for

remote inhibit/reset and output relays are also located.

There are two versions of Unipoint controller available. The mV version is for use with 3 wire

mV ammable gas detectors such as the Signalpoint or Sensepoint range of ammable

detectors. The 4-20mA version is for use with 2 wire and 3 wire 4-20mA source detectors such

as the Signalpoint or Sensepoint range of toxic and oxygen detectors. It has 4 buttons: ‘s’

up, ‘t’ down, ‘x’ reset and ‘3’ OK, that are used navigate through the menus and change the

conguration settings.

*All Honeywell Analytics gas detectors and third party detectors subject to overall power

requirements.

4 Installation

WARNING

Unipoint is designed for installation and use in indoor safe area

non-explosive atmospheres. Installation must be in accordance

with the recognised standards of the appropriate authority in the

country concerned. Prior to carrying out any installation ensure local

regulations and site procedures are followed. The detectors used with

Unipoint are often designed for use in hazardous atmospheres. Refer

to the individual detector instructions for details of their installation.

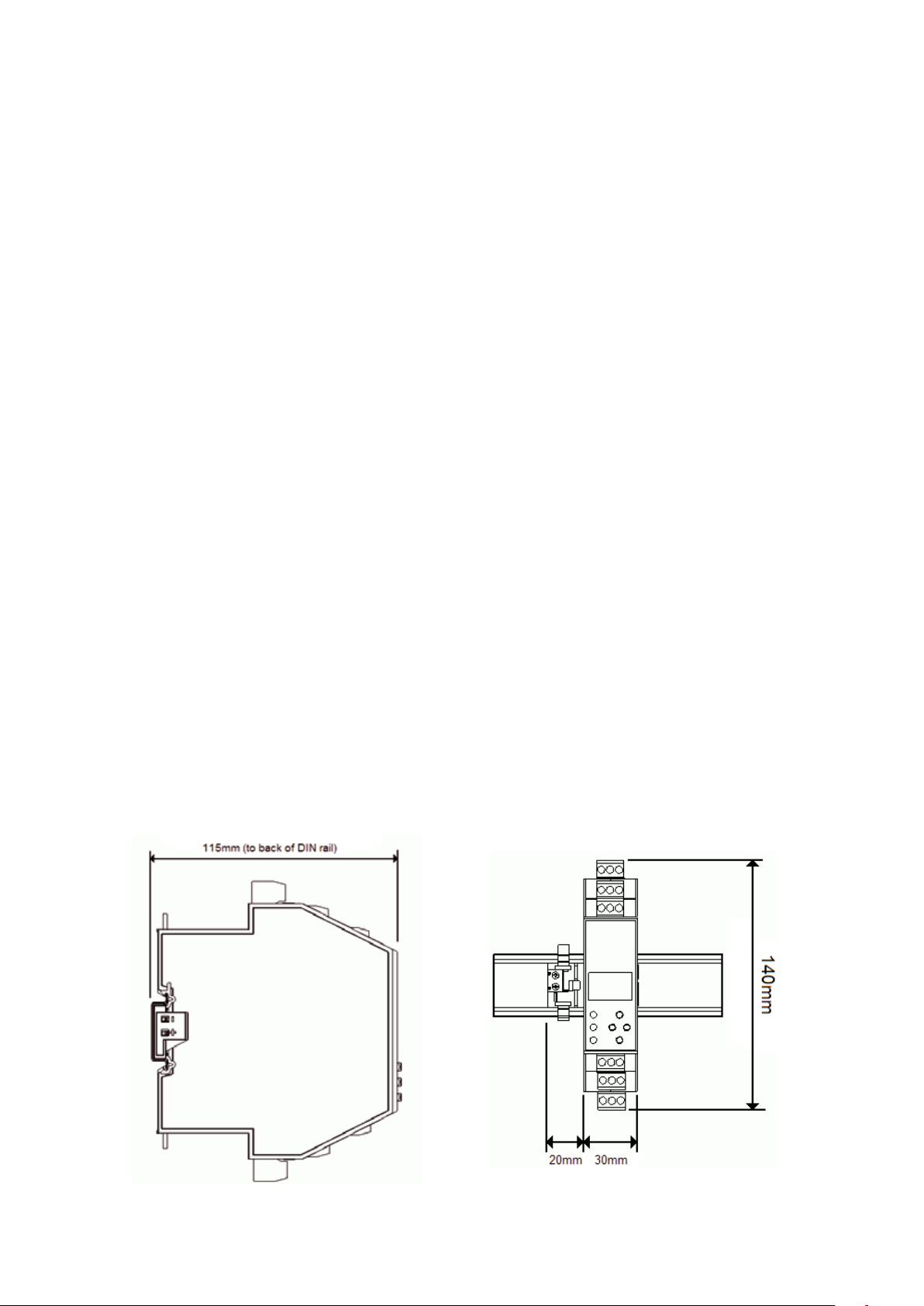

4.1 Mechanical Installation

Outline Dimensional Drawing

4

Page 5

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

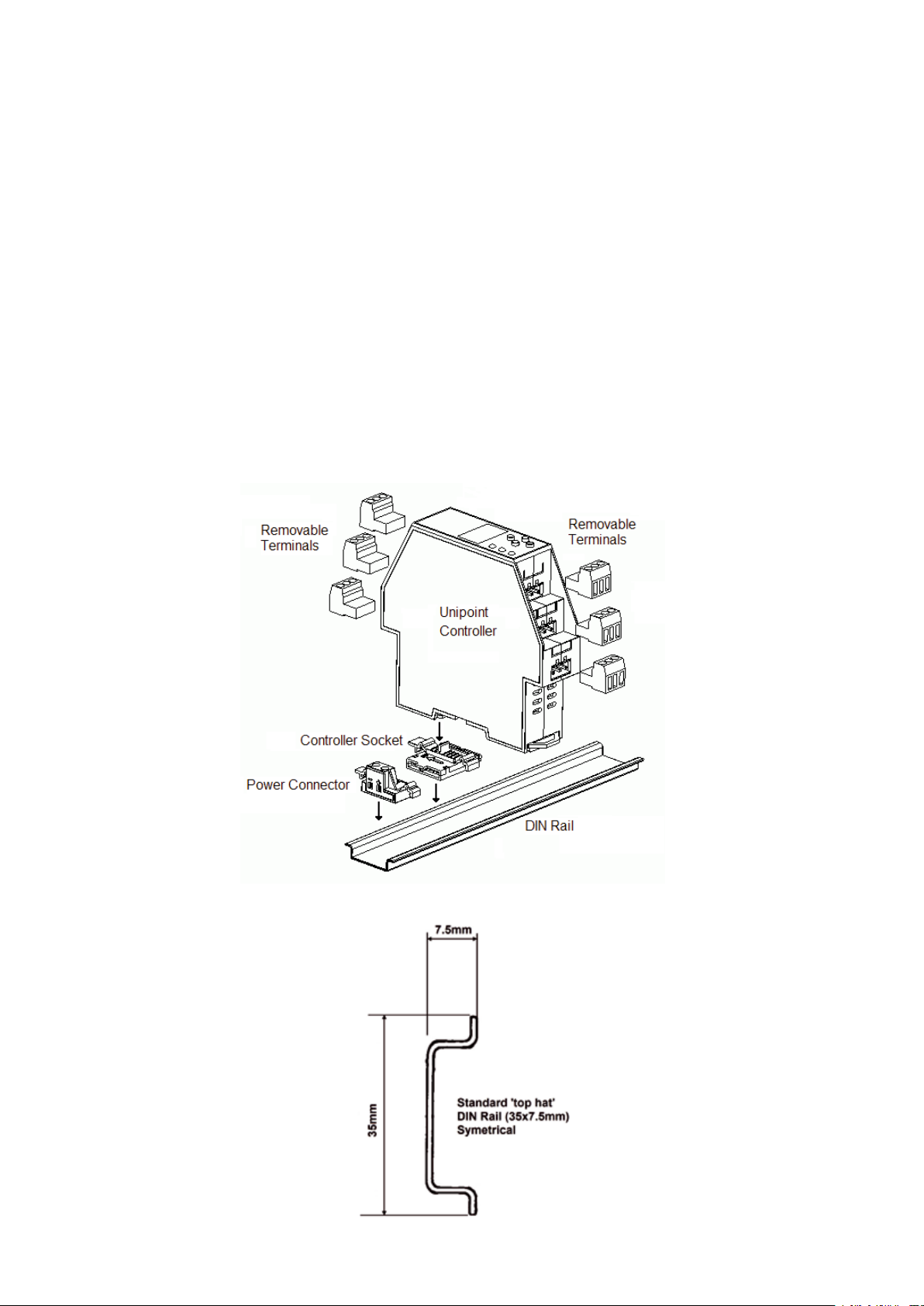

The Unipoint controller is mounted on standard symmetrical ‘top hat’ DIN Rail (35 x 7.5mm).

To attach the Unipoint controller to the DIN rail follow the procedure below use the Installation

Diagram as reference.

1. Clip the Unipoint controller socket on to the DIN rail (note the correct orientation from the

diagram below).

2. Clip the power connector on to the DIN rail beside the controller socket.

3. Slide the connector and socket together until clip engages.

4. Attach the Unipoint Controller on to the socket by gently but rmly pushing it down onto the

socket until it clips in place.

5. Additional Unipoint Controllers can be added to the DIN rail on the right hand side of the rst

unit. Clip additional controller sockets to rail and slide together until clips engage. Then attach

the additional Unipoint Controllers.

Note: If mounting the Unipoint controller(s) inside an enclosure, ensure that the temperature inside

the enclosure does not exceed the specified operating temperature.

Installation Drawing

DIN Rail Drawing

5

Page 6

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

4.2 Electrical Installation

4.2.1 Unipoint Controller Selection

Detector Gas Type Nº Wires Unipoint Controller

Required

Signalpoint Flamable

Toxic

Sensepoint Flamable

Toxic

Sensepoint Plus Flamable

Toxic

4.2.2 Power Connection

Max number of Unipoint controllers on one DIN Bus

Detector Type Max number of

3 wire mV 8

2 wire mA 8

3 wire mA 4

Unipoint Controller Maximum Power Consumption

3

2

3

2

3

3

controllers

mV

mA

mV

mA

mA

mA

Unipoint

Controller status Relays Power

version

mV Normal operation, no faults, no alarms.

Zero cable resistance.

mV Normal operation, no faults, no alarms.

Max loop cable resistance (28 ohms)

mV All alarms, no faults. Max cable

resistance (28 ohms)

mA Normal operation, no faults, no alarms.

Inclusive of 2 wire signal loop current.

mA All alarms, no faults. Inclusive of 2 wire

signal loop current.

1 includes power to detector

2 excludes power to 3 wire mA detector.

All controllers with default conguration.

Fault Alarm

Energised De energised 2.4W

Energised De energised 3.6W

Energised Energised 4.8W

Energised De energised 1.8W

Energised Energised 3.0W

1

1

1

2

2

6

Page 7

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

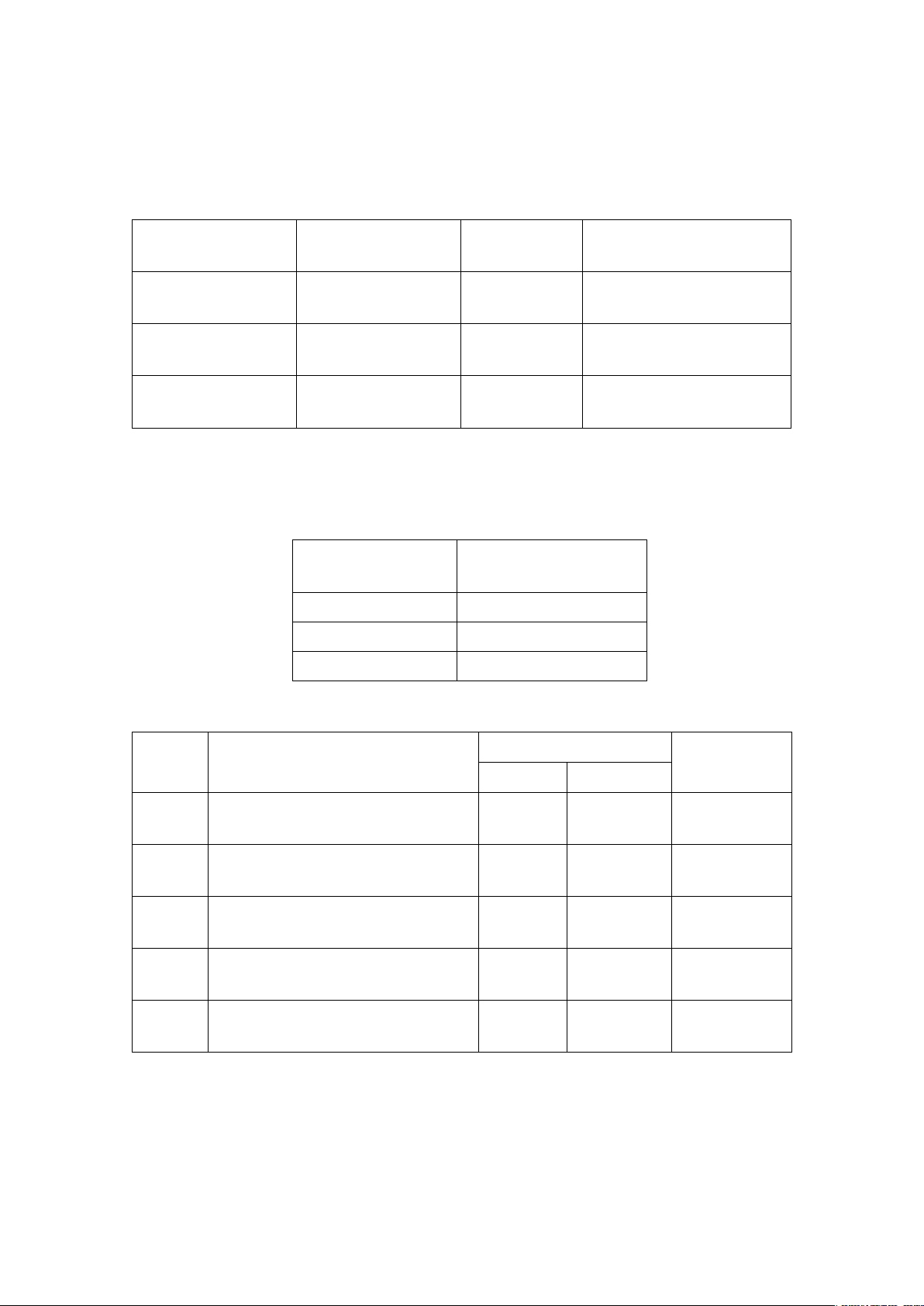

4.2.3 Terminal Detail

All electrical connections except power are made via removable terminals located on the top

and bottom of the controller. The power connection is made via the power connector attached

to the DIN rail.

For security we recommend the use of Key Switches for the remote reset and inhibit inputs

mounted on the front of the enclosure in which the Unipoint is mounted.

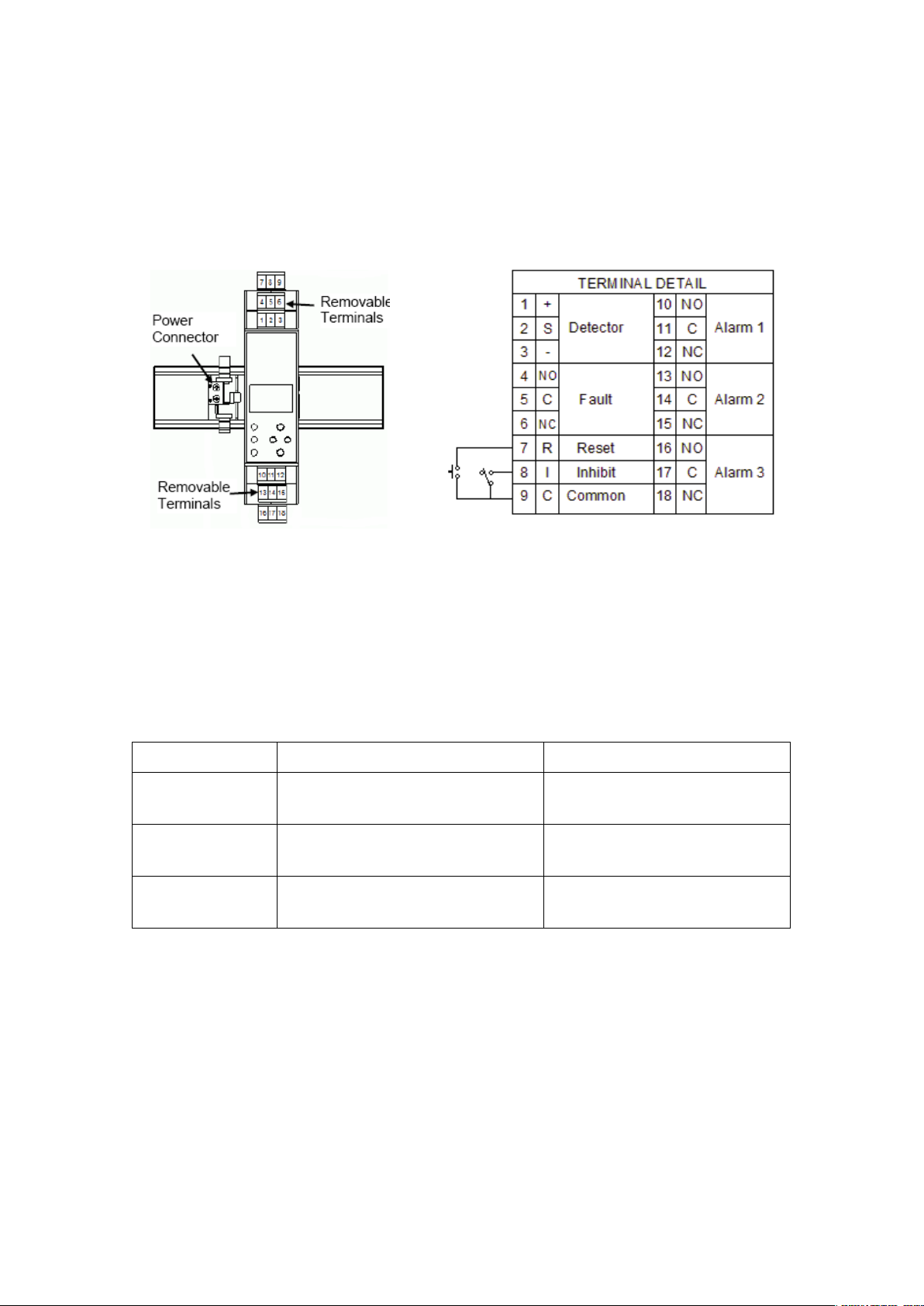

4.2.4 Detector Types

Unipoint can accept signals from three types of detector. The table below summarizes the

types of detector compatible with Unipoint.

Type of detector Output to detector Recommended detector

2 wire 4-20mA Controller Input (18-32Vdc)-1.5*Vdc,

30mA (max). Sense resistor 33 Ohms.

3 wire 4-20mA

source

Controller Input (18-32Vdc)-1.5*Vdc,

0.5A (max). Sense resistor 33 Ohms.

3 wire mV bridge 2.4-8.6V, 200mA constant current.

Max cable loop resistance 28 Ohms.

* Voltage drop in Unipoint Controller

Signalpoint or Sensepoint Toxic

and Oxygen

Sensepoint Plus

Signalpoint or Sensepoint

Flammable

7

Page 8

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

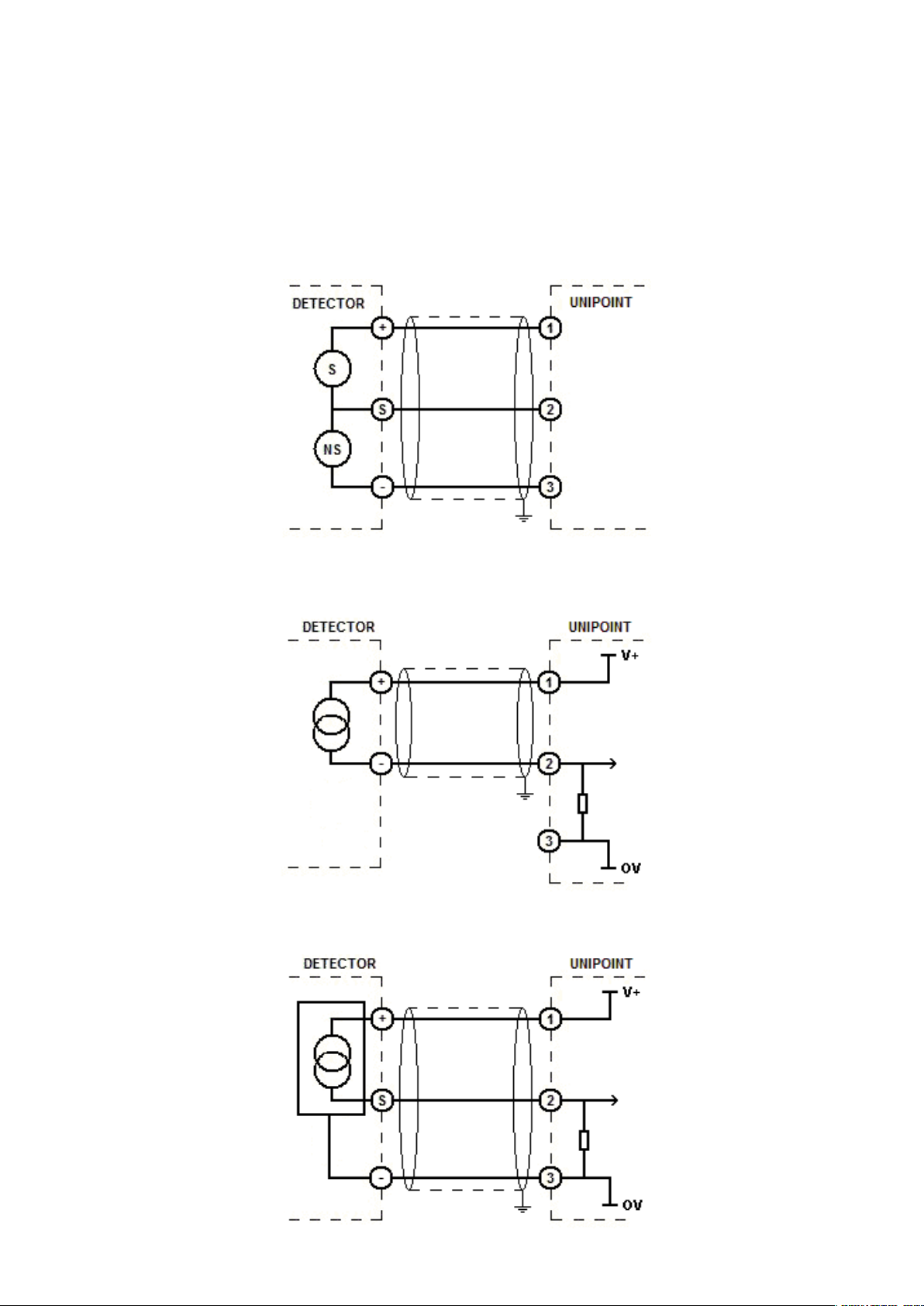

4.2.5 Generic Detector Wiring Schematics

To connect the detector to the Unipoint use a 2 or 3 wire cable (as appropriate) that is suitably

armoured (e.g. Steel Wire Armour) or conduit according to local requirements. Acceptable wire

cross sectional area is from 0.5 to 1.5mm2 with overall screen. Connect the screen to ground at

the enclosure that the Unipoint is mounted in.

3 Wire mV Bridge

2 Wire 4-20mA

3 Wire 4-20mA Source

8

Page 9

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

4.3 Maximum Cable Lengths

4.3.1 mA Detectors

To calculate the maximum cable run length from power source to the detector refer to the

following example diagram and formula.

Rloop = (Vcontroller - 1.5V - Vdetector min) / Idetector

Maximum cable run length = Rloop / cable per metre resistance where:

Rloop = maximum working cable loop resistance

Vcontroller = maximum available supply voltage at controller

Vdetector min = minimum voltage at which the connected sensor can operate

(sensor dependent, see individual sensor technical manual/

data sheets)

Idetector = sensor maximum drawn current. 30mA for 2 wire mA detectors.

See individual detector technical manual/data sheets for max power

consumption of 3 wire detectors.

4.3.2 mV Detectors

To calculate the maximum cable run length to the detector refer to the following typical

example cable resistances. Max cable loop resistance = 28 ohms.

Solid Copper Conductor

Cross Sectional Area Maximum resistance at 20ºC

(mm2) AWG (ohm/bucle/km)

0.50 21 72

0.75 19 50

1.00 18 36

1.50 16 24

Stranded Copper Conductor

Cross Sectional Area Maximum resistance at 20ºC

(mm2)

0.50 21 73.6

0.75 19 49

AWG

(ohm/bucle/km)

1.00 18 35.2

1.50 16 23.4

9

Page 10

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

5 Default Conguration

Unipoint has user congurable settings that allow the set up of the system to individual

application requirements. Unipoint is supplied from the factory with a default conguration.

These congurations are based on settings typically used in gas detection systems.

Details of how to recongure Unipoint are given in section 7.

5.1 Unipoint mV Input Version

Function Default conguration

Password 000 (Disabled)

Display range and units 0-100%LEL

Alarm Relay 1 Alarm level 1 10%LEL (Rising)

Alarm Relay 2 Alarm level 2 25%LEL (Rising)

Alarm Relay 3 Alarm level 3 50%LEL (Rising)

Fault Relay Non-latching, normally energized, de-energizes on fault.

Inhibit Controller inhibit activates fault relay.

Non-latching, normally de energized, energizes on alarm.

Relay activation delay=0 seconds

Relay de-activation hold=0 seconds

(Single Pole change over, 240Vac/30Vdc, 3A max)

Non-latching, normally de energized, energizes on alarm.

Relay activation delay=0 seconds

Relay de-activation hold=0 seconds

(Single Pole change over, 240Vac/30Vdc, 3A max)

Latching, normally de energized, energizes on alarm.

Relay activation delay=0 seconds

Relay de-activation hold=0 seconds

(Single Pole change over, 240Vac/30Vdc, 3A max)

(Single Pole change over, 240Vac/30Vdc, 3A max)

5.2 Unipoint 4-20mA Input Version

Function Default conguration

Password 000 (Disabled)

Display range and units 0-100ppm

Current input 0 mA Fault (open circuit)

Alarm Relay 1 Alarm level 1 10% of full scale (Rising)

Alarm Relay 2 Alarm level 2 25% of full scale (Rising)

Alarm Relay 3 Alarm level 3 50%LEL (Rising)

Fault Relay Non-latching, normally energized, de-energizes on fault.

Inhibit Controller inhibit activates fault relay and de-activates alarm relays.

Detector Type 2 Wire 4-20mA

4.0 to 20.0mA Gas reading (normal operation)

1.5 to 2.5mA Inhibit from sensor (configuration mode)

>20.0mA Overrange

Non-latching, normally de energized, energizes on alarm.

Relay activation delay=0 seconds

Relay de-activation hold=0 seconds

(Single Pole change over, 240Vac/30Vdc, 3A max)

Non-latching, normally de energized, energizes on alarm.

Relay activation delay=0 seconds

Relay de-activation hold=0 seconds

(Single Pole change over, 240Vac/30Vdc, 3A max)

Latching, normally de energized, energizes on alarm.

Relay activation delay=0 seconds

Relay de-activation hold=0 seconds

(Single Pole change over, 240Vac/30Vdc, 3A max)

(Single Pole change over, 240Vac/30Vdc, 3A max)

Field inhibit active (1.5 to 2.5mA on detector input).

10

Page 11

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

6 Switch On

After connecting power, the controller enters a self test routine: All LCD segments ash, the

fault and alarm LED ash, the sounder operates three times, the RAM, ROM and EEPROM are

checked and the software version is displayed. If no faults are found (see section 7.5 for fault

codes) the unit enters a detector warm up period indicted by a count down from 60 to 0 on the

display. During this time the controller is inhibited (‘Inh’) so all alarms and faults are inactive.

At the end of the warm-up period the controller checks for detector and eld wiring faults. If a

fault is found, the fault code is displayed (see section 7.5 for fault codes). If no fault is found

the controller enters normal operation and will display current gas reading and alarm(s) if

appropriate.

7 Initial Conguration

WARNING

Unipoint must be zero and span calibrated with the detector

before operation.

If the default conguration shown in section 5.1 (mV type controller) or 5.2 (mA type controller)

does not match the application requirements, follow the procedures below to recongure the

controller.

Notes: If using a mA version controller with a 3 wire mA type detector, carry out the

procedure in section 7.1 rst to set the correct detector type.

If conguring the controller for use with an Oxygen detector, skip the ‘Set zero’ instructions

(steps 7-14) and use 20.9% (background air oxygen level) as the span calibration point.

After completing all the steps in a menu, the 3 button must be pressed to save the changes.

Press x at any time to ignore the changes made in the current menu.

1. Press the st buttons together to enter the conguration mode.

2. Press 3 to enter the ‘Set Range and Units (FS)’ menu.

3. The default range ashes. Press the st buttons to select the required range.

4. Press 3 to set the new range.

5. The default units start ashing. Press the st buttons to select the required units.

6. Press 3 to set the new units. (See section 9 for available ranges and units).

7. Press the t button to select the ‘Set Zero (0)’ menu.

8. Press 3 to enter the ‘Set Zero (0)’ menu.

9. The current zero gas reading is displayed.

10. Apply zero gas to the detector.

11. Press 3 when the reading is stable.

12. The display will show ‘---’ while calculating the zero point and then ‘0’ when complete. If

the zero fails ‘FFF’ is displayed.

13. Remove the zero gas from the detector.

14. Press 3 to complete the zero calibration.

15. Press the t button to select the ‘Set Span (S)’ menu.

16. Press 3 to enter the ‘Set Span (S)’ menu.

17. 50% of the set range ashes.

18. Press st buttons to set the concentration of the span calibration gas concentration

being used.

19. Press 3 to set the span calibration concentration.

20. Apply the span calibration gas to the detector.

21. The ‘live’ gas reading is displayed.

22. If the reading is too low ‘S-L’ is displayed, if too high ‘S-H’ is displayed.

11

Page 12

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

23. When the reading is stable press 3.

24. ‘---’ is displayed while calculating the new span.

25. The display then shows the new span value. If span fails ‘FFF’ is displayed.

26. Remove the span gas from the detector and allow the display to return to zero.

Note: Allowing the reading to return to zero before exiting ensures no accidental alarms are

triggered.

27. Press 3 to return to the menu.

28. Press the 3 button to select the ‘Set Alarms (A1)’ menu.

29. Press 3 to enter the ‘Set Alarms (A1)’ menu.

30. The current alarm 1 set point ashes.

31. Press st buttons to change the A1 set point.

32. Press 3 to conrm.

33. The display shows the current alarm relay on delay in seconds.

34. Press st buttons to change the alarm relay on delay.

35. Press 3 to conrm.

36. The display shows the current alarm relay off (hold) delay in seconds.

37. Press st buttons to change the alarm relay off delay.

38. Press 3 to conrm.

39. The display shows the current alarm 1 relay conguration.

40. Press st buttons to select either ‘F’ for falling or ‘r’ for rising alarm point.

41. Press 3 to conrm.

42. Press st buttons to select either ‘E’ for normally energized or ‘d’ for normally de-energized relay.

43. Press 3 to conrm.

44. Press st buttons to select either ‘L’ for latching or ‘n’ for non-latching relay.

45. Press 3 to conrm.

46. The display now shows the current alarm 2 level.

47. Repeat steps 31 to 46 for alarm 2 and then alarm 3.

48. Press ‘x’ to return to normal operation.

Note: For details of other settings in the configuration menu refer to section 9.

7.1 Setting Detector type (mA version only)

The default detector type setting for a mA version controller is 2 wire. If using a 3 wire mA type

detector carry out the procedure below:

1. Press the st buttons together to enter the conguration mode.

2. Press s or t buttons to select the ‘Detector Type (IP)’ menu.

3. The current detector input type ashes (2L=2 wire mA).

4. Press the st buttons to select 3L=3 wire mA).

5. Press 3 to conrm.

6. Press x to return to normal operation.

7. Follow the procedures in section 7 to complete the initial conguration.

12

Page 13

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

8 Normal Operation

In normal operation the green Power LED is illuminated and the 1st line of the LCD shows the

current gas reading. The 2nd line is used to display text codes that provide additional information about the type of event that has occurred. An alarm, fault/inhibit LED and built in sounder

are also used when signaling events.

8.1 Display and Pushbutton Layout

Gas Label Area*

Gas Reading

Measurement Units

Event Code

s Pushbutton

Power LED

Fault/Inhibit LED

3 Pushbutton

Alarm LED

t Pushbutton

X Pushbutton

*A packet of stick on gas labels are supplied with each Unipoint Controller

13

Page 14

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

8.2 Normal Operation LCD Event Codes

The display event codes are shown below:

NORMAL OPERATION DISPLAY TEXT CODES

CODE EVENT TYPE

A - 1 Alarm point 1 exceeded

A - 2 Alarm point 2 exceeded

A - 3 Alarm point 3 exceeded

O F F All outputs disabled

F X X Fault. XX=Fault code

I n h Remote or eld* inhibit

8.3 Display, Sounder and Relay Operation

The table below shows the default operation of the display, sounder and relays for given

events.

EVENT LCD LEDS* SOUNDER RELAY

ALARM FAULT/INH A1 A2 A3 F

Alarm 1 threshold exceeded A-1 ashing off on X

Alarm 2 threshold exceeded A-2 ashing off on X X

Alarm 3 threshold exceeded A-3 ashing off on X X X

Fault FXX off ashing on X

Inhibit Inh off ashing off X

Overange Or/A3 ashing off on X X X

*LED ash frequency: Alarm = 2Hz, Fault = 1Hz and Inhibit = 0.5Hz

8.4 Accept/Resetting Alarms

In normal operation, the X button on the controller front panel or a switch connected to the

remote reset terminal is used to reset/accept alarm events. The effect of reset/accept

dependent on gas reading and alarm latching setting is described below:

Gas reading still exceeds alarm threshold Gas reading below alarm threshold

Latched alarm Sounder stops. Flashing alarm LED changes

to steady. Gas reading and alarm code

displayed on LCD. Alarm relay remains in

alarm state.

Unlatched alarm Sounder stops. Flashing alarm LED changes

to steady. Gas reading and alarm code

displayed on LCD. Alarm relay remains in

alarm state.

Sounder stops. Alarm LED is turned off. The

LCD alarm code clears. Alarm relay returns to

original state.

Alarm indications and relay operation reset

automatically without need for reset/accept.

Note: If the controller is in inhibit when an alarm threshold is exceeded the alarm LED only will

operate. See section 10 for details of how the relay delay and hold function effects the

operation of the unit.

14

Page 15

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

8.5 Fault Codes

Below are the fault codes and recommended action to clear the fault.

FAULT CODE DESCRIPTION TROUBLE SHOOT

F - S Sensor / wiring fault Check sensor / eld wiring

F N D Negative drift Calibrate detector

F I F Excessive interference Check eld wiring

F R RAM fault Replace controller

F C Memory failure Replace controller

F E Conguration error Replace controller

8.6 Inhibit

The controller is put into inhibit via a normally open switch connected to the inhibit terminal or

when entering conguration mode. The inhibit is maintained until the switch is opened again or

on return to normal operation mode.

Additionally, an inhibit signal of between 1.5mA to 2.5mA can be signaled to the controller from

a eld device. This facility is only available on mA version controllers (see section 9).

When in inhibit the alarm relay and sounder do not operate. The alarm LED will operate if the

alarm threshold is exceeded. The 2nd line of the LCD will show Inh (except in conguration

mode where a slow ashing fault LED indicates the inhibit).

The controller can also be disabled using the disable function in the conguration mode (see

section 9).

See section 10 for details of how the relay delay and hold function is affected by inhibit.

8.7 Overrange

When the gas reading exceeds full scale ‘Or’ replaces the gas reading to indicate an overrange

condition. The 2nd line of the LCD continues to show the alarm state. If alarm level 3 is

congured latching then the overrange condition will also latch (default for 3 wire mV version).

8.8 Self Test

The controller enters a self test routine at power on. It can also be forced into a self test by

pressing the 3 button in normal operation. The controller automatically conducts a self test at

regular intervals.

15

Page 16

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

OK

OK

OK

RETURNS TO MAIN MENU

NEW RANGE AND UNITS SETTINGS CONFIRMED.

3

MAIN MENU

NEW ZERO SETTING CONFIRMED. RETURNS TO

3

TO MAIN MENU

NEW SPAN SETTING CONFIRMED. RETURNS

3

DISPLAYED. REMOVE GAS

SPANNED READING. IF SPAN FAILS 'FFF' IS

'---' DISPLAYED WHILE MEASURING THEN NEW

3

3

PRESS TO SELECT 'F'=FALLING OR

ALARM 1 RELAY CONFIGURATION DISPLAYED.

3

900 secs)

PRESS TO SELECT ALARM OFF DELAY (0 to

3

'r'=RISING

MAIN MENU. REPEAT FOR ALARM 2 & 3.

NEW ALARM SETTINGS CONFIRMED. RETURNS TO

3

TO MAIN MENU

NEW FAULT RELAY SETTINGS CONFIRMED. RETURNS

3

MAIN MENU

NEW PASSWORD CONFIRMED. RETURNS TO

3

TO CHANGE THIRD DIGIT.

THIRD DIGIT OF PASSWORD FLASHES. PRESS

3

OK

OK

NOTES:

Detector inhibit signal range = 1.5mA to 2.5mA.

All steps in the respective menu option must be completed and 3 pressed for the changes to be saved. Pressing X before confirmation of

new settings returns to main menu with no changes to configuration.

*See section 9 for available ranges and units.

**If configuring the controller for use with an Oxygen detector, skip the ‘Set zero’ instructions and use 20.9% (background air oxygen level)

as the span calibration point.

***Only available on mA input version

OK

9 Conguration

From normal mode press the st buttons together to enter conguration mode. If no password has been set the display will go directly to the menu

selection. If a password has been set then the display will show ‘OOO’ and the 1st digit will ash. Press st to change the rst digit of the password.

Press 3 to move to the next digit. Repeat to set the 2nd and 3rd digits of the password. Press x at any time to exit and return to normal mode. Press

3 after setting the 3rd digit to conrm the password and enter the menu selection. If the password entered is incorrect the display will return to normal

mode. Use the table below to help navigate the menu and make conguration changes.

UNITS FLASH. PRESS TO SELECT NEW UNITS.

3

OK

TO SELECT NEW RANGE

RANGE FLASHES. PRESS

3

OK

RANGE AND

READING DISPLAYED. IF ZERO FAILS 'FFF' IS

'---' DISPLAYED WHILE MEASURING THEN ZERO

3

APPLY ZERO GAS.

CURRENT ZERO GAS READING DISPLAYED.

3

SET ZERO

UNITS (FS)*

DISPLAYED. REMOVE GAS.

(0)**

APPLY CALIBRATION GAS. LIVE GAS READING

3

50% OF RANGE FLASHES.

3

SET SPAN

DISPLAYED. 'S-L' IF TOO LOW, 'S-H' IF TOO HIGH.

PRESS

TO SET CAL GAS CONCENTRATION

(S)**

(0 to 900 secs)

PRESS TO SELECT ALARM ON DELAY

3

TO CHANGE.

CURRENT ALARM 1 SET POINT FLASHES. PRESS

3

(A1, A2, A3)

SET ALARMS

LATCHING

ON INHIBIT OR 'In'=NO ACTION ON INHIBIT.

PRESS TO SELECT 'IF'=FAULT RELAY ACTION

PRESS TO SELECT 'L'=LATCHING OR 'n'=NON-

3

'd'=DE-ENERGIZED.

PRESS TO SELECT 'E'=ENERGIZED OR

FIRST FAULT RELAY SETIING FLASHES. PRESS

SECOND DIGIT OF PASSWORD FLASHES. PRESS

3

ENERGIZED.

TO SELECT 'E'=ENERGIZED OR 'd'=DE-

FIRST DIGIT OF CURRENT PASSWORD FLASHES.

3

RELAY (F)

SET FAULT

3

3

SET PASS-

TO CHANGE SECOND DIGIT.

PRESS TO CHANGE FIRST DIGIT.

WORD (PAS)

OUT OF INHIBIT.

DETECTOR INHIBIT SETTING CONFIRMED. RETURNS

3 SIMULTANEOUSLY FOR >1 SECOND TO TAKE UNIT

LOWER LINE OF DISPLAY SHOWS 'OFF'. PRESS X AND

3

3

DISPLAY SHOWS ‘dIS’

PRESS TO SELECT 'Inh'= DETECTOR IN-

3

3

FIELD INHIBIT

DISABLE (dIS)

TO MAIN MENU.

DETECTOR INPUT SETTING CONFIRMED. RETURNS TO

3

MAIN MENU.

OK

'3L'=3 WIRE mA

CURRENT DETECTOR INPUT TYPE FLASHES.

PRESS TO SELECT '2L'= 2 WIRE mA OR

HIBIT ON OR 'FAL' FOR DETECTOR INHIBIT OFF

(FIh)***

3

DETECTOR

OK

TYPE (IP)***

16

Page 17

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

10 Ranges and Units

Below are the possible combinations of range and units for the two Unipoint Controller types:

Unipoint Controller Units Available Full Scale Ranges

%LEL

2.00; 3.00; 5.00; 10.0; 15.0; 20.0; 25.0; 50.0 of 100

mV or mA version

%VOL

PPM 2.00; 3.00; 5.00; 10.0; 15.0; 20.0; 25.0; 50.0; 100; 150;

200; 300; 400; 500 of 1000

11 Alarm Relay On/Off Delay

Part of the ‘Set Alarms’ conguration allows a user programmable delay for each alarm

threshold between the detection of an alarm and the activation of the alarm relay output, and

a programmable hold between the clearing of an alarm and the release of the relay output. The

delay times are adjustable over the range 0 to 900 seconds (900sec equals 15mins).

The default delay times are 0 (no delay).

WARNING

If an alarm relay activation delay is set to greater than 0 secs the

presence of a gas concentration in excess of the alarm threshold will

not be immediately signaled.

11.1 Alarm Relay On Delay

The programmable alarm relay delay operates in the following manner:

• If the delay is set, then in the event of the GAS CONCENTRATION EXCEEDING the alarm

threshold the following occurs:

• The LCD, LED, and buzzer signal the alarm.

• The alarm relay output does not signal the occurrence of the alarm immediately.

• The delay counts down.

• When the delay has expired, the relay output then signals the alarm.

• If during the delay the GAS CONCENTRATION FALLS below the alarm threshold and the

alarm is congured as NON-LATCHING, the indication of the alarm on the LCD, LED, and

buzzer is removed and the delay reset.

• If during the delay the gas CONCENTRATION FALLS below the alarm threshold and the

alarm is congured as LATCHING, the indication of the alarm on the LCD, LED, and buzzer

remains, the delay continues to run and the relay output is updated when the delay time

has expired.

• If during the delay the GAS CONCENTRATION IS ABOVE the alarm threshold and the

ACCEPT/RESET INPUT/KEY is activated to accept the alarm, the LCD, LED, and buzzer

will respond as per section 7.4, the delay continues to run and the relay output is updated

when the delay time has expired.

• If during the delay the GAS CONCENTRATION FALLS BELOW the alarm threshold, the alarm

is congured as LATCHING, and the ACCEPT/RESET EXTERNAL INPUT/KEY is activated to

reset the alarm, the LCD, LED, buzzer and the delay time reset.

17

Page 18

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

• If during the delay the unit is placed into INHIBIT by either the external inhibit or by entering

the conguration mode, the delay will be reset. On exiting the inhibit mode the relay output

will be updated.

• If during the delay a FAULT is signaled, the delay will continue and the relay output updated

when the delay time has expired. (The alarm will continue to be signaled on the sounder,

LED, and LCD after the fault occurs. The relay output will be updated to reect the alarm

when the time expires.)

11.2 Alarm Relay Off Delay

The programmable alarm relay hold operates in the following manner.

• If the hold time is set, then in the event of the GAS CONCENTRATION FALLING below the

alarm threshold after previously exceeding the alarm threshold for a period of time greater

than the delay time (i.e. the relay output is reecting the active alarm) and the alarm

threshold is congured as NON-LATCHING the following occurs:

• The LCD, LED, and buzzer will stop signaling the alarm.

• The alarm relay does not signal the absence of the alarm immediately.

• The hold time counts down.

• When the hold time expires, the relay output is updated to signal the absence of

the alarm.

• If during the hold time the gas CONCENTRATION RISES back above the alarm threshold,

the LCD, LED, and buzzer signal the re-occurrence of the alarm and the hold time is reset.

• If during the hold time the ACCEPT/RESET EXTERNAL INPUT/KEY is activated, the relay

output is updated immediately.

• If during the hold time the unit is placed into INHIBIT by either the external inhibit or by

entering the conguration mode, the hold time is reset. On exiting the inhibit mode the relay

output is updated immediately.

• If during the hold time a FAULT is signaled, the hold time is reset and the relay output

is updated immediately.

• If the alarm is congured as LATCHING, the hold time has no effect upon the operation of

the unit. i.e. The signaling of a latched alarm via the relay output will removed immediately

the accept/reset external input/key is activated.

12 Maintenance

The Unipoint controller has no user serviceable parts. Honeywell Analytics recommend that the

controller’s conguration and operation are checked annually.

The gas detectors connected to the controller should be checked and if necessary zero and

span calibrated by following the procedures detailed in their user guides.

18

Page 19

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

13 Ordering Information

Unipoint Controllers

Unipoint Controller (mV input version) 2306B2000

Unipoint Controller (mA input version) 2306B1000

Spares

Unipoint Terminal Block Plug (x2) 2306B3010

Unipoint DIN rail socket kit 2306B3020

Unipoint power connector kit 2306B3030

14 Warranty Statement

All products are designed and manufactured to the latest internationally recognized standards

by Honeywell Analytics under a Quality Management system that is certied to ISO 9001.

As such Honeywell Analytics warrants its products against defective parts and workmanship

and will repair or (at its option) replace any instruments which are or may become defective

under proper use within 12 months from date of commissioning by an approved Honeywell

Analytics representative or 18 months from date of shipment from Honeywell Analytics, whichever is the sooner. This warranty does not cover disposable batteries or damage caused by

accident, abuse, abnormal operating conditions or poisoning of sensor.

Defective goods must be returned to Honeywell Analytics premises accompanied by a detailed

description of any issue. Where return of goods is not practicable Honeywell Analytics reserves

the right to charge for any site attendance where any fault is not found with he the equipment.

Honeywell Analytics shall not be liable for any loss or damage whatsoever or howsoever occasioned which may be a direct or indirect result of the use or operation of the Contract Goods

by the Buyer or any Party.

This warranty covers instrument and parts sold to the Buyer only by authorized distributors,

dealers and representatives as appointed by Honeywell Analytics. The warranties set out in this

clause are not pro rata, i.e. the initial warranty period is not extended by virtue of any works

carried out there under.

19

Page 20

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

15 Appendix A- Specication

Specication

Use The Unipoint controller provides integrators with a exible and low cost solution to the many applications

User interface

Operation Two pushbuttons for normal operation of resetting alarms and initiating self diagnostic test of system.

Backlit display Units of measure, digital gas reading and event code

Other indication Ultra-bright steady/ashing LEDs subject to condition; alarm (red), power (green), fault (amber). In-built

Termination

Environmental

IP Rating IP30 (Install in suitable enclosure)

Weight 225g (Controller only)

Operational

Temperature

Humidity

Pressure

Storage -25°C to +60°C / -13°F to +140°F, 20 to 80%RH (non condensing)

Inputs

Supply Nominal 24Vdc (18-32Vdc). Max power mV = 4.8W (including power to detector), mA= 3.0W (excluding

Detector type 3 wire mV bridge

requiring ammable, toxic or oxygen gas detection to be incorporated into their control systems. Unipoint

is designed to use industry standard DIN rail allowing it to be easily installed into many different types of

plastic or metal, indoor or outdoor, hazardous or non hazardous area enclosures. It is designed for use

with any mV ammable gas detector as well as any 2 or 3 wire 4-20mA gas detector (subject to overall

power requirements).

Four buttons for user programmable functions via intuitive menu

audible alarm 63dB at 0.3 meters.

Easily accessible plug in screw type terminals. Terminals accept maximum wire diameter 1.5mm

o

C to +55oC / 14oF to 131oF (Performance approval -10°C to +40°C / 14°F to 104°F)

-10

10 to 90%RH (non condensing)

90-110kPa

power to 3 wire detector).

e.g. Sensepoint or

Signalpoint ammable

gas detectors

2 wire, 4-20mA, loop

powered e.g. Sensepoint

or Signalpoint toxic or

oxygen gas detectors

3 wire, 4-20mA, source output e.g. Sensepoint Plus

and Pro ammable, toxic and oxygen gas detectors

2

Detector supply 2.4-8.6V, 200mA

constant current.

Maximum loop

resistance: 28 Ohms

Outputs

Relays Alarm 1 Alarm 2 Alarm 3 Fault

Rating SPCO / 3A,

240Vac/30Vdc

(non inductive load)

Default setting Non Latching

Normally de-energized

Energize on alarm

Factory setting 10%FSD

User congurable options Latching/non-latching

Energized/de-energized

Alarm trip point

Rising/falling

Alarm on / off delay (0 to

900 seconds)

Approvals

EMC/RFI EN50270

Electrical safety EN61010

Performance ATEX measuring function EN60079-29-1

SIRA10ATEX8243X

Other CE, TUV.

Input (18-32Vdc)-1.5Vdc,

30mA max.

SPCO / 3A,

240Vac/30Vdc

(non inductive load)

Non Latching

Normally de-energized

Energize on alarm

Factory setting 25%FSD

Latching/non-latching

Energized/de-energized

Alarm trip point Rising/falling

Alarm on / off delay (0 to

900 seconds)

Input (18-32Vdc)-1.5Vdc, 0.5A max.

SPCO / 3A,

240Vac/30Vdc

(non inductive load)

Latching (mV)

Non Latching (mA)

Normally de-energized

Energize on alarm

Factory setting 50%FSD

Latching/non-latching

Energized/de-energized

Alarm trip point

Rising/falling

Alarm on / off delay (0 to

900 seconds)

SPCO / 3A,

240Vac/30Vdc

(non inductive load)

Non Latching

Normally energized

De-energize on fault/

power loss

Latching/non-latching

Energized/de-energized

20

20

Page 21

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

16 Approvals

Unipoint is performance approved to EN60079-29-1 (measuring function) for use with Signalpoint, Sensepoint (Combustible) and any 4-20 mA device.

Caution: Unipoint is a safe area device. It must not be installed in hazardous areas.

Special Conditions of Use

1. The user/installer shall comply with the following environmental restrictions that apply to the

use of this equipment, as stated in the product manual.

Temperature (Equipment): -10°C to 40°C

Temperature (Standard combustible sensor): -40°C to 80°C

Temperature (High temperature sensor): -55°C to 150°C

Humidity: 10% to 90%

Pressure: 90 kPa to 110 kPa

2. The user/installer shall install these products taking into account any restrictions or special

conditions for safe use that are applicable to the previously certied devices that are used in

their construction.

3. When used, the Sensepoint and the Signalpoint Gas detectors shall be powered from Unipoint DIN controller.

21

Page 22

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

17 EC Declaration of Conformity

EC Declaration of Conformity

The undersigned of

Honeywell Analytics Ltd

4 Stinsford Road

Poole, Dorset

BH17 0RZ

UK

Declares that the products listed below

Unipoint Controller (mA input version) 2306B1000

Unipoint Controller (mV input version) 2306B2000

The Unipoint is a simple DIN rail mounted controller offering integrators a flexible and low cost solution to

incorporate flammable, toxic or oxygen gas detection into their control systems.

are in conformity with the provisions of the following European Directive(s), when installed, operated, serviced and maintained in

accordance with the installation/operating instructions contained in the product documentation:

2004/108/EC EMC Directive

2006/95/EC Low Voltage Directive

94/9/EC ATEX Directive – Equipment for use in Potentially Explosive Atmospheres

and that the standards and/or technical specifications referenced below have been applied or considered:

Harmonised Standard Description

EN 50270:2006

BS EN 50271:2002

EN 60079-29-1:2007 Explosive atmospheres. Gas detectors. Performance requirements of detectors for flammable gases

EN 61010-1:2001 Safety requirements for electrical equipment for measurement, control and laboratory use.

Notified Body for ATEX: Certificate Number Quality Assurance Notification Number

Sira Certification Service Sira 10ATEX8243X Baseefa ATEX 5192

Rake Lane

Eccleston Type Approval

Chester II (2)/2 G D

CH4 9JN

Notified Body Number: 0518

Year of CE marking: 2005

Electromagnetic Compatibility – Electrical apparatus for the detection and measurement of combustible

gases, toxic gases or oxygen

Electrical apparatus for the detection and measurement of combustible gases, toxic gases or oxygen.

Requirements and tests for apparatus using software and/or digital technologies

Signature:

Name: Steve Hamilton

Position: Senior Regulatory Compliance Engineer

Date: 9 September 2010

Declaration Number: 2004Y0014_01/A03209

Declaration of Conformity in accordance with EN ISO/IEC 17050-1:2010

22

Page 23

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

18 Notes

23

Page 24

UNIPOINT OPERATING MANUAL 2306M5001 MAN0638 ISSUE 7 01/2011

Find out more

www.honeywellanalytics.com

Contact Honeywell Analytics:

Europe, Middle East, Africa, India

Life Safety Distribution AG

Weiherallee 11a

CH-8610 Uster

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

gasdetection@honeywell.com

Americas

Honeywell Analytics Inc.

405 Barclay Blvd.

Lincolnshire, IL 60069

USA

Tel: +1 847 955 8200

Toll free: +1 800 538 0363

Fax: +1 847 955 8210

detectgas@honeywell.com

Asia Pacific

Honeywell Analytics Asia Pacific

#508, Kolon Science Valley (I)

187-10 Guro-Dong, Guro-Gu

Seoul, 152-050

Korea

Tel: +82 (0)2 6909 0300

Fax: +82 (0)2 2025 0329

analytics.ap@honeywell.com

Technical Services

EMEAI: HAexpert@honeywell.com

US: ha.us.service@honeywell.com

AP: ha.ap.service@honeywell.com

www.honeywell.com

Please Note:

While every effort has been made to ensure

accuracy in this publication, no responsibility

can be accepted for errors or omissions.

Data may change, as well as legislation, and you

are strongly advised to obtain copies of the most

recently issued regulations, standards, and guidelines.

This publication is not intended to form the

basis of a contract.

Issue 7 01/2011

H_MAN0638_V7

2306-M-5001 ECO A03469

© 2011 Honeywell Analytics

11197

24

Loading...

Loading...