Page 1

UMC800 Controller

Installation and User Guide

Doc. No.: 51-52-25-61

Release: F

Last Revision Date: 4/01

Sensing and Control

Page 2

Notices and Trademarks

Copyright 2001 by Honeywell

Release F April, 2001

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact

your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of

coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer’s sole

remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and

fitness for a particular purpose. Specifications may change without notice. The information we supply is believed

to be accurate and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Sensing and Control

Honeywell

11 West Spring Street

Freeport, Illinois 61032

Honeywell is a U.S. registered trademark of Honeywell

Other brand or product names are trademarks of their respective owners.

ii UMC800 Controller Installation and User Guide Release F

4/01

Page 3

About This Document

Abstract

This document provides descriptions and procedures for the installation, operation and maintenance of the UMC800

Controller hardware.

References

The following list identifies all documents that may be sources of reference for material discussed in this

publication.

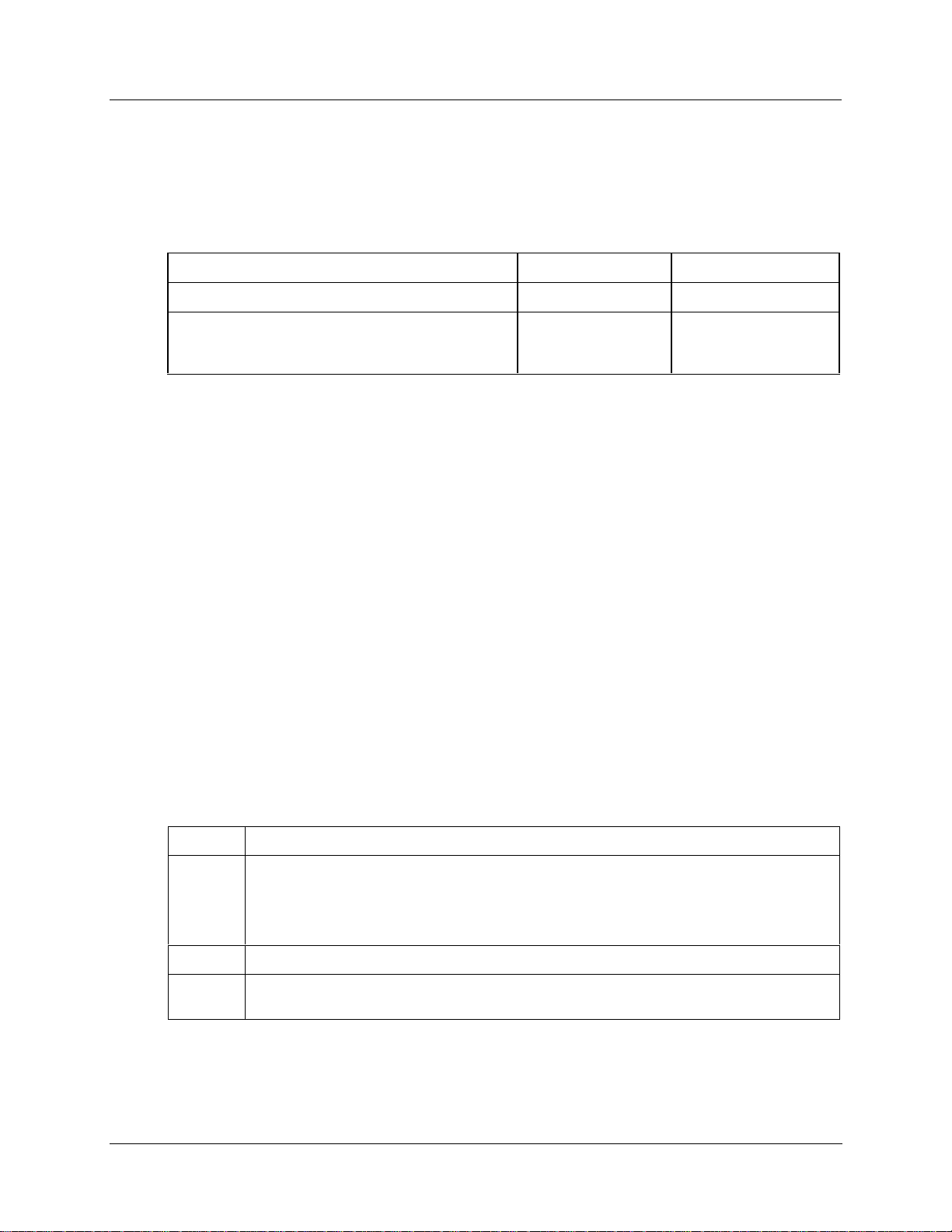

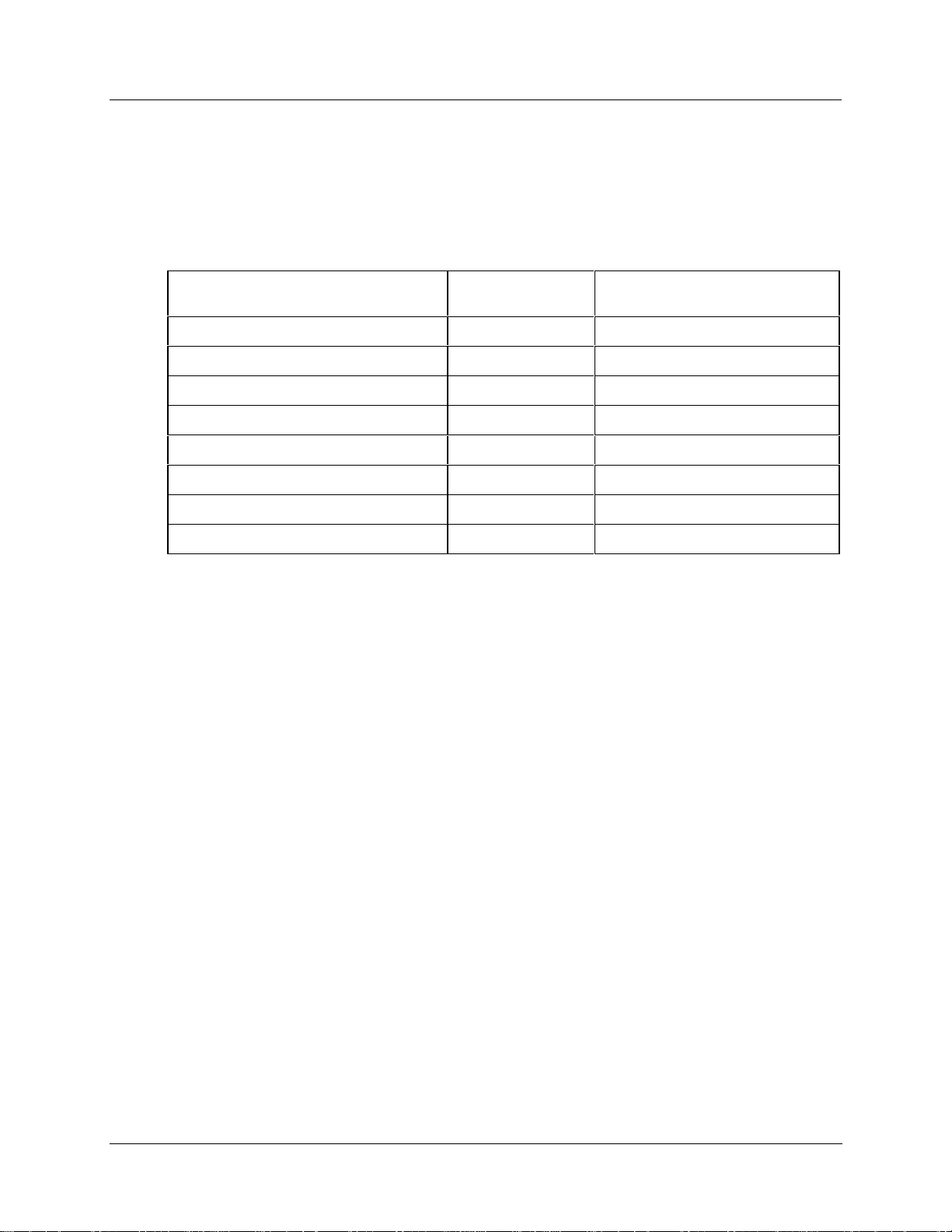

Document Title ID #

UMC800 Technical Overview Specification 51-52-03-24

UMC800 Operator Interface User Guide 51-52-25-62

UMC800 Control Builder User Guide 51-52-25-63

UMC800 Function Block Reference Guide 51-52-25-64

UMC800 RS232 Communications Reference Manual 51-52-25-76

UMC800 User Utility User’s Guide 51-52-25-77

Modbus® RTU Serial Communications User Manual 51-52-25-87

How to Apply Digital Instrumentation in Severe Electrical Noise Environments 51-52-05-01

Contacts

World Wide Web

The following lists Honeywell’s Wor ld Wide Web sites that will be of interest to our customers.

Honeywell Organization WWW Address (URL)

Corporate

Sensing and Control

International

Telephone

Contact us by telephone at the numbers listed below.

Organization Phone Number

United States and Canada Honeywell 1-800-423-9883 Tech. Support

Asia Pacific

Europe Honeywell PACE, Brussels, Belgium [32-2] 728-2111

Latin America Honeywell, Sunrise, Florida U.S.A. (954) 845-2600

Honeywell Asia Pacific

Hong Kong

http://www.honeywell.com

http://www.honeywell.com/sensing

http://www.honeywell.com/Business/global.asp

1-888-423-9883 Q&A Faxback

(TACFAQS)

1-800-525-7439 Service

(852) 2829-8298

Release F UMC800 Controller Installation and User Guide iii

4/01

Page 4

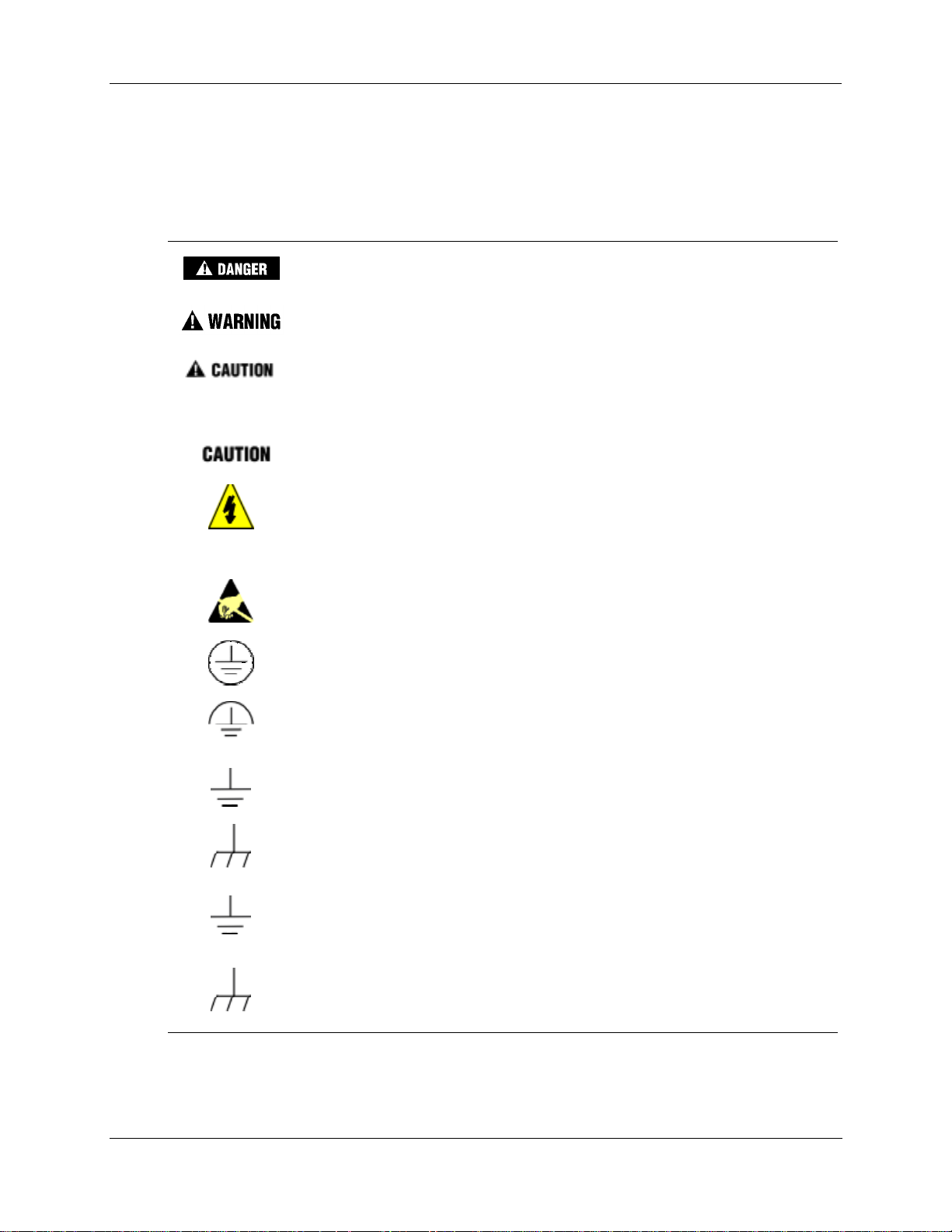

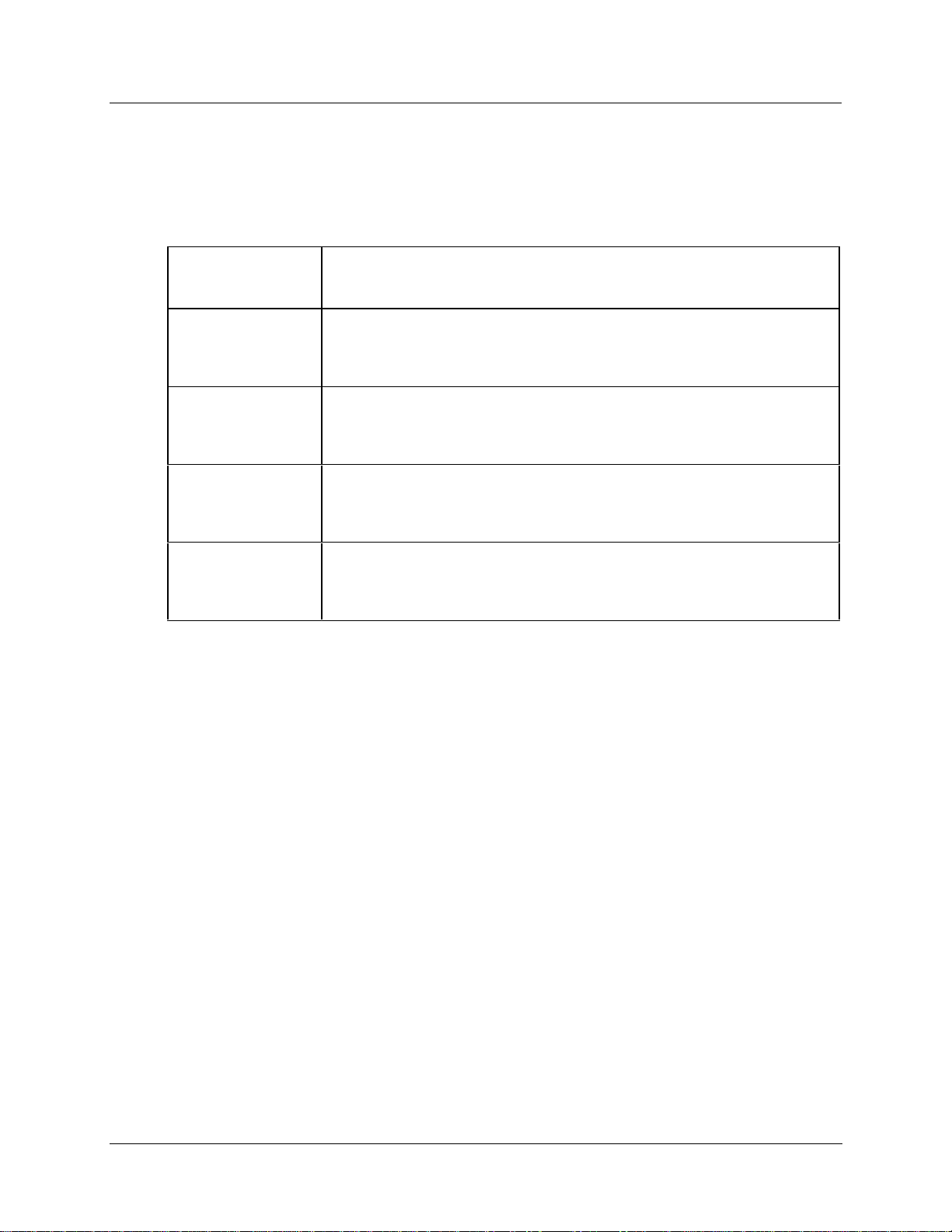

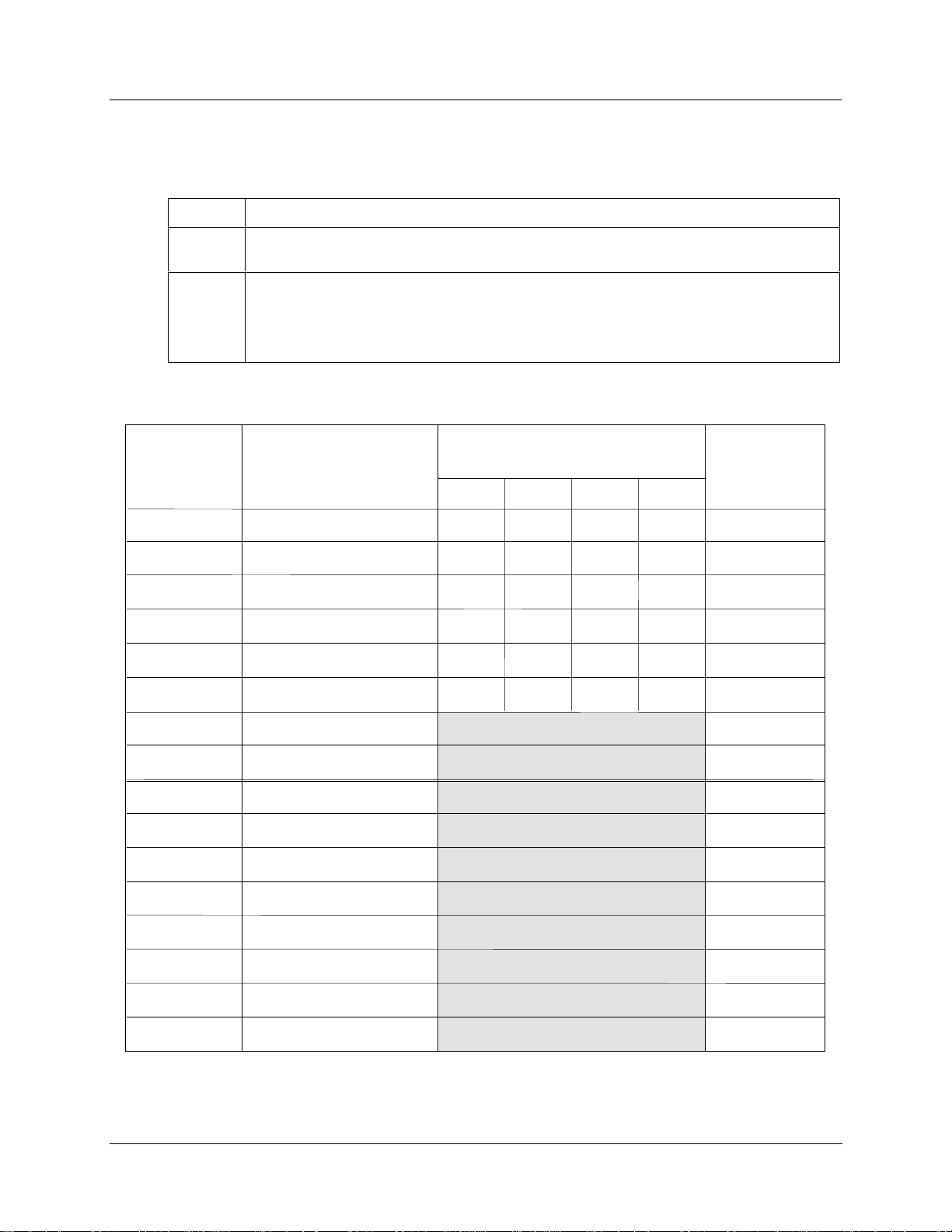

Symbol Definitions

The following table lists those symbols that may be used in this do cument to denote certain conditions.

Symbol Definition

This DANGER symbol indicates an imminently hazardous situation, which,

if not avoided, will result in death or serious injury.

This WARNING symbol indicates a potentially hazardous situation, which, if

not avoided, could result in death or serious injury.

This CAUTION symbol may be present on Control Product instrumentation

and literature. If present on a product, the user must consult the

appropriate part of the accompanying product literature for more

information.

This CAUTION symbol indicates a potentially hazardous situation, which, if

not avoided, may result in property damage.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms,

42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these

instructions could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

Protective Earth (PE) terminal. Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requir eme nts.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requir eme nts.

iv UMC800 Controller Installation and User Guide Release F

4/01

Page 5

Contents

Introduction.............................................................................................1

Purpose........................................................................................................................1

UMC800 Controller ......................................................................................................2

CE Conformity (Europe)...............................................................................................2

UMC800 Overview.................................................................................. 3

UMC800 Description....................................................................................................3

Feature Summary.........................................................................................................4

Equipment Identification..........................................................................5

Controller Components ................................................................................................5

Operator Interface........................................................................................................7

Control Builder..............................................................................................................8

Serial Communication Ports.......................................................................................10

Pre-Installation Considerations............................................................. 11

Introduction.................................................................................................................11

Mounting and Wiring.............................................................................15

Site Preparation..........................................................................................................15

Mounting the Controller..............................................................................................16

Plug-in Module Locations...........................................................................................18

Signal Wiring..............................................................................................................23

Wiring Communication Links......................................................................................36

Remote Access..........................................................................................................44

Power Supply Wiring..................................................................................................51

Operation..............................................................................................52

Power Up / Power Down............................................................................................52

Operational Modes and Controls ...............................................................................53

File Downloading........................................................................................................56

Code Download..........................................................................................................57

Warm Start / Cold Start ..............................................................................................58

Status Indicators.........................................................................................................59

RS 485 Port Configuration (Communication Board Option) ......................................61

Release F UMC800 Controller Installation and User Guide v

4/01

Page 6

Maintenance .........................................................................................63

Overview ....................................................................................................................63

Routine Maintenance .................................................................................................64

Controller Calibration .................................................................................................65

Replacement Procedures...........................................................................................70

Diagnostics and Troubleshooting..........................................................79

Overview ....................................................................................................................79

Controller Diagnostics ................................................................................................79

Fault Detection and Troubleclearing..........................................................................81

Parts List...............................................................................................91

UMC800 Controller ....................................................................................................91

Specifications........................................................................................93

Introduction.................................................................................................................93

Controller Design........................................................................................................93

I/O Module Configuration...........................................................................................93

Design........................................................................................................................97

Environmental and Operating Conditions ..................................................................99

PV Inputs..................................................................................................................100

Multilanguage Safety Sheets

Service Centers

vi UMC800 Controller Installation and User Guide Release F

4/01

Page 7

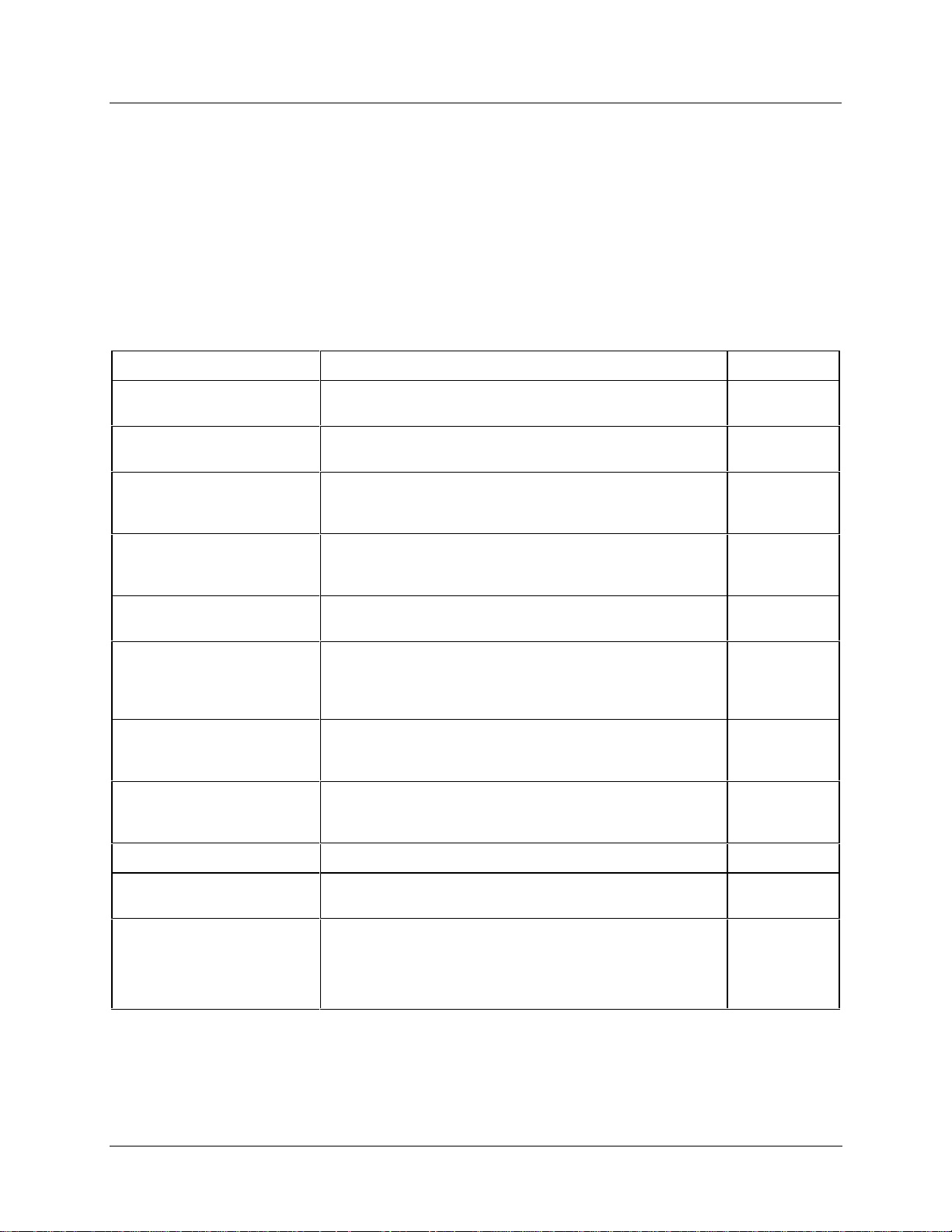

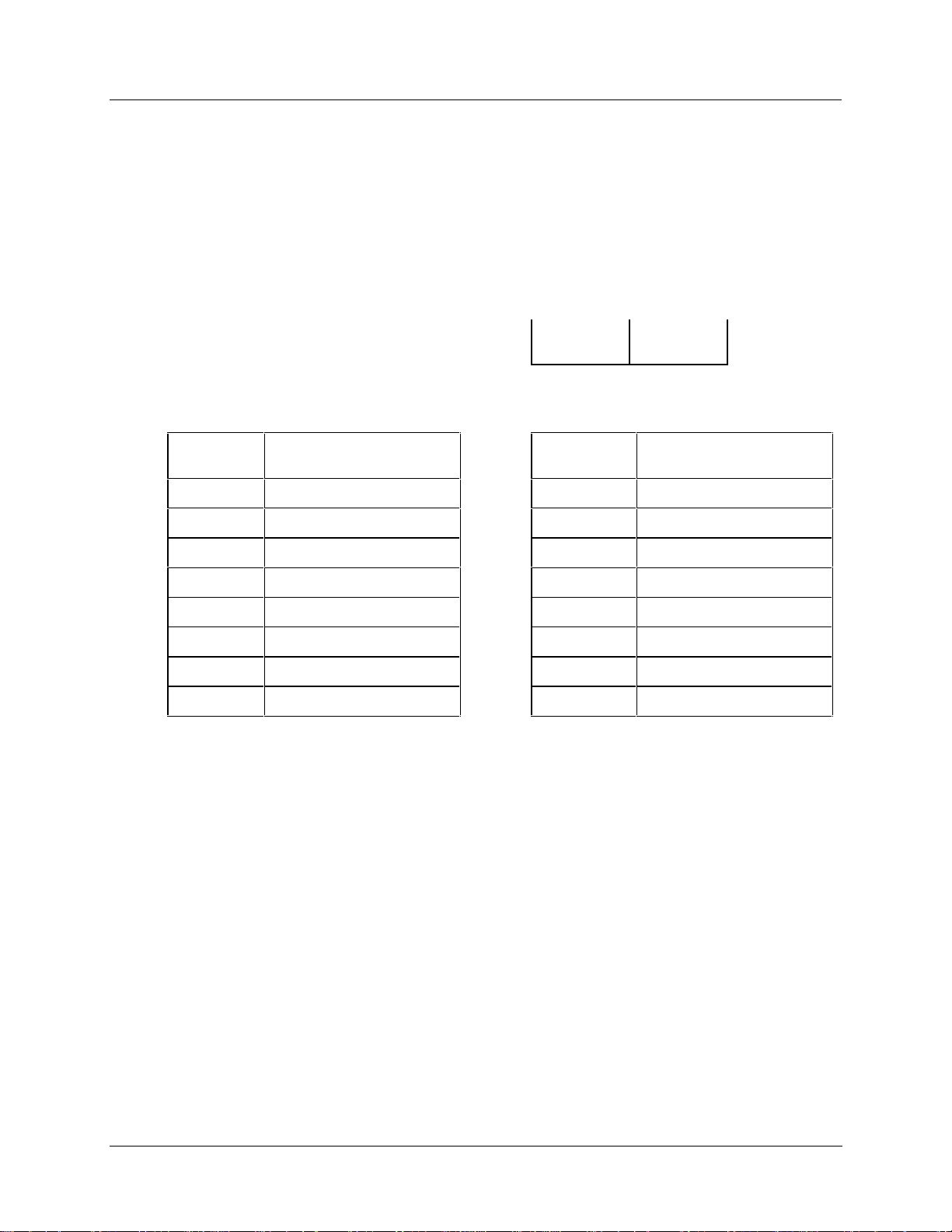

Tables

Table 1 Controller plug-in I/O module types................................................................................................................6

Table 2 Communication port descriptions..................................................................................................................10

Table 3 Operating limits.............................................................................................................................................11

Table 4 Permissible wiring bundles............................................................................................................................ 13

Table 5 Power supply input requirements...................................................................................................................16

Table 6 I/O module identification...............................................................................................................................19

Table 7 I/O module installation limitations................................................................................................................20

Table 8 I/O module identification record....................................................................................................................22

Table 9 Universal analog input module specifications...............................................................................................25

Table 10 Summary of communication link connections to controller........................................................................37

Table 11 Configuration connector pinouts..................................................................................................................37

Table 12 Null modem cable construction...................................................................................................................38

Table 13 Operator interface connector pinouts...........................................................................................................40

Table 14 Power supply wiring....................................................................................................................................51

Table 15 Controller mode switch summary................................................................................................................55

Table 16 Controller downloading summary...............................................................................................................56

Table 17 Scan rates per inputs configured ..................................................................................... .............................58

Table 18 Controller status LEDs.................................................................................................................................59

Table 19 Controller status LEDs.................................................................................................................................80

Table 20 Details of the diagnostic summary display............................................................................ ......................81

Table 21 Details of the I/O module diagnostics display.............................................................................................87

Table 22 Controller modem troubleshooting..............................................................................................................89

Release F UMC800 Controller Installation and User Guide vii

4/01

Page 8

Figures

Figure 1 UMC800 components.....................................................................................................................................3

Figure 2 UMC800 controller hardware.........................................................................................................................5

Figure 3 551 operator interface.....................................................................................................................................7

Figure 4 552 operator interface.....................................................................................................................................7

Figure 5 1041 operator interface...................................................................................................................................7

Figure 6 Typical Control Builder graphic display ........................................................................................................8

Figure 7 UMC800 controller enclosure......................................................................................................................15

Figure 8 UMC800 controller enclosure dimensions...................................................................................................17

Figure 9 UMC800 controller plug-in slots..................................................................................................................18

Figure 10 I/O module PWA and terminal...................................................................................................................19

Figure 11 I/O module terminal block (all except 16 point DI) ...................................................................................23

Figure 12 Field wiring shield termination...................................................................................................................24

Figure 13 AI module terminal block connections.......................................................................................................25

Figure 14 Recommended wiring for one pH sensor input..........................................................................................26

Figure 15 AO module terminal block connections.....................................................................................................27

Figure 16 DI module terminal block connections.......................................................................................................29

Figure 17 DO module terminal block connections.....................................................................................................30

Figure 18 DO module relay contact setting................................................................................................................31

Figure 19 PI/FI module terminal block connections....................................................................................................32

Figure 20 PI/FI Module Input Filter Cutoff Frequency setting...................................................................................33

Figure 21 Pulse / Frequency Input Connections..........................................................................................................33

Figure 22 Pulse / Frequency card digital output connections ......................................................................................35

Figure 23 Communication port connectors.................................................................................................................36

Figure 24 Ferrite clamp installation............................................................................................................................39

Figure 25 Terminal connections.................................................................................................................................41

Figure 26 COMM A and B port wiring (2-wire and 4-wire)......................................................................................42

Figure 27 RS 485 port wiring (2 wire)........................................................................................................................43

Figure 28 Power supply terminal connections............................................................................................................51

Figure 29 Controller mode switch location.................................................................................................................54

Figure 30 Controller status LEDs...............................................................................................................................60

Figure 31 COMM A and B ports on CPU module......................................................................................................61

Figure 32 Controller components that contain calibration values...............................................................................66

Figure 33 AI module terminal block...........................................................................................................................68

Figure 34 AO module jumper ST1.............................................................................................................................69

Figure 35 Controller components and location...........................................................................................................70

Figure 36 Power supply fuse and CPU battery location.............................................................................................72

Figure 37 I/O module terminal blocks (not shown: 16 point DI)................................................................................75

viii UMC800 Controller Installation and User Guide Release F

4/01

Page 9

Purpose

This Installation and User guide assists in the installation, start up, operation, maintenance and

troubleshooting of the UMC800 Controller.

The information in this guide is organized as follows:

Introduction

Purpose

Introduction

Topic Description Page

UMC800 Overview

Equipment Identification A high-level physical and functional description of the

Pre-installation

Considerations

Mounting and Wiring Information and procedures to successfully install the

Installation Checkout and

Power Up

Operation Power up and power down routines, operational modes and

Maintenance Procedures are given covering routine maint enan ce and the

Diagnostics and

Troubleshooting

Provides a concise description of the UMC800 control

system, its applications, architecture and its features

UMC800 components

Lists a number of things to consider when planning the

controller installation. Environmental factors as well as

methods to minimize interference are dis cu sse d.

UMC800 controller and its components. Interconnecting

wiring to other UMC800 components is also covered.

Provides a checklist to complete before power up. Covers

power up procedure.

controls, software download routines, warm and cold start

routines, Status LEDs, and scan rates are covered in this

section.

replacement of controller componen ts. Infor mat ion on I/O

module calibration is presented.

Provides description of controller status and error conditions.

Provides corrective actions necessary to clear fault

conditions.

3

5

11

15

44

52

63

79

Parts List A list of replacement parts for the controller. 91

Specifications

Supplemental Installation

Information

Release F UMC800 Controller Installation and User Guide 1

4/01

Summary of electrical, physical, environmental and

performance specification s.

Provides helpful information for installing digital equipment in

severe electrical noise environments.

Refer to document 51-52-05-01 How to Apply Digital

Instrumentation in Severe Electrical Noise Environments.

93

––

Page 10

Introduction

UMC800 Controller

UMC800 Controller

The UMC800 is industrial process control equipment that must be mounted. The wiring terminals must be

enclosed within a panel.

CE Conformity (Europe)

This product is in conformity with the protection requirements of the following European Council

Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC Directive. Conformity of

this product with any other “CE Mark” Directive(s) shall not be assumed.

Deviation from the installation conditions specified in this manual, and the following special conditions,

may invalidate this product’s conformity with the Low Voltage and EMC Directives.

ATTENTION

The emission limits of EN 50081-2 are designed to provide reasonable protection against

harmful interference when this equipment is operated in an industrial environment. Operation

of this equipment in a residential area may cause harmful interference. This equipment

generates, uses, and can radiate radio frequency energy and may cause interference to radio

and television reception when the equipment is used closer than 30 meters (98 feet) to the

antenna(e). In special cases, when highly susceptible apparatus is used in close proximity, the

user may have to employ additional mitigating measures to further reduce the electromagnetic

emissions of this equipment.

2 UMC800 Controller Installation and User Guide Releas e F

4/01

Page 11

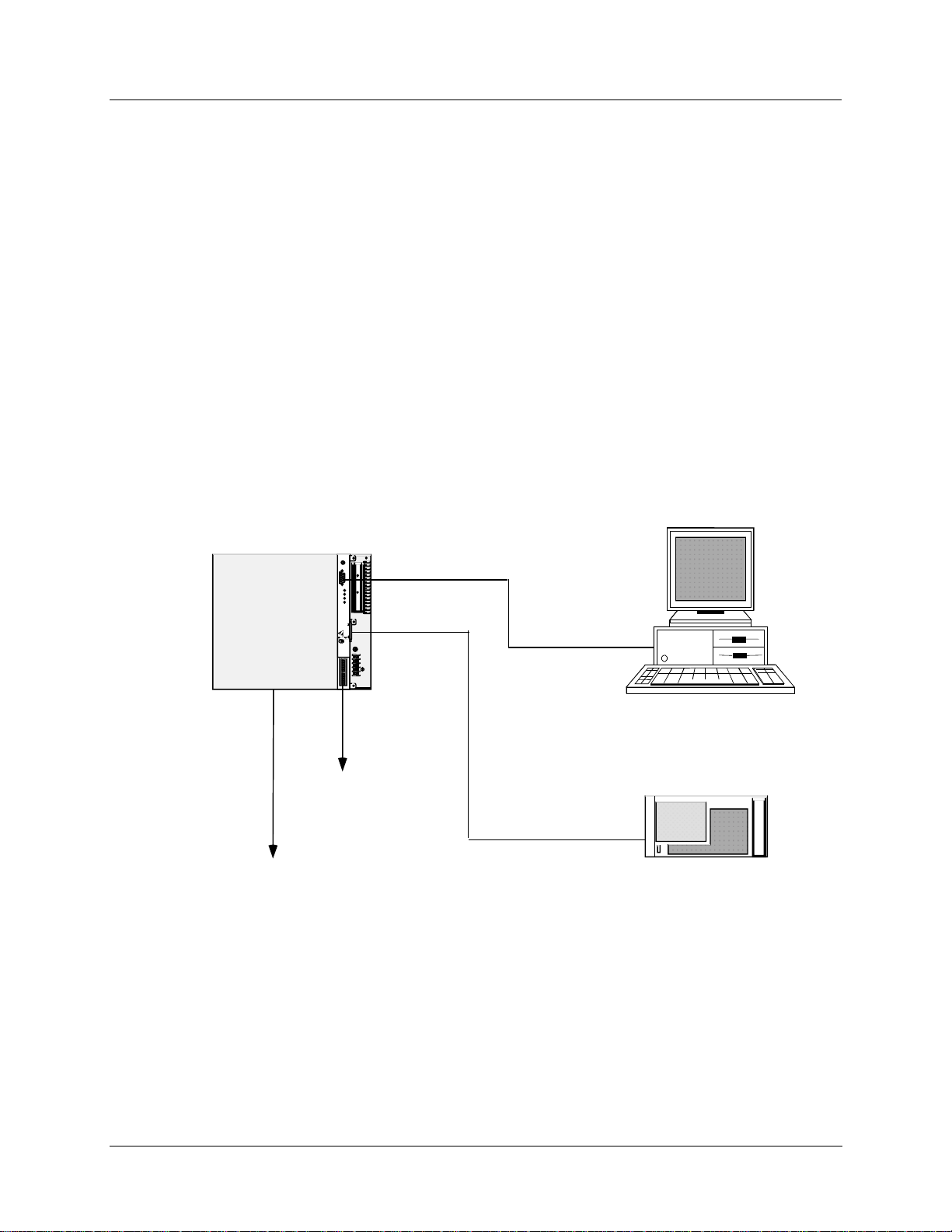

UMC800 Description

The Universal Multiloop Controller (UMC800) is a modular controller designed to address the analog and

digital control requirements of small unit processes. With up to 16 analog control loops, four setpoint

programmers, and an extensive assortment of analog and digital control algorithms, the UMC800 is an

ideal control solution for furnaces, environmental chambers, ovens, reactors, cookers, freeze dryers,

extruders, and other processes with similar control requirements.

Accommodating up to 64 universal analog inputs, 16 analog outputs, and 96 digital inputs/outputs, the

UMC800 provides the appropriate balance of input and output hardware for these smaller unit processes.

The UMC800 uses separate hardware for control functions and operator interface functions to provide

greater installation flexibility. See Figure 1. The controller incorporates card slots capable of supporting up

to 16 input and output modules that can be mixed to satisfy the hardware requirements of a specific

application. The operator interface uses a color graphic LCD display to provide a variety of display

presentations for viewing control loops, setpoint programs, and other analog and digital status.

UMC800 Overview

UMC800 Description

UMC800 Overview

PC or Laptop with

Control Buil der

Conf igura tion Sof twa re,

On -Li n e H el p an d

User Utility So ftware

UMC800

Co ntroller

OFFLINE

RUN

PROG RAM

CONFIGURATI ON

POWER

LoBA T

FORC E

RUN

Replac e batte ry with T adiran T L510 1/S

See users gui de for ins truct ions.

only. Use of another battery m ay

present a ris k of fir e or expl osio n.

_

DISP LAY

100 - 230 V ~

BAT

50 / 60 Hz

100 VA MAX.

F 3,15 A T

L1

L2 /

N

COMM B COMM A

RS 485 Serial

Communications with

Modbus RTU Protocol

(Option al)

To Field

Devices

Operator Int erface

Figure 1 UMC800 components

A separate “Control Builder” configuration software program is used for system configuration that

operates on a Windows 95- or NT-based PC. The software program uses graphic symbols and line drawing

connections to create custom control strategies. Menus are provided in the software to allow selection of

screens for the operator interface and to customize screen access methods and operator keys. Completed

configurations are loaded into the control system using a dedicated communications port in the controller,

or optionally, via floppy disk. A separate User Utility software program (also running on a PC) is used to

create, edit, save, open and download individual recipe, profile and data storage files. Calibration of the

analog input and output modules can be performed through this utility program. A modem connection

Release F UMC800 Controller Installation and User Guide 3

4/01

Page 12

UMC800 Overview

Feature Summary

through the Configuration port allows remote access to the controller via the Control Builder and User

Utility programs. This will enable trouble shooting, configuration c hanges and firmware upgrade.

The optional communications board adds two bi-directional, multi-drop RS 485 serial communication

interfaces to the controller CPU module. The COMM A port uses Modbus RTU protocol and is a

master/slave link allowing up to 31 controllers to be connected to a single host computer. The computer

initiates all communication. COMM B port allows the controller to operate as a master device to up to 16

slave Modbus compatible devices. Data transferred through this port is integrated into the user’s control

strategy through read and write function blocks. Applications might include writing controller data (set

points, process variables, etc.) to a strip chart recorder to produce a hard copy of process performance, or to

read data from other controllers.

Feature Summary

• Up to 16 control loops, including:

− Proportional Integral Derivative (PID),

− ON/OFF,

− Three Position Step Control (TP SC) , and

− Carbon Potential.

• Auto-tuning for each control loop

• Up to 64 Universal Analog Inputs

• Up to 16 Analog Outputs

• Up to 96 Digital Inputs/Outputs

• Up to 50 Recipes with up to 50 variables each

• Up to 4 Setpoint Programmers, 3500 total segments

• Setpoint Profile and Recipe storage, up to 70 programs

• Setpoint Scheduler, 10 stored schedules

• Function Block Graphic Configuration with up to 250 blocks

• Large assortment of algorithms for combination of analog and logic functions

• Extensive Alarm and Event monitoring

• Operator interface with a selection of graphic displays

• Carbon Potential, Dewpoint and Relative Humidity Co ntro l

• Optional 3-1/2” floppy disk drive for data archiving, setpoint program and recipe storage

• Universal Power (100 to 240 Vac or Vdc) or 24 VA RH)

• UL, CE, and CSA approved, Y2K compliant C/DC (optional)

• Industrial Operating Range (0 °C to 55 °C, 10 % to 90 %

• UL, CE, and CSA Approved, Y2K compliant

4 UMC800 Controller Installation and User Guide Releas e F

4/01

Page 13

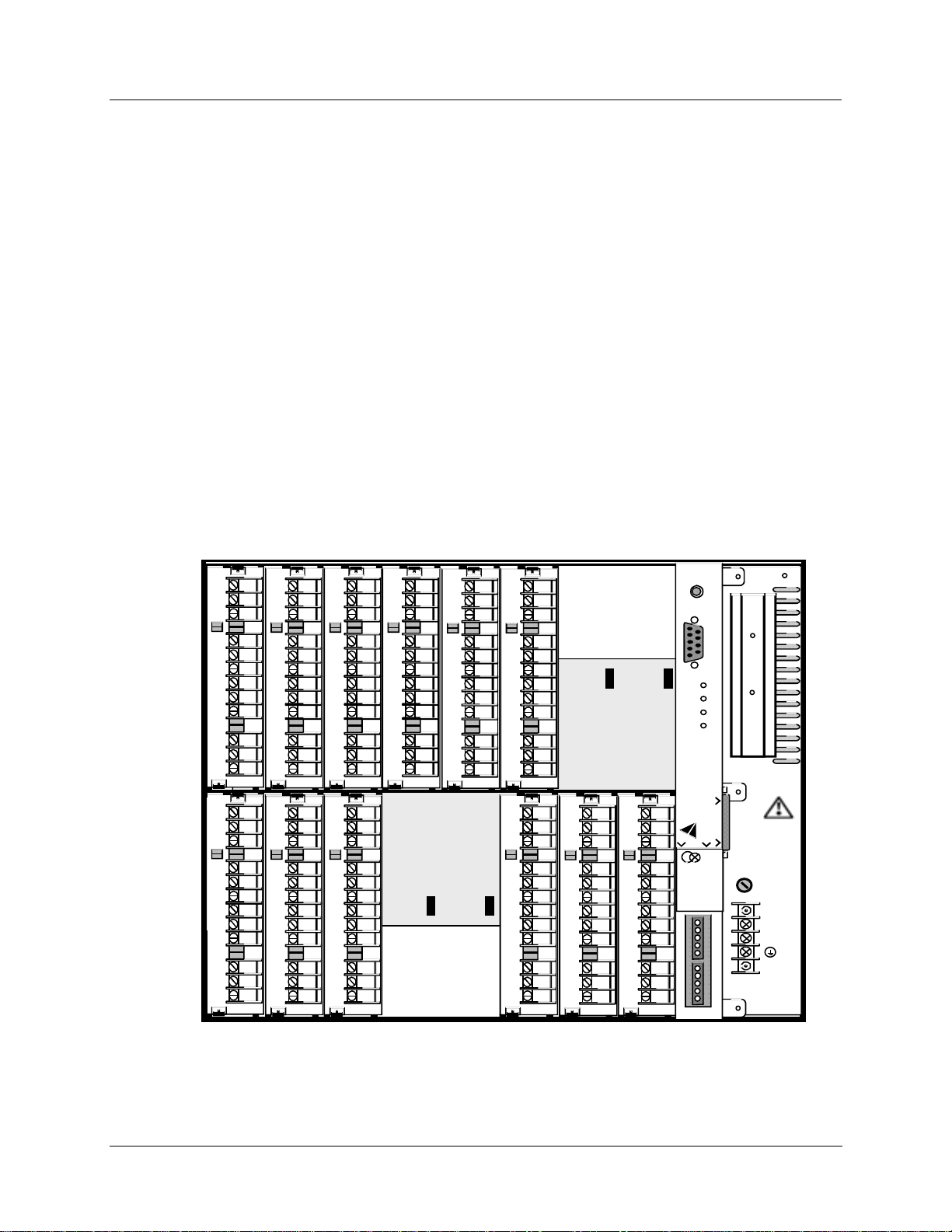

Equipment Identification

Controller Components

Enclosure

The UMC800 controller illustrated in Figure 2 consists of a single metal enclosure that houses the

following controller components:

• Power supply module that plugs into the controller common backplane.

• CPU module with two serial communications ports. An optional communications board provides two

RS485 serial communication ports (slave and master) that support Modbus® RTU protocol.

• Backplane assembly capable of supporting up to 16 input or output modules.

• Various types of I/O processing modules that plug into the common backplane.

• Removable terminal blocks that connect the I/O modules with the field wiring.

Equipment Identification

Controller Components

• Battery back-up power for RAM and real time clock in the event of power interruption.

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

12

11

10

9

8

7

6

5

4

3

2

1

OFFLINE

RUN

PROGRAM

POWER

LoBAT

FORCE

RUN

Replace battery with Tadiran TL5101/S

only. Use of another battery may

present a risk of fire or explosion.

See user’s guide for instructions.

BAT

CONFIGURATION

_

100 - 240 V ~

DISPLAY

50 / 60 Hz

100 VA MAX.

COMM B COMM A

F 3,15 A T

250V

L1

L2 / N

Figure 2 UMC800 controller hardware

Release F UMC800 Controller Installation and User Guide 5

4/01

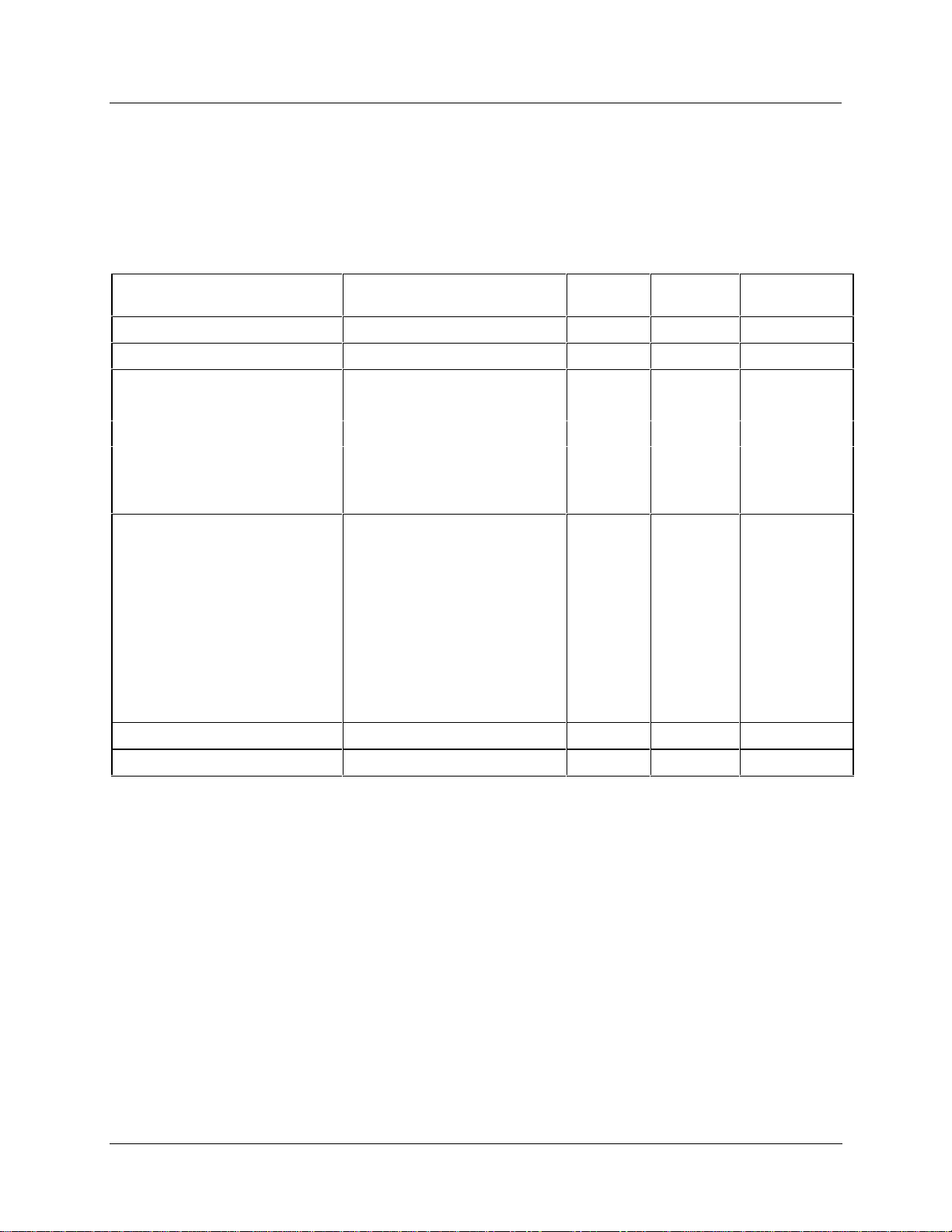

Page 14

Equipment Identification

Controller Components

I/O modules

Eleven different module types can be installed in the controller to support both analog and digital inputs

and outputs of various types and signal levels. The signal type and I/O capacity for each module type is

indicated in Table 1.

Table 1 Controller plug-in I/O module types

Module Type Signal Types Maximum

I/O

Universal Analog Inputs (AI) mV, V, mA, T/C, RTD, Ohms 64 4 16

Analog Outputs (AO) 0 mA to 20 mA 16 4 4

Digital Inputs (DI) - 4 types:

AC 100/240 Vac 96 6 16

DC 24 Vdc 96 6 16

Logic Dry contacts

(5 mA - 5 Vdc)

16 point Dry contacts 48 16 3

Digital Outputs (DO) - 4 types:

AC 100/240 Vac 96 6 16

AC

High current outputs

DC 24 Vdc 96 6 16

Relay SPST normally open (NO) or

Pulse Input/Frequency Input 24 Vdc 64 4 16

100/240 Vac

With:

2 outputs rated @ 2 A

4 outputs rated @ 0.5 A

normally closed (NC) contact.

(User configurable)

96 6 16

12 2 12

60 6 10

I/O per

card

Maximum no.

of cards

pH Power Module ± 15 Vdc 8 4 2

NOTE: Total combined digital I/O is 96 points.

Control architecture

The UMC800 uses a function block configuration architecture to develop control strategies for both analog

and digital operations. A function block may represent a physical input or output, a group of physical inputs

or outputs, an internal calculation, or an internal function such as a PID algorithm. More than 70 standard

UMC800 function block algorithm types are available for configuring analog and logic functions.

Typically, a function block algorithm type may be used any number of times up to the limit of 250 blocks.

Some of these with specific limitations are:

• Control loops (i.e., PID, ON/OFF, TPSC, and Carbon potential)—eight or sixteen maximum

• Setpoint programmer and associated support blocks—four maximu m

• Setpoint Scheduler and associated support blocks—one maximum

• Time proportioning output blocks—sixteen maximum

• Pushbutton blocks—four maximu m

• 4 Selector Switch blocks—four maximum

• Modbus Slave blocks—sixteen maximum

6 UMC800 Controller Installation and User Guide Releas e F

4/01

Page 15

Operator Interface

The UMC800 operator interface (Figure 3, Figure 4, and Figure 5) provides a graphic LCD display and a

monoplaner keyboard to allow operator access to all controller functions. The operator interface becomes

operational once a valid database is configured in the controller. Modification and customization of the

operator interface is performed using Control Builder software. With the software, data points can be

identified (tagged) using eight character names. Once named, these data points may be accessed by the

operator interface using a standard set of display formats and a predefined menu hierarchy. Customized

display access and the assignment of selected displays to keyboard buttons may be developed using Control

Builder software. Selected displays such as bargraphs, trends, and overview displays will require the user to

specify the individual data points to be represented on the display.

Equipment Identification

Operator Interface

F1

F2

F3

ESC

F4

1 2 3 4 5

Figure 3 551 operator interface

?

ALARM

Honeywell

F1

F2

F3

F4

KB

1 2 3 4 5

ESC

?

ALARM

Figure 4 552 operator interface

7 8 9

F1

4 5 6

1 2 3

F2

0 . -

F3

F4

?

ESC

1 2 3 4 5 6 7 8

Figure 5 1041 operator interface

Release F UMC800 Controller Installation and User Guide 7

4/01

Page 16

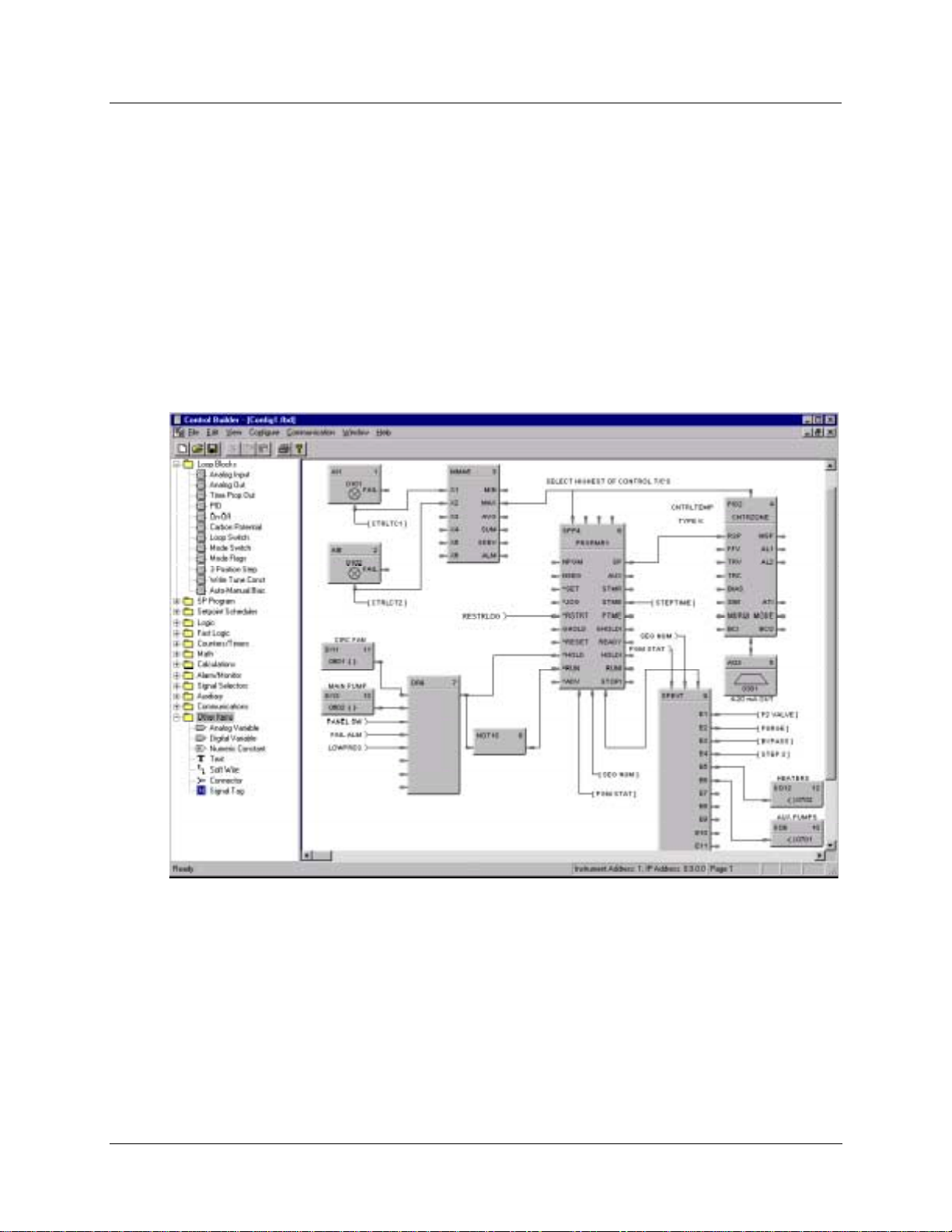

Equipment Identification

Control Builder

Control Builder

All controller and operator interface configuration is performed using Control Builder software on a

separate PC operating with Windows

TM

95 or WindowsTM NT 4.0. All configuration is performed off-line

(computer disconnected from the controller and operator interface). The configuration is downloaded in a

separate operation as a complete file through a dedicated RS-232 communication port on the controller.

Once a configuration is installed into the controller and operator interface, the Control Builder software

may be used to monitor areas of the configuration to verify proper op eration. Co ntro ller configuration

development is performed using "Drag and Drop” techniques for positioning graphic icons on a CRT

display from a list of available functions. See Figure 6. Signal flow connectio ns from icon to icon complete

the controller configuration. The Control Builder software will create a graphic dia gram 1 page high by 20

pages wide. The completed diagram may be printed on 20 pages of 8.5" x 11.5" paper. Each configuration

is saved as a single PC file. Multiple files may be saved o n the PC. The Control Builder can concurrently

open multiple configuration files.

Figure 6 Typical Control Builder graphic display

8 UMC800 Controller Installation and User Guide Releas e F

4/01

Page 17

Completed configurations may also be saved on 3.5" floppy disk and loaded into the controller and

operator interface through an optional 3.5" floppy disk drive, eliminating the need for a direct connection of

a PC to the controller.

Each analog signal flow line of the configuration may be labeled with an 8-character name, 4-character

engineering unit definition, and may have a decimal point location specified. Digital signal lines may be

identified with an 8-character name and 6-character ON and OFF label.

Signal tag descriptions are used by the operator interface to present on-line status.

Control Builder software may also be used to reconstruct a n existing controller configuration by uploading

the configuration from the controller for maintenance or diagnostic purposes.

Operator Interface configuration is performed by identifying values to show on predefined display

templates and defining the display access buttons.

Control Builder on-line help

Equipment Identification

Control Builder

The on-line help system provides a convenient and quick way to look up any task you are performing in the

Control Builder program. This Windows

any time you request help, a help topic appears that pertains to where you are in the program. For example,

if you are focused on a particular program window, you will get a help topic that describes that window. If

you are in a particular dialog box or entry field, you will get a help topic that describes that dialog box or

entry field.

Within a help window there may be hotspots which are shown as highlighted text. If you cl ick on the

highlighted text, a pop-up box with a definition or a separate window of information that corresponds to the

designated hotspot topic will appear.

The help menu, which is accessible from any main menu, can be used to display an index and the contents

of all help topics in the program.

A right-click on a Function Block provides topic help for that block.

User utility

A separate user utility program is available, which is a windows-based program, and is designed for enduser administration tasks of the UMC800. This utility allows you to create, edit, and download recipes,

setpoint profiles, setpoint schedules and data storage files. Controller files can be downloaded and uploaded

at the PC. Using the communications menu and dialog boxes, communications parameters can be setup to

match your PC communications settings. A loopback test can be initiated to verify communications

between your PC and the controller, and an error summary provides data for troubleshooting

communications problems. The maintenance menu provides access to controller diagnostic data and allows

users to initiate calibration of selected I/O modules.

help system offers context-sensiti ve he lp which means that at

Release F UMC800 Controller Installation and User Guide 9

4/01

Page 18

Equipment Identification

Serial Communication Ports

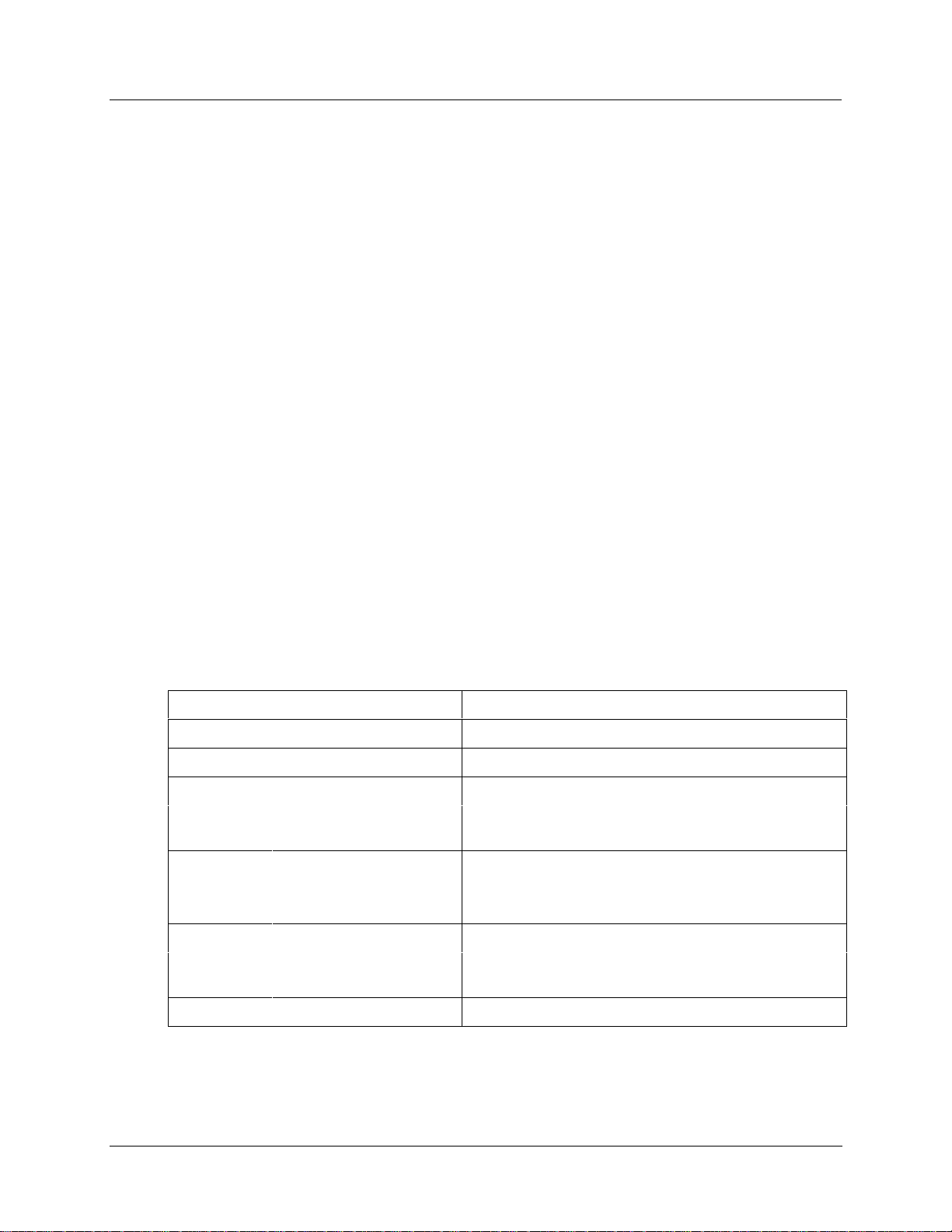

Serial Communication Ports

The controller contains dedicated serial ports for external communications. These are described in Table 2.

Table 2 Communication port descriptions

Communication

Port

(on CPU Module)

Configuration

Display

COMM A

(with optional

communication

board)

COMM B

(with optional

communication

board)

Description

Configuration Port - This RS232 port is a dedicated connection for

communications with a PC running the Control Builder configuration program .

The communications link layer protocol is proprietary. Communication is

through a null modem cable or through a modem.

This RS 422 port is a dedicated connection for communications with the

operator interface. Separate power leads included in the cable also supply

power to the operator interface. The communications link layer is proprietary

and not intended for external use.

RS 485 Serial communication port using Modbus RTU protocol. This port allows

the controller to operate as a slave device on a multi-drop bus with up to 31

other UMC800 controllers and Modbus compatible devices. A PC host can be

connected to the bus and used for controller configuration and monitoring tasks.

RS 485 Serial communication port using Modbus RTU protocol. This port allows

the controller to operate as a master device to up to 16 slave Modbus

compatible devices. Data transferred through this port is integrated into the

user’s control strategy through read and write function blocks.

10 UMC800 Controller Installati on and User Guide Release F

4/01

Page 19

Introduction

Installation of the controller consists of mounting and wiring the controller according to the guidelines

given in this section. The controller is industrial control equipment that must be panel mounted within an

enclosure. The wiring terminals must be enclosed within the enclosure.

Read the pre-installation information, check the model number interp r etation [Controller model number

(page 21)], and become familiar with your model selections, then proceed with installation.

While the UMC800 has been designed for use in most industrial environments, there are certain

requirements that should be considered regarding installation and wiring to ensure optimum performance.

Many of the problems associated with electronic control equipment can be traced to the primary ac power

system. Disturbance, such as electrical noise, power interruptions, and lightning, must be factored into the

planning of the primary power system so the control equip ment will perform satisfactorily and

continuously.

In addition to the precaution of the separation of signal and power wiring in separate conduits, this section

suggests some other measures that can be taken to minimize the effects of electromagnetic interference

(EMI) and radio frequency interference (RFI), voltage surges and static electricity.

Pre-Installation Considerations

Introduction

Pre-Installation Considerations

Operating limits

We recommend that you review and adhere to the operating limits listed in Table 3 when you install the

controller.

Ambient Temperature

Relative Humidity 10 % to 90 % RH at 40 °C (104 °F)

Vibration

Mechanical Shock

Power

Power Consumption 100 VA Maximum

Table 3 Operating limits

Condition Specifications

32 °F to 131 °F (0 °C to 55 °C)

Frequency

Acceleration

Acceleration

Duration

Voltage

Frequency (Hz)

14 Hz to 250 Hz

1 g

1 g

30 ms

100 V to 240 V (24 V optional)

50/60 Hz or dc

Release F UMC800 Controller Installation and User Guide 11

4/01

Page 20

Pre-Installation Considerations

Introduction

Electrical considerations

The controller is considered “open equipment” per EN 61010-1, Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use, Part 1: General Requirements. Conformity with

72/23/EEC, the Low Voltage Directive requires the user to provide adequate protection against a shock

hazard. The user shall install this controller in an enclosure that limits OPERATOR access to the rear

terminals.

Controller grounding

PROTECTIVE BONDING (grounding) of this controller and the enclosure in which it is installed shall be

in accordance with National Electrical Code (ANSI/NFPA 70) and local electrical codes.

Taking electrical noise precautions

Electrical noise is composed of unabated electrical signals that produce undesirable effects in

measurements and control circuits.

Digital equipment is especially sensitive to the effects of electrical noise. You should use the following

methods to reduce these effects:

• Supplementary bonding of the controller enclosure to a local ground, using a No. 12 (4 mm

conductor, is recommended. This may help minimize electrical noise and transients that may adversely

affect the system.

2

) copper

• Separate External Wiring - separate connecting wires into bundles (see Table 4) and route the individual

bundles through separate conduits or metal trays.

• Use shielded twisted pair cables for all Analog I/O, Process Variable, RTD, Thermocouple, dc millivolt,

low level signal, 4-20 mA, Digital I/O, and computer interface circuits.

• Use suppression devices for additional noise protection. You may want to add suppression devices at the

external source. Appropriate suppression devices are commercially available.

• Refer to document 51-52-05-01 How to Apply Digital Instrumentation in Severe Electrical Noise

Environments for additional installation guidance.

12 UMC800 Controller Installati on and User Guide Release F

4/01

Page 21

Permissible wire bundling

Table 4 shows which wire functions should be bundled together.

Bundle No. Wire Functions

Pre-Installation Considerations

Introduction

Table 4 Permissible wiring bundles

1

2

3

• Line power wiring

• Earth ground wiring

• Control relay output wiring

• Line voltage alarm wiring

Analog signal wire, such as:

• Input signal wire (thermocouple, 4 mA to 20 mA, etc.)

• 4-20 mA output signal wiring

• Slidewire feedback circuit wiring

• Digital input signals

• Communications

• Low voltage alarm relay output wiring

• Low voltage wiring to solid state type control circuits

Release F UMC800 Controller Installation and User Guide 13

4/01

Page 22

Pre-Installation Considerations

Introduction

14 UMC800 Controller Installati on and User Guide Release F

4/01

Page 23

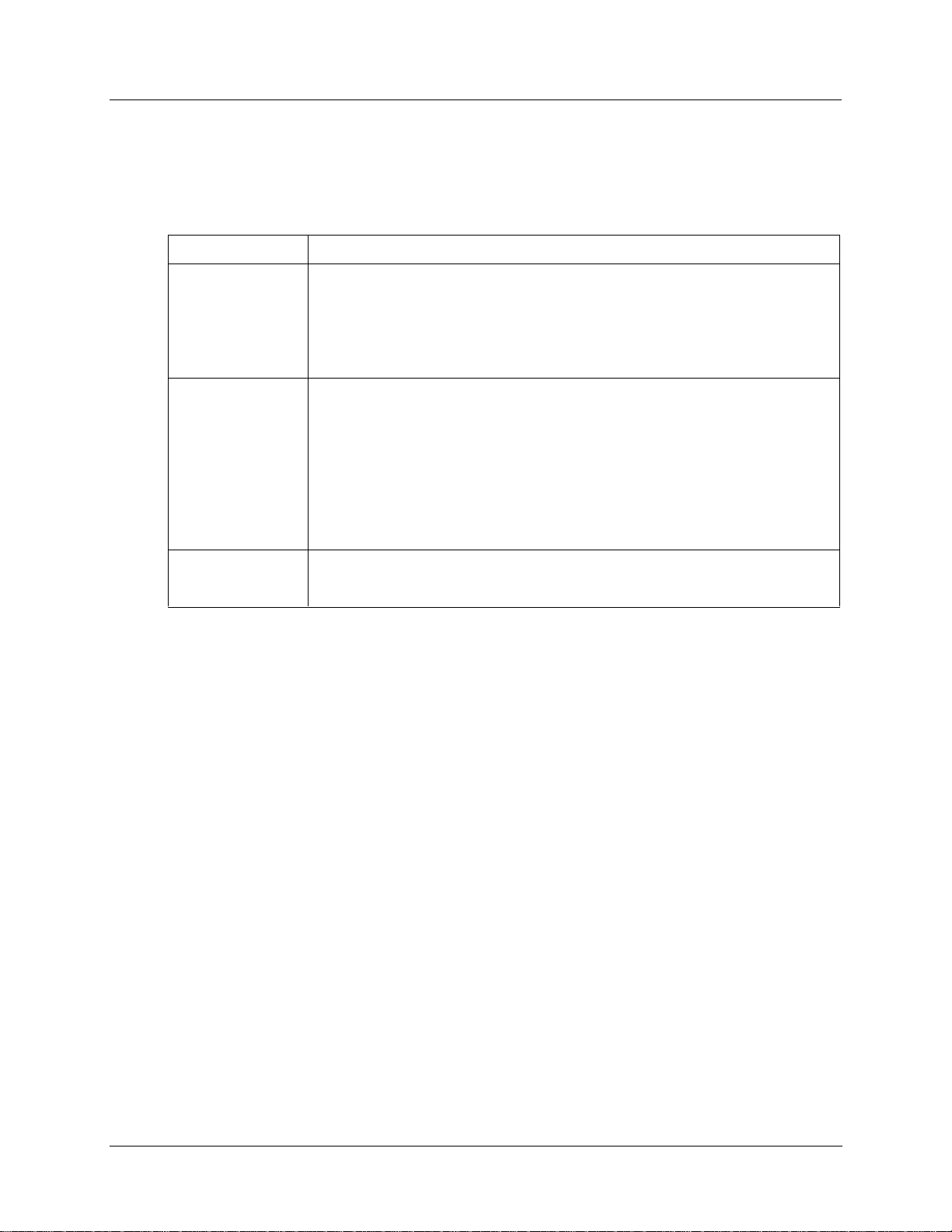

Site Preparation

The UMC800 must be mounted within an enclosure. Hardware is provided to surface mount the controller

to a panel or other suitable surface. Be sure that there is sufficient clearance for mounting the controller

enclosure and the external wiring.

UMC enclosure and components

The controller enclosure houses all circuit assemblies of the UMC controller. See Figure 7. The power

supply and CPU are modules that plug into slots on the right hand side of the enclosure. Both modules have

metal covers on the front where indicators, switches and connectors are located. All external connections to

the power supply and CPU are made on the front panels of these modules.

A front cover can be removed by two screws to access the I/O modules. There are two rows of card guides

to accommodate up to 16 plug-in I/O modules. External signal wiring to field devices are made with

removable terminal blocks that attach to the front of each I/O module. Optional terminal strips can be used

to provide shield termination of field wiring.

Mounting and Wiring

Site Preparation

Mounting and Wiring

Power supply, CPU and I/O modules are connected through a common backplane within the enclosure. All

external wiring for power supply and I/O modules are brought out through rubber grommets located at the

top and bottom of the enclosure. The CPU features two connections for external communications. One

provides a cable connection to a PC for configuration and database file management; the other connection

accommodates a cable to the operator interface. An optional communication board provides two RS 485

serial communications ports (slave and master) using Modbus RTU protocol.

External Wiring

Access Holes

Front

Cover

CPU Module

Power Supply

Figure 7 UMC800 controller enclosure

Release F UMC800 Controller Installation and User Guide 15

4/01

Page 24

Mounting and Wiring

Mounting the Controller

Power requirements

The standard supply uses 100/240 Vac or Vdc input ranges for its source. The input requirements are listed

in Table 5. Instructions for wiring the power supply are found in Table 5.

100-240 Vac or dc (+10 % or –15 %) 50/60 Hz or dc 100 VA maximum

24 Vac or dc (optional)

24 Vac (+25 % or –15 %) or

24 Vdc (+50 % or –8% )

Assembling parts

Assemble all parts of the UMC800 along with tools required to mount the UMC800 hardware. You should

have these tools on hand:

• Tool box that includes a center punch and a standard complement of flat blade and Phillips head

screwdrivers as well as box-end and open-end wrenches.

Table 5 Power supply input requirements

Voltage Input Frequency Power Consumption

50/60 Hz or dc 100 VA maximum

• A drill tap and drill with number 9 drill bit for drilling clearance holes as ap plicable.

• Tools for measuring and marking location of clearance holes and cutout on panel as well as cutting a

hole in the panel.

Mounting the Controller

Mounting controller enclosure on a panel

The controller enclosure is made to be surface mounted within an enclosure. The controller can be mounted

so that the power supply is at the righthand side, or the controller can be rotated 90 degrees so that the

power supply is at the top. For either mounting, there must be sufficient space allowed for routing the

external wiring.

Four holes at the back of the enclosure are provided for surface mounting with screws. Use the steps in the

table below to mount the controller enclosure on a panel.

Step Action

1

2

Layout mounting hole patterns on panel according to dimensions shown in Figure 8. Or,

position controller enclosure on panel and use enclosure as a template.

NOTE: Rotate the mounting dimensions 90 degrees to mount the enclosure sideways with

the power supply at the top.

Drill and tap mounting holes for 1/4-20 (or M6) machine screws (supplied by us er).

3

16 UMC800 Controller Installati on and User Guide Release F

Position enclosure on panel so holes in enclosure align with holes in panel. Secure enclosure

to panel with 1/4-20 (or M6) machine screws using external tooth washers.

4/01

Page 25

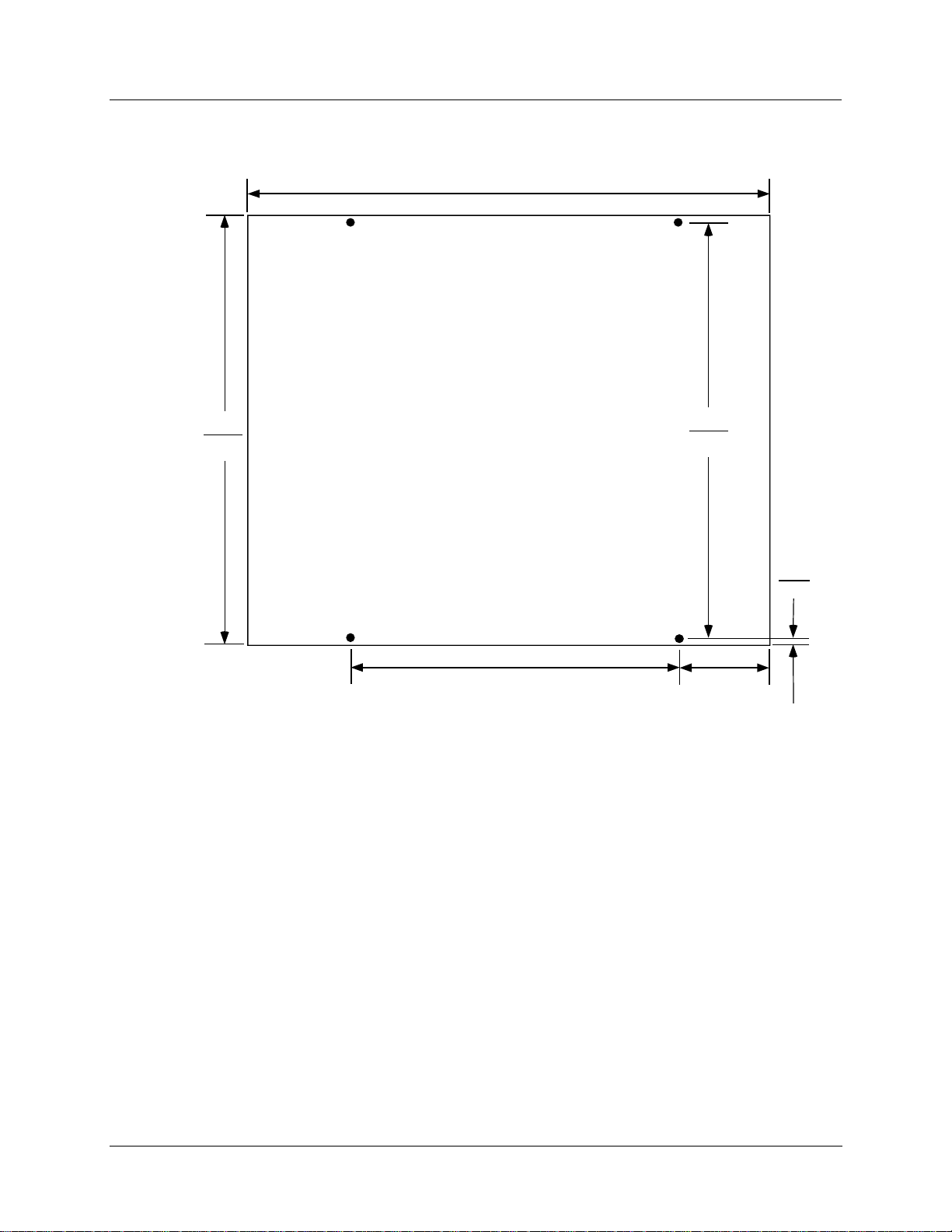

Enclosure mounting dimensions

Mounting and Wiring

Mounting the Controller

13.027

330.89

11.77

298.96

inches

Dimensions =

millimeters

_________

7.0

177.8

11.37

286.26

0.25

6.35

3.013

76.53

NOTE: Allow 7.0” (178 mm) depth to mounting dimensions for controller enclosure and cabling. To

mount the controller so that t he po wer supply is at the top, rotate the mounting dimensions 90 degrees.

Figure 8 UMC800 controller enclosure dimensions

Release F UMC800 Controller Installation and User Guide 17

4/01

Page 26

Mounting and Wiring

Plug-in Module Locations

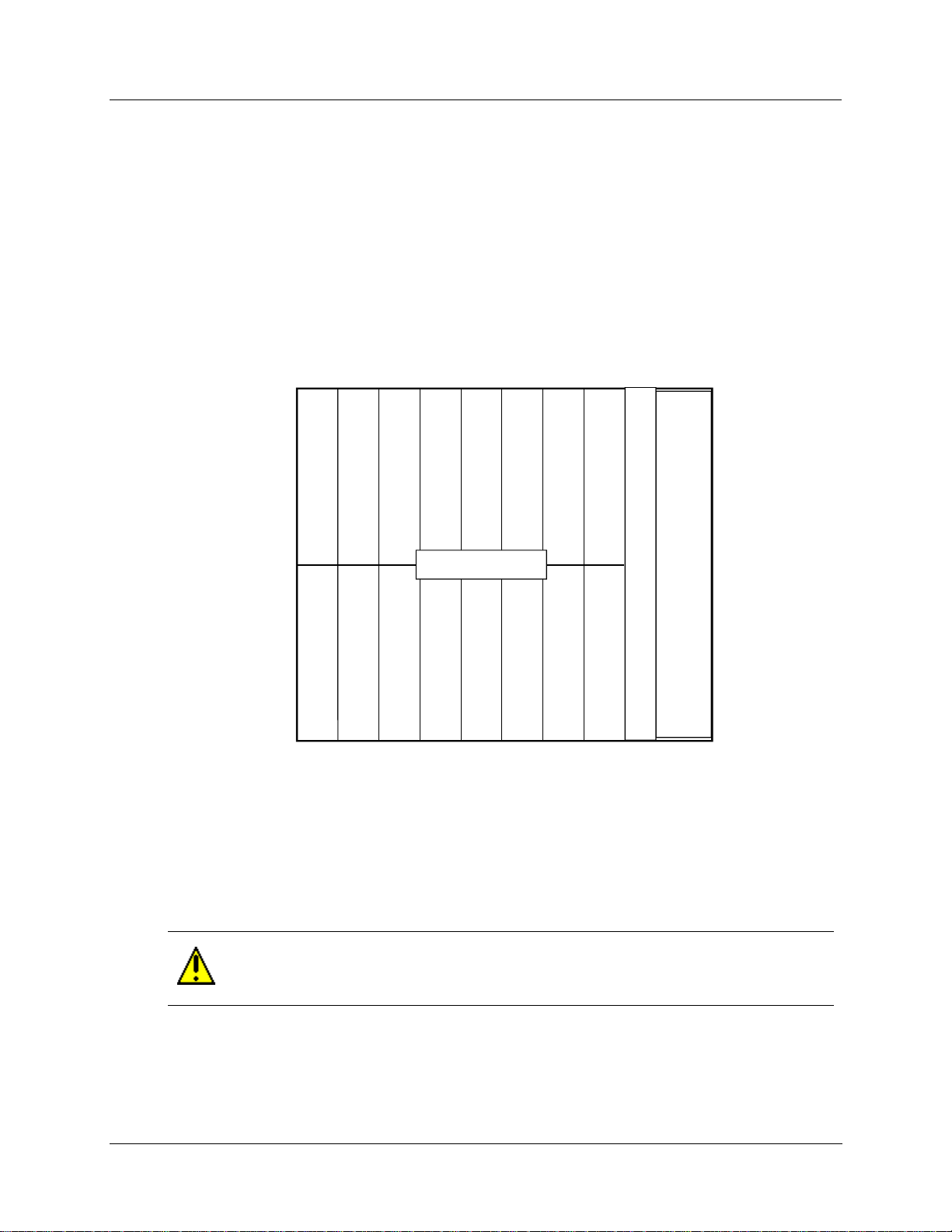

Plug-in Module Locations

Common backplane

The controller backplane provides common connections for the power supply, CPU and I/O modules. All

modules are installed into the backplane in their assigned slots designated by the controller model number.

[See Controller model number (page 21).] The power supply and CPU occupy the slots on the right side of

the enclosure. See Figure 9. Slots for the I/O modules are numbered from 1 to 16 to be consistent with I/O

address assignment when using the PC control builder software.

Slots 1-8 (left to right) comprise the lower slots.

Slots 9-16 (left to right) comprise the upper slots.

9 10 11 12 13 14 15 16

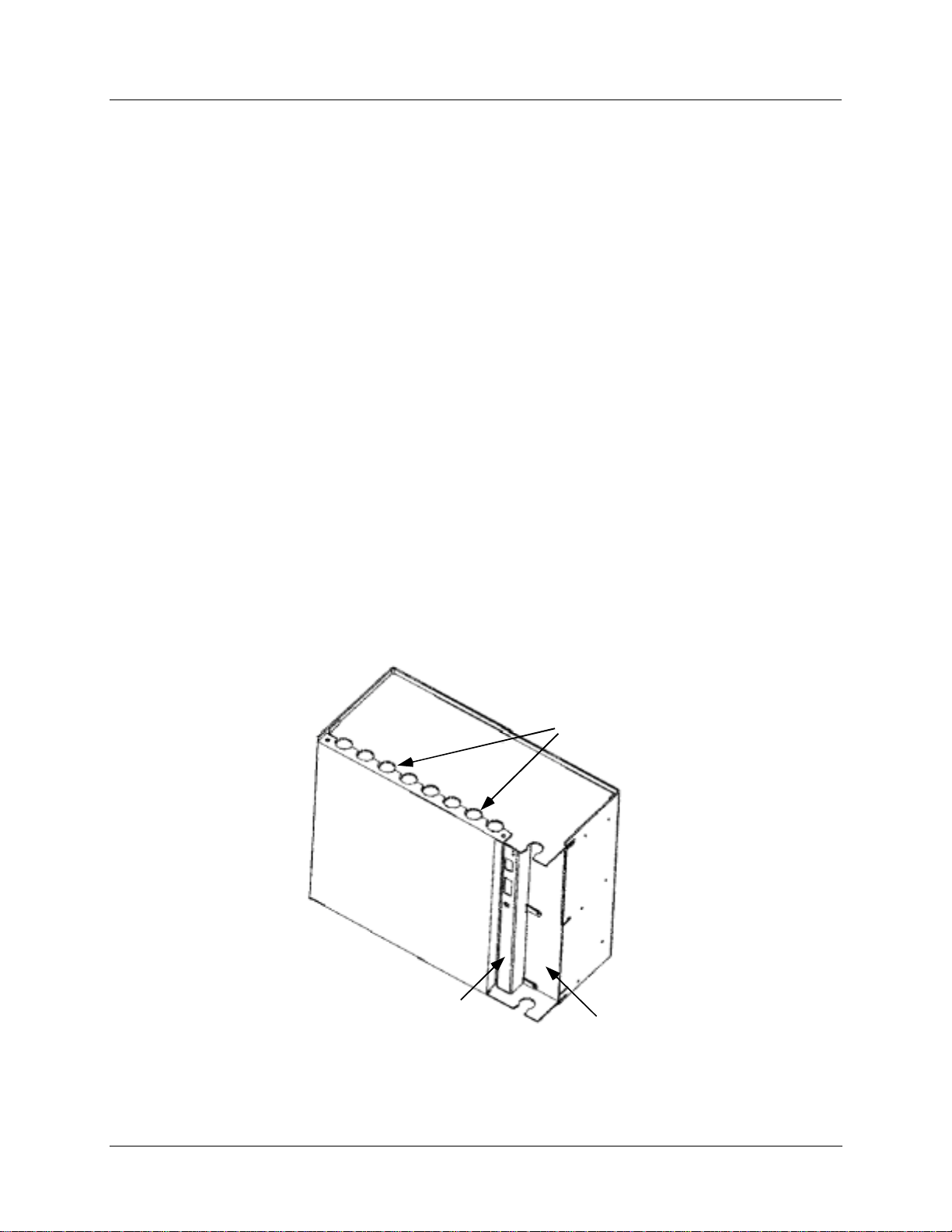

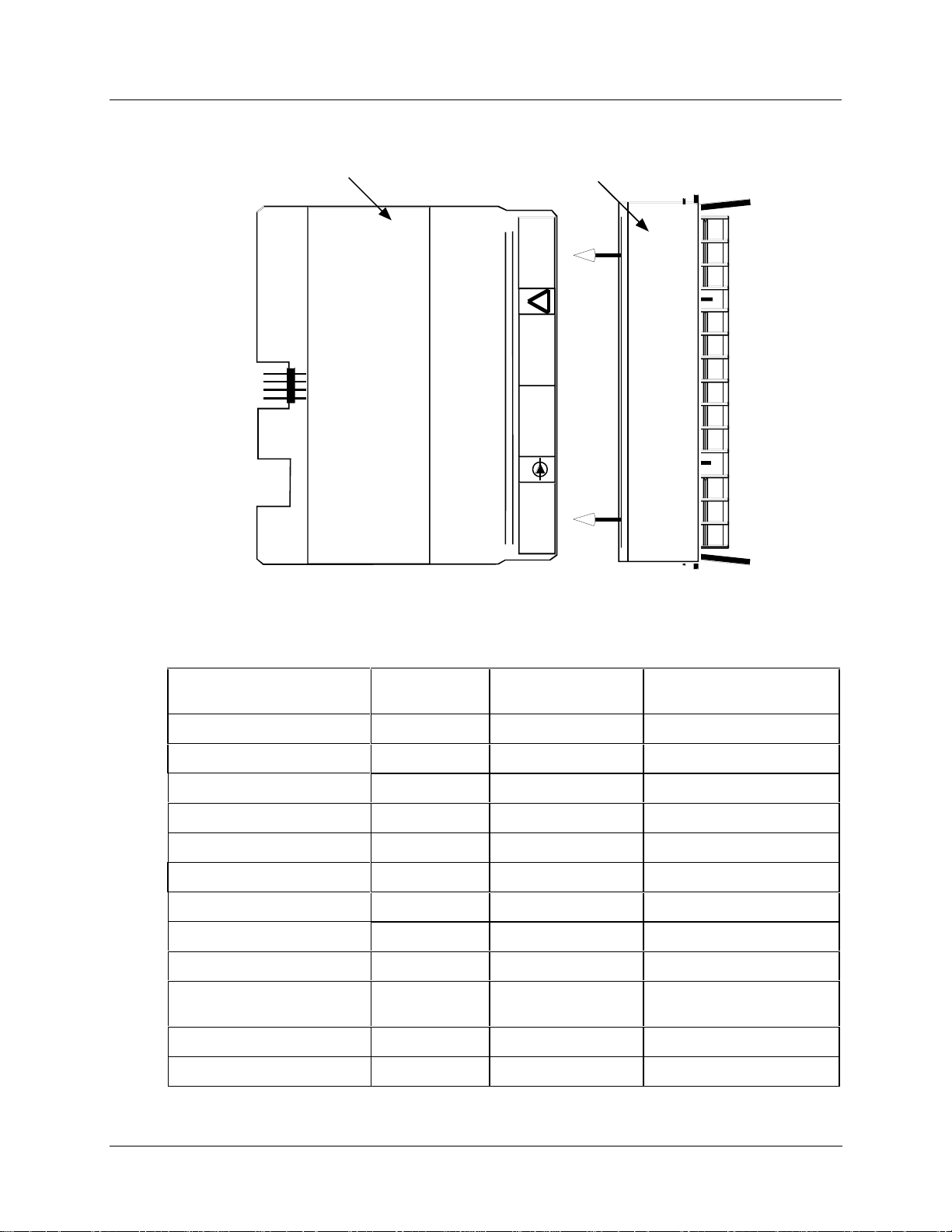

I/O module identification

I/O modules consist of a Printed Wiring Assembly (PWA) and a color-coded terminal block. Each module

type is identified by a number label attached to a colored terminal block. Typically, red terminal blocks

indicate AC voltage inputs and outputs and black terminal blocks i ndicate low voltage modules. See Figure

10 for an example. Module type and terminal block identification are described in Table 6.

CAUTION

Do not switch the terminal boards and I/O module PWAs. The color and number designation

of the terminal boards should match the correct I/O module type.

I/O Module Slots

1 2 3 4 5 6 7 8

Figure 9 UMC800 controller plug-in slots

CPU

Power

Supply

18 UMC800 Controller Installati on and User Guide Release F

4/01

Page 27

Mounting and Wiring

Plug-in Module Locations

I/O Module

PWA

Figure 10 I/O module PWA and terminal

Terminal

Block

+

OUT 4

_

!

+

OUT 3

_

+

OUT 2

_

mA

0-20

+

OUT 1

_

Table 6 I/O module identification

Module Type ID Number

Analog Input (AI) 1 Black 46190305-503

Analog Output (AO) 2 Black 46190314-503

Digital Input (DI) - Logic 3 Black 46190311-503

Digital Input (DI) - DC 4 Black 46190347-501

Digital Input (DI) - AC 5 Red 46190350-501

Digital Input (DI) - 16 point B Orange or Beige 46190353-501

Digital Outputs (DO) - Relay 6 Red 46190308-503

Digital Outputs (DO) - DC 7 Black 46190341-501

Digital Outputs (DO) - AC 8 Red 46190344-501

Digital Outputs (DO) - Higher

A Red 46190344-502

Current AC

± 15 Vdc pH Power Module C Black 51450921-501

Pulse/Frequency Input D Black 46190360-501

Terminal Block

Color

Part Number

Release F UMC800 Controller Installation and User Guide 19

4/01

Page 28

Mounting and Wiring

Plug-in Module Locations

I/O module limits

The controller backplane accommodates I/O module types, subject to the limitations as shown in Table 7.

Slot Locations identify the allowable locations in the controller for each I/O module type. Maximum

Allowed describes the maximum I/O configuration for each I/O type in a controller.

Table 7 I/O module installation limitations

I/O Module Type Slot Locations

(See Figure 9)

Universal Analog Input (ID: 1) 1 through 16 16 modules (64 points)

Analog Output (ID: 2) 1 through 10 4 modules (16 points)

Digital Input (ID: 3,4,5) 1 through 16 16 modules (96 points)*

Digital Input 16 point (ID: B) 14 through 16 3 modules (48 points)*

Digital Output (ID: 6,7,8) 1 through 8 8 modules (48 points)*

Digital Output (ID: A) 9 through 16 2 modules (12 points)*

± 15 Vdc pH Power Module (ID: C) 5, 6 2 modules (8 points)

Pulse/Frequency Input (ID: D) 1 through 16 16 modules (64 points)

Maximum Allowed

NOTE: Total combined I/O of all types is limited by the 16 available controller I/O slots.

* Total of 96 DI/DOs allowed for all types combined.

20 UMC800 Controller Installati on and User Guide Release F

4/01

Page 29

Controller model number

The controller model number speci fied on your purchase order indicates the I/O module types and the

assigned slot location of each I/O module present in the controller.

modules are defined below.

Example of controller model number

Mounting and Wiring

Plug-in Module Locations

The number fields that identify I/O

Controller Model Number

I/O module types and controller

locations for . . . Slots 1 to 8 Slots 9 to 16

8001 - 000 - 0E - 01122300 - 56800000

So the number 01122300 - 56800000 indicates that the controller is equipped with I/O module types in the

following slot locations:

Controller

Slot #

1 Blank (0) 9 DI AC Input (5)

2 Analog Input (1) 10 DO Relay Output (6)

3 Analog Input (1) 11 DO AC Output (8)

4 Analog Output (2) 12 Blank (0)

5 Analog Output (2) 13 Blank (0)

6 DI Logic Input (3) 14 Blank (0)

7 Blank (0) 15 Blank (0)

8 Blank (0) 16 Blank (0)

I/O Module Type

(Module ID)

Controller

Slot #

I/O Module Type

(Module ID)

NOTE: The numbers (in parenthesis) that identify the I/O module types are defined in Table 6.

Release F UMC800 Controller Installation and User Guide 21

4/01

Page 30

Mounting and Wiring

Plug-in Module Locations

Verify I/O module locations

The table below outlines the steps for identifying and recording the I/O module types in the controller.

Step Action

1

2

Controller

Slot No.

1

2

3

4

5

Verify that the module types installed in the controller card slots are correct according to the

controller model number. Refer to Table 6 to identify the module types.

Use to record the location, module type and signal type/range for each I/O module installed

in the controller.

NOTE Module types should be installed in accordance with the limitations described in

Table 7.

Table 8 I/O module identification record

Signal Type/Range

I/O Module Type

(AI, AO, DI, DO, or PI/FI)

(mV, V, mA, T/C, RTD, Ohms, pH)*

Al Ch 1 Al Ch 2 Al Ch 3 Al Ch 4

Terminal Block

Color

6

7

8

9

10

11

12

13

14

15

16

* An Analog Input (AI) Module can be configured to accept multiple input types.

22 UMC800 Controller Installati on and User Guide Release F

4/01

Page 31

Signal Wiring

I/O module wiring

Terminal blocks are installed to the front of the I/O modules for connecting field device wiring as shown in

Figure 11. Terminal blocks are color coded and numbered to identify the I/O module type. (See Table 6.)

The terminal blocks are removable so that I/O modules can be replaced without disconnecting the field

wiring from the terminal blocks. Wire gauge sizes 16 to 22 AWG can be used to connect to the terminal

blocks. The field wiring exits through rubber grommets at the top or bottom of controller enclosure. The

rubber grommets are removed by sliding the grommet forward with the terminal block and the attached

field wiring.

I/O Module

Identification

12

11

10

9

8

7

6

5

4

Mounting and Wiring

Signal Wiring

Locks

2

Field Wiring

Terminals

3

2

1

Locks

Figure 11 I/O module terminal block (all except 16 point DI)

Release F UMC800 Controller Installation and User Guide 23

4/01

Page 32

Mounting and Wiring

Signal Wiring

Analog input / analog output field wiring

Shielded twisted pairs are recommended (and required for CE approval) for analog input (AI) and analog

output (AO) module field wiring. If a cabinet shield termination point is not available, the optional shield

termination bracket may be used, (specify part number 51309814-501). The shield termination point is a

bracket attached at the top and/or bottom on the front of the controller enclosure. The wiring shields are

attached using the screws of the shield termination. Figure 12 shows the field wiring termination strip

attached to the bottom front of the enclosure.

Figure 12 Field wiring shield termination

24 UMC800 Controller Installati on and User Guide Release F

4/01

Page 33

Analog inputs (module ID 1)

A universal Analog Input module accepts a variety of input signals from field devices as summarized in

Table 9. Figure 13 illustrates the terminal block connection s for the various inputs. See Specifications

section for more details on all I/O module specifications. One AI module can be configured to accept

multiple input types.

Table 9 Universal analog input module specifications

Specification Description

Input Types mV, V, mA, T/C, RTD, and Ohms

Number of Inputs 4 per module, up to 16 modules per controller (64 inputs)

Mounting and Wiring

Signal Wiring

RTD

RTD

RTD

RTD

Signal Source

Input Impedance

12

+

11

-

10

1

+

9

-

8

7

+

6

-

5

4

3

+

2

-

1

Thermocouple with cold junction compensation, for operation between 32 °F to

176 °F (0 °C to 80 °C)

Line resistance up to 1000 ohms, T/C, mV, mA, V

RTD Pt 100 3-wire connections, 40 ohms balanced max.

10 Megohms for T/C, mV inputs,

> 1 Megohms for volt inputs

Field Wiring

Channel 4

Thermocouple Input

+

T/C, mV, V

-

Current Input mA

4 to 20

mA

*

Source

+

-

Channel 3

Ground T er minal

* A 250 ohm res istor is required f or

the input range.

RTD Input (3 wires)

+

-

RTD

Ground Terminal

Channel 2

Channel 1

Ground Terminal

mV, V Inputs

mV or V

Source

Ground Terminal

+

-

Figure 13 AI module terminal block connections

Release F UMC800 Controller Installation and User Guide 25

4/01

Page 34

Mounting and Wiring

Signal Wiring

Field wiring for one pH sensor input (module ID C)

Figure 14 indicates the recommended wiring for one pH sensor input. Note that two analog input channels

are required, one for the pH sensor and one for temperature. Similar wiring may be used for additional

sensors. A UMC800 controller can accommodate 2 power modules for a total of up to 8 pH inputs.

UMC800 Controll er

Mod 1

Mod 4

pH 1 Sensor

Temp

pH 1 Sensor

mV

-

+

Analog Input

Module

Red/Black

Red

White

Orange

Black

COM

White/Black

(Unused)

Green

Blue

12

1

+

-

+

-

1

Jumper

12

C

-

C

+

-

C

+

-

C

+

1

UMC800 Shield Connector Kit

Part No. 51309814-501

Figure 14 Recommended wiring for one pH sensor input

Power Su pply Module

26 UMC800 Controller Installati on and User Guide Release F

4/01

Page 35

Analog outputs (module ID 2)

The Analog Output (AO) module provides four outputs at 0 mA to 20 mA (configurable for 4 mA to

20 mA or any span between 0 mA to 20 mA). When not used for an analog output, an output channel may

be used to power a transmitter with 24 Vdc power. The controller will support up to 4 AO modules, for a

total of 16 outputs. Figure 15 shows the terminal connections for the AO module. See Specifications

section for details on all I/O module specifications.

Mounting and Wiring

Signal Wiring

12

11

10

9

8

7

Channel 4

2

Field Wiring

Load

Channel 3

Ground Terminal

4 to 20 mA Output

+

-

4 to 20 ma

Generator

Gnd

6

5

4

3

2

Channel 2

Channel 1

Fiel d Wiring

24 V

+

DC

Power

-

1

Gnd

ATTENTION

Channels not used as analog outputs can be used to supply a transmitter with 24 Vdc power.

Figure 15 AO module terminal block connections

Release F UMC800 Controller Installation and User Guide 27

4/01

Page 36

Mounting and Wiring

Signal Wiring

Digital inputs

Three types of Digital Input (DI) modules accept four types of input signals.

1. Logic Input (Module ID 3 and B)

2. DC Input (Module ID 4)

3. AC Input (Module ID 5)

4. Pulse/Frequency Input (Module ID D)

Each type is described on the following pages. Figure 16 shows the terminal block connections for all DI

modules. See Specifications section for details on all I/O module speci fications.

ATTENTION

16 Point Digital Input module (ID B) has 32 terminals. If you are using 2 wires per DI, use 22

gage wires so all 32 wires can fit through the rubber grommet in the controller case. See

Figure 16.

28 UMC800 Controller Installati on and User Guide Release F

4/01

Page 37

Module B

Identifiable by

32 screws

2

+

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

Each odd-numbered

terminal is internally

grounded.

Gnd

DI 16

DI 15

DI 14

DI 13

DI 12

DI 11

DI 10

DI 9

DI 8

DI 7

DI 6

DI 5

DI 4

DI 3

DI 2

DI 1

Module ID

#3, 4, or 5

12

11

10

Mounting and Wiring

Signal Wiring

DI 6

DI 5

9

8

7

6

5

4

3

2

1

DI 4

DI 3

DI 2

DI 1

Module ID B (16 DI)

Logic Input (Conta ct Closure)

For 2 wires per DI, must use 22-gage wire to fit 32

wires through rubber grommet on case.

R

Field Wiring

Dry SW

Module ID B (16 DI)

Logic Input (Contact Closure)

For 1 common wire for all DIs, use 16-22 gage wire.

Field Wiring

Dry SW

Gnd

+ VCC

R

Gnd

+ VCC

• One wire per DI. Each wire goes to

Marshalling field connector (user provided).

• One common wire from Marshalling field

connector to any ground connector on the

16 pt. DI terminal.

Marshalling field

connector

Figure 16 DI module terminal block connections

Logic

Logic

Module ID #3

Logic Input (Contact Closure)

Field Wiring

Module ID #4

DC Input (24 Vdc )

Field Wiring

+

24V

-

Module ID #5

AC Input (120/240 Vdc)

Field Wiring

Dry SW

L1

L2

R

Gnd

+ VCC

+ VCC

+

R

-

+ VCC

R

Release F UMC800 Controller Installation and User Guide 29

4/01

Page 38

Mounting and Wiring

Signal Wiring

Digital outputs

There are four types of Digital Output (DO) modules that provide three types of Off/On control.

1. Relay (alarm) output (Module ID 6) 46190308-503

2. DC output (Module ID 7) 46190341-501

3. AC output (Module ID 8) 46190344-501

4. AC high output (Module ID A) 46190344-502

Figure 17 shows the terminal block connections for the DC output and AC output DO modules. See

Specifications section for details on all I/O module speci fication s.

Module ID #6

Relay(Alarm) Output

Module ID

#6, 7, 8,

or A

12

11

10

9

8

7

6

5

4

3

2

1

Modul e ID A

AC Output (120/240Vdc)

Wiring same as module 8.

Maximum Load Cur rent:

Outputs

DO 1 – 4 @ .5A

DO 5 and 6 @ 2A

DO 6

DO 5

DO 4

DO 3

DO 2

DO 1

Field Wiring

L1

L2

Load

Module ID #7

DC IOutput (24 Vdc)

Field Wiring

+

24V

-

Load

Module ID #8

AC Output (120/240 Vdc)

Field Wiring

L1

L2

Load

Fuse

Fuse

R

VCC

Figure 17 DO module terminal block connections

30 UMC800 Controller Installati on and User Guide Release F

4/01

Page 39

Mounting and Wiring

Signal Wiring

The Digital Output module with relay outputs (Module ID 6 ) contain jumpers to set the de-energized state

of the relay contacts. The relays are factory set to normally open (NO) for each output on the relay alarm

module, as shown in Figure 18.

To change the state of the contacts: Use a pair of needle-nose pliers and move the jumper from the location

NO (normally closed) to the location NC (normally closed).

Digital Output

Module

Normally Open

Contacts

NO

NC

NC6

S6

NO6

NC5

S5

NO5

NC4

S4

NO4

NC3

S3

NO3

NC2

S2

NO2

NC1

S1

NO1

Normally Closed

Contacts

12

11

10

!

9

8

7

6

5

4

NO NC

3

2

1

Figure 18 DO module relay contact setting

Release F UMC800 Controller Installation and User Guide 31

4/01

Page 40

Mounting and Wiring

Signal Wiring

Pulse input/frequency input module with digital outputs

Figure 19 shows the terminal block connections for Pulse/Frequency Input Module. See Specifications

section for details on all I/O module specifications.

ATTENTION

16 Point Digital Input module (ID D) has 32 terminals. If you are using 2 wires per DI, use 22

gage wires so all 32 wires can fit through the rubber grommet in the controller case. See

Figure 19.

Module ID - D

Identifiable by

32 screws

2

+

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

Each odd-numbered

terminal is internally

grounded.

Gnd

Input 1 +

Input 1 Input 2 +

Input 2 DO1 +

DO1 DO2 +

DO2 DO3 +

DO3 -

DO4 +

DO4 Input 3 +

Input 3 Input 4 +

Input 4 -

Figure 19 PI/FI module terminal block connections

32 UMC800 Controller Installati on and User Guide Release F

4/01

Page 41

Pulse input/frequency input jumpers

The Pulse/Frequency Input Module with Digital Outputs (M odule ID D) contain jumpers to set the deenergized Input Filter Cutoff Frequency. All four inputs are factory set to 500 KHz as shown in Figure 23.

To change, use needle nose pliers and move the jumper(s) to the desired position. See the figure below for

the default positions and jumper settings for 100 KHz and 5 KHz.

4

6

1

9

0

3

6

0

-

5

0

1

Pulse/Frequency Input Board

OFF

JX1 -

JX2 -

ON

Mounting and Wiring

Signal Wiring

1

500KHz

2

1

100KHz

2

1

5KHz

2

JA1

JA2

JB1

JB2

Figure 20 PI/FI module input filter cutoff frequency setting

Pulse/frequency card wiring

The pulse frequency card input is designed to accept a contact closure type transmitter. The typical wiring

circuit is shown below.

+

-

Pulse Transmitter

MOSFET, Open Collector, or

Contact Closure drive.

V Supply (DC)

R

L

V Return (DC)

JC2

JC1

JD2

JD1

+

RT=1k

+

Note: All puls e

-

frequency inputs

share a return

connection that is

common to all pulse /

frequency inputs on a

card.

Pulse / Frequency Input Card

Input Connections

Figure 21 Pulse/frequency input connections

Release F UMC800 Controller Installation and User Guide 33

4/01

Page 42

Mounting and Wiring

Signal Wiring

V supply

Choose a supply that is compatible with the environmental require ments o f your application. The supply

voltage must be within the requirement of both the transmitter and the pulse input card. Typically a low

cost 12 Vdc unregulated supply can be used in most applications provided in meets applicable regulatory

requirements. 1k ohm termination resistors (R

the internal resistor must meet pulse frequency card requirements. The circuit in Figure 21 provides for a

1 k ohm load resistor and a 12 V supply. The actual pulse voltage seen across the pulse \ frequency input is

divided by R

volts. For a 1 k ohm load the minimum V supply will be 3 V (R

V return

The pulse / frequency cards pulse inputs are optically isolated from other circuitry but share a common

isolated supply common. When multiple inputs are used the supply voltage returns will be connected to a

common reference internal to the pulse frequency card. The pulse / frequency cards digital outputs are

optically isolated from all inputs and each other.

R

L

The maximum sink current specified by the pulse transmitter specifies the minimum load resistance.

Typically R

) are built into the pulse frequency card. The voltage across

T

/(RL+RT) V

T

is within the range of 100 to 100k ohms. A 1 k ohm resistor is typically recommended.

L

= 6 V. The VIH minimum pulse threshold voltage for the pulse input card is 3

Supply

)/ RT = 6V.

L+RT

The transmitter often provides a selection for the pulse duration or width. The pulse input card internal R/C

filtering will attenuate short pulse widths. Below is a table for filter and pulse width settings for several

pulse freque nc y ran ge s.

Max Pulse Frequency Typical Filter Jumper Setting Pulse Width Range

100kHz 500 K Hz 2 uSec to 9 uSec

10kHz 100 K Hz 9 uSec to 90 uSec

1kHz 5 K Hz 180 uSec to 900uSec

100Hz 5 K Hz 180 uSec to 9mSec

(Vsupply = 12 Vdc, RL = 1 K ohm)

The minimum pulse frequency is 10 Hz regardless of the filter jumper settings.

The pulse frequency card input wiring requirements must be compatible with both the pulse frequency card

and the transmitter manufactures specifications. A typical transmitter will specify the maximum supply

voltage and the maximu m sink current.

34 UMC800 Controller Installati on and User Guide Release F

4/01

Page 43

Pulse frequency card outputs

The pulse frequency card outputs are open collector drivers designed to drive a maximum of 100 mA. All

Pulse Frequency card digital outputs are optically isolated from each other. The maximum supply voltage

must not exceed 27 Volts dc.

Mounting and Wiring

Signal Wiring

V Supply (DC) 27 V Max

IL (100mA Max)

V Return (DC)

+

+

Pulse / Frequency Input Card

DO connections

Figure 22 Pulse/frequency card digital output connections

Release F UMC800 Controller Installation and User Guide 35

4/01

Page 44

Mounting and Wiring

Wiring Communication Links

Wiring Communication Links

Serial communications ports

The controller communicates through a number of serial ports. The CPU module contains two serial ports.

One is an RS 232 connection to a PC and another is dedicated for connection to the operator interface. The

CPU with optional communications features two additional RS 485 serial ports.

The serial port connectors on the CPU module are shown in Figure 23. Table 10 summarizes the

communication link connections to the controller and other reference data for wiring details.

OFFLINE

PROGRAM

RUN