Page 1

KD6i Series

USER

MANUAL

Rev. D KDMU000799

02/6/04

Page 2

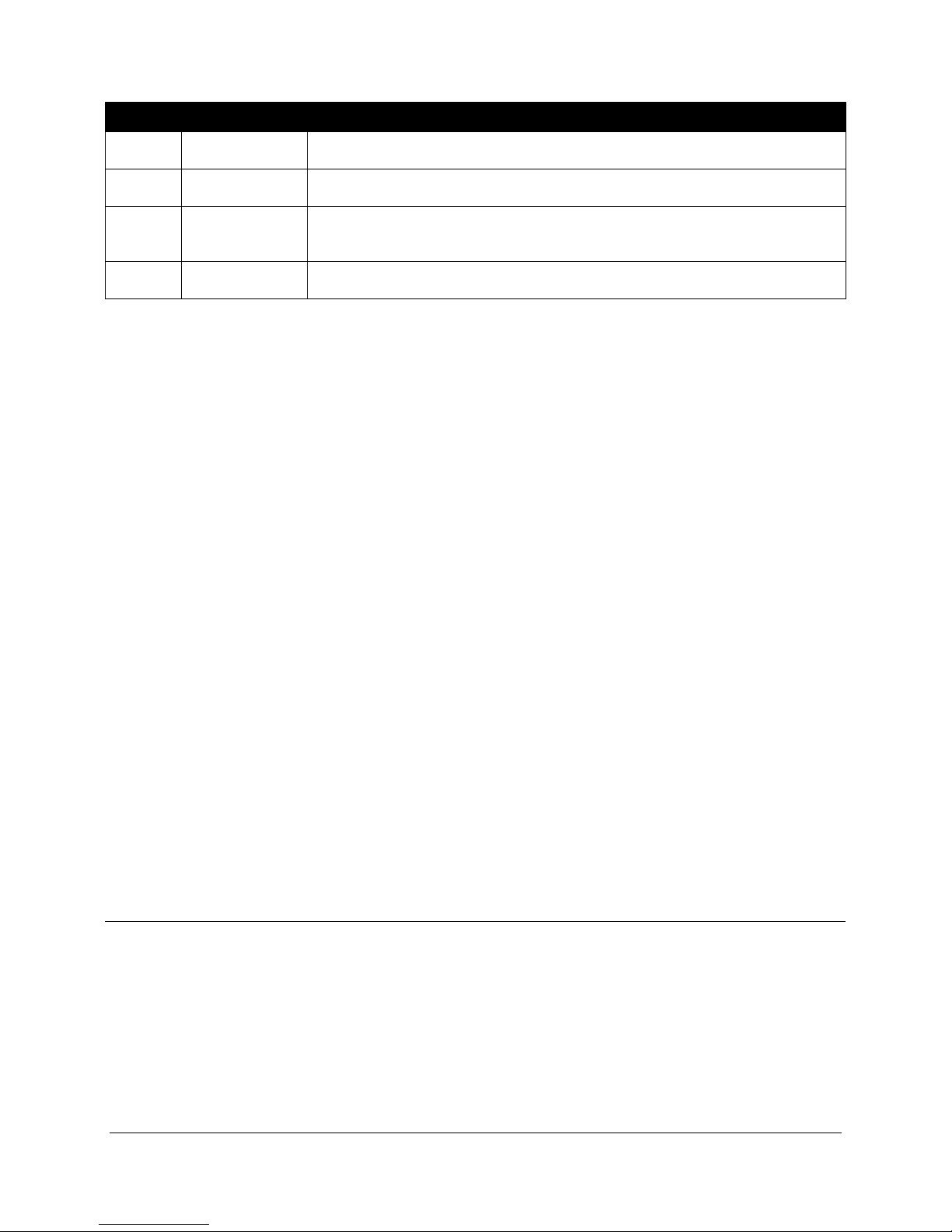

ISSUE DATE REVISIONS

A June 2003

B June 2003

C July 2003

D Feb 2004

Initial Release

Minor formatting changes (PCN 1494).

Correct model configurator (PCN 1540). Changed all Honeywell Video

Solutions references to Honeywell Video Systems.

PCN 1717 – revise jumpers W1 and W2

2003-2004 HONEYELL INTERNATIONAL INC.

ALL RIGHTS RESERVED

HONEYWELL VIDEO SYSTEMS

1305 WATERS RIDGE DRIVE

LEWISVILLE, TX 75057

(972) 353-6500

ALL RIGHTS RESERVED. NO PART OF THIS PUBLICATION MAY BE REPRODUCED BY ANY MEANS

WITHOUT WRITTEN PERMISSION FROM HONEYWELL VIDEO SYSTEMS.

THE INFORMATION IN THIS PUBLICATION IS BELIEVED TO BE ACCURATE IN ALL RESPECTS. HOWEVER,

HONEYWELL VIDEO SYSTEMS CANNOT ASSUME RESPONSIBILITY FOR ANY CONSEQUENCES RESULTING

FROM THE USE THEREOF. THE INFORMATION CONTAINED HEREIN IS SUBJECT TO CHANGE WITHOUT

NOTICE. REVISIONS OR NEW EDITIONS TO THIS PUBLICATION MAY BE ISSUED TO INCORPORATE SUCH

CHANGES.

Rev. D ii KDMU000799

02/6/04

Page 3

FCC COMPLIANCE STATEMENT

INFORMATION TO THE USER: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO

COMPLY WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF

THE FCC RULES. THESE LIMIT S ARE DESIGNED TO PROVIDE REASON ABLE PROTECTION

AGAINST HARMFUL INTERFERENCE WHEN THE EQUIPMENT IS OPERATED IN A

COMMERCIAL ENVIRONMENT. THIS EQUIPMENT GENERATES, USES, AND CAN RADIATE

RADIO FREQUENCY ENERGY AND, IF NOT INSTALLED AND USED IN ACCORDANCE W ITH

THE INSTRUCTION MANUAL, MAY CAUSE HARMFUL INTERFERENCE TO RADIO

COMMUNICATIONS. O PERATION OF THIS EQUIPM ENT IN A RESIDENTIAL AR EA IS LIKELY

TO CAUSE HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO

CORRECT THE INTERFERENCE AT HIS OWN EXPENSE.

CAUTION: CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY THE PARTY

RESPONSIBLE FOR COM PLIANCE COULD VOID THE US ER’S AUTHORIT Y TO OPERATE THE

EQUIPMENT.

THIS CLASS A DIGITAL APPARATUS COMPLIES WITH CANADIAN ICES-003.

CET APPAREIL NUMERIQUE DE LA CLASSE A EST CONFORME À LA NORME NMB-003

DU CANADA.

USERS OF THE PROD UCT ARE RESPONSIBLE FOR CHEC KING AND COMPLYING WITH ALL

FEDERAL, STATE, AND L OCAL LAWS AND STATUTES CONCERN ING THE MONITORING AND

RECORDING OF VIDEO AND A UDIO SIGNALS. HONE YWELL VIDEO SYSTEM S SHALL NOT BE

HELD RESPONSIBLE FOR THE USE OF THIS PRODUCT IN VIOLATION OF CURRENT LAWS

AND STATUTES.

Rev. D iii KDMU000799

02/6/04

Page 4

IMPORTANT SAFEGUARDS

READ INSTRUCTIONS – Al l safety and operating ins tructions s hould be rea d before the unit is

1.

operated.

RETAIN INSTRUCTIONS – The s afety and operating instruc tions should be retaine d for future

2.

reference.

HEED WARNINGS – All warnings on the unit and in the operating instructions should be

3.

adhered to.

FOLLOW INSTRUCTIONS – All operating and use instructions should be followed.

4.

CLEANING – Unplug the unit from the outlet before cleaning. Do not use liquid cleaners or

5.

aerosol cleaners. Use a damp cloth for cleaning.

ATTACHMENTS – Do not use attac hments not recommended b y the product manuf acturer as

6.

they may result in the risk of fire, electric shock, or injury to persons.

WATER AND MOISTURE – Do not use this unit near water or in an unprotected outdoor

7.

installation, or any area which is classified as a wet location.

ACCESSORIES - Do not place this product on an unstabl e cart, stand, trip od, brack et, or table.

8.

The product may fall, causing serious injury to a child or adult and serious damage to the

equipment. Use only with a cart, stand, tripod, bracket, or table recommended by the

manufacturer, or sold with the product. Any mounting of the product should follow the

manufacturer’s instructions and should use a mounting accessory recommended by the

manufacturer. Wall or shelf mounting should follow the manufacturer’s instructions and should

use a mounting kit approved by the manufacturer.

9. A product and cart comb ination should be moved with car e. Quick stops, excessive

force, and uneven surfaces may cause the product and cart combination to overturn.

VENTILATION - Slots and openings in the cabinet and the back or bottom are provided for

10.

ventilation and to ensur e reliable operat ion of the equipment and t o protect it from over heating.

These openings must not be blocked or covered. The ope nings should never be blocked by

placing the product o n a bed, sofa, rug, or other sim ilar surface. Equipment sh ould never be

placed near or over a radi ator or heat register. This pr oduct should not be placed in a bui lt-in

installation, such as a bookcase or rack unless proper ventilation is provided or the

manufacturer’s instruc tions hav e been adh ered to.

POWER SOURCES – This product should be operated only from the type of power source

11.

indicated on the mark ing label. If you are not sure of the t ype of power suppl ied to your hom e,

consult your product dealer or local power company. For products designed to oper ate from

battery power or other sources, refer to the operating instructions.

GROUNDING OR POLARIZATION – The power supply supplied with th is uni t m ay be equipped

12.

with a polarized alternati ng- curr ent line plug ( a plug ha ving on e blade wider than t he other ). T his

plug will fit into th e power outlet o nly one way. This is a safety feature. If you are unable to ins ert

the plug fully into the o utlet, try reversing the plug. If the plug sh ould still fail to fi t, contact your

electrician to replace your obsolete outlet. Do not defeat the safety purpose of the polarized

plug.

OVERLOADING – D o not overloa d outl ets and exten sion cor ds as t his c an resu lt in a risk of fire

13.

or electric shock.

Rev. D iv KDMU000799

02/6/04

Page 5

IMPORTANT SAFEGUARDS, CONTINUED

POWER-CORD PROTECTION – Power supply cords should be routed so that they are not

14.

likely to be walked on or pinched by items placed upon or against them, paying particular

attention to cords and plu gs, convenience receptacles, and the p oint where they exit from the

monitor.

OBJECT AND LIQUID ENTRY – Never push objects of any k ind into this un it through openings

15.

as they may touch dangerous voltage points or short-out parts that could result in a fire or

electric shock. Never spill liquid of any kind on the unit.

SERVICING – Do not atte mpt to service this unit yourself as opening or rem oving covers may

16.

expose you to dangerous voltage or other hazards. Refer all servicing to qualified service

personnel.

DAMAGE REQUIRING SERVICE – Unplug the unit from the outlet and refer servicing to

17.

qualified service personnel under the following conditions:

a. When the power-supply cord or plug is damaged.

b. If liquid has been spilled, or objects have fallen into the unit.

c. If the unit has been exposed to rain or water.

d. If the unit does not operate norm ally by following t he operating i nstructions. A djust onl y

those controls that are co vered by the operat ing instr uctions as an im proper adjus tment

of other controls may result in damage and will often require extensive work by a

qualified technician to restore the unit to its normal operation.

e. If the unit has been dropped or the enclosure has been damaged.

f. When the unit exhibits a distinct change in performance - this indicates a need for

service.

REPLACEMENT PARTS – When replacement parts are required, be sure the service technician

18.

has used replacement par ts specified by the manufactur er or have the same characteris tics as

the original part. Unauthorized substitutions may result in fire, electric shock or other hazards.

SAFETY CHECK – Upon completion of any service or repairs to this unit, ask the service

19.

technician to perform safety checks to determine that the unit is in proper operating condition.

LIGHTNING AND POWER LINE SURGES – For add ed protection of this unit dur ing a lightning

20.

storm, or when it is lef t unattended and unuse d for long periods of tim e, unplug it from the wall

outlet and disconnec t t he cable system. T his wil l pr ev ent damage to the unit due to l ig htn ing an d

power-line surges.

HEAT – The product should be situated away from heat sources such as radiators, heat

21.

registers, stoves, or other products (including amplifiers) that produce heat.

INSTALLATION – Do not insta ll the unit in an extremely hot or humid location, or in a place

22.

subject to dust or m echanic al vibratio n. The u nit is n ot design ed to be waterpro of. Exposur e to

rain or water may damage the unit.

WALL OR CEILING MOUNTING – The produc t should be mounted t o a wall or ceiling onl y as

23.

recommended by the manufacturer.

Rev. D v KDMU000799

02/6/04

Page 6

WARNING

• TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE T HIS PRODUCT

TO RAIN OR MOISTURE.

• DO NOT INSERT ANY METALLIC OBJECT THROUGH VENTILATION GRILLS.

• THIS UNIT MUST BE OPERATED WITH A PROPERLY GROUNDED 3-PIN CONNECTION.

NON-OBSERVANCE OF THIS STANDARD PRACTICE MAY RESULT IN A STATIC

ELECTRICITY BUILD-UP THAT MAY RESULT IN AN ELECTRIC SHOCK WHEN EXTERNAL

CONNECTIONS ARE TOUCHED.

CAUTION

CAUTION

RISK OF ELECTRIC SH OC K

DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTR IC SHOCK,

DO NOT RE MOVE C OVER (OR BAC K) .

NO USER-SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

EXPLANATION OF GRAPHICAL SYMBOLS

The lightning flash with arrowhead symbol, within an equilateral triangle, is

intended to alert the user to the presence of uninsulated "dangerous voltage"

within the product's enclosure that may be of sufficient magnitude to constitute

a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert the user

to the presence of important operating and maintenance (servicing) instruction

in the literature accompanying the product.

Rev. D vi KDMU000799

02/6/04

Page 7

DECLARATION OF CONFORMITY

To The European Community Council Directive 89/336/EEC

ISSUED BY: Ultrak, Inc.

4465 Coonpat h Road NW

Carroll, OH 43112

USA

Tel: (740) 756-9222

Fax: (740) 756-4237

MANUFACTURER: Ultrak, Inc.

DATE OF ISSUE: July 31, 1998

TYPE OF EQUIPMENT: CCTV and Security Surveillance Equipment

MODEL NUMBER: Domes

DD: May be followed by any number of alphanumeric characters. Can not contain an “X”

Scans*

DF, DS, DC, or DH:

May be followed by any number of alphanumeric characters. Can not contain an “H”

D1F, D1S, D1C, or D1H:

May be followed by any number of alphanumeric characters. Can not contain an “X”

SmartScan III’s*

39, 3A, 3B, or 3C:

May be followed by any number of alphanumeric characters. Must contain a “C” in

UltraDome KD6*

KD6 May be followed by any number of alphanumeric characters. Must contain a “P” in

KDS May be followed by any number of alphanumeric characters.

KD6 Z-Series*

KDZ May be followed by any num ber of alphanumeric characters.

ZD2 Series*

ZD2 May be followed by any number of alphanumeric characters.

Yokes*

FX-X1, SM-X1, FX9-X1, FX9-X2, SM9-X1, SM9-X2

Power Supply

TR-24/D/CE, TR-24/WSPX

*Standard EN60065 does not apply.

#Standard 87/404/EEC Simple Pressure Directive does not apply. Pressure is less than 0.5273 kg/cm

STANDARDS TO WHICH

CONFORMITY IS DECLARED:

EN50081-1 Emissions Standard, and EN50082- 1 Imm uni ty Standard

EN55022 Radia ted, Cl ass A, EN55022 Conducted, Class A, IEC-1000-4-2, ESD,

IEC-1000-4-3, RF Fields, IEC-1000-4-4, Fast Transie n ts/Burst.

EN60065 - Safety Requirements for Audio, video and similar electronics apparatus.

Ultrak, Inc. hereby declares that the models specified above conform to the directive and standard as specified.

Donald L. Stephenson

Compliance Engineer

517775-5 Rev. M March 5, 2002

#

after the seventh field. (Note: “-“ are not considered fields.)

after the seventh field.

after the seventh field.

the seventh field or after.

the seventh field.

2-

.

.

Rev. D vii KDMU000799

02/6/04

Page 8

IMPORTANT NOTICE

All companies make changes and improvements in their products. Because this product can be set up

to interface with equipment other than Ultrak branded products, there is a possibility that the interface

protocols may have changed since this product was tested with the interfacing equipment. Therefore,

this unit may not be currently compatible with equipment produced by other manufacturers.

The existence of past successful installations proves our intent to provide equipment compatible with

other manufacturers, but does not guarantee success.

We recommend purchasing a single unit for bench testing prior to purchasing and installing this product

in quantity. Should any problems occur, we will provide technical support (at the user’s expense) to

analyze the interface protocols of your system. The end user must agree to provide reasonable access

to the system in order to study and correct the protocol incompatibility.

In the event that we are unable to make the units work together in the system, we will accept the return

of any Ultrak products associated with the installation and refund the amounts paid for these products.

Because we recommend bench testing the equipment prior to installation, Honeywell Video Systems

will not be liable for any installation cost, lost revenues, or other cost resulting from the incompatibility.

Rev. D viii KDMU000799

02/6/04

Page 9

TABLE OF CONTENTS

SECTION 1: INTRODUCTION.....................................................................................................................1

1.1 PRODUCT DESCRIPTION........................................................................................................1

1.2 EQUIPMENT HANDLING..........................................................................................................2

1.2.1 Domes...........................................................................................................................2

1.2.2 UltraDome KD6i Assembly ...........................................................................................2

1.2.3 Camera Lens ................................................................................................................2

1.3 MODELS....................................................................................................................................3

SECTION 2: KD6i SCAN INSTALLATION .................................................................................................4

2.1 OVERVIEW................................................................................................................................4

2.2 RECEIVER BOARD SETTINGS................................................................................................5

2.2.1 Defining Protocol (Switches 1-4) ..................................................................................6

2.2.2 Setting Baud Rate and Parity .......................................................................................7

2.2.3 Addressing....................................................................................................................8

2.3 VIDEO BOARD........................................................................................................................10

2.4 SCAN MODULE INSTALLATION............................................................................................11

2.5 LINER INSTALLATION............................................................................................................13

SECTION 3: KD6i LOWER DOME MODULE...........................................................................................14

3.1 LOWER DOME MODULE INSTALLATION.............................................................................14

3.1.1 Indoor Dome with Safety Lanyard Installed on Back Can at Factory.........................14

3.1.2 Indoor Dome with Safety Lanyard Installed on Lower Dome at Factory....................15

3.1.3 Rugged Dome.............................................................................................................16

3.1.4 Outdoor Weather Dome..............................................................................................16

SECTION 4: NAVIGATING MENUS..........................................................................................................17

4.1 INTRODUCTION .....................................................................................................................17

4.2 MENU STRUCTURE ...............................................................................................................18

SECTION 5: SETUP ..................................................................................................................................20

5.1 MAIN MENU ............................................................................................................................20

5.1.1 Language....................................................................................................................21

Rev. D ix KDMU000799

02/6/04

Page 10

TABLE OF CONTENTS, CONTINUED

5.2 DISPLAY OPTIONS.................................................................................................................22

5.2.1 Camera Message........................................................................................................22

5.2.2 Sectors........................................................................................................................22

5.2.3 PreShot Names...........................................................................................................22

5.2.4 Digital Zoom Message ................................................................................................22

5.2.5 Startup Screen Message ............................................................................................23

5.2.6 Change Camera Name Location ................................................................................23

5.2.7 Change Sector Name Location...................................................................................23

5.2.8 Crosshairs...................................................................................................................23

5.3 CONTROL OPTIONS ..............................................................................................................24

5.3.1 PASS...........................................................................................................................24

5.3.2 Auto-Pivot ...................................................................................................................24

5.3.3 Program Alarms..........................................................................................................25

5.3.4 Pan and Tilt Options ...................................................................................................27

5.3.5 Default Function..........................................................................................................30

5.3.6 Auto Focus..................................................................................................................31

5.3.7 VectorScan Auto Focus..............................................................................................31

5.4 DIAGNOSTIC OPTIONS .........................................................................................................32

5.4.1 Coordinates.................................................................................................................32

5.4.2 Error Table..................................................................................................................32

5.4.3 Clear the Memory .......................................................................................................33

5.4.4 Clear the Error Table ..................................................................................................33

5.4.5 Display Error Table Codes ..........................................................................................33

5.4.6 Restore Default Settings.............................................................................................34

5.4.7 Reset Scan and Camera ............................................................................................35

5.4.8 Upload New Firmware to KD6i ...................................................................................35

5.5 CAMERA OPTIONS ................................................................................................................36

5.5.1 Zoom and Focus.........................................................................................................36

5.5.2 Exposure Control ........................................................................................................37

5.5.3 NightShot Control........................................................................................................37

5.5.4 White Balance.............................................................................................................38

5.5.5 Still PreShot ................................................................................................................40

5.5.6 Vertical Phase.............................................................................................................41

5.6 FUNCTION PROGRAMMING .................................................................................................41

5.6.1 PTZ Tour.....................................................................................................................41

5.6.2 VectorScan .................................................................................................................43

Rev. D x KDMU000799

02/6/04

Page 11

TABLE OF CONTENTS, CONTINUED

SECTION 6: OPERATION USING STANDARD PROTOCOL (DIAMOND, MUX-100) ...........................45

6.1 INTRODUCTION .....................................................................................................................45

6.2 RESET KD6i ............................................................................................................................45

6.3 CONTROLLING SCAN ASSEMBLIES....................................................................................45

6.4 FREEZE AND UNFREEZE VIDEO .........................................................................................46

6.5 FLASHBACK OPERATION .....................................................................................................46

6.6 PRESHOTS .............................................................................................................................47

6.6.1 List Programmed PreShots.........................................................................................48

6.6.2 Go To PreShot Command ..........................................................................................48

6.7 VECTORSCAN (VIDEO TOUR)..............................................................................................49

6.7.1 List Programmed VectorScans...................................................................................49

6.7.2 List Contents of a VectorScan ....................................................................................49

6.7.3 Run VectorScan..........................................................................................................50

6.7.4 Run VectorScan Continuous ly....................................................................................50

6.7.5 Stop VectorScan.........................................................................................................50

6.8 SECTOR ID .............................................................................................................................51

6.8.1 List Programmed Sectors ...........................................................................................51

6.9 PRIVACY ZONES....................................................................................................................52

SECTION 7: PROGRAMMING USING STANDARD PROTOCOL (DIAMOND, MUX-100)......................53

7.1 INTRODUCTION .....................................................................................................................53

7.2 PROGRAMMING PRESHOT S ................................................................................................ 54

7.3 PROGRAMMING VECTORSCANS ........................................................................................55

7.3.1 Editing VectorScans....................................................................................................56

7.3.2 Deleting VectorScans .................................................................................................56

7.4 PROGRAMMING SECTOR IDs ..............................................................................................57

7.4.1 Editing Sectors............................................................................................................58

7.4.2 Deleting Sector IDs.....................................................................................................58

7.5 PROGRAMMING PRIVACY ZONES.......................................................................................58

7.5.1 Programming Privacy Zones ......................................................................................58

Factory set password..................................................................................................59

7.5.2 Editing Privacy Zones .................................................................................................60

7.5.3 Deleting Privacy Zones...............................................................................................60

7.5.4 Changing the Privacy Zone Password........................................................................60

7.6 PROGRAMMING PTZ TOURS ...............................................................................................61

7.7 PTZ TOUR OPERATION.........................................................................................................61

Rev. D xi KDMU000799

02/6/04

Page 12

TABLE OF CONTENTS, CONTINUED

SECTION 8: OPERATION USING MAXPRO, PELCO P CODE, PELCO D CODE,

BURLE, OR VCL CONTROL SYSTEM...............................................................................63

8.1 INTRODUCTION .....................................................................................................................63

8.2 RESET KD6i ............................................................................................................................63

8.3 CONTROLLING SCAN ASSEMBLIES....................................................................................63

8.4 FREEZE / UNFREEZE VIDEO ................................................................................................64

8.5 FLASHBACK OPERATION .....................................................................................................64

8.6 PRESHOTS .............................................................................................................................65

8.7 VECTORSCANS (VIDEO TOUR)............................................................................................67

8.7.1 List Programmed VectorScans...................................................................................67

8.7.2 List Contents of a VectorScan ....................................................................................67

8.7.3 Run VectorScan..........................................................................................................67

8.7.4 Run VectorScan Continuous ly....................................................................................68

8.7.5 Stop a VectorScan......................................................................................................68

SECTION 9: PROGRAMMING USING MAXPRO, PELCO P CODE, PELCO D CODE,

BURLE, OR VCL CONTROL SYSTEM...............................................................................69

9.1 INTRODUCTION .....................................................................................................................69

9.2 PROGRAMMING PRESHOT S ................................................................................................ 69

9.3 PROGRAMMING VECTORSCANS ........................................................................................69

9.4 PROGRAMMING SECTOR IDS..............................................................................................69

9.5 PROGRAMMING PRIVACY ZONES.......................................................................................69

9.6 PROGRAMMING PTZ TOURS ...............................................................................................69

9.7 PTZ TOUR OPERATION.........................................................................................................70

SECTION 10: OPERATION USING AMERICAN DYNAMICS CONTROL SYSTEM...............................71

10.1 INTRODUCTION .....................................................................................................................71

10.2 RESET KD6i ............................................................................................................................71

10.3 CONTROLLING SCAN ASSEMBLIES....................................................................................71

10.4 FREEZE / UNFREEZE VIDEO ................................................................................................72

10.5 FLASHBACK OPERATION .....................................................................................................72

10.6 PRESHOTS .............................................................................................................................72

10.7 VECTORSCAN (VIDEO TOUR)..............................................................................................74

10.7.1 List Programmed VectorScans...................................................................................74

10.7.2 List Contents of a VectorScan ....................................................................................74

10.7.3 Run VectorScan..........................................................................................................74

10.7.4 Run VectorScan Continuous ly....................................................................................75

10.7.5 Stop VectorScan.........................................................................................................75

Rev. D xii KDMU000799

02/6/04

Page 13

TABLE OF CONTENTS, CONTINUED

SECTION 11: PROGRAMMING USING AMERICAN DYNAMICS CONTROL SYSTEM........................76

11.1 INTRODUCTION .....................................................................................................................76

11.2 PROGRAMMING PRESHOT S ................................................................................................ 76

11.3 PROGRAMMING VECTORSCANS ........................................................................................76

11.4 PROGRAMMING SECTOR IDS..............................................................................................76

11.5 PROGRAMMING PRIVACY ZONES.......................................................................................76

11.6 PROGRAMMING PTZ TOURS ...............................................................................................76

11.7 PTZ TOUR OPERATION.........................................................................................................77

SECTION 12: TROUBLESHOOTING........................................................................................................78

12.1 TROUBLESHOOTING PROCEDURES ..................................................................................78

12.2 NO VIDEO ...............................................................................................................................78

12.3 VIDEO PROBLEMS (CAT5 OPTION ONLY) ..........................................................................79

12.4 VIDEO, BUT NO CONTROL....................................................................................................79

12.5 SCAN OPERATES BY ITSELF ...............................................................................................80

12.6 ERRATIC SCAN OPERATION................................................................................................81

12.7 LENS OUT OF OPTICAL FOCUS...........................................................................................81

12.8 CANNOT FIND HOME OR DOES NOT GO TO PRESHOT...................................................82

12.9 SCAN DRIFTS IN ONE DIRECTION (UP, DOWN, LEFT, RIGHT).........................................82

12.10 SCAN IS JERKY......................................................................................................................82

SECTION 13: MAINTENANCE..................................................................................................................83

13.1 MAINTENANCE SCHEDULE..................................................................................................83

13.2 REMOVING LOWER DOME MODULE...................................................................................83

13.2.1 Indoor Back Can Module or Pendant Dome...............................................................83

13.2.2 Indoor Back Can with Digital Interface........................................................................84

13.2.3 Weather Dome............................................................................................................84

13.3 REMOVING THE KD6i SCAN FROM THE BACK CAN, PENDANT DOME,

OR WEATHER DOME.............................................................................................................84

13.4 DOME CLEANING PROCEDURE...........................................................................................85

13.4.1 Clear Dome And Smoked Dome ................................................................................85

Rev. D xiii KDMU000799

02/6/04

Page 14

TABLE OF CONTENTS, CONTINUED

SECTION 14: REPLACEMENT PARTS....................................................................................................86

14.1 INTRODUCTION .....................................................................................................................86

14.2 ULTRADOME KD6i INDOOR BACK CAN...............................................................................87

14.3 ULTRADOME KD6i INDOOR PENDANT TOP DOME ...........................................................88

14.4 ULTRADOME KD6i INDOOR LOWER DOME MODULE .......................................................89

14.5 ULTRADOME KD6i OUTDOOR TOP WEATHER DOME.......................................................90

14.6 ULTRADOME KD6i OUTDOOR BOTTOM WEATHER DOME...............................................91

14.7 KD6i RUGGED DOME TOP ....................................................................................................92

14.8 KD6i RUGGED DOME BOTTOM............................................................................................93

14.9 KD6i SCAN ..............................................................................................................................93

SECTION 15: SPECIFICATIONS..............................................................................................................96

15.1 BACK CAN / LOWER DOME MODULES................................................................................96

15.2 SCAN MODULE.......................................................................................................................97

FIGURES and TABLES

Figure 1: Receiver Board, Part Number 519541-1020.................................................................................5

Figure 2: Video Board, Part Number 519539-10 20 (NT SC) ......................................................................10

Figure 3: Installation, Lower Dome with Safety Lanyard Installed at Factory on Back Can ......................12

Figure 4: Liner Installation..........................................................................................................................13

Figure 5: Installation, Lower Dome with Safety Lanyard Installed at Factory on Lower Dome..................15

Figure 6: Installation, Lower Dome with Safety Lanyard Installed on Lower Dome...................................16

Table 1: Modulo 256 Addressing..................................................................................................................9

Table 2: Preprogrammed Preshots (Maxpro, Pelco P Code, Pelco D Code,

Burle, and VCL Control Systems)...............................................................................................66

Table 3: Preprogrammed Preshots (American Dynamics Control Systems).............................................73

Rev. D xiv KDMU000799

02/6/04

Page 15

INTRODUCTION

1.1 PRODUCT DESCRIPTION

SECTION 1:

Cameras available with the UltraDome KD6i are:

843216-1010 Color NTSC w/4.1-73.8mm

843216-1011 Color NTSC w/4.1-73.8mm, IR

843216-1012 Color PAL w/4.1-73.8mm

843216-1013 Color PAL w/4.1-73.8mm, IR

An UltraDome KD6i is a pan and tilt mechanism containing a camera and lens that

is controlled remotely by an operator using an American Dynamics, Burle, Diamond

series, Maxpro series, Pelco (P and D code only), or VCL control system.

The UltraDome KD6i is housed in a back can (for dropped or hard ceiling

applications) or pendant dome for indoor applications and in a Weather Dome for

outdoor applications. The whole assembly is often referred to as a "dome.”

The pan and tilt mechanism with camera and lens is often referred to as a "scan.”

The indoor pendant top dome can be mounted on Ultrak’s indoor pendant ceiling

dome mount or indoor wall dome mount. The weather dome can be mounted on

Ultrak’s outdoor wall mount, pendant mount, roof mount, or parapet mount.

Part # Description

Rev. D 1 KDMU000799

02/6/04

Page 16

1.2 EQUIPMENT HANDLING

1.2.1 Domes

1.2.2 UltraDome KD6i Assembly

It is extremely important to treat the surface of all domes (smoked and clear) with the

same care as you would a fine camera lens.

• Always handle the dome from its outside surface.

• Refer to Section 13 - Maintenance

• Only use non-abrasive cleaners for acrylic plastic on the clear and smoked

domes.

The UltraDome KD6i consists of:

• the pan and tilt mechanism;

• camera with zoom lens;

Available camera models are:

• power supply board; and

• digital receiver board.

for dome cleaning procedures

Do not attempt to remove the camera from the scan assembly. If a camera or lens

requires service, the entire scan assembly must be sent back to the factory.

1.2.3 Camera Lens

• Handle the camera lens with extreme care.

• Never touch the lens surface.

• Refer to Section 13 - Maintenance

CAUTION: The receiver board and power supply board

on the scan assembly have static sensitive devices.

The KD6i assembly is shipped in a pink bag that is static

dissipating. The unit should be handled in this bag until

installed. If the unit is shipped, it must be shipped in the

pink bag or an equivalent static dissipating enclosure.

for information on cleaning the camera lens.

Rev. D 2 KDMU000799

02/6/04

Page 17

A

A

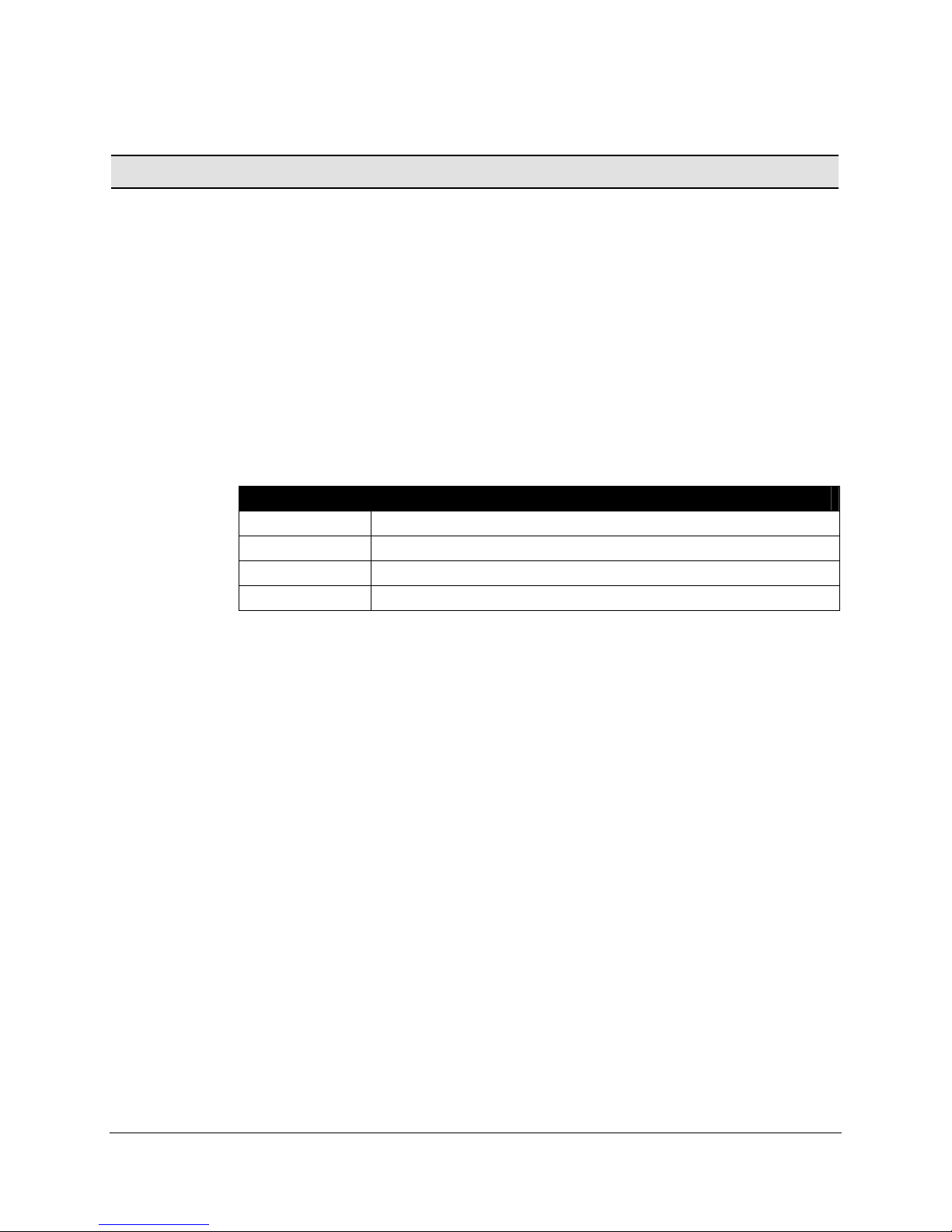

1.3 MODELS

Indoor

Part Number:

KD6

Camera Type:

Dome Type:

Lower Dome

and Trim

Ring Options:

Format:

Transmission:

*Not available on Rugged models.

Additional Trim ring options available as requested.

Contact local Account Executive.

Outdoor

High Res Color Camera

Color & B/W "Nightshot" Camera

Drop/Hard Ceiling

Pendant

Rugged

Smoked Lower Dome, BLK Trim

Smoked Lower Dome, W HT Trim*

Clear Lower Dome, BLK Tri m

Clear Lower Dome, WHT Trim*

PAL

NTSC

Standard RS-485 Transmission

Cat5/Up-the-Coax

AD Manchester/Burle BiPhas e

B

D

P

R

1

2

4

5

P

N

1

4

M

Part Number:

KD6

Camera Type: High Res Color Came ra

Color & B/W "Nightshot"Camera B

Dome Type:

Lower Dome:

Format: PAL P

Transmission:

Power supply not included on outdoor domes.

Recommended models are TR24WSPL and KZ0224NEMA.

Weather/Nitro RS-485 Transmission

Rugged RS-485 Transmission

Weather/Nitro Cat5/Up-the-Coax

Rugged Cat5/Up-the-Coax

AD Manchester/Burle BiPhase

Standard Weather

Nitrogen Pressurized

Rugged R

Smoked Lower Dome

Clear Lower Dome

W

E

1

4

NTSC N

1

H

4

J

M

Rev. D 3 KDMU000799

02/6/04

Page 18

2.1 OVERVIEW

SECTION 2:

KD6i SCAN INSTALLATION

Installation Process:

The instructions and detailed information for installing and operating the KD6i are

contained in several sections. Instructions in this manual assume that the back can

module installation is complete.

The following list is an overview of the installation steps, along with references to

more specific details. Follow the detailed instructions under each section/subsection

referenced.

1. Set switches on the KD6i receiver board. (Refer to Section 2.2

2. Set W8 jumper on video board. (Refer to Sec t ion 2.3

3. Install scan module. (Refer to Section 2.4

4. Remove or reinstall liner, as needed. (Refer to Section 2.5

5. Install the lower dome module. (Refer to Section 3.0

.)

.)

.)

.)

.)

Rev. D 4 KDMU000799

02/6/04

Page 19

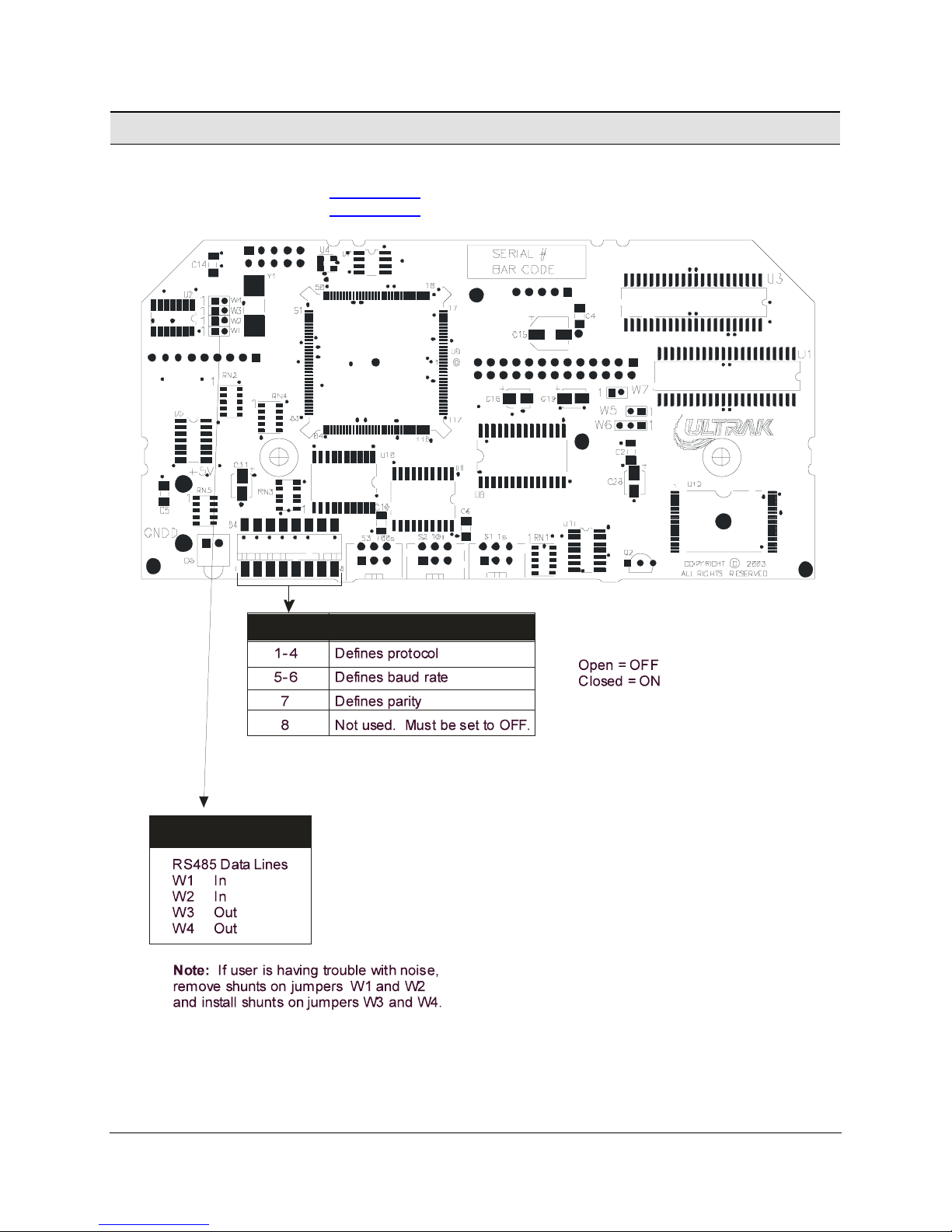

2.2 RECEIVER BOARD SETTINGS

1. Set the switches as required on the KD6i receiver board.

Refer to Section 2.2.1

Refer to Section 2.2.3

for switch settings.

for addressing.

Switch S4

Jumpers W1-W4

Use

Figure 1: Receiver Board, Part Number 519541-1020

Rev. D 5 KDMU000799

02/6/04

Page 20

2.2 SCAN MODULE INSTALLATION, CONTINUED

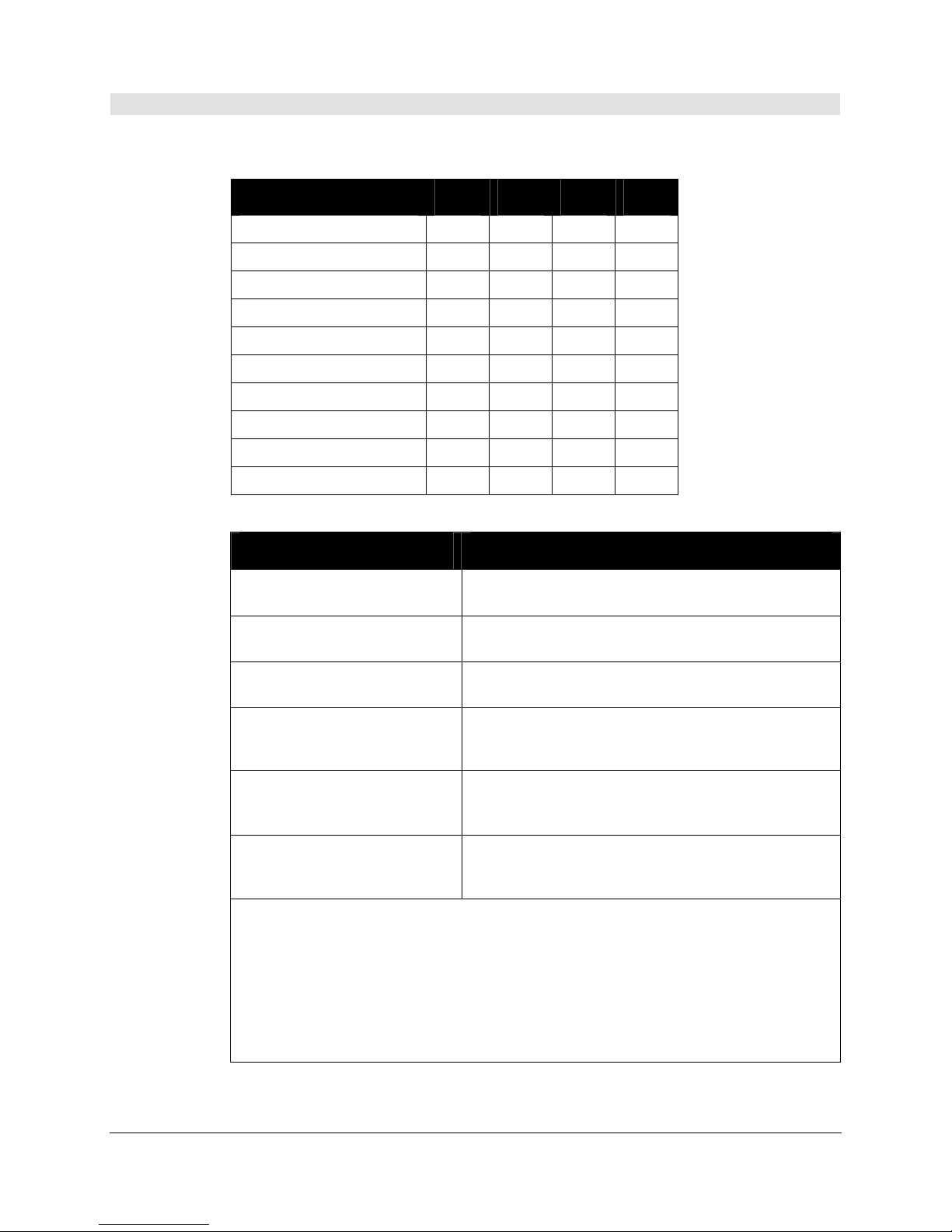

2.2.1 Defining Protocol (Switches 1-4)

Standard Diamond OFF OFF OFF OFF

Maxpro ON OFF OFF OFF

MUX100 OFF ON OFF OFF

AD ON ON OFF OFF

Pelco P OFF OFF ON OFF

VCL ON OFF ON OFF

Pelco D OFF ON ON OFF

iPro ON ON ON OFF

Pelco P_AD OFF OFF ON ON

Pelco D_AD OFF ON ON ON

Protocol 1 2 3 4

Javelin equipment Set the Javelin controller for Diamond protocol and

KD6i with an AD1281/1 Code

Distributor

KD6i with a Sennetech Code

Translator, Model SCT-1036

KD6i with the Manchester

Code Interface Board and an

AD control system

KD6i with the Manchester

Code Interface Board and a

Burle control system

KD6i with the Digital Interface Set the KD6i address to 000 and the control system

NOTE: If the switches are set to something other than the above settings, the scan

The standard Pelco P and D selections use special PreShots numbered in

Equipment Protocol

set the KD6i unit for Maxpro protocol.

Set the KD6i to American Dynamics protocol.

Set the KD6i to Maxpro protocol.

Set the KD6i to American Dynamics protocol.

Set the KD6i to Maxpro protocol.

to UPF. Set the KD6i to standard (Diamond)

protocol.

defaults to Standard protocol.

the 80’s and 90’s. The Pelco P w/AD PreShots and the Pelco D w/AD

PreShots selections set the protocol for Pelco P and Pelco D code

respectively, but use special PreShot numbers less than 32 for KD6i menus

and setup.

Rev. D 6 KDMU000799

02/6/04

Page 21

2.2 SCAN MODULE INSTALLATION, CONTINUED

2.2.2 Setting Baud Rate and Parity

The communications baud rate and the parity are set using DIP switch S4 positions

4, 5, 6, and 7. The control system and the scan must be set at the same baud rate

and parity for proper operation. All protocols are set for 8 data bits.

DIP switch 4, position 8 must always be set to OFF.

Baud Rate / Parity / Data Bits S4-5 S4-6 S4-7 S4-8

2400 Baud / No Parity / 8 data bits OFF OFF OFF OFF

2400 Baud / Even Parity / 8 data bits OFF OFF ON OFF

4800 Baud / No Parity / 8 data bits ON OFF OFF OFF

4800 Baud / Even Parity / 8 data bits ON OFF ON OFF

9600 Baud / No Parity / 8 data bits OFF ON OFF OFF

9600 Baud / Even Parity / 8 data bits OFF ON ON OFF

19.2K Baud / No Parity / 8 data bits ON ON OFF OFF

19.2K Baud / Even Parity / 8 data bits ON ON ON OFF

NOTE:

Settings for the protocols are as follows:

Protocol Baud Parity

Rev. D 7 KDMU000799

02/6/04

Standard, Maxpro, AD 9600 baud Even Parity

VCL 9600 baud No Parity

MUX-100 19.2k baud Even Parity

Pelco P 4800 baud No Parity

Pelco D 2400 baud No Parity

iPro NA NA

Page 22

2.2 RECEIVER BOARD, CONTINUED

2.2.3 Addressing

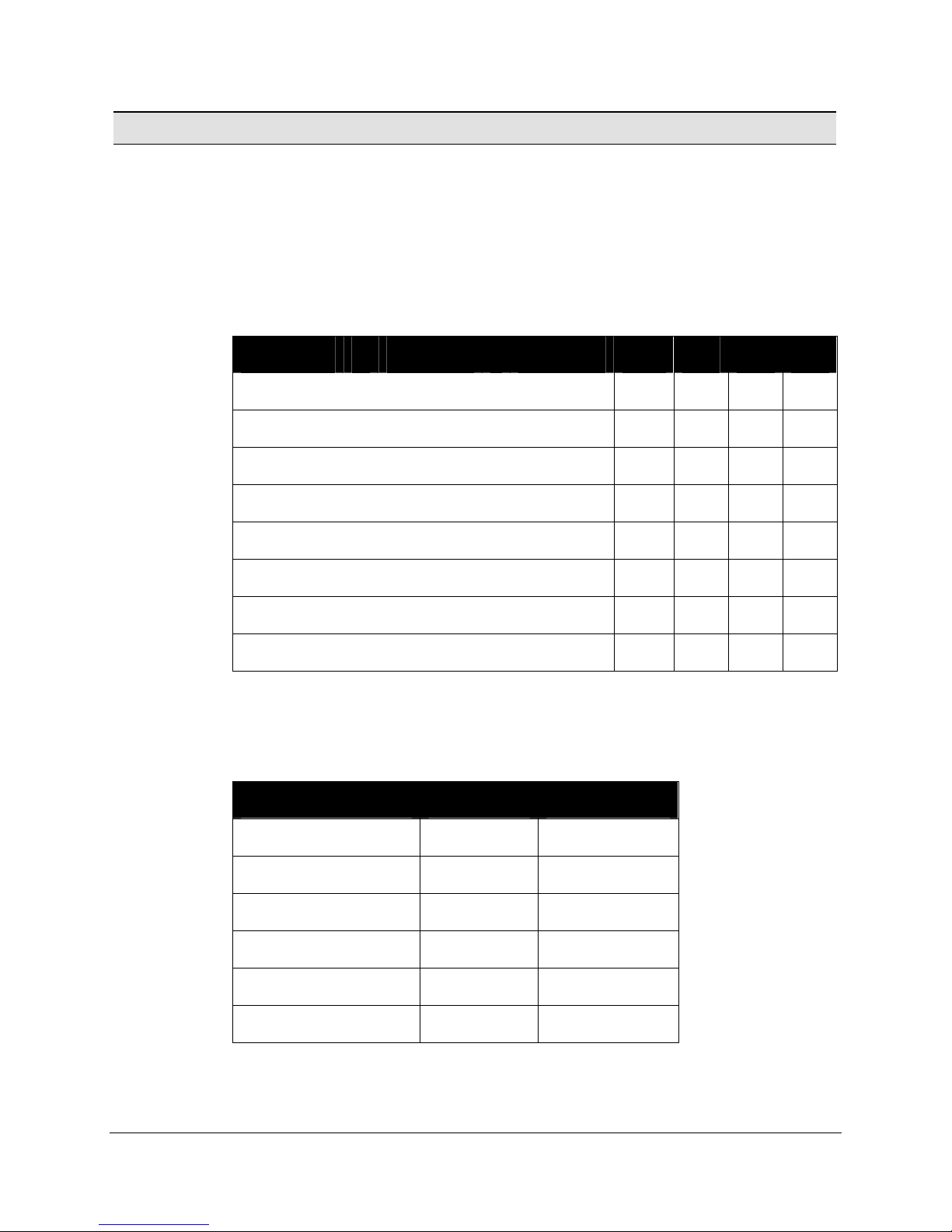

Each UltraDome KD6i must be given a unique address (camera number) set by the

operator at the control system to control the scan. The address is defined using rotary

switches S1, S2, and S3 on the receiver board. Addresses are set from 001 to 989.

Addresses 990 to 999 are reserved for factory testing. If the switches are set to 000,

the scan responds to all commands with all addresses and there is no communication

error checking.

ADDRESS

S1

S2

S3

Ones Digit

Tens Digit

Hundreds Digit

The addressing scheme is modulo 256. The scan is physically addressed 1-989,

but all scans addressed above 256 must be controlled using camera numbers 1-255.

NOTE: If the control system is set for MUX-100 (19.2K) protocol, addresses

256, 512, and 768 cannot be used. These are unattainable values in a

MUX-100 control packet.

NOTE: The three address switches, S1, S2, and S3, must be set to 0, 0, 0 when the

KD6i is installed in a back can with the digital inter f ac e boar d and is instal le d

in a network.

NOTE: If you are using the KD6i with control equipment other than Ultrak Diamond

series, please consult the instruction manuals provided with your control

equipment for addressing the dome. For example, if you are using a

Maxpro control system, the addressing scheme is 1-16. The KD6i address

is determined by the switch settings and the port the KD6i is connected to on

the switch.

Another example is if you are using the scan with the Manchester Code

Interface Board and an American Dynamics control system, the

addressing scheme is 1-64, the same addressing scheme as an AD switch.

Refer to the manuals provided with your control system for help in

addressing the KD6i dome.

Refer to Table 1

to cross reference camera addresses to camera control numbers

using modulo 256.

Rev. D 8 KDMU000799

02/6/04

Page 23

2.2 RECEIVER BOARD, CONTINUED

1-256 1-256

257

513

769

990 - 999 (reserved) 222-231

Modulo 256 Addressing

Camera Number

Set using Switches

(Video Display)

258

259

.

.

510

511

512

514

515

.

.

766

767

768

770

771

.

.

987

988

989

(JPD Series Controller Displa y)

Table 1:

Camera Number*

for Control Purposes

1

2

3

.

.

254

255

256

1

2

3

.

.

254

255

256

1

2

3

.

.

219

220

221

*NOTES:

• The camera number transmitted in the protocol for control purposes must be one

less than the number shown in column two above. For example, if the rotary

switches are set for camera address 1 on the KD6i, the command packet sent to

the KD6i for control purposes must contain camera address 0 to control the KD6i.

If the switches are set for camera address 513, the command packet sent to the

KD6i for control purposes must contain camera address 0 to control the KD6i.

Rev. D 9 KDMU000799

02/6/04

• The control system (protocol) used to control the KD6i is defined on DIP switch

S4 on the receiver board.

Page 24

2.3 VIDEO BOARD

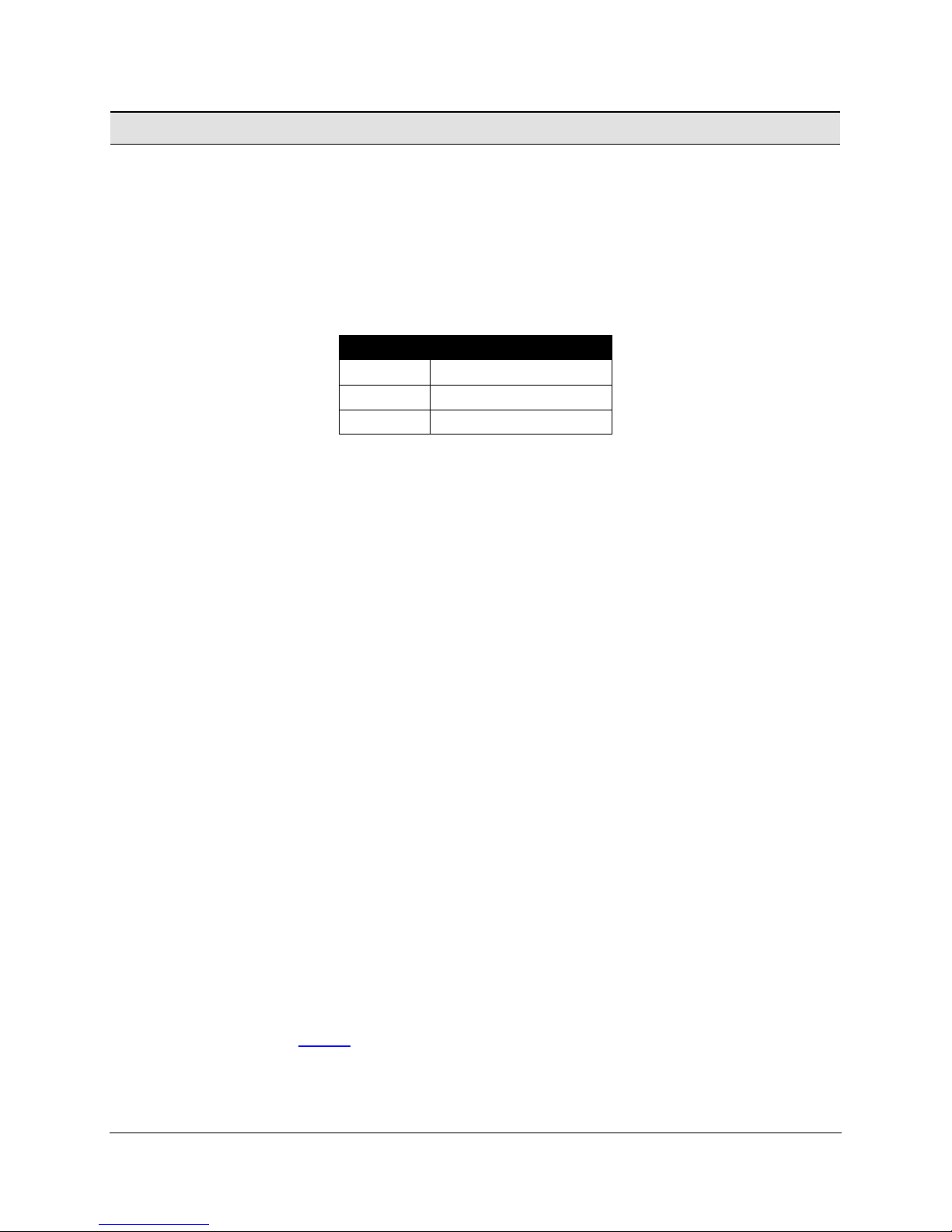

1. Set jumper W8 on the video board as shown in Figure 2

.

Jumper W8 on the video board, part number 519539-1020 (NTSC) or 5195392020 (PAL), must be set as shown in Figure 2. For the CAT-5/UTC option, the

back can or top dome must have the CAT5/UTC interface board, part number

518753-1030.

NOTE: Use the CAT5/UTC settings for the Manchester Interface Board.

CAUTION: The black jumper must be on pin 1 of W8 for

standard units or equipment damage may occur.

BLACK

JUMPER

W8

CONNECTOR P10

FROM SCAN WIRI NG

HARNESS

FOR STAN DARD KD6 UNITS

CONNECTOR P10 MUST BE

CAUTION

BLACK JUMPER AND

ON W8 AS SHOWN.

UCT/CA T5 &

MANCHESTER OPTIONS

REMOVE A ND DISC AR D

BLACK J UMPER.

W8

Figure 2: Video Board, Part Number 519539-1020 (NTSC)

CONNECTOR P10

FROM SCAN WIRING

HARNESS

Rev. D 10 KDMU000799

02/6/04

Page 25

2.4 SCAN MODULE INSTALLATION

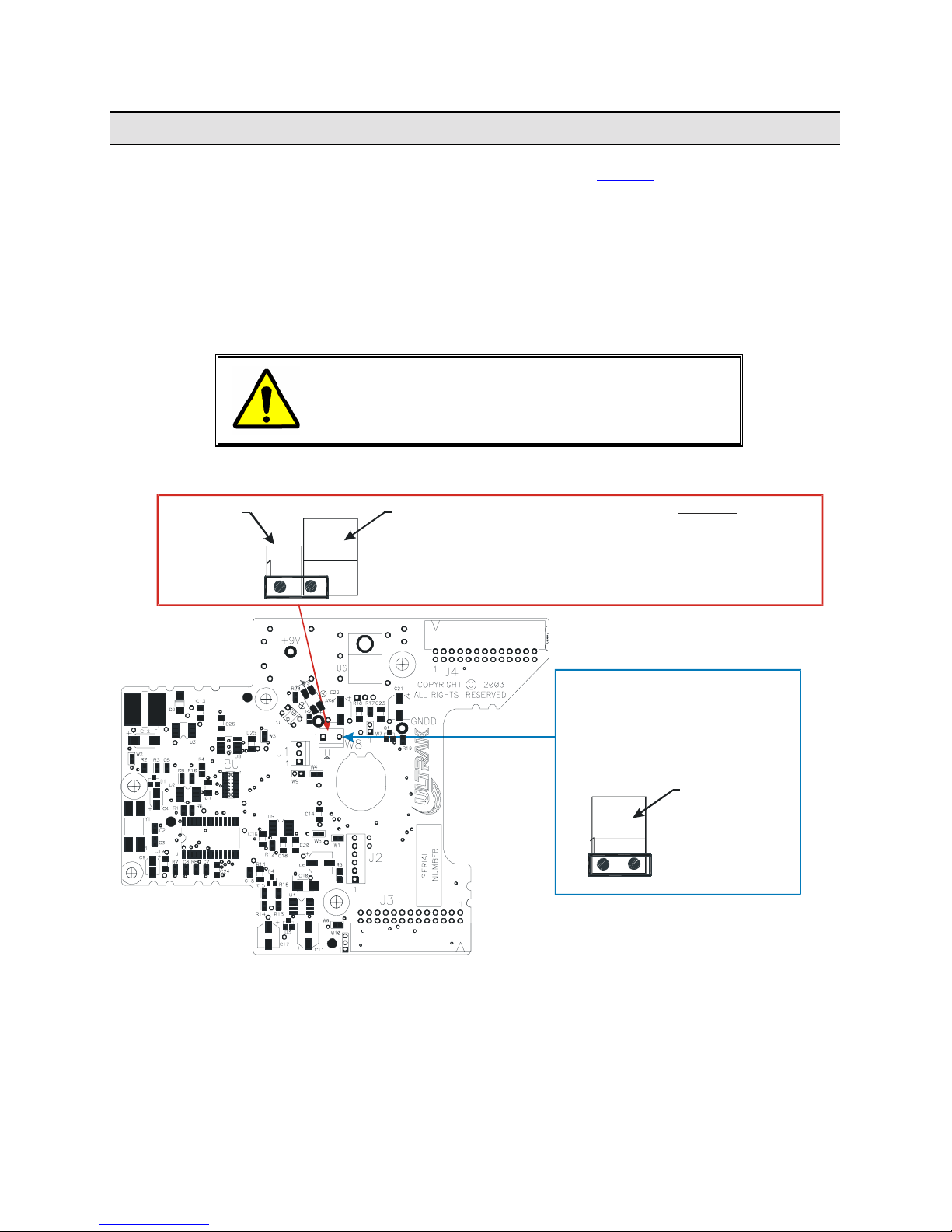

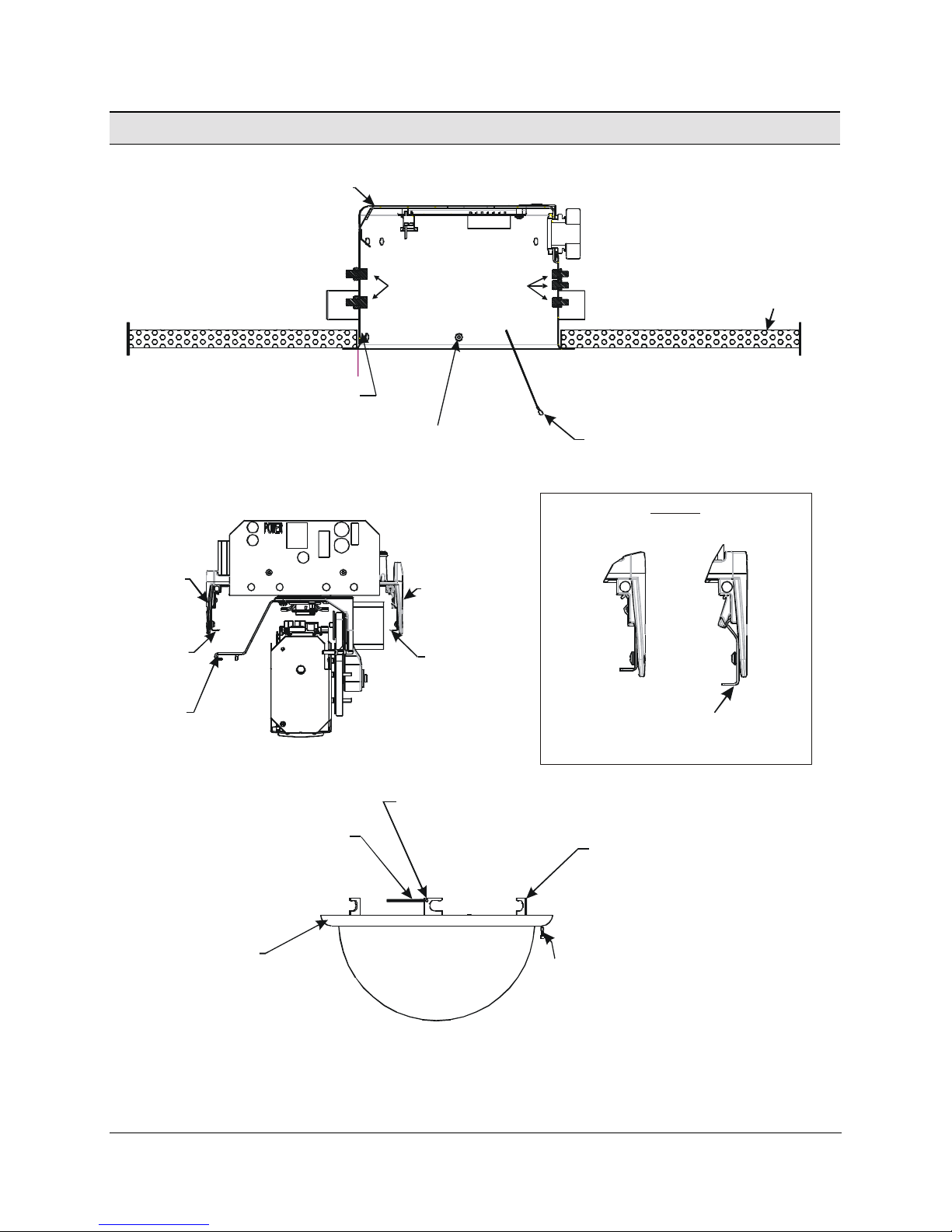

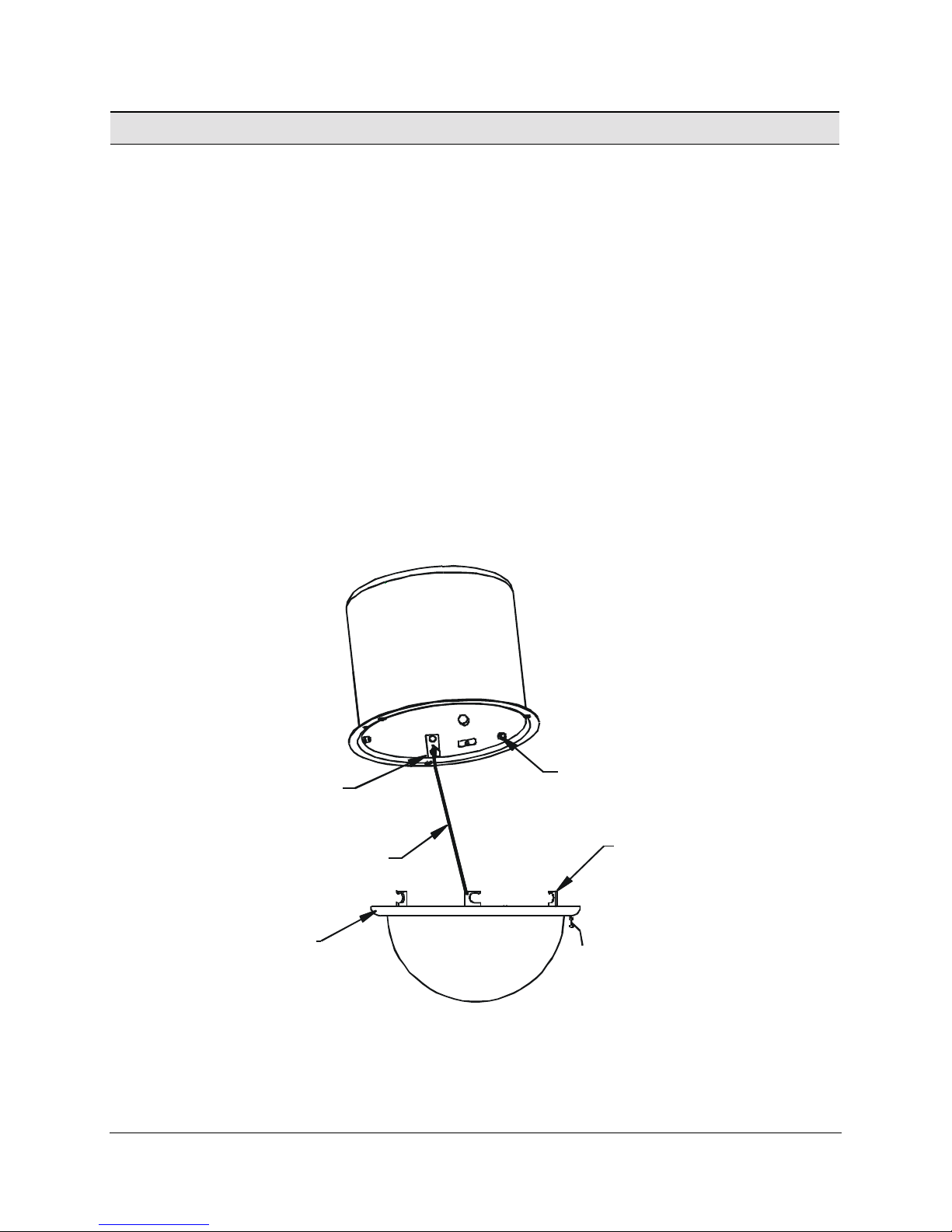

Ensure that the latches on the KD6i are in the locked position. See Figure 3, Detail A.

Hold the KD6i scan module by the liner mounting bracket, the liner itself, or the

latches. DO NOT HOLD THE KD6i SCAN MODULE BY THE CAMERA. Locate the

yellow sticker with a black dot in the center on one of the latches on the scan module.

Align this sticker with the same sticker in the back can module or top dome. The KD6i

narrow mounting slot aligns with the three small scan alignment studs in the back can

module and the wide mounting slot aligns with the two large scan alignment studs in

the back can module. The connector on the top of the scan module aligns with the

connector in the top of the back can module or top dome.

Push the KD6i scan module into the back can module until both latches click into the

holes on the back can module. You should hear two clicks. Press firmly on both

latches to ensure proper installation. Gently tug on the scan module to verify it is

locked in position.

NOTE: The hard ceiling back can module is shown. Installation of the KD6i scan

module in the Dropped Ceiling, Pendant, and Weather back can modules is

the same. Installation of the lower dome module depends on whether the

lanyard is installed at the factory on the lower dome or on the top dome (as

shown below). Refer to Figure 3

The bottom weather dome is not shown. Refer to Figure 6

or Figure 5 depending on your equipment.

for an illustration

of the bottom weather dome.

Rev. D 11 KDMU000799

02/6/04

Page 26

A

(

)

2.4 SCAN MODULE INSTALLATION, CONTINUED

BACK CAN

MOUNTING

SLOT

LATCH

LOCKED

POSITION

LINER

BRACKET

LOOK FOR YELLOW STICKER

WITH BLACK DOT IN CENTER

(ALIGN WITH SAME STICKER

ON KD6i SCAN LATC H)

SCAN ALIGNMENT STUDS

BOTTOM DOME

MOUNTING POSTS

(3 PLACES)

MOUNTING

SLOT

LATCH

LOCKED

POSITION

SEE DETAIL A

DRYWALL

CEILING

TTACH LANYARD TO BOTTOM DOME

DET AIL A

LOCKED

POSITION

LOOK FOR YELLOW STICKER WITH

BLACK DOT IN CENTER ON ONE OF LATCHES

(ALIGN WITH SAME STICKER IN TOP HAT)

RELEASED

POSITION

LANYARD MUST BE

INSTALLE D AS SHOWN

PARA LLEL T O TRIM RING

TRIM

RING

Figure 3: Installation, Lower Dome with Safety Lanyard Installed at Factory on Back Can

Rev. D 12 KDMU000799

02/6/04

MOUNTING POST FOR

SAFETY CABLE FROM

BACK CAN

LOWER DOME

MOUNTING TABS HOOK

ON POSTS IN BACK CAN

(3 PLACES)

2-56 CAPTIVE SCREW

(CE COMPLIANCE FOR

INSTALLING LOWER DOME

Page 27

2.5 LINER INSTALLATION

The liner installed on the KD6i scan can be removed if it is not required for your

application.

1/4-Turn

Latch

Liner

Liner

Mounting Bracket

"U-Bend"

Figure 4: Liner Installation

To remove the liner:

1. Turn the ¼-turn latches counterclockwise to release the liner.

2. Slide the liner out of the “U-bend” of the liner mounting bracket.

To reinstall the liner:

1. Insert the edge of the liner into the “U-bend” of the liner mounting bracket.

2. Line up the two ¼-turn latches on the liner with the holes on the liner m ountin g

bracket.

3. Insert the ¼-turn latches into the holes and turn clockwise to secure the liner to

the mounting bracket.

Rev. D 13 KDMU000799

02/6/04

Page 28

SECTION 3:

KD6i LOWER DOME MODULE

3.1 LOWER DOME MODULE INSTALLATION

1. Remove the lens cap from the camera lens.

2. Install the bottom dome. Follow instructions shown for the specific type of mount.

CAUTION: Always handle the bottom dome by the flange

around the dome. Do not touch the inside surface of the

dome.

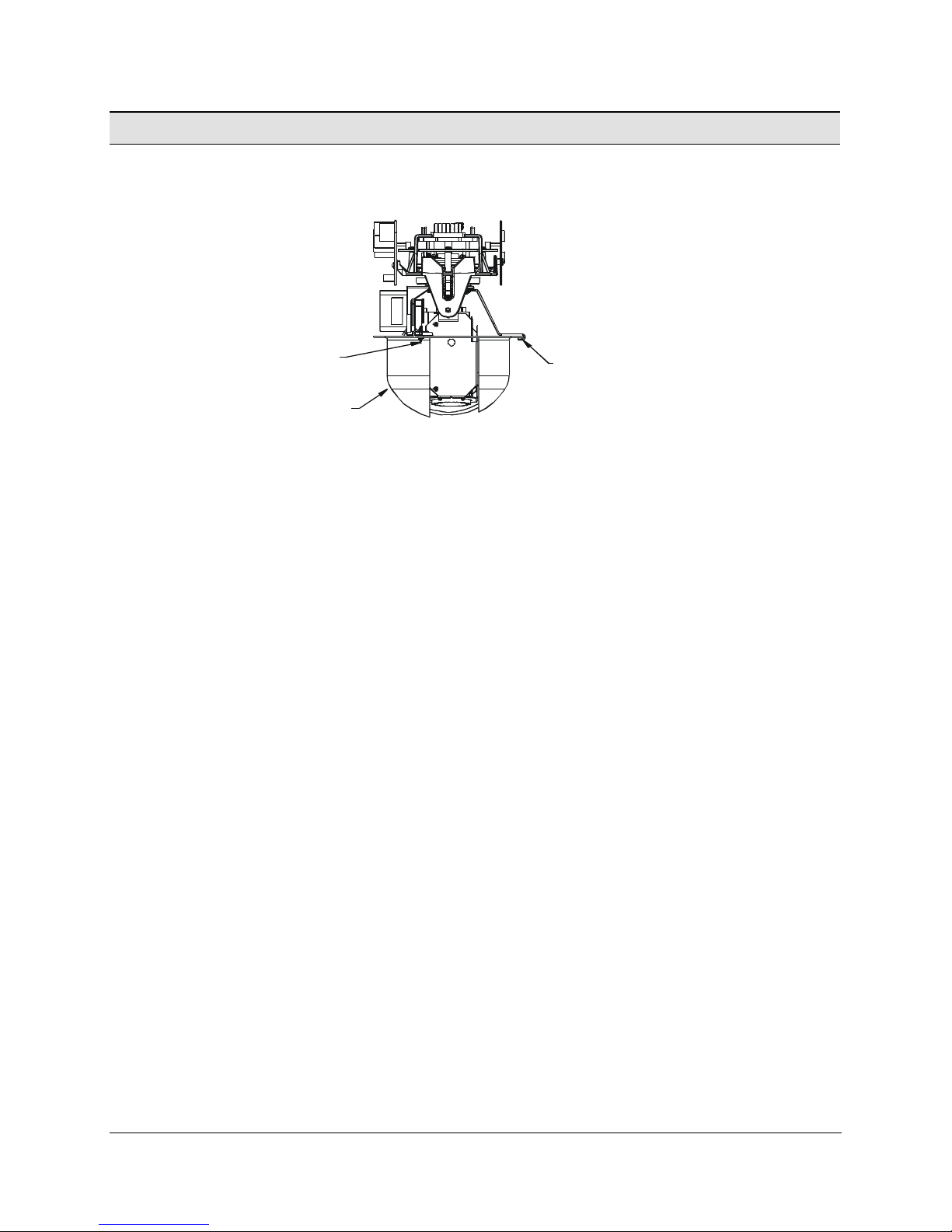

3.1.1 Indoor Dome with Safety Lanyard Installed on Back Can at Factory

1. Attach the safety cable from the back can module to the bottom dome.

a. Remove the acorn nut on the mounting screw on the bottom dome.

b. Hook the safety cable eyelet over the screw on the bottom dome and

thread the acorn nut onto the screw. Ensure safety cable is positioned

as shown in drawing. Ensure cable is perpendicular to bracket and

parallel to bottom dome trim ring.

2. For installations requiring CE compliance, perform the following step, otherwise,

go to step 3.

a. Locate the bag containing a lock screw and 5/64” hex key (supplied with

the bottom dome).

b. Insert the 2-56 lock screw through the hole in the bottom dome trim ring

and screw it into the bottom dome inner ring.

3. Align the bottom dome with the back can module or pendant dome and twist to

lock the bottom dome brackets over the mounting posts. For CE compliance,

tighten the lock screw in the bottom dome with the 5/64” hex key until it is snug.

DO NOT OVERTIGHTEN.

Refer to Figure 3 for illustration of installation.

Rev. D 14 KDMU000799

02/6/04

Page 29

(

3.1 LOWER DOME MODULE INSTALLATION, CONTINUED

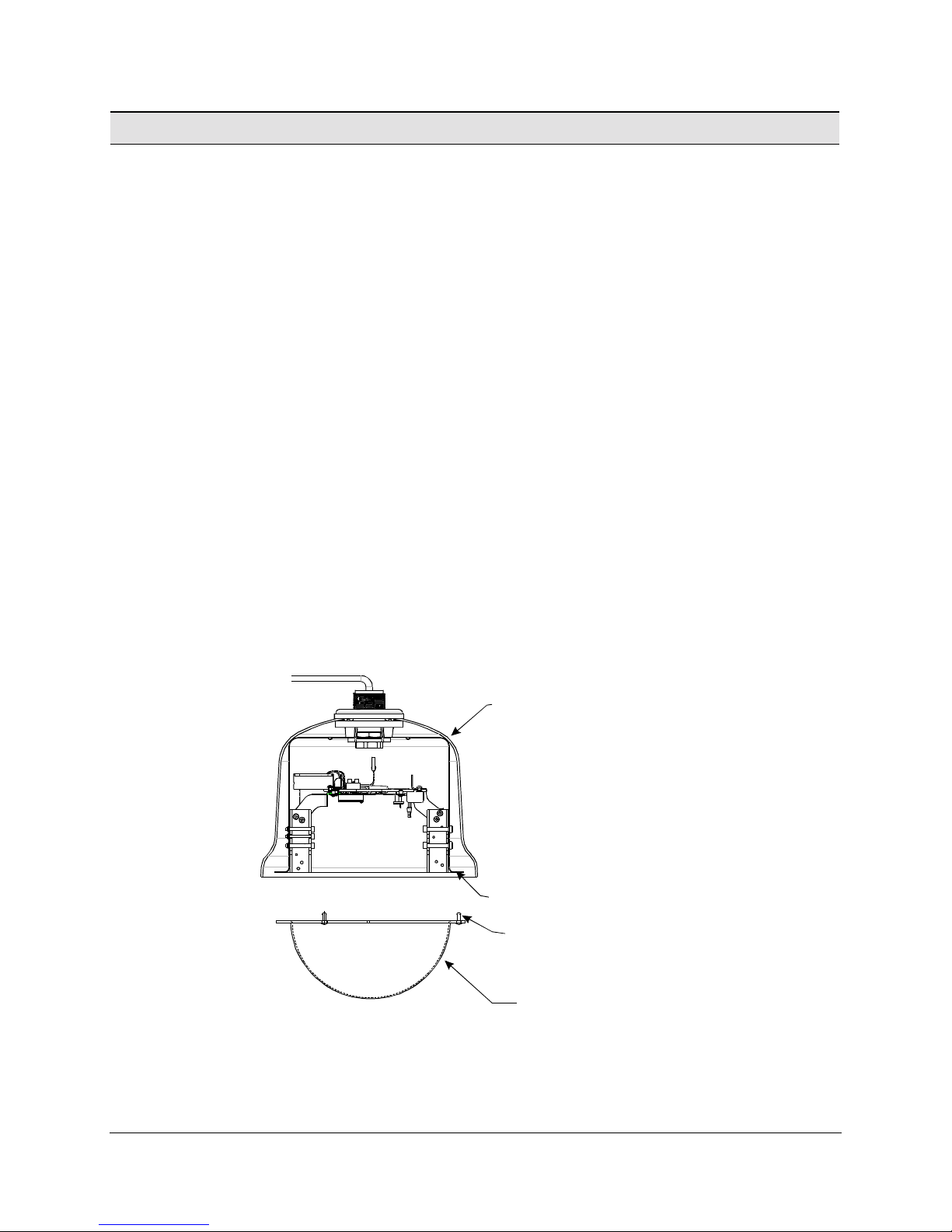

3.1.2 Indoor Dome with Safety Lanyard Installed on Lower Dome at Factory

1. Locate the safety lanyard on the bottom dome.

2. Slide the ball on the lanyard into the clip on the top dome as shown in the

illustration.

3. For installations requiring CE compliance, perform the following steps, otherwise,

go to step 4.

a. Locate the bag containing a lock screw and 5/64” hex key (supplied with

the bottom dome).

b. Insert the 2-56 lock screw through the hole in the bottom dome trim ring

and screw it into the bottom dome inner ring.

4. Align the bottom dome with the top and twist to lock the bottom dome brackets

over the mounting posts. For CE compliance, tighten the lock screw in the bottom

dome with the 5/64” hex key until it is snug. DO NOT OVERTIGHTEN.

SAFETY LANYARD

SAFETY CABLE

TRIM RING

Figure 5: Installation, Lower Dome with Safety Lanyard Installed at Factory on Lower Dome

Rev. D 15 KDMU000799

02/6/04

CLIP

LOWER DOME

LOWER DOME

MOUNTING POSTS

(3 PLACES)

MOUNTING TABS

HOOK ON POSTS

IN BACK CAN

(3 PLACES)

2-56 CAPTIVE SCREW

CE COMPLIANCE FOR

INSTALLING LOWER

DOME)

Page 30

3.1 LOWER DOME MODULE INSTALLATION, CONTINUED

3.1.3 Rugged Dome

1. Insert the three posts on the bottom dome in the three holes on the top dome.

2. Push the bottom dome up until it is snug against the top dome.

3. Insert the key in the lock on the bottom dome.

4. Turn the key clockwise in the lock until the latch is between the brackets in the top

dome.

3.1.4 Outdoor Weather Dome

1. Line up the quarter turn fasteners on the bottom dome with the metal clips in the

holes on the top dome and align the safety cable on the top dome with the

mounting hole on the bottom dome.

2. Using a Phillips screwdriver, push the quarter turn fasteners up through the holes

in the top dome and turn ¼-turn clockwise until locked.

3. Insert the screw on the safety cable into the hole on the bottom dome and tighten.

WEATHER DOME

LOWER DOME MOUNTING HOLES

WITH CLIPS (3 PLACES)

1/4-TURN FASTENERS (3 PLACES)

SECURES LOWER DOME TO

BACK CAN

LOWER DOME

Figure 6: Installation, Lower Dome with Safety Lanyard Installed on Lower Dome

Rev. D 16 KDMU000799

02/6/04

Page 31

4.1 INTRODUCTION

SECTION 4:

NAVIGATING MENUS

Examples:

The UltraDome KD6i pan and tilt units feature on-screen menus for setting up the

receiver board and for enabling special features available for customer use.

All units are set up at the factory before shipment; but can be easily changed in the

field using the on-screen menus.

Refer to your system controller user manual for the keystrokes to access the KD6i

setup menu and the keystrokes to navigate through the options.

• When using a JPD-100 Diamond series controller and a KBD-100 keyboard,

press SHIFT+F1 to access the KD6i setup menu.

• When using the MXSYS04E and a KEGS5000 controller,

press

Use numeric keys on the controller to access menu options.

Press

Press

• When using a Maxpro, VCL, Pelco P, Pelco D, or Burle controller send the scan

to PreShot 90. When using an American Dynamics controller, send the scan to

PreShot 61. To select a menu option when using these controllers, use the tilt up

and down function on the controller to move the cursor to the desired number

beside the option, then press Iris Open. The pan left and right commands may

also be used to move horizontally between fields in a table. The Iris Close

function is used to exit (ESC to exit) menus

to send an ESC command to the KD6i and exit the KD6i menu.

to remove the KEGS5000 from the KD6i menu mode.

to access the KD6i setup menu.

Rev. D 17 KDMU000799

02/6/04

• When using an UltraKey (with default menu programming):

1. Press the MENU soft key (on left side of screen).

2. Press the Dome Setup soft key on the screen.

3. Press the ENT (hard) key.

To access menu options, use the numeric hard or soft keys on the controller.

The ESC soft key sends an ESC command and exits the KD6i menu.

The EXIT soft key removes the UltraKey from the KD6i menu mode.

• The menu options either toggle between the available choices or call up another

menu.

Page 32

4.1 INTRODUCTION, CONTINUED

The controller must meet the following requirements:

• The KD6i being setup must be selected as the primary control camera on the

controller where the keyboard is connected (if using JPD100 series controllers).

• The video from the scan must be displayed on the control monitor.

• The controller must have manual control of the scan.

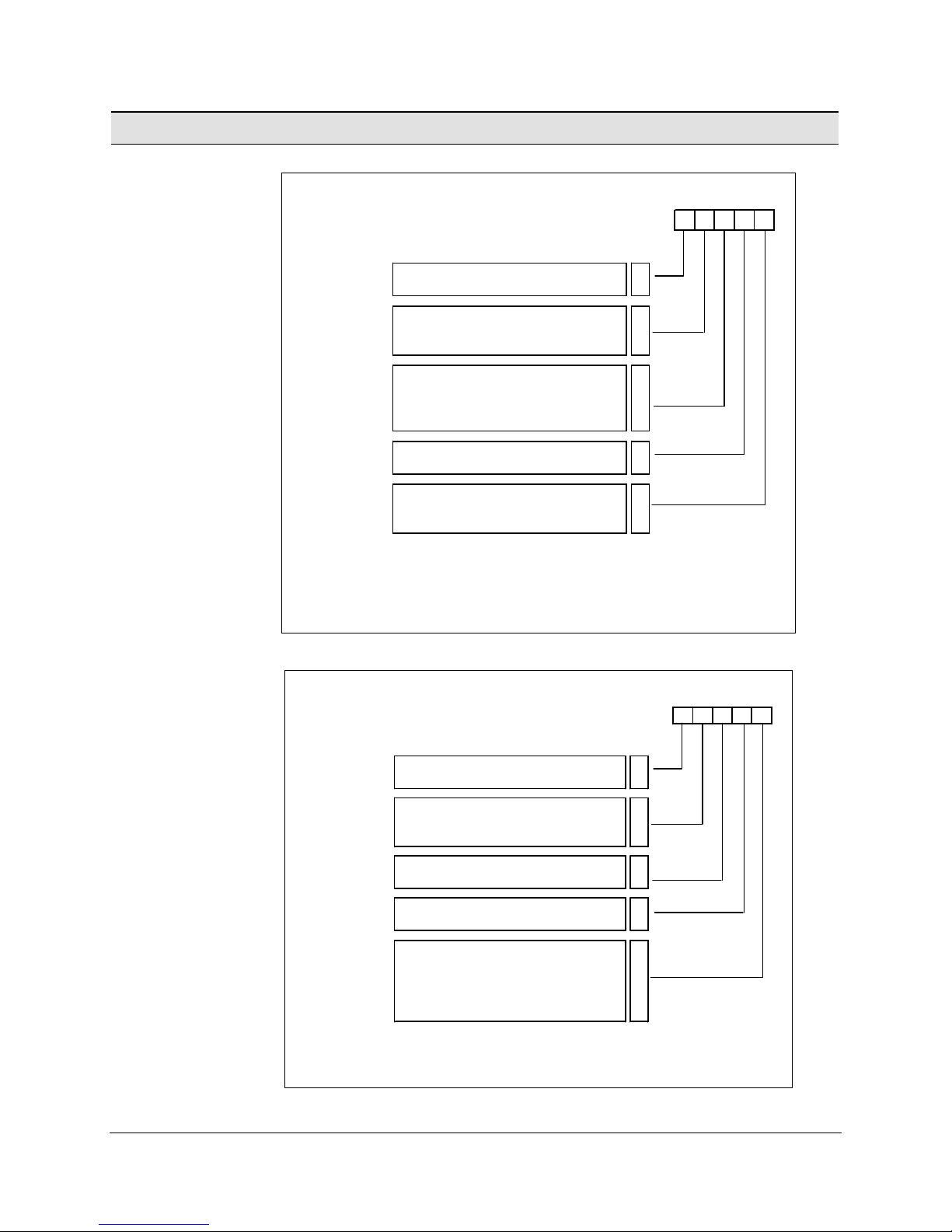

4.2 MENU STRUCTURE

The following setup tree shows the options under each menu in the main setup menu.

Use of specific menus/settings is explained in the Operation sections of the manual.

Rev. D 18 KDMU000799

02/6/04

Page 33

Rev. D 19 KDMU000799

02/6/04

4.2 MENU STRUCTURE, CONTINUED

ULTRADOME KD6i SETUP TREE

1. Language

- English

- French

- German

- Italian

- Spanish

- Polish

2. Display Options 3. Control Opt ions 4. Diagn ostic Options 5 . Camera Options 6. Function

Programming

1. Camera Options

(ON/OFF)

1. PASS (ON/OFF) 1. Coordinates (ON/OFF) 1. Zoom and Focus

- Max Digital Zoom

(1x/2x/4x/8x)

- Manual Speed (0-8)

1. PTZ Tour

1

- Run a T o ur

- Program a Tour

- Delete a Tour

2. Sectors (ON/OFF) 2. Auto Pivot (ON/OFF) 2. Error Table (ON/OFF) 2. Exposure Control

- Exposure Lev el

- Backlight Compensation

2. Program a

VectorScan

2

3. PreShot Name

(ON/OFF)

3. Program Alarms

- PreShot/VectorScan/PTZ

- Enable/Disable

3. Clear th e Memory

(Does not clear

privacy zones)

3. NightShot Control

- NightShot Mode (Auto/Man)

- NightShot (ON/OFF) (Manual Mode)

- Activate (2-28dB, 1/4s-1/60s)

3

- Deactivate (0-28dB, 1/8s-1/60s)

3

4. Digital Zoom Msg

(ON/OFF)

4. Set Pan and Tilt Options

- Manual Speed (400/200/100)

- Pan Rever se (ON/OFF)

- Tilt Reve rse (ON/OFF)

- +2 Degree Tilt Limit (ON/OFF)

- Find Home on Startup (ON/OFF)

- Pan Offset

4. Clear th e Error Table 4. White Balance

- High Light WB Mode

- Low Light W B Mode

- Low Light Level (2-28dB, 1/4s -1/60s)

3

- Manual White Balance

5. Start-Up Screen

Msg (ON/OFF)

5. Set Default Function

- PreShot/VectorScan/Tour

- Delay

- Enabled/Disabled

5. Display Error Table

Codes

5. Still PreShot (ON/OFF)

(OFF=default)

6. Change Camera

Name Location

6. Auto Focus

- Z

- PTZ

- OFF

6. Restore Default

Settings (all menus)

6. Vertical Phase Edge

- Positi ve

- Negative

- None

- NA*

7. Change Sector

Name Location

7. VectorScan Auto Focus

(ON/OFF)

7. Scan & Camera Reset 7. V ertical Phase

- 1-180

- NA*

8. Crosshairs 8. Upload New Firmware

to KD6

1

2

3

Only displayed when using Standard (Diamond) or iPro protocol

Only displayed when using Maxpro, VCL, Pelco P, Pelco D, American Dynamics, or Burle protocol

Values shown are fo r came ras 8 43216-1011 and 843216 -101 3 only.

NA* - Not available - camera models CA447S4N, CA447S4P, CA470S4N, CA470S4P, 843216-1010, and 843216-1012 do not support this feature.

Shift + F1 PreShot 26 PreShot 90

(Diamond Standard Protocol); (American Dynamica, Pelco P, Pelco D Protocol); (Maxpro, VCL, or Burle Protocol)

Refer to your system controller manual to access KD6i setup menus.

Page 34

5.1 MAIN MENU

SECTION 5:

SETUP

NOTE:

• Refer to Section 6

(programming) when using standard protocol.

(operation) and Section 7

Operation and programm ing when using iPr o prot ocol

is the same as standard protocol.

• Refer to Section 8

(operation) and Section 9

(programming) when using Maxpro, Pelco P Code,

Pelco D Code, Burle, or VCL control systems.

• Refer to Section 10

(operation) and Section 11

(programming) when using an American Dynamics

control system.

Upon power-up of an UltraDome KD6i,

the scan displays an initiali zat ion sc reen

and counts down from 15 to 0. The

standard start-up message screen can be

turned ON or OFF from the main menu.

If the start-up screen message is ON, the

following screen is displayed.

---- UltraDome KD6i ----

Protocol Standard

9600 baud even parity-8 bits

Camera FDB-EX48B

Honeywell Video Systems

519543-1980

Please wait . . . 15

NOTE: T he protocol li ne dis p lays the

protocol set by DIP switch S4.

If the start-up screen message is OFF,

this screen is displayed:

After the countdown, the scan accepts

control commands. Refer to the

controller users’ manuals provided with

X

Please wait. . . 8

your controller for operating procedures.

The first time a scan receives control data with its address, the scan finds home then

performs the command. After the scan finds home, it performs all control commands

with its address immediately.

Rev. D 20 KDMU000799

02/6/04

Page 35

5.1 MAIN MENU, CONTINUED

On-screen menus are used to set up the receiver board and enable special features.

The MAIN MENU is used to enable and position displays as well as adjust several

basic settings that allow customization of the display.

Each setting on the MAIN MENU is explained in detail in this section.

To make these settings and adjustments,

access the MAIN MENU. If using the

JPD100 and KBD100, select SHIFT + F1.

Refer to section 4.1 for additional

examples on accessing the MAIN MENU.

5.1.1 Language

Set Language by selecting 1 from the

MAIN MENU. Continue to select 1 to

toggle between language optio ns

(English, French, German, Italian,

Spanish, or Polish).

---- UltraDome KD6i ---519543-1980

1 Language ............................. English

2 Display Options

3 Control Options

4 Diagnostic Options

5 Camera Options

6 Function Programming

ESC to Exit

---- UltraDome KD6i ---519543-1980

1 Language ............................. English

2 Display Options

3 Control Options

4 Diagnostic Options

5 Camera Options

6 Function Programming

ESC to Exit

Rev. D 21 KDMU000799

02/6/04

Page 36

5.2 DISPLAY OPTIONS

The camera message, digital zoom setting, PreShot title, and Sector ID title displays

can be enabled or disabled for each unit. The position of the camera ID display and the

Sector ID display is set using the Display Options menu. The current digital zoom

setting is displayed on the same line as the camera ID on the right side of the monitor.

Select option 2 Display Options from the

MAIN MENU.

Several options toggle only between

ON and OFF. Selecting each option

toggles the value.

Refer to the controller user’s manual for

operation of the controller to perform

these functions.

5.2.1 Camera Message

From the DISPLAY OPTIONS menu,

select 1 to turn the camera ID display

ON or OFF. Selecting 1 toggles the value

between ON and OFF.

---- UltraDome KD6i ---519543-1980

1 Language.............................. English

2 Display Options

3 Control Options

4 Diagnostic Options

5 Camera Options

6 Function Programming

ESC to Exit

DISPLAY OPTIONS

1 Camera Msg............................... ON

2 Sectors....................................... ON

3 PreShot Names .......................... ON

4 Digital Zoom Msg........................ ON

5 Startup Screen Msg.................... ON

6 Change Camera Name Loc.

7 Change Sector Name Loc.

8 Crosshairs

ESC to Exit

5.2.2 Sectors

From the DISPLAY OPTIONS menu, select 2 to turn Sector titles ON or OFF.

5.2.3 PreShot Names

From the DISPLAY OPTIONS menu, select 3 to turn PreShot titles ON or OFF.

5.2.4 Digital Zoom Message

From the DISPLAY OPTIONS menu, select 4 to turn the actual digital zoom

magnification display ON or OFF. The digital zoom setting is displayed on the right side

of the monitor on the same line as the camera ID display. If camera name location is

changed, digital zoom setting display is also changed.

Rev. D 22 KDMU000799

02/6/04

Page 37

5.2 DISPLAY OPTIONS, CONTINUED

5.2.5 Startup Screen Message

5.2.6 Change Camera Name Location

From the DISPLAY OPTIONS menu,

select 5 to turn the startup screen display

ON or OFF.

If the startup screen display is ON,

it displays the standard screen.

If the startup screen is OFF, an alternate

screen is displayed upon power up.

From the DISPLAY OPTIONS menu,

select 6 to change the position of the

ID display. Use ↑↑↑↑ and ↓↓↓↓ to position the

camera ID, then select Enter when done.

---- UltraDome KD6i ----

Protocol Standard

9600 baud even parity-8 bits

Camera FDB-EX48B

Honeywell Video Systems

519543-1980

Please wait . . . 15

X

Please wait. . . 8

Use ↑↓ keys to position the

Name. Hit ‘Enter’ when done.

5.2.7 Change Sector Name Location

5.2.8 Crosshairs

From the DISPLAY OPTIONS menu, select 8 to display crosshairs on the display.

Rev. D 23 KDMU000799

02/6/04

From the DISPLAY OPTIONS menu,

select 7 to change the position of the

Sector ID title display. Use ↑↑↑↑ and ↓↓↓↓ to

position the Sector ID, then select Enter

when done.

This is useful when using Pan Offset.

Cam nnn

********Sector********

Use ↑↓ keys to position the

Name. Hit ‘Enter’ when done.

Page 38

5.3 CONTROL OPTIONS

Select 3 from the MAIN MENU to set

control options. Control of a Scan

assembly includes pan, tilt, zoom , f ocus ,

and iris.

Refer to the controller user’s manual for

operation of the controller to perform

these functions.

5.3.1 PASS

If the PASS function is enabled, the pan

and tilt speed range is a function of the

lens zoom angle. As the lens is zoomed

in, the maximum pan and tilt speeds are

reduced and the low speed control is

expanded.

NOTE: At 12X zoom, the scan moves

very slowly.

---- UltraDome KD6i ---519543-1980

1 Language ............................. English

2 Display Options

3 Control Options

4 Diagnostic Options

5 Camera Options

6 Function Programming

ESC to Exit

CONTROL OPTIONS

1 PASS.............................................ON

2 Auto-Pivot......................................ON

3 Program Alarms

4 Set Pan and Tilt Options

5 Set Default Function

6 Auto Focus........................................Z

7 VectorScan Auto Focus ...............OFF

ESC to Exit

To enable/disable PASS, select 1 and toggle between ON (enable) and OFF (disable).

5.3.2 Auto-Pivot

If the Auto Pivot feature is enabled, the

pan and tilt unit automaticall y pans the

camera 180° when the camera reaches

vertical. This feature is used to assist the

operator in tracking an individual that

passes directly under the camera.

To enable/disable Auto-Pivot, select 2

1 PASS.............................................ON

2 Auto-Pivot......................................ON

3 Program Alarms

4 Set Pan and Tilt Options

5 Set Default Function

6 Auto Focus........................................Z

7 VectorScan Auto Focus ...............OFF

ESC to Exit

CONTROL OPTIONS

and toggle between ON (enable) and OFF

(disable).

Rev. D 24 KDMU000799

02/6/04

Page 39

5.3 CONTROL OPTIONS, CONTINUED

To perform this function:

1. Position the camera lens so it is not vertical.

2. Using the controller, tilt the camera down until the camera lens is vertical (pointing

at the floor) and continue tilting down with the controller.

3. The pan and tilt unit pans the camera 180° and then begins to tilt up.

It continues to tilt up as long as the controller remains in the “down” position.

When the Scan unit reaches its tilt up limit, the Scan returns to normal operation.

If the controller is returned to its neutral position before the Scan reaches its tilt up

limit, the Scan returns to normal operation.

5.3.3 Program Alarms

The UltraDome KD6i has four alarm inputs

for normally open dry contacts. When a

contact closes, an alarm occurs.

Alarms can be enabled or disabled and

the scan can be programmed to go to a

PreShot, start a VectorScan, or start a

PTZ tour when an alarm occurs.

1 PASS.............................................ON

CONTROL OPTIONS

2 Auto-Pivot......................................ON

3 Program Alarms

4 Set Pan and Tilt Options

5 Set Default Function

6 Auto Focus........................................Z

7 VectorScan Auto Focus ...............OFF

ESC to Exit

NOTE: If an alarm is disabled, the UltraDome KD6i does not respond to a change of

state in the alarm contact. The UltraDome KD6i does not perform the

programmed PreShot, VectorScan, or PTZ. If a PreShot, VectorScan, or PTZ

Tour is not programmed for an alarm, the UltraDome KD6i does not respond

to a change of state in the contact.

To program alarms, select 3 from the

Control Options Menu.

The Program Alarms screen displays.

See table below for field entry.

Press Enter when finished programm ing

alarms.

FUN NUM ENA

1 _ __ _

2 _ __ _

3 _ __ _

4 _ __ _

PVT Y-N

Press ‘Enter’ when done.

Program Alarms

Field Usage

FUN (function)

NUM (number)

Enter function to perform. (P=PreShot, V=VectorScan, T=PTZ Tour.)

Enter the number of the PreShot, VectorScan, or PTZ Tour.

ENA (enable) Enter Y to enable or N to disable the alarm .

Rev. D 25 KDMU000799

02/6/04

Page 40

5.3 CONTROL OPTIONS, CONTINUED

If: Then:

Alarm is disabled The scan ignores a change of state in the alarm input.

Alarm is enabled and not

programmed

Alarm is enabled and

programmed

More than one alarm

occurs

The scan ignores a change of state in the alarm input.

The scan performs the action programmed for the

alarm input when a change of state occurs.

• Scan adds AL and the alarm number to the video

signal.

• AL flashes until all alarms are acknowledged.

• Alarm status is displayed on-screen on the same

line as the Camera ID display.

• Alarm number flashes until the contact returns to

its normal state.

The scan performs the action for the first alarm and

adds the other alarm numbers to the video in

numerical order.

• When the first alarm is acknowledged, the scan

performs the action for the next alarm with the

lowest number. For example, alarm contacts 2,

4, and 3 close in the order stated. The monitor

display appears as AL-234. The scan performs

the action programmed for alarm 2.

• The AL continues to flash until all alarms are

acknowledged and then is removed from the

display.

• The alarm numbers flash until the alarm contacts

return to normal (open). When alarm 2 is

acknowledged, the number 2 is removed from the

alarm display and the scan performs the

programmed action for alarm 3. When alarm 3 is

acknowledged, the number 3 is removed from the

alarm display and the scan performs the

programmed action for alarm 4.

Rev. D 26 KDMU000799

02/6/04

NOTE: An alarm can be acknowledged before the contact returns to normal;

however the KD6i will not respond to the alarm again until the contact has

reopened and closed again.

Page 41

5.3 CONTROL OPTIONS, CONTINUED

5.3.4 Pan and Tilt Options

Select 4 to set the pan and tilt manual

control options.

1. Manual Speed deg/s –

Select 1 to change the manual