Page 1

UDC3200

51-52-03-39

4/07

Page 1 of 13

Universal Digital Controller

Overview

New Power and Flexibility

The UDC3200 Universal Digital

Controller packs new powerful features

in the popular 1/4 DIN size.

Unmatched application power includes:

Infrared (IR) Configuration interface,

two universal analog inputs and a Math

Algorithm. When these are combined

with the Accutune III™ tuning with fuzzy

logic overshoot suppression, the result

is price/performance leadership.

Application flexibility is assured by the

universal analog inputs, universal AC

power supply, two digital inputs, a

maximum of five analog and digital

outputs, RS422/485 Modbus RTU or

Ethernet 10Base-T TCP/IP

communication protocols, simple

configuration plus total field upgrade

capability for any optional feature.

Features

• 2 Universal Analog Inputs

• 0.20% Accuracy

Fast scanning rate (166ms)

•

• Up to 5 Output Types

• 2 Digital Inputs

• Math Functions

• Ethernet and Modbus

communication

• Infrared PC & Pocket PC

configuration

• NEMA4X and IP66 front face

protection

• Multilanguage prompts

• ¼ DIN Size

• Jumper free configuration

• Easily Field Upgradable

Bright, dual displays with multi-language

prompts (in English, French, German,

Spanish, or Italian) make the operator

interface easy to read, understand, and

operate. Simple keystrokes let you set

operating parameters that meet your

process control needs.

Analog Inputs

The UDC3200 has two analog inputs

with a typical accuracy of ±0.20% of fullscale input and a typical resolution of 16

bits. Both analog inputs are sampled

six times per second (every 166 ms).

The first, or Process Variable input,

can be one of the various

thermocouple, RTD, Radiamatic or

linear actuations. Linear actuations

have thermocouple, RTD, and

Radiamatic transmitter characterization

capability as a standard feature. Linear

actuations also have square root

capability.

The optional second input is isolated

and accepts the same actuations as

input one, or it provides the Slidewire

input for Position Proportional control.

All actuations and characterizations

are keyboard configurable. Cold

junction compensation is provided for

thermocouple type inputs. Upscale,

downscale or failsafe sensor break

protection is keyboard configurable. A

configurable digital filter of 0 to 120

seconds provides input signal

damping.

Thermocouple Health - In addition to

the standard configurable upscale,

downscale or failsafe output burnout

selections, the condition of the

thermocouple can be monitored to

determine if it is good, failing or in

danger of imminent failure.

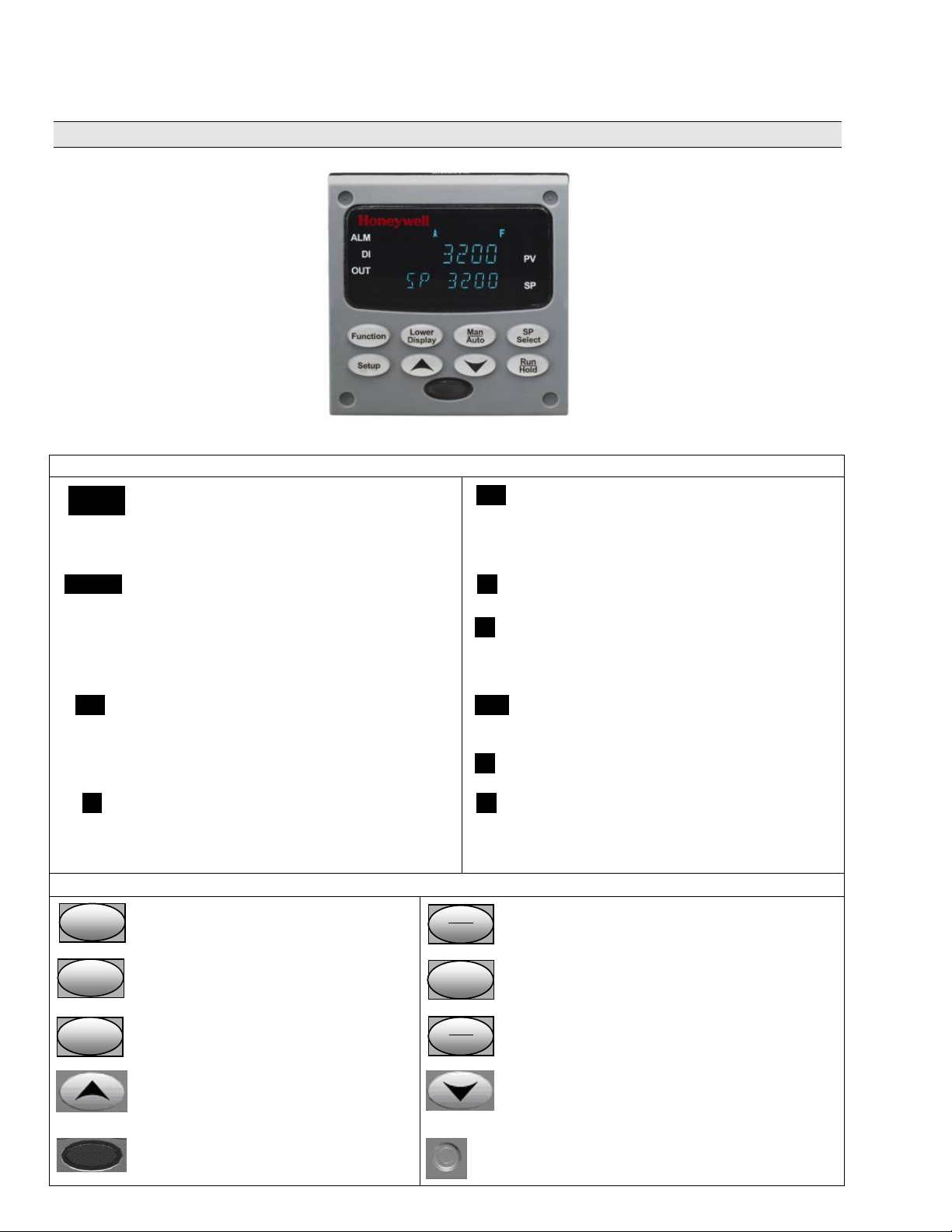

Figure 1 - UDC3200 Universal Digital Controller

Specification

Math Functions

Algorithm—A pre-configured

algorithm is available for easy

implementation. This includes the

capability of using a Ratio and Bias

with any input. You can select from the

following menu:

Feedforward Summer—Uses either

input, followed by a Ratio/Bias

calculation, summed directly with the

computed PID output value to provide

a resultant output to the final control

element (standard feature).

Weighted Average —Computes the

weighted average of a PV or SP for

the control algorithm from two inputs

(standard feature).

Feedforward Multiplier—Uses any

input, multiplied by the calculated PID

output to provide a resultant output

which is sent to the final control

element (standard feature).

Summer/Subtractor—Will add or

subtract inputs with the result used as

the derived PV.

Multiplier/Divider—Uses the analog

inputs to calculate a derived PV.

Available with or without Square Root.

Input High/Low Select—Specifies the

PV input as the higher or lower of the

two inputs.

Honeywell Process Solutions, Industrial Measurement and Control, 512 Virginia Drive, Fort Washington, PA 19034

Printed in U.S.A. ν © Copyright 2007 — Honeywell

Page 2

51-52-03-39

Page 2

Digital Inputs

Two* isolated digital inputs are provided

for remote dry contact closure to select

one of the following actions:

• Manual control mode.

• Local setpoint 1.

• Local setpoint 2.

• Local setpoint 3.

• Direct controller action.

• Hold SP Ramp/Program.

• Select PID set 2.

• PV = Input 2.

• ReRun - SP Ramp/Program.

• Run - SP Ramp/Program.

• External program reset.

• Disable PID integral action.

• Manual mode, failsafe output.

• Disable keyboard.

• Output 1 = Fixed value

• Start Timer.

• Auto/Manual Station

• Initiate Tuning.

• Initiate PV Hot Start.

• Output 1 tracks Input 2.

• To Remote Setpoint.

• PID reset feedback via Input 2

• Purge

• Low Fire

• To Latching Manual Mode.

Also, the digital inputs can allow one of

the following selections to be combined

with one of the above selections:

• Select PID set 2.

• Direct controller action.

• Local setpoint 2 or Local setpoint 1.

• Disable Accutune

• To Run – SP Ramp/Program

*The 2nd Current Output and the 2nd

Digital Input are mutually exclusive.

Selection is made via a keyboard entry.

Outputs and Control

Output Types - The UDC3200 may

have as many as five outputs made up

of the following types:

• Current Outputs (4-20 or 0-20 ma)

• Electromechanical Relays (5 amps)

• Solid State Relays (1 amp)

• Dual Electromechanical Relays (2

amps)

• Open Collector Outputs

Output Algorithms - The UDC3200 is

available with one or more of the

following output algorithms:

• Time Proportional provides On-Off

or Time Proportional (Relay) output.

• Current Proportional supplies

proportional direct current output for

final control elements, which require

a 4-20mA signal. Output can be

easily configured via the keyboard

for 0-20mA operation without

recalibration.

• Position Proportional—Positions a

reversible motor with a feedback

slidewire in proportion to the output

of the control algorithm. Requires

two output relays and the optional

second analog input.

• Current Proportional Duplex is

Similar to current proportional but

provides a second set of tuning

parameters and a split range current

output or a second current output

via the Auxiliary output option, for

the heat and cool zones.

• Time Proportional Duplex Depending on which control

algorithm you select, this duplex

output algorithm can provide On-Off

Duplex, Time Proportional Duplex,

or Three Position Step Control. The

time proportional duplex output

provides independent PID tuning

constants and two time proportional

outputs; one for heat zone above

50% output, and one for cool zone

below 50% output.

• Current/Relay Duplex

(Relay=Heat) - A variation of

Duplex with Current active for 0 to

50% output (PID Set 2) and Relay 2

active 50 to 100% output (PID Set

1). Note that only one alarm is

available for this output type.

• Relay/Current Duplex

(Relay=Cool) - A variation of

Duplex with Current active for 50 to

100% output and Relay 2 is active

for 0 to 50% output. Note that only

one alarm is available for this output

type.

Control Algorithms - Depending on the

output algorithms specified, the

controller can be configured for the

following control algorithms:

• On-Off

• PID-A

• PID-B

• PD with Manual Reset

• Three Position Step Control:

The TPSC algorithm allows the

control of a valve (or other actuator),

with an electric motor driven by two

controller output relays; one to move

the motor upscale, the other

downscale without a feedback

slidewire linked to the motor shaft.

Three Position Step is an automatic

back-up mode to Position

Proportional Control if the feedback

slidewire signal should fail

• 3 control modes: Manual, Automatic

with Local Setpoint, Automatic with

Remote Setpoint

Alarms

One or two electromechanical alarm

relays are available to activate external

equipment when preset alarm setpoints

are reached. Each of the two alarms

can be set to monitor two independent

setpoints. Each alarm setpoint can be

either high or low alarm. The alarm

type can be selected to be either of the

inputs, the Process Variable, Deviation,

Output, Shed from communications,

PV rate of change, or to alarm on

manual mode activation or a Current

Output Open failure. It can also be

used as an On or Off event at the

beginning or end of a Ramp/Soak

segment. The alarm hysteresis is

configurable from 0 to 100% of range.

• Alarms can be configured as

latching or non-latching.

• Alarm blocking is also available

which allows start-up without alarm

energized until after it first reaches

the operating region.

• PV rate of change alarm.

• Loop break alarm.

• Timer output reset.

• Diagnostic Alarm

Communication

A communications link is provided

between the UDC3200 and a host

computer or PLC via the RS422/485

Modbus® RTU or Ethernet TCP/IP

communications option. An infrared

communication link is also available

allowing a non-intrusive configuration

of the instrument.

Miscellaneous Features

Auxiliary Output* - Either or both of

the two current outputs can function as

an Auxiliary Output which can be

scaled from 4-20 ma for 0 to 100% for

any range. It can be configured to

represent Input 1, Input 2, PV, active

Setpoint, Local SP1, Deviation, or the

Control Output.

Transmitter Power - This output

provides up to 30 volts dc to power a 2wire transmitter (it requires the use of

alarm 2 open collector output selection

or the second current output).

Three Local and one Remote

Setpoints - Can be configured to

provide three Local and one Remote

Setpoints, which are selectable either

via the keyboard or by Digital Input.

Universal Switching Power -

Operates on any line voltage from 90 to

264 Vac 50/60 Hz without jumpers. 24

Vac/dc instrument power is available

as an option.

Page 3

Miscellaneous Features (continued)

Timer - This standard feature provides a

configurable time period of 0 to 99 hours,

59 minutes or units of minutes and

seconds. It can be started via the

keyboard, alarm 2, or by a digital input.

The timer output is Alarm 1, which

energizes at the end of the Timer Period.

Alarm 1 can be automatically reset. The

Timer Period can be changed between

each batch. Status is shown on the lower

display.

Moisture Protection - The NEMA4X

and IP66 rated front face permits use in

applications where it may be subjected

to moisture, dust, or hose-down

conditions.

Setpoint Ramp/Soak Programming

(Optional) - Enables you to program and

store six Ramp and six Soak segments

for setpoint programming. Run or Hold of

program is keyboard or remote digital

switch selectable.

Setpoint Rate - Lets you define a ramp

rate to be applied to any local setpoint

change. A separate upscale or

downscale rate is configurable. A single

setpoint ramp is also available as an

alternative.

CE Mark - Conformity with 73/23/EEC,

Low Voltage Directive and 89/336/EEC,

the EMC Directive as a standard feature.

Approval Body Options - CSA

certification is available as an option. UL

listing is standard.

Two Sets of Tuning Constants - Two

sets of PID parameters can be

configured for each loop and

automatically or keyboard selected.

Data Security - Five levels of keyboard

security protect tuning, configuration,

and calibration data, accessed by a

configurable 4-digit code. Nonvolatile

EEPROM memory assures data integrity

during loss of power.

Diagnostic/Failsafe Outputs -

Continuous diagnostic routines detect

failure modes, trigger a failsafe output

value and identify the failure to minimize

troubleshooting time.

High Noise Immunity - The controller is

designed to provide reliable, error-free

performance in industrial environments

that often affect highly noise-sensitive

digital equipment.

Quality/Support - The UDC3200 is

covered by an 18-month warranty and

backed up by a toll-free phone number

for technical assistance (US Only).

Accutune III™ - This standard feature

provides a truly plug and play tuning

algorithm, which will, at the touch of a

button or through a digital input,

accurately identify and tune any process

including those with deadtime and

integrating processes. This speeds up

and simplifies start-up plus allows

retuning at any setpoint. The algorithm

used is an improved version of the

Accutune III

possibilities are now offered when tuning

your process: Fast Tune and Slow Tune.

Fast Tune will tune the process in such

a way that the temp is reached faster, a

slight overshoot will be allowed.

Slowtune will minimize overshoot, but it

will take more time for the process

temperature to reach the target setpoint.

Heat/Cool (Duplex Tune) will

automatically tune both the heating and

cooling sides of the process.

Fuzzy Logic - This standard feature

uses fuzzy logic to suppress process

variable overshoot due to SP changes or

externally induced process disturbances.

It operates independently from Accutune

III™ tuning. It does not change the PID

constants, but temporarily modifies the

internal controller response to suppress

overshoot. This allows more aggressive

tuning to co-exist with smooth PV

response. It can be enabled or disabled

depending on the application or the

control criteria.

Indicators—Provide alarm, control

mode, and temperature unit indication.

There is also indication of when

Remote Setpoint is active, the status

of the control relays, and whether a

setpoint program is in Run or Hold

mode.

TM

algorithm. Two

Operator Interface

51-52-03-39

Page 3

Displays— During normal operation,

the upper display is dedicated to the

process variable (4-digits) and special

annunciator features. During

configuration, the upper display

provides guidance for the operator

through prompts (7-characters).

During normal operation the lower

display shows key-selected operating

parameters such as Output, Setpoints,

Inputs, Deviation, active Tuning

Parameter Set, Timer Status, or minutes

remaining in a setpoint ramp (4 digits).

During configuration, the lower display

provides guidance for the operator

through prompts (8-characters).

You decide how the controller is to

interact with the process by selecting,

through simple keystrokes, the

functions you want.

Multi-language prompts guide the

operator step-by-step through the

configuration process assuring quick

and accurate entry of all configurable

parameters. Five languages are

available via configuration: English,

French, German, Spanish and Italian.

Decimal Point Location—

Configurable for none, one, two or three

places.

Dedicated Keys—Provide direct

access setpoint modes and setpoint

program status to simplify and speed

operation.

Universal Outputs – UDC3200

provides “out of the box” operations,

with no need to open the case. There

are no jumpers to connect, no switches

to set, and no hardware configuration

required.

Physical Description

The controller is housed in a 4.5-inch

(114 mm) deep, black plastic case with

a dark gray elastomer bezel, that is

panel mounted in a 1/4 DIN cutout.

(See Figure 4.) The plug-in chassis

allows easy access to the controller

board and its various option boards.

All power, input, and output wiring are

connected to screw terminals on the

rear panel. (See Figure 5.)

Page 4

51-52-03-39

Page 4

32003200

Operator Interface

Figure 2 – Front Face

Display Indicators

Upper display with 4 larger digits shows Process

Variable value (normal operation) and special

annunciator features. During Configuration, the

upper display provides guidance for the operator

through prompts (7 – characters)

Control Relay 1 and/or 2 annunciation.

OUTOUT

SP 3200SP 3200

ALMALM

DIDI

FunctionFunctionFunction

SetupSetup

Lower

Lower

Lower

Display

Display

Display

During normal operation, the lower display shows

key-selected operating parameters such as

Output, Setpoints, Inputs, Deviation, active Tuning

Parameter Set, Timer Status, or minutes remaining

in a setpoint ramp (4 digits). During configuration,

the lower display provides guidance for the

operator through prompts (8-characters).

Alarm 1 and/or Alarm 2 annunciation.

Digital Input 1 and/or 2 annunciations.

Keys and Functions

Selects functions within each configuration

group.

Scrolls through the configuration groups.

Returns Controller to normal display from

Set Up mode. Toggles various operating

parameters for display.

Increases setpoint or output value.

Increases the configuration values or

changes functions in Configuration mode

groups.

Infrared transceiver

Man

Man

Man

Auto

Auto

Auto

SP

SP

SP

Select

Select

Select

Run

Run

Run

Hold

Hold

Hold

FF

Indicates either degrees Fahrenheit or Centigrade.

Or

CC

Indicates either Manual

MANMAN

Or

Or

Auto mode.

AA

Indicates either Local Setpoint #1. The lower

SPSP

display also shows other control information and

other setpoints. A bar is lighted next to the lower

display when the setpoint currently being used is

shown on the lower display.

Selects Manual or Auto mode.

Hold key down to cycle through configured setpoints.

Enables Run/Hold of the SP Ramp or Program plus

Timer start.

Decreases setpoint or output value. Decreases the

configuration values or changes functions in

Configuration mode groups.

NEMA4X and IP66 screw attachment (each corner)

Page 5

51-52-03-39

Page 5

PC & Pocket PC Software

Features

• Create configurations with intuitive software program

running on a Pocket PC, a Desktop or a laptop

computer.

• Create/edit configurations live. Just connect software to

the controller via a communications port.

• Create/edit configurations offline and download to

controller later via a communications port.

• Communication types available on every UDC3200:

• Infrared (standard)

• RS-485 (optional)

• Ethernet (optional)

• Same port types on UDC2500 and UDC3500 allow

interconnectivity

• This software is available in English, Spanish, Italian,

German and French.

Infrared Communications

The infrared connection provides a non-intrusive wireless

connection with the instrument and maintains NEMA4X and

IP66 integrity.

No need to get access to the back of the controller to

communicate with the instrument, no need to take your

screw driver to wire the communication cable, no wiring

mistake possible! You can now duplicate an instrument’s

configuration, upload or download a new configuration in a

matter of seconds, just by pointing your Pocket PC in the

direction of the instrument.

Aim & Upload! It takes less than 2 seconds to upload a

configuration from an instrument! You can then save the

configuration file onto your PC or pocket PC for review,

modification or archiving.

Furthermore, this software also gives you important

maintenance information on the controller: instantly, get

information on the current operating parameters, digital

inputs and alarm status, identify internal or analog input

problems.

Question: What if I have several controllers on the same

panel? How can I be sure I am communicating with the

correct one?

Answer: The Infrared port is normally “off”. You activate the

infrared port on a particular controller by pressing any key.

You can now communicate with the controller. If no

communications are received for 4 minutes, the IR port will

be shut down again. Each controller may also be assigned a

different communications address.

Screen capture of the configuration software running on a

Pocket PC

Ethernet Communications

Widely used by manufacturers, the Ethernet connection, which uses Modbus TCP/IP, allows the controller to connect to other

Ethernet networks and exchange data with computers or devices on that network for monitoring or managing your process

from almost any location.

The Ethernet cable can be connected to a hub (using a straight through cable) or directly to a PC (using a crossed cable or

straight through cable reconfigured at the UDC3200 terminals)

The controller can be configured via the PC software. This software allows the user to configure all of the parameters

included in the instrument and to monitor various parameters in the controller.

The controller can be configured to send an Email when an alarm condition has been encountered. The Email address and

gateway are configured using the PC software.

Page 6

51-52-03-39

Page 6

Specifications

Design

CE Conformity (Europe) This product is in conformity with the protection requirements of the following European

Product Classification Class I: Permanently Connected, Panel Mounted Industrial Control Equipment with

Enclosure Rating Panel Mounted Equipment: This controller must be panel mounted. Terminals must be

Installation Category

(Overvoltage Category)

Pollution Degree Pollution Degree 2: Normally non-conductive pollution with occasional conductivity caused

EMC Classification Group 1, Class A, ISM Equipment (EN 55011, emissions), Industrial Equipment (EN61326,

Method of EMC

Assessment

Declaration of Conformity Approval Body Ratings CE (Standard)

Analog Inputs (One or Two)

(See Table 1 for Input

Actuations)

Analog Input Signal Failure

Operation

Analog Input Filter

Stray Rejection Common Mode

Council Directives: 73/23/EEC, the Low Voltage Directive, and 89/336/EEC, the EMC

Directive. Conformity of this product with any other “CE Mark” Directive(s) shall not be

assumed.

protective earthing (grounding).

within the panel enclosure.

Front Bezel: NEMA3R and IP54, or NEMA4X and IP66 with 4 screws

Category II: Energy-consuming equipment supplied from the fixed installation.

Local level appliances, and Industrial Control Equipment.

by condensation. (Ref. IEC 664-1)

immunity)

Technical File (TF)

51453663

UL Listed (Optional): UL61010C-1 CSA Certified (Optional): CSA1010-1 Accuracy:

• ± 0.20% of full scale typical (± 1 digit for display)

• Can be field calibrated to ± 0.05% of full scale typical

• 16-bit resolution typical

Sampling Rate: Both inputs are sampled six times per second Temperature Stability: ± 0.01% of Full Scale span / ˚C change—typical Input Impedance:

• 4-20 Milliampere Input: 250 ohms

• 0-10 Volt Input: 200K ohms

• All Other: 10 megohms

Maximum Lead Wire Resistance:

• Thermocouples: 50 ohms/leg

• 100 ohm, 200 ohm and 500 ohm RTD: 100 ohms/leg

• 100 ohm Low RTD: 10 ohms/leg

Burnout Selections: Upscale, Downscale, Failsafe or None

Thermocouple Health: Good, Failing, Failure Imminent or Failed

Failsafe Output Level: Configurable 0-100% of Output range

Software: Single pole lowpass section with selectable time constants, off to 120 seconds,

available on both analog inputs.

AC (50 or 60 Hz): 120 dB (with maximum source impedance of 100 ohms) or ±1 LSB (least

significant bit) whichever is greater with line voltage applied.

DC: 120 dB (with maximum source impedance of 100 ohms) or a ±1 LSB whichever is

greater with 120 Vdc applied.

DC (to 1 KHz): 80 dB (with maximum source of impedance of 100 ohms) or ±1 LSB

whichever is greater with 50 Vac applied.

Normal Mode

AC (50 or 60 Hz): 60 dB (with 100% span peak-to-peak maximum)

Page 7

51-52-03-39

Page 7

Specifications

Design

Digital Inputs (Two)

(Optional)

Controller Output Types

Alarm Outputs (Optional) One SPDT electromechanical relay. A second alarm is available if the second control relay

+30 Vdc source for external dry contacts or isolated solid-state contacts. Digital Inputs are

isolated from line power, earth ground, analog inputs and all outputs except for the Second

Current Output.

On contact closure the controller will respond according to how each digital input is

configured. Opening the contact causes a return to previous state.

The second Digital Input is mutually exclusive with the Second Current Output.

Electromechanical Relays (One or Two)

SPDT contacts. Both Normally Open and Normally Closed contacts are brought out to the

rear terminals.

Internally socketed

Resistive Load: 5 amps @ 120 Vac or 240 Vac or 30 Vdc

ϕ

Inductive Load (cos

Inductive Load (L/R = 7 msec): 3.5 amps @ 30 Vdc

Motor: 1/6 H.P.

Dual Electromechanical Relays

Two SPST relays. One Normally Closed contact for each relay is brought out to the rear

terminals. This option takes the place of one of the above electromechanical relays, and is

especially useful for Time Duplex or Three Position Step Control or Position Proportional

Control applications. Instruments with this option can have a total of 4 relays plus one

current output.

Internally socketed

Resistive Load: 2 amps @ 120 Vac, 240 Vac or 30 Vdc

Inductive Load (cos

Inductive Load (L/R = 7 msec): 1 amp @ 30 Vdc

Solid State Relays (One or Two)

SPST solid-state contacts consisting of a triac N.O. output.

Internally socketed

Resistive Load: 1.0 amp @ 25°C and 120 or 240 Vac

0.5 amp @ 55°C and 120 or 240 Vac

Inductive Load: 50 VA @ 120 Vac or 240 Vac

Minimum Load: 20 milliamps

Open Collector Outputs (One or Two)

Socketed assembly replacing a relay. Opto-isolated from all other circuits except current

output, but not from each other. Internally powered @ 30 Vdc.

Note: Applying an external power supply to this output will damage the instrument.

Maximum Sink Current: 20 mA

Overload Protection: 100 mA

Current Outputs (One or Two)

These outputs provide a 21 mA dc maximum into a negative or positive grounded load or

into a non-grounded load. Current outputs are isolated from each other, line power, earth

ground and all inputs. Outputs can be easily configured via the keyboard to be 0 to 20 or 4

to 20 mA without field calibration and for either direct or reverse action.

Either or both current outputs can be used in an Auxiliary Output mode. This Auxiliary

Output can be configured to represent Input, PV, Setpoint, Deviation, or Control output.

The range of an Auxiliary Output can be scaled per the range of the selected variable and

can be set anywhere between 0 to 21 mA.

The Second Current Output is mutually exclusive with the second Digital Input.

Resolution: 14 bits over 0 to 21 mA

Accuracy: 0.05% of full scale

Temperature Stability: 0.01% F.S./°C

Load Resistance: 0 to 1000 ohms

is not used for control purposes.

Up to four setpoints are independently set as high or low alarm, two for each relay.

Setpoint can be on any Input, Process Variable, Deviation, Manual Mode, Failsafe, PV

Rate, RSP Mode, Communication Shed, or Output. A single adjustable hysteresis of 0.0 to

100.0% is provided. The alarm can also be set as an ON or OFF event at the beginning of

a setpoint ramp/soak segment.

Alarm Relay Contacts Rating

Resistive Load: 5 amps at 120 Vac or 240 Vac or 30 Vdc

= 0.4): 3 amps @ 130 Vac or 250 Vac

ϕ

= 0.4): 1 amp @ 130 Vac or 250 Vac

Page 8

51-52-03-39

Page 8

Specifications

Design

RS422/485 Modbus RTU

Communications Interface

(Optional)

Ethernet TCP/IP

Communications Interface

(Optional)

RS-485 and Ethernet

Transaction rates

Infrared Communications

(Standard)

Controller Output

Algorithms

Digital Displays Vacuum fluorescent, alphanumeric

Indicators Alarm Relay Status (ALM 1 or 2)

Modes of Operation

Baud Rate: 4800, 9600,19,200 or 38,400 baud selectable

Data Format: Floating point or integer

Length of Link:

2000 ft (600 m) max. with Belden 9271 Twinax Cable and 120 ohm termination resistors

4000 ft. (1200 m) max. with Belden 8227 Twinax Cable and 100 ohm termination

resistors

Link Characteristics: Two-wire (half-duplex), multi-drop Modbus RTU protocol, 15 drops

maximum or up to 31 drops for shorter link length.

Type: 10Base-T

Length of Link: 330 ft. (100 m) maximum. Use Shielded twisted-pair, Category 5 (STP

CAT5) Ethernet cable.

Link Characteristics: Four-wire plus shield, single drop, five hops maximum

IP Address: IP Address is 10.0.0.2 as shipped from the Factory

Recommended network configuration: Use Switch rather than Hub in order to maximize

UDC Ethernet performance

Configuration: Ethernet parameters are configured via the Process Instrument Explorer.

Email: The capacity to send an Email is provided. This must be configured via the Process

Instrument Explorer.

Host computer must allow a minimum of 20 milliseconds between Read transactions and a

minimum of 200 milliseconds between Write transactions.

Type: Serial Infrared (SIR)

Length of Link: 3 ft. (1 m) maximum for IrDA 1.0 compliant devices

Baud Rate: 19,200 or 38,400 baud selectable

On-Off or Time Proportional

One relay or open collector output. Control action can be set for direct or reverse.

Time Proportional Relay Resolution: 3.3 msec

On-Off Duplex, Three Position Step Control, or Time Proportional Duplex

Two relays or open collector outputs. Control action can be set for direct or reverse.

Time Proportional Relay Resolution: 3.3 msec

Current Proportional

A single 4-20 mA current output signal that can be configured for direct or reverse action.

Current Proportional Duplex

This can be a single current output can providing both heat and cool signals (4-12 mA cool,

12-20 mA heat) or a combination of both current outputs with the First Current Output

providing the Heat output (Heat = 50 to 100% of range) and Second Current Output

providing the Cool output (Cool = 0 to 50% of range). Both are 4-20 mA signals that can be

set for direct or reverse action.

Position Proportional

Two SPDT electromechanical or solid-state relays (recommended) operate any motor

having a 100-ohm to 1000-ohm feedback slidewire.

Current/Time Duplex

Variation of time proportional duplex for Heat/Cool applications. Time proportional output

(heat or cool) is a relay. Current proportional output (Heat or Cool) is a 4-20 mA signal that

can be fed into a negative or positive grounded load of 0 to 1000 ohms and is operational

over 50% of range or the entire range.

A seven-character upper display dedicated to the process variable (4 digits).

Alternate information displayed during configuration mode.

An eight-character lower display primarily shows key selected operating parameters (4

digits). Alternate information displayed during configuration mode.

Control Mode (A or MAN)

Temperature Units (F or C)

Active Set Point (

Control Relay Status (OUT 1 or 2)

Digital Input Status (DI 1 and 2)

Manual

Automatic with Local Setpoint

Automatic with Remote Setpoint

)

Page 9

Specifications

Design

Dimensions See Figure 4.

Mounting Panel-mounted, 4.5-inch (114 mm) depth

Wiring Connections Screw terminals on the rear of the case. (See Figure 5.)

Power Consumption 20 VA maximum (90 to 264 Vac)

15 VA maximum (24 Vac/dc)

Power Inrush Current

Weight 3 lbs. (1.3 kg)

10A maximum for 4 ms (under operating conditions), reducing to a maximum of 225 mA (90

to 264 Vac operation) or 750 mA (24 Vac/dc operation) after one second.

CAUTION

power is supplied. Otherwise, the controllers may not start up normally due to voltage drop

from the inrush current.

When applying power to more than one UDC3200, make sure that sufficient

Specifications

Environmental and Operating Conditions

Parameter Reference Rated Operative Limits Transportation and Storage

51-52-03-39

Page 9

Ambient Temperature

Relative Humidity

Vibration

Frequency (Hz)

Acceleration (g)

Mechanical Shock

Acceleration (g)

Duration (ms))

Line Voltage (Vdc)

Line Voltage (Vac)

90 to 264 Vac

24 Vac Frequency (Hz)

(For Vac)

* The maximum RH rating applies only up to 40°C (104°F). For higher temperatures, the RH specification is derated to maintain constant moisture content.

25 ± 3°C

77 ± 5°F

10 to 55* 10 to 90* 5 to 90* 5 to 95*

0

0

0

0

+24 ±1 +22 to +27 +20 to +30 - -

120 ±1

240 ±2

24 ± 1

50 ±0.2

60 ±0.2

15 to 55°C

58 to 131°F

0 to 70

0.4

1

30

90 to 240

20 to 27

49 to 51

59 to 61

0 to 55°C

32 to 131°F

0 to 200

0.6

5

30

90 to 264

20 to 27

48 to 52

58 to 62

–40 to 66°C

–40 to 151°F

0 to 200

0.5

20

30

- -

- -

- -

- -

- -

Page 10

51-52-03-39

Page 10

Table 1—Input Actuations

Range

Input Actuation °F °C

Thermocouples

(Per ITS-90)

B

E

E (low)

J

J (med)

J (low)

K

K (med)

K (low)

NiMo-NiCo (NNM90)

NiMo-NiCo (low)

Nicrosil-Nisil (NIC)

NIC (low)

R

S

T

T (low)

W5W26

W5W26 (low)

PR40-PR20

Honeywell Radiamatic

Type RH

Type RI

Differential Thermocouple

(1)

User enters the range manually per RI type and application.

(2)

Factory calibrated for pair of J thermocouples at an ambient temperature

mean of 450°F / 232°C. Can be Field Calibrated for other input types and

ranges

.

0 to 3300

–454 to 1832

–200 to 1100

0 to 1600

20 to 900

20 to 550

0 to 2400

–20 to 1200

–20 to 750

32 to 2500

32 to 1260

0 to 2372

0 to 1472

0 to 3100

0 to 3100

–300 to 700

–200 to 500

0 to 4200

0 to 2240

32 to 3216

0 to 3400

0 to 9999 max.

(2)

-50 to 150 –46 to 66

(1)

–18 to 1816

–270 to 1000

–129 to 593

–18 to 871

–7 to 482

–7 to 288

–18 to 1316

–29 to 649

–29 to 399

0 to 1371

0 to 682

–18 to 1300

–18 to 800

–18 to 1704

–18 to 1704

–184 to 371

–129 to 260

–18 to 2315

–18 to 1227

0 to 1880

–18 to 1871

–18 to 9999 max

Range

Input Actuation °F °C

RTD

Per IEC-60751 (1995)

IEC Alpha = 0.00385

100 ohms

100 ohms (low)

200 ohms

500 ohms

Linear

Milliamps

Millivolts

Volts

Combinational

Carbon

Oxygen

(1)

Slidewire

(3)

Requires external dropping resistor assembly (Honeywell supplied).

(4)

Combinational types require the use of two Inputs.

(5)

This is the input range. The slidewires themselves should be 100 ohm to

1000 ohm types.

–300 to 1200

–300 to 300

–300 to 1200

–300 to 1200

–184 to 649

–184 to 149

–184 to 649

–184 to 649

4 to 20 mA

0 to 20 mA

(3)

(3)

0 to 10 mV

0 to 50 mV

0 to 100 mV

1 to 5 V

0 to 5 V

0 to 10V

(4)

(3)

0 to 1250 mV

–30 to 510 mV

0 to 1000 ohms

(5)

Page 11

General Reference Data

_

_

51-52-03-39

Page 11

Isolation

(Functional)

Surge Withstand

Capability (SWC)

Radio Frequency

Interference

(RFI)

AC Power: Electrically isolated from all other inputs and outputs and earth ground to withstand a HIPOT

potential of 1900 Vdc for 2 seconds per Annex K of EN61010-1.

Analog Inputs and Outputs: Are isolated from each other and all other circuits at 850 Vdc for 2 seconds.

Digital Inputs and Digital Outputs: Electrically isolated from all other circuits to withstand a HIPOT

potential of 850 Vdc for 2 seconds per Annex K of EN61010-1.

Relay Contacts: With a working voltage of 115/230 Vac, these are electrically isolated from all other

circuits to withstand a HIPOT potential of 345 Vdc for 2 seconds per Annex K of EN61010-1

Immunity: ANSI/IEEE C37.90.1, Surge Withstand Capability (SWC) (Formerly IEEE 472). Mains power

input and relay contact outputs: 2.5 kV, Common Mode and Differential Mode. All other circuits: 1.0 kV,

Common Mode and Differential Mode. The instrument is capable of meeting these test levels with no

component failures, no reset, and no incorrect outputs.

Immunity: No effect on performance from a 5 W walkie-talkie operated at 27, 151 or 450 MHz, one meter

from the controller.

Model Number Interpretation

Instructions

Select the desired key number. The arrow to the right marks the selection available.

Make the desired selections fr om Tables I through VI using the column below the

proper arrow. A dot ( ) denotes availability.

Key Number

_ _ _ _ _ _ _ _

KEY NUMBER - UDC3200 Single Loop Controller

Digital Controller for use with 90 to 264Vac Power DC3200

Digital Controller for use with 24Vac/dc Power DC3201

I

- - - - _ _ _ _ _- _

_ _ _

Description

IIIII IV

_ _ _

V

VI

_

Selection

Availability

TABLE I - Specify Control Output and/or Alarms

C _

E _

A _

T _

R _

_ 0

_ B

_ E

_ A

_ T

Output #1

Output #2 and Alarm

#1 or Alarms 1 and 2

Current Output (4 to 20ma, 0 to 20 ma)

Electro Mechanical Relay (5 Amp Form C)

Solid State Relay (1 Amp)

Open Collector transistor output

Dual 2 Amp Relays (Both are Form A) (Heat/Cool Applications)

No Additional Outputs or Alarms

One Alarm Relay Only

E-M Relay (5 Amp Form C) Plus Alarm 1 (5 Amp Form C Relay)

Solid State Relay (1 Amp) Plus Alarm 1 (5 Amp Form C Relay)

Open Collector Plus Alarm 1 (5 Amp Form C Relay)

TABLE II - Communications and Software Selections

Communications

Software Selections

Reserved

Infrared interface

None

Auxiliary Output/Digital Inputs (1 Aux and 1 DI or 2 DI)

RS-485 Modbus Plus Auxiliary Output/Digital Inputs

10

Base-T Ethernet (Modbus RTU) Plus Auxiliary Output/Digital Inputs

Standard Functions, Includes Accutune

Math Option

Set Point Programming (1 Program, 12 Segments)

Set Point Programming Plus Math

No Selection

Infrared Interface Included (Can be used with a Pocket PC)

0 _ _ _

1 _ _ _

2 _ _ _

3 _ _ _

_ 0 _ _

_ A _ _

_ B _ _

_ C _ _

_ _ 0 _

_ _ _ R

TABLE III - Input 1 can be changed in the field using external resistors

Input 1

Input 2

TC, RTD, mV, 0-5V, 1-5V

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA, 0-10V

Carbon, Oxygen or Dewpoint (Requires Input 2)

None

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA, 0-10V

Slidewire Input (Requires two Relay Outputs) _ 40

1 _ _

2 _ _

3 _ _

1 6 0

_ 00

_ 10

_ 20

Continued

Page 12

51-52-03-39

Page 12

Model Number Interpretation (continued)

TABLE IV - Options

Approvals

Tags

Future Options

TABLE V - Product Manuals

Manuals

Certificate

TABLE VI

No Selection

CE (Standard)

CE, UL and CSA

None

Linen Customer ID Tag - 3 lines w/22 characters/line

Stainless Steel Customer ID Tag - 3 lines w/22 characters/line

None

None

None

Product Information on CD - All Languages 0 _

English Manual E _

French Manual F _

German Manual G _

Italian Manual I _

Spanish Manual

None

Certificate of Conformance (F3391)

None 0 _

Figure 3—Model Number Interpretation

0 _ _ _ _

1 _ _ _ _

_ 0 _ _ _

_ T _ _ _

_ S _ _ _

_ _ 0 _ _

_ _ _ 0 _

_ _ _ _ 0

S _

_ 0

_ C

Dimensions

The controller is housed in a 4.5-inch (114 mm) deep, black plastic case with a dark gray elastomer bezel that can be panel

mounted in a 1/4 DIN cutout. The plug-in chassis allows easy access to the controller board and its various option boards. All

power, input, and output wiring are connected to screw terminals on the rear panel. (See Figure 5.)

Max. panel thickness

mm

inches

92,0 + 0,8

-0,00

3,62 + 0,03

Panel

Cutout

19,1

.75

9,0

0,35

90,6

3,57

108,6

4,28

-0,00

92,0 + 0,8

-0,00

3,62 + 0,03

-0,00

Figure 4—UDC3200 Controller and Cutout Dimensions

17,9

0,70

113,1

4,45

Page 13

AC/DC

AC/DC

Line

Line

Voltage

Voltage

Output #2/

Output #2/

Alarm #2

Alarm #2

51-52-03-39

Page 13

Wiring Diagram

y

y

a

a

l

l

r

Digital Input #2Digital Input #1

Digital Input #2Digital Input #1

10 +

10 +

11 –

11 –

Earth Ground

Earth Ground

Hot

Hot

Neutral

Neutral

+

+

-

-

r

R

R

S

S

l

l

l

l

o

o

C

C

n

n

e

e

Alarm #1

Alarm #1

r

o

o

t

t

c

c

e

e

y

y

a

a

l

l

e

e

R

R

S

S

e

e

l

l

g

g

n

n

i

i

S

S

p

p

O

O

12 +

12 +

13 –

13 –

L1

L1

L2/N

L2/N

4

4

5

5

6

6

7

7

8

8

9

9

SHIELD 14

SHIELD 14

RXD - 15

RXD - 15

RXD + 16

RXD + 16

TXD -17

TXD -17

TXD + 18

TXD + 18

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

Ethernet

Ethernet

2ndCurrent Output

2ndCurrent Output

12 +

12 +

13 -

13 -

C

C

D

19

19

20

20

21

21

22

22

22

23

23

23

24

24

24

25

25

26

26

27

27

RS485

RS485

16 SHIELD

16 SHIELD

17 D+ (B)

17 D+ (B)

18 D -(A)

18 D -(A)

D

+

+

-

-

R

R

T

T

D

D

u

u

o

o

A

A

m

m

p

p

O

O

+

+

-

-

Input #2

Input #2

Same as Input #1

Same as Input #1

plus Slidewire input

plus Slidewire input

+

+

-

-

Th

Th

e

e

rm

rm

r

t

t

u

u

p

p

t

t

C

C

n

n

e

e

S

S

+

+

-+-

-+-

L

L

i

i

n

n

e

e

a

a

r

r

o

o

c

c

o

o

u

u

p

p

l

l

e

e

e

e

o

o

y

y

R

R

ct

ct

a

a

y

y

l

i

i

n

n

V

V

a

a

t

t

S

S

n

n

i

i

S

S

250

250

250

ohm

ohm

ohm

e

e

a

a

r

r

e

e

t

t

l

l

g

g

m

m

A

A

l

e

e

R

R

e

e

l

l

a

a

u

u

D

D

2

2

1

1

Input #1

Input #1

a

a

l

l

e

e

R

R

Output #1

Output #1

Open

Open

Open

Wiper

Wiper

Wiper

Close

Close

Close

e

e

l

l

l

l

o

o

d

d

i

i

l

l

o

o

+

+

-

-

L

L

V

V

/

/

m

m

Figure 5—External Wiring Diagram

Ordering Information

For the complete ordering information on the UDC3200, request Model Selection Guide 51-51-16-80.

Honeywell offers a full line of Sensors, Transmitters, and Final Control Devices for use with the

UDC3200 Universal Digital Controller. These devices include:

• Thermocouples,

• RTDs,

• Pressure Transmitters,

• Flow Transmitters,

• Liquid Level Transmitters,

• Valves,

• Actuators, and

• Electric Motors.

Specifications are subject to change without notice.

® Modbus is a trademark of AEG Modicon

Page 14

51-52-03-39

Page 14

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship.

Contact your local sales office for warranty information. If warranted goods are returned to Honeywell during

the period of coverage, Honeywell will repair or replace without charge those items it finds defective. The

foregoing is Buyer's sole remedy and is in lieu of all other warranties, expressed or implied, including

those of merchantability and fitness for a particular purpose. Specifications may change without notice.

The information we supply is believed to be accurate and reliable as of this printing. However, we assume no

responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up

to the customer to determine the suitability of the product in the application.

Distributor :

For more information, contact Honeywell sales at:

US: 1-800-343-0228

Canada: 1-800-461-0013

Honeywell Process Solutions

Industrial Measurement and Control

512 Virginia Drive

Fort Washington, PA 19034

51-52-03-39 0407 Printed in USA www.honeywell.com/ps

Loading...

Loading...