Page 1

51-52-25-129

October 2004

Quick Start Guide for UDC3200 Universal Digital Controller

For detailed instructions see UDC3200 Controller Product Manual 51-52-25-119.

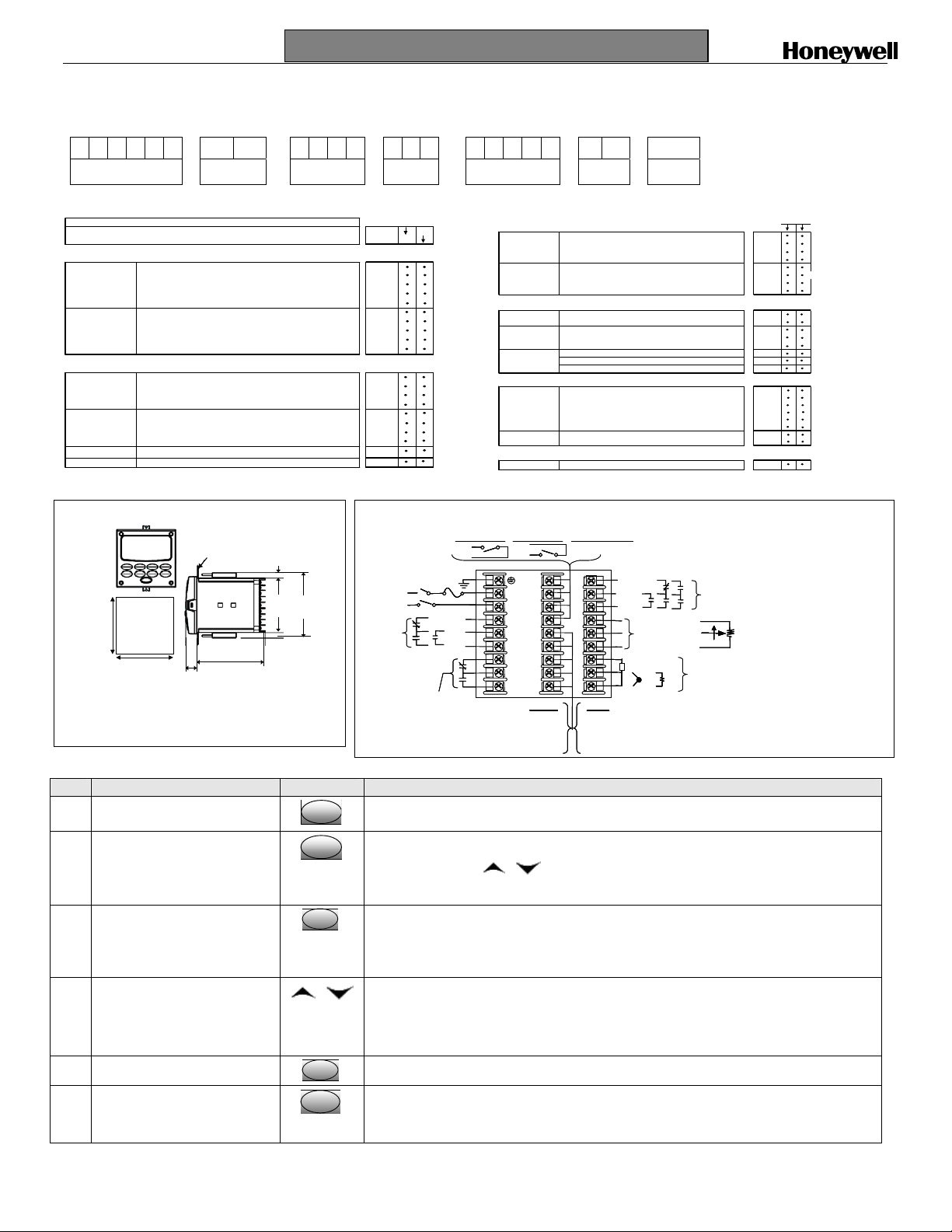

Step 1. Model Number Interpretation

Write your controller model number in the boxes. Then refer to Tables I, II, III,IV,V,VI and circle the corresponding options to identify your controller’s features. A dot

indicates the feature is available.

-

Key Number

Table I

II

KEY NUMBER - UDC3200 Single Loop Controller

Digital Controller for use with 90 to 264Vac Power DC3200

Digital Controller for use with 24Vac/dc Power DC3201

TABLE I - Specify Control Output and/or Alarms

Output #1

Output #2 and Alarm

#1 or Alarms 1 and 2

TABLE II - Communications and Software Selections

Communications

Software Selections

Reserved

Infrared interface

Current Output (4 to 20ma, 0 to 20 ma)

Electro Mechanical Relay (5 Amp Form C)

Solid State Relay (1 Amp)

Open Collector transistor output

Dual 2 Amp Relays (Both are Form A) (Heat/Cool Applications)

No Additional Outputs or Alarms

One Alarm Relay Only

E-M Relay (5 Amp Form C) Plus Alarm 1 (5 Amp Form C Relay)

Solid State Relay (1 Amp) Plus Alarm 1 (5 Amp Form C Relay)

Open Collector Plus Alarm 1 (5 Amp Form C Relay)

None

Auxiliary Output/Digital Inputs (1 Aux and 1 DI or 2 DI)

RS-485 Modbus Plus Auxiliary Output/Digital Inputs

10

Standard Functions, Includes Accutune

Math Option

Set Point Programming (1 Program, 12 Segments)

Set Point Programming Plus Math

No Selection

Infrared Interface Included (Can be used with a Pocket PC)

Description

Base-T Ethernet (Modbus RTU) Plus Auxiliary Output/Digital Inpu ts

Selection

0 _ _ _

1 _ _ _

2 _ _ _

3 _ _ _

_ 0 _ _

_ A _ _

_ B _ _

_ C _ _

_ _ 0 _

_ _ _ R

Step 2. Dimensions and mounting

Max. panel thickness

17,9

0,70

19,1

.75

113,1

4,45

mm

inches

92,0 + 0,8

-0,00

3,62 + 0,03

-0,00

Panel

Cutout

92,0 + 0,8

-0,00

3,62 + 0,03

-0,00

9,0

0,35

90,6

3,57

108,6

4,28

Step 3. Wiring

Output #2/

Output #2/

Alarm #2

Alarm #2

C _

E _

A _

T _

R _

_ 0

_ B

_ E

_ A

_ T

AC/DC

AC/DC

Line

Line

Voltage

Voltage

III

Availability

e

e

l

l

g

g

n

n

i

i

S

S

a

a

l

l

e

e

R

R

Earth Ground

Earth Ground

y

y

R

R

S

S

S

S

o

o

C

C

n

n

e

e

p

p

O

O

Alarm #1

Alarm #1

l

l

l

l

c

c

e

e

10 +

10 +

11 –

11 –

Neutral

Neutral

+

+

-

-

r

r

o

o

t

t

IV

TABLE III - Input 1 can be changed in t he field using external resistors Selection

Input 1

Input 2

TABLE IV - Options

Approvals

Future Options

TABLE V - Product Manuals

Manuals

Certificate

TABLE VI

No Selection

Digital Input #2Digital Input #1

Digital Input #2Digital Input #1

12 +

12 +

13 –

13 –

L1

Hot

Hot

L1

L2/N

L2/N

4

4

5

5

6

6

7

7

8

8

9

9

SHIELD 14

SHIELD 14

TC, RTD, mV, 0-5V, 1-5V

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA, 0-10V

Carbon, Oxygen or Dewpoint (Requires Input 2) 1 6 0

None

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA

TC, RTD, mV, 0-5V, 1-5V, 0-20mA, 4-20mA, 0-10V

Slidewire Input (Requires two Relay Outputs) _ 40

CE (Standard)

CE, UL and CSA

None

Tags

Linen Customer ID Tag - 3 lines w/22 characters/line

Stainless Steel Customer ID Tag - 3 lines w/22 characters/line

None

None

None

Product Information on CD - All Languages 0 _

English Manual E _

French Manual F _

German Manual G _

Italian Manual I _

Spanish Manual

None

Certificate of Conformance (F3391)

None 0 _

2ndCurrent Output

2ndCurrent Output

12 +

12 +

13 -

13 -

19

19

10

10

20

20

11

11

21

21

12

12

22

22

22

13

13

14

14

23

23

23

15

15

24

24

24

16

16

25

25

17

17

26

26

18

18

27

27

Ethernet

Ethernet

RXD - 15

RXD - 15

RXD + 16

RXD + 16

TXD - 17

TXD - 17

TXD + 18

TXD + 18

RS485

RS485

16 SHIELD

16 SHIELD

17 D+ (B)

17 D+ (B)

18 D - (A)

18 D - (A)

V

t

t

u

u

p

p

t

t

u

u

o

o

o

o

C

C

A

A

n

n

m

m

e

e

p

p

C

C

o

o

S

S

D

O

D

O

+

+

+

+

-

-

-

-

Input #2

Input #2

Same as Input #1

Same as Input #1

plus Slidewire input

plus Slidewire input

+

+

+

+

-+-

-+-

-

-

R

R

T

T

Li

Li

T

T

he

he

n

n

D

D

e

e

r

r

m

m

a

a

r

r

oc

oc

V

V

o

o

u

u

p

p

l

l

e

e

VI

Availability

DC 3200 3201

1 _ _

2 _ _

3 _ _

_ 00

_ 10

_ 20

0 _ _ _ _

1 _ _ _ _

_ 0 _ _ _

_ T _ _ _

_ S _ _ _

_ _ 0 _ _

_ _ _ 0 _

_ _ _ _ 0

S _

_ 0

_ C

y

y

a

a

l

l

r

r

e

e

o

o

t

t

y

y

R

R

c

c

a

a

y

y

l

l

e

e

e

e

l

l

t

t

l

l

a

a

e

e

l

l

a

a

t

R

t

R

e

e

S

S

R

R

e

e

l

l

l

l

d

d

g

g

i

i

a

a

l

l

n

n

u

u

i

i

S

S

D

D

2

2

Output #1

Output #1

1

1

Open

Open

Open

Wiper

Wiper

Wiper

Close

Close

Close

+

+

Input #1

Input #1

250

250

250

ohm

ohm

ohm

-

-

Li

Li

n

n

e

e

a

a

r

r

m

m

/

/

m

m

A

A

V

V

Step 4. Configuration Procedure

Step Operation Press Result

1 Enter Set Up Mode

2 Select any Set Up Group

SetupSetup

SetupSetup

Upper Display = SET

Lower Display = TUNING (This is the first Set Up Group title)

Sequentially displays the other Set Up group titles shown in the prompt hierarchy. (See 5.

Configuration Record Sheet for prompts.)

You can also use the

or keys to scan the Set Up groups in both directions. Stop at the Set

Up group title that describes the group of parameters you want to configure. Then proceed to the

next step.

3 Select a Function Parameter

FunctionFunctionFunction

Upper Display = the current value or selection for the first function prompt of the selected Set Up

group.

Lower Display = the first Function prompt within that Set Up group.

Sequentially displays the other function prompts of the Set Up group you have selected. Stop at the

function prompt that you want to change, then proceed to the next step.

4 Change the Value or Selection

or

Increments or decrements the value or selection that appears for the selected function prompt.

change the value or selection of a parameter while in Set Up mode but then decide not

to enter it, press the MAN/AUTO key once. This will recall the original configuration.

This “recall” procedure does not work for a Field Calibration process. Field Calibration is

5 Enter the Value or Selection

6 Exit Configuration

FunctionFunctionFunction

Lower

Lower

Lower

Display

Display

Display

a one-way operation.

Enters value or selection made into memory after another key is pressed.

Exits configuration mode and returns controller to the same state it was in immediately preceding

entry into the Set Up mode. It stores any changes you have made.

If you do not press any keys for 30 seconds, the controller times out and reverts to the mode and

display used prior to entry into Set Up mode.

If you

Page 1 of 4

Page 2

51-52-25-129

October 2004

Quick Start Guide for UDC3200 Universal Digital Controller

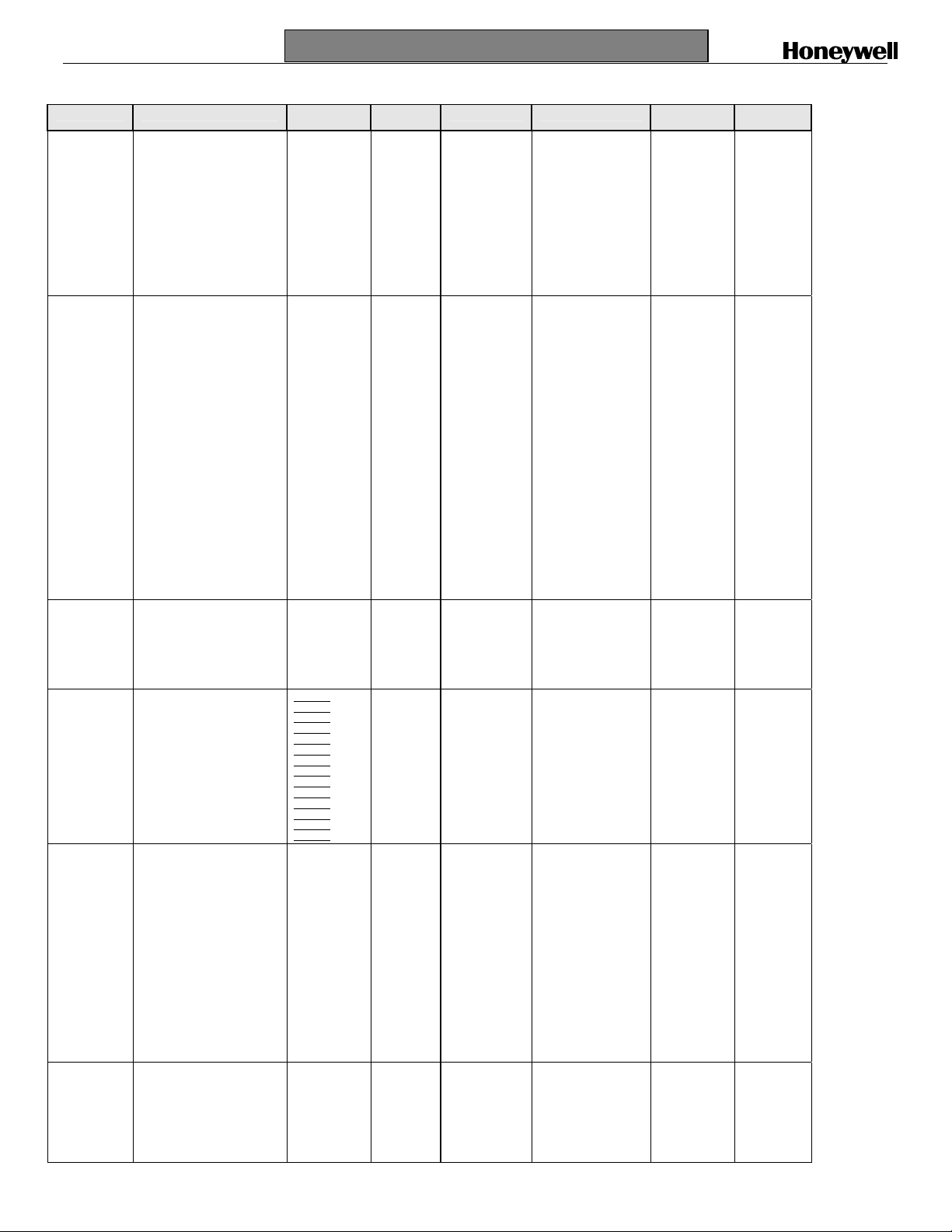

Step 5. Configuration Record Sheet

Enter the value or selection for each prompt on this sheet so you will have a record of how your controller was configured.

Group Prompt Function Prompt Value or

TUNING PROP BD or GAIN

SPRAMP SP RAMP

ACCUTUNE FUZZY

ALGOR CONT ALG

OUTALG OUT ALG

INPUT1 IN1 TYPE

GAINVALn

RATE MIN

RSET MIN or RSET RPM

MAN RSET

PROPBD2 or GAIN 2

RATE2MIN

RSET2MIN or RSET2RPM

CYC SEC or CYC SX3

CYC2 SEC or CYC2 SX3

SECURITY

LOCKOUT

AUTO MAN

SP SEL

RUN HOLD

TIME MIN

FINAL SP

HOTSTART

SP RATE

EU/HR UP

EU/HR DN

HOTSTART

SP PROG

ACCUTUNE

DUPLEX

AT ERROR

TIMER

PERIOD

START

L DISP

INP ALG1

MATH K

CALC HI

CALC LO

ALG1 INA

ALG1 INB

ALG1 INC

ALG1BIAS

PCT CO

RLYSTATE

RLY TYPE

MOTOR TI

CUR OUT

CO RANGE

LOW VAL

HIGH VAL

XMITTER1

IN1 HIgh

IN1 LOw

RATIO1

BIAS IN1

FILTER1

BURNOUT1

EMMISIV1

Selection

_______

READ ONLY

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

Read Only

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

Factory

Setting

1.000

----

0.00

1.0

0.0

1.00

0.00

1.00

20

20

0

CALIB

ENABLE

ENABLE

ENABLE

DISABLE

3

1000

DISABLE

DISABLE

0

0

DISABLE

DISABLE

DISABLE

DISABLE

MANUAL

NONE

PIDA

DIS

0:01

KEY

TREM

KEY

MIN

CURRENT

1 OF 2 ON

MECHAN

30

DISABLE

4-20Ma

0.0

100.0

0-10mV

LINEAR

1000

0

1.00

0.0

1

NONE

0.00

Group Prompt Function Prompt Value or

INPUT2

CONTRL PV SOURC

OPTION AUXOUT

COM ComSTATE

ALARMS A1S1 VA

DISPLY DECIMAL

IN2 TYPe

XMITTER2

IN2 HIgh

IN2 LOw

RATIO2

BIAS IN2

FILTER2

BURNOUT2

EMMISIV2

PID SETS

SW VALU E

LSP’S

RSP SRC

AUTO BIAS

SP TRACK

PWR MODE

PWR OUT

SP HiLIM

SP LoLIM

ACTION

OUT RATE

PCT/M UP

PCT/M DN

OUT HiLIM

OUT LoLIM

I Hi LIM

I Lo LIM

DROPOFF

DEADBAND

OUT HYST

FAILMODE

FAILSAFE

MAN AUTO

AUTO OUT

PBorGN

MINRPM

CO RANGE

LOW VAL

HIGH VAL

DIG INP 1

DIG1 COMB

DIG INP 2

DIG2 COMB

Com ADDR

IR ENABLE

BAUD

TX_DELAY

WSFLOAT

SHEDENAB

SHEDTIME

SHEDMODE

SHDSP

UNITS

CSP RATO

CSP_BIAS

LOOPBACK

A1S2 VA

A2S1 VA

A2S2 VA

A1S1TYPE

A1S2TYPE

A2S1TYPE

A2S2TYPE

A1S1 HL

A1S1 EV

A1S2 HL

A1S2 EV

A2S1HL

A2S1EV

A2S2HL

A2S2EV

ALHYST

ALM OUT1

BLOCK

DIAGNOST

TEMPUNIT

PWR FREQ

RATIO 2

LANGUAGE

Selection

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

_______

Factory

Setting

1-10mV

LINEAR

1000

0

1.00

0

1

NONE

0.00

INPUT 1

1 ONLY

0.00

1 ONLY

NONE

DISABLE

NONE

MANUAL

LAST

1000

0

REVERSE

DISABLE

0

0

100

0.0

100.0

0.0

0

1.0

0.5

NO LATCH

0.0

---

--GAIN

MIN

DISABLE

4-20mA

0.O

100.0

NONE

DIS ABLE

NONE

DISABLE

DISABLE

3

ENABLE

19200

1

FP_B

DISABLE

30.0

LAST

TP LSP

PERCNT

1.0

0

DISABLE

90

10

95

5

NONE

NONE

NONE

NONE

HIGH

-LOW

-HIGH

-LOW

--

0.1

NO LAT

DISABLE

DISABLE

XXXX

NONE

60 HZ

DISABLE

ENGLISH

Page 2 of 4

Page 3

51-52-25-129

October 2004

(Ethernet addresses are accessible via PIE Tool)

Quick Start Guide for UDC3200 Universal Digital Controller

Step 6. Start Up Procedure for Operation

Step Operation Press Result

Man

Man

1 Select Manual

Mode

2 Adjust the Output

3 Enter the Local

Setpoint

4 Select Automatic

Mode

5 Tune the

Controller

Man

Auto

Auto

Auto

or

Lower

Lower

Lower

Display

Display

Display

or

Man

Man

Man

Auto

Auto

Auto

SetupSetup

Until “M” indicator is ON.

The controller is in manual mode.

To adjust the output value and ensure that the final control element is functioning correctly.

Upper Display = PV Value

Lower Display = OUT and the output value in %

Upper Display = PV Value

Lower Display = SP and the Local Setpoint Value

To adjust the local setpoint to the value at which you want the process variable maintained.

The local setpoint cannot be changed if the Setpoint Ramp function is running.

Until “A” indicator is ON.

The controller is in Automatic mode.

The controller will automatically adjust the output to maintain the process variable at setpoint.

Make sure the controller has been configured properly and all the values and selections have

been recorder on the Configuration Record Sheet.

Refer to Tuning Set Up group to ensure that the selections for PBor GAIN, RATE T, and I

MIN, or I RPM have been entered.

Use ACCUTUNE to tune the controller.

Procedure for Changing the Local Setpoints

Step Operation Press Result

Lower

Lower

1 Select the

Setpoint

Lower

Display

Display

Display

2 Change the

Value

3 Return to PV

Display

Lower

Lower

Lower

Display

Display

Display

Procedure for Switching Between Setpoints

You can switch Local and Remote setpoints or between two Local setpoints when configured.

ATTENTION The REMOTE SETPOINT value cannot be changed at the keyboard.

Step Operation Press Result

1 Select the

Setpoint

Select

Select

Select

Additional Operating Procedures

Until you see:

Upper Display = PV

Lower Display = SP or 2SP or 3SP (Value)

To change the Local Setpoint to the value at which you want the process maintained. The

or

display “blinks” if you attempt to enter setpoint values beyond the high and low limits..

To store immediately or will store after 30 seconds.

SP

SP

SP

To switch between the Three Local Setpoints and/or the Remote Setpoint.

ATTENTION “KEY ERROR” will appear in the

lower display, if:

• the remote setpoint or additional local setpoints are not configured as a setpoint source

• you attempt to change the setpoint while a setpoint ramp is enabled, or

• if you attempt to change the setpoint with the setpoint select function key disabled.

Page 3 of 4

Page 4

51-52-25-129

October 2004

Viewing the Operating Parameters

Press the LOWER DISPLAY key to scroll through the operating parameters listed.

The lower display will show only those parameters and their values that apply to your specific model.

Quick Start Guide for UDC2500 Limit Controller

Lower Display Key Parameter Prompts

Lower Display Description

OUT XX.X OUTPUT—Output value is shown in percent with one decimal point for all output types except

SP XXXX LOCAL SETPOINT #1—Also current setpoint when using SP Ramp.

2SP XXXX LOCAL SETPOINT #2

3SP XXXX LOCAL SETPOINT #3

RSP XXXX REMOTE SETPOINT

1IN XXXX INPUT 1—Used only with combinational input algorithms.

2IN XXXX INPUT 2

POS XX SLIDEWIRE POSITION—Used only with TPSC applications that use a slidewire input.

CSP XXXX COMPUTER SETPOINT—When SP is in override.

DEV XXXX DEVIATION—Maximum negative display is –999.9.

PIDSET X TUNING PARAMETER —where X is either 1 or 2.

ET HR.MN ELAPSED TIME—Time that has elapsed on the Timer in Hours.Minutes.

OTR HR.MN TIME REMAINING—Time remaining on the Timer in Hours.Minutes. The “O” is a rotating clock

RAMPXXXM SETPOINT RAMP TIME—Time remaining in the Setpoint Ramp in minutes.

SPN XXXX SETPOINT NOW—Current Setpoint when SP Rate is enabled. The SP XXXX display shows the

XXRAHR.MN RAMP SEGMENT NUMBER AND TIME REMAINING—Set Point Programming display. XX is

XXSKHR.MN SOAK SEGMENT NUMBER AND TIME REMAINING— Set Point Programming display. XX is

RECYC XX NUMBER OF SP PROGRAM RECYCLES REMAINING

To BEGIN RESET SP PROGRAM TO START OF FIRST SEGMENT

RERUN RESET SP PROGRAM TO START OF CURRENT SEGMENT

AUX XXXX AUXILIARY OUTPUT—Displayed only when output algorithm is not Current Duplex.

BIA XXXX BIAS—Displays the manual reset value for algorithm PD+MR.

TUNE OFF LIMIT CYCLE TUNING NOT RUNNING—Appears when Accutune is enabled but not operating.

DO FAST

Three Position Step Control (TPSC). For TPSC, when no slidewire is connected, this display is

an estimated motor position and is shown with no decimal point.

For Position Proportional Control, if the slidewire fails, then the instrument automatically

switches over to TPSC and the OUT display changes with it.

face.

“target” or final setpoint value.

the current segment number and HR.MN is the time remaining for this segment in

Hours.Minutes.

the current segment number and HR.MN is the time remaining for this segment in

Hours.Minutes.

Limit Cycle Tuning with the objective of producing quarter-damped tuning parameters. This

tuning may result in PV overshoot of the SP setting.

DO SLOW

Limit Cycle Tuning with the objective of producing damped or Dahlin tuning parameters,

depending upon the detected process deadtime. The tuning parameters calculated by this

selection are aimed at reducing PV overshoot of the SP setting.

Page 4 of 4

Loading...

Loading...