Page 1

51-52-25-158, Revision 1.0

November 2020

UDC2800 Universal Digital Controller Quick Start Guide

Getting started

When start up the controller for the first time, it is required to enter the initial password and a new password. The initial password is 1234.

Overview

This document is a quick start guide for UDC2800 controller. For detailed instructions, see UDC2800 Product Manual.

To Download the Product Manual:

1. In a web browser, enter

If you are a new user, register at this website first.

2. In the Search box, enter UDC2800 Product Manual (#51-52-25-157), and click the Search icon.

3. Select PRODUCT DOCUMENTS & DOWNLOADS. The All Support Search Results page appears with the search results.

4. Click the package to download it.

https://www.honeywellprocess.com/support, and login.

Model Number Interpretation

Write your controller’s model number in the spaces provided below and circle the corresponding items in each table. This information will also

be useful when you wire your controller.

• Select the desired Key Number. The arrow to the right marks the selection available.

• Make the desired selections from Table I to Table VI. A dot ‘·’ denotes availability.

Key Number I II III IV V VI

_ _ _ _ _ _

Key Number – UDC2800 Single Loop Controller

Description Selection Availability

_ _ _ _ _ _ _ _ _ _ _ _ _ _

Table IV – Options

Approvals CE (Standard)

CE, UL and CSA

Tags None

Stainless Steel Customer ID Tag – 3 lines w/22 characters/line

Future options None _ _ 0 • •

Table IV – Options

Documents Quick Start Guide - English 0_ • •

Certificate None

Certificate of Conformance (F3391)

Table VI – Extended Warranty

Extended Warranty None

Extended Warranty Additional 1 year

Extended Warranty Additional 2 year

0_ _

1_ _

_ 0 _

_ T _

_ 0

_ C

•

•

•

•

•

•

0

1

2

•

•

•

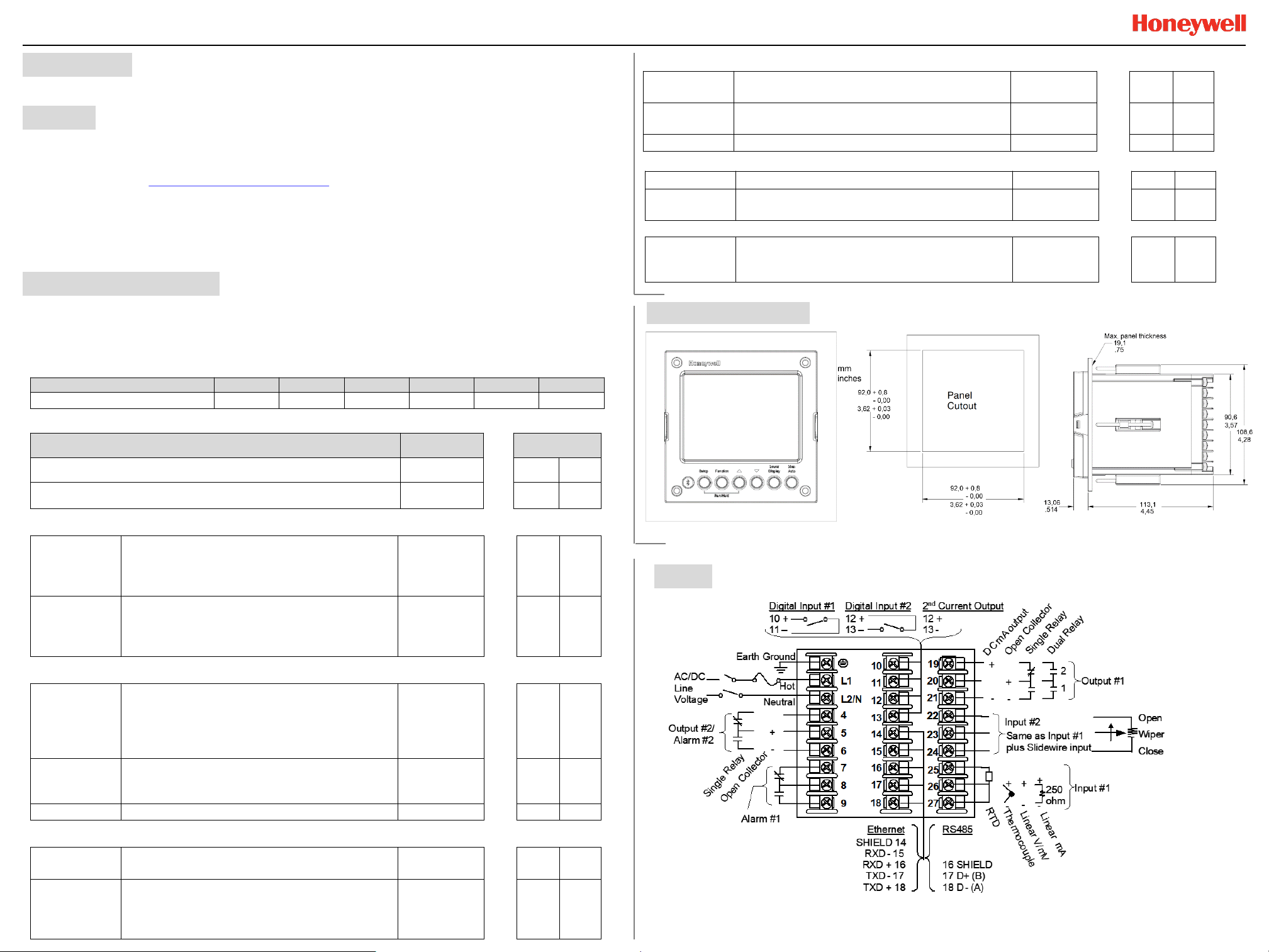

Dimensions and Mounting

•

•

•

•

•

•

•

•

•

Digital Controller for use with 100 to 240 Vac Power DC2800

Digital Controller for use with 24 Vac/dc Power DC2900 ↓

Table I – Specify Control Output and/or Alarms

Output #1 Current Output (4 to 20 ma, 0 to 20 ma)

Electro Mechanical Relay (5 Amp Form C)

Open Collector transistor output

Dual 2 Amp Relays (Both are Form A) (Heat/Cool Applications)

Output #2 and

Alarm #1 or Alarms

1 and 2

Table II – Communications and Software

Communications None

Software Limit Controller

Future options None _ _ 0 • •

No Additional Outputs or Alarms

One Alarm Relay Only

E-M Relay (5 Amp Form C) Plus Alarm 1 (5 Amp Form C Relay)

Open Collector Plus Alarm 1 (5 Amp Form C Relay)

Auxiliary Output/Digital Inputs (1 Aux and 1 DI or 2 DI)

RS-485 Modbus Plus Auxiliary Output/Digital Inputs

10/100M Base-T Ethernet (Modbus RTU) Plus Auxiliary

Output/Digital Inputs

Standard Software

Standard S/W and Setpoint Program

C _

E _

T _

R _

_ 0

_ B

_ E

_ T

0_ _

1_ _

2_ _

3_ _

_ L _

_ S _

_ F _

↓

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

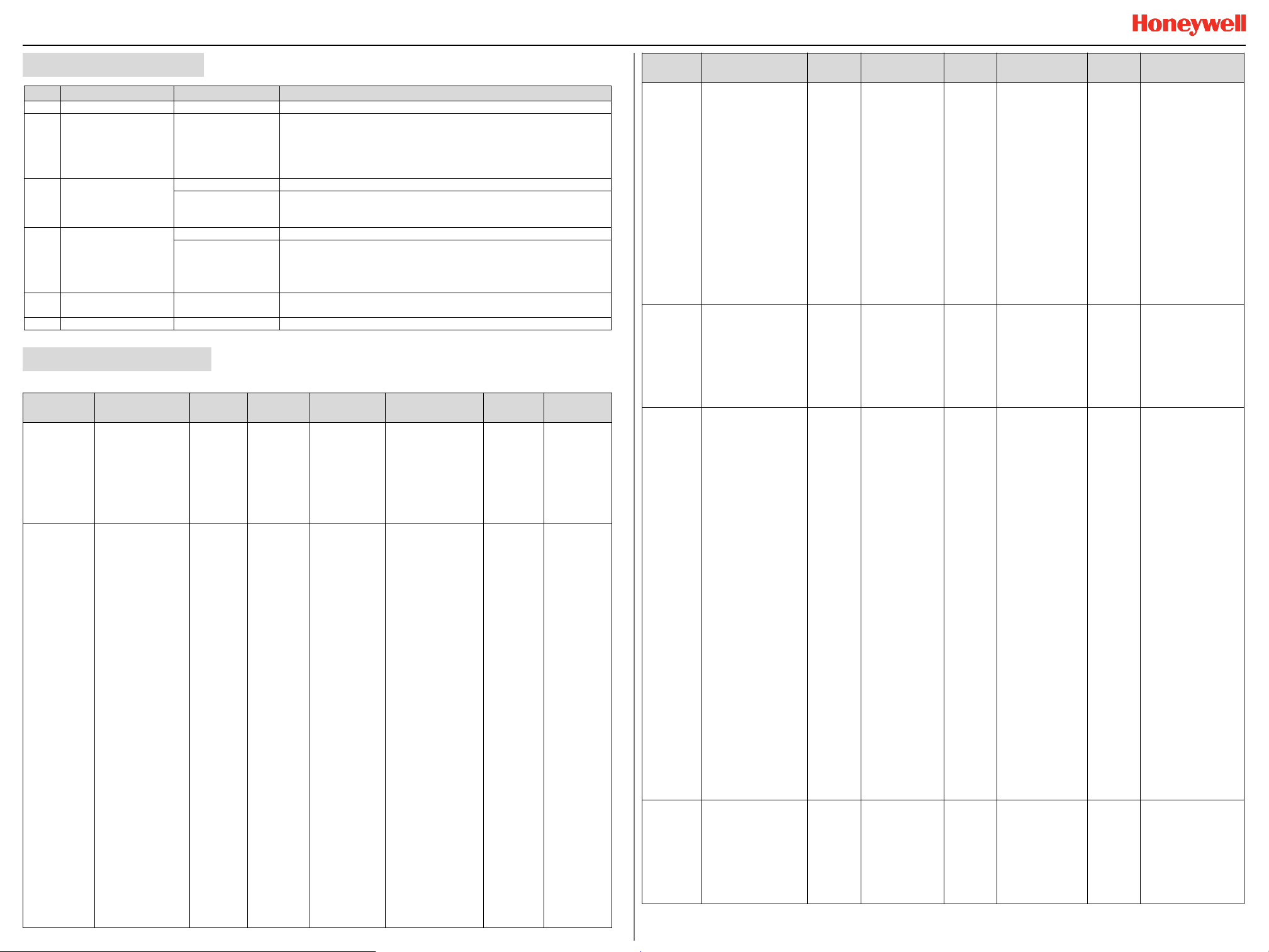

Wiring

•

•

•

•

•

•

•

•

•

•

•

Table III – Input 1 can be changed in the field using external resistors

Input 1 TC, RTD, mV, 0-5V, 1-5V, 0-10V

TC, RTU, mV, 0-5V, 1-5V, 0-10V, 0-20mA, 4-20mA

Input 2 None

TC, RTD, mV, 0-5V, 1-5V, 0-10V

TC, RTU, mV, 0-5V, 1-5V, 0-10V, 0-20mA, 4-20mA

Carbon, Oxygen or Dewpoint (Provides 2 Inputs)

1_ _

2_ _

_ 00

_ 10

_ 20

_ 60

•

•

•

•

•

b

•

•

•

•

•

b

Page 2

51-52-25-158, Revision 1.0

November 2020

UDC2800 Universal Digital Controller Quick Start Guide

Configuration Procedure

Step Operation Press Result

1 Enter Set Up Mode Setup key Enter in the first set up group, Security.

2 Select any Set Up group

3

4

5

6 Exit Configuration Lower Display key Exit the set up mode, and returns to the main screen.

Select a Function

parameter

Change the Value or

Selection

Enter the Value or

Selection

Setup key or Increment

or Decrement keys

Function key Enter in the first function prompt of the selected set up group.

Increment or

Decrement keys

Function key Enter in the value or selection of the selected function prompt.

Increment or

Decrement keys

Function key Enter value or selection made into memory.

Sequentially displays the other set up groups shown in the prompt hierarchy.

See Configuration Record Sheet for prompts.

You can also use the Increment or Decrement keys to scan the set up groups

in both directions. Stop at the set up group tile that describes the group of

parameters you want to configure. Then proceed to the next step.

Press Increment or Decrement keys to display the other function prompts of

the selected set up group. Stop at the function prompt that you want to

change.

Increment or decrement the value or selection that appears for the selected

function prompt.

You can press the Increment and Decrement keys at the same time to move the

current editable digit one step left.

Configuration Record Sheet

Enter the value or selection for each prompt on this sheet so you will have a record of how your controller was configured.

Group Prompt Function Prompt Value or

Security

Tuning

Password

Lockout

Auto/Man Key

Run/Hold Key

SP Select Key

Restore Settings

Change Password

Proportional Band 1

or

Gain 1

Rate Min

Reset Mins/Rpt 1

or

Reset Rpts/Min 1

Manual Reset

Proportional Band 2

or

Gain 2

Rate 2 Min

Reset Mins/Rpt 2

or

Reset Rpts/Min 2

Proportional Band 3

or

Gain 3

Rate 3 Min

Reset Mins/Rpt 3

or

Reset Rpts/Min 3

Proportional Band 4

or

Gain 4

Rate 4 Min

Reset Mins/Rpt 4

or

Reset Rpts/Min 4

Cycle Time 1 Sec

Cycle Time 2 Sec

Selection

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

Factory

Setting

0

Calibration

Enable

Enable

Enable

Disable

- -

- -

1.000

0.00

1.00

- -

0

- -

1.000

0.00

1.00

- -

- -

1.000

0.00

1.00

- -

- -

1.000

0.00

1.00

- -

20

20

Group Prompt Function Prompt Value or

Accutune

SP

Ramp/Program

Fuzzy Suppression

Accutune

Duplex Output

Error Status

SP Ramp Function

Ramp Time Min

Ramp Final SP

SP Rate Function

Rate Up EU/HRr

Rate Down EU/Hr

SP Program Function

Soak Deviation

Program Termination

Program End State

Key Reset/Rerun

Hot Start

Selection

――――

――――

――――

Read only

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

Factory

Setting

Disable

Disable

Manual

None

Disable

3

1000

Disable

0

0

Disable

0

Last SP

Disable

Disable

Disable

Group

Prompt

Algorithms Control Algorithm

Input1

Control

Options

Function Prompt Value or

Timer Function

Period Hrs:Mins

Start Trigger

Low Display

Reset Trigger

Increment

Input Algorithm 1

Math K

Calculated High

Calculated Low

Algorithm 1 Input A

Algorithm 1 Input B

Algorithm 1 Input C

Percent CO

Algorithm 1 Bias

Percent H2

Input 1 Type

Input 1 Transmitter

Input 1 High Value

Input 1 Low Value

Input 1 Ratio

Input 1 Bias

Input 1 Filter

Input 1 Burnout

PV Source

PID Sets

Switchover Value 1/2

Switchover Value 2/3

Switchover Value 3/4

Local SP Source

Remote SP Source

Autobias

SP Tracking

Power Up Mode

SP High Limit

SP Low Limit

Action Direction

Output Rate

Rate Up % Min

Rate Down % Min

Output High Limit

Output Low Limit

Integral High Limit

Integral Low Limit

Dropoff

Deadband

Output Hysteresis

Failsafe Mode

Failsafe Value

SW Failsafe Value

Preset Manual Output

Preset Auto Output

Proportion Unit

Reset Unit

Auxiliary Output

CO Range

CO Low Value

CO High Value

DI 1 Function

DI 1 Combination

DI 2 Function

DI 2 Combination

Selection

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

Factory Setting Group

PID A

Disable

0.01

Keyboard

Timer Remaining

Keyboard

Minutes

None

1.0

1000

0

Input 1

Input 2

None

0.200

0.000

1.000

0-10 mV

Linear

1000

0

1.00

0

1

No Burnout

Input 1

1 Set

0.00

0.00

0.00

1 Local SP

None

Disable

None

Manual/Local SP

1000

0

Reverse

Disable

0

0

100

0

100

0

0

1.0

0.5

Non Latching

0

--

0

0

Gain

Minutes/Repeat

Disable

4-20 mA

0.0

100.0

None

Disable

None

Disable

Prompt

Output Output Algorithms

Input2 Input 2 Type

Alarms A1S1 Type

Display Decimal Digits

Function Prompt Value or

Selection

――――

Output Range

Relay State

Relay Type

Motor Time

Current Output

CO Low Value

CO High Value

CO Range

Input 2 Transmitter

Input 2 High Value

Input 2 Low Value

Input 2 Ratio

Input 2 Bias

Input 2 Filter

Input 2 Burnout

A1S1 Value

A1S1 State

A1S1 Event

A1S1 Delay

A1S1 Hysteresis

A1S2 Type

A1S2 Value

A1S2 State

A1S2 Event

A1S2 Delay

A1S2 Hysteresis

A2S1 Type

A2S1 Value

A2S1 State

A2S1 Event

A2S1 Delay

A2S1 Hysteresis

A2S2 Type

A2S2 Value

A2S2 State

A2S2 Event

A2S2 Delay

A2S2 Hysteresis

Alarm Output 1

Alarm Blocking

AO/CO Diagnostic

Temperature Unit

Input 2 Ratio

Language

TC Diagnostics

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

Factory Setting

Model No. dependent

100 Percent

1 Off 2 On

Electromechanical

30

Disable

0.0

100.0

4-20mA

0-10 mV

Linear

1000

0

1.00

0

1

No Burnout

None

90

High Alarm

End of Segment

0

0.1

None

10

Low Alarm

Begin of Segment

0

0.1

None

95

High Alarm

End of Segment

0

0.1

None

5

Low Alarm

Begin of Segment

0

0.1

Non Latching

Disable

Disable

None

None

Disable

English

Enable

Page 3

51-52-25-158, Revision 1.0

November 2020

UDC2800 Universal Digital Controller Quick Start Guide

Configuration Record Sheet

Group Prompt Function Prompt Value or Selection Factory Setting

Communication

Communication with RS485

board (Accessible via

Communication set up group or

Honeywell EasySet)

Communication with Ethernet

board (Accessible via

Communication set up group or

Honeywell EasySet)

Status

Bluetooth Function

Bluetooth ID

Bluetooth MAC Address

Communication Type

Modbus Address

Baud Rate

Response Delay

Word Order for Float

Ethernet Address

Subnet Mask Address

Default Gateway

Shed Function

Shed Time

Shed Mode

Shed SP Recall

Computer SP Unit

Computer SP Ratio

Computer SP Bias

Local Loopback

Bluetooth Function

Bluetooth ID

Bluetooth MAC Address

Communication Type

Modbus Address

Baud Rate

Response Delay

Word Order for Float

Shed Function

Shed Time

Shed Mode

Shed SP Recall

Computer SP Unit

Computer SP Ratio

Computer SP Bias

Local Loopback

Bluetooth Function

Bluetooth ID

Bluetooth MAC Address

Communication Type

Modbus Address

Baud Rate

Response Delay

Word Order for Float

Ethernet Address

Subnet Mask Address

Default Gateway

Shed Function

Shed Time

Shed Mode

Shed SP Recall

Computer SP Unit

Computer SP Ratio

Computer SP Bias

Software Version

Failsafe Status

Self Tests

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

――――

Read only

Read only

Read only

Disable

UXXXXXXXX

XX:XX:XX:XX:XX:XX

Disable

3

19200

1

FP B 0123

10.0.0.2

255.255.255.0

0.0.0.0

Disable

30

Last Mode

To Local SP

Engineering Unit

1.00

0

Disable

Disable

UXXXXXXXX

XX:XX:XX:XX:XX:XX

Disable

3

19200

1

FP B 0123

Disable

30

Last Mode

To Local SP

Engineering Unit

1.00

0

Disable

Disable

UXXXXXXXX

XX:XX:XX:XX:XX:XX

Disable

3

19200

1

FP B 0123

10.0.0.2

255.255.255.0

0.0.0.0

Disable

30

Last Mode

To Local SP

Engineering Unit

1.00

0

- -

- -

- -

Start Up Procedure for Operation

It is required to enter the initial password and a new password when start up the controller for the first time. The initial password is 1234.

For more information of interface displays, see "Function of displays“ in UDC2800 Product Manual.

Step Operation Press Result

Select Manual Mode Man Auto key

1

Adjust the Output Increment or

2

3 Enter the Local Setpoint Lower Display key

Select Automatic Mode Man Auto key

4

Tune the Controller Setup key

5

Decrement keys

Increment or

Decrement keys

Until "Manual" is displayed under MODE.

The controller is in manual mode.

Lower Display = OUT and the output value in %.

To adjust the output value and ensure that the final control element is functioning

correctly.

Until the required "SP" and the Local Setpoint Value are displayed.

To adjust the local setpoint to the value at which you want the process variable

maintained.

Attention: The local setpoint 1 cannot be changed if the Setpoint Ramp function is

running.

Until “Auto” is displayed under MODE. The controller is in Automatic mode.

The controller will automatically adjust the output to maintain the process variable at

setpoint.

Make sure the controller has been configured properly and all the values and

selections have been recorded on the Configuration Record Sheet.

Refer to Tuning Set Up group to ensure that the selections for Proportional Band or

Gain, Rate Min, and Reset Mins/Rpt, or Reset Rpts/Min have been entered.

Use Accutune to tune the controller. See "Accutune III" in UDC2800 Product Manual.

Setpoints

You can configure the following setpoints for the UDC2800 controller.

• A Single Local Setpoint

• 2 Local Setpoints

• 3 Local Setpoints

• 4 Local Setpoints

• Up to 4 Local Setpoints and 1 Remote Setpoint

Changing the Setpoint value

Step Operation Press Result

1

2

Select the Setpoint Low Display key

Adjust the Output Increment or

Decrement keys

Switching between Setpoints

You can switch Local and Remote setpoints or between two Local setpoints when configured. The Remote Setpoint value cannot be changed

at the keyboard.

To switch between Setpoints

Press the Function key to switch the four Local Setpoints and/or the Remote Setpoint.

Attention: “KEY ERROR” appears if:

• the remote setpoint or additional local setpoints are not configured as a setpoint source.

• you attempt to change the setpoint while a setpoint ramp/program is running.

• you attempt to change the setpoint with the setpoint select function key disabled.

• while a setpoint ramp/program is not terminated.

Until you see:

Lower Display = SP or 2SP or 3SP, or 4SP (Value)

To change the Local Setpoint to the value at which you want the process maintained.

The display “blinks” if you attempt to enter setpoint values beyond the high and

low limits.

The configured setpoint will be stored immediately.

Page 4

51-52-25-158, Revision 1.0

November 2020

UDC2800 Universal Digital Controller Quick Start Guide

Viewing the operating parameters

Under the main screen, press the Lower Display key to scroll through the operating parameters listed in table below. The lower display will

show only those parameters and their values that apply to your specific model.

Lower Display Description

OUT XXX.X

COUT XXX.X

EOUT XXX.X

SP XXXX.XXX

2SP XXXX.XXX

3SP XXXX.XXX

4SP XXXX.XXX

RSP XXXX.XXX

CSP XXXX.XXX

SPN XXXX.XXX

DEV XXX.X

1 IN XXXX.XXX

2 IN XXXX.XXX

PID Set X

BIAS XXXX

AUX XXX.X

TEL O XXH: XXM

Or

TEL O XXM: XXS

TRE O XXH: XXM

Or

TRE O XXM: XXS

RAMP XXXM: XXS

PXSX RA XXH:XXM:XXS

PXSX RA XXX/M (0~999)

PXSX RA XXX/H (0~999)

PXSX SK XXH:XXM:XXS Program X(1-8) Segment(1-8) Soak XXH:XXM:XXS remaining

Recycle XX

To Begin

Rerun

ACTU TUNE OFF

ACTU DO SLOW

ACTU DO FAST

Output value is shown in percent with one decimal point.

Appears when Shed function is Enabled, and Output Override register is successful override by Modbus (In Slave

Mode) .

Appears when Shed function is Enabled, and the controller is in Slave Mode, push A/M key to enter Emergency

Mode.

Local Setpoint #1, appears when Control Algorithm is configured as ANY algorithm except Disable in the

Algorithms set up group.

It also appears for current setpoint when using SP Ramp.

Local Setpoint #2, appears when the following two conditions are satisfied:

• In the Algorithms set up group, configure Control Algorithm as ANY algorithm except Disable.

• In the Control set up group, configure Local SP Source as 2/3/4 Local SPs.

Local Setpoint #3, appears when the following two conditions are satisfied:

• In the Algorithms set up group, configure Control Algorithm as ANY algorithm except Disable.

• In the Control set up group, configure Local SP Source as 3/4 Local SPs.

Local Setpoint #4, appears when the following two conditions are satisfied:

• In the Algorithms set up group, configure Control Algorithm as ANY algorithm except Disable.

• In the Control set up group, configure Local SP Source as 4 Local SPs.

Remote Setpoint, appears when the following two conditions are satisfied:

• In the Algorithms set up group, configure Control Algorithm as ANY algorithm except Disable.

• In the Control set up group, configure Remote SP Source as ANY selection except Disable.

Computer Setpoint, when SP is in override.

• In the Algorithms set up group, configure Control Algorithm as ANY algorithm except Disable.

• In the Communication set up group, enable Shed Function. And CSP is successfully override by SP override

through Modbus.

Setpoint Now—Current Setpoint when SP Rate is enabled. The SP XXXX.XXX display shows the “target” or final

setpoint value.

SPN is not equal with the target SP.

Deviation

Input 1—Used only with combinational input algorithms.

Input 2

Tuning Parameter, where X is either 1, 2, 3 or 4.

BIAS, displays the manual reset value for algorithm PD+MR.

Auxiliary Output, displayed only when output algorithm is not Current Duplex.

Elapsed Time, time that has elapsed on the Timer in Hours: Minutes, or Minutes: Seconds.

The "O‘ is a clockwise running clock.

Time Remaining, time remaining on the Timer in Hours: Minutes, or Minutes: Seconds.

The "O" is a counter-clockwise running clock.

Setpoint Ramp Time—Time remaining in the Setpoint Ramp in minutes.

Program X(1-8) Segment X(1-8) Ramp XXH:XXM:XXS remaining

X and XX is current program or segment or time remaining

Initial hold states Ramp time should be remaining time

X and XX is current program or segment or time remaining

Initial hold states Soak time should be remaining time

Number of SP Program Recycles Remaining

Reset SP Program to Start of First Segment

Reset SP Program to Start of Current Segment

Limit Cycle Tuning not Running, appears when Accutune is enabled but not operating.

Limit Cycle Tuning with the objective of producing damped or Dahlin tuning parameters, depending upon the

detected process deadtime. The tuning parameters calculated by this selection are aimed at reducing PV

overshoot of the SP setting.

Limit Cycle Tuning with the objective of producing quarter-damped tuning parameters. This tuning may result in

PV overshoot of the SP setting.

Notices

This document contains Honeywell proprietary information. Information contained herein is to be used solely for the purpose submitted, and

no part of this document or its contents shall be reproduced, published, or disclosed to a third party without the express permission of

Honeywell International Sàrl.

While this information is presented in good faith and believed to be accurate, Honeywell disclaims the implied warranties of merchantability

and fitness for a purpose and makes no express warranties except as may be stated in its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any direct, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Copyright 2020 - Honeywell International Sàrl

Trademarks

Honeywell®, Experion®, PlantScape®, SafeBrowse®, and TotalPlant® are registered trademarks of Honeywell International, Inc.

Other brand or product names are trademarks of their respective owners.

Other trademarks

Microsoft and SQL Server are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or other

countries.

Trademarks that appear in this document are used only to the benefit of the trademark owner, with no intention of trademark infringement.

Third-party licenses

This product may contain or be derived from materials, including software, of third parties. The third party materials may be subject to

licenses, notices, restrictions and obligations imposed by the licensor. The licenses, notices, restrictions and obligations, if any, may be found

in the materials accompanying the product, in the documents or files accompanying such third party materials, in a file named third_party_

licenses on the media containing the product, or at

Support

For support, contact your local Honeywell Process Solutions Customer Contact Center (CCC). To find your local CCC visit the website,

https://www.honeywellprocess.com/en-US/contactus/customer-support-contacts/Pages/default.aspx.

How to report a security vulnerability

For the purpose of submission, a security vulnerability is defined as a software defect or weakness that can be exploited to reduce the

operational or security capabilities of the software.

Honeywell investigates all reports of security vulnerabilities affecting Honeywell products and services.

To report a potential security vulnerability against any Honeywell product, please follow the instructions at:

us/product-security.

Documentation feedback

You can find the most up-to-date documents on the Honeywell Process Solutions Support website at: www.honeywellprocess.com.

If you have comments about Honeywell Process Solutions documentation, send your feedback to:

Use this email address to provide feedback, or to report errors and omissions in the documentation. For immediate help with a technical

problem, contact HPS Technical Support through your local Customer Contact Center, or by raising a support request on the Honeywell

Process Solutions Support website.

Training classes

Honeywell holds technical training classes that are taught by process control systems experts. For more information about these classes,

contact your Honeywell representative, or see

Factory Information

Company Name: HONEYWELL System Sensor de Mexico, S. de R.L. de C.V .

Company Address: Avenida Miguel De La Madrid, #8102 Colonia Lote Bravo Ciudad Juarez, Chihuahua, C.P. 32695, México

http://www.honeywell.com/en-us/privacy-statement.

https://www.honeywell.com/en-

hpsdocs@Honeywell.com.

http://www.automationcollege.com.

Loading...

Loading...