Technical Handbook

Touchpoint Plus

i

Revision History

Revision Comment Date

Issue 01 First Issue and initial translations 30/05/2015

Issue 02 Added new chapters, new data and final translations 09/06/2015

Issue 03 Completely Revised; added Expansion Unit, Dual Input Module and Modbus 29/02/2016

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 ii Technical Handbook

Disclaimer

In no event shall Honeywell be liable for any damages or injury of any nature or kind, no matter how caused, that arise

from the use of the equipment referred to in this manual.

Strict compliance with the safety procedures set out and referred to in this manual, and extreme care in the use of the

equipment, are essential to avoid or minimise the chance of personal injury or damage to the equipment.

The information, figures, illustrations, tables, specifications, and schematics contained in this manual are believed to be

correct and accurate as at the date of publication or revision. However, no representation or warranty with respect to such

correctness or accuracy is given or implied and Honeywell will not, under any circumstances, be liable to any person or

corporation for any loss or damages incurred in connection with the use of this manual.

The information, figures, illustrations, tables, specifications, and schematics contained in this manual are subject to

change without notice.

Unauthorised modifications to the gas detection system or its installation are not permitted, as these may give rise to

unacceptable health and safety hazards.

Any software forming part of this equipment should be used only for the purposes for which Honeywell supplied it. The

user shall undertake no changes, modifications, conversions, translations into another computer language, or copies

(except for a necessary backup copy).

In no event shall Honeywell be liable for any equipment malfunction or damages whatsoever, including (without limitation)

incidental, direct, indirect, special, and consequential damages, damages for loss of business profits, business

interruption, loss of business information, or other pecuniary loss, resulting from any violation of the above prohibitions.

Warranty

Honeywell Analytics warrants the Touchpoint Plus system against defective parts and workmanship, and will repair or (at

its discretion) replace any components that are or may become defective under proper usage within 12 months from the

date of commissioning by a Honeywell Analytics approved representative* or 18 months from shipment from Honeywell

Analytics, whichever is sooner.

This warranty does not cover consumable, batteries, fuses, normal wear and tear, or damage caused by accident, abuse,

improper installation, unauthorized use, modification or repair, ambient environment, poisons, contaminants or abnormal

operating conditions.

This warranty does not apply to sensors or components that are covered under separate warranties, or to any 3

cables and components.

Any claim under the Honeywell Analytics Product Warranty must be made within the warranty period and as soon as

reasonably practicable after a defect is discovered. Please contact your local Honeywell Analytics Service representative

to register your claim.

This is a summary. For full warranty terms please refer to the Honeywell Analytics’ General Statement of Limited Product

Warranty, which is available on request.

* A Honeywell Analytics approved representative is a qualified person trained or employed by Honeywell Analytics, or a

qualified person trained in accordance with this manual.

Copyright Notice

Microsoft, MS and MS–DOS are registered trademarks of Microsoft Corp.

Other brand and product names mentioned in this manual may be trademarks or registered trademarks of their respective

companies and are the sole property of their respective holders.

Honeywell is the registered trademark of Honeywell Automation and Control Systems (ACS).

Touchpoint is a registered trademark of Honeywell Analytics (HA).

Find out more at www.honeywellanalytics.com

Conditions of Use

rd

-party

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 iii Technical Handbook

Conditions of Use

This page deliberately blank.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 iv Technical Handbook

Contents

Chapter 1. Important Information .......................................................................................... 1

1.1 Regulatory Approval Markings ................................................................................................ 1

1.2 Additional Product Markings ................................................................................................... 1

1.3 TPPL Mandatory Warning ......................................................................................................... 1

1.4 TPPL General Warnings ........................................................................................................... 2

1.5 TPPL General Cautions ............................................................................................................ 3

1.6 How to Use this Manual ............................................................................................................ 3

1.6.1 Intended Readers .............................................................................................................. 3

1.6.2 Conventions Used ............................................................................................................. 3

1.6.3 Associated Manuals .......................................................................................................... 4

Chapter 2. Safety Hazards, Warnings and Ca u tions ........................................................... 5

2.1 Safety ......................................................................................................................................... 5

2.1.1 Warnings and Cautions ..................................................................................................... 5

2.1.2 Safety Hazards .................................................................................................................. 6

2.2 Location and Description of Warning Labels ......................................................................... 8

2.2.1 Safety Warning Labels ...................................................................................................... 8

2.3 Electrical Hazards ..................................................................................................................... 9

2.3.1 General Safety Precautions .............................................................................................. 9

2.3.2 Component Testing and Replacement .............................................................................. 9

2.3.3 Good Practice ................................................................................................................. 10

2.3.4 Lithium Battery Hazard .................................................................................................... 10

2.3.5 Training of Personnel ...................................................................................................... 12

2.3.6 Conditions Satisfying Local, National and International Safety Regulations ................... 12

2.3.7 Due Authorisation ............................................................................................................ 12

2.3.8 Approved Maintenance and Servicing Procedures ......................................................... 12

Chapter 3. System General Description .............................................................................. 13

3.1 How to Open and Close the Enclosure ................................................................................. 15

3.2 Equipment Specification ........................................................................................................ 16

3.2.1 Power Requirements (Controller Unit only) ..................................................................... 16

3.2.2 Weights ........................................................................................................................... 17

3.2.3 Dimensions ..................................................................................................................... 17

3.2.4 Ambient Operating Temperature ..................................................................................... 17

3.2.5 Overall Ambient Operating Humidity ............................................................................... 17

3.2.6 Storage Conditions (Without batteries) ........................................................................... 17

3.2.7 Storage Conditions (With batteries) ................................................................................ 17

3.2.8 IP Rating ......................................................................................................................... 17

3.2.9 Construction .................................................................................................................... 17

3.2.10 Touchpoint Plus Packaging ........................................................................................... 18

3.2.11 Packaging Components for Return to Manufacturer ..................................................... 18

3.2.12 Disposal (WEEE Directive)............................................................................................ 18

3.3 TPPL Construction .................................................................................................................. 18

3.3.1 TPPL Basic Control Unit ................................................................................................. 18

3.3.2 TPPL Expansion Unit ...................................................................................................... 19

3.3.3 TPPL DIP Switches ......................................................................................................... 19

Chapter 4. System Mechanical Installation ........................................................................ 21

4.1 Wall Mounting Requirements ................................................................................................. 22

4.1.1 Wall Mount Fixings .......................................................................................................... 23

Chapter 5. Electrical Power Connection and Interfacing .................................................. 25

5.1 Power Connection ................................................................................................................... 25

5.1.1 AC Power Supply ............................................................................................................ 26

5.1.2 DC Power Supply ............................................................................................................ 27

5.1.3 Backup Battery Pack ....................................................................................................... 27

5.2 Cabling and Connection Requirements ................................................................................ 28

5.2.1 AC Mains Voltage Power Cables .................................................................................... 28

5.2.2 DC Power Cables ............................................................................................................ 28

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 v Tec hnical Handbook

Contents

5.2.3 Field Device Cables ........................................................................................................ 28

5.2.4 Optional Expansion Unit Connection ............................................................................... 29

5.2.5 Main Module Connections ............................................................................................... 30

5.2.6 Expansion Module Power Connections ........................................................................... 31

5.2.7 TPPL DIP Switches ......................................................................................................... 32

5.2.8 Ethernet Connection (Option).......................................................................................... 32

5.2.9 Module / Field Device Connections ................................................................................. 33

5.2.10 mA Input Module Connections ...................................................................................... 34

5.2.11 mV Input Module Connections ...................................................................................... 38

5.2.12 Dual Input Module Connections .................................................................................... 39

5.2.13 mA Output Module Connections ................................................................................... 40

5.2.14 Relay Output Module Connections ................................................................................ 41

5.3 Modbus Remote Terminal Unit (RTU) and Transmission Control Protocol (TCP) Connections

42

5.3.1 Modbus Configuration ..................................................................................................... 44

Chapter 6. Commissioning ................................................................................................... 45

6.1 Menu Structure ........................................................................................................................ 45

6.1.1 The Information Menu ..................................................................................................... 45

6.1.2 The Configuration Menu .................................................................................................. 46

6.1.3 The Maintenance Menu .................................................................................................. 47

6.1.4 System Test Menu .......................................................................................................... 47

6.2 First Time Switch On ............................................................................................................... 48

6.3 Logging In/Out ......................................................................................................................... 49

6.3.1 How to Log In .................................................................................................................. 49

6.3.2 How to Log Out ............................................................................................................... 49

6.3.3 Password Rules .............................................................................................................. 49

6.3.4 How To Change a Password .......................................................................................... 50

6.3.5 Forgotten Passwords ...................................................................................................... 50

6.4

Date, Time and

6.4.1 How to Set or Change Date, Time and Language Settings ............................................. 51

6.5 Service Contact Settings ........................................................................................................ 51

6.6 Touch Panel Configuration .................................................................................................... 52

6.6.1 How to Change the Backlight Timeout and Brightness ................................................... 52

6.6.2 How to Calibrate the Touch Panel ................................................................................... 52

6.7 Latching Alarms ...................................................................................................................... 52

6.8 Remote Reset / Acknowledge / Inhibit Switch Options ........................................................ 55

6.9 Data Logging ........................................................................................................................... 55

6.9.1 To set or change Data Logging: ...................................................................................... 55

6.10 TPPL TCP/IP Address ........................................................................................................... 56

6.11 Network Settings for WEB and MODBUS TCP.................................................................... 56

6.12 Modbus RTU Settings ........................................................................................................... 57

6.13 Commission Input / Output Modules ................................................................................... 58

6.14 Channel Configuration .......................................................................................................... 58

6.14.1 Introduction ................................................................................................................... 58

6.14.2 Configuring a Channel (mA Input and mV Input Channels) .......................................... 59

6.14.3 Editing a Configured Channel ....................................................................................... 60

6.14.4 Editing mA Input Channel Settings ................................................................................ 60

6.14.5 Editing mV Input Channel Settings ................................................................................ 64

6.14.6 Editing Relay Output Channel Settings ......................................................................... 66

6.15 Calibrating Input Channels ................................................................................................... 68

6.15.1 Adjusting the mV Sensor Baseline ................................................................................ 69

6.15.2 Calibrating a mV Input Channel .................................................................................... 69

6.15.3 Calibrating a mA Input Channel .................................................................................... 71

6.16 Backing Up the Configuration Settings ............................................................................... 73

6.16.1 How to Back Up the Configuration: ............................................................................... 73

6.16.2 How to Restore the Configuration ................................................................................. 73

Language Settings

................................................................................... 51

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 vi Technical Handbook

Contents

Chapter 7. Touchpoint Plus User Guide ............................................................................. 75

7.1 User Interface General ............................................................................................................ 75

7.2 Touchscreen ............................................................................................................................ 76

7.3 Switching On and Off .............................................................................................................. 76

7.4 Menu Items and Access Levels ............................................................................................. 77

7.4.1 Navigation – Active Access Level Icons .......................................................................... 79

7.5 SD Card Usage ........................................................................................................................ 79

7.5.1 Checking the Capacity of the SD Card ............................................................................ 79

7.5.2 Inserting or Replacing SD Cards ..................................................................................... 80

7.6

Normal Operation (Safety

7.7 Operating Overview ................................................................................................................ 81

7.7.1 Touchscreen ................................................................................................................... 81

7.7.2

User Interface

7.7.3 Navigating the Channel Detail Screens.

6.6.3 Navigation – Active

7.7.4 Navigation – Menu .......................................................................................................... 85

7.8 Responding to Alar

7.8.1

View Active

7.8.2

Accept or Acknowledge

7.8.3

Reset a Latched

7.9

Event Information ................................................................................................................... 87

7.9.1

Viewing Event

7.9.2 Accepting / Acknowledging Active Events ....................................................................... 87

7.9.3

Resetting Latched Events ............................................................................................... 88

7.10

Inhibiting Channels ............................................................................................................... 88

7.10.1 To Inhibit Input Channels: ............................................................................................. 88

7.10.2 To Clear Inhibits: ........................................................................................................... 88

7.10.3 To Change Inhibit Timeouts .......................................................................................... 88

7.11

Viewing Input Channels and Input

7.12

Viewing Output

7.13

Viewing the Trend

7.14 Viewing and Exporting Event History .................................................................................. 92

7.14.1 To View the Event History: ............................................................................................ 92

7.14.2 To Export the Event History: ......................................................................................... 92

7.15 Accessing the System Information and Service Contact Details...................................... 92

7.16 System State and Syste m Failure Relays ........................................................................... 92

7.17 Monitoring TPPL via the Optional Web Interface ............................................................... 93

7.17.1 Web Interface Configuration ......................................................................................... 93

7.17.2 Web Interface Navigation .............................................................................................. 95

Alarms

Channels

Functions)

Scr

een

.................................................................................................... 81

Events and Filtering

ms......................................................................................................... 86

....................................................................................................... 86

an Active

Alarm

.................................................................................................. 87

Information

.................................................................................................. 90

Graph

................................................................................................... 91

................................................................................. 81

............................................................................ 83

...................................................................... 84

Alarm

.................................................................... 86

.......................................................................................... 87

Details

.................................................................... 89

Chapter 8. Daily / Shift Checks ............................................................................................ 97

Chapter 9. Routine Maintenance and Scheduled Testing ................................................. 99

9.1 Routine Maintenance .............................................................................................................. 99

9.1.1 Weekly Checks ............................................................................................................... 99

9.2 Routine Testing ..................................................................................................................... 100

9.2.1 Exercising the Audio/Visual Alarms ............................................................................... 100

9.2.2 Exercising the Relays .................................................................................................... 101

9.2.3 Checking the mA Outputs ............................................................................................. 101

9.2.4 Calibrating mV Input Channels...................................................................................... 102

9.3 Periodic Scheduled Testing ................................................................................................. 104

9.3.1 Introduction ................................................................................................................... 104

9.3.2 Field Inputs Test ............................................................................................................ 105

9.3.3 Cause and Effect Test ................................................................................................... 105

Chapter 10. Repairs, Replacements and Upgrades ......................................................... 107

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 vii Technical Handbook

Contents

10.1 How to Decommission and Remove a Serviceable I/O Module ...................................... 107

10.1.1 To Remove a Serviceable Module .............................................................................. 107

10.2 How to Replace a Faulty I/O Module .................................................................................. 108

10.2.1 To Replace a Faulty Module ....................................................................................... 108

10.3 How to Add a New I/O Module ............................................................................................ 109

10.3.1 To Add a New Module ................................................................................................. 109

10.4 How to Update the Sensor Catalogue ............................................................................... 110

10.4.1 To Update the Sensor Catalogue ................................................................................ 110

10.5 How to Backup / Restore the System Configuration ........................................................ 111

10.5.1 To Create a Backup File ............................................................................................. 111

10.5.2 To Restore the Configuration From a Backup File ...................................................... 112

10.6 How to Update Firmware .................................................................................................... 113

10.6.1 How to Check Firmware Compatibility ........................................................................ 113

10.6.2 How to Update the Firmware....................................................................................... 114

10.7 Back up Battery Maintenance ............................................................................................ 115

10.7.1 Recommended Backup Battery Maintenance ............................................................. 115

10.7.2 How to Replace the Backup Battery ............................................................................ 115

10.8 Return to Factory Default Settings .................................................................................... 116

10.8.1 To Reset the Touchpoint Plus to its Factory Default Settings ..................................... 116

Chapter 11. Troubleshooting ............................................................................................. 117

11.1 Calling for Technical Support. ........................................................................................... 117

Chapter 12. Technical Specifications ................................................................................ 119

12.1 Environmental ..................................................................................................................... 119

12.2 User Interface and Main Module ........................................................................................ 119

12.3 I/O Modules .......................................................................................................................... 120

12.3.1 mA Input Module ......................................................................................................... 120

12.3.2 mV Input Module ......................................................................................................... 120

12.3.3 Dual Input Module ....................................................................................................... 120

12.3.4 mA Output Module ...................................................................................................... 121

12.3.5 Relay Output Module .................................................................................................. 121

12.3.6 Expansion Module ....................................................................................................... 121

12.4 Power Supplies.................................................................................................................... 121

12.4.1 External Supplies ........................................................................................................ 121

12.4.2 Backup Battery ............................................................................................................ 122

12.5 Enclosures ........................................................................................................................... 122

12.5.1 Wall Mount Enclosure ................................................................................................. 122

Chapter 13. Certifications ................................................................................................... 123

13.1 EC Declaration of Conformity ............................................................................................ 123

13.2 National and International Certificates of Compliance .................................................... 124

Chapter 14. Replacement Parts and Optional Extras ...................................................... 125

14.1 Spare Parts .......................................................................................................................... 125

14.2 Publications ......................................................................................................................... 126

Chapter 15. TPPL Configuration Code .............................................................................. 129

Chapter 16. Icon Glossary .................................................................................................. 131

Chapter 17. Compatible Sensors ....................................................................................... 133

Chapter 18. Configurable Parameter Reference Guide ................................................... 135

Chapter 19. Fault Codes ..................................................................................................... 139

Chapter 20. List of Figures ................................................................................................. 141

Chapter 21. List of Tables ................................................................................................... 143

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 viii Technical Handbook

Important Information

ONLY. READ AND UNDERSTAND THE INSTRUCTION MANUAL COMPLETELY BEFORE

Chapter 1. Important Information

The Equipment referred to in this manual contains components and assemblies that are each certified for use in a variety

of differing environments, and it is the site owner’s responsibility to confirm the suitability of the equipment prior to its

installation and use.

The Equipment assemblies referred to in this manual are collectively certified for use in a flammable gas detection system

only. Any other use is not currently certified and is not authorised by the manufacturer.

Please check the product rating plate and look for the following marks to ensure that the supplied equipment is suitable for

its intended location and purpose:

1.1 Regulatory Approval Markings

Products bearing the CE mark conform to all applicable European Directives as stated on the Honeywell product specific

EC Declaration of Conformity.

Products bearing the UL mark conform to the requirements for Ordinary Locations. The letters C and US mean that the

product is additionally certified for use in Canada and the United States of America.

1.2 Additional Product Markings

Products bearing this mark must not be disposed of in domestic waste. They must always be taken to a specialist Waste

Electrical and Electronic Equipment (WEEE) disposal or recycling facility. A box under the mark may show the type of

hazardous material in the product, e.g. the letters Pb would show that the item contains Lead.

Products bearing this mark are recyclable and should not be disposed of as normal landfill waste.

1.3 TPPL Mandatory Warning

FOR SAFETY REASONS THIS EQUIPMENT MUST BE OPERATED BY QUALIFIED PERSONNEL

OPERATING OR SERVICING THE EQUIPMENT.

POUR DES RAISONS DE SÉCURITÉ, CET ÉQUIPEMENT DOIT ÊTRE UTILISÉ, ENTRETENU ET

RÉPARÉ UNIQ UEMENT PAR UN PER SONN EL QUA LIFIÉ. ÉTUDI ER LE M ANUEL D ’IN STRUCT ION S

EN ENTIER AVANT D’UTILISER, D’ENTRETENIR OU DE RÉPARER L’ÉQUIPEMENT.

WARNING

ATTENTION

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 1 Technical Handbook

Important Information

1.4 TPPL General Warnin g s

1) The equipment specified in this manual is only to be installed by the Manufacturer’s trained personnel, or by

competent persons trained in accordance with the Manufacturer’s installation instructions.

2) Install ation must be in accordance with the recognized standards of the appropriate authority in the country

concerned. Refer to local, national and co mpa ny regulatio ns.

3) Do not operate the Touchpoint Plus system or its components outside of their rated operating specification.

4) Touchpoint Plus must not be operated in Oxygen enriched atmospheres, i.e. greater than 25% v/v Oxygen.

5) All equi pment containing a User Interface m ust be suit ably protect ed fr om direct sunlight and rain.

6) Power Supply Fluctuations are not to exceed DC 18 – 32 V SELV Supply or ±10 % of nominal.

7) All versions of Enclosure apparatus are electrical Class 1, and must be connected to Protective Earth (Ground).

8) The Touchpoint Plus installation must include a means of isolating or disconnecting the input voltage supply.

The isolation or disconnection device must be conveniently located close to the system and be clearly labelled.

For an AC mains voltage supply, the isolation or disconnection device must disconnect both the line and

neutral poles, but maintain earth (ground) continu ity .

9) The Touchpoint Plus input voltage supply must include over-current protection.

10) All cabling must be appropriately rated and approved in accordance with local, national and company

regulations, and suitable for the installation. Additionally, cabling must satisfy requirements defined in the

manuals of connected field devices, in particular if the field device is certified for use in a hazardous location.

11) All signal cables and interconnections must be shielded and the shields terminated only at the unified earth

(ground) bus bar situated inside the enclosure

12) All conduits and cable armour shall be bonded to protective earth (ground), and care must be taken to avoid

ground loops and to avoid contact with cable shielding.

13) Cable entry glands, blanking plugs, reducers, adaptors and breather devices must be suitably approved and

must not reduce the IP rating or protection levels. Items should not be used if there is a high risk of mechanical

damage to the equipment or enclosure.

14) Access doors and entry points must be kept closed when the system is energised in normal operation.

15) The TPPL Enclosures must be securely closed and the locking handle security screws must be fully tightened

during normal operation.

16) All equipment in this manual is rated to +2000 m (6562 ft) altitude maximum.

17) For safety reasons this equipment must be operated by qualified personnel only. Read and understand the

Instruction Manual completely bef ore oper at in g or servic ing the equip ment.

18) Touchpoint Plus systems may contain hazardous live terminals. Appropriate precautions should be taken

during operation, installation, and maintenance and servicing. Specifically, operators must have appropriate

training and experience to be aware of the hazards to which they may be exposed, and of measures to

minimise risk to themselves or other people.

19) The protection provided by TPPL may be impaired or lost if the equipment is installed or used in an incorrect,

unspecified or unauthorised way.

20) Be aware that extended exposure of a detector element to certain concentrations of combustible gases and air

can introduce stress to the element that may seriously affect its performance, and therefore recalibration should

be carried out or the sensor replaced, or both, after an alarm due to an indication of a high conce ntration.

21) When used in a Gas Detection summing up r ole, the gas reading may be higher than the actual concentration

at any one detector head location, or it may be the actual concentration at one specific detector head.

22) Exposure to some chemicals may degrade the sealing properties of materials used in the alarm relay.

23) Do not open TPPL enclosures or disconnect/reconnect equipment until power has been isolated and the area

is made safe / non-hazardous. This includes replacing backup batterie s.

24) Substitution of any components may impair suitability for Class I, Division 2.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 2 Technical Handbook

Important Information

1) Touchpoint Plus SMPS, Input and Output Modules have no user serviceable parts. In the unlikely event of a

1.5 TPPL General Cautions

failure, the item must be replaced using only manufacturer supplied parts.

2) Do not use sharp objects to operate the Touchscreen as this could irreparably damage the User Interface and

adversely affect its IP rating.

3) Use only soft, damp cloths or screen wipes to clean the Touchpoint Plus. Do not use solvents or abrasives as

they will cause irreparab le damage.

4) Once commissioned, Touchpoint Plus is inte nded for continu ous oper a tion .

5) Undo the security screws before pulling the locking handle. Failing to do so may irreparably damage the

enclosure.

6) Do not place any objects on top of the enclosures as this may cause overheating and may cause the enclosure

to fall from the wall.

1.6 How to Use this Manual

1.6.1 Intended Readers

This Manual should be read by everyone who operates or monitors the Touchpoint Plus gas detection system.

Only personnel who have been fully trained by Honeywell are authorised to Install, Set-up, Service, and Test, Repair, or

Recondition Honeywell gas detection systems.

Personnel, who work on, or in the area of, the Touchpoint Plus Gas detection system must be made aware of the

Before unpacking the system, please read the documentation that accompanies it.

contents of Chapter 2 – Safety Hazards, Warnings and Cautions.

IMPORTANT

1.6.2 Conventions Used

The following conventions are used in this manual:

Boot up refers to the action of starting the software from cold.

Menu>Configuration>Channel highlights a sequence of commands (including button touches).

mV Sensor refers to a mV Bridge Sensor.

Reboot refers to shutting down and restarting the software without interrupting the power supply.

Restart refers to cycling the power off and then on again.

SELV refers to Safety Extra-Low-Voltage devices.

[Start] highlights unique button touches.

Start up refers to the action of switching on the system.

Touch refers to all direct interactions with the Touchscreen, whether by finger or stylus.

TPPL refers to the Touchpoint Plus Gas Detection System.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 3 Technical Handbook

1.6.3 Associated Manuals

This TPPL Technical Handbook should be used in conjunction with ancillary component and field device user guides or

documentation.

This TPPL Technical Handbook (MAN 0984) is available in the following languages:

• Chinese (Simplified) Pt. Nr. 3011M5013

• Dutch Pt. Nr. 3011M5014

• English (UK) Pt. Nr. 3011M5001

• French (Canada) Pt. Nr. 3011M5015

• French (France) Pt. Nr. 3011M5016

• German Pt. Nr. 3011M5017

• Italian Pt. Nr. 3011M5018

• Japanese Pt. Nr. 3011M5019

• Korean Pt. Nr. 3011M5020

• Portuguese (Brazil) Pt. Nr. 3011M5021

• Portuguese (Portugal) Pt. Nr. 3011M5022

• Russian Pt. Nr. 3011M5023

• Spanish (Mexico) Pt. Nr. 3011M5024

• Spanish (Spain) Pt. Nr. 3011M5025

• Swedish Pt. Nr. 3011M5011

• USA (English) Pt. Nr. 3011M5012

The supplementary TPPL Modbus Installation and Setup Guide (#3011M5027) is available in English only, and is

recommended for OEMs and Modbus specialists only.

Important Information

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 4 Technical Handbook

Safety Hazards, Warnings And Cautions

Chapter 2. Safety Hazards, Warnings and Cautions

2.1 Safety

Incorrect set-up, maintenance, operation or modification of the Touchpoint Plus gas detection system or its installation

may constitute a serious hazard to the health and safety of personnel and their environment. It is therefore imperative that

the contents of this chapter are thoroughly understood by everyone who has access to the gas detection system or its

associated equipment.

When properly installed, this gas detection system enclosure is rated as IP65.

It may be installed in a Pollution Degree 2 (i.e. laboratory, office or control room) or Pollution Degree 3 (i.e. unheated

boiler room) environment as defined by IEC/UL/EN 61010–1: Safety requirements for electrical equipment for

measurement, control and laboratory use.

In all cases, several hazards may be present when operating or servicing the equipment and extreme caution must be

exercised at all times. The hazards that may be encountered include:

• Class 1 electrical hazards (AC 110/220 V, DC 18–32 V)

• Mechanical hazards (Heavy components, swinging access doors, locking handles etc.)

• Environmental hazards (toxic atmospheres)

• Fire and Ignition hazards

Touchpoint Plus is not ATEX/IECEx certified, and it shall only be installed in safe areas where there are no

flammable atmospheres, and where oxygen concentrations cannot exceed 25% v/v O

Touchpoint Plus is suitable for use in Class I, Division 2, Groups A, B, C, and D, or non-hazardous locations only.

DANGER

.

2

2.1.1 Warnings and Cautions

Safety of this equipment is reinforced by the use of safety labels that are fixed to the equipment in a visible manner. The

labels used and their location is detailed in Ch.2.2.1 Safety Warning Labels.

Other likely hazard occurrence and severity is indicated throughout this manual by the use of signal words accompanied

by a hazard description and an internationally recognisable hazard symbol, as shown in the three example boxes below:

Danger indicates an imminent hazard that, if not avoided, is extremely likely to result in death or serious injury.

Warning indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

Caution indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

It is also used to alert the user against unsafe working practices and potential damage to equipment.

DANGER

WARNING

CAUTION

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 5 Technical Handbook

Safety Hazards, Warnings And Cautions

live terminals.

2.1.2 Safety Hazards

The following specific hazards are associated with the installation and use of this equipment:

Touchpoint Plus is Not ATEX/IECEx certified, and it shall only be installed in safe areas where there are no

Touchpoint Plus is suitable for use in Class I, Division 2, Groups A, B, C, and D or non-hazardous locations only.

Lithium batteries may cause severe injury or death if swallowed, and may catch fire or explode if mishandled,

Always handle batteries with care, keep them out of the reach of children, and dispose of them carefully in

Batteries (regardless of type) shall only be handled, fitted, removed or replaced in non-haz ardou s (safe) area s.

All power supplies must be hard wired and must include a circuit breaker (RCD / RCCB) and, close by and

unobstructed, a means of manually isolating and locking–out the power supply without breaking the protective

Lethal current may be present in this equipment when electrical power is applied and after it is removed. There is

Isolate power before opening electrical access panels. Ensure residual current is fully discharged before touching

Lethal current may be generated both internally and externally to the system. All installations, including

enclosures and external units, must be grounded to protective earth, and must be capable of staying earthe d

The Protective Earth (Ground) symbol is shown to the left, and it always has a green background. Do not confuse

The Touchpoint Plus system and/or its sensors may become contaminated by the ambient environment in which

it or they are used. It is the Customer’s sole responsibility to ensure that all appropriate safety precautions are

DANGER – IGNITION HAZARD

flammable atmospheres, and where oxygen concentrations cannot exceed 25% v/v O

WARNING – LITHIUM BATTERY HAZARDS

recharged, burned or disposed of incorrectly.

accordance with local regulations.

WARNING – LETHAL VOLTAGE PRESENT

earth (ground) connection.

Removable plug/socket connection is not permitted under any circumstance.

WARNING – LETHAL VOLTAGE PRESENT

a risk of death or injury from electrical shock when access doors are open.

WARNING – LETHAL VOLTAGE PRESENT

(grounded) when the power supply is interrupted.

it with the chassis earth and equipment earth symbols shown below it.

WARNING – TOXIC WASTE AND HARMFUL BY-PRODUCTS

taken before handling any components or transferring them to any other party.

.

2

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 6 Technical Handbook

Safety Hazards, Warnings And Cautions

2.1.2 Safety Hazards (Cont.)

The following general hazards are associated with the use of this equipment:

DO NOT USE WATER if a lithium battery overheats or burns, as it may make the fire worse and it may cause an

This equipment contains a number of potentially toxic substances that may pose a health or environmental

hazard if exposed to very high temperatures, VOCs or corrosives, or if improperly handled or disposed of.

Each Touchpoint Plus enclosure is heavy and weighs considerably more when packed. Ensure that a Manual

Handling Risk Assessment is carried out before moving or installing the system, and ensure that enclosures are

Touchpoint Plus uses high energy AC and DC currents that may cause arc ing and spar ks if shorted out. Always

Touchpoint Plus can be used to control loud alarms and sirens. Always wear hearing protection when working in

Touchpoint Plus houses static-sensitive component s. Alw ay s isol ate power and discharge circuits before

Batteries may explode if mistreated. Do not disassemble them or dispose of in fire.

CAUTION – HEALTH AND ENVIRONMENTAL HAZARDS

fitted securely to a suitable vertical surface. Do not place objects on the enclosures.

Always follow a Safe System of Work when carrying out any work involving Safety Systems.

WARNING – FIRE OR EXPLOSION HAZARD

WARNING – DO NOT USE WATER

explosion.

Evacuate the area immediately and call Emergency Services.

CAUTION – RISK OF INJURY AND DAMAGE

CAUTION – RISK OF EYE INJURY

wear eye protection when the enclosure is open.

CAUTION – RISK OF HEARING DAMAGE

the vicinity of loud or high-pitched noises.

CAUTION – RISK OF EQUIPMENT DAMAGE

touching internal components. Always take anti-static precautions.

CAUTION – RISK OF INJURY OR DAMAGE

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 7 Technical Handbook

Safety Hazards, Warnings And Cautions

2.2 Location and Description of Warning Labels

2.2.1 Safety Warning Labels

In accordance with the requirements of European Standard EN 60825–1, appropria t e warning labels are mounted in

specified locations on the equipment. This is to indicate conditions under which the user could be subjected to electrical

hazards.

Figure 1. Quick Start Guide Label

(Not to Scale)

Figure 3. Protective Earth (Ground) Point Figure 4. Equipment Earth (Ground) Point

This Protective Earth (Ground) location point label is

used inside the system and is not normally visible to

the operator.

Figure 5. Internal Label Positions

This Equipment Earth (Ground) location point label is

used inside the system and is not normally visible to

the operator.

Figure 2. Rating Label

(External – Not Shown Below)

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 8 Technical Handbook

Safety Hazards, Warnings And Cautions

2.3 Electrical Hazards

Gas detection systems contain electr i cal sup pli es that are potentially dangerous and hence suitable precautions must

be taken to prevent the risk of electrocution. This is especially important when untrained/unqualified persons are

allowed to open the enclosure (e.g. to access/remove/refit the SD Card).

2.3.1 General Safety Precautions

• Read the relevant manual before beginning any operating or service procedures.

• Only personnel trained and certified by Honeywell are authorised to service, fit or remove internal parts.

• Only the minimum number of trained personnel, consistent with safety, should have access to the area while work is

being carried out. If necessary, erect warning signs and barriers.

• Follow accepted working procedures and codes of practice as well as the electrical safety code for the site where the

equipment is installed.

• Never operate the equipment under normal conditions with d oor s open, access panels removed or shorting links

fitted.

• Do not ‘Live Test’ without a Safe System of Work (SSoW).

• Always keep the area around the equipment dry and free of obstructions.

• Switch off and Isolate the equipment if water ingress is suspected or confirmed.

• Never operate the equipment if any Mains power cable is frayed or damaged.

• Never wear wristwatches, rings, bracelets, or other jewellery when working around electrical circuits or moving parts.

• Take anti-static precautions when working on electronic circuits.

• Never work on electrical equipment alone.

2.3.2 Component Testing and Replacement

Before carrying out any electrical testing or component replacement:

• Read this Manual to become familiar with the location of high voltage components.

• Isolate the system at the main circuit breaker, lock it in the ‘Off’ position, and attach a notice indicating that

maintenance work is in progress.

• Always wait for 5 minutes after isolating the equipment to ensure that stored energy has dissipated.

• Never assume the polarity of cabling or replacement components. Refer to electrical schematics or contact Honeywell

for confirmation.

• Use only Honeywell approved replacement parts.

Only Honeywell trained and certified maintenance technicians are authorised to carry out component testing and

replacement. Unauthorised work may result in a potentially dangerous situation and will invalidate the

Antistatic Precautions are required to prevent severe damage to electronic components.

WARNING – UNAUTHORISED PERSONNEL

ANTI–STATIC PRECAUTIONS

manufacturer’s warranty.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 9 Technical Handbook

Safety Hazards, Warnings And Cautions

Antistatic Precautions

As with all modern electronic circuits, the Printed Circuit Boards (PCBs) in Touchpoint Plus systems utilise some static-

sensitive components that can be severely damaged if subjected to static discharge. Static can be generated on the

human body by friction or movement and is discharged through the first contacted route to earth. It can also jump gaps

between items of differing electrical potential.

Static damage is not always immediately apparent and can cause component failure at any time after the static discharge

has occurred. It is, therefore, very important that everyone takes the following precautions when handling PCBs:

• An industry approved antistatic wrist strap, containing a resistive component greater than 1Megohm, must be worn

and connected to an effective earth (ground) point. The continuity between the strap and earth (ground) must be

checked regularly.

• PCBs must only be handled by their non-conductive edges. Do not allow any components, conductive tracks or

contacts to come into proximity with the body, clot hing , machinery, power source or any material other than a staticdissipative mat.

• W ith the exception of assemblies containing batteries, anti-static packaging must be used for transporting PCBs and

Integrated Circuits (ICs). All Touchpoint Plus electronic components are ship ped in appro priate packaging that can be

re-used when returning items for test or repair.

• Avoid wearing clothing manufactured from, or containing a high proportion of, man-made fibres. These can build up a

high static potential that may not be discharged through the body or wrist strap.

An effective earth (ground) point is the protective earth (ground) bus bar inside the enclosure. This can be used to connect

a suitable anti-stat ic w r ist st rap provided that the Gas detection system is connect ed to protective earth (ground) via the

mains power supply cable.

If installed correctly, the equipment earth (ground) point is connected directly to mains earth (ground) via

protective earth and the mains power supply cable, and the e arth (ground) circuit cannot be broken by operating

the Isolator switch or circuit breaker.

IMPORTANT

2.3.3 Good Practice

After switching off the system, it is good practice to wait at least 15 seconds before switching it on again. This allows the

circuits and RAM to dis charge adequately before being powered-up again. Failing to do so may cause data corruption.

2.3.4 Lithium Battery Hazard

Lithium batteries are fitted to Touchpoint Plus as backup power sources.

Replace the factory installed battery pack TPPLOIBB with Honeywell Analytics Asia Pacific replacement battery pack part

no. TPPLSIBB and the PCB CMOS battery with type CR2032 only.

Use of other batteries may present a risk of fire or explosion.

Lithium batteries may cause severe injury or death if swallowed, and may catch fire or explode if mishandled,

Always handle lithium batteries with care, keep them out of the reach of children, and dispose of them carefully

Batteries shall only be fitted, removed or replaced in non-hazardous (safe) areas.

LITHIUM BATTERY TOXIC AND FIRE HAZARDS

recharged, burned or disposed of incorrectly.

in accordance with local regulations.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 10 Tec hnical Handbook

Safety Hazards, Warnings And Cautions

Product Compliance

This product complies with the following standards and directives.

Other safety directives may apply to the complete system installation if an OEM’s product is integrated into other

equipment or machinery.

Safety Compliance

Hazardous Location

(Non-Incendive)

Electrical Safety

EMC/RFI

Low Voltage Directive

Gas Performance*

* ISA 12.13.01 and CSA C22.2 No.152 approvals are applicable only to mV sensors Model 705 and MPD or any suitably

certified mA sensor.

Note: The Equipment referred to in this manual contains components and assemblies that are each certified for use in a

variety of differing environments, and it is the site owner’s responsibility to confirm the suitability of the equipment prior to

its installation and use.

Please check the product rating plate and look for the following marks to ensure that the supplied equipment is

suitable for its intended location and purpose:

Products bearing the CE mark conform to all applicable European Directives as stated on the Honeywell product specific

EC Declaration of Conformity.

Products bearing the UL mark conform to the requirements for Ordinary Locations. The letters C and US mean that the

product is certified for use in Canada and the United States of America.

Read and understand the instruction manual before operating or servicing the equipment.

Class 1, Division 2, Groups A,B,C,D, Temp. Code T4

ISA 12.12.01-2013

CSA C22.2 No. 213-M1987

CAN/CSA C22.2 No. 61010-1 and No.142

UL 61010–1 (3

IEC/EN 61010–1 (3rd Edition)

EN 50270

IEC/EN 61010–1 (3

ISA 12.13.01 and CSA C22.2 No. 152

rd

Edition); UL508

rd

Edition)

IMPORTANT

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 11 Tec hnical Handbook

Safety Hazards, Warnings And Cautions

Conditions of Use

This Touchpoint Plus equipment shall only be operated:

• By properly trained personnel.

• Under Honeywell approved conditions.

• W ith due authorisation.

• Using approved maintenance and servicing procedures.

2.3.5 Training of Personnel

Honeywell and / or its distributors can provide training for operators and maintenance personnel. Personnel who have

been trained in operation and maintenance shall be limited to carrying out only those procedures and tasks taught during

the training course. Honeywell certified maintenance technicians must carry out all other tasks.

Honeywell can also provide additional or advanced training. Retraining is recommended periodically and whenever the

equipment / installation is changed or upgraded.

2.3.6 Conditions Satisfying Local, National and International Safety Regulations

Approved conditions must satisfy the requir em ents of applic able national and international safety standards and statutory

requirements relating to electrical, EMC, and health hazards. In addition, they must satisfy the requirements of the Site

Safety Officer and the local safety regulations.

2.3.7 Due Authorisation

Before any production, maintenance, or servicing procedure is carried out; written authorisation must be obtained from

one of the following personnel to confirm that the proposed task satisfi es the nec es sary safe ty conditio ns:

• A competent authorised person having a professional qualification in an appropriate technical discipline.

• The Factory, Technical or Engineering Manager responsible for the working area.

• The Site Safety Officer or an authorised Honeywell representative or approved distributor.

2.3.8 Approved Maintenance and Servicing Procedures

Approved Maintenance and Servicing Procedures are those stipulated in this manual or as authorised separately by

Honeywell.

It may be necessary to establish a temporary Locally Controlled Area (LCA) to restrict access during maintenance, testing

or servicing of this equipment.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 12 Tec hnical Handbook

System General Description

SD Card

Audio / Visual Alarm

mA Loop Sensors

Relays / Actuators

mA Loop

mV Bridge Sensors

Chapter 3. System General Description

Figure 6. T ouchpoint Plus Wall-Mounted Controller

The Touchpoint Plus is an entry level (or upgrade) touch-screen digital Controller for general industrial and commercial

gas detection systems. It has eight input channels, with a further eight channels available through an optional expansion

unit (see Note below).

It can handle a wide range of milliamp, millivolt, and catalytic sensors through analogue inputs, and it can contr ol vari ous

outputs such as audible and visible signals and solenoid valves.

The cabinets are constructed from high-impact plastic and have fully-sealed, easy opening access. They are supplied with

a wall mounting or can be directly mounted to any solid vertical surface or rack. Cable entry is via entry glands on the

lower side.

Touchpoint Plus is rated IP65, which means that it is dustproof and can be subjected to low-pressure water without

significant ingress. This makes it particularly suited to offices, control rooms and unheated boiler rooms.

Note: Currently Touchpoint Plus is only available as a composite Gas Detection System, but please contact Honeywell

Analytics for details about future upgrades.

Figure 7. Typical Installation Options

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 13 Tec hnical Handbook

System General Description

Enclosure Door

with Touchscreen

Motherboard

SMPS

Modules

Backplane

Enclosure

LCD Unit

Common Data

Communication Cable

Backup Battery

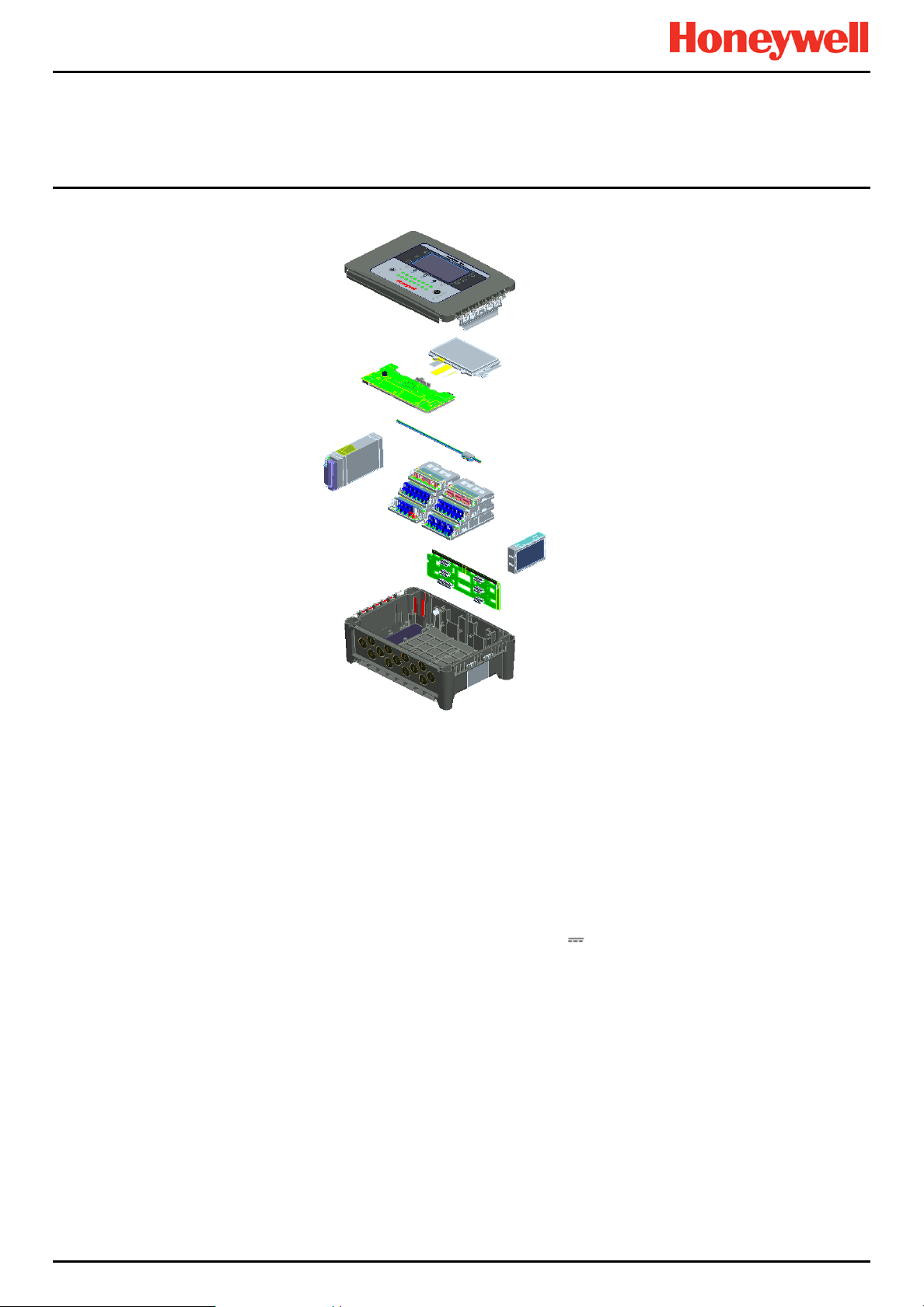

Figure 8. TPPL Controller Exploded View

Both the Touchpoint Plus and its optional expansion unit have the option for AC, DC and battery backup power supplies,

but the optional Expansion Unit has no motherboard or display (LCD).

Features of the Controller unit:

• Colour LCD Touch Screen with multi-language GUI and menus

• Password protection

• Flexible Mains Power Input: 50 – 60 Hz 110/220 V ~ (AC), 18 – 32 V

for combined Base and Expansion Units

• Up to 8 channels of Analogue Input (0–22 mA, Bridge mV for Cat bead)

• 2 or 3-wire signal inputs

• Up to 24 channels of user configurable relay controlled Output

• Up to 8 channels of configurable mA Output

• Alarm update on Acknowledge

• Automatic Self-Diagnostic with error codes

• Event recording

• SD Card

(DC), Max 105 W for a single unit or 210W

Pt. No. 3011M5001_3 14 Tec hnical Handbook

MAN0984_Iss 3_02/16 Touchpoint Plus

System General Description

1 2 3

3.1 How to Open and Close the Enclosure

1) Ensure that it is safe to open the enclosure and, if necessary switch off and isolate electrical power.

2) Unscrew the two x 3 mm Hex socket security screws (1) until they become loose (2).

3) With a gloved hand only, pull the handle until it comes free (3). Do not apply undue force.

4) Open the enclosure door fully.

Figure 9. Undoing the Two Security Screws and Opening the Enclosure

5) Closure is the reverse of this procedure, but care must be taken not to exert undue force, and you must not press on

the membrane or touch screen areas.

Note: The door recess has an environmental seal that requires some pressure to close the door correctly. The enclosure

handle is the primary method of applying this pressure but you can assist it by pressing firmly on the door edge directly

above the handle as you press on the handle itself.

TPPL enclosures must be fully closed and secured during normal operation.

CAUTION

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 15 Tec hnical Handbook

System General Description

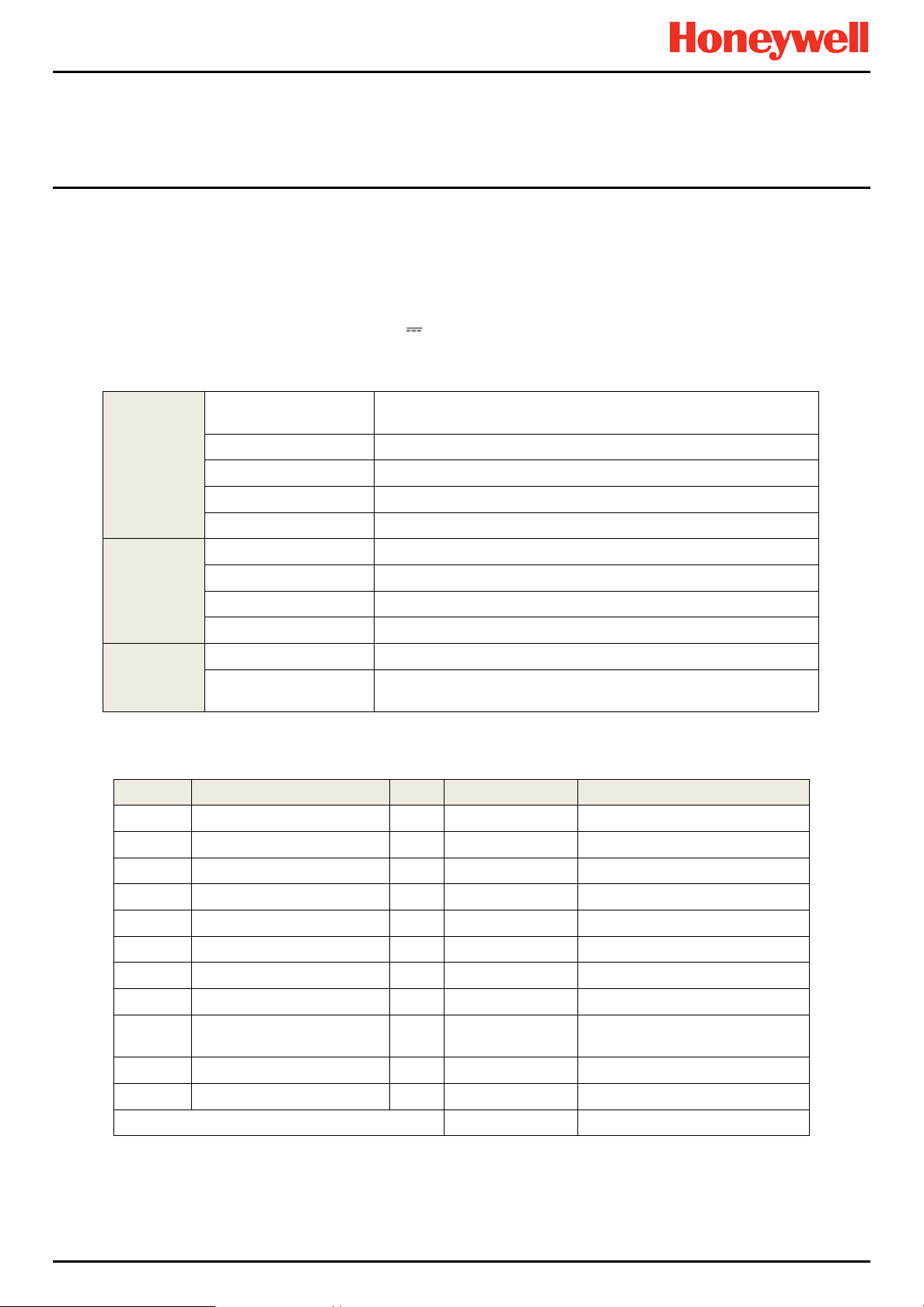

3.2 Equipment Specification

3.2.1 Power Requirements (Controller Unit only)

The Touchpoint Plus system is designed to operate on a single phase, 50 to 60 Hz, 110/220 V~ (AC) supply with a typical

power consumption of less than 105 W.

Alternatively it can be connected to an 18–32 V (DC) supply with typical power consumption less than 105W.

The system can contain an optional backup battery to guard against short-term power disruption.

Voltage Range AC

AC Frequency Range 50 – 60 Hz ± 6%

Input

Output

Protection

Nr. Power Usage Qty Max Power (W) Remarks

1 UI Module 1 3.6

2 Main Module 1 1.7

3 mA Input Module 1 0.9 Not includin g Field Device power

4 mA input Field Devices 8 40.0 mA Input Module power only

5 mV Input Module 1 8.5

6 Dual Input Module 1 9.4

7 mA Output Module 2 8.6

8 Relay Output Module 2 2.0

9

10 Audio/Visual Alarm 4 28.8

11 SMPS Power Loss — 14.0

MAXIMUM PERMITTED CONSUMPTION 104.9

AC Current Draw (typ.) 3 A @ 115 VAC, 2A @ 230 VAC

Cold-start Current (typ.) 40 A @ 230 VAC

Leakage Current <2 mA @ 240 VAC

DC Voltage 24 V

Rated Current 6.5 A

Current Range 0 – 6.5 A

Rated Power 156 W

Overload 110 – 150 % rated output power

Over-Volt

Table 1. Power Supply (SMPS RS–150–24) Electrical Ratings

Charging power for backup

battery pack

AC 110/220 V manually switchable

300 VAC surge for 5 sec without damage

27.6 – 32.4 VDC Hiccup mode, which recovers automatically when

the fault is removed.

1 5.3

Table 2. Maximum Power Consumption Calculations

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 16 Tec hnical Handbook

3.2.2 Weights

Note: Based on one input module, two mA output modules, two output relays, SMPS and backup battery for the basic unit

and expansion unit respectively.

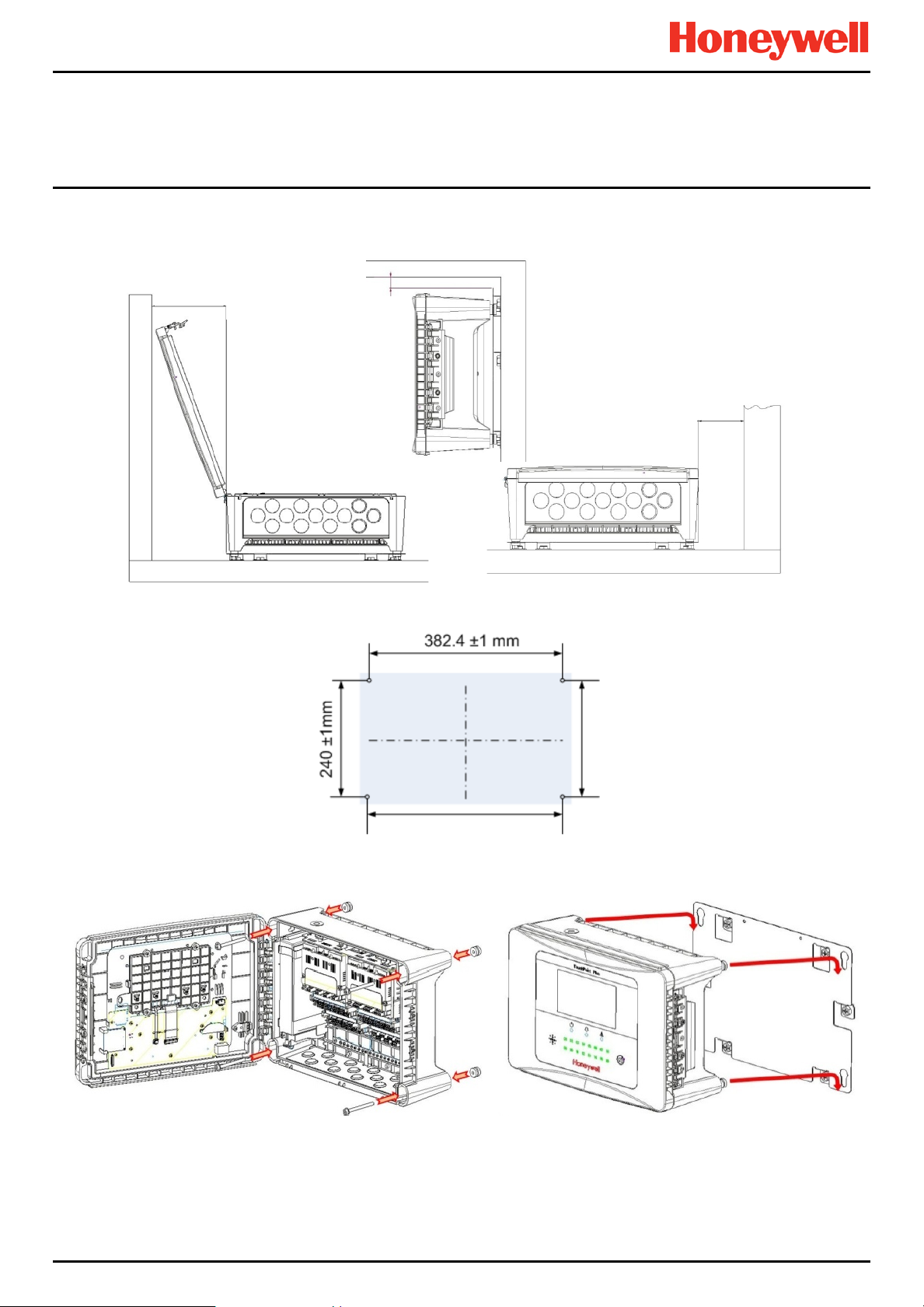

3.2.3 Dimensions

System General Description

TPPL Basic Unit TPPL Expansion Unit

System alone

System with packaging

Table 3. System Weights

External Dimension Millimetres Inches

Depth

Length

Width

Table 4. System Dimensions

8.5 Kg (18.7 lbs) 8 Kg (17.6 lbs)

9 Kg (20 lbs) 8.5 Kg (18.7 lbs)

156 6.2

426 16.9

300 11.8

3.2.4 Ambient Operating Temperature

–10 °C to +55 °C (14 °F to 131 °F)

3.2.5 Overall Ambient Operating Humidity

5 % to 95 %RH, non-condensing

3.2.6 Storage Conditions (Without batteries)

–25 °C to +60 °C (-13 °F to 140 °F), @ 5 % to 95 %RH, non-condensing

3.2.7 Storage Conditions (With batteries)

1 year: –20 °C to +25 °C (–4 °F to +077 °F)

3 months: –20 °C to +45 °C (–4 °F to +113 °F)

1 month: –20 °C to +60 °C (–4 °F to +140 °F)

3.2.8 IP Rating

The enclosures are sealed to IP65 when appropriate cable entry glands are used.

3.2.9 Construction

The system cabinets are constructed from PC ABS plastic with a secured quick release front access door panel.

The Controller door panel holds a touch sensitive colour LCD with a membrane cover over additional buttons, LEDs and

an audible warning horn.

Inside the Controller cabinet is a Switched-Mode Power Supply (SMPS) providing a nominal DC 24 V output, an optional

Lithium-ion backup battery, a Main Module, a mA/mV Input Module, two mA Output Modules, two Relay Modules,

protection fuses, and the control and user interface electronics.

The optional expansion unit holds the same modules and optional backup battery, but has no controller or user interface.

Both enclosures contain a common Earth (ground) rail that must be bonded to Protective Earth (Ground) through an

isolation switch that does not disconnect the Earth line.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 17 Tec hnical Handbook

System General Description

1

2 4 5 6 7

14

11

15

3

10 8 9

16

13

12

3.2.10 Touchpoint Plus Packaging

• Touchpoint Plus outer packaging is made from cardboard. Facilities for recycling are widely available.

• Touchpoint Plus inner packaging is made from Stratocell

recycled into new Stratocell

®

where such recycling facilities exist.

3.2.11 Packaging Components for Return to Manufacturer

Honeywell is unable to accept any consignment that does not conform to the European Classification, Labelling and

Packaging (CLP) Regulations (EC) 1272/2008.

Please consult your distributor, supplier, or the manufacturer if you require further advice.

3.2.12 Disposal (WEEE Directive)

The system contains Lithium batteries and a number of homogenous hazardous materials. These should be disposed of

carefully in accordance with the WEEE Directive and local laws and guidelines. Under no circumstances can they be

disposed of as domestic waste.

3.3 TPPL Construction

The TPPL system consists of a basic Control Unit and an optional Expansion Unit, as shown below.

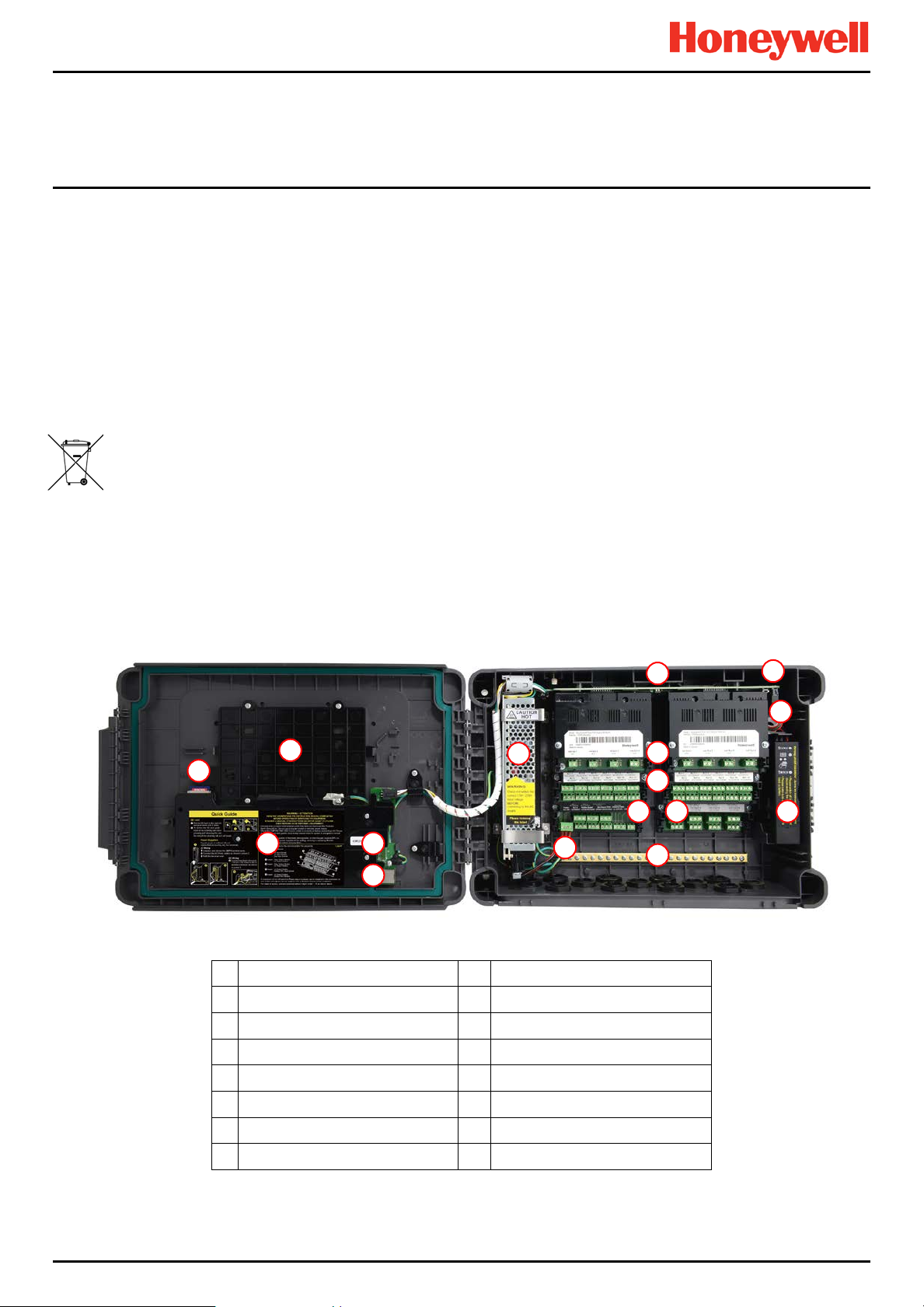

3.3.1 TPPL Basic Control Unit

This figure shows the building blocks of the basic Touchpoint Plus system.

Figure 10. Controller Unit Layout Before Installation

®

, Low-Density Polyethylene (LDPE) foam. The foam can be

1

Touchscreen PCB

2

SD Card

3

Motherboard

4

Modbus Terminals (option)

5

Ethernet Connector

6

Switched Mode Power Supply

7

DIP Switch (on backplane)*

8

Battery On / Off Switch

* The DIP Switch (14) is used to enable / disable the optional expansion box. See Ch.3.3.3 TPPL DIP Switches for further

information.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 18 Tec hnical Handbook

9

Battery Connector

10

mA Output Modules

11

Relay Output Modules

12

Main Module

13

Input Module (mA/mV/Dual)

14

Backup Battery

15

Power Terminal

16

Earth (Ground) Bus Bar

System General Description

1 2 4

5

6

7

14

11

15 3 10 8 9

16

13

12

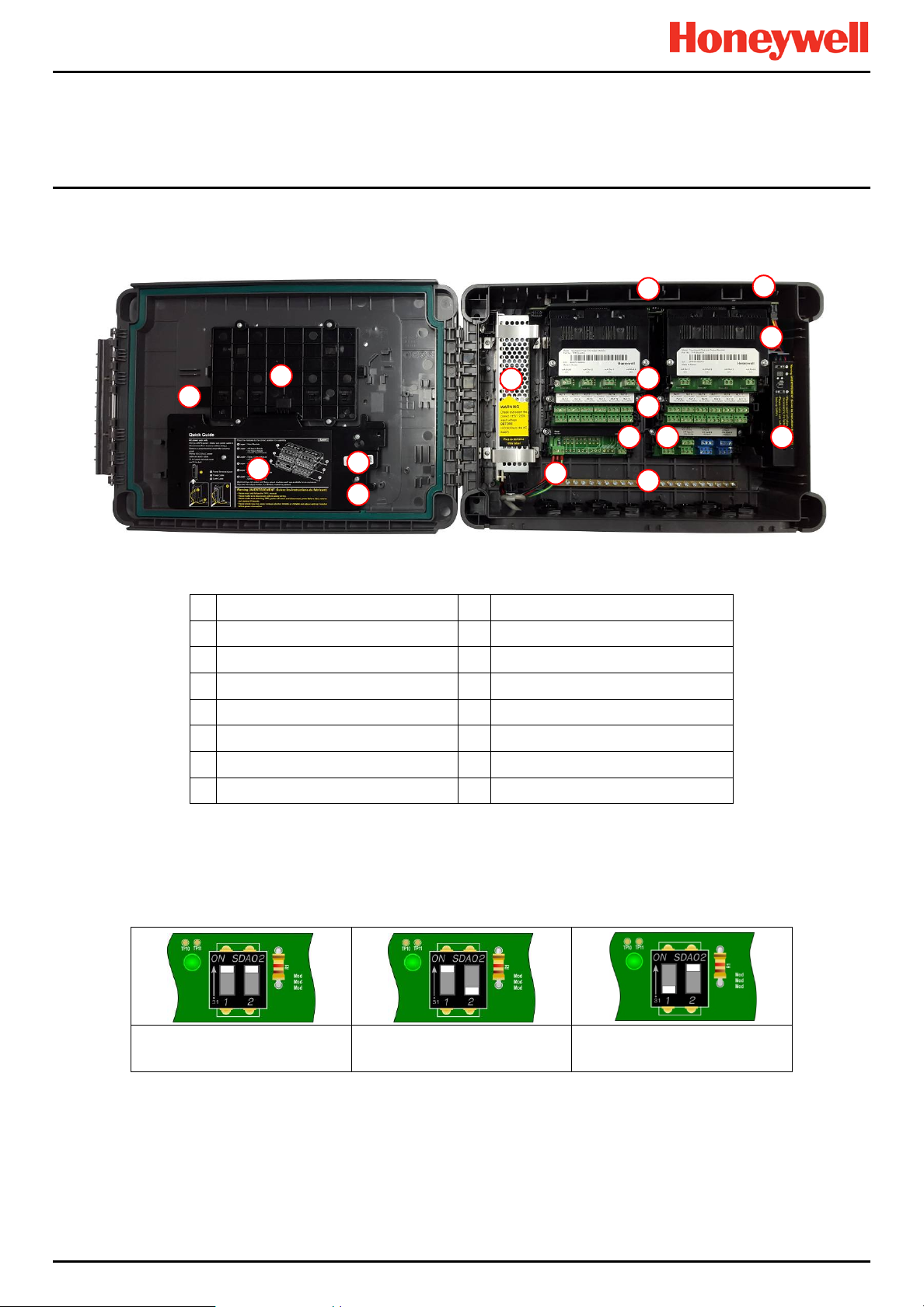

3.3.2 TPPL Expansion Unit

This figure shows the building blocks of the Touchpoint Plus Expansion Unit.

Figure 11. Expansion Unit Layout Before Installation

1

No Touchscreen

2

No SD Card

3

No Motherboard

4

No Modbus Terminals

5

No Ethernet Connector

6

Switched Mode Power Supply

7

DIP Switch (on backplane)*

8

Battery On / Off Switch

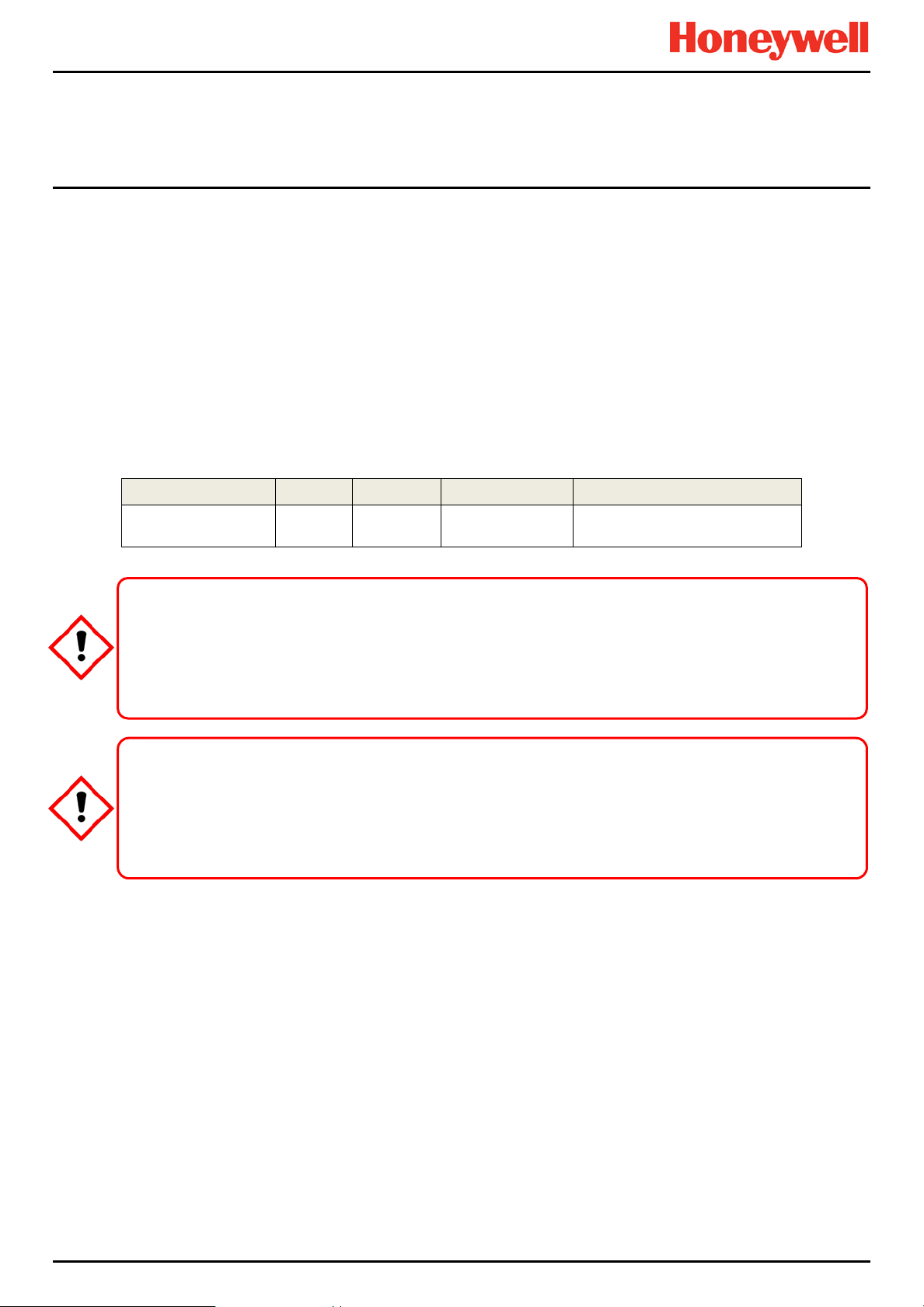

3.3.3 TPPL DIP Switches

TPPL Backplanes have a DIP switch (item 14 in the figures above) that controls the interaction between the master (basic)

and the optional expansion unit backplanes. Once set these DIP switches need not be altered.

Basic Unit

Both On

9

Battery Connector

10

mA Output Modules

11

Relay Output Modules

12

Main Module (Power and CAN only)

13

Input Module (Dual shown)

14

Backup Battery

15

Power Terminal

16

Earth (Ground) Bus Bar

Basic Unit with Slave

1 On, 2 Off

Expansion Unit

1 Off, 2 On

Figure 12. Backplane DIP Switch Settings

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 19 Tec hnical Handbook

System General Description

This page deliberately blank.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 20 Tec hnical Handbook

System Mechanical Installation

Chapter 4. System Mechanical Installation

The system can be directly wall-mounted or on an optional mounting fixture. Whichever method is chosen, the mounting

must be sound, secure, and capable of supporting the weight of the enclosure plus the weight of any cables and glands.

When choosing a location, it must be easily visible and accessible, with room to mount an external power isolator. There

must also be room to fully open the access door, which opens to the left, and room to easily access the door locking

handle and its securing screws, which are situated on the right. If using the optional expansion unit there must be

sufficient room between them to access the locking handle and its securing screws.

The units should be mounted so that the screen can be easily accessed and seen, but they should not obstruct accesses,

walkways or exits.

Although the units are IP65 when installed correctly, they should be mounted away from heat sources, out of direct

sunshine, and should be protected from rain, severe weather, steam or excess humidity and condensation.

These units have only passive cooling, so an adequate airflow must be maintained to prevent overheating.

Assembly IP NEMA Pollution Degree Remarks

Wall mounted cabinet 65 4X 2

It is the Customer’s responsibility to ensure that the equipment is correctly installed, and that cable entry glands

Failure to do so will invalidate the quoted IP / NEMA / Pollution ratings and may invalidate the warranty.

The units as supplied have two hex-socket securing screws in the access door handle, and these have to be fully

unscrewed prior to opening the handle. Failing to do so could cause irreparable damage to the housing.

The handle must be correctly locked and the screws must be correctly tightened when the unit is in normal

operation. Failing to fully secure the enclo sur e is unsafe and will invalidate product certification.

or blanks of the appropriate IP rating are correctly used.

CAUTION

CAUTION

When properly installed using the

appropriate cable entry glands

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 21 Tec hnical Handbook

System Mechanical Installation

Minimum Left Wall

Clearance 200 m m

Minimum Right Wall

Clearance 150 mm

Minimum Ceiling

Clearance 250 m m

4.1 Wall Mounting Requirements

For details and drawings please refer to Pt. No. 3011G0459_F Installation Clearance pdf.

Figure 13. Installation Clearance Measurements

Figure 14. Wall Mounting Template

Figure 15. Wall and Plate Mounting Points

You can use the wall mounting plate as its own template and location guide, and you should ensure that the mounting

bolts are adjusted to fit the plate bayonet holes before fixing the plate to the wall.

MAN0984_Iss 3_02/16 Touchpoint Plus

Pt. No. 3011M5001_3 22 Tec hnical Handbook

System Mechanical Installation

Enclosure Corner

Plate

should be determined by the surface material and the type of anchor required.

4.1.1 Wall Mount Fixings

You will require the following locally sourced items to install the Touchpoint Plus:

Tool to undo the enclosure access handle security screws:

• 3 mm Hex key

Suggested Fixings to screw the enclosure to the wall only:

• Screw Max. Dia.: 6.4 mm (#14) dome or cheese head screw

• Screw Min. Length: 76 mm (3 in.) – Normal fix

• Washer Max. Dia: 14.3 mm (0.56 in.)

Suggested Fixings for using the Mounting Plate:

For the plate, choose fixings appropriate to the surface and the weight of the enclosure plus cables. You will also need to

use suitable bolts, washers and lock nuts (see diagram below).

Ideally you will mount the enclosure and cables on a ≥20 mm ply board to allow cable troughs to be used.

The sizes above are given to allow for clearance in the TPPL Enclosure. The actual length and type of fixing

CAUTION

Wall or

Board

Figure 16. Fixing Orientation When Using the Optional Mounting Plate

Note:

You should ensure that washers between the TPPL enclosure and the wall or mounting plate are sufficiently large to

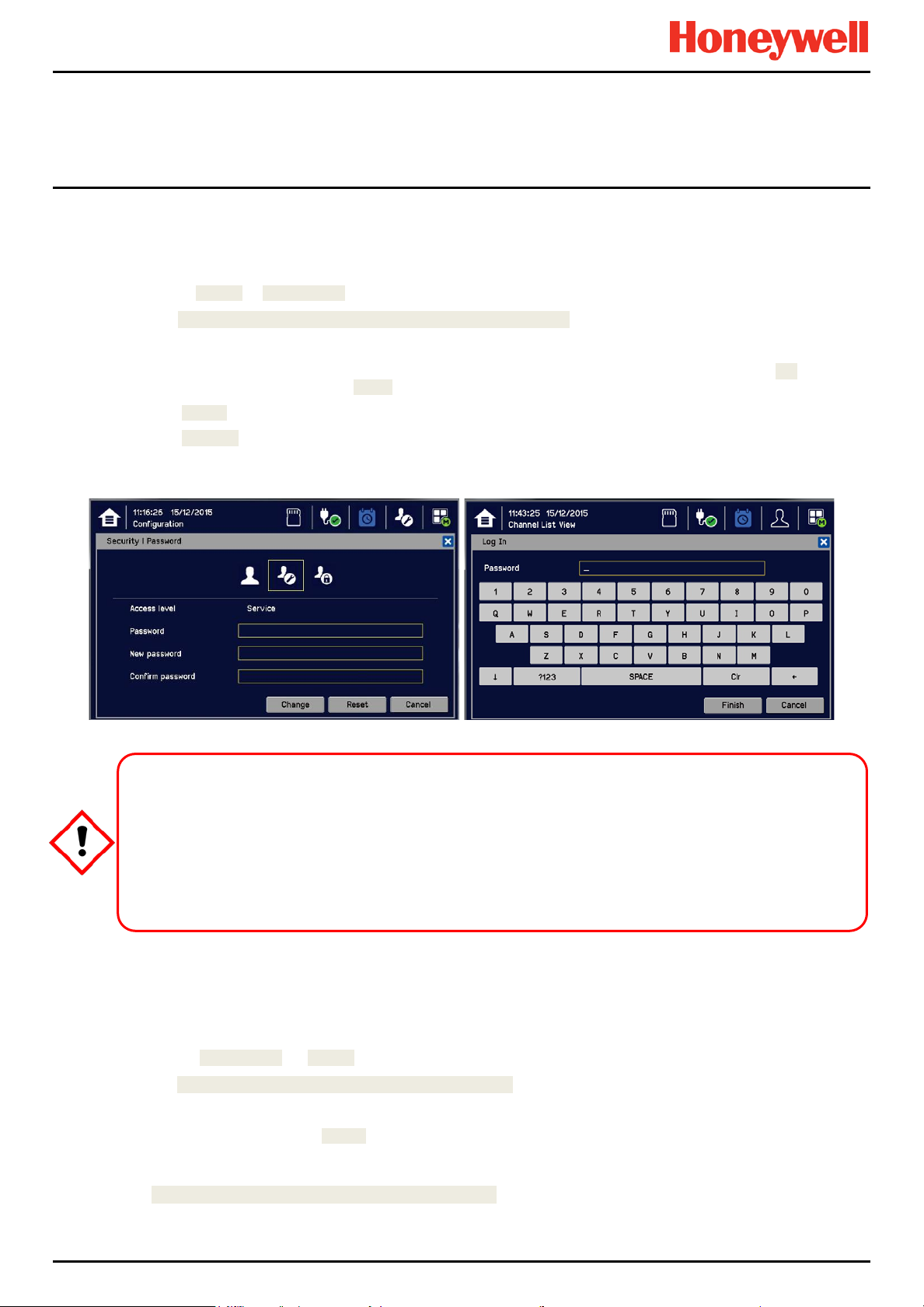

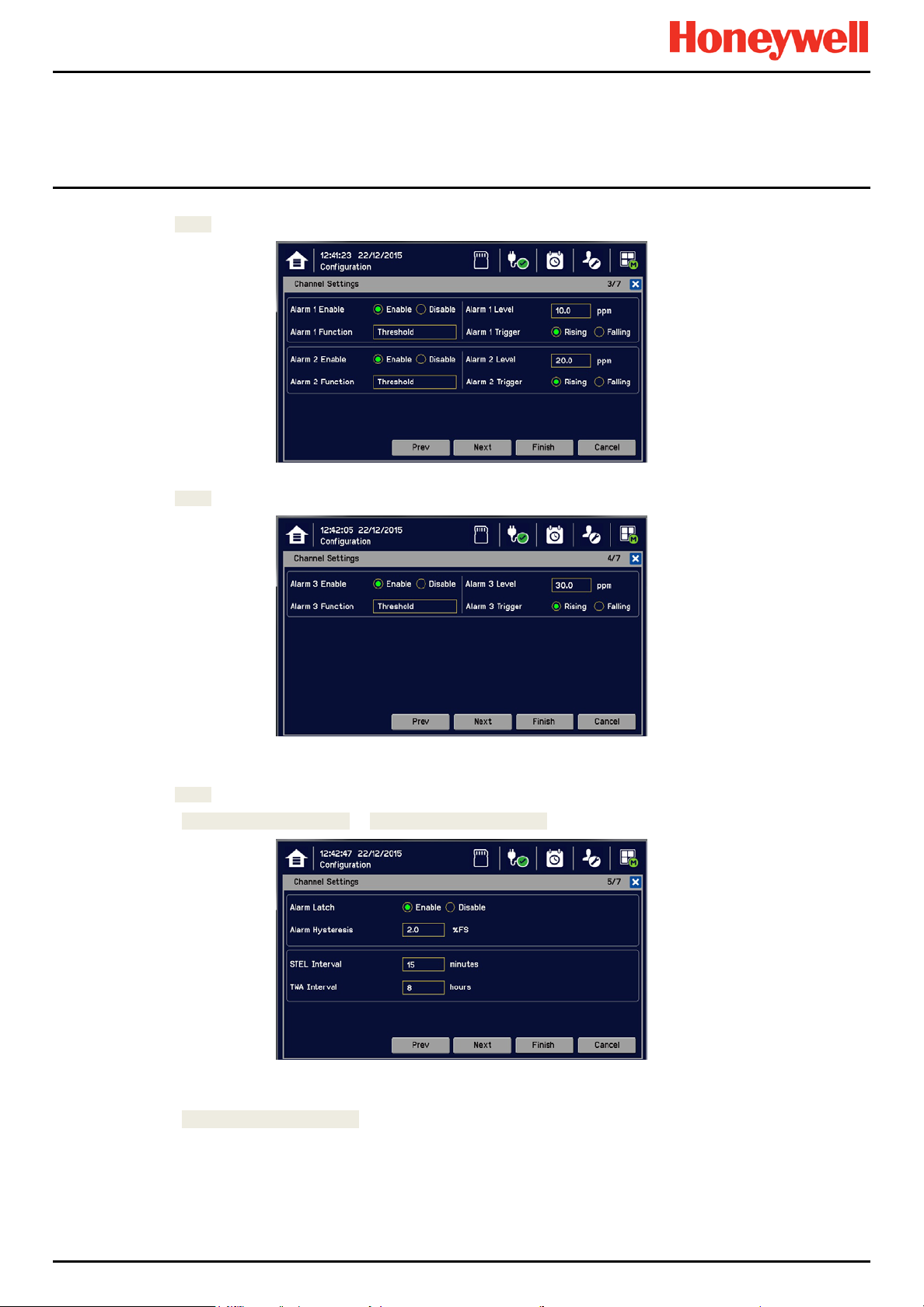

spread the load evenly.