TP970 and TP9600 Series

Pneumatic Thermostats

ENGINEERING DATA

Contents

Introduction .............................................................................................................................. 2

Fundamentals of

Thermostat Operation .............................................................................................................................. 2

General................................................................................................................. 2

Flapper-Nozzle Operation.................................................................................... 2

Valve Unit Operation ............................................................................................ 2

Low-Capacity, Single-Temperature

TP973A, B and TP9630 A, B

Thermostats .............................................................................................................................. 4

TP970A-D and TP9600A, B

High-Capacity, Single-Temperature

Thermostats .............................................................................................................................. 6

TP971A-C and TP9610A, B

High-Capacity, Dual-Temperature

Thermostats .............................................................................................................................. 7

TP972A and TP9620A High-Capacity,

Heating/Cooling Thermostat .............................................................................................................................. 10

General................................................................................................................. 4

Operation.............................................................................................................. 5

Direct Action.................................................................................................. 5

Reverse Action.............................................................................................. 5

General................................................................................................................. 6

Operation.............................................................................................................. 6

Direct Action.................................................................................................. 6

Reverse Action.............................................................................................. 7

TP971B and TP9610B ......................................................................................... 7

TP971C ................................................................................................................ 7

TP971A and TP9610A ......................................................................................... 7

Daytime Operation ............................................................................................... 8

Nighttime Operation ............................................................................................. 8

Manual DAY Override........................................................................................... 9

General................................................................................................................. 10

Operation.............................................................................................................. 12

TP974A Room

Temperature Sensor .............................................................................................................................. 12

General................................................................................................................. 12

Operation.............................................................................................................. 12

Copyright © 1997 Honeywell Inc. • All Rights Reserved

77-9382-1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

INTRODUCTION

This Engineering Data sheet provides detailed information

on the operation of TP970 and TP9600 Ser ies Pneumatic

Thermostats (Thermostats). These Thermostats use the

force-balance design with high nozzle feedback for stability.

The TP970 and TP9600 Series includes the following

thermostat models:

— TP970A-D and TP9600A, B:

High capacity

Proportional control

Single temperature

— TP971A-C and TP9610A, B:

Dual temperature

Day/night control (automatic switchover through

diaphragm logic)

Two sensing elements

Individual setpoint control

— TP972A and TP9620A, B:

High capacity

Heating/cooling control (automatic switchover

through diaphragm logic)

Two sensing elements (one for heating control,

one for cooling control)

— TP973A, B and TP9630A, B:

Low capacity

Proportional control

Single temperature

— TP974A:

Room temperature sensor

Used as a remote temperature transmitter for the RP920

Pneumatic Controller

This Engineering Data sheet describes the TP973A, B and

TP9630A, B Thermostats first, because they are the

simplest.

FUNDAMENTALS OF THERMOSTAT

OPERATION

General

throttling range (TR) adjustment) has a fixed branchline

pressure (BLP) for each temperature within the temperature

and throttling range settings. The forces within the nozzleflapper-bimetal assembly always seek a balanced condition;

giving the same BLP for the same temperature regardless of

fluctuations in main air or the relative positions of the nozzle,

flapper, and bimetal.

Flapper-Nozzle Operation

Flapper-nozzle operation is generally the same for all TP970

and TP9600 Thermostats. The Thermostat provides a

branchline air pressure that is a function of the ambient

temperature in the room or controlled space. As shown in

Figure 1, the force of the temperature-sensing bimetal acting

on one side of the flapper (Force A) is balanced by the

feedback force of the pilot pressure through the nozzle

acting on the other side of the flapper (Force B).

SETPOINT

THROTTLING RANGE

ADJUSTMENT

FORCE A

FLAPPER

NOZZLE

FORCE B

BIMETAL

IN BALANCED STATE,

FORCE B EQUALS FORCE A

Fig. 1. Flapper-Nozzle-Bimetal Assembly.

The position of the flapper over the nozzle changes and

creates a new pilot pressure when the bimetal force changes

(through temperature or setpoint change). This pilot pressure

feeds into the valve unit, which converts the low-capacity

pilot pressure to a high-capacity branchline change (see the

Valve Unit Operation section). Feedback at the nozzle

regulates the pressure to negate the effect of normal main

air supply fluctuations on the branch line.

Adjusting the throttling (proportioning) range changes the

flapper lever position. Moving the setpoint cam changes the

bimetal operating force and thus the setpoint.

KNOB

CALIBRATION

SCREW

SETPOINT

CAM

C6046

In force-balance design, two forces oppose each other until

they are equal, or balanced. The TP970 and TP9600 Series

Thermostats use the force of the bimetal to close the flapper

over the nozzle and the opposing force of the air pressure in

the nozzle chamber to lift the flapper (see the FlapperNozzle Operation section). When the forces are equal, a

force-balance condition exists.

The throttling range setting and the calibration reference

temperature determine the Thermostat span and calibration

point. At control point the nozzle-flapper-bimetal assembly

(acting through the calibration screw, setpoint cam, and the

77-9382—1

Valve Unit Operation

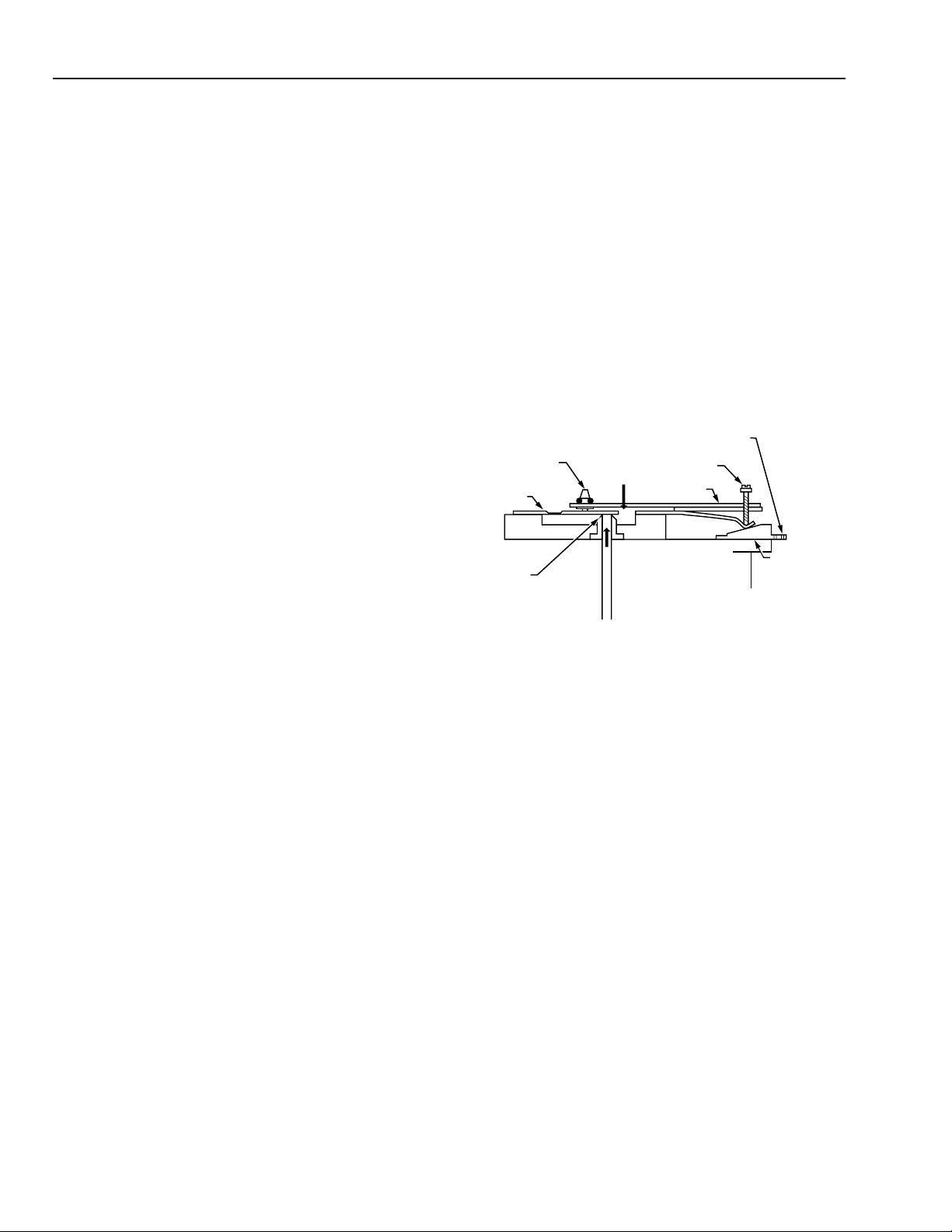

TP970, TP9600, TP971, TP9610, TP972, and TP9620

Thermostats use force-balance valve units to amplify airflow

and minimize air consumption without loss of required device

capacity. Figure 2 is a cross-section of a TP970 and TP9600

Thermostat showing the relationship of the valve unit to the

bimetal, nozzle, and other components.

2

TP790 AND TP9600 SERIES PNEUMATIC THERMOSTATS

POINT A

EXHAUST AIR

POINT B

MAIN LINE

BRANCH

LINE

PILOT AIR

C6049-1

NOTE: THE SEAL AT POINT A DOES NOT

ALLOW AIR TO EXHAUST.

VALVE

THROTTLING RANGE

ADJUSTMENT

FLAPPER

BLEED

BRANCHLINE

PRESSURE TAP

EXHAUST

BRANCHLINE

CHAMBER

PILOT

PILOT

CHAMBER

Fig. 2. Cross Section of TP970 and TP9600 Thermostat Showing Valve Unit and Airflow.

TP970, TP9600, TP971, TP9610, TP972, and TP9620

Thermostats are designed around a valve unit for flow

amplification rather than conventional pressure amplification.

Branchline chamber and pilot chamber design are such that

branch pressure is equal to nozzle pressure at a higher

capacity.

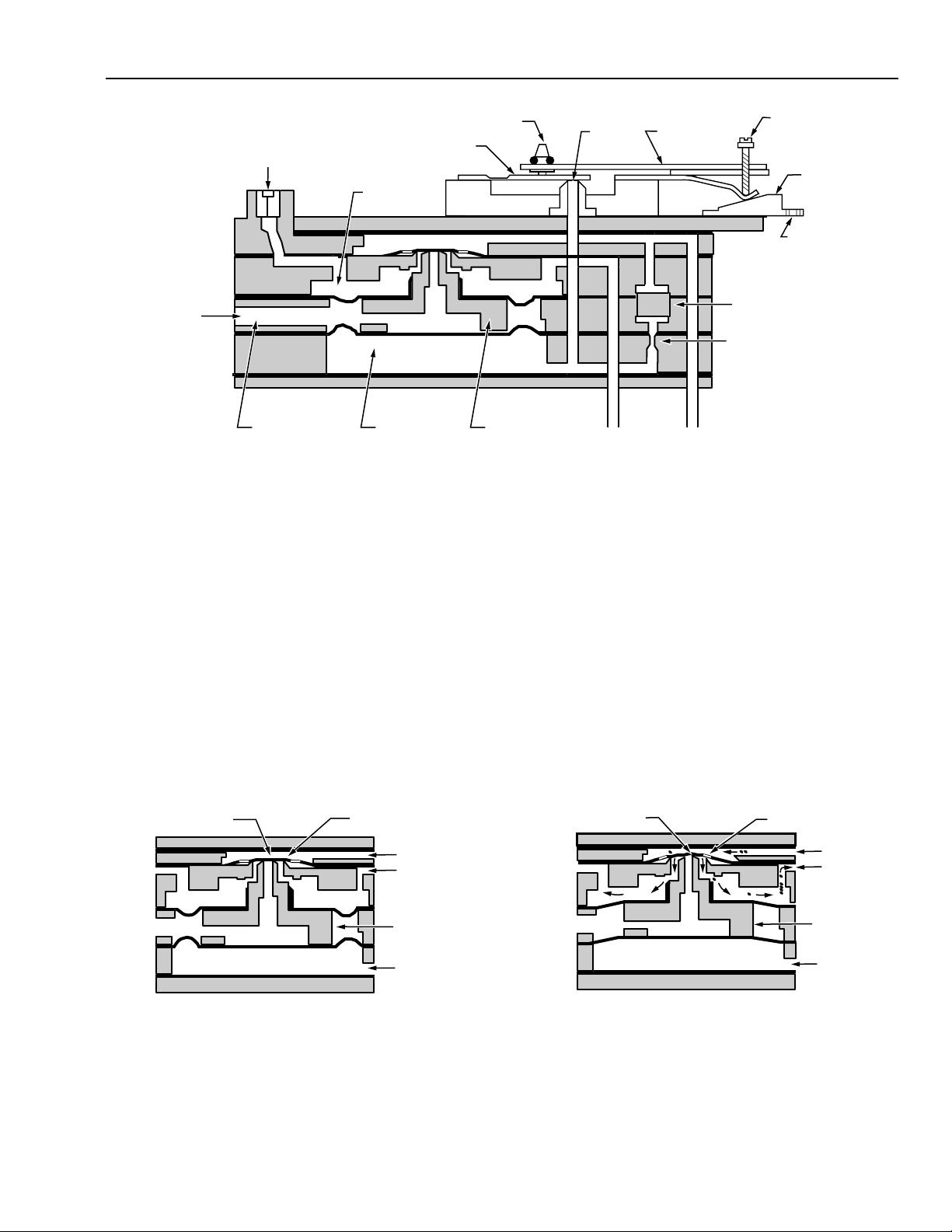

Figures 3, 4, and 5 are cross-sections of the valve unit only,

showing air passages and the pilot-branch diaphragm

relationship.

Figure 3 shows a valve unit in a strategic or balanced

condition. All the forces are equal; BLP equals the pilot-line

pressure.

No main air enters the branchline chamber and no exhaust

air leaves the branchline chamber. In this static condition,

the valve is sealed at both Points A and B, preventing airflow.

CALIBRATION

SCREW

SETPOINT

CAM

SETPOINT

KNOB

C6047-1

VALVE

NOZZLE

BRANCH LINE

BIMETAL

MAIN

LINE

FILTER

RESTRICTOR

Figure 4 shows the valve unit supplying air to the branch

line. This condition occurs when the bimetal sensing element

forces the Thermostat flapper to ward the nozzle, decreasing

the nozzle-flapper gap and increasing the pilot pressure.

The increased pilot pressure against the pilot diaphragm

overcomes the force of the BLP on the branchline

diaphragm. This change opens the valve unit at Point B,

allowing main air to flow into the branch line. BLP builds until

the pressure against the branch diaphragm again equals the

pressure against the pilot chamber diaphragm. The main

airflow then shuts off, bringing the valve unit into a balanced

condition at a new pressure.

With direct-acting bimetal sensors, a temperature increase

closes the nozzle-flapper gap; with reverse-acting bimetal

sensors, a temperature increase opens the nozzle-flapper

gap. The arrows in the air passages in Figure 4 show the

direction of airflow.

EXHAUST

POINT A

BRANCH

PILOT CHAMBER

POINT B

MAIN LINE

BRANCH

CHAMBER

VALVE

PILOT AIR

Fig. 3. Valve Unit Flow Amplifier in a

Balanced (Static) Condition.

LINE

C6048-1

Fig. 4. Valve Unit Shown with Pilot

Chamber Pressure Increased.

3

77-9382—1

TP970 AND TP9600 SERIES PNEUMATIC THERMOSTATS

Figure 5 shows the valve unit bleeding down the BLP. This

condition occurs when the bimetal sensing element relaxes

its force against the flapper, allowing the nozzle-flapper gap

to increase.

POINT A

VALVE

PISTON

EXHAUST

AIR

NOTE: THE SEAL AT POINT A DOES NOT

ALLOW AIR TO EXHAUST.

Fig. 5. Valve Unit Shown with Pilot

Chamber Pressure Decrease.

The reduction in pilot pressure against the pilot diaphragm

allows the BLP to overcome the pressure in the pilot

chamber. This change moves the valve piston down, sealing

off Point B and opening Point A. Branchline air bleeds off

until the pressure against the branchline diaphragm equals

the pressure against the pilot chamber diaphragm. When the

pressures become equal, the exhaust air is shut off at Point

A. The valve unit is again in a balanced condition at the new

pressure. The arrows in the air passages in Figure 5 show

the direction of airflow.

The preceding explanation of valve unit operation is very

important to understanding TP970, TP9600, TP971, TP9610,

TP972, and TP9620 operation. As can be seen from Figures

3, 4, and 5, pilot pressure changes affect BLP changes in

the same ratio. There is no pressure gain to amplify errors as

with other pneumatic Thermostats. Still, the main air supply

being switched through the valve unit, provides fast, high

capacity increase and decrease of BLP.

POINT B

MAIN LINE

BRANCH

LINE

VALVE

PILOT AIR

C6050-1

THROTTLING

RANGE

ADJUSTMENT

FLAPPER

BIMETAL

NOZZLE

AIR CONNECTION

FILTER AND

RESTRICTOR

SETPOINT

KNOB

CALIBRATION

SCREW

SETPOINT

CAM

SETPOINT

KNOB

C6051

Fig. 6. Basic TP973 and TP9630 Thermostat.

The TP973 and TP9630 are used on one- or two-pipe

systems. Connections are made to main and branch for twopipe applications (see Fig. 7). The main air connector is

plugged when used on one-pipe applications (Fig. 8). This

causes the Thermostat to operate like any other bleed-type

thermostat with a remote restrictor.

SETPOINT

KNOB

CALIBRATION

SCREW

FLAPPER

THROTTLING RANGE

ADJUSTMENT

BIMETAL

TP973A, B AND TP9630 A, B LOW CAPACITY, SINGLE-TEMPERATURE

THERMOSTA TS

General

The TP973A, B TP9630A, B (Fig. 6) are the simplest

Thermostats in the TP970 and TP9600 Series. Ever y other

model includes the basic TP973 and TP9630 assembly with

additions. Air going to the controlled device from the TP973

and TP9630 passes through an internal restrictor. The

TP973A and TP9630A are direct acting (signal pressure

increases as the temperature increases); the TP973B,

reverse acting (signal pressure increases as the temperature

decreases).

77-9382—1

NOZZLE

NOZZLE

CHAMBER

RESTRICTOR

MAIN LINE

CAM

SLOPE

BRANCH

LINE

BACKPLATE

TO CONTROLLED

DEVICE

SETPOINT

CAM

C6052

Fig. 7. TP973 and TP9630 Operating Section.

4

Loading...

Loading...