Page 1

Technical Handbook

Touchpoint Plus

i

Page 2

Revision History

Revision Comment Date

Issue 01 First Issue and initial translations 30/05/2015

Issue 02 Added new chapters, new data and final translations 09/06/2015

ii

Page 3

Disclaimer

In no event shall Honeywell be liable for any damages or injury of any nature or kind, no matter how caused,

that arise from the use of the equipment referred to in this manual.

Strict compliance with the safety procedures set out and referred to in this manual, and extreme care in the

use of the equipment, are essential to avoid or minimize the chance of personal injury or damage to the

equipment.

The information, figures, illustrations, tables, specifications, and schematics contained in this manual are

believed to be correct and accurate as at the date of publication or revision. However, no representation or

warranty with respect to such correctness or accuracy is given or implied and Honeywell will not, under any

circumstances, be liable to any person or corporation for any loss or damages incurred in connection with the

use of this manual.

The information, figures, illustrations, tables, specifications, and schematics contained in this manual are

subject to change without notice.

Unauthorized modifications to the gas detection system or its installation are not permitted, as these may give

rise to unacceptable health and safety hazards.

Any software forming part of this equipment should be used only for the purposes for which Honeywell

supplied it. The user shall undertake no changes, modifications, conversions, translations into another

computer language, or copies (except for a necessary backup copy).

In no event shall Honeywell be liable for any equipment malfunction or damages whatsoever, including

(without limitation) incidental, direct, indirect, special, and consequential damages, damages for loss of

business profits, business interruption, loss of business information, or other pecuniary loss, resulting from

any violation of the above prohibitions.

Warranty

Honeywell Analytics warrants the Touchpoint Plus system against defective parts and workmanship, and will

repair or (at its discretion) replace any components that are or may become defective under proper usage

within 12 months from the date of commissioning by a Honeywell Analytics approved representative* or 18

months from shipment from Honeywell Analytics, whichever is sooner.

This warranty does not cover consumable, batteries, fuses, normal wear and tear, or damage caused by

accident, abuse, improper installation, unauthorized use, modification or repair, ambient environment,

poisons, contaminants or abnormal operating conditions.

This warranty does not apply to sensors or components that are covered under separate warranties, or to any

3rd-party cables and components.

Any claim under the Honeywell Analytics Product Warranty must be made within the warranty period and as

soon as reasonably practicable after a defect is discovered. Please contact your local Honeywell Analytics

Service representative to register your claim.

This is a summary. For full warranty terms please refer to the Honeywell Analytics” General Statement of

Limited Product Warranty, which is available on request.

* A Honeywell Analytics approved representative is a qualified person trained or employed by Honeywell

Analytics, or a qualified person trained in accordance with this manual.

Copyright Notice

Microsoft, MS and MS–DOS are registered trademarks of Microsoft Corp.

Other brand and product names mentioned in this manual may be trademarks or registered trademarks of

their respective companies and are the sole property of their respective holders.

Honeywell is the registered trademark of Honeywell Automation and Control Systems (ACS).

Touchpoint is a registered trademark of Honeywell Analytics (HA).

Find out more at www.honeywellanalytics.com

iii

Page 4

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Contents

Chapter 1 – Important Safety Information ............................................................................ 1

1.1 Cautions................................................................................................................................. 3

1.1.1 Intended Readers .......................................................................................................... 3

1.1.2 Conventions Used ......................................................................................................... 4

1.1.3 Associated Manuals ....................................................................................................... 4

Chapter 2 – Safety Hazards, Warnings and Cautions ......................................................... 5

2.1 Safety ..................................................................................................................................... 5

2.1.1 Warnings and Cautions .................................................................................................. 5

2.1.2 Safety Hazards .............................................................................................................. 6

2.2 Location and Descri pt ion of War ning Labels ....................................................................... 8

2.2.1 Safety Warning Labels ................................................................................................... 8

2.3 Electrical Hazards.................................................................................................................. 9

2.3.1 General Precautions ...................................................................................................... 9

2.3.2 Component Testing and Replacement ........................................................................... 9

2.3.3 Antistatic Precautions .................................................................................................. 10

2.3.4 Good Practice .............................................................................................................. 10

2.3.5 Lithium Battery Hazard ................................................................................................ 10

2.4 Product Com pliance ............................................................................................................ 11

2.5 Condit ions of Use ................................................................................................................ 12

2.5.1 Training of Personnel ................................................................................................... 12

2.5.2 Conditions Satisfying Local, National and International Safety Regulations ................... 12

2.5.3 Due Authorisation ........................................................................................................ 12

2.5.4 Approved Maintenance and Servicing Procedures ....................................................... 12

Chapter 3 – System General Description ........................................................................... 13

3.1 Equipment Specification ..................................................................................................... 15

3.1.1 Power Requirements ................................................................................................... 15

3.1.2 Weights ....................................................................................................................... 16

3.1.3 Dimensions ................................................................................................................. 16

3.1.4 Ambient Operating Temperature .................................................................................. 16

3.1.5 Overall Ambient Operating Humidity ............................................................................ 16

3.1.6 Storage Conditions (Without batteries) ......................................................................... 16

3.1.7 Storage Conditions (With batteries) .............................................................................. 16

3.1.8 IP Rating ..................................................................................................................... 16

3.1.9 Construction ................................................................................................................ 16

3.1.10 Touchpoint Plus Packaging ........................................................................................ 17

3.1.11 Packaging Components for Return to Manufacturer ................................................... 17

3.1.12 Disposal (WEEE Directive) ........................................................................................ 17

3.2 System Construction........................................................................................................... 17

Chapter 4 – System Mechanical Installation ...................................................................... 18

4.1 How to O pe n a nd Close the Enclosure ............................................................................... 19

4.2 Wa ll Mounting Requirements .............................................................................................. 20

4.2.1 Wall Mount Fixings ...................................................................................................... 21

Chapter 5 – Electrical Power Connection and Interfacing ................................................ 22

5.1 Powe r Connection ............................................................................................................... 22

5.1.1 AC Power Supply ........................................................................................................ 23

5.1.2 DC Power Supply ........................................................................................................ 24

5.1.3 Backup Battery Pack ................................................................................................... 24

5.2 Cabli ng Requirem e nt s ......................................................................................................... 25

5.2.1 AC Mains Voltage Power Cables ................................................................................. 25

5.2.2 DC Power Cables ........................................................................................................ 25

5.2.3 Field Device Cables ..................................................................................................... 25

5.2.4 Optional Expansion Unit Connection (available late 2015) ............................................ 26

5.2.5 Main Module Connections............................................................................................ 27

5.2.6 mA Input Module Connections ..................................................................................... 29

5.2.7 mV Input Module Connections ..................................................................................... 33

5.2.8 mA Output Module Connections (each) ........................................................................ 34

iv

Page 5

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Contents

5.2.9 Relay Output Module Connections ............................................................................... 35

Chapter 6 – Touchpoi nt Plus Operating Instructions ....................................................... 37

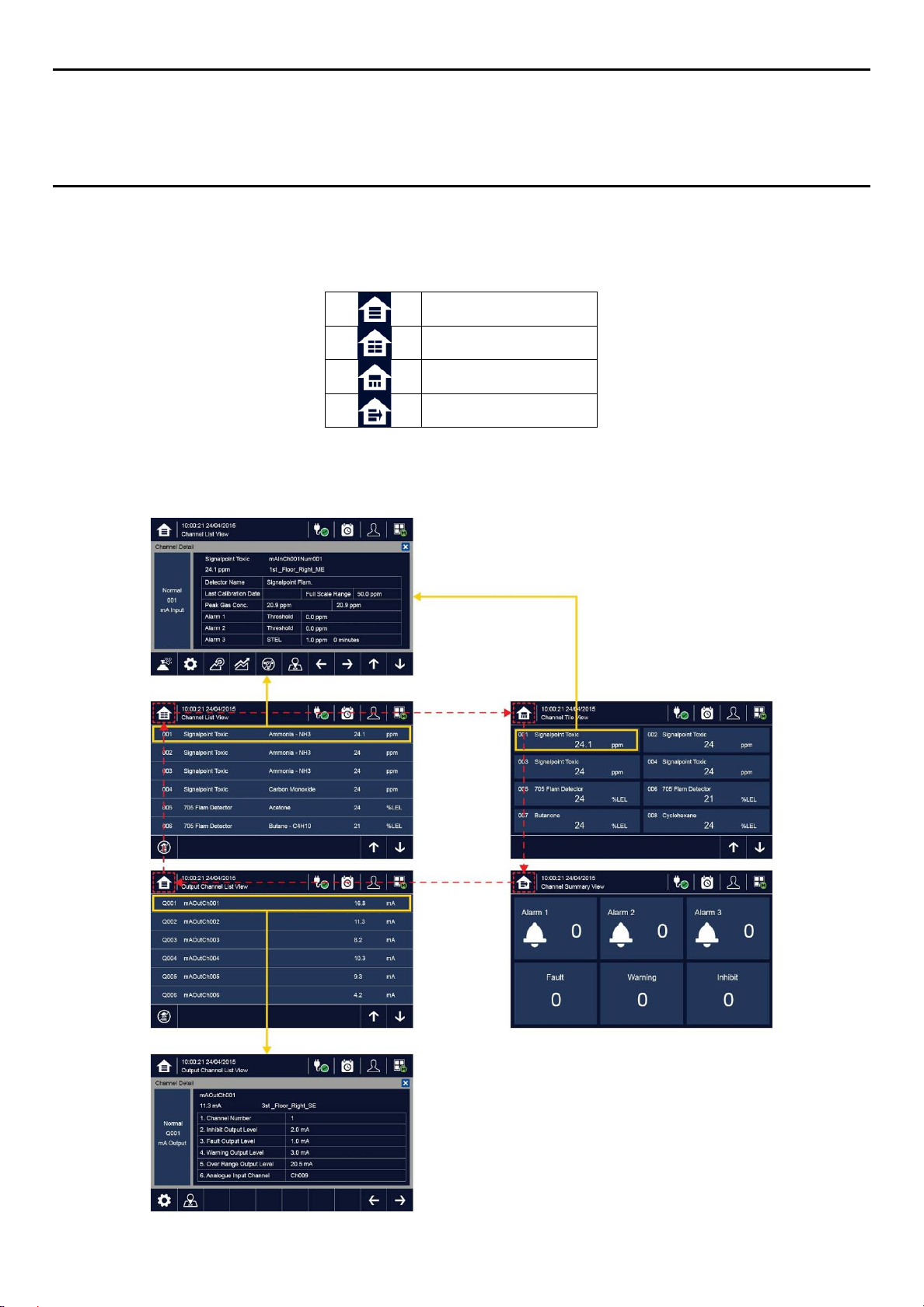

6.1 User Interface General ........................................................................................................ 37

6.2 Menu Items and Access Levels .......................................................................................... 38

6.3 Touchscreen (Colour Resistive) ......................................................................................... 40

6.4 SD Card ................................................................................................................................ 40

6.5 Norm a l O pe ration (Safety

6.6 Overview –

6.6.1 User Interface

6.6.2 Navigation – Inputs and Outputs

6.6.3 Navigation – Active

6.6.4 Navigation – Menu ...................................................................................................... 44

6.6.5 Navigation – Active Access Level Icons ....................................................................... 45

6.7 Alarms

6.7.1 View active

6.7.2 Acknowledge

6.7.3 Reset a latched

6.8 Faults and W

6.8.1 View Faults and W

6.8.2 Acknowledging an Active Fault or Warning................................................................... 47

6.8.3 Reset a Latched Fault or

6.9 Inhibit ................................................................................................................................... 47

6.10 Viewing Input Channels and Input

6.11 Viewing Output

6.12 Viewing the Trend

6.13 To Vie w E v e nt His t ory and Export .................................................................................... 50

6.14 Checkin g t he Ca pa city of the S D Ca rd ............................................................................. 50

6.15 Accessing the System Information and Service Contact Details .................................... 50

6.16 System State Relays .......................................................................................................... 50

Touchscreen Interface

................................................................................................................................ 45

alarms

arnings

Channels

Functions)

Scr

een ................................................................................................. 41

Events and Filtering

..................................................................................................... 45

an active

alarm

......................................................................................................... 46

Graph

alarm

................................................................................................. 46

arnings

Warning

............................................................................................... 49

................................................................................................ 49

............................................................................... 41

.................................................................................. 41

Screens

.................................................................................. 45

......................................................................................... 46

Details

.................................................................. 42

.................................................................... 43

............................................................................. 47

................................................................... 48

Chapter 7 – Commissioning ................................................................................................ 51

7.1 Introduction ......................................................................................................................... 51

7.2 First Time Switch On ........................................................................................................... 51

7.3 Date, Time and

7.3.1 How to Set or Change Date, Time and Language Settings: .......................................... 52

7.4 Progr a m P a s s w ords ............................................................................................................ 52

7.5 Commission Input / O ut put Modules .................................................................................. 53

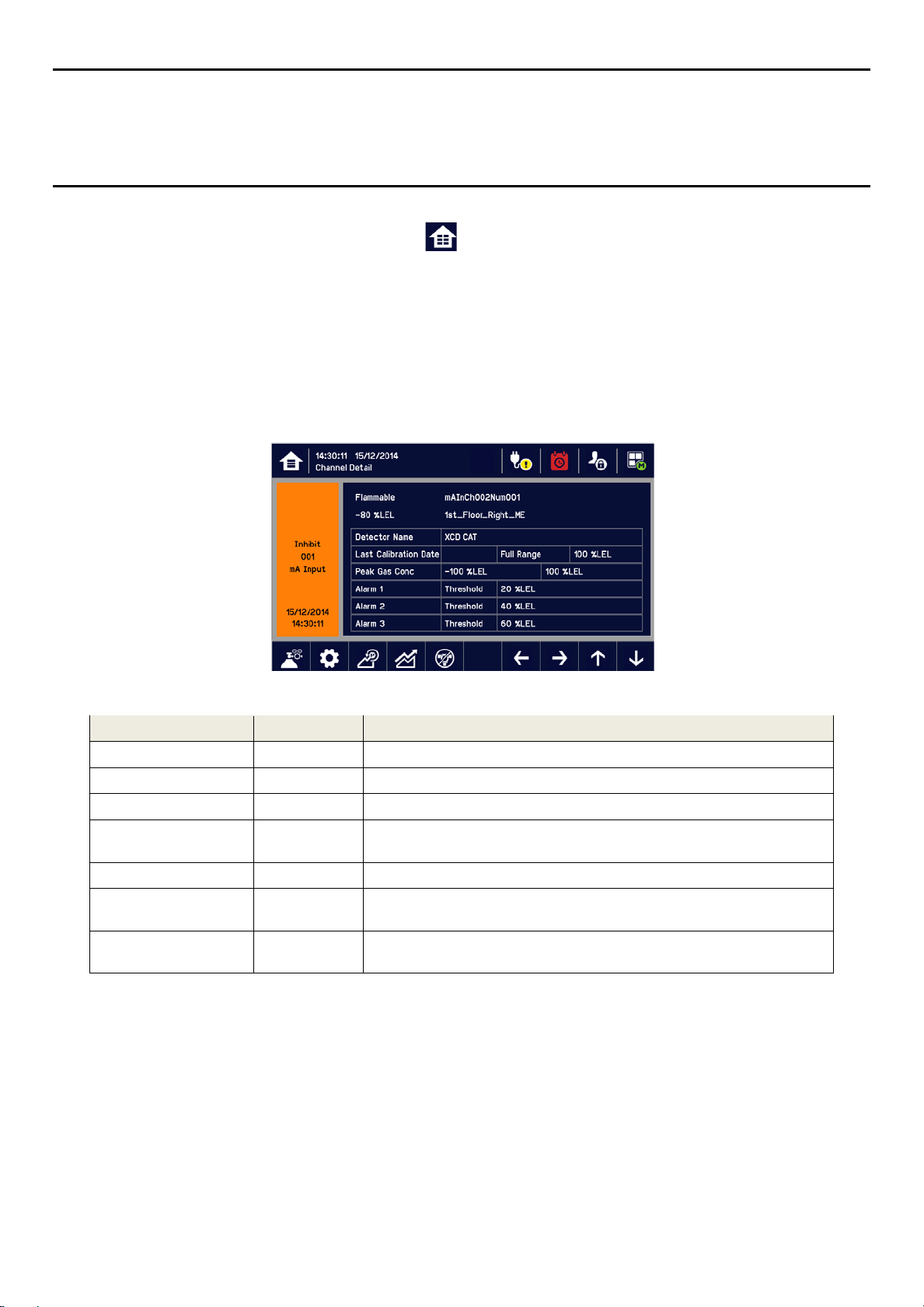

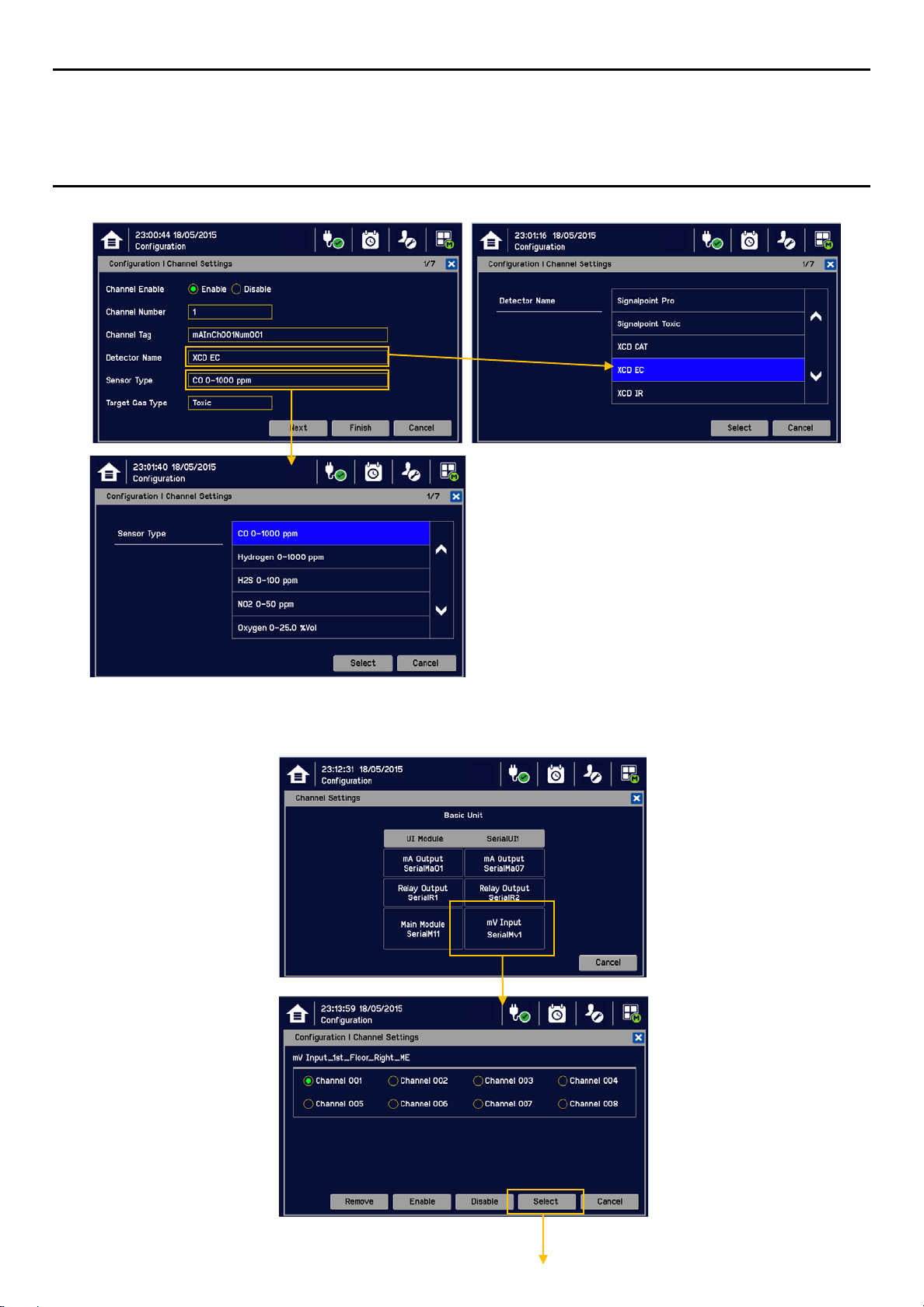

7.6 Channel Configurat ion ........................................................................................................ 53

7.6.1 Introduction ................................................................................................................. 53

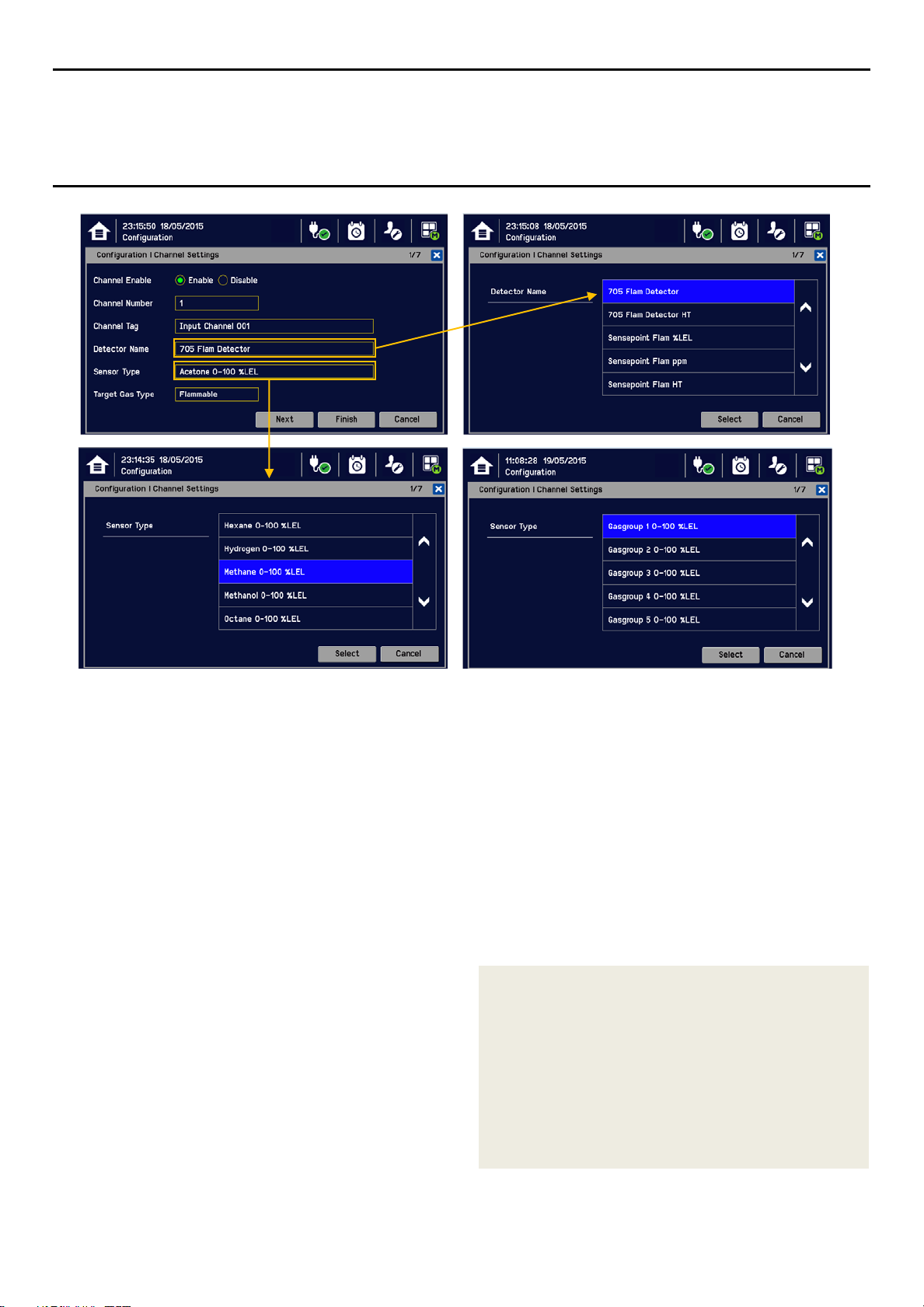

7.6.2 Configuring a Channel (mA input and mV input channel) .............................................. 54

7.6.3 Editing a Configured Channel ...................................................................................... 55

7.6.4 Editing mA Input Channel Settings (In Pictures) ........................................................... 55

7.6.5 Editing mV Input Channel Settings (In Pictures) ........................................................... 56

7.6.6 Editing Relay Output Channel Settings ........................................................................ 57

7.6.7 Editing Relay Output Channel Settings (In Pictures) ..................................................... 58

7.7 Data Logging ....................................................................................................................... 59

7.8 Touch Pa ne l Configurat ion ................................................................................................. 59

7.8.1 How to Calibrate the Touch Panel ................................................................................ 59

7.9 Serv ic e Cont a c t S e t t ings ..................................................................................................... 60

7.10 Back up Configuration ...................................................................................................... 60

7.11 Calibrating mV Input C ha nnels ......................................................................................... 61

7.11.1 Adjusting the mV Sensor Baseline ............................................................................. 61

7.11.2 Calibrating a mV Sensor Channel .............................................................................. 61

Language Settings

................................................................................. 52

v

Page 6

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Contents

7.12 Calibrat e mA input channel loops .................................................................................... 62

Chapter 8 – Maintenance ..................................................................................................... 63

8.1 Routine Ma intenance........................................................................................................... 63

8.1.1 Weekly Checks ............................................................................................................ 63

8.1.4 Exercising the Audio/Visual Alarm ................................................................................ 64

8.2 Test ing t he Touchpoint P lus S y s t e m.................................................................................. 65

8.2.1 Introduction ................................................................................................................. 65

8.2.2 Field Inputs Test .......................................................................................................... 65

8.2.3 Cause and Effect Test ................................................................................................. 66

8.3 How to Replac e a Fa ulty I/O Mod ule ................................................................................... 67

8.4 How to Add a New I/O Module............................................................................................. 68

8.5 How to Decom m is sion and Remove an I/O Module ........................................................... 68

8.6 How to Upda t e t he S e nsor Catalogue ................................................................................. 69

8.7 How to Ba c k up / Restore c onf iguration.............................................................................. 69

8.8 How to Upda t e Firmware ..................................................................................................... 70

8.8.1 How to Check System Compatibility ............................................................................. 70

8.8.2 How to Update the Firmware........................................................................................ 70

8.9 How to Cha nge the SD Car d ............................................................................................... 71

8.10 How t o Ca librate mV Input Channels ................................................................................ 72

8.11 Back up Bat t e ry Maintena nc e ........................................................................................... 74

8.11.1 Recommended Scheduled Maintenance .................................................................... 74

8.11.2 How to Replace the Battery Pack ............................................................................... 74

8.12 Ret urn to Factory De f a ult S e t t ings ................................................................................... 75

Chapter 9 – Troubleshooting .............................................................................................. 76

9.1 Calli ng f or Technic a l S upport. ............................................................................................ 76

Chapter 10 – Technical Specifications ............................................................................... 77

10.1 Env ironmental ................................................................................................................... 77

10.2 Use r Interfac e a nd Ma in Module ....................................................................................... 77

10.3 I/ O Module s ........................................................................................................................ 78

10.3.1 mA Input Module ....................................................................................................... 78

10.3.2 mV Input Module ....................................................................................................... 78

10.3.3 mA Output Module ..................................................................................................... 78

10.3.4 Relay Output Module ................................................................................................. 79

10.4 Pow e r Supplies .................................................................................................................. 79

10.4.1 External Supplies ....................................................................................................... 79

10.4.2 Backup Battery .......................................................................................................... 79

10.5 Enclosures ......................................................................................................................... 80

10.5.1 Wall Mount Enclosure ................................................................................................ 80

Chapter 11 – Certifications .................................................................................................. 81

11.1 EC de c laration of co nf ormity ............................................................................................ 81

11.2 Nat ional and Internationa l Ce rtificates of Complia nc e .................................................... 81

Chapter 12 – Replacement Parts and Optional Extras ...................................................... 82

Chapter 13 – TPPL Configuration Information .................................................................. 83

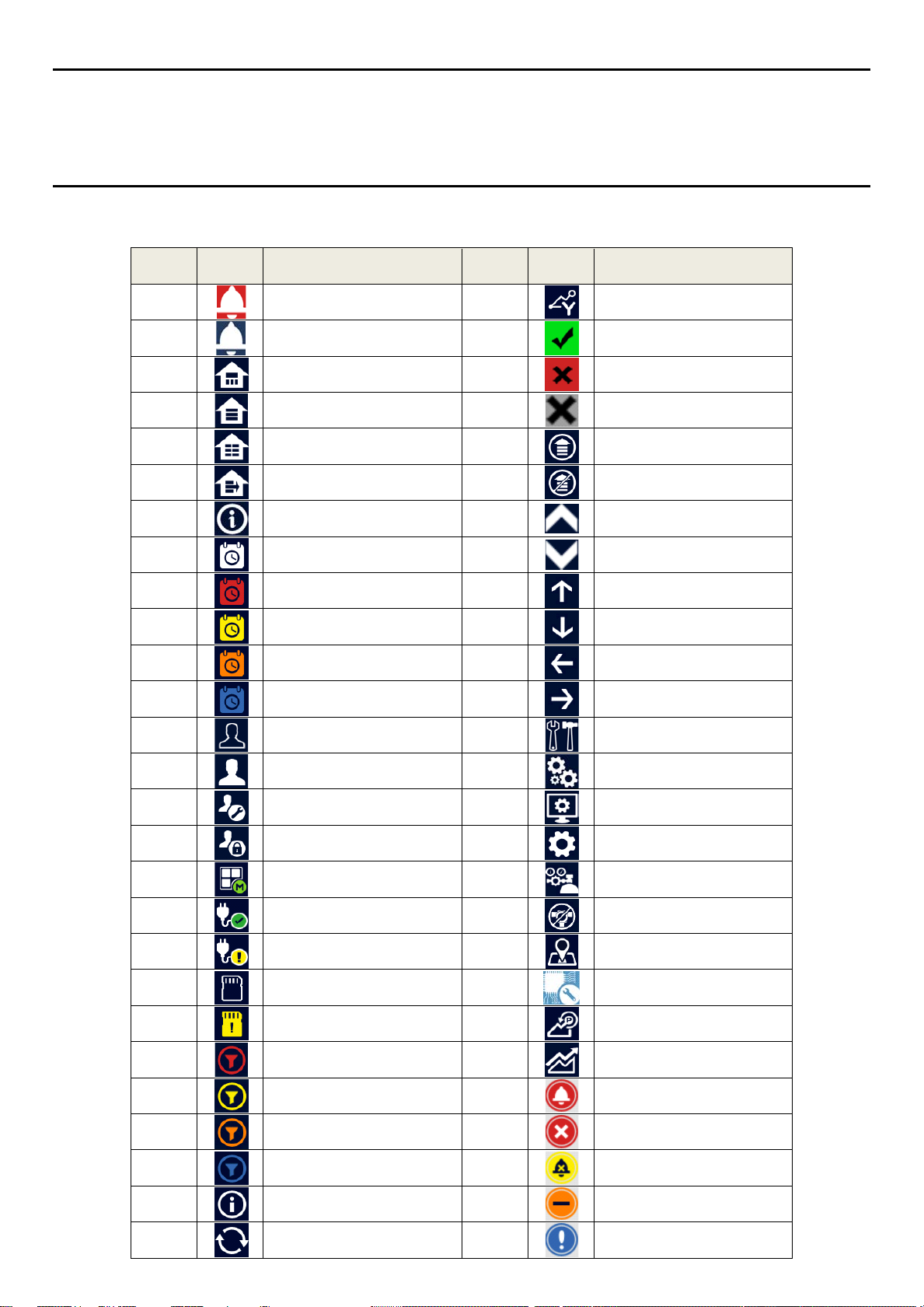

Chapter 14 – Glossary of Icons ........................................................................................... 84

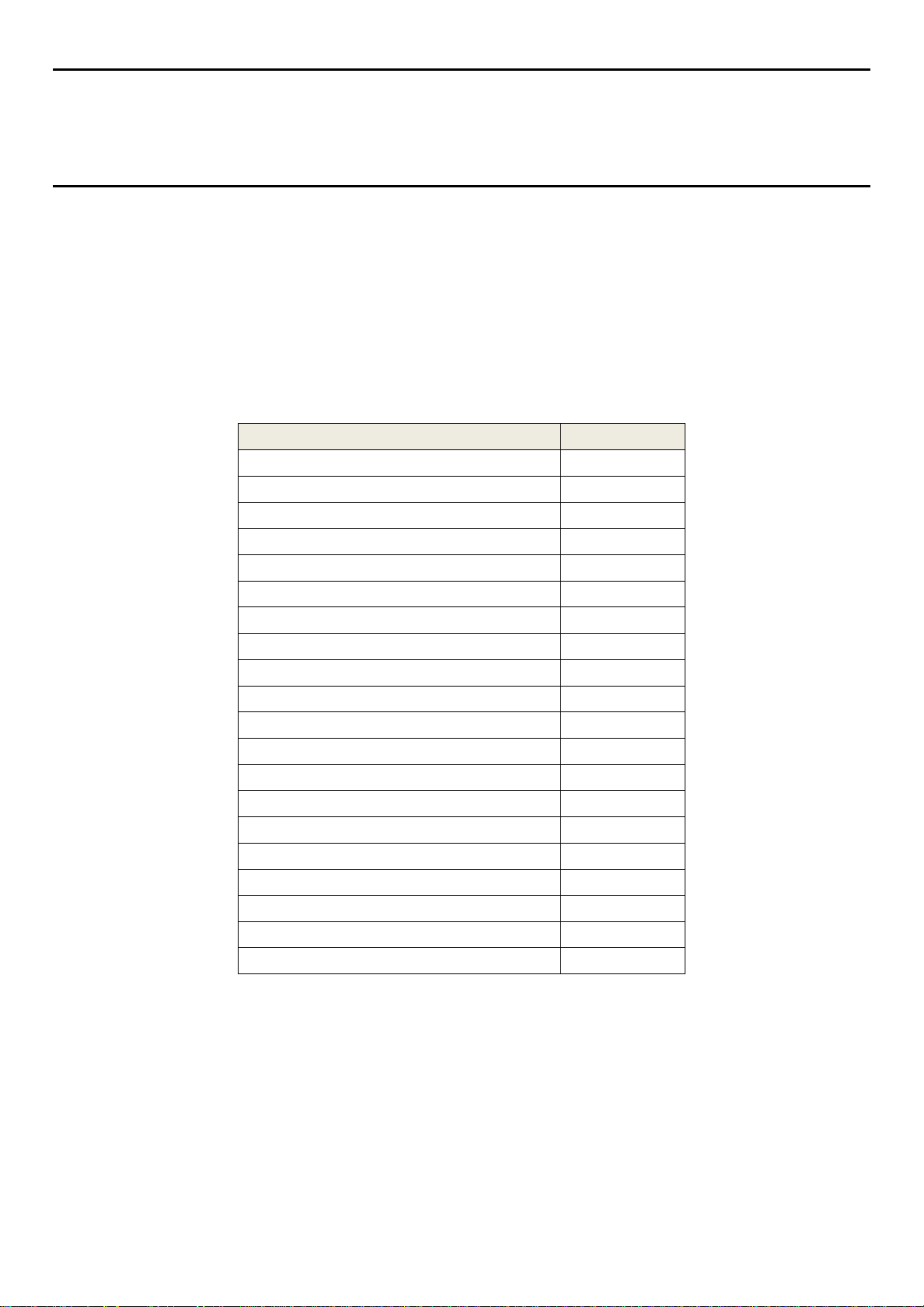

Chapter 15 – Compatible Sensors ...................................................................................... 86

Chapter 16 – Configurable Parameter Reference Guide ................................................... 87

Chapter 17 – Fault Codes .................................................................................................... 90

Chapter 18 – List of Figu r es ................................................................................................ 91

Chapter 19 – List of Tables .................................................................................................. 92

vi

Page 7

MAN0984_Iss 2_06/15 Touchpoint Plus

ONLY. READ AND UNDERSTAND THE INSTRUCTION MANUAL COMPLETELY BEFORE

Technical Handbook

Important Safety Information

Chapter 1 – Important Safety Information

The Equipment referred to in this manual contains components and assemblies that are each certified for use

in a variety of differing environments, and it is the site owner’s responsibility to confirm the suitability of the

equipment prior to its installation and use.

The Equipment assemblies referred to in this manual are collectively certified for use in a flammable gas

detection system only. Any other use is not currently certified and is not authorized by the manufacturer.

Please check the product rating plate and look for the following marks to ensure that the supplied equipment

is suitable for its intended location and purpose:

Products bearing the CE mark conform to all applicable European Directives as stated on the Honeywell

product specific EC Declaration of Conformity.

Products bearing the UL mark conform to the requirements for Ordinary Locations. The letters C and US

mean that the product is certified for use in Canada and the United States of America.

FOR SAFETY REASONS THIS EQUIPMENT MUST BE OPERATED BY QUALIFIED PERSONNEL

OPERATING OR SERVICING THE EQUIPMENT.

POUR DES RAISONS DE SÉCURITÉ, CET ÉQUIPEMENT DOIT ÊTRE UTILISÉ, ENTRETENU ET

RÉPARÉ UNIQUE MENT PAR UN PERSON NEL Q UALIF IÉ. ÉTU DIER LE MANUEL D’INSTRUCTIONS

EN ENTIER AVANT D’UTILISER, D’ENTRETENIR OU DE RÉPARER L’ÉQUIPEMENT.

WARNING

ATTENTION

1

Page 8

MAN0984_Iss 2_06/15 Touchpoint Plus

WARNINGS

company regulations, and suitable for the installation. Additionally, cabling must satisfy

Technical Handbook

Important Safety Information

1) The equipment specified in this manual is only to be installed by the Manufacturer’s trained

personnel, or by competent persons trained in accordance with the Manufacturer’s installation

instructions.

2) Installation must be in accordance with the recognized standards of the appropriate authority in the

country concerned. Refer to local, national and company regulations.

3) Do not operate the Touchpoint Plus system or its components outside of their rated operating

specification.

4) Touchpoint Plus must not be operated in Oxygen enriched atmospheres, i.e. greater than 25% v/v

Oxygen.

5) All equipment containing a User Interface must be suitably protected from direct sunlight and rain.

6) Power Supply Fluctuations are not to exceed DC 18 – 32 V SELV Supply or ±10 % of nominal.

7) All versions of Enclosure apparatus are electrical Class 1, and must be connected to Protective

Earth (Ground).

8) The Touchpoint Plus installation must include a means of isolating or disconnecting the input

voltage supply. The isolation or disconnection device must be conveniently located close to the

system and be clearly labelled. For an AC mains voltage supply, the isolation or disconnection

device must disconnect both the line and neutr al poles, but maintain earth (ground) continuity.

9) The Touchpoint Plus input voltage supply must include over-cu rrent protec tion.

10) All cabling must be appropriately rated and approved in accordance with local, national and

requirements defined in the manuals of connected field devices, in particular if the field device is

certified for use in a hazardous location.

11) All signal cables and interconnections must be shielded and the shields terminated only at the

unified earth (ground) bus bar situated inside the enclosure

12) All conduits and cable armour shall be bonded to protective earth (ground), and care must be taken

to avoid ground loops and to avoid contact with cable shielding.

13) Cable entry glands, blanking plugs, reducers, adaptors and breather devices must be suitably

approved and must not reduce the IP rating or protection levels. Items should not be used if there is

a high risk of mechanical damage to the equipment or enclosure.

14) Access doors and entry points must be kept closed when the system is energised in normal

operation.

15) Enclosure locking handle security screws must be fully tightened during normal operation.

16) All equipment in this manual is rated to +2000 m (6562 ft) altitude maximum.

17) For safety reasons this equipment must be operated by qualified personnel only. Read and

understand the Instruction Manual completely before operating or servicing the equipment.

18) Touchpoint Plus systems may contain hazardous live terminals. Appropriate precautions should be

taken during operation, installation, and maintenance and servicing. Specifically, operators must

have appropriate training and experience to be aware of the hazards to which they may be

exposed, and of measures to minimise risk to themselves or other people.

19) The protection provided by the equipment may be impaired if the equipment is used in a manner

not specified or authorised by the manufacturer.

2

Page 9

MAN0984_Iss 2_06/15 Touchpoint Plus

WARNINGS

Technical Handbook

Important Safety Information

20) Be aware that extended exposure of a detector element to certain concentrations of combustible

1.1 Cautions

gases and air can introduce stress to the element that may seriously affect its performance, and

therefore recalibration should be carried out or the sensor repl aced, or both, after an alarm due to

an indication of a high concentration.

21) When used in a Gas Detection summing up role, the gas reading may be higher than the actual

concentration at any one detector head location, or it may be the actual concentration at one

specific detector head.

1) Touchpoint Plus SMPS, Input and Output Modules have no user serviceable parts. In the unlikely event of

a failure, the item must be replaced using only manufacturer supplied parts.

2) Do not use sharp objects to operate the touchscreen as this could irreparably damage the User Interface

and adversely affect its IP rating.

3) Use only soft, damp cloths or screen wipes to clean the Touchpoint Plus. Do not use solvents or

abrasives as they will damage the User Interface.

4) Once commissioned, Touchpoint Plus is intended for continuous operation.

5) Undo the security screws before pulling the locking handle. Failing to do so may irreparably damage the

enclosure.

1.1.1 Intended Readers

This Manual should be read by everyone who operates or monitors the Touchpoint Plus gas detection system.

Only personnel who have been fully trained by Honeywell are authorized to Install, Set-up, Service, and Test,

Repair, or Recondition Honeywell gas detection systems.

Personnel, who work on, or in the area of, the Touchpoint Plus Gas detection system must be made aware of the

Important

contents of Chapter 2 – Safety.

Before unpacking the system, please read the documentation that accompanies it.

3

Page 10

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Important Safety Information

1.1.2 Conventions Used

The following conventions are used in this manual:

“TPPL” refers to the Touchpoint Plus Gas Detection System.

“Start up” refers to the action of switching on the system ready for use.

“Restart” refers to cycling the power off and then on again.

“Boot up” refers to the action of starting the software from cold.

“Reboot” refers to shutting down and restarting the software without interrupting the power supply.

“mV Sensor” refers to mV Bridge Sensor.

“SELV” refers to Self-Enclosed Low Voltage devices.

1.1.3 Associated Manuals

This manual should be used in conjunction with any manuals provided with ancillary components and

sensors.

This manual is available in 14 user languages:

• Chinese (Simplified)

• Dutch

• English

• French (Canada)

• French (France)

• German

• Italian

• Japanese

• Korean

• Portuguese (Brazil)

• Portuguese (Portugal)

• Russian

• Spanish (Mexico)

• Spanish (Spain)

4

Page 11

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

Chapter 2 – Safety Hazards, Warnings and Cautions

2.1 Safety

Incorrect set-up, maintenance, operation or modification of the Touchpoint Plus gas detection system or its

installation may constitute a serious hazard to the health and safety of personnel and their environment. It is

therefore imperative that the contents of this chapter are thoroughly understood by everyone who has access

to the gas detection system or its associated equipment.

When properly installed, this gas detection system enclosure is rated as IP65.

It may be installed in a Pollution Degree 2 (i.e. laboratory, office or control room) or Pollution Degree 3 (i.e.

unheated boiler room) environment as defined by IEC/UL/EN 61010–1: Safety requirements for electrical

equipment for measurement, control and laboratory use.

In all cases, several hazards may be present when operating or servicing the equipment and extreme caution

must be exercised at all times. The hazards that may be encountered include:

• Class 1 electrical hazards (AC 110/220 V, DC 18–32 V)

• Mechanical hazards (Heavy components, swinging access doors)

• Environmental hazards (toxic atmospheres)

• Fire and Ignition hazards (Touchpoint Plus is not ATEX/IECEx Zone 1 certified, and cannot be used in

flammable atmospheres, or where oxygen concentrations >25% v/v O2)

2.1.1 Warnings and Cautions

Safety of this equipment is reinforced by the use of safety labels that are fixed to the equipment in a visible

manner. The type of safety labels used and their location is detailed in this chapter. The degree of

seriousness of the hazard is indicated in this manual by the use of the following signal words accompanied by

a suitable hazard symbol:

Indicates an imminent hazard that, if not avoided, is extremely likely to result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury. It is also

used to alert the user against unsafe working practices and potential damage to equipment.

Danger

Warning

Caution

5

Page 12

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.1.2 Safety Hazards

The following specific hazards are associated with the installation and use of this equipment:

Touchpoint Plus is Not ATEX/IECEx certified, and it may only be installed in safe areas where there are no

flammable atmospheres, and no oxygen concentrations >25% v/v O

All power supplies must be hard wired and must include a circuit breaker (RCD / RCCB) and, close by and

unobstructed, a means of manually isolating and locking–out the power supply without breaking the protective

Removable plug/socket connection is not permitted under any circumstance.

Lethal current may be present in this equipment when electrical power is applied. There is a danger of death or

injury from electrical shock. Isolate power before opening electrical access panels. Ensure residual current is fully

Lethal current may be generated both internally and externally to the system. All installations, including

enclosures and external units, must be grounded to protective earth, and must be capable of staying earthed

The Protective Earth (Ground) symbol is shown to the left, and always has a green background. Do not confuse

The Touchpoint Plus system and/or its sensors may become contaminated by the ambient environment in which

it or they are used. It is the Customer’s sol e responsibility to ensure that all appropriate safety precautions are

Warning – Toxic Waste and Harmful By-Products

taken before handling any components or transferring them to any other party.

Danger – Ignition Hazard

Warning – Lethal Voltage Present

earth (ground) connection.

Warning – Lethal V ol t age Present

discharged before touching live terminals.

Warning – Lethal Voltage Present

(grounded) when the power supply is interrupted.

it with the chassis earth symbols shown below it.

.

2

6

Page 13

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.1.2 Safety Hazards (Cont.)

The following general hazards are associated with the use of this equipment:

This equipment contains a number of potentially toxic substances that may pose a health or environmental

hazard if exposed to very high temperatures, VOCs or corrosives, or if improperly handled or carelessly disposed

Each Touchpoint Plus enclosure is heavy and weighs considerably more when packed. Ensure that a Manual

Handling Risk Assessment is carried out before moving or installing the system, and ensure that the enclosure is

Touchpoint Plus uses high energy AC and DC currents that may cause arcing and sparks if shorted out. Always

Touchpoint Plus can be used to control loud alarms and sirens. Always wear hearing protection when working in

Battery may explode if mistreated. Do not disassemble or dispose of in fire.

Warning – Fire or Explosion Hazard

Warning – DO NOT USE WATER

DO NOT USE WATER if a lithium battery overheats or burns,

as this may make the fire worse and may cause an explosion.

Evacuate the area and call Emergency Services.

Caution – Health and Environ mental Hazards

of.

Caution – Risk of Injury and Damage

fitted securely to a suitable surface.

Caution – Risk of Eye Injury

wear eye protection when the enclosure is open.

Caution – Risk of Hearing Damage

the vicinity of loud noises.

7

Page 14

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.2 Location and Description of Warning Labels

2.2.1 Safety Warning Labels

In accordance with the requirements of the European Standard EN 60825–1, appropriate warning labels are

mounted in specified locations on the equipment. This is to indicate conditions under which the user could be

subjected to electrical hazards.

Figure 1. Quickstart Guide Label

(Not to Scale)

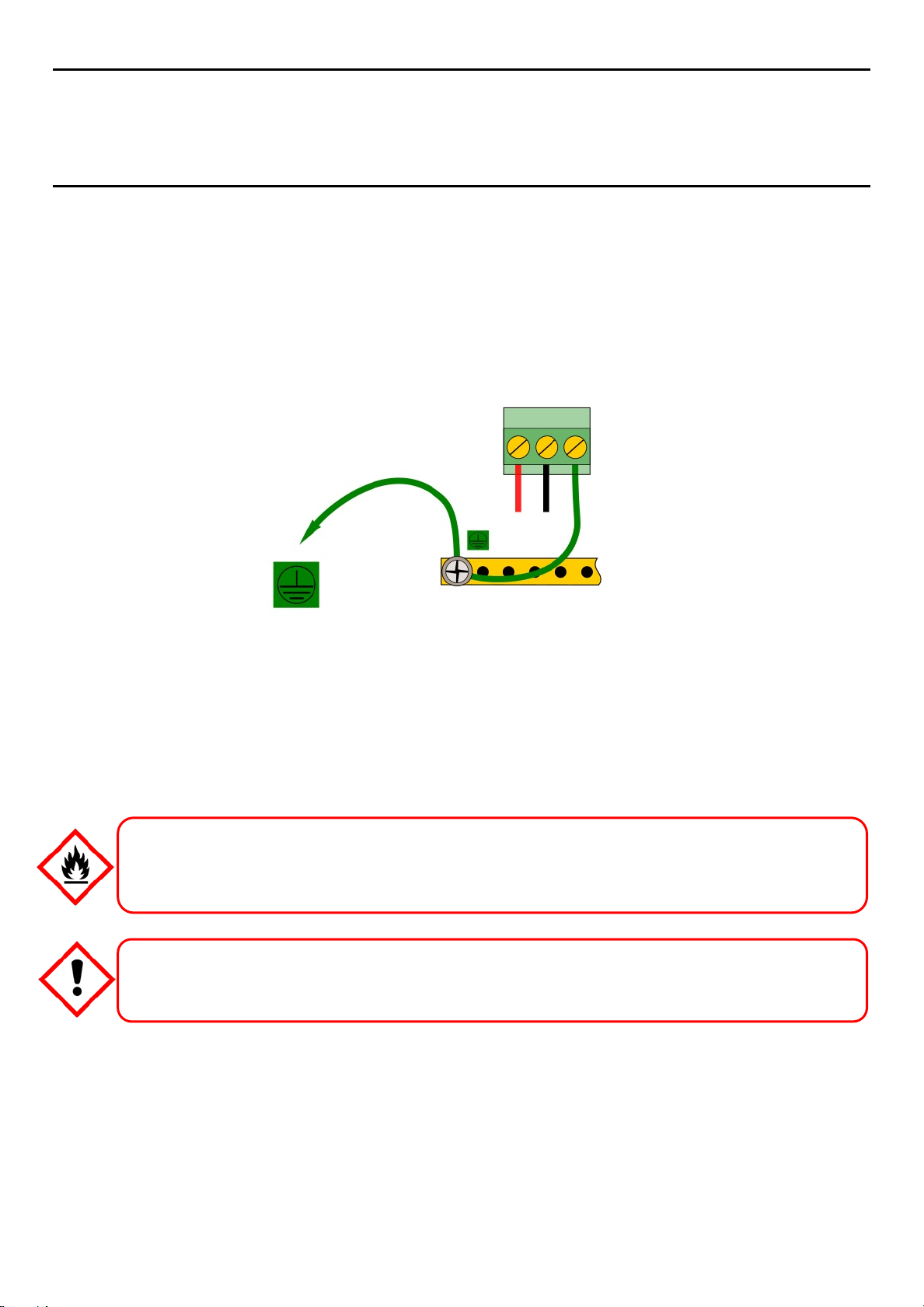

Figure 3. Protective Earth (Ground) Point Figure 4. Equipment Earth (Ground) Point

This Protective Earth (Ground) location point label is

used inside the system and is not normally visible to

the operator.

Figure 2. SMPS Voltage Warning Label

(Removed During Installation)

This Equipment Earth (Ground) location point label is

used inside the system and is not normally visible to

the operator.

Figure 5. Internal Label Positions

8

Page 15

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.3 Electrical Hazards

Gas detection systems contain electrical supplies that are potentially dangerous and hence precautions must

be taken to prevent the risk of electrocution.

2.3.1 General Precautions

• Read the relevant manual before beginning any operating or service procedures.

• Only personnel trained and certified by Honeywell are authorized to service, fit or remove internal parts.

• Only the minimum number of trained personnel, consistent with safety, should have access to the area

while work is being carried out. If necessary, erect warning signs and barriers.

• Follow accepted working procedures and codes of practice as well as the electrical safety code for the site

where the equipment is installed.

• Never operate the equipment under normal conditions with access panels removed or shorting links fitted.

• Do not “Live Test” without a Safe System of Work (SSoW).

• Always keep the area around the equipment dry and free of obstructions.

• Switch off and Isolate the equipment if water ingress is suspected or confirmed.

• Never operate the equipment if any Mains power cable is frayed or damaged.

• Never wear wristwatches, rings, bracelets, or other jeweler when working around electrical circuits or

moving parts.

• Take anti-static precautions when working on electronic circuits.

• Never work on electrical equipment alone.

2.3.2 Component Testing and Replacement

Before carrying out any electrical testing or component replacement:

• Read this Manual to become familiar with the location of high voltage components.

• Isolate the system at the main circuit breaker, lock it in the “Off” position, and attach a notice indicating

that maintenance work is in progress.

• Always wait for 5 minutes after isolating the equipment to ensure that stored energy has dissipated.

• Never assume the polarity of cabling or replacement components. Refer to electrical schematics or

contact Honeywell for confirmation.

• Use only Honeywell approved replacement parts.

Only Honeywell trained and certified maintenance technicians are authorised to carry out component testing and

replacement. Unauthorised work may result in a potentially dangerous situation and will invalidate the

Antistatic Precautions are required to prevent severe damage to electronic components.

Warning – Unauthorised Personnel

manufacturer’s warranty.

Anti–Static Precautions

9

Page 16

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.3.3 Antistatic Precautions

As with all modern electronic circuits, the Printed Circuit Boards (PCBs) in Touchpoint Plus systems utilize

some static-sensitive components that can be severely damaged if subjected to static discharge. Static can be

generated on the human body by friction or movement and is discharged through the first contacted route to

earth. It can also jump gaps between items of differing electrical potential.

Static damage is not always immediately apparent and can cause component failure at any time after the

static discharge has occurred. It is, therefore, very important that everyone takes the following precautions

when handling PCBs:

• An industry approved antistatic wrist strap, containing a resistive component greater than 1Megohm, must

be worn and connected to an effective earth (ground) point. The continuity between the strap and earth

(ground) must be checked regularly.

• PCBs must only be handled by their non-conductive edges. Do not allow any components, conductive

tracks or contacts to come into proximity with the body, clothing, machinery, power source or any material

other than a static-dissipative mat.

• With the exception of assemblies containing batteries, anti-static packaging must be used for transporting

PCBs and Integrated Circuits (ICs). All Touchpoint Plus electronic components are shipped in appropriate

packaging that can be re-used when returning items for test or repair.

• Avoid wearing clothing manufactured from, or containing a high proportion of, man-made fibers. These

can build up a high static potential that may not be discharged through the body or wrist strap.

An effective earth (ground) point is the protective earth (ground) bus bar inside the enclosure. This can be

used to connect a suitable anti-static wrist strap provided that the Gas detection system is connected to

protective earth (ground) via the mains power supply cable.

If installed correctly, the equipment earth (ground) point is connected directly to mains earth (ground) via

protective earth and the mains power supply cable. It is not dependent on the position of the Isolator switch or

Important

circuit breaker.

2.3.4 Good Practice

After switching off the system, it is good practice to wait at least 15 seconds before switching it on again. This

allows the circuits and RAM to discharge adequately before being powered-up again. Failing to do so may

cause data corruption.

2.3.5 Lithium Battery Hazard

Lithium batteries are fitted to Touchpoint Plus as backup power sources.

Replace the factory installed battery pack TPPLOIBB with Honeywell Analytics Asia Pacific replacement

battery pack part no. TPPLSIBB and the PCB CMOS battery with type CR2032 only.

Use of other batteries may present a risk of fire or explosion.

10

Lithium batteries may cause severe injury or death if ingested, and may catch fire or explode if mishandled,

Always handle lithium batteries with care, keep them out of the reach of children, and dispose of them carefully in

Lithium Battery Toxic and Fire Hazards

recharged, burned or disposed of incorrectly.

accordance with local regulations.

Page 17

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.4 Product Compliance

This product complies with the following standards and directives.

Other safety directives may apply to the complete system installation if an OEM’s product is integrated into

other equipment or machinery.

Safety Compliance

Electrical Safety

EMC/RFI

Low Voltage Directive

Gas Performance*

CAN/CSA C22.2 No. 61010-1 and No.142

UL 61010–1 (3

IEC/EN 61010–1 (3

EN 50270

IEC/EN 61010–1 (3rd Edition)

ISA 12.13.01 and CSA C22.2 No. 152

rd

Edition); UL508

rd

Edition)

* ISA 12.13.01 and CSA C22.2 No.152 approval is applicable only to mV sensors Model 705 and MPD or any

suitably certified mA sensor.

Note: The Equipment referred to in this manual contains components and assemblies that are each certified

for use in a variety of differing environments, and it is the site owner’s responsibility to confirm the suitability of

the equipment prior to its installation and use.

Please check the product rating plate and look for the following marks to ensure that the supplied

equipment is suitable for its intended location and purpose:

Products bearing the CE mark conform to all applicable European Directives as stated on the Honeywell

product specific EC Declaration of Conformity.

Products bearing the UL mark conform to the requirements for Ordinary Locations. The letters C and US

mean that the product is certified for use in Canada and the United States of America.

Read and understand the instruction manual before operating or servicing the equipment.

Important

11

Page 18

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Safety Hazards, Warnings And Cautions

2.5 Conditions of Use

This Touchpoint Plus equipment should only be operated under the following circumstances:

• By properly trained personnel.

• Under approved conditions.

• With due authorization.

• Using approved maintenance and servicing procedures.

2.5.1 Training of Personnel

Honeywell and / or its distributors can provide training for operators and maintenance personnel. Personnel

who have been trained in operation and maintenance shall be limited to carrying out only those procedures

and tasks taught during the training course. Honeywell certified maintenance technicians must carry out all

other tasks.

Honeywell can also provide additional or advanced training. Retraining is recommended periodically and

whenever equipment is upgraded.

2.5.2 Conditions Satisfying Local, National and International Safety Regulations

Approved conditions must satisfy the requirements of applicable national and international safety standards

and statutory requirements relating to electrical, EMC, and health hazards. In addition, they must satisfy the

requirements of the Site Safety Officer and the local safety regulations.

2.5.3 Due Authorization

Before any production, maintenance, or servicing procedure is carried out; written authorization must be

obtained from one of the following personnel to confirm that the proposed task satisfies the necessary safety

conditions:

• A competent authorized person having a professional qualification in an appropriate technical discipline.

• The Factory, Technical or Engineering Manager responsible for the working area.

• The Site Safety Officer or an authorized Honeywell representative or approved distributor.

2.5.4 Approved Maintenance and Servicing Procedures

Approved Maintenance and Servicing Procedures are those stipulated in this manual or as authorized

separately by Honeywell.

It may be necessary to establish a temporary Locally Controlled Area (LCA) to restrict access during

maintenance, testing or service of this equipment.

12

Page 19

MAN0984_Iss 2_06/15 Touchpoint Plus

SD Card

Audio / Visual Alarm

mA Loop Sensors

Relays / Actuators

mA Loop

mV Bridge Sensors

Technical Handbook

System General Descri ption

Chapter 3 – System General Description

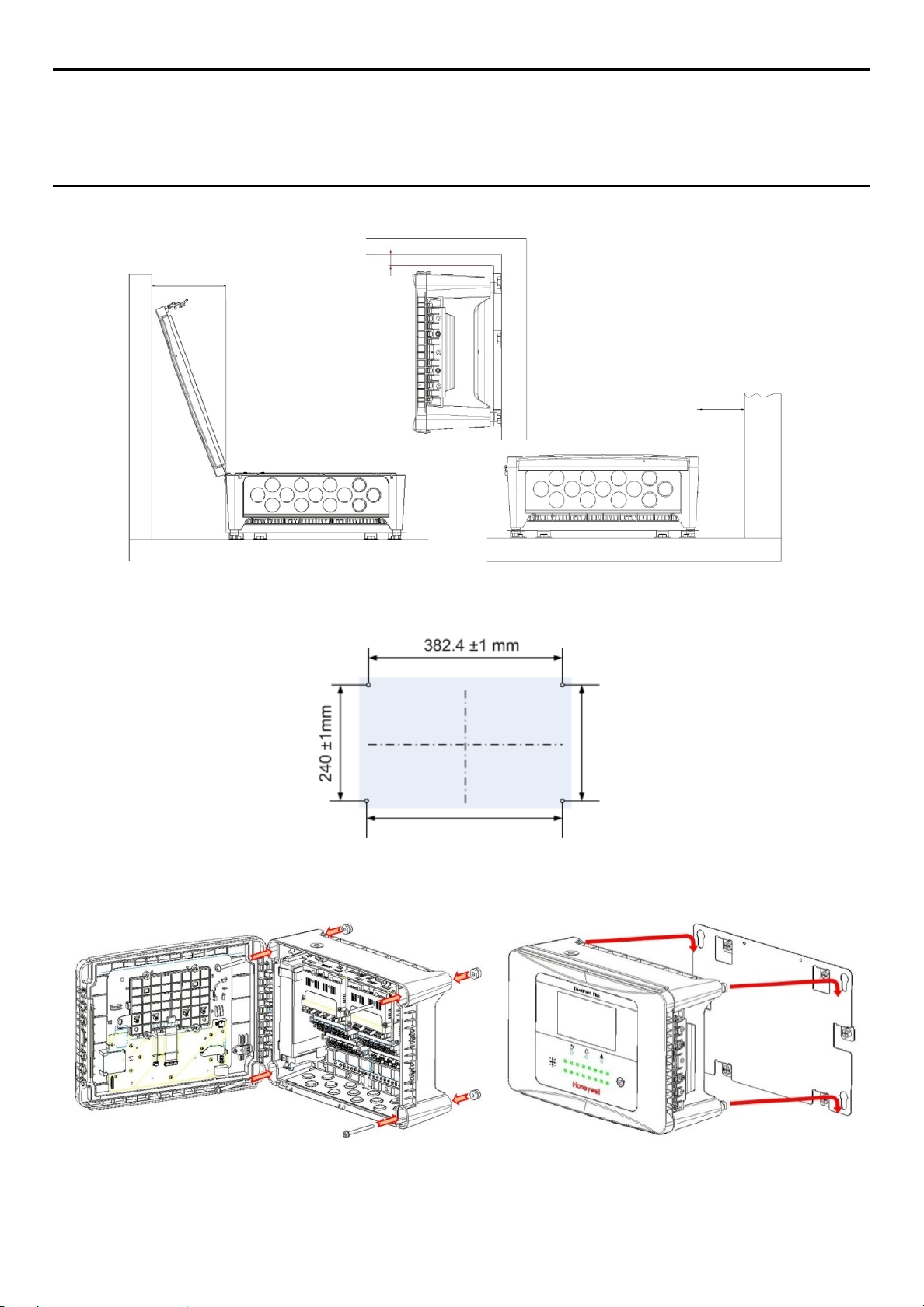

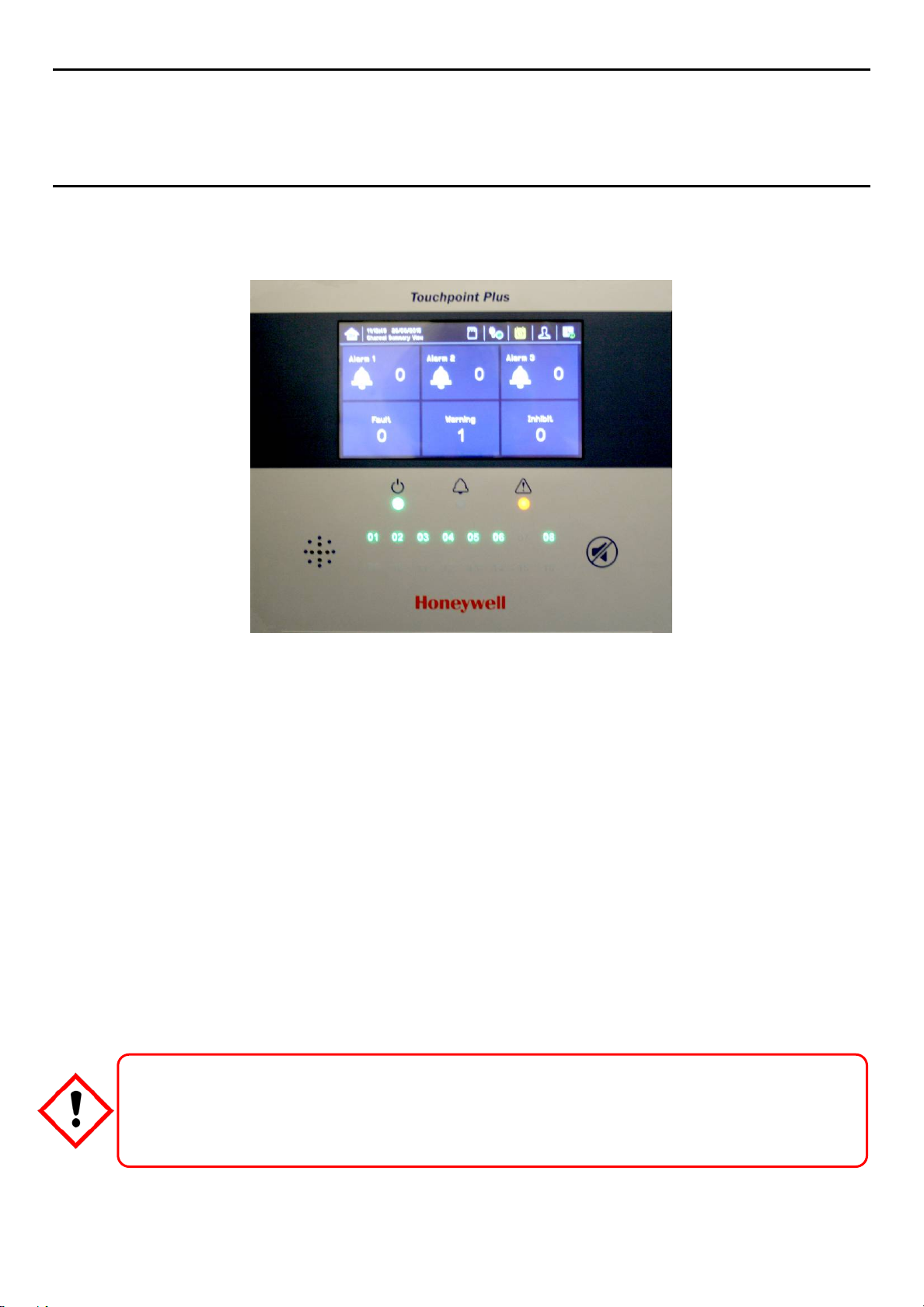

Figure 6. Touchpoint Plus Wall-Mounted Controller

The Touchpoint Plus is an entry level (or upgrade) touch-screen digital Controller for general industrial and

commercial gas detection systems. It has eight input channels, with a further eight channels available through

an optional expansion unit*.

It can handle a wide range of milliamp, millivolt, and catalytic sensors through analogue inputs, and it can

control various outputs such as audible and visible signals and solenoid valves.

The cabinets are constructed from high-impact plastic and have fully-sealed, easy opening access. They are

supplied with a wall mounting or can be directly mounted to any solid vertical surface or rack. Cable entry is

via entry glands on the lower side.

Touchpoint Plus is rated IP65, which means that it is dustproof and can be subjected to low-pressure water

without significant ingress. This makes it particularly suited to offices, control rooms and unheated boiler

rooms.

*Currently Touchpoint Plus is only available as a stand-alone Gas Detection System, but please contact

Honeywell Analytics for details about future upgrades. (The expansion box is currently planned for release in

late 2015.)

Figure 7. Typical Installation Options

13

Page 20

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

System General Descri ption

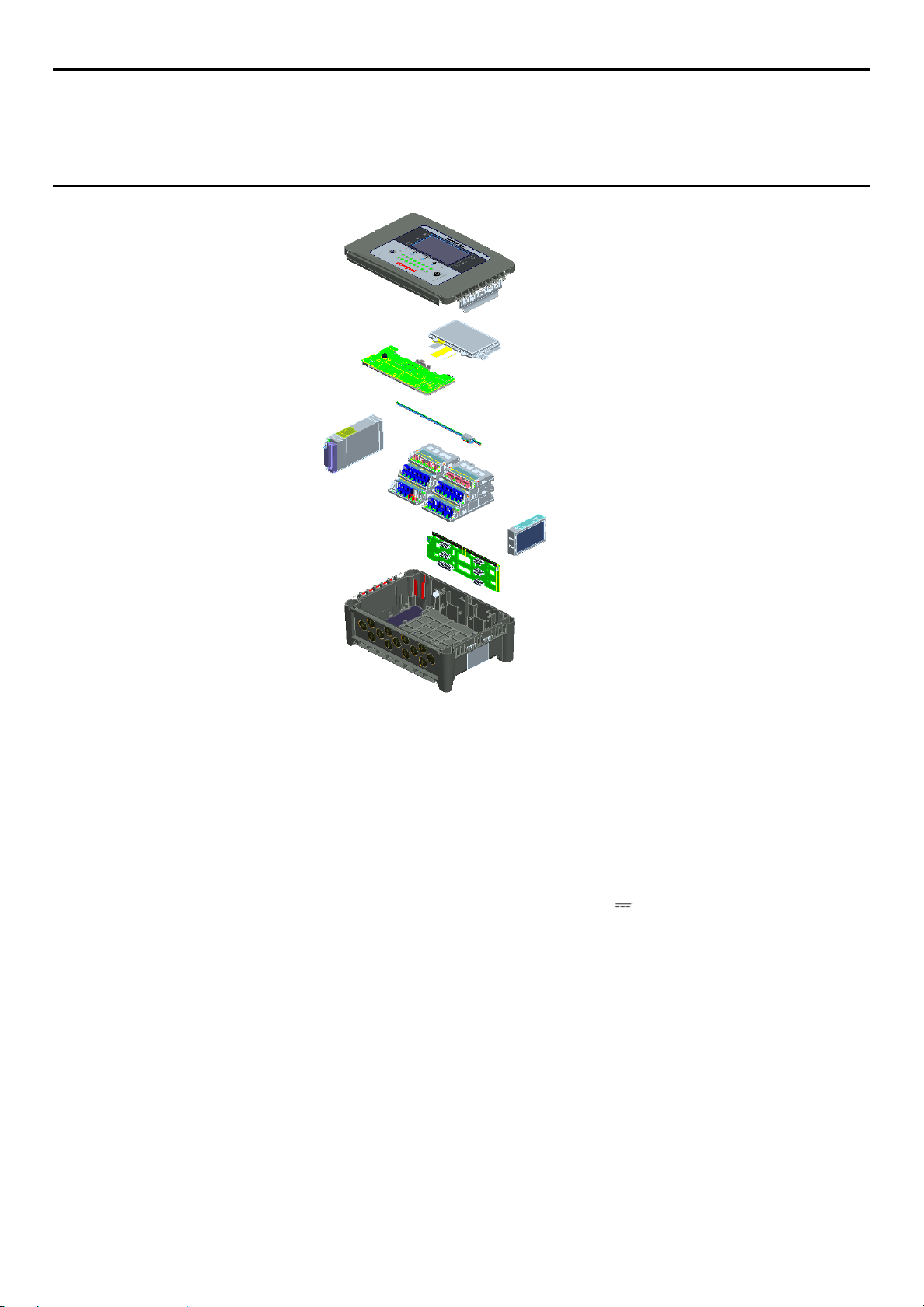

Figure 8. TPPL Controller Exploded View

Both the Touchpoint Plus and its optional expansion unit have the option for AC, DC and battery backup

power supplies.

Note: The expansion unit will be available from late 2015.

Other features:

• Color LCD Touch Screen with multi-language GUI and menus

• Password protection

• Flexible Mains Power Input: 50 – 60 Hz 110/220 V ~ (AC), 18 – 32 V (DC), Max 105 W

• Up to 8 channels of Analogue Input (0–22 mA, Bridge mV for Cat bead)

• 2 or 3-wire signal inputs

• Up to 24 channels of user configurable relay controlled Output

• Up to 8 channels of configurable mA Output

• Alarm update on Acknowledge

• Automatic Self-Diagnostic with error codes

• Event recording

• SD Card

14

Page 21

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

System General Descri ption

3.1 Equipment Specification

3.1.1 Power Requirements

The Touchpoint Plus system is designed to operate on a single phase, 50 to 60 Hz, 110/220 V~ (AC) supply

with a typical power consumption of less than 105 W.

Alternatively it can be connected to an 18–32 V (DC) supply with typical power consumption less than

105W.

The system can contain an optional backup battery to guard against short-term power disruption.

Input

Output

Protection

Voltage Range AC

AC Frequency Range 50 – 60 Hz ± 6%

AC Current Draw (typ.) 3 A @ 115 VAC, 2A @ 230 VAC

Cold-start Current (typ.) 40 A @ 230 VAC

Leakage Current <2 mA @ 240 VAC

DC Voltage 24 V

Rated Current 6.5 A

Current Range 0 – 6.5 A

Rated Power 156 W

Overload 110 – 150 % rated output power

Over-Volt

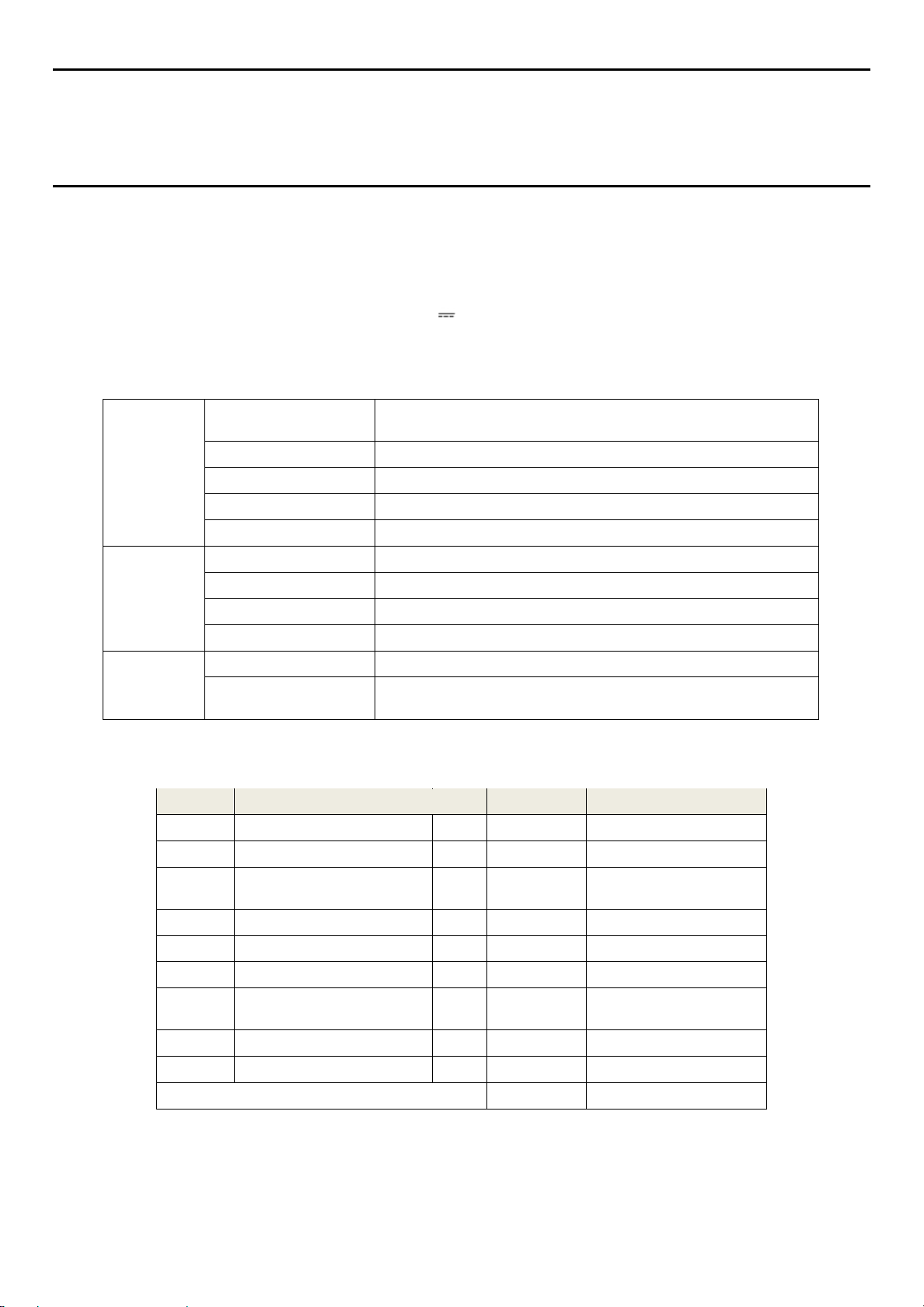

Table 1. Power Supply (SMPS RS–150–24) Electrical Ratings

No Modules Qty Power (W) Remarks

1 UI Module 1 3.6 Max

2 Main Module 1 1.7 Max

3 mA Input Module 1 0.9

4 mA input Field Device Power 8 40.0 Max

5 mA Output Module 2 8.6 Max

6 Relay Output Module 2 2.0 Max

7

Charging power for backup

battery pack

AC 110/220 V manually switchable

300 VAC surge for 5 sec without damage

27.6 – 32.4 VDC Hiccup mode, which recovers automatically when

the fault is removed.

Max (not including

detector power)

1 5.3 Max

8 Audio/Visual Alarm 4 28.8 Max

9 SMPS Power Loss — 14.0 Max

MAX TOTAL 104.9

Table 2. System Power Calculations

—

15

Page 22

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

System General Descri ption

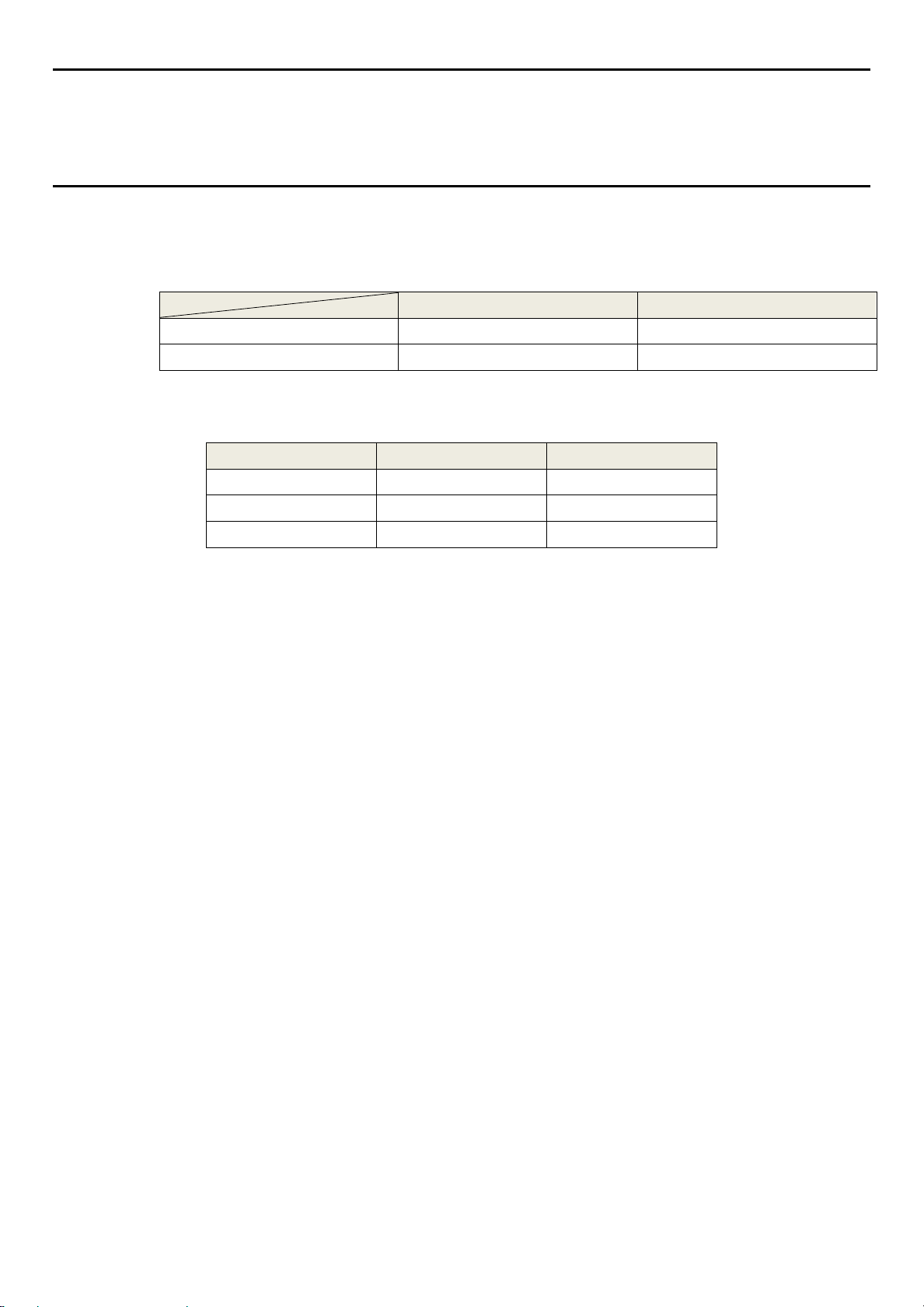

3.1.2 Weights

Note: Based on one input module, two mA output modules, two output relays, SMPS and backup battery for

the basic unit and expansion unit respectively.

TPPL Basic Unit TPPL Expansion Unit

System alone

System with packaging

Table 3. System Weights

3.1.3 Dimensions

External Dimension Millimeters Inches

Depth

Length

Width

8.5 Kg (18.7 lbs) 8 Kg (17.6 lbs)

9 Kg (20 lbs) 8.5 Kg (18.7 lbs)

156 6.2

426 16.9

300 11.8

Table 4. System Dimensions

3.1.4 Ambient Operating Temperature

–10 °C to +55 °C (14 °F to 131 °F)

3.1.5 Overall Ambient Operating Humidity

5 % to 95 %RH, non-condensing

3.1.6 Storage Conditions (Without batteries)

–25 °C to +60 °C (-13 °F to 140 °F), @ 5 % to 95 %RH, non-condensing

3.1.7 Storage Conditions (With batteries)

1 year: –20 °C to +25 °C (–4 °F to +077 °F)

3 months: –20 °C to +45 °C (–4 °F to +113 °F)

1 month: –20 °C to +60 °C (–4 °F to +140 °F)

3.1.8 IP Rating

The enclosures are sealed to IP65 when appropriate cable entry glands are used.

3.1.9 Construction

The system cabinets are constructed from PC ABS plastic with a secured quick release front access door

panel.

The Controller door panel holds a touch sensitive color LCD with a membrane cover over additional buttons,

LEDs and an audible warning horn.

Inside the Controller cabinet is a Switched-Mode Power Supply (SMPS) providing a nominal DC 24 V output,

an optional Lithium-ion backup battery, a Main Module, a mA/mV Input Module, two mA Output Modules, two

Relay Modules, protection fuses, and the control and user interface electronics.

The optional expansion unit holds the same modules and optional backup battery, but has no controller or

user interface.

Both enclosures contain a common Earth (ground) rail that must be bonded to Protective Earth (Ground)

through an isolation switch that does not disconnect the Earth line.

16

Page 23

MAN0984_Iss 2_06/15 Touchpoint Plus

1 2 3 4 4 5 5 7 6

8

12

10

9

11

Technical Handbook

System General Descri ption

3.1.10 Touchpoint Plus Packaging

• Touchpoint Plus outer packaging is made from cardboard. Facilities for recycling are widely available.

• Touchpoint Plus inner packaging is made from Stratocell®, Low-Density Polyethylene (LDPE) foam. The

foam can be recycled into new Stratocell® where such recycling facilities exist.

3.1.11 Packaging Components for Return to Manufacturer

Honeywell is unable to accept any consignment that does not conform to the European Classification,

Labeling and Packaging (CLP) Regulations (EC) 1272/2008.

Please consult your distributor, supplier, or the manufacturer if you require further advice.

3.1.12 Disposal (WEEE Directive)

The system contains Lithium batteries and a number of homogenous hazardous materials. These should be

disposed of carefully in accordance with the WEEE Directive and local laws and guidelines. Under no

circumstances can they be disposed of as domestic waste.

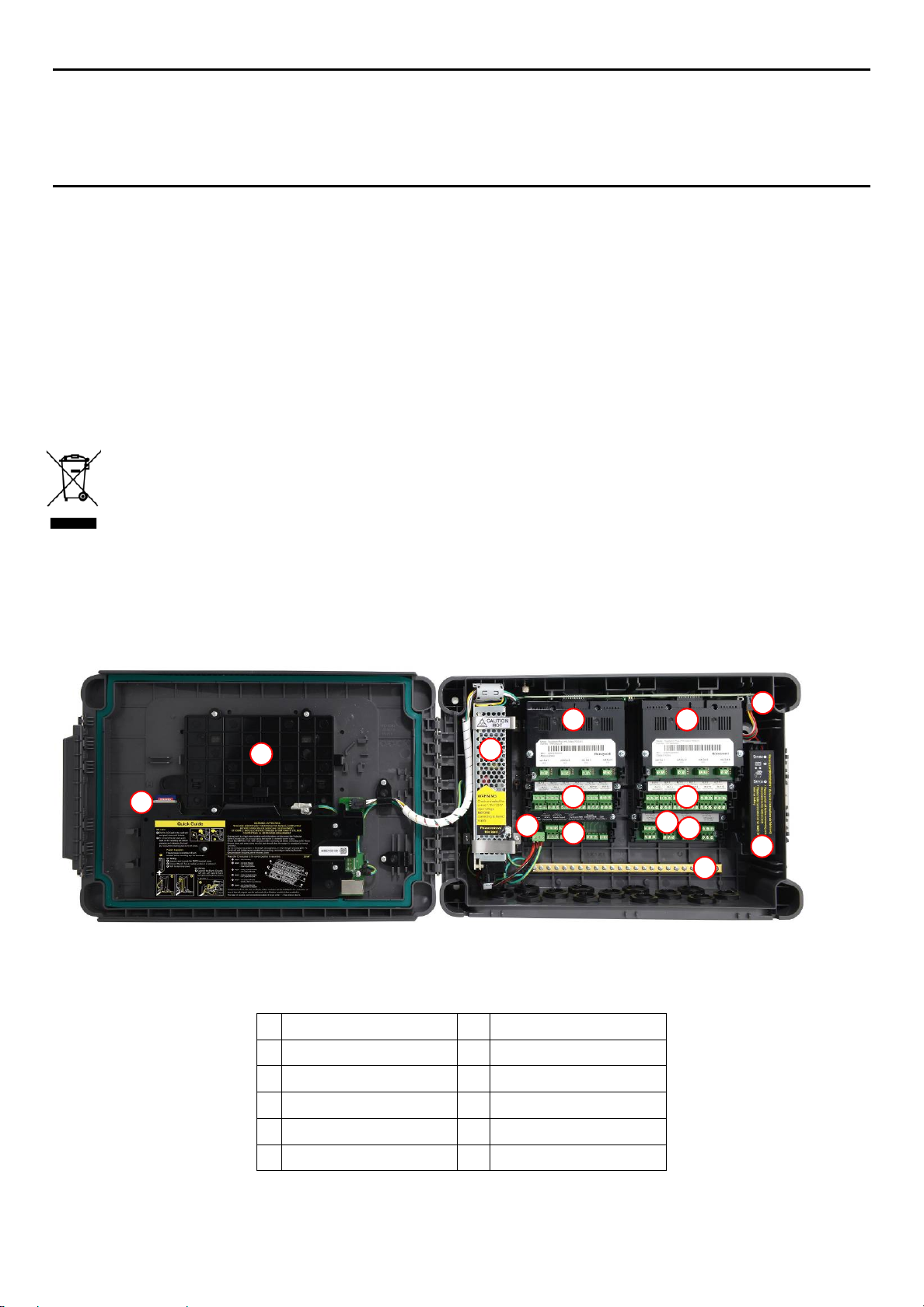

3.2 System Construction

This figure shows the basic building blocks of the Touchpoint Plus system. The optional Expansion Unit will

not have any of the items seen on the left hand (door) panel.

1

2

3

4

5

6

Figure 9. System Layout Before Installation

Touchscreen

SD Card

SMPS

mA Output Modules

Relay Output Modules

Power Terminal

7

Main Module

8

mA Input Modules

9

mV Input Modules

10

Earth (Ground) Bus Bar

11

Battery On / Off Switch

12

Backup Battery

17

Page 24

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

System Mechanical I nst all at ion

Chapter 4 – System Mechanical Installation

The system can be directly wall-mounted or on an optional mounting fixture. Whichever method is chosen, the

mounting must be sound, secure, and capable of supporting the weight of the enclosure plus the weight of

any cables and glands.

When choosing a location, it must be easily visible and accessible, with room to mount an external power

isolator. There must also be room to fully open the access door, which opens to the left, and room to easily

access the door locking handle and its securing screws, which are situated on the right. If using the expansion

unit (available late 2015), there must be room to mount both boxes side-by-side with space between them to

access the locking handle and its securing screws.

The units should be mounted so that the screen can be easily accessed and seen, but they should not

obstruct accesses, walkways or exits.

Although the units are IP65 when installed correctly, they should be mounted away from heat sources, out of

direct sunshine, and should be protected from rain, severe weather, steam or excess humidity and

condensation.

These units have only passive cooling, so an adequate airflow must be maintained to prevent overheating.

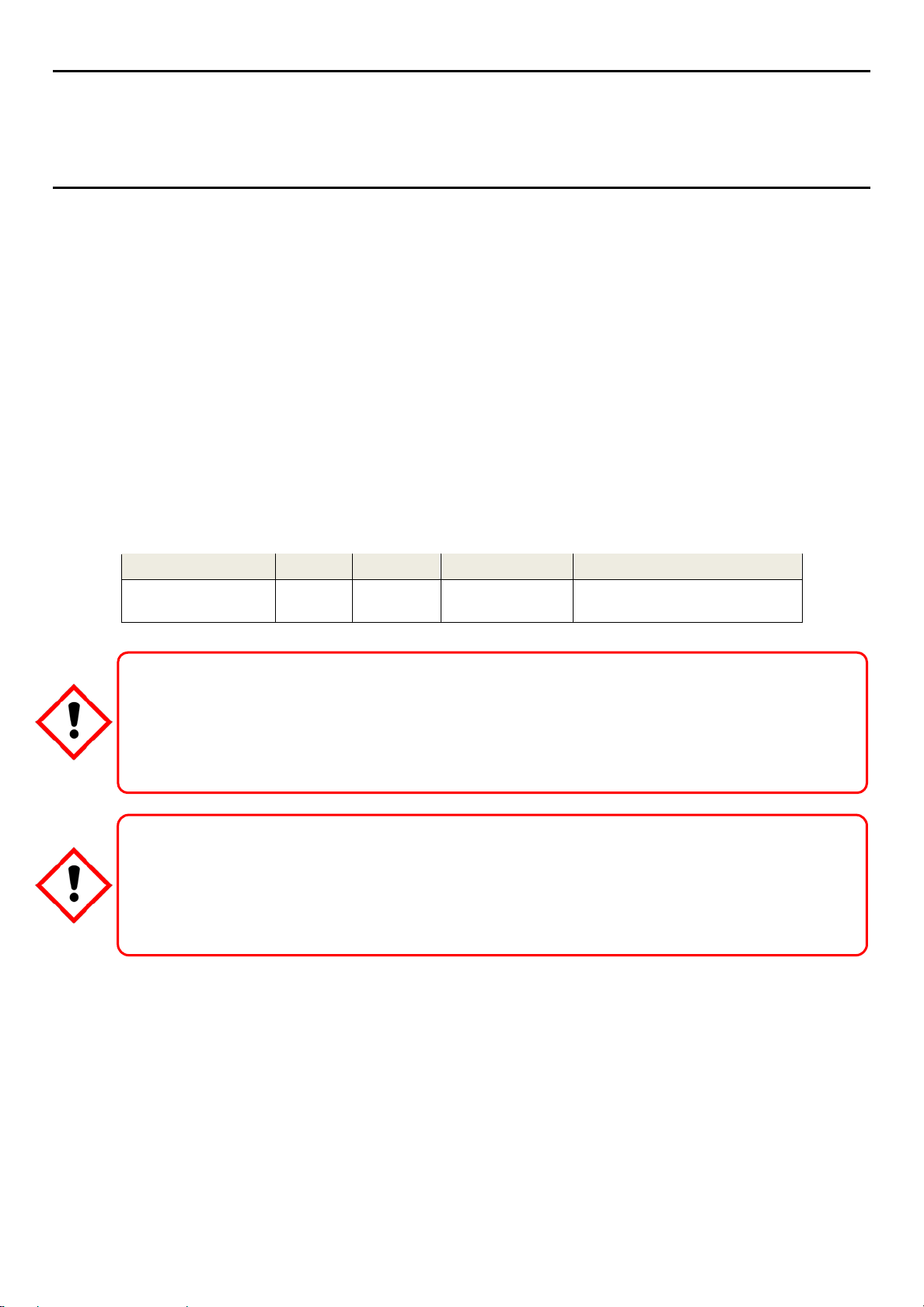

Assembly IP NEMA Pollution Degree Remarks

Wall mounted cabinet 65 4X 2

It is the Customer’s responsibility to ensure that the equipment is correctly installed, and that cable entry glands

Failure to do so will invalidate the quoted IP / NEMA / Pollution ratings and may invalidate the warranty.

The units as supplied have two hex-socket securing screws in the access door handle, and these have to be

undone prior to opening the handle. Failing to do so could cause irreparable damage to the housing.

The handle must be correctly locked and the screws must be correctly tightened when the unit is in operation.

Failing to fully secure the enclosure is unsafe and will invalidate product certification.

or blanks of the appropriate IP rating are correctly used.

Caution

Caution

When properly installed using the

appropriate cable entry glands

18

Page 25

MAN0984_Iss 2_06/15 Touchpoint Plus

1 2 3

Technical Handbook

System Mechanical I nstallation

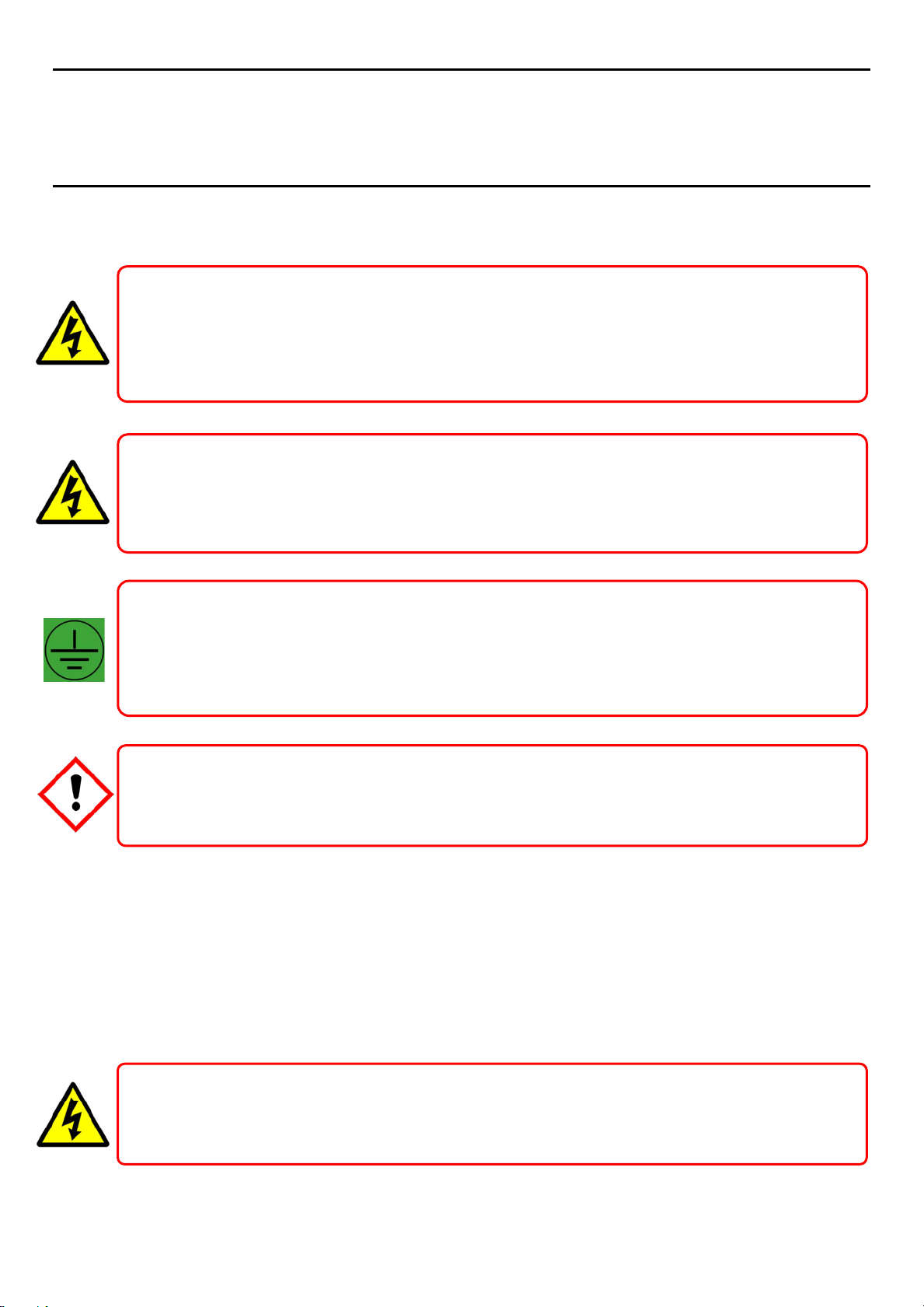

4.1 How to Open and Close the Enclosure

1) Ensure that it is safe to open the enclosure and, if necessary switch off and isolate electrical power.

2) Unscrew the two 3mm Hex socket security screws (1) until they become loose (2).

3) With a gloved hand only, pull the handle until it comes free (3). Do not apply undue force.

4) Open the enclosure door fully.

Figure 10. Undoing the Security Screws and Opening the Enclosure

5) Closure is the reverse of this procedure, but care must be taken not to exert undue force, and you must

not press on the membrane or touch screen areas.

Note: The door recess has an environmental seal that requires some pressure to close the door correctly.

The enclosure handle is the primary method of applying this pressure but you can assist it by pressing on the

door edge directly above the handle as you press on the handle itself.

19

Page 26

MAN0984_Iss 2_06/15 Touchpoint Plus

Minimum Wall

Clearance 175.5 mm

Minimum Wall Clearance 100 mm

Technical Handbook

System Mechanical I nstallation

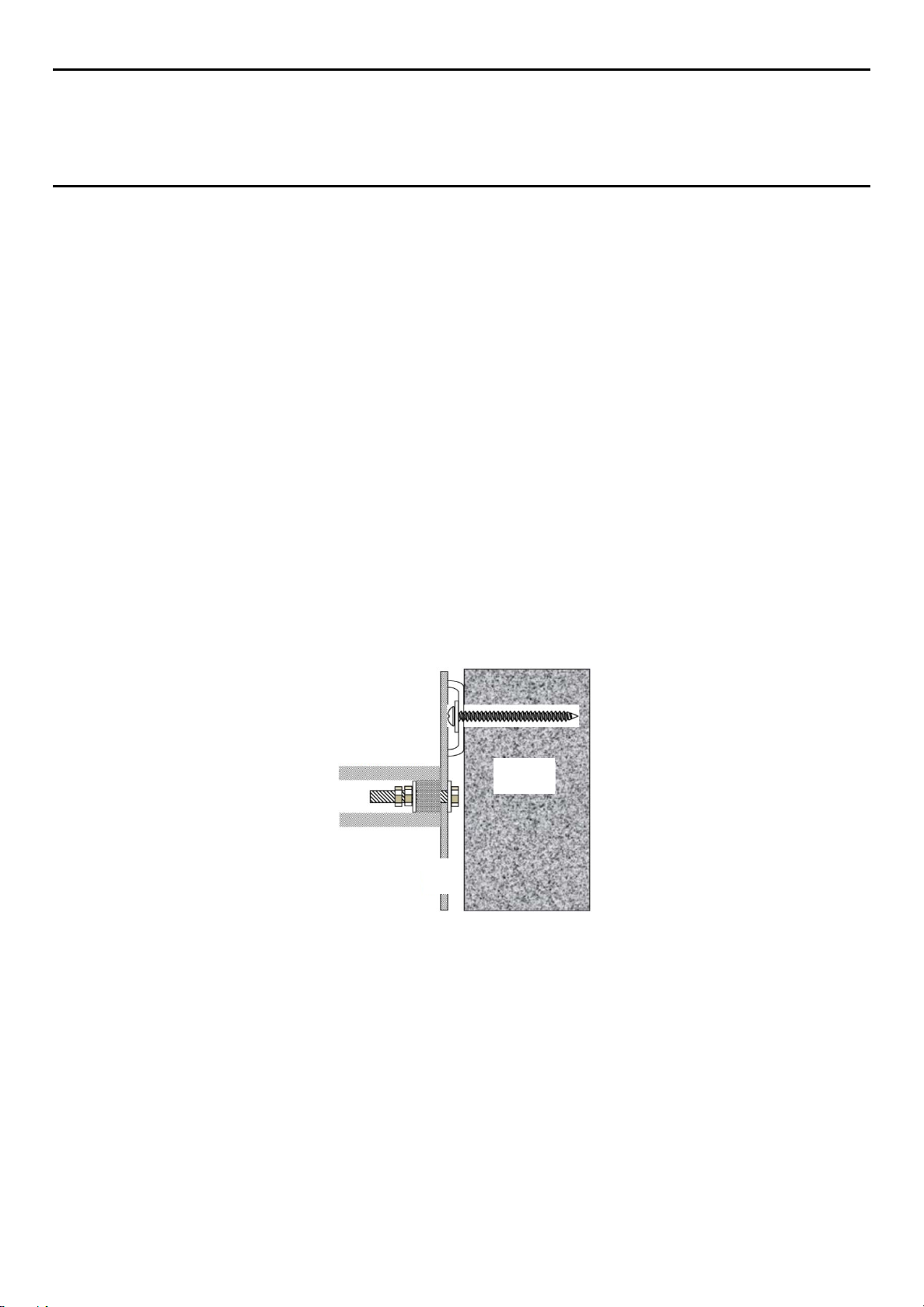

4.2 Wall Mounting Requirements

Minimum Ceiling Clearance 20 mm

Figure 11. Installation Clearance Measurements

Figure 12. Wall Mounting Template

Figure 13. Wall and Plate Mounting Points

You can use the wall mounting plate as its own template and location guide, and you should ensure that the

mounting bolts are adjusted to fit the plate bayonet holes before fixing the plate to the wall.

20

Page 27

MAN0984_Iss 2_06/15 Touchpoint Plus

Enclosure Corner

Plate

Technical Handbook

System Mechanical I nstallation

4.2.1 Wall Mount Fixings

You will require the following locally sourced items to install the Touchpoint Plus:

Tool to undo the enclosure access handle security screws:

• 3 mm Hex key

Suggested Fixings to screw the enclosure to the wall only:

• Screw Max. Dia: 6.4 mm (#14) dome or cheese head screw

• Screw Min. Length: 76 mm (3 in.) – Normal fix

• Washer Max. Dia: 14.3 mm (0.56 in.)

Note: The sizes above are given to allow for clearance in the TPPL Enclosure. The actual length and type of

fixing should be determined by the surface material and the type of anchor required.

Suggested Fixings for using the Mounting Plate:

For the plate, choose fixings appropriate to the surface and the weight of the enclosure plus cables. You will

also need to use suitable bolts, washers and lock nuts (see diagram below).

Ideally you will mount the enclosure and cables on a ≥20 mm ply board to allow cable troughs to be used.

Figure 14. Fixing Orientation When Using the Optional Mounting Plate

Wall or

Board

Note:

You should ensure that washers between the TPPL enclosure and the wall or mounting plate are sufficiently

large to spread the load evenly.

• For metal conduit, use a metal ground plate (i.e. Part No: TPPLOMGND).

• For external visual/audio outlet, ensure IP65 is maintained (i.e. Part No: M-700123).

• For cable gland, use type PG16 and tighten to 44.2 lb-in torque.

21

Page 28

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Electrical Pow er And Inter f acing

Chapter 5 – Electrical Power Connection and Interfacing

All power supplies must be hard wired and must include a circuit breaker (RCD / RCCB), and (close by and

unobstructed) a means of manually isolating and locking out the power supply without breaking the protective

Removable plug and socket connection is not permitted under any circumstance.

Lethal current may be present in this equipment when electrical power is applied. There is a danger of death or

injury from electrical shock. Isolate power before opening electrical access panels. Ensure residual current is fully

Lethal current may be generated both internally and externally to the system. All installations, including remote

units and cables, must be connected to protective earth, and must be capable of remaining so when the power

Honeywell can accept no responsibility for any damage or injury caused by incorrect or faulty wiring.

It is the custo me r ’s r esponsibility to provide appropriate power supplies to the TPPL and detectors.

Warning – Electrical Shock Hazard

earth (ground) connection.

Warning – Electrical Shock Hazard

discharged before touching live terminals.

Warning – Electrical Shock Hazard

supply is interrupted.

Protective earth is shown by the green sym bol on the left.

Warning

5.1 Power Connection

The TPPL systems are factory set to operate at a manually switchable voltage of AC 110/220 V on single

phase, 50 to 60 Hz supplies. They can also be connected to DC 18 – 32 V SELV without backup battery or

DC 24 – 32 V SELV if using the backup battery option.

All systems have a typical peak power consumption of less than 105 W, and must be directly connected to

supplies via a Main Isolator Switch that leaves protective earth (ground) permanently connected. The circuit

should incorporate a Residual Current Device or Residual Current Circuit Breaker (RCD or RCCB).

TPPL systems are not certified for connection to domestic power supplies.

The system is normally supplied with the voltage pre-set to the customer’s specifica ti o n . If the supplied voltage is

22

incorrect, it must be altered prior to connecting to the mains power supply.

Warning

Page 29

MAN0984_Iss 2_06/15 Touchpoint Plus

AC Line

AC Common

F – Ground (Not Us ed)

AC Input

DC Output

-Ve DC

-Ve DC

+24 VDC

+24 VDC

+24 V DC In

Ve DC Return

Earth (Ground)

Protective

System Ground Bus Bar

Technical Handbook

Electrical Pow er And Inter f acing

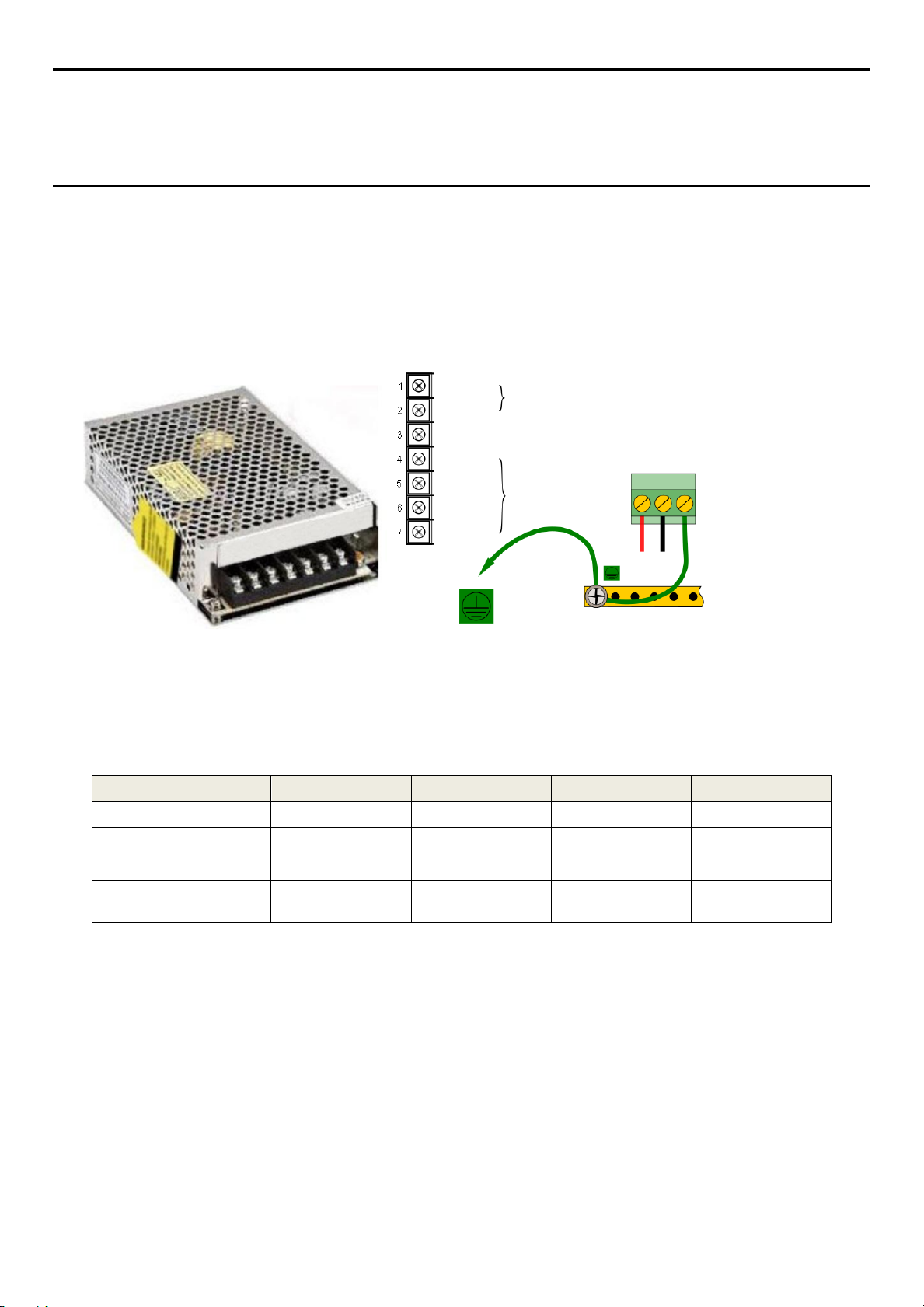

5.1.1 AC Power Supply

To confirm or alter the pre-set operating voltage, open the system front cover, locate the SMPS transformer

on the left side and, if required, change the voltage selector using a screwdriver at the point shown by the

yellow and black label below:

Figure 15. Switched Mode Power Supply (SMPS) Connections

Earth

(Ground)

-

Note: Mains Earth (Ground) must only be connected to the protective earth (ground) rail, and not to the

SMPS.

Regional power cable wires are colored in accordance with the following code:

Wire Europe USA CAN India/Pakistan

Protective Earth (Ground) Green + Yellow Green Green Green

Isolated Earth (Ground) — Green + Yellow Green —

Neutral Blue White White Black

Line Brown Blue, Red, or Black Red or Black

Red, Yellow, or

Blue

Table 5. Regional Power Cable Colors

Before making any electrical connections or changes ensure that:

• the mains supply isolator switch is in the Off position

• the system is set up to operate at the correct voltage

Refer to Ch. 3.1.1 Power Requirements for further information on system electrical specifications.

Note 1: Input voltage of less than DC 23.5 V will fail to charge the backup battery, and it will generate a

“battery unchargeable” warning message.

Note 2: Field detectors may need their own power supplies if they exceed 15 W per channel or a combined

total of 40 W. Refer to Table 7: mA Input Module Connections for further information.

23

Page 30

MAN0984_Iss 2_06/15 Touchpoint Plus

will be reduced if the charging supply is <24 V.

+24 V DC In

-Ve DC Retur n

Earth (Gr ound)

Technical Handbook

Electrical Pow er And Inter f acing

5.1.2 DC Power Supply

It is possible to power the Touchpoint Plus controller directly from a DC 18 – 32 V supply without using AC

supplies at all. However, batteries alone may quickly drop below the minimum DC 18 V requirement when

under load.

Note: The system must still be connected to protective earth (ground) when using an external DC supply.

Protective

Earth

(Ground)

System Ground Bus Bar

Figure 16. Connections for DC 24 V Supply

5.1.3 Backup Battery Pack

The Touchpoint Plus can have an optional rechargeable 24 volt Lithium-Ion Battery Pack. This would normally

be charged by the SMPS, but can be charged by a separate DC 23.5 – 32 V supply.

Note: The backup battery requires minimum 24 V input to fully charge, and it has a non-replaceable 15 A

over-current protection fuse so do not exceed 32 V, 5 A charging input.

DO NOT USE WATER as this can cause them to burn violently or they may explode.

The battery should be charged at DC 24 – 32 V. The backup battery will not be fully charged and the backup time

Danger

In the event of Lithium batteries overheating:

Important

24

Page 31

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Electrical Pow er And Inter f acing

5.2 Cabling Requirements

All cabling shall be appropriately rated and approved in accordance with national and local regulations.

Additionally, cabling must satisfy the requirements defined in the manuals of connected field devices, particularly

if the field device is certified for use in a hazardous location.

Signal cables should be shielded to avoid spurious signals, and shall be bonded to prot ective earth (Ground).

5.2.1 AC Mains Voltage Power Cables

Care must be taken to avoid Ground feedback loops.

Warning

Use a properly rated AC power (mains) cable, certified and installed in accordance with local and national

regulations. The Touchpoint Plus terminals will accept only copper wire sizes in the range 0.4 – 4 mm2 (solid

core), 0.4 – 3 mm2 (stranded core), or 21 – 12 AWG (T

1.35 Nm (11.9 lb-in).

5.2.2 DC Power Cables

Use a properly rated DC power (mains) cable, certified and installed in accordance with local and national

regulations. The Touchpoint Plus terminals will accept only sizes 0.9 – 3.3 mm2 (solid or stranded copper

cores), or 18 – 12 AWG (T

5.2.3 Field Device Cables

Field Device cabling (sensors, lights, solenoids, etc.) should be appropriate to the zone classification, and in

accordance with the device manufacturer’s recommendations. Refer to local and national regulations where

appropriate, and to the device user manual.

All sensor field cables must be screened and earthed (grounded) in order to:

• ensure correct operation of the system

• avoid spurious signals

• provide lightning protection

• Meet European Standards for RFI and EMC

The I/O modules will accept only copper wire sizes to a maximum of 2 mm² or 14 – 30 AWG, with the

terminals torqued to 0.5 Nm (4.4 lb-in).

Ensure that the maximum loop resistance is not exceeded, as specified by the device manufacturer.

Ensure that the correct power level is present at the field device, as specified by the device manufacturer, and

does not exceed the TPPL supply limit of 15W per channel individually or 40 / 68 W in total. (See the notes

under 5.2.5 Main Module Connections for more details about power consumption and availability.)

I.e. if a device’s supply requirement is 24 VDC 0.5 A, then the power requirement is 24 V x 0.5 A (V x I) = 12

W. If you use 240m of AWG 22 cable (R = 0.05 Ω/m), the power line dissipation is 0.05 Ω/m x 240m x 0.52 A

(R x I2) = 3 W. Therefore the total power requirement is 15 W (12 + 3).

You should also test the cable resistance in situ as its actual resistance is relative to T

any added end of line (EOL) resistance).

>80 °C). The mains terminals should be torqued to

amb

>80 °C). The mains terminals should be torqued to 0.5 Nm (4.4 lb-in).

amb

(taking into account

amb

25

Page 32

MAN0984_Iss 2_06/15 Touchpoint Plus

AC Line

AC Common

+24 V DC

DC Return

Earth (Gr ound)

+24 V DC

DC Return

Earth (Gr ound)

AC Line

AC Common

Ground

Ve DC

Ve DC

+24 VDC

+24 VDC

Touchpoint Plus Controller

Optional Expansion Unit

Technical Handbook

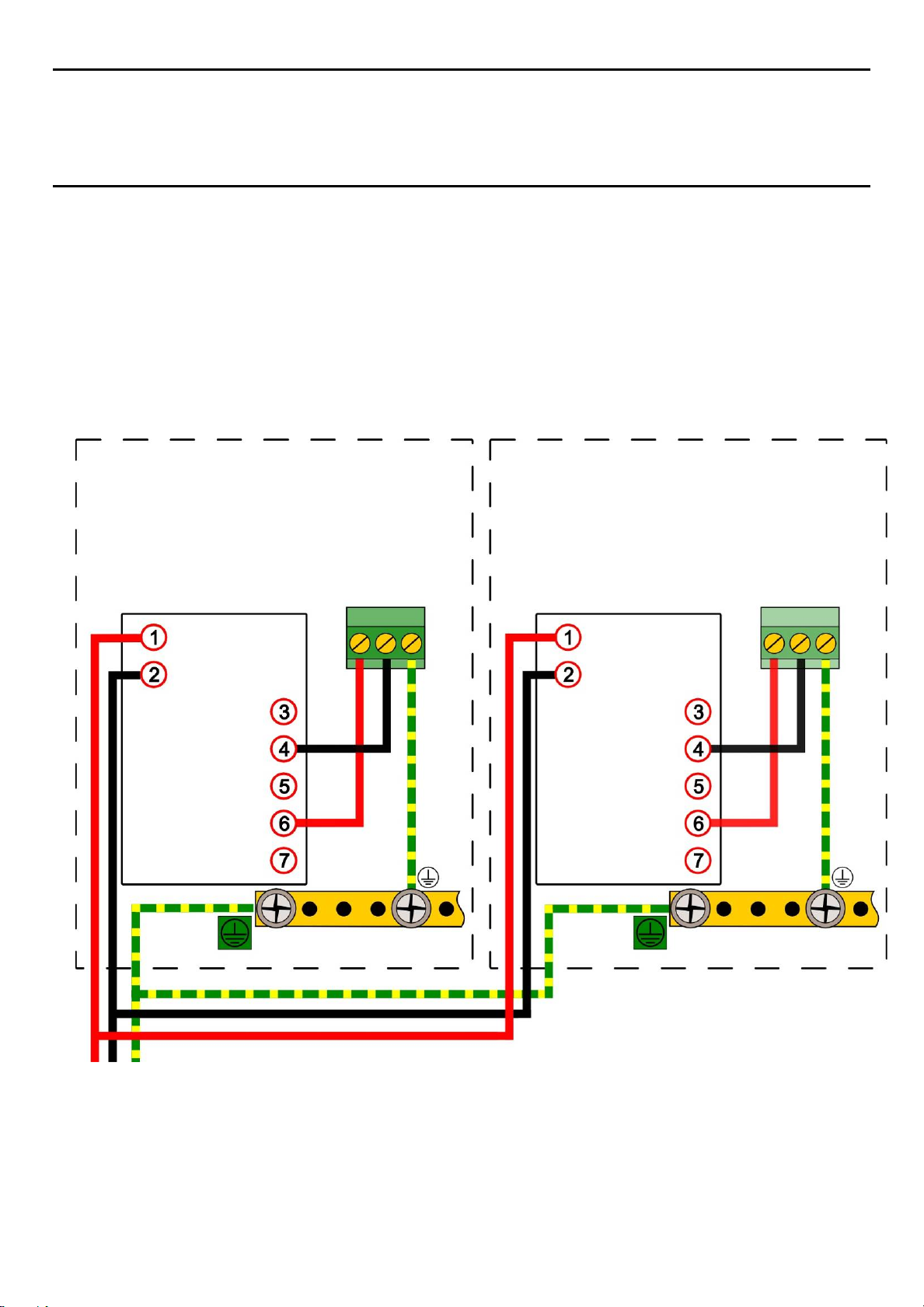

5.2.4 Optional Expansion Unit Connection (available late 2015)

Electrical Pow er And Inter f acing

In general, the expansion unit should have the same cabling and similar power requirements as the

Controller:

• 2-core cable plus Earth

• Shielded signal cables

• <10 meters from the controller

• avoid Earth (Ground) loops

The SMPS can deliver 150 W maximum, however a basic unit and an expansion unit each need 105 W so

must be wired as shown below when using AC Mains input.

F-Ground

-Ve DC

-Ve DC

+24 VDC

+24 VDC

Ground Bus Bar

Note: The SMPS is attached to chassis ground and does not need a separate ground connection.

Figure 17. Connecting the Touchpoint Plus and Optional Expansion Unit to a Mains Supply

–

F-

-

-

Ground Bus Bar

–

26

Page 33

MAN0984_Iss 2_06/15 Touchpoint Plus

Technical Handbook

Electrical Pow er And Inter f acing

5.2.5 Main Module Connections

Input / Output Field device Label Terminal

24 VDC +DC 1

Power

Channel Relay 001

(Alarm, Fault, Warning Or Inhibit)

Channel Relay 002

(Alarm, Fault, Warning Or Inhibit)

System Relay 003

(System Failure)

Dedicated Alarms

(Max 300 mA per channel)

External Alarm Power

GND –DC 2

Earth

— NC 4

— COM 5

— NO 6

— NC 7

— COM 8

— NO 9

— NC 10

— COM 11

— NO 12

Visible

Audible 1 A1 16

Audible 2 A2 17

Audible 3 F 18

— +24 VDC 19

— +24 VDC 20

— +24 VDC 21

Common 3.3 V 22

–

+24 VDC 13

VIS 14

Unused 15

3

Remote Inputs (Note 4)

Expansion Unit Connection

Table 6. Main Module Connections

Reset R1 23

Inhibit R2 24

CAN_High CAN_H 25

CAN_Low CAN_L 26

Note 1: +24 VDC Nominal = Controller Input (18 to 32 VDC) – 1.8 VDC (the max voltage drop in the TPPL).

Note 2: Alarm Terminals 13, 19, 20, and 21 can supply +24 VDC at ≤ 28 W combined but this 28 W can

instead be used to increase the power available to field sensors if external audible and visible alarms are not

connected.

I.e. the 8 sensor channels would normally have ≤40 W of combined available power, but this can be increased

to 68.8 W if terminals 13 – 21 are unused.

Note 3: You must supply sensors with external power if more than 40 / 68 W total power is required (See

Note 2).

Note 4: Maximum R

resistance for a remote reset/inhibit switch is 18 Ω, i.e. ≤500 m of 1 mm2 shielded

loop

cable.

27

Page 34

MAN0984_Iss 2_06/15 Touchpoint Plus

Touchpoint Plus

Main Module

Open

Drain

R Load

Touchpoint Plus

Main Module

Reset

(NO non-latched Sw.)

Inhibit

(NO latched Sw.)

Technical Handbook

Electrical Pow er And Inter f acing

Figure 18. Dedicated Alarm Circuit Connections

Figure 19. Optional Remote Reset and Inhibit Switch Connections

Maximum R

resistance for a remote reset/inhibit switch is 18 Ω, i.e. ≤500 m of 1 mm2 shielded cable.

loop

It is the user’s responsibility to ensure that Remote Reset / Inhibit switches are guarded against unauthorised

Warning

access or tampering.

28

Page 35

MAN0984_Iss 2_06/15 Touchpoint Plus

Touchpoint Plus

mA Input Module

Sensor

Technical Handbook

Electrical Pow er And Inter f acing

5.2.6 mA Input Module Connections

Note: mA input channels are limited to 15 W per channel to a combined total of 40 W (68 W if Main Module

Terminals 13 to 21 are not used). Sensors requiring more than 15 W (i.e. IR-F9 (Max 28W) must have their

own power supplies.

mA Input Channel Field device Label Terminal

+24 VDC +DC 1

1

0 VDC –DC 2

4 – 20 mA signal Sig 3

+24 VDC +DC 4

2

3

4

5

6

7

8

0 VDC –DC 5

4 – 20 mA signal Sig 6

+24 VDC +DC 7

0 VDC –DC 8

4 – 20 mA signal Sig 9

+24 VDC +DC 10

0 VDC –DC 11

4 – 20 mA signal Sig 12

+24 VDC +DC 13

0 VDC –DC 14

4 – 20 mA signal Sig 15

+24 VDC +DC 16

0 VDC –DC 17

4 – 20 mA signal Sig 18

+24 VDC +DC 19

0 VDC –DC 20

4 – 20 mA signal Sig 21

+24 VDC +DC 22

0 VDC –DC 23

4 – 20 mA signal Sig 24

Table 7. mA Input Module Connections

Figure 20. Three Wire Device Powered by a mA Input Module