Page 1

Series TMVL

THERMOSTATIC EXPANSION VALVES

INTERCHANGEABLE ORIFICE CARTRIDGE, SEPARATE SOLDER BASE

PRODUCT DATA

Features

• Only one valve body necessary for internal and

external pressure equalisation. Connection for

pressure coupler is integrated in the solder base.

• TMVL: Valve body and solder base with internal

pressure equalisation; for single injection in

installations with one or more cooling circuits.

• TMVLX:Valve body and solder base with external

pressure equalisation; for optimal evaporation

effectiveness in all applications. Obligatory for

multiple injection by liquid distributors.

• Combi adsorber charge

The same valve can be used for different

refrigerants (see table on page 2)

Controller charge is high sensitive and responsive

thus lowest possible level of superheat can be

TMVLX-W

TMVLX-D

Application

Thermostatic expansion valves series TMVL are used in

general refrigeration and for original equipment.

Plants with one or more refrigerant circuits such as

refrigerated cabinets even with cramped mounting conditions,

ice and cream machines, milk cooling systems, cold stores,

air conditioning systems and heat pumps.

Materials

Body

Thermal head

Connection tubes

Copyright © 2009 Honeywell GmbH • Subject to change without notice EN0H-1902GE23 R0709

brass

stainless steel

copper

achieved

Charge is not sensitive to effects of temperature on

the capillary tube and valve head

Damping characteristic results in stable control

behaviour

• Suitable for systems with hot gas defrosting

• Adjustable superheat setting

• Solder connections

• Solder base available in two-way construction and in

angle construction

• Extreme durable due to stainless steel head and

stainless steel diaphragm welded using protective gas

• Interchangeable orifice cartridges

• Refrigerants: R134a, R401A, R12

R22, R407C, R407A, R422D

R404A, R507A, R402A, R407B, R502

R124, R227, R410A

Further refrigerants on request.

Specification

Nominal capacity range

Evaporating temp. range

Maximum pressure PS

Maximum test pressure PF

Max. ambient temperature

Max. bulb temperature

Static superheat

Length of capillary tube

Bulb diameter

0.52 to 22.4 kW R22

(small orifice graduation for

optimal control behaviour, interchangeable orifice cartridges)

see table on page 2

see table on page 2

see table on page 2

100 °C

140 °C

approx. 3 K

1.5 m

12 mm

Page 2

SERIES TMVL

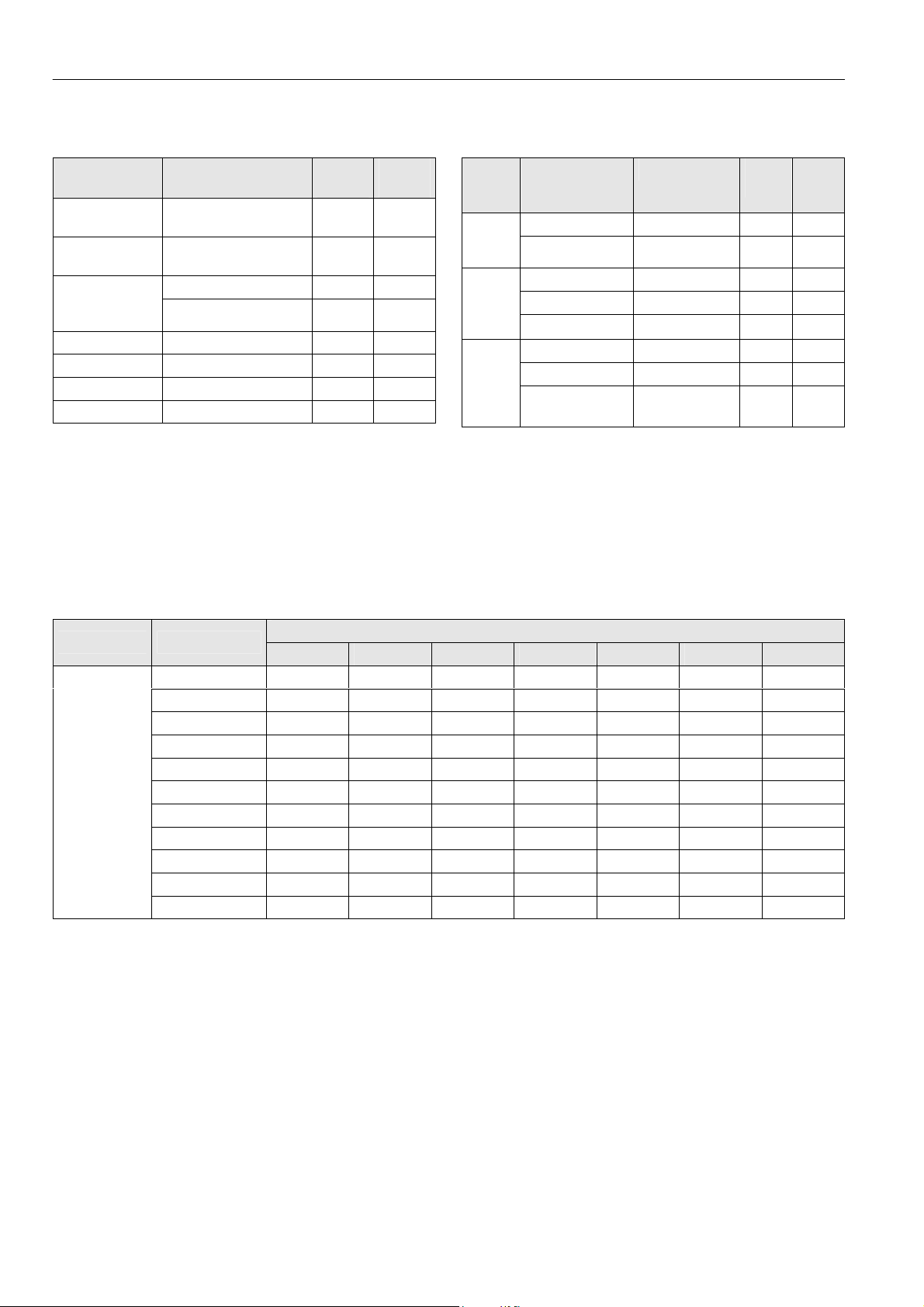

Thermal Charges and Temperature Ranges

1. Adsorber charge

Refrigerant

R134a, R401A,

R12

R22, R407C,

R407A, R422D

R404A, R507A,

R402A, R407B,

R502

R124 +20 °C to -30 °C 29 31.9

R227 +20 °C to -30 °C 29 31.9

R407C +15 °C to -30 °C 36 39.6

R410A +15 °C to -20 °C 40 44

Further refrigerants on request.

Thermal systems with adsorber charge are completely

insensitive to effects of temperature on the capillary tube and

valve head. It reacts only according to the temperature of the

bulb.

Thus, Honeywell TMVL valves with combi adsorber charge

work absolutely reliable, even in icy condition or while

defrosting using hot gas.

Evaporation

temperature range

+15 °C to -30 °C 34 37.4

+15 °C to -45 °C 36 39.6

±0 °C to -50 °C 36 39.6

+15 °C to -30 °C 36 39.6

PS

(bar(a))

PF

(bar(a))

2. Adsorber charge with pressure limiting performance MOP

Refrigerant

R134a,

R401A,

R12

R22,

R407C,

R407A,

R422D

R404A,

R507A,

R402A,

R407B,

R502

Further refrigerants and MOP on request

Evaporation

temperature

range

+5 °C to -30 °C MOP A +15 °C 34 37.4

-10 °C to -30 °C MOP A ±0 °C 29 31.9

+5 °C to -45 °C MOP A +15 °C 36 39.6

-10 °C to -45 °C MOP A ±0 °C 29 31.9

-27 °C to -45 °C MOP A -18 °C 29 31.9

-10 °C to -50 °C MOP A ±0 °C 36 39.6

-20 °C to -50 °C MOP A -10 °C 34 37.4

-27 °C to -50 °C MOP A -18 °C 34 37.4

MOP PS

(bar(a))

PF

(bar(a))

Capacities

Type Orifice size

0.3 0.36 0.52 0.50 0.36 0.36 0.36 0.62

0.5 0.69 0.99 0.95 0.67 0.68 0.69 1.2

0.7 1.0 1.4 1.3 0.92 0.97 0.98 1.6

1.0 1.4 2.0 1.9 1.3 1.4 1.4 2.4

1.5 2.2 3.2 3.1 2.2 2.2 2.3 3.8

TMVL

* Capacities are based on t0 = +4 °C, tc = +38 °C and 1 K subcooled liquid refrigerant entering the valve.

For other operating conditions see capacity charts in Honeywell catalogue or consult the Honeywell software.

2.0 2.9 4.0 3.9 2.7 2.8 2.9 4.8

2.5 4.0 5.8 5.6 3.9 4.1 4.1 6.9

3.0 6.6 9.3 8.9 6.3 6.5 6.6 11.1

3.5 8.7 12.2 11.7 8.3 8.6 8.7 14.6

4.5 11.8 17.0 16.4 11.3 12.0 12.1 20.3

4.75 15.9 22.4 21.6 15.3 15.8 15.9 26.8

R134a R22 R407C R422D R404A R507A R410A

Nominal capacity (kW)*

EN0H-1902GE23 R0709 2 Honeywell GmbH • Subject to change without notice

Page 3

Dimensions and Weights

SERIES TMVL

Connections Type

Inlet

(A)

TMVL - - - approx. 0.43

6 mm ODF 10 mm ODF -

1/4" ODF 3/8" ODF -

VLS

angle construction

VLSX

angle construction

VLS

two-way construction

VLSX

two-way construction

10 mm ODF 12 mm ODF -

3/8" ODF 1/2" ODF -

12 mm ODF 16 mm ODF -

1/2" ODF 5/8" ODF -

6 mm ODF 10 mm ODF 6 mm ODF

1/4" ODF 3/8" ODF 1/4" ODF

10 mm ODF 12 mm ODF 6 mm ODF

3/8" ODF 1/2" ODF 1/4" ODF

12 mm ODF 16 mm ODF 6 mm ODF

1/2" ODF 5/8" ODF 1/4" ODF

10 mm ODF 12 mm ODF -

3/8" ODF 1/2" ODF -

12 mm ODF 16 mm ODF -

1/2" ODF 5/8" ODF -

10 mm ODF 12 mm ODF 6 mm ODF

3/8" ODF 1/2" ODF 1/4" ODF

12 mm ODF 16 mm ODF 6 mm ODF

1/2" ODF 5/8" ODF 1/4" ODF

Outlet

(B)

Pressure

equaliser (C)

Weight

(kg)

approx. 0.16

approx. 0.17

approx. 0.16

approx. 0.17

TMVL

VLS(X) - two-way VLS(X) - angle VD

Honeywell GmbH • Subject to change without notice 3 EN0H-1902GE23 R0709

Page 4

SERIES TMVL

Type Code / Order Information (Part Programme)

1. Valve body

TMVL R22 MOP A -18 °C

Series

Refrigerant

Adsorber charge with MOP

() = without MOP

2. Solder base

VLS X

Series

Pressure equalisation:

X = external

() = internal

Solder connection ODF

(inlet x outlet)

D = two-way construction

W = angle construction

3. Orifice cartridge

10 mm x

12 mm

W

Series

Orifice size

VD 0.5

Installation

• The valves may be installed in any position.

• The external pressure equaliser line should be 6 mm or

1/4" in diameter and is to be connected downstream of the

remote bulb. An overbow is recommended in order to

prevent the ingress of oil into the equaliser line.

• The bulb should preferably be positioned on the upper half

of a horizontal suction line but never after a liquid trap. As

a general rule, bulbs of expansion valves should be

insulated to prevent them being affected by the ambient

temperature.

• Do not bend or squeeze the bulb when tightening the bulb

clamp

• The screws fixing the valve body to the solder base must

be tightened in diagonal sequence (torque 12 Nm).

• Constructive modifications at the valve are not allowed.

• Never quench the solder base with water after soldering,

this may cause cracks and distort the sealing surfaces.

Superheat Adjustment

In general the Honeywell valves should be installed with the

factory setting for the used refrigerant unaltered.

At combi adsorber valves the label on the capillary tube

indicates how to adjust the adjusting spindle (with arrow for

direction), depending on the refrigerant used. This correction

of the adjustment is essential to ensure that the control

performance of the valve is correct. The refrigerant used must

be marked on the label.

This superheat adjustment is calibrated for lowest

superheating and optimum evaporator utilisation. However,

should it be necessary to adjust the superheat, turn the

adjusting spindle as follows:

Turning clockwise

Turning

counterclockwise

One turn of adjusting spindle alters superheat setting by

approx. 0.55 bar. Increase of superheat setting results in a

lower MOP-value and vice versa.

reduced refrigerant mass flow,

=

increase of superheat

increased refrigerant mass

=

flow, decrease of superheat

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

74821 Mosbach/Germany

Phone: +49 (0)

Fax: +49 (0)

62 61 / 81-475

62 61 / 81-461

Manufactured for and on behalf of the

Environment and Combustion Controls

Division of Honeywell Technologies Sàrl,

1180 Rolle, Z. A. La Pièce 16, Switzerland

by its authorized representative Honeywell GmbH

E-Mail: cooling.mosbach@honeywell.com

KAT-TMVL-002

www.honeywell-cooling.com

EN0H-1902GE23 R0709 4 Honeywell GmbH • Subject to change without notice

Loading...

Loading...