Page 1

Installation and Operations Guide

31-00098-01

TB3026B, TB3026B-W

© Honeywell 31-00098-01

Page 2

Important safety information and installation

!

precautions

Read all instructions

Failure to follow all instructions may result in equipment damage or a hazardous condition. Read all instructions

carefully before installing equipment.

Local codes and practices

Always install equipment in accordance with the National Electric Code and in a manner acceptable to the local

authority having jurisdiction.

Electrostatic sensitivity

This product and its components may be susceptible to electrostatic discharge (ESD). Use appropriate ESD

grounding techniques while handling the product. When possible, always handle the product by its non-electrical

components.

High voltage safety test

Experienced electricians, at first contact, always assume that hazardous voltages may exist in any wiring

system. A safety check using a known, reliable voltage measurement or detection device should be made

immediately before starting work and when work resumes.

Lightning and high-voltage danger

Most electrical injuries involving low-voltage wiring result from sudden, unexpected high voltages on normally

low-voltage wiring. Low-voltage wiring can carry hazardous high voltages under unsafe conditions. Never install

or connect wiring or equipment during electrical storms. Improperly protected wiring can carry a fatal lightning

surge for many miles. All outdoor wiring must be equipped with properly grounded and listed signal circuit

protectors, which must be installed in compliance with local, applicable codes. Never install wiring or equipment

while standing in water.

Wiring and equipment separations

All wiring and controllers must be installed to minimize the possibility of accidental contact with other potentially

hazardous and disruptive power and lighting wiring. Never place 24VAC or communications wiring near other

bare power wires, lightning rods, antennas, transformers, or steam or hot water pipes. Never place wire in any

conduit, box, channel, duct or other enclosure containing power or lighting circuits of any type. Always provide

adequate separation of communications wiring and other electrical wiring according to code. Keep wiring and

controllers at least six feet from large inductive loads (power distribution panels, lighting ballasts, motors, etc.).

Failure to follow these guidelines can introduce electrical interference and cause the system to operate

erratically.

Warning

This equipment has been tested and found to comply with the limits for a class A digital device, pursuant to part

15 of the FCC rules. These limits are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference, in which case the user will be required to correct the interference at his own expense.

© 2016 Honeywell. All Rights Reserved.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of

your use, or modification to, the literature. You will defend and indemnify Honeywell, its affiliates and

subsidiaries, from and against any liability, cost, or damages, including attorneys’ fees, arising out of, or resulting

from, any modification to the literature by you.

Questions, corrections, or comments?

To improve our information products and better serve our readers, your feedback is vital. If you have any

questions, corrections, or comments about this publication or any other information products, please send e-mail

to WEBsSquad@honeywell.com.

2

31-00098-01 © Honeywell

Page 3

Contents

Installation and Operations Guide

About the BACnet FF 4

About this document and related publications 5

BACnet FF dimensions 6

Mounting guidelines 7

Installing the wallplate 7

Wiring the wallplate 8

Mounting the BACnet FF faceplate 9

Mounting a door/window sensor 9

Mounting a PIR occupancy motion sensor 11

Terminals and wiring 12

Power supply guidelines and requirements 14

BACnet FF power ratings 14

Selecting a transformer 14

Power supply grounding and wiring 14

Backup power 15

MS/TP LAN Wiring 16

Terminating MS/TP LAN cabling 16

Grounding the MS/TP LAN shield 17

Terminating resistors 17

Configuration 18

Adjusting the date and time 18

Setting the MAC address and device instance 18

Installer setup (ISU) codes 20

Pairing a sensor to a wireless BACnet FF 22

Fixed field service codes 24

Operational overview 25

Configuring a DDCMULTI application 27

Application Sequences and Configuration Settings 28

[AP] 0: Air-to-air heat pump 29

[AP] 1: Water-source heat pump 29

[AP] 2: Air-to-air heat pump 46

[AP] 3: Water source heat pump 46

[AP] 4: Air Conditioning Unit 63

[AP] 5: Air Conditioning Unit 79

[AP] 6: 4 Pipe Fan Coil Unit 96

[AP] 7: 4 Pipe Fan Coil Unit 112

[AP] 8: 4 Pipe Fan Coil Unit 128

[AP] 9: 4 Pipe Fan Coil Unit 146

[AP] 10: Air to Air Heat Pump 164

[AP] 11: 2 Pipe Fan Coil Unit 183

[AP] 12: 2 Pipe Fan Coil Unit 201

[AP] 13: 2 Pipe Fan Coil Unit with Change Over Control 219

[AP] 14: 2 Pipe Fan Coil Unit with Change Over Control 237

[AP] 15: 2 Pipe Fan Coil Unit 255

[AP] 16: 2 Pipe Fan Coil Unit with Change Over Control 272

[AP] 17: 4 Pipe Fan Coil Unit 290

[AP] 18: 2 Pipe Fan Coil Unit with Change Over Control 309

Appendix A: BACnet object and property reference 327

Appendix B: Ordered list of control points 343

Appendix C: Quick reference 347

Appendix D: Canadian conformance statements 348

Contents

|

© Honeywell 31-00098-01 3

Page 4

Installation and Operations Guide

|

About the BACnet FF

The Honeywell BACnet FF (models TB3026B and TB3026B-W) is a

communicating sensor/fixed application controller with built-in humidity sensor.

The TB3026B-W is the wireless version with an onboard wireless receiver for

wireless occupancy control.

Electrical inputs and outputs wire directly to field equipment. The BACnet FF

comes pre-loaded with nineteen applications that support common uses. These

applications can be selected and some of the parameters adjusted at the

controller without the need for a BACnet front end.

Operational information and control data is available to other building

controllers and systems through the BACnet protocol (ANSI/ASHRAE

standard). This enables a BACnet FF to share data and execute commands

initiated from other BACnet-compliant devices.

BACnet FF

4

31-00098-01 © Ho neywell

Page 5

Installation and Operations Guide

About this document and related publications

|

About this document and related publications

This document provides information about installing and wiring a BACnet FF to

equipment, power, and communication channels. It also shows how to operate

the user interface.

IMPORTANT Always install equipment in accordance with the National

Electric Code and in a manner acceptable to the local authority having

jurisdiction (AHJ). No guidelines, instructions, installation practices, or other

information presented in this guide may be interpreted to supersede or modify

the local codes and practices of the AHJ.

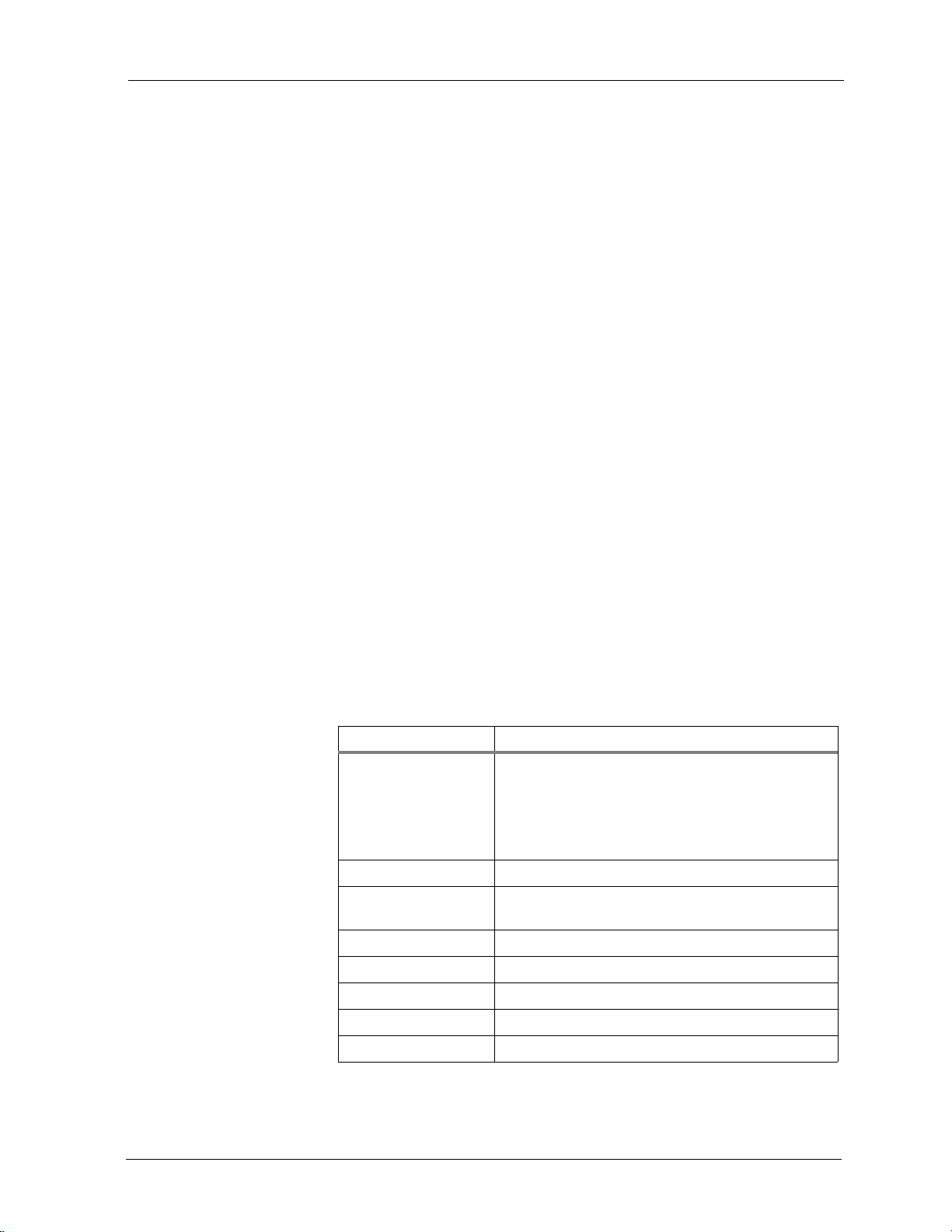

Ta bl e 1 Other documentation related to BACnet FFs

Document (ID) Contains

Installation Instructions (31-00093) Instructions on how to install, wire

and perform initial configuration for

the BACnet FF

Product Data

(31-00096)

WEBs-AX Configuration Wizard Guide

(31-00097)

Summary of capabilities and

specifications

Instructions on how to configure the

BACnet FF through the WEBs based

wizard

© Honeywell 31-00098-01 5

Page 6

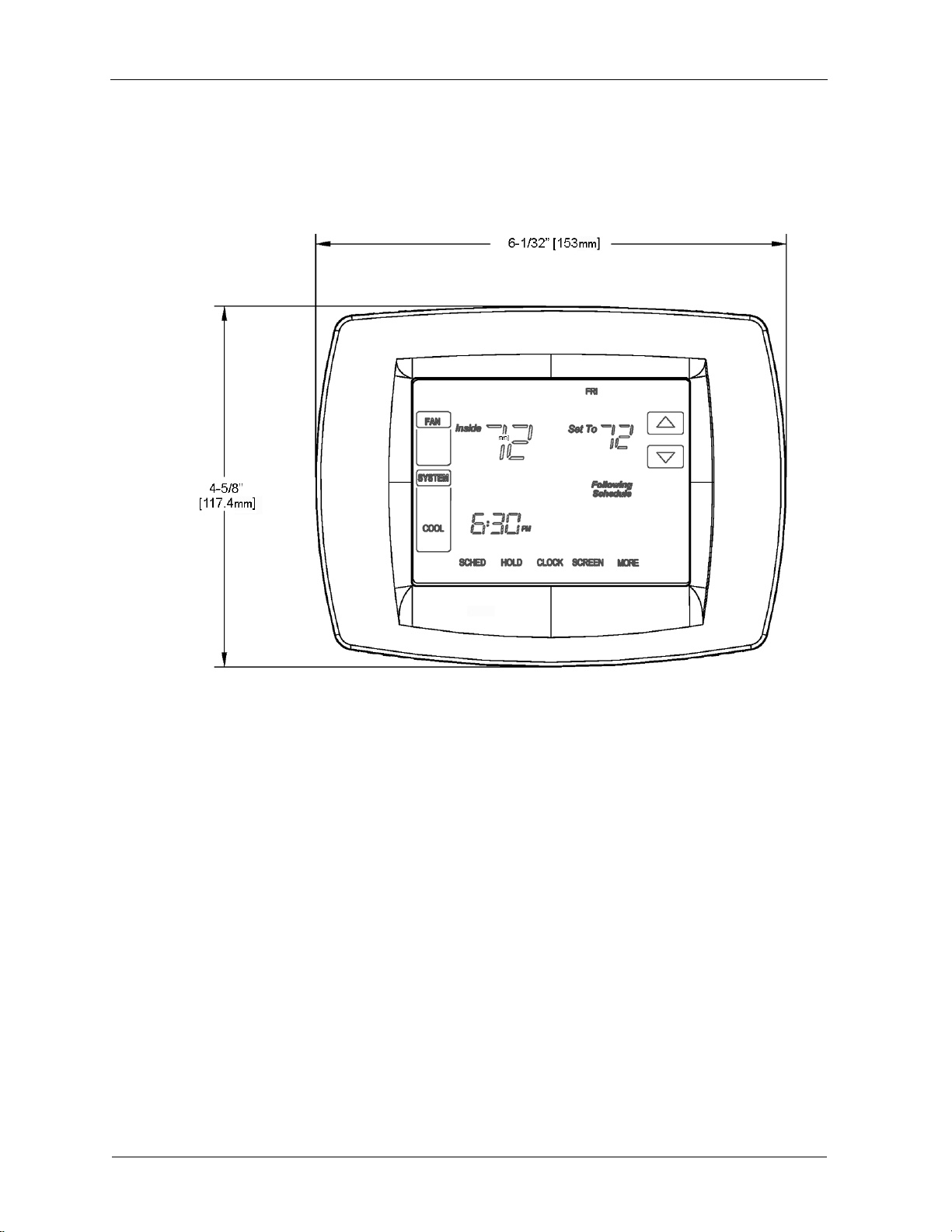

Installation and Operations Guide

BACnet FF

|

BACnet FF dimensions

The BACnet FF consists of a mounting plate and a circuit board with a plastic

cover. See the BACnet FF Installation Instructions (31-00093) for more

information.

Figure 1 TB3026B and TB3026B-W dimensions

6

31-00098-01 © Ho neywell

Page 7

Mounting guidelines

The BACnet FF is designed to be wall-mounted indoors, with dimensions ideal

for mounting to a single-gang electrical box.

Mount in a clean, dry location away from windows, air ducts, and other places

where environmental factors may affect temperature and humidity readings. If

you mount the BACnet FF on the interior of an outside wall, thoroughly insulate

so outside air behind the sensor does not affect the sensor reading.

To meet requirements of the Americans with Disabilities Act, mount no higher

than 48" from the floor and with a minimum clear floor space of 30" X 48" (760

X 1220 mm).

CAUTION Thoroughly read all instructions before mounting and wiring.

Always install equipment in accordance with applicable electric codes and the

instructions.

Installing the wallplate

The BACnet FF can be mounted horizontally on the wall or on a 4 in. x 2 in.

(101.6 mm x 50.8 mm) wiring box.

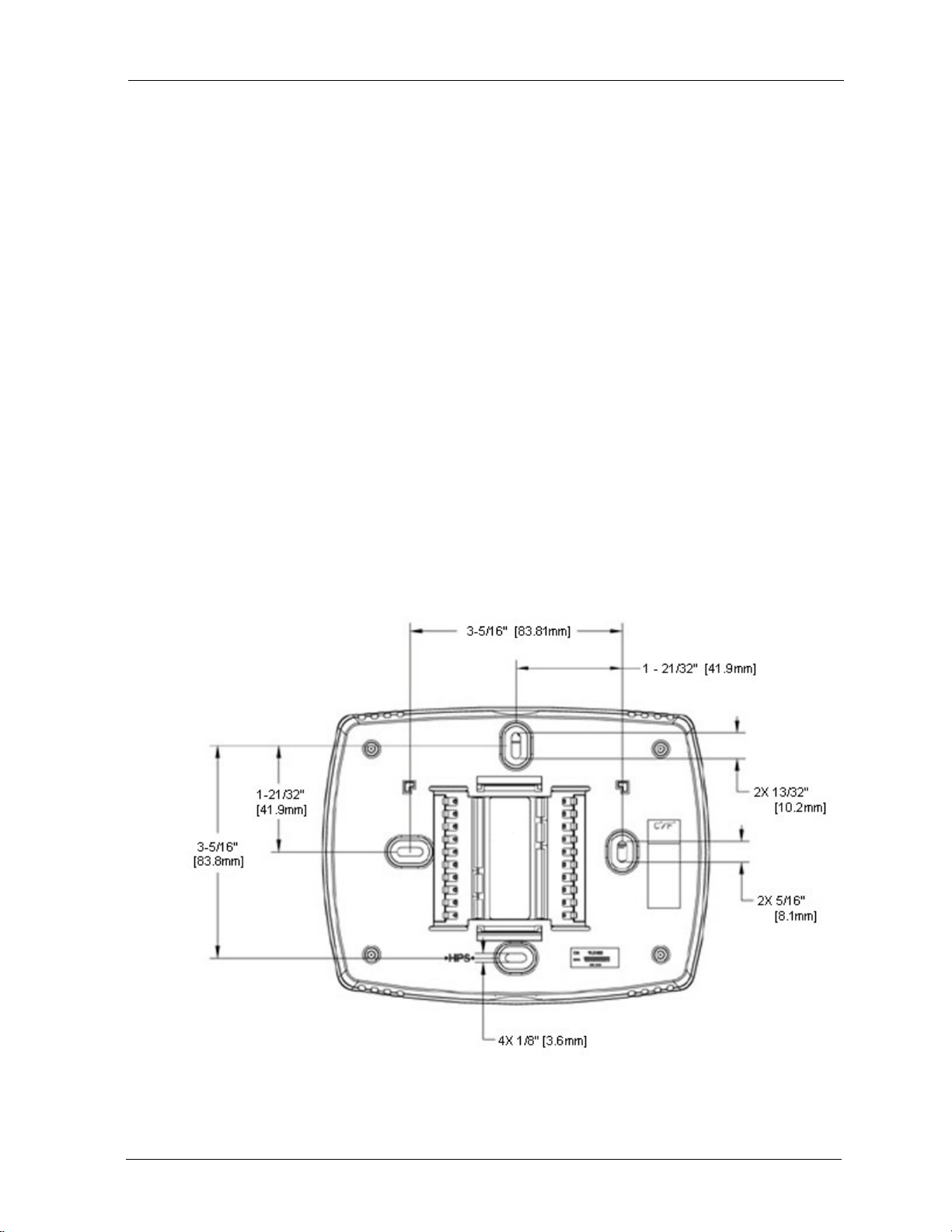

Installation and Operations Guide

Mounting guidelines

|

To install the wallplate

1. Position and level the wallplate (for appearance only).

2. Use a pencil to mark the mounting holes.

Figure 2 Wallplate dimensions

3. Remove the wallplate from the wall and, if drywall, drill two 3/16-in.

holes in the wall, as marked. For firmer material such as plaster, drill

© Honeywell 31-00098-01 7

Page 8

Installation and Operations Guide

Wiring the wallplate

CAUTION Disconnect power before wiring. Failure to do so may result in

electrical shock or equipment damage.

BACnet FF

|

two 7/32-in. holes. Gently tap anchors (provided) into the drilled holes

until flush with the wall.

4. Position the wallplate over the holes, pulling wires through the wiring

opening.

5. Insert the mounting screws into the holes and tighten.

To wire the wallplate

1. Connect wires to the terminal block using Figure 3 as a guide.

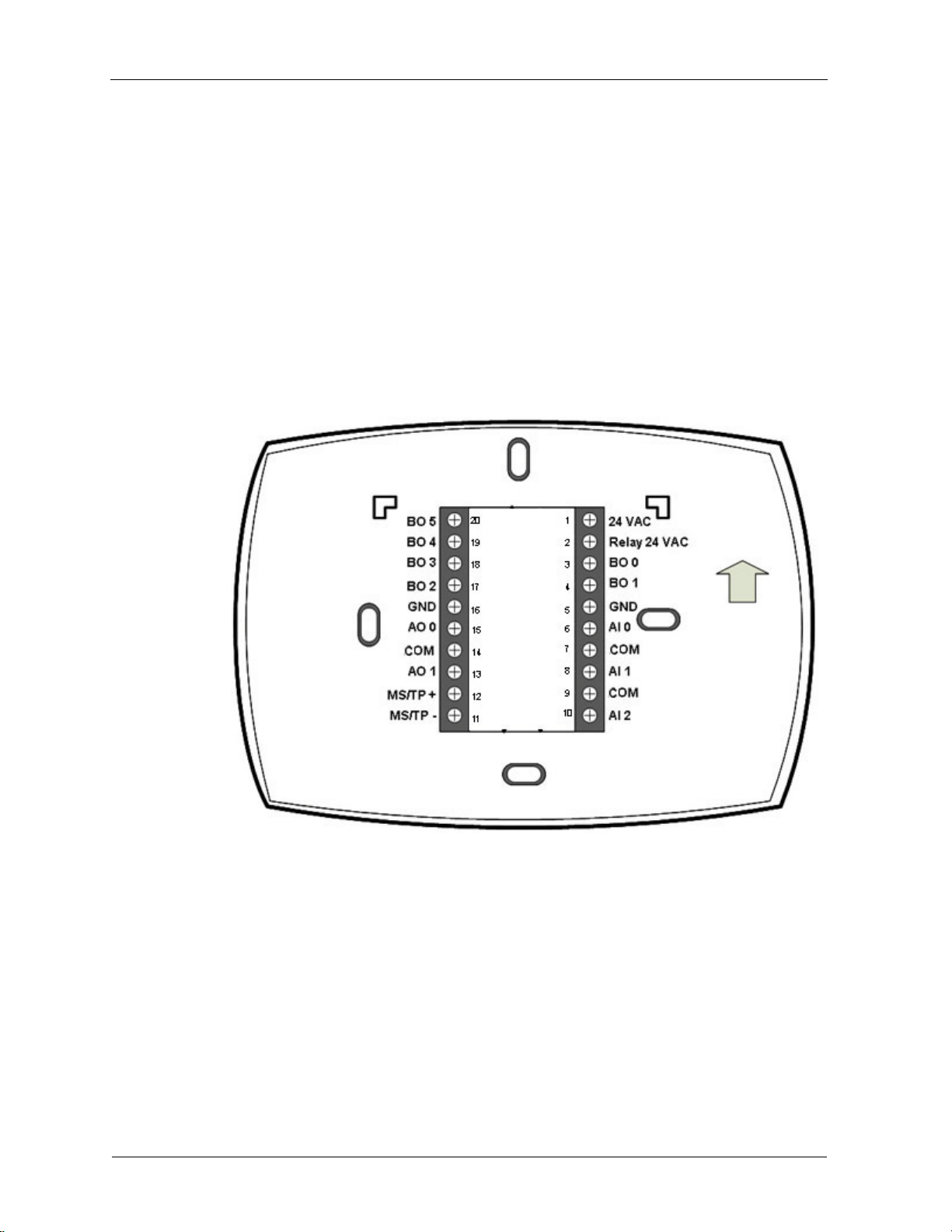

Figure 3 Terminal assignments and pin numbers

2. Securely tighten each screw.

3. Push excess wire back into the hole.

4. Plug the hole with nonflammable insulation to prevent drafts from

affecting the BACnet FF.

Note A jumper is pre-installed between pins 1 and 2 (24 VAC and

Relay 24 VAC). This supplies 24 VAC to BO 1, BO 3, and BO 4. It can

be removed if you want to power these inputs from a separate power

supply.

8

31-00098-01 © Ho neywell

Page 9

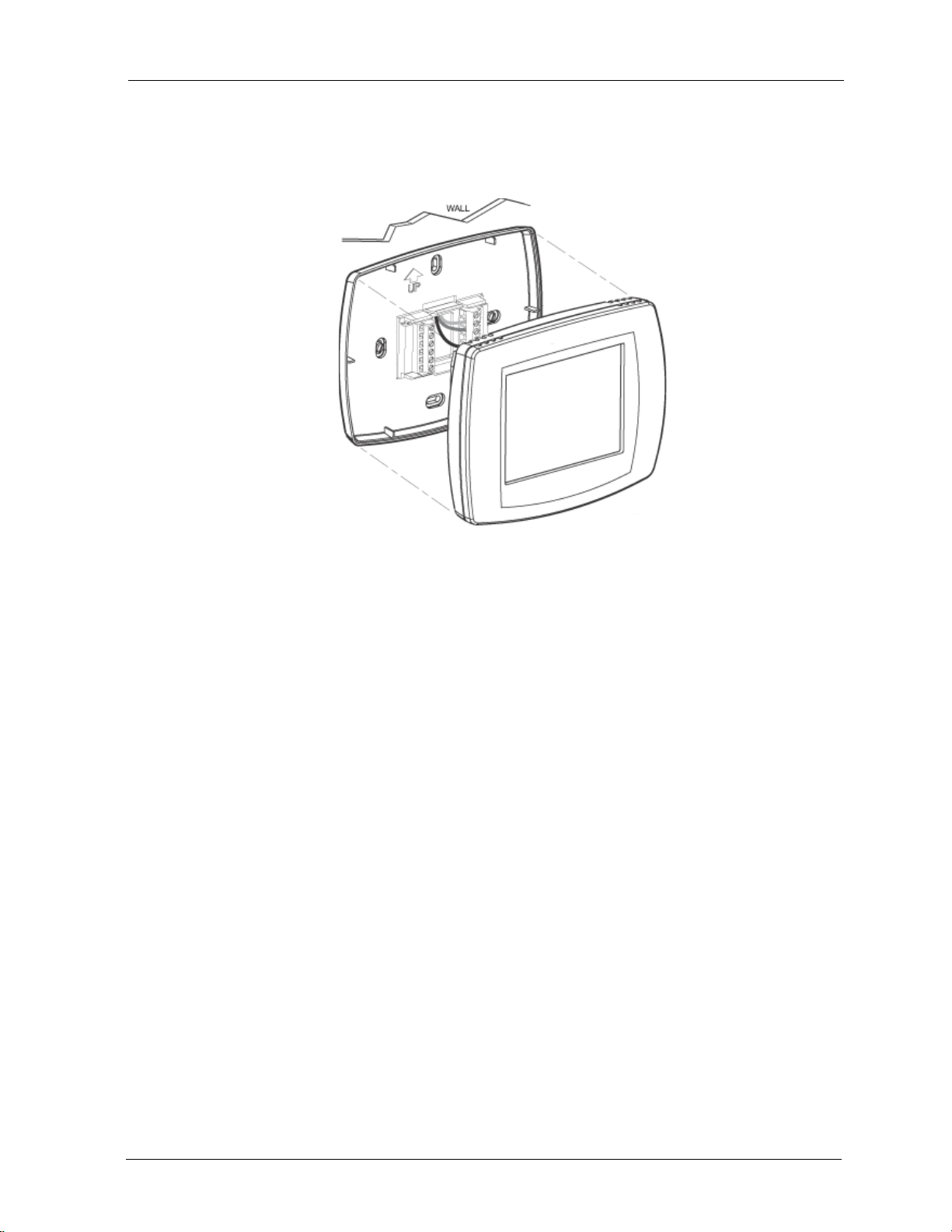

Mounting the BACnet FF faceplate

To mount the BACnet FF faceplate, align the terminal blocks with the pins on

the back of the BACnet FF and push the faceplate straight onto the wallplate.

Installation and Operations Guide

Mounting guidelines

|

Figure 4 BACnet FF faceplate mounting

Mounting a door/window sensor

These instructions apply to the primary door sensor and an optional second

door/window sensor, WSK-24.

Note The BACnet FF supports a maximum of 8 door/window sensors.

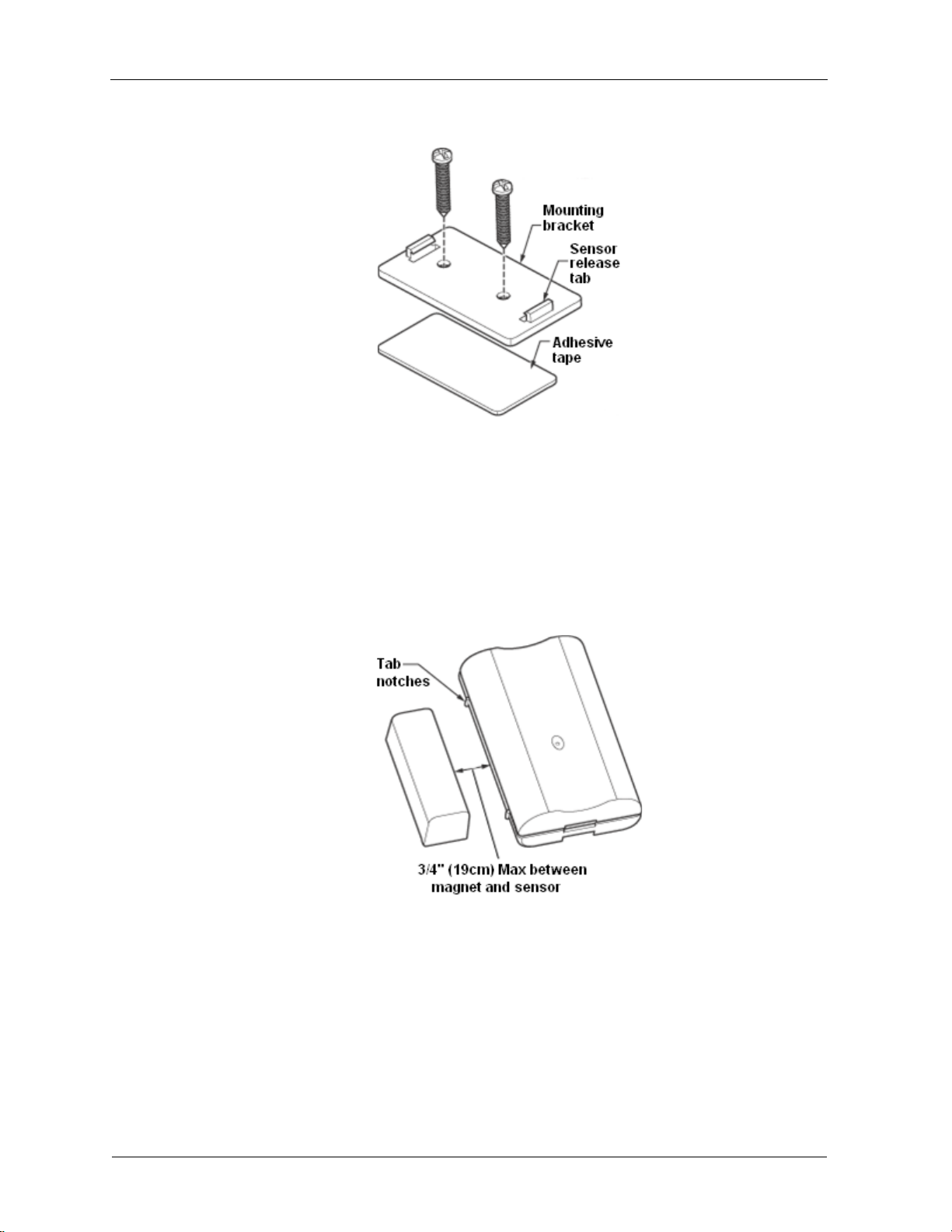

To mount a door sensor

1. Remove the battery tab.

Note Completely remove the battery tab or the BACnet FF will not

operate.

2. Remove the plastic mounting bracket from the door sensor housing.

3. Place the mounting bracket for the door sensor high on the frame of the

door. Secure the bracket to the door frame using the two screws or

adhesive tape provided.

© Honeywell 31-00098-01 9

Page 10

Installation and Operations Guide

BACnet FF

|

4. Door sensor bracket mounting

5. Make sure the notched side of the door sensor is pointing in the

direction that you will mount the magnet.

6. Snap the sensor into the mounting bracket.

7. Align one end of the magnet with the notched side of the door sensor

housing.

8. Mount the magnet a maximum of 3/4 in. (19 mm) from the door sensor.

Figure 5 Maximum distance between door sensor and magnet

9. Secure the magnet to the door by using the two screws or adhesive tape

provided. An optional spacer is provided.

10

10. Open and close the door to ensure that there is no interference.

31-00098-01 © Ho neywell

Page 11

Installation and Operations Guide

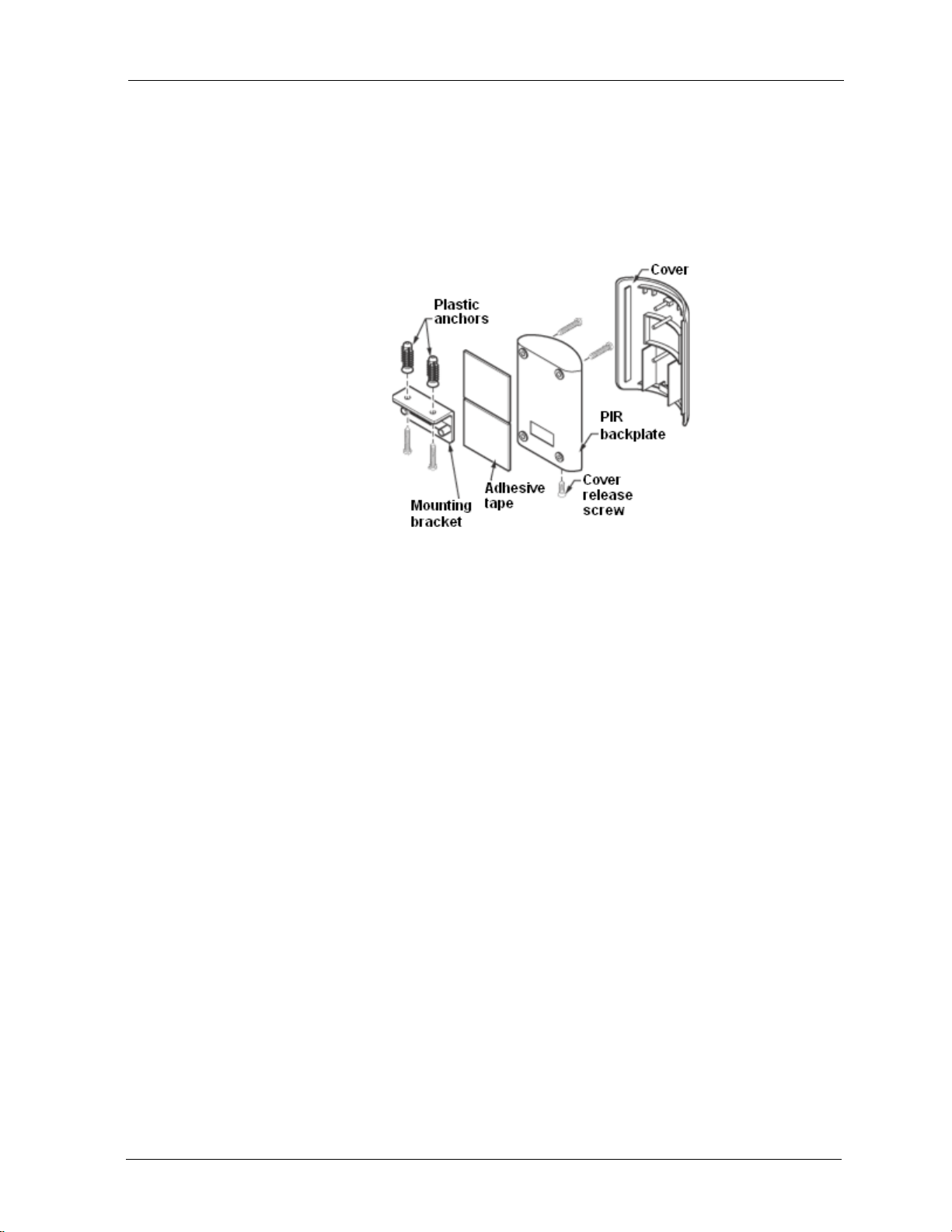

Mounting a PIR occupancy motion sensor

Note The BACnet FF supports a maximum of 3 passive infrared (PIR) sensors.

To mount a PIR motion sensor

1. T ake off the cover by removing the cover release screw on the bottom of

the PIR backplate.

Mounting guidelines

|

Figure 6 PIR occupancy motion sensor mounting options

2. Insert three AAA batteries.

3. Secure the PIR sensor to the wall using one of the following options:

• Wall Mount option 1: Use adhesive tape to secure the PIR backplate

to the wall.

• Wall mount option 2: Using either the top or bottom two holes of the

PIR backplate, insert the two long screws to secure the PIR

backplate to the wall.

• Ceiling mount option: Align the m ounting bracket and PIR

backplate. Insert the two small screws into the top holes of the

backplate and secure it to the bracket. Use the two long screws (and,

if necessary, the optional plastic anchors) to mount the bracket and

PIR backplate to the ceiling.

4. Replace the PIR sensor cover and cover release screw.

© Honeywell 31-00098-01 11

Page 12

Installation and Operations Guide

Terminals and wiring

The BACnet FF label identifies wiring terminals by number and function.

T erminals are numbered from top to bottom, beginning with 1 on the upper right

side of the wallplate and continuing top-to-bottom on the right side of the

controller. I/O terminals carry an additional numeric identifier that corresponds

to the software I/O. Use this section to identify terminals on the BACnet FF. See

later sections for more specific instructions, cautions, and recommendations.

Power supply terminals

Use terminals 1 and 5 to connect the 24V AC power supply to the BACnet FF.

Ground terminals

These terminals are used for terminating the grounded leg of the 24VAC circuit

and the return grounds of BOs.

COM terminals

These terminals are used for terminating the return grounds of AIs and AOs.

Universal inputs (AIs)

Use these terminals (in conjunction with adjacent GND terminals) to connect

universal inputs. Input terminals accept a variety of signal types.

BACnet FF

|

Binary outputs (BOs)

Use these terminals to connect BO loads (ON/OFF control). Terminate the BO

return ground to the panel/enclosure ground or a GND terminal on the BACnet

FF.

WARNING! Do not apply line voltage to source pins.

Analog outputs (AOs)

Use these terminals to connect AO-loads (modulating control). The AO-return

ground must terminate to the nearest GND terminal.

MS/TP LAN terminals

Use terminals 11(MS/TP-) and 12 (MS/TP+) to connect the BACnet MS/TP

LAN to the BACnet FF. Maintain polarity throughout the entire LAN. See

“MS/TP LAN Wiring” on page 16 for more information.

12

31-00098-01 © Ho neywell

Page 13

Using terminal blocks

Installation and Operations Guide

The BACnet FF uses header-style termination blocks to simplify field wiring of

power, communications, and I/Os. Terminal blocks accept wire gage from

12–24AWG.

To terminate wire to a BACnet FF

1. Strip approximately 1/8” of the wire jacket from the end of the wire.

2. Use a small screwdriver (1/8” max) to turn the adjustment screw fully

counter-clockwise. The clamps in the wire slot separate as you turn the

screw.

3. Insert the stripped end of the wire into it (try to get the jacket flush with

the terminal block). If using stranded wire, be sure to insert all strands

into the wire slot. If terminating multiple wires, trim wires to same

length and tightly twist exposed wire together.

4. Hold the wire in place and turn the adjustment screw clockwise to

tighten it until the clamps in the wire slot secure the wire.

5. Tug gently on the wire to ensure it is secure.

Terminals and wiring

|

© Honeywell 31-00098-01 13

Page 14

Installation and Operations Guide

BACnet FF

|

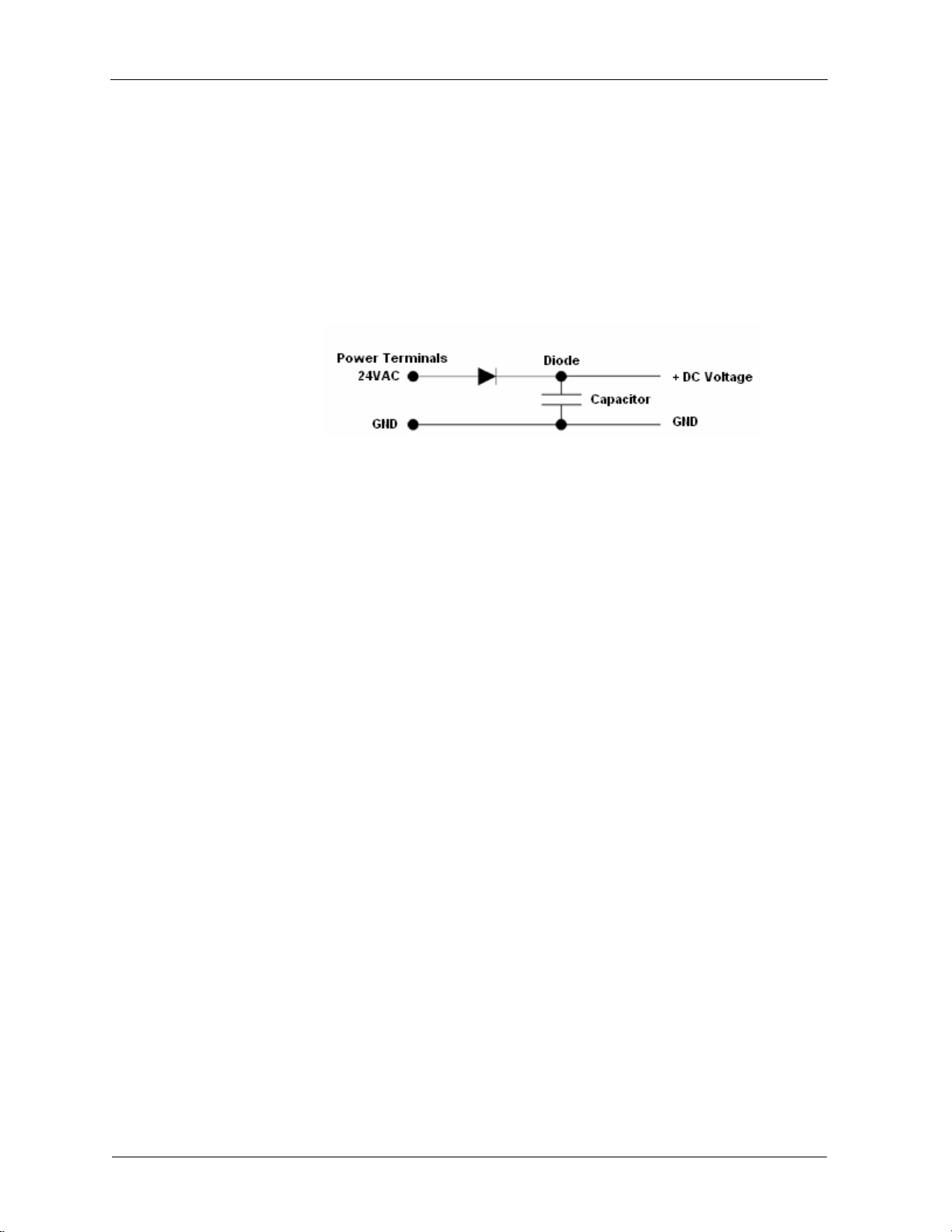

Power supply guidelines and requirements

BACnet FF uses 24VAC power from a UL Listed Class 2 24VAC transformer

(not provided). The BACnet FF uses a half-wave rectifier to convert the AC

power supply to onboard power. This enables multiple BACnet FFs with

half-wave power supplies to be powered from a single, grounded transformer.

CAUTION Half-wave devices and full-wave devices must not use the same AC

transformer. If a BACnet FF will share its power supply with another device,

make sure that the other device utilizes a half-wave rectifier and that polarity of

wiring is maintained. Failure to do so can result in equipm en t dam a ge.

Figure 7 Internal BACnet FF power wiring schematic, half-wave rectifier

BACnet FF power ratings

The BACnet FF minimum current draw is 24 VAC @50ma leading to ~1.2VA.

The minimum applies when the BACnet FF supports no binary output (BO)

loads. If the BACnet FF supports AOs, the minimum VA rating includes the

draw of all AO-loads energized at maximum rating. The maximum power draw

is the minimum VA rating plus the power draw when all BOs are energized at

maximum capacity .

Selecting a transformer

The safest way to size a transformer is to ensure that the maximum VA load

rating of the BACnet FF is less than 85% of the Nameplate VA rating of the

transformer. Even if all outputs are not presently used, this ensures that each

BACnet FF has sufficient power for future equipment additions.

IMPORTANT Transformer sizing should never exceed the maximum UL Class

2 rating.

Power supply grounding and wiring

When connecting power to the BACnet FF, ensure that one leg of the VAC

secondary circuit connects to a known earth ground. Also ensure that the GND

terminal on the BACnet FF connects to the same known earth ground.

Supplying a high-quality ground connection to a BACnet FF and then properly

connecting the BACnet FF to the ground is one of the most important things you

can do to ensure a trouble-free installation.

14

The 24VAC secondary leads are not interchangeable. Once a lead connects to

the GND terminal on the BACnet FF, it is the grounded lead. Observe and

maintain polarity for subsequent connections. The GND terminal provides a

reference ground for the circuit board and communications wiring. Use 18 AWG

cable for best results.

31-00098-01 © Ho neywell

Page 15

Installation and Operations Guide

WARNING Ensure that all BACnet FF power, communications, and I/O

cabling are grounded according to these instructions. Failure to follow these

instructions may result in BACnet FF operational and communication failures or

equipment damage.

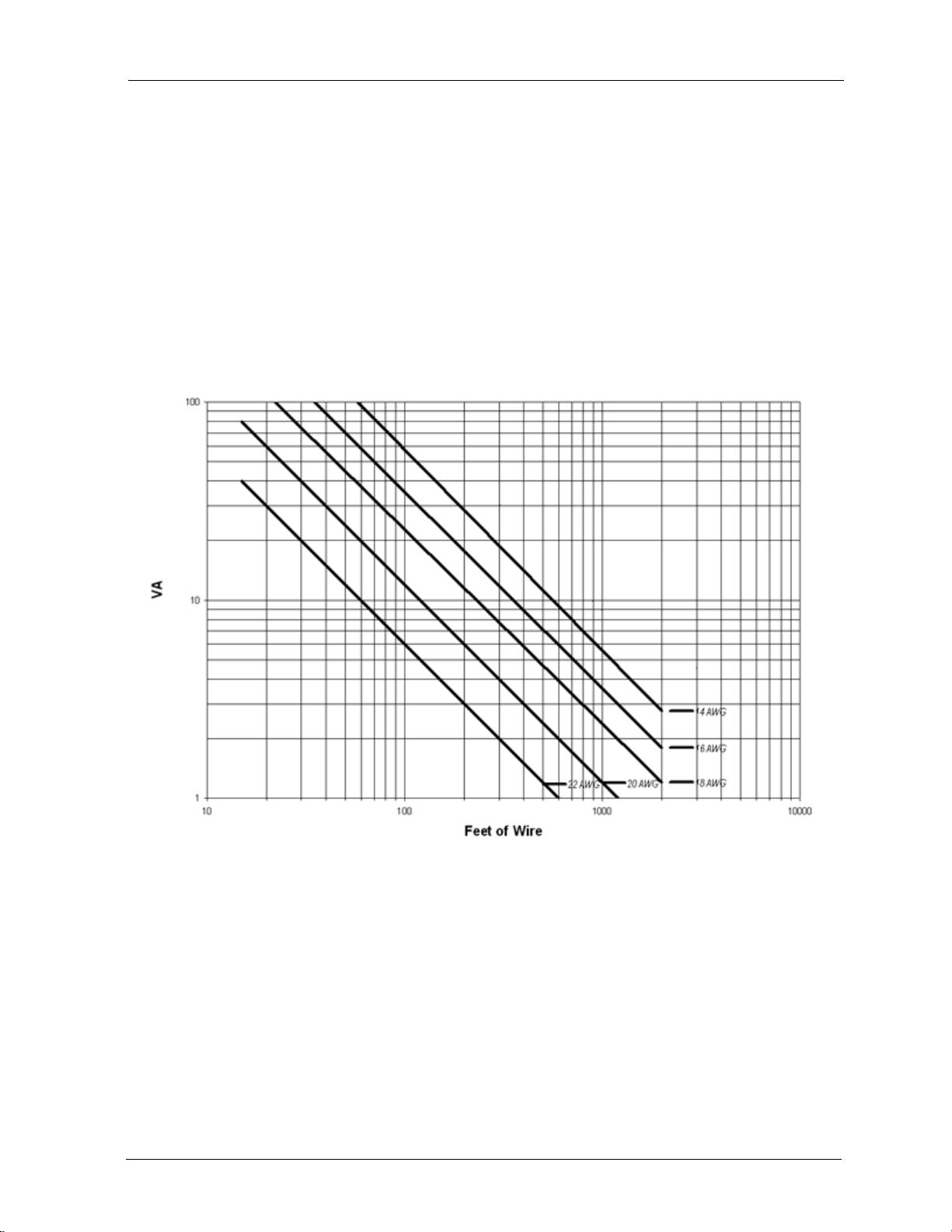

Power supply wire selection

If you are considering long power supply wiring runs, using the right wire size is

critical. If the wire is too small, the resistance may be too high, resulting in a low

voltage supply to the BACnet FF. This is known as line loss. The wire size is

based on the length of the wire run and the current draw of the BACnet FF. Use

Figure 8 to determine wire size; obtain additional information from the

transformer manufacturer.

Power supply guidelines and requirements

|

Figure 8 BACnet FF wiring recommendations

Backup power

The BACnet FF features a built-in supercapacitor that will run the on-board

clock for ten days in the event of power loss.

© Honeywell 31-00098-01 15

Page 16

Installation and Operations Guide

MS/TP LAN Wiring

The BACnet FF communicates on the site-wide BACnet system over a

twisted-pair MS/TP LAN, which uses the EIA–485 signaling standard. BACnet

FFs are master devices on the MS/TP LAN.

BACnet FF

|

Each BACnet FF employs a high-quality EIA–485 transceiver and exerts

load on the MS/TP LAN.

Ta bl e 2 MS/TP LAN facts

Transmission speed 9.6, 19.2, 38.4, 76.8Kbps (configured at global

controller).

Layout Bus.

Cabling BACnet specifies the following. Shielded, twisted-pair

cabling with characteristic impedance between 100 and

130W. Distributed capacitance between conductors

must be less than 30 pF/foot (100 pF/m). Distributed

capacitance between conductor and shield must be less

than 60 pF/foot (200 pF/m). Foil or braided shield

acceptable.

Segment length 4000 ft. (1071 m.) per segment using recommended

wire.

Maximum devices

overall

Depends on classification of devices as master or slave.

Maximum number of master devices is 128. Maximum

number of slave devices or devices overall (mixed

master and slave) is 255. This includes BACnet FFs,

BACnet global controllers (all are considered masters)

and any other devices, regardless of their relative unit

loads.

¼ unit

Maximum devices

per segment

Repeaters Required when making runs longer than 4000 ft. Three

Terminating

resistors

Shield grounding Ground shield drain wire at single point earth (panel)

Terminating MS/TP LAN cabling

MS/TP terminations are located on the lower left of the BACnet FF wallplate.

Maintain polarity of the MS/TP wire run throughout the MS/TP LAN.

Depends on relative unit load of devices (see

“Terminating MS/TP LAN cabling” on page 16).

repeaters maximum between any two devices.

Matched resistors required at each end of segment bus

wired across (+) and (–). Use matched precision

resistors rated ¼W ±1% / 80 - 130 Ohms.

ground, not BACnet FF ground. Tape off shield drain

wire at other end. Tie shield drain wire through at each

BACnet FF.

16

31-00098-01 © Ho neywell

Page 17

Grounding the MS/TP LAN shield

Proper shield grounding of the MS/TP cabling can help minimize the risk of

communications problems and damage to equipment because of transient

voltage spikes (for example, lightning strikes).

Follow these guidelines for grounding MS/TP cable shields:

• Each MS/TP segment should have a single point of shield ground,

preferably as close to the middle of the cabling run as possible.

• Do not ground the MS/TP shield using a BACnet FF terminal.

• Never ground both ends of a shield; differences in potential between the

grounds may induce current on the shield, causing interference.

• At termination conn ectin g points, tie the shield through with a wire nut.

• At ungrounded, exposed shield points (the end of a segment), tape back

the shield to the wire jacket or, for optimum transient shunting, use

100V gas discharge tubes or 120V MOVs between shield and ground.

Terminating resistors

Matched terminating resistors wired across MS/TP+ and MS/TP– are required at

the last device on each end of the MS/TP segment for signal integrity (Figure 9).

Installation and Operations Guide

MS/TP LAN Wiring

|

Optimum segment performance typically requires “tuning,” a process by which

the value of the terminating resistors is selected based on the wave form of

signals on the segment. View wave forms using an industrial scope meter. The

goal is to have as square a wave form as possible with an amplitude greater than

200 mV. Resistors affect the wave form as follows:

• When the resistance value decreases, the amplitude of the wave form

decreases and becomes more square.

• When the resistance value increases, the amplitude of the wave form

increases and becomes less square.

Typically, precision resistors in the range 80-130 Ohms (+

results. Ideally, the value of the terminating resistors should match the rated

characteristic impedance of the installed cable. For example, if the installed

MS/TP cable has a listed characteristic impedance of 100 Ohm, install 100 Ohm

matched precision resistors.

CAUTION Do not mismatch terminating r e sistors. Ensure that both resistors

on a segment have the same value.

Note Typically, White is Data - and Black is Data +.

1%) yield acceptable

Figure 9 Terminating resistor detail

© Honeywell 31-00098-01 17

Page 18

Installation and Operations Guide

BACnet FF

|

Configuration

Once the BACnet FF is mounted and wired, configure it from the BACnet FF

touchscreen.

Adjusting the date and time

When the controller is first powered up, you may need to set the date and time.

These are set at the factory, but the on-board power supply may have run down.

If this happens, adjust the date and time.

To adjust the time

1. Touch Clock at the bottom of the screen.

1. Use the arrows to adjust the year, month, and day.

2. Press DONE.

3. Adjust the time and press DONE.

T o manually adju st the date and ti me after initial setup, see “Clock operation” on

page 25.

Setting the MAC address and device instance

The factory default MAC address is 0. Valid MAC addresses are 0-127. The

default device instance is 0009999. Valid device instances are 0-4194302.

Note The device instance can also be set using a BACnet Supervisor

To set the MAC address and device instance at the display

1. From the home screen, press SYSTEM (left side of the screen).

Five blank touch keys will appear at the bottom of the screen.

18

31-00098-01 © Ho neywell

Page 19

Installation and Operations Guide

E

CANC

MO

USASU

SYSTE

OFF

g

Schedule

de

Se

o

M19923

Configuration

|

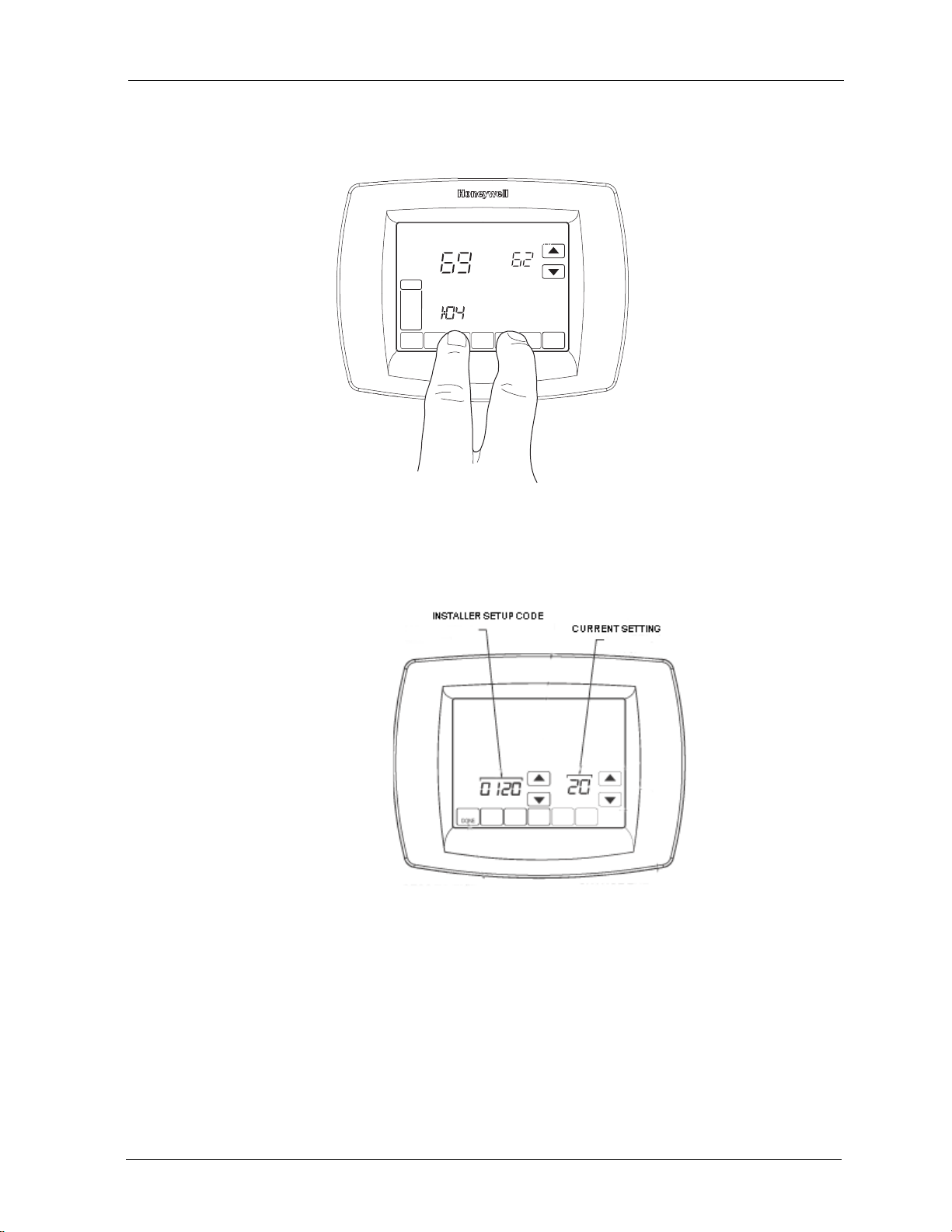

2. Press and hold the two blank keys on either side of the center key for

approximately five seconds (see Figure 10).

T

Insi

DON

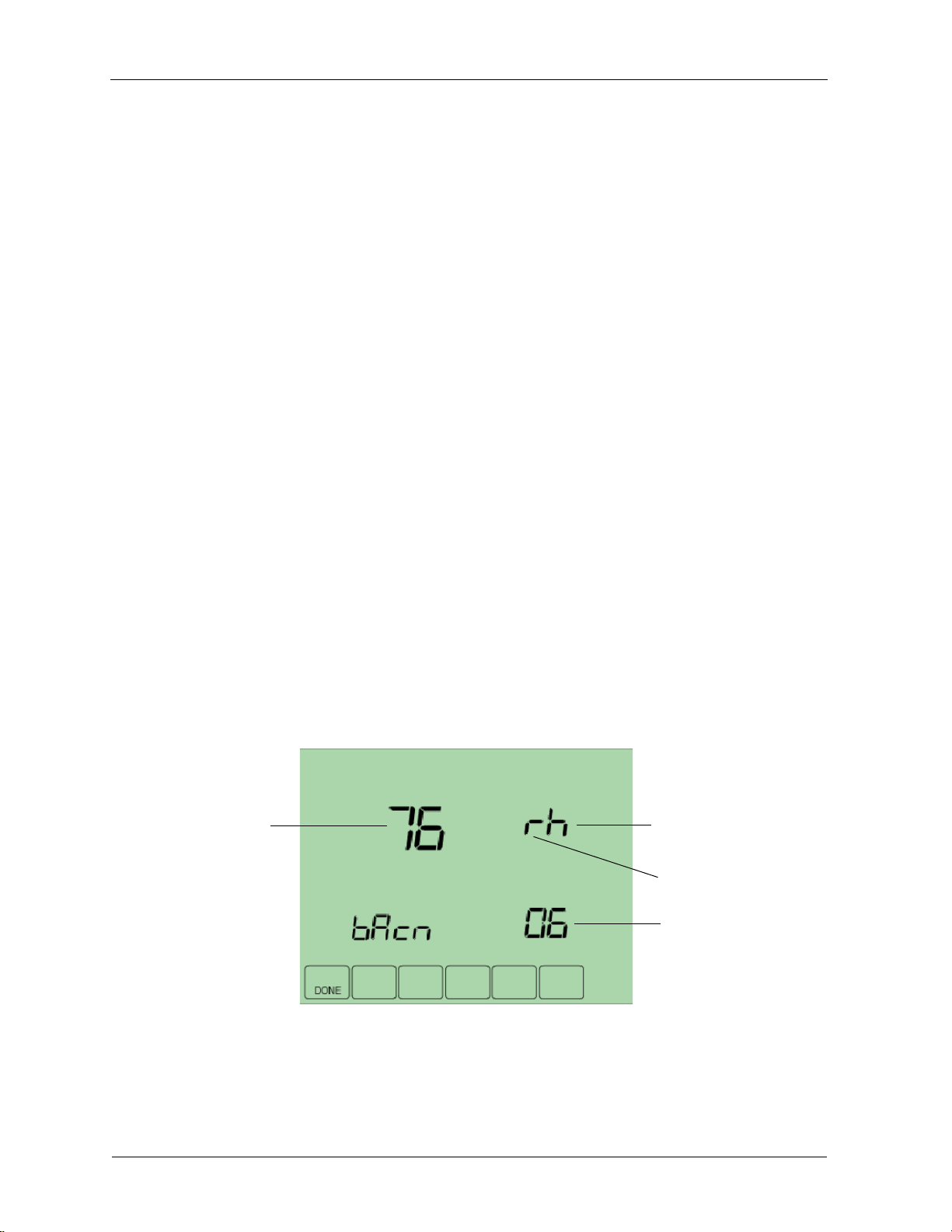

Figure 10 Entering ISU mode

t T

Followin

The installer setup (ISU) screen appears. An ISU code is displayed in

the lower left. It is a four-digit code beginning with zero. The current

setting is displayed in the lower right.

Figure 11 ISU screen

3. Use the down arrow next to the installer setup code to advance to ISU

code 800.

4. Use the up and down arrows next to the current setting to set ISU code

800 (MAC address) to a value between 0 and 127.

5. Set ISU code 801 (first digit of device instance) to a value between 0

and 4.

Note The device instance is set by entering values in four separate

ISU codes. See example on page 20.

© Honeywell 31-00098-01 19

Page 20

Installation and Operations Guide

BACnet FF

|

6. Set ISU code 802 (second and third digits of device instance) to a value

7. Set ISU code 803 (fourth and fifth digits of device instance) to a value

8. Set ISU code 804 (sixth and seventh digits of device instance) to a value

9. Press Done to exit installer setup.

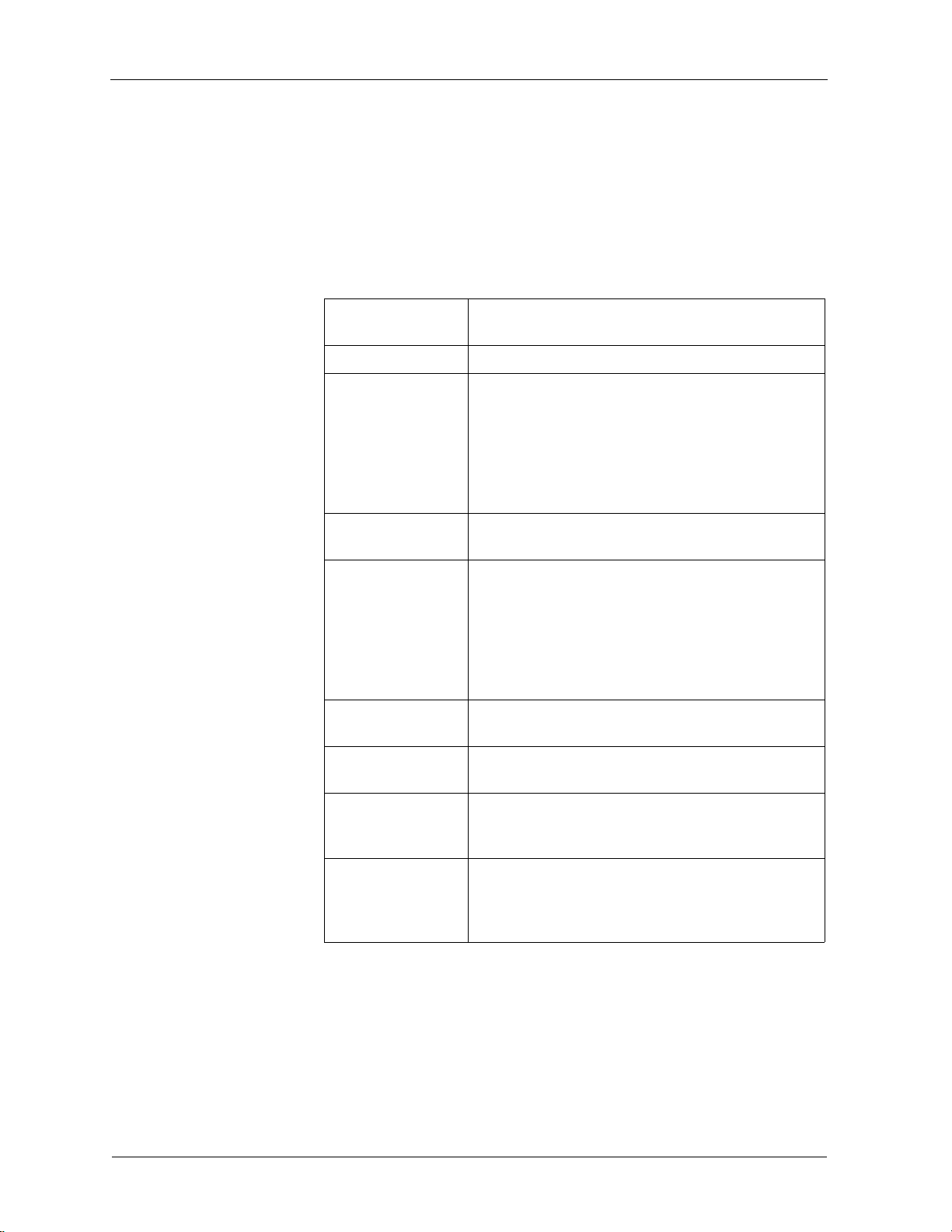

Installer setup (ISU) codes

Installer setup mode provides access to functions specific to installation of a

BACnet FF. Some BACnet FF configuration parameters can be altered from the

ISU screens. The ISU parameters can also be accessed via BACnet.

between 00 and 99.

between 00 and 99.

between 0 and 99.

For example, if you want to set the MAC address to 15 and the device

instance to 1876, you would use these settings:

ISU code 800=15

ISU code 801=0

ISU code 802=00

ISU code 803=18

ISU code 804=76

You can require a PIN to access ISU mode by setting AV-133 to a non-zero,

four-digit number.

To access the ISU screens

1. From the home screen, press SYSTEM (left side of the screen).

2. Five blank touch keys appear on the bottom of the screen between the

Done and Cancel keys. Press and hold the two blank keys on either side

of the center key for approximately five seconds. See Figure 10.

3. If a PIN code is required, use the top arrows to select the first two digits

of the code and the bottom arrows to select the third and fourth digits of

the code, and then press DONE.

The ISU screen appears.

4. Use the arrows to select parameters and values. See Table 3 for details.

5. Press DONE.

20

31-00098-01 © Ho neywell

Page 21

Installation and Operations Guide

Note After five minut es of inacti vit y, the ISU screen reverts to the

main screen.

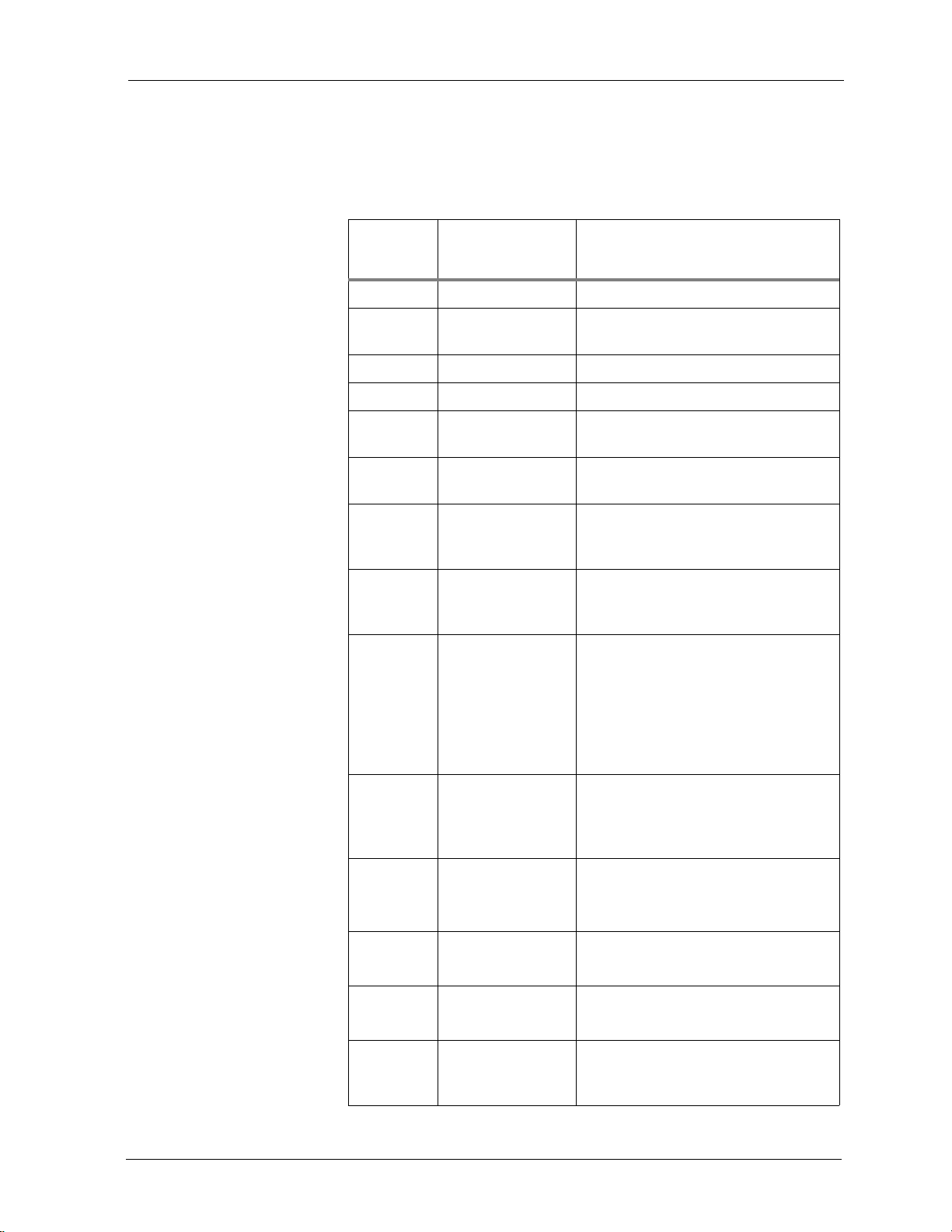

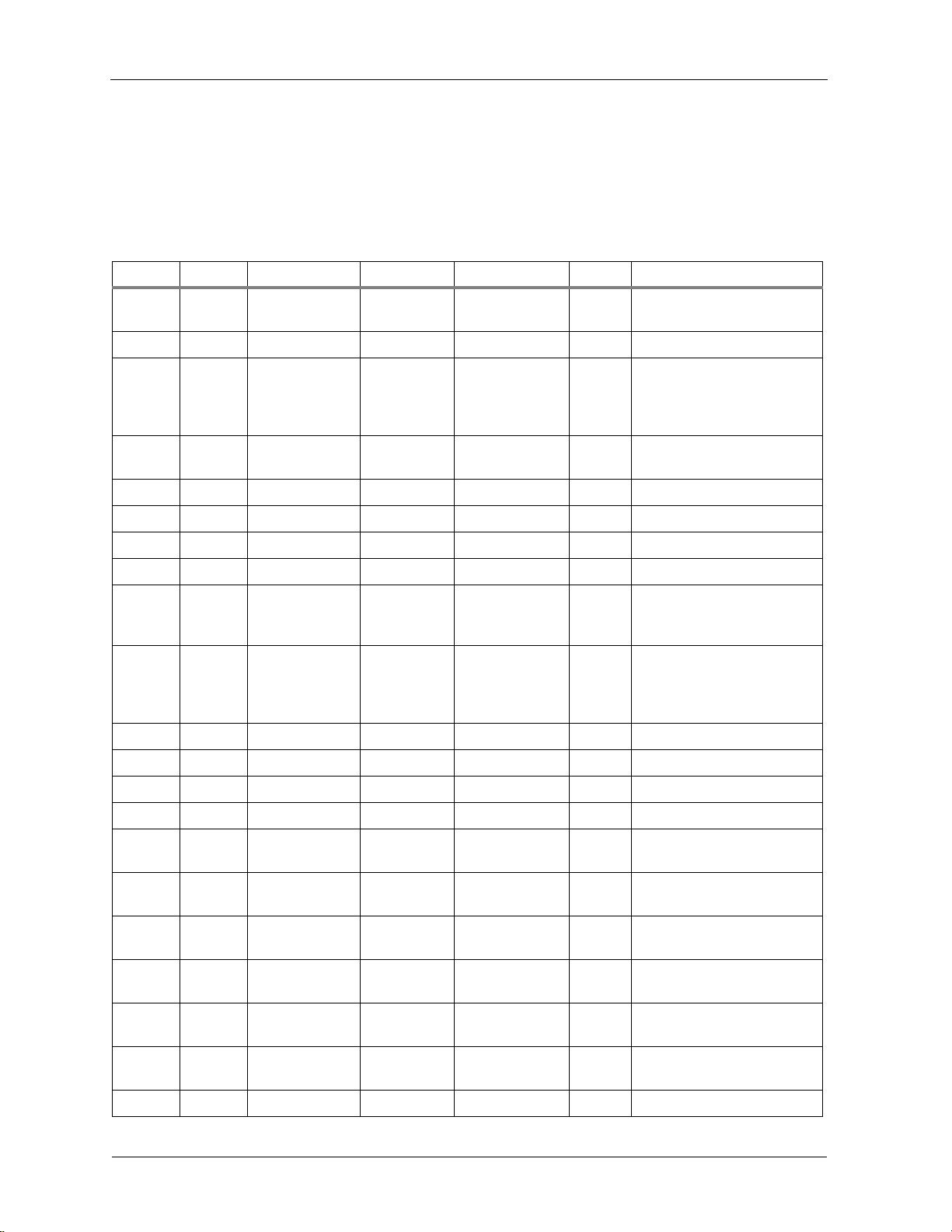

Table 3 provides a list of ISU param e ters

Ta bl e 3 ISU parameters

ISU

Parameter

Code

Description Allowed Values

120 Year, first 2 digits 19-21

Configuration

|

130 Year, second 2

00-99 (00-54 if ISU 200=21)

digits

140 Month 1-12

150 Day 1-31

160 Schedule format

BV-133

280 Backlight control

BV-79

320 Swap

English/Metric

0 – not programmable (BV-133=0) 4 – 7

day programmable (BV-133=1)

0 – on for 20 seconds after keypress

1 – low always on, bright after keypress

1 – show opposite units to specified in

DDC header

BV-69

330 Daylight saving

AV-127

500 Filter change

reminder

AV-124

0 – off; no automatic adjustments

1 – pre 2007 scheme

2 – 2007 and later scheme

0 – reminder not used

1 – 10 days

2 – 30 days

3 – 60 days

4 – 90 days

5 – 120 days

6 – 365 days

510 Hum pad change

reminder

AV-125

520 UV lamp change

reminder

0 – reminder not used

1 – 90 days

2 – 180 days

3 – 365 days

0 – reminder not used

1 – 365 days

AV-126

540 Program periods

AV-129

640 Clock format

BV-83

670 Keypad lock

AV-128

© Honeywell 31-00098-01 21

2 – Wake/Sleep

4 – Wake/Leave/Return/Sleep

12 – 12 hour (BV-83=0)

24 – 24 hour (BV-83=1)

0 – no lock

1 – access temperature settings only

2 – fully locked

Page 22

Installation and Operations Guide

Ta bl e 3 ISU parameters

BACnet FF

|

ISU

Parameter

Code

Description Allowed Values

700 Sensed room

temperature offset

(AV-138)

701 Sensed room

humidity offset

(AV-139)

702 Sensed outside air

temperature offset

(AV-140)

703 Sensed outside

humidity offset

(AV-141)

800 MS/TP MAC 0-127

801 BACnet Device

Instance - first digit

802 BACnet Device

Instance second and

third digits

803 BACnet Device

Instance forth and

fifth digits

-4 to +4 degrees F

-5% TO +5%

Humidity cannot be adjusted above

100% or below 0%.

-4 to +4 degrees F

-5% TO +5%

Humidity cannot be adjusted above

100% or below 0%.

0-4

00-99

00-99

804 BACnet Device

Instance sixth and

seventh digits

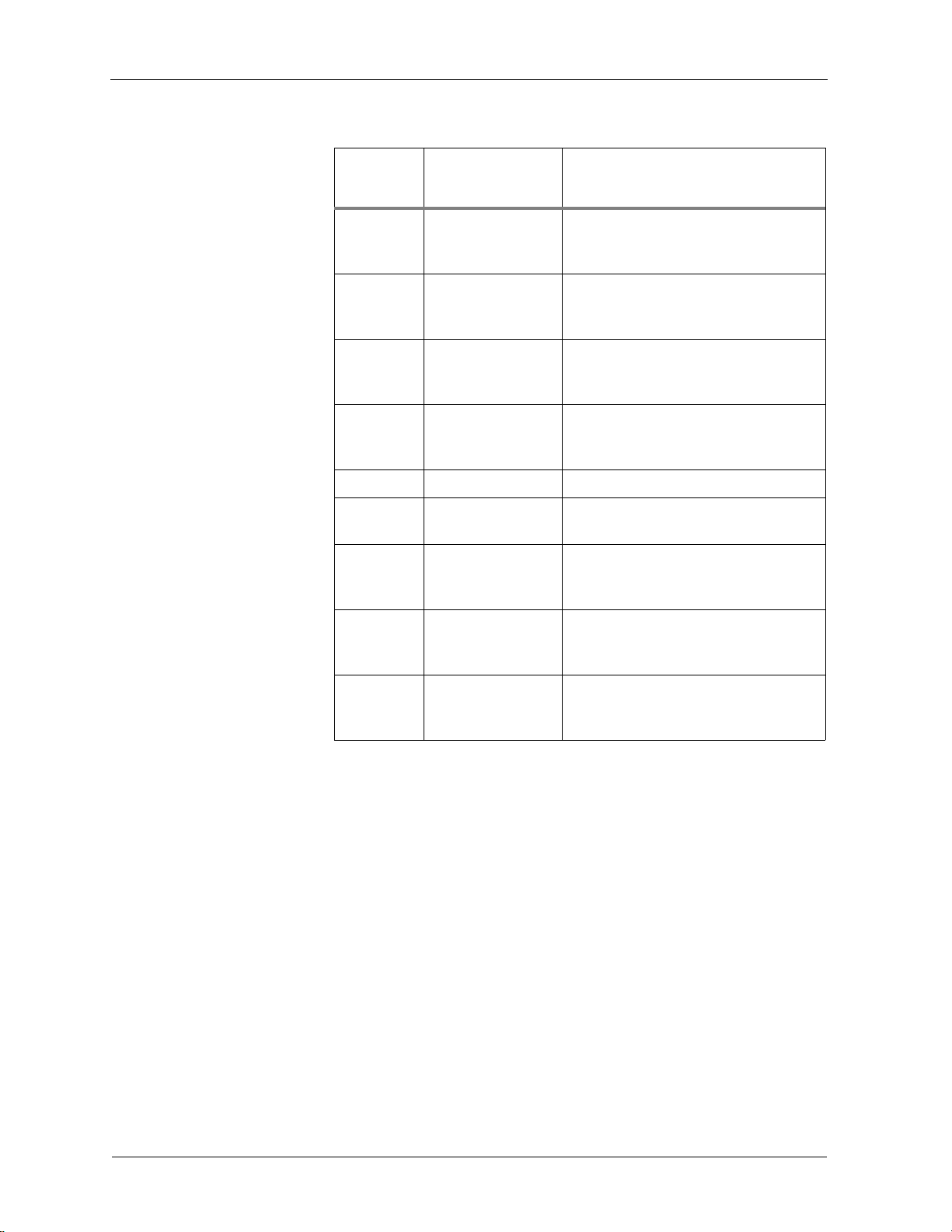

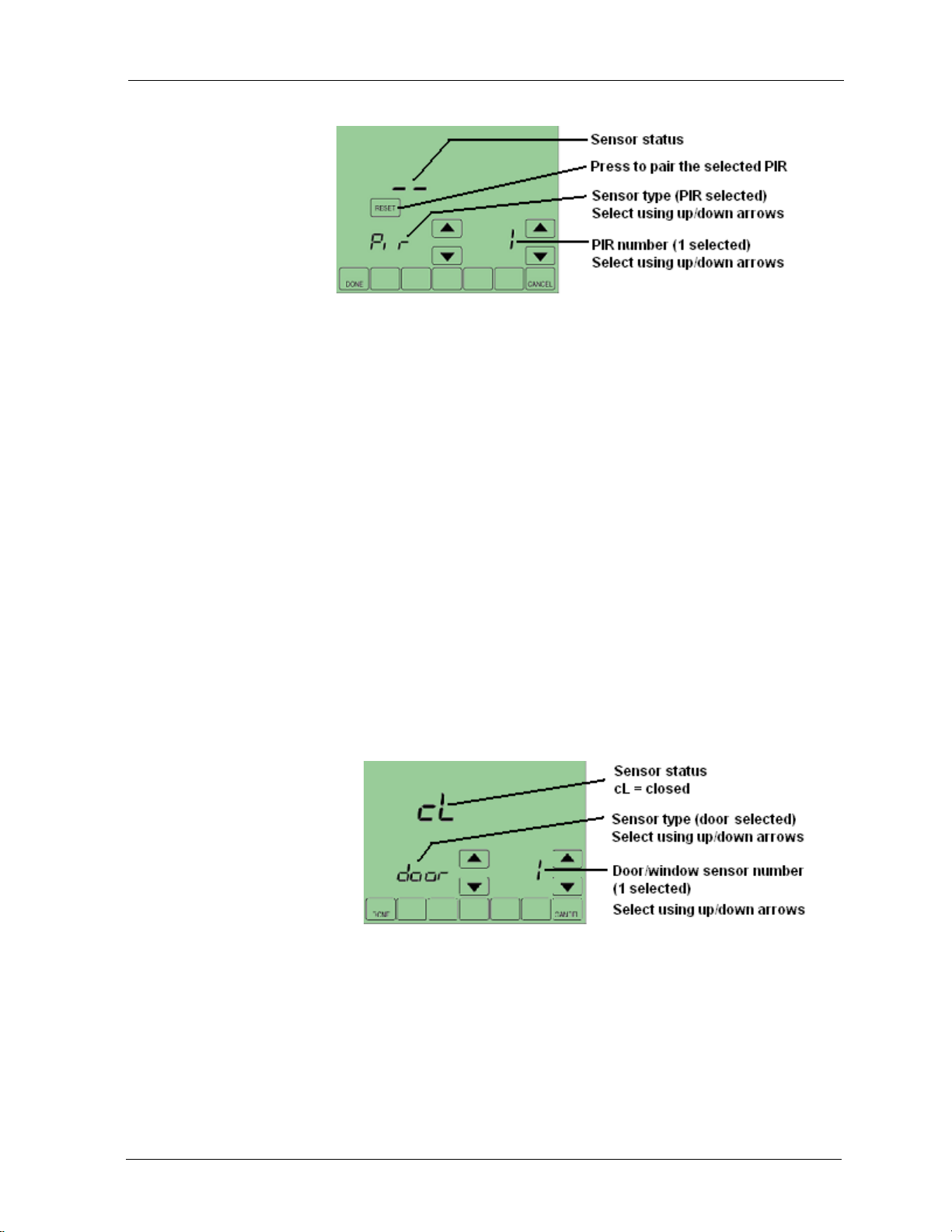

Pairing a sensor to a wireless BACnet FF

The BACnet FF and wireless sensor kits (WSK-24) ship unpaired, verified by

two dashes in the Sensor Status field on the BACnet FF’s Wireless Sensor Setup

screen. To pair them, issue a pairing command from the BACnet FF and then

activate the sensor.

Accessed from Field Service Mode, the BACnet FF’s W i reless Sensor Setup

Mode includes diagnostic screens for configuration and checkout of associated

sensors. With :UC displayed in Field Service Mode, press the blank key (blank

area) just to the left of the blank center key, and then press the down arrow key

next to the :UC parameter.

Door/window sensors may be paired to any available sensor number in the range

1-8. When cycling through sensor numbers on the Wireless Sensor Setup screen,

unpaired sensor numbers show a status of --.

PIR sensors may be paired to any available sensor number in the range 1-3.

00-99

22

31-00098-01 © Ho neywell

Page 23

Installation and Operations Guide

Figure 12 Wireless Sensor Setup screen

To pair a sensor to a BACnet FF

1. Make sure the battery is installed and activated in the sensor.

2. If the sensor is a door/window switch, align the magnet so that the

sensor is in the closed position. If the sensor is a PIR sensor, cover the

PIR.

IMPORTANT! Verify that the sliding door/window contact is closed

and cover all other PIRs to prevent interference during the pairing

process.

|

Configuration

3. On the BACnet FF select the sensor to pair and then press Reset.

The RESET key disappears and WAIT is displayed indicating that the

BACnet FF is waiting to pair the sensor with the next device that

receives a radio signal.

4. Activate the sensor you want to pair.

Note Pairing times out after 10 seconds of no pairing activity.

5. Verify that the BACnet FF and sensor successfully paired.

Paired = sensor status is displayed, replacing --.

Timed out = RESET is displayed and sensor status

is --.

Figure 13 Door sensor number 1 paired and in closed status.

To erase sensor-to-BACnet FF pairings

1. While viewing any sensor status screen while pairing is not taking

place, press the blank key to the left of CANCEL.

2. Press the blank key to the right of DONE.

The sensor status field displays --, indicating unpaired.

© Honeywell 31-00098-01 23

Page 24

Installation and Operations Guide

Fixed field service codes

Field service mode enables technicians to query and command key operating

variables in the BACnet FF while at the BACnet FF touchscreen. A technician

presses a particular key sequence at the BACnet FF to enter field service mode.

In field service mode a technician uses the left arrows to scroll through data

codes and the right arrows to change the value associated with a code.

The lower left of the LCD shows the two-digit data code and the main area

displays the data value. A pre-defined list of data codes is available within the

description of each application. See Ta ble 8 as an example for applications 0 and

1. “Configuring a DDCMULTI application” on page 27 provides mo re

information about these settings.

Note When using the local user interface to change applications (AV-49), the

application defaults will NOT change and must be changed manually.

You can deny users access to field service mode by setting BV-68 to ON. You

can also require a PIN code in order to enter field service mode by setting

AV-132 to the desired PIN number.

Field service mode ends automatically if there is no key activity for five minutes.

BACnet FF

|

Setting field service codes

To set field service codes

1. From the home screen, press SYSTEM (left side of the screen).

2. Press and hold the center bottom key (blank) for about five seconds. See

Figure 10.

3. If a PIN code is required, use the top arrows to select the first two digits

of the code and the bottom arrows to select the third and fourth digits of

the code, and then press DONE.

The field service screen appears.

4. Press the left up or down arrows until the desired code appears. See

T able 8 on page 42 for the list of Setup Codes. NOTE: All applications

use the same Setup Codes.

5. Press the right up or down arrows to adjust the value associated with the

code.

6. Press the left up or down arrows to accept the change and scroll to a

different code.

7. Press DONE to exit field service mode.

24

31-00098-01 © Ho neywell

Page 25

Operational overview

The BACnet FF operates in one of three modes - Setpoint, Occupancy Single

Setpoint, and Occupancy Dual Setpoint.

Common features

This section describes features common to all operating modes. For descriptions

of mode-specific features, see “Checking MS/TP communication” on page 26

and “Checking MS/TP communication” on page 26.

LCD backlight operation

BV-79 controls backlight operation. If BV-79 is OFF, the backlight turns ON

when any key is pressed and stays on for 20 seconds after there is no key activity.

If BV-79 is ON, the backlight is ON continuously.

Clock operation

The BACnet FF’s real-time clock provides time and date for displaying the date

and time, implementing daylight savings settings, and implementing schedules.

If AC power is lost, a supercapacitor will power the clock for ten days. If the

date and time are lost, the BACnet FF will display the set time and date screens

when powered up.

Installation and Operations Guide

Operational overview

|

Note The real-time clock is separate from the CPU time keeping utility. It only

affects the items listed in this section.

Daylight savings (DLS) settings can be controlled by a BACnet FF or by a

BACnet Supervisor. If installer setup (ISU) parameter 330 is set to non-zero, the

BACnet FF will control DLS settings. If ISU 330 is zero, DLS is controlled by a

BACnet Supervisor.

The clock accepts time syncs from a BACnet Supervisor. If configured in DDC,

the date and time can also be set manually using the display. To den y a user

permission to set the clock, set BV-116 to 1.

The last time command, whether from the user screen or BACnet, takes

precedence.

To adjust the real-time clock

1. Press CLOCK.

2. Use the arrow keys to select a year, month, and day.

3. Press DONE.

4. Select a time.

5. Press DONE.

© Honeywell 31-00098-01 25

Page 26

Installation and Operations Guide

Baud rate

Requests seen

Headers seen

MAC address

BACnet FF

|

MORE key navigation

The MORE key allows a programmer to make additional screens available to

users. Enabling the display of one or more of these screens causes the MORE

key to appear on the main screen. The screens that can be made available are:

• Outside air temperature

• Inside/outside humidity

When the user presses MORE, the first enabled screen appears. Pressing

MORE again displays the next screen.

Touchscreen cleaning

If the display screen needs to be cleaned, the user presses SCREEN. The display

will lock for 30 seconds allowing the user to wipe the screen without pressing

any keys. When the display reads 0, press SCREEN to continue cleaning or

DONE to quit. Use a non-abrasive glass cleaner.

Checking MS/TP communication

You can check MS/TP communication from the display. The BACnet FF will

indicate if MS/TP packets and headers have been seen, the baud rate, and the

MAC address.

To check MS/TP communication

1. Enter field service mode. See “To set field service codes” on page 24.

2. Ensure the UC code is displayed.

3. Press the blank key usually labeled MORE (bottom row, second from

right).

4. Press the down arrow near the UC code.

The MS/TP communication screen appears.

26

5. Press DONE twice to exit.

31-00098-01 © Ho neywell

Page 27

Installation and Operations Guide

Configuring a DDCMULTI application

The BACnet FF is pre-loaded with DDC that lets you select one of multiple

applications. Applications for heat pumps, A/C units, and fan coil units are all

contained in the same DDC file. Using one of these applications, an installer can

configure the controller in the field - just set the MS/TP parameters, device

instance, and application [AP] (AV-49) parameters and it is ready to go.

Note When using the local user interface to change applications (AV-49), the

application defaults will NOT change and must be changed manually. However,

The Niagara-based configuration wizard will change the application specific

default values.

Advanced application settings will require a BACnet connection to a BACnet

BMS. These detailed application settings need to be reviewed to ensure all are

set correctly before enabling the device's outputs.

CAUTION Setting the [OE] field service code to ON powers up the outputs.

Ensure that the outputs are configured correctly before setting OE to ON.Failure

to do so may result in equipment damage.

1. Set field service code [OE] (BV-2) to ON to power up the outputs.

Configuring a DDCMULTI application

|

2. Press DONE.

© Honeywell 31-00098-01 27

Page 28

Installation and Operations Guide

BACnet FF

|

Application Sequences and Configuration Settings

Table 4 shows settings for all 19 applications and should be referenced

accordingly

Ta bl e 4 Primary settings for the 19 apps

Code Point Value Default Options Units Notes

160 BV-133 Internal Sched

Enable

280 BV-79 Backlight ON Inactive

320 BV-69 Swap Eng -

Don't use this is

on custom

screen

330 AV-127 Day Light

Savings Option

500 AV-124 Filter Period 0 0

510 AV-125 Pad Period 0 0

Inactive Inactive/Active

2 0-2 0 - disable, 1 - pre 2007, 2 -

2007+

520 AV-126 UV Period 0 0

540 AV-129 Prog Periods 0 0

640 BV-83 Clock Fmt

Inactive 12 hr

Active 24 hr

670 AV-128 Keypad Lock

0-no lock,

1-temp settings

only, 2-locked

700 AV-138 Temp Offset 0 0

701 AV-139 Humidity Offset 0 0

702 AV-140 OA Temp Offset 0 0

703 AV-141 Humidity Offset 0 0

BV-141 Deny Schedule

Edits

BV-114 Deny Schedule

View

BV-115 Deny

Permanent Hold

BV-130 Deny Vacation

Hold

Inactive Inactive/Active

Inactive Inactive/Active

Inactive Inactive/Active

Inactive Inactive/Active

28

BV-116 Deny Clock

Adjust

AV-132 FS PIN 0 0 Pin locks field service

AV-133 ISU PIN 0 0 Pin locks ISU service access

Inactive Inactive/Active

access

31-00098-01 © Ho neywell

Page 29

Installation and Operations Guide

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

Heat Pumps: Apps 0 and 1

[AP] 0: Air-to-air heat pump and

[AP] 1: Water-source heat pump

Single-speed fan with binary output start/stop. optional analog variable-speed

fan control, 1-stage auxiliary heat, optional floating or analog economizer.

Fan mode control (AV-17)

• 1 = continuous

• 2 = cycle with heating

• 3 = cycle with heating/cooling

Configurable Occupancy Modes

• SYSTEM Block: AUTO/OFF selection (Occupied/Unoccupied)

• Occupancy mode (AV-123=0, default): Schedules Occupancy states

Inputs and Outputs

• Setpoint mode (AV-123=1): Schedules Setpoints

• Dual setpoint mode (AV-123=2): Dual setpoints when Occupied

• Internal schedules enabled when BV-133 is active or ISU 160=4

• BMS schedules enabled when BV-56 is active

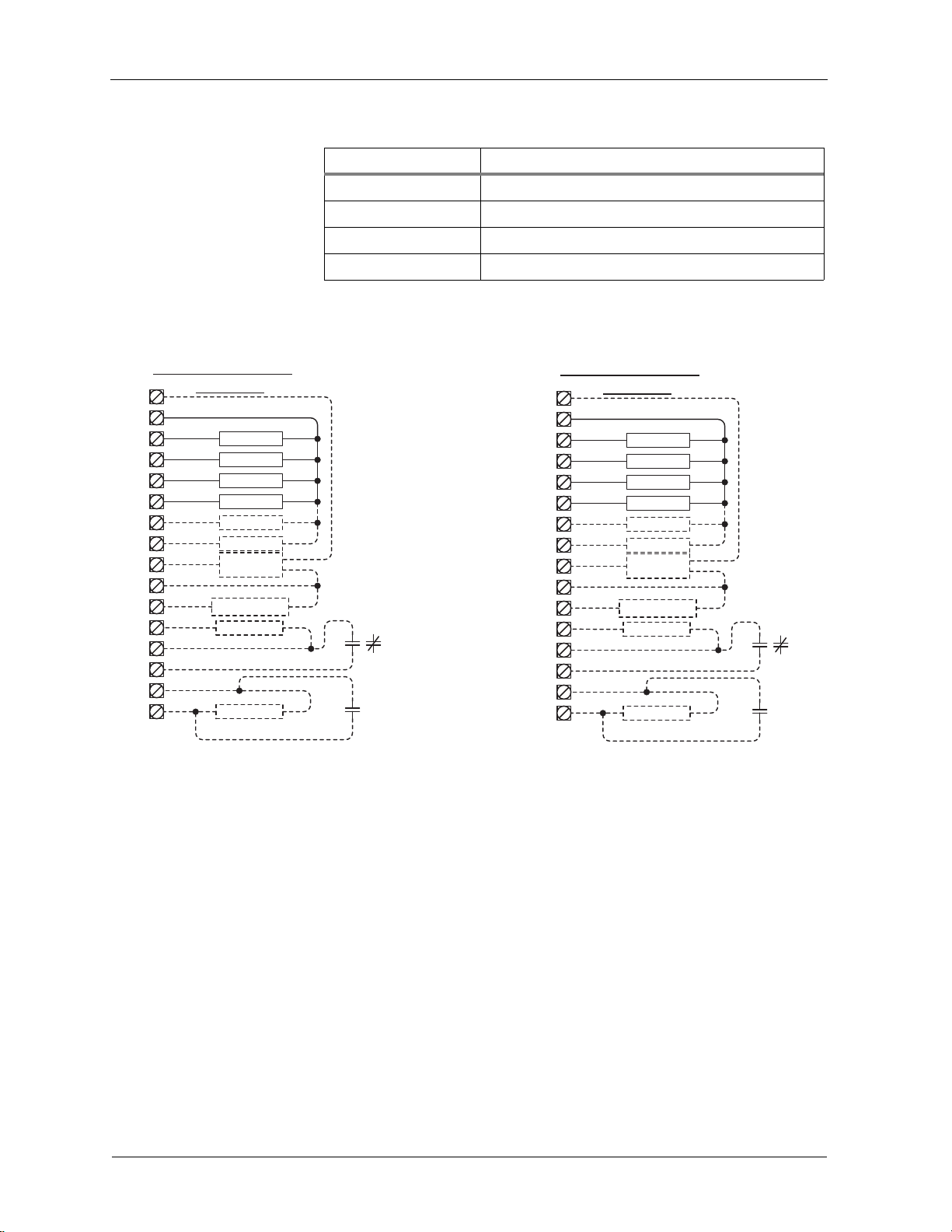

Ta bl e 5 Inputs and Outputs: [AP] 0 and [AP] 1

Point Function

AI-0 Optional:

Use as space sensor in place of the internal space

sensor AV-104 (Set BV-32 active and BV-47 inactive)

Use as an outdoor-air sensor; maps to display

AV-103 (Set BV-47 active and BV-32 inactive)

BI-1 Optional standby input (for PIR/door/window sensor)

AI-2 Supply-air sensor (optional, but required for

economizer option)

BI-2 Normally-open condensate sensor (optional)

BO-0 Fan

BO-1 Heat-pump compressor

BO-2 Reversing valve

BO-3 Heating stage 1 (optional)

© Honeywell 31-00098-01 29

Page 30

Installation and Operations Guide

Fan

HP Cmpr

Rev Vlv

Htg Stg 1

Econ Opn

Econ

Econ Cls

Controller Terminations

HPH1 AP 0

GND

5

BO 0

BO 1

BO 2

BO 3

BO 4

BO 5

AO 1

G

Y1

O/B

W1

EC

EC

EC

0-10Vdc

Com

14

AO 0

C

RC24VAC

1

24V

Com

BI/AI 1

COM

BI/AI 2

COM

BI/AI 0

Sensor *

SA Sensor

Optional

Standby

N.C. or N.O.

Optional

Condensate

alarm or fail

VC

VFD /SCR

4-20ma

* Optional space or outside temperature sensor.

4-20ma

Ta bl e 5 Inputs and Outputs: [AP] 0 and [AP] 1

Point Function

BO-4 Economizer open (optional)

BO-5 Economizer close (optional)

AO-0 Economizer (optional)

AO-1 Analog fan speed (optional)

Wiring diagrams

BACnet FF

|

Controller Terminations

RC24VAC

C

G

Y1

O/B

W1

EC

EC

EC

VC

0-10Vdc

4-20ma

4-20ma

HPH1 AP 1

HP Cmpr

Rev Vlv

Htg Stg 1

Econ Opn

Econ Cls

Econ

VFD /SCR

Sensor *

SA Sensor

GND

BO 0

BO 1

BO 2

BO 3

BO 4

BO 5

AO 0

Com

14

AO 1

BI/AI 0

COM

BI/AI 1

COM

BI/AI 2

1

5

Fan

24V

Com

Optional

Standby

N.C. or N.O.

Optional

Condensate

alarm or fail

Figure 14 Controller terminations: [AP] 0, [AP] 1

Sequences of Operation

SYSTEM Block Control (BV-102)

30

* Optional space or outside temperature sensor.

Controller outputs are disabled when Enable Outputs [OE] BV-2 OF/On is in the

OF (inactive) state. Do not enable outputs until you are certain the wiring and

configuration is correct and complete.

When the unit is configured to run in Occupancy Mode, the SYSTEM Block

allows the user direct control of occupied or unoccupied state from the controller

display. Selecting “Auto” places the controller in Occupied state. Selecting

“OFF” places the controller in unoccupied state.

The SYSTEM Block can be hidden by setting BV-102 inactive. When the

SYSTEM Block is hidden occupancy states are controlled exclusively by the

onboard or BMS schedules.

31-00098-01 © Ho neywell

Page 31

Installation and Operations Guide

If onboard or BMS schedules are enabled, the “OFF” selection will override the

controller’s scheduled state and force the unit into Unoccupied state. If you do

not want the user to have this ability, set BV-102 inactive to hide the SYSTEM

Block.

You can optionally change the behavior of the SYSTEM Block “OFF” setting so

that instead of placing the controller in the Unoccupied state, the controller will

turn the fan off. Heating and cooling are disabled when the fan is off. The fan

will remain off until the user changes the SYSTEM Block to “Auto.” Set BV-10

to active to allow this option.

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

Figure 15 Display: SYSTEM Block OFF; SYSTEM Block AUTO

Configure schedules

The BACnet FF can be configured to follow an internal schedule by setting ISU

parameter 160 or BV -133. The BACnet FF may also be scheduled by a BMS. Set

BV-56 to active to enable BMS schedules. BV-133 changes to inactive when

BV-56 is active.

If the internal schedule is OFF, the user can adjust the setpoint (within setpoint

limits).

Schedules are stored in flash memory so they persist through power cycles.

Occupancy control (AV-123 = 0, default)

The controller operates in Occupied state when the Occupied Command (BV -64)

is turned ON by any of the following:

• When the controller’s SYSTEM Block “AUTO” is selected by the user

• By local internal schedule, which writes to BV-40 at priority 16

• By a command sent from a BMS schedule or BMS operator override,

writing to BV-40.

Note If the user is allowed to command the SYSTEM Block, this

command is at priority 10. BMS schedules should write to one of the

BV-40 priorities 12-16 to avoid overriding the user command.

• When the occupant has initiated an aft er-hours override by pressing the

override arrows on the touch screen.

The Unoccupied Setpoints are activated when the controller’s SYSTEM Block is

set to “OFF” by the user.

© Honeywell 31-00098-01 31

Page 32

Installation and Operations Guide

When operating in the Unoccupied state, the override up/down arrows can be

pressed to force the controller into the Occupied state for up to 4 hours (default

value). The override time limit (AV-97) is adjustable from a minimum of 0.2

hours to a maximum of 9.5 hours.

Setting BV-9 to active enables the controller to default to Occupied state

whenever communication with the BMS is lost continuously for more than 5

minutes. The command to Occupied state is implemented by setting BV-64 to

active.

Occupied, Unoccupied, and Standby Heating and Cooling

Setpoints

When operating in the Unoccupied state, the cooling and heating setpoint revert

to specific values:

When operating in the Occupied state, the cooling and heating setpoints are

calculated as offsets from the user adjustable Space Setpoint (AV-90):

BACnet FF

|

• Current Cooling Setpoi nt (AV-99) = Unoccupied Cooling Setpoint

(AV-95)

• Current Heating Setpoint (AV-100) = Unoccupied Heating Setpoint

(AV-96)

• Current Cooling Setpoint (AV-99) = AV-90 plus AV-93 plus Demand

Offset (AV-106)

• Current Heating Setpoint (AV-100) = AV-90 minus AV-94 minus

Demand Offset (AV-106)

When operating in the Standby mode, the Current Cooling Setpoint and Current

Heating Setpoint are calculated as for occupied mode as described above.

However the standby offset ([SO]:, AV-19) is transferred to the Demand Offset

(AV-106) before the computations, resulting in relaxed setpoints during standby

operation.

User adjustment of the Space Setpoint (AV-90) value is limited by the Setpoint

High Limit (AV-91) and the Setpoint Low Limit (AV-92).

Ta bl e 6 Setpoint values in Occupancy control

Field Code De scription

[:SP] AV-90 Space Setpoint

[:HI] AV-91 Setpoint High Limit

[:LO] AV-92 Setpoint Low Limit

[:CO] AV-93 Cooling Setpoint Offset

32

[:HO] AV-94 Heating Setpoint Offset

[:UC] AV-95 Un occupied Cooling Setpoint

[:UH] AV-96Unoccupied Heating Setpoint

31-00098-01 © Ho neywell

Page 33

Installation and Operations Guide

Ta bl e 6 Setpoint values in Occupancy control

Field Code De scription

[CS] AV-99 current calculated Cooling Setpoint

[HS] AV-100 current calculated Heating Setpoint

-- AV-106 demand offset (AV-106 value updates AV-99, AV-100)

[SO] AV-19 standby offset; 0 minimum, 6 maximum degrees DDC transfers value to

AV-106

Setpoint control (AV-123 = 1)

In setpoint mode, the controller logically emulates residential thermostats. The

space temperature is controlled to "SP Mode Cooling SP" (AV-108) and "SP

Mode Heating SP" (AV-109). These setpoints are writable using BACnet. Each

schedule period consists of a start time, a heating setpoint, and a cooling

setpoint. The maximum number of periods per day is configured using ISU

parameter 540 (AV-129). A value of 2 specifies two periods per day -- Wake and

Sleep. A value of 4 specifies four periods per day -- Wake, Leave, Return, and

Sleep. The scheduler selects the last valid period start before the present time as

the period to use. Setpoint mode schedules are not accessible using BACnet. The

only way to view, edit and save a schedule is from the unit's LCD screen.

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

Note Setpoints are writable using BACnet but schedules are not accessible

using BACnet.

If the Standby mode is active, the heating and cooling setpoints are adjusted by

the standby offset ([SO]:, AV-19).

Note The SYSTEM Block is hidden when the controller is in Setpoint control

mode.

Figure 16 Setpoint mode display: single-speed fan

Schedule setpoint overrides in Setpoint mode

An override is created using one of three modes.

Temporary- press an arrow next to a setpoint. The words "Hold Temperature

Unit" appear above the time display, which shows the default ending time (the

© Honeywell 31-00098-01 33

Page 34

Installation and Operations Guide

BACnet FF

|

beginning of the next schedule transition). Use the arrows to adjust the ending

time. Wait a few seconds. The arrows next to the ending time disappear and the

override takes effect.

Permanent- press HOLD. The words “Permanent Hold" appear below the time

display and the override takes effect.

Vacation- while in Permanent Hold, press HOLD. The words "Hold

Temperature Unit" appear above the time display. Use the arrows to select the

number of days (1-365) you want to override to last. Wait a few seconds. The

arrows next to the ending time disappear and the override takes effect.

Pressing CANCEL returns the BACnet FF to the current schedule.

The Setpoint mode override status (AV-113 and MV-13), hold until time

(AV-130), and the number of vacation days left (AV-130) can be adjusted

remotely using BACnet or by DDC.

A user's ability to set Permanent or Vacation holds can be disallowed by setting

BV-115 and BV-130, respectively.

Dual setpoint mode (AV-123 = 2)

In dual setpoint mode, the following quantities are used:

• Occupied Heating SP (AV-109)

• Occupied Cooling SP (AV-108)

• Unoccupied Heating SP (AV-96)

• Unoccupied Cooling SP (AV-95)

• Heating SP Limit (how high the heating setpoint can be set) (AV-92)

• Cooling SP Limit (how low the cooling setpoint can be set) (AV-91)

AV-109 and AV -108 are used to control Occupied Cooling and Occupied Heating

Setpoints. Both are writable using BACnet or the device screen. When the space

is occupied (BV-67 = Active), AV-109 and AV-108 are transferred to the current

heating and cooling setpoints (AV-100 and AV-99).

IMPORTANT! DDC sh ould not use AV-109 or AV-108 directly.

When the space is unoccupied, the Unoccupied Heating and Cooling Setpoints

(AV-96 and AV-95) get transferred to the current heating and cooling setpoints

(AV-100 and AV-99). The Unoccupied heating and cooling setpoints are not

user-adjustable but they are adjustable using field service mode or an operator

34

31-00098-01 © Ho neywell

Page 35

Installation and Operations Guide

Figure 17 Dual setpoint display in Occupied mode: occupied heating setpoint AV-109, user-adjustable and

occupied cooling setpoint AV-108, user-adjustable.

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

workstation. Unoccupied heating and cooling setpoints are not transferred to

AV-109 and AV-108 during unoccupied periods.

Note Use the MORE key to view OSA temperature and humidity values on

subsequent screens.

Fan mode control

Writes to AV-109 and AV-108 are limited by the Setpoint High and Low Limits

(AV-91 and AV-92). Writes to AV-109 and AV-108 are also limited to the heating

setpoint less than the cooling setpoint by a minimum of one degree.

Occupancy mode

During occupancy mode the fan operates based on the selected Fan Mode.

• Fan Control AV-17 = 1: Fan runs continuously for ventilation.

• Fan Control AV-17 = 2: Fan runs continuously for cooling and cycles on

for heating demand. When in Cooling mode, the fan runs continuously.

When in Heating mode, the fan cycles on only when the heating signal

calls for the fan to run.

• Fan Control AV-17 = 3: Fan cycles on when cooling or heating is

selected or during Unoccupied mode only when called to run by cooling

or heating demand.

Setpoint mode

• AV-227 =1: Fan cycles on for cooling and for heating demand.

• AV-227 =2: Fan runs continuously.

Analog fan speed control (optional)

The fan speed analog output AO-1 will ramp from 0-100% based on the heating

or cooling signal demand.

Note Variable speed drives run at minimum motor RPM even if AO-1 is zero

when in run mode.

© Honeywell 31-00098-01 35

Page 36

Installation and Operations Guide

BACnet FF

|

Standby Heating and Cooling setpoints

Standby state is a power-saving function of Occupancy mode. It occurs when the

space is scheduled Occupied, but sensors detect there are no humans in the

space. In this case the occupied heating and cooling setpoints are relaxed by the

Standby Offset [SO]. When the Standby input is active, the economizer is

controlled to its fully-closed position. The value of the Standby Offset [SO] may

be set between a minimum of 0 and a maximum of 12 degrees.

Examples: If [:CS] = 72, [:HS] = 69, and [SO] = 4 then the setpoints are relaxed

to [:CS] = 76, and [:HS] = 65.

Occupied Standby state, wired contacts

A door/window contact, light switch, or PIR is wired to the standby input BI-1.

The switch polarity normally open/normally closed is configured by BV-3 [uL].

Set BV-3 inactive for normally open contacts, active for normally closed

contacts. When the controller is in the Occupied state and the Standby input

(BI-1) is triggered, the room status switches to Occupied Standby state (refer to

Standby Heating and Cooling calculated Setpoints above). A BMS can also be

configured to monitor BI-1 for door/window ajar alarms.

Standby logic: In Standby state, BI-1 is active (e.g. a window is open). BV-4 is

active and the value of the Standby Offset, [SO] AV-19, is transferred to the

Demand Offset, AV-106. The [SO] AV -19 default is 4, the minimum is 0, and the

maximum is 12.

Occupied Standby state, wireless contacts (TB3026B-W only)

The wireless-controller interface sets BV-149 active. BV-149 in the active state

overrides the wired input at BI-1, which no longer has standby control

functionality. If normal standby operation is required, BV-148 should be set to

inactive allowing BI-1 to have standby control as it does on the non-wireless

version. Any of up to 3 wireless PIR motion sensors can be configured and

paired to the controller to sense room occupancy. Any of up to 8 wireless

Window/Door sensors can be configured and paired to the controller to monitor

open/closed status of windows or doors. When the controller is scheduled

Occupied, if any window or door is opened and closed with no motion detected

after 180 seconds, the room status switches to Occupied Standby state. The

controller returns to the Occupied state when motion is detected. If a door or

window is left open for more than 180 seconds, the controller sets to Standby

state.

Standby logic: In Standby state, BV-4 is active and the value of the Standby

Offset, [SO] AV-19, is transferred to the Demand Offset, AV-106. The [SO]

AV-19 default is 4, the minimum is 0, and the maximum is 12.

Optional BI-1 input configuration (TB3026B-W only)

Input BI-1 on the BACnet FF may be used for point monitoring by a BMS.

• A dry contact normally open (e.g., filter status DPS, etc.)

• Standby Offset AV-19 is used by the wireless standby monitoring logic.

Do Not set to zero (0).

36

31-00098-01 © Ho neywell

Page 37

Installation and Operations Guide

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

Heating and Cooling Demand

Heating (AV-0) and Cooling (AV-1) signals are generated from the Space

Temperature and the current Heating and Cooling Setpoints using a

proportional-integral (PI) control algorithm. The two signals are compared, and

the smaller one is set to zero to prevent any simultaneous heating and cooling. In

the event of a Bad Space Sensor Alarm, both heating and cooling signals are set

to zero.

Upon power-up or any transition to Occupied state, the integral component is

re-initialized for both the Heating Signal and Cooling Signal PI control loops.

Heating and Cooling Signals — PI settings

The Heating signal PI settings are Heating Signal Kp (AV-41) and Heating

Signal Ki (AV-42). The Cooling Signal PI settings are Cooling Signal Kp

(AV-43) and Cooling Signal Ki (AV-44).

Compressor Control

Reversing Valve

The reversing valve does not change positions until the compressor has been

OFF for at least 60 seconds. The reversing valve is set to the heating position

(ON) when the heating signal exceeds 10 and the heating lockout is OFF.

Otherwise the reversing valve is in the cooling position. Anti-cycle protection

prevents the valve from changing positions more than once every two minutes.

Some air-to-air heat pumps require the reversing valve to be activated in order to

have the coil in Cooling mode. For cooling with the reversing valve active (ON),

change [HC] or BV-21 to reverse the valve action.

AC-HP Control Mode (AV-40 set to 1)

The compressor commanded cycles ON when the current value of the

compressor control signal is equal to or greater than the compressor start demand

setpoint. The compressor command remains ON until the control signal drops

below the stop setpoint. The compressor command setpoints are adjustable from

the display . When the fan requests AC cooling, BV-7 is ON. When BV-7 is OFF,

the fan stops after a short delay. The compressor will not start unless the fan is

ON. An anti-cycle timer prevents short-cycling the compressor.

AV-68 AC-HP Compr Start Demand % (set at 20% default).

AV-69 AC-HP CMPR Stop Deadband % (default set at 1%)

AV-27 is minimum On time MON in minutes (anti-cycle).

AV-57 is minimum OFF time MOF in seconds (anti-cycle).

AC-HP control mode (AV-40, default set at 2)

Note AC or HP mode 1= ON-OFF (Demand Compare Control), 2= Analog to

Binary Cycle Time Control.

The compressor control signal is selected between the Heating signal and the

Cooling signal, depending on the status of the Heating/Cooling mode.

© Honeywell 31-00098-01 37

Page 38

Installation and Operations Guide

For Heating mode, the compressor signal ranges 0-100 as the Heating signal

ranges 0-65. The Heating signal range 65-100 is reserved for auxiliary heat

control.

For Cooling mode, the compressor signal ranges 0-100 as the Cooling signal

ranges 0-100.

The compressor cycles ON for a percentage of the Compressor Cycle Time [Cc]

according to the current value of the compressor-control signal. The Compressor

Cycle Time [Cc] is adjustable from the display. Recommended cycle time range

is 6-12 minutes. The compressor does not start unless the fan is ON. When the

reversing valve changes position, there is a short delay before compressor

operation is allowed. The Cooling or Heating Signal is processed by an

analog-to-binary timer that controls the BO’s ON/OFF duration. Runtime and

compressor starts are accumulated.

When either the Cooling Lockout is ON or the Low-Supply-T emperature Alarm

is ON, the compressor-control signal is set to zero, disabling the compressor

without overriding the minimum ON time. The cooling lockout setting is

controlled by [cL]. A normally-open condensate sensor can be connected across

BI-2. If BI-2 is shorted (indicating condensate is sensed) AI-2 reads 572.

Compressor operation is locked out until the condensate alarm lock out clears.

BACnet FF

|

When the Heating Lockout is ON, the compressor control signal is set to zero.

The heating lock out temperature is controlled by the [hL] setting.

Compressor timing

Cycle times and minimum on/off times need to be set for operation of the

heat-pump compressor.

Water source [AP] 1

The compressor control (BV-31 WS HP Water Loop OK) must be enabled from

the display or a BMS, ensuring that the water-source temperature is within the

operating range for the heat pump and that water is flowing in the water-source

loop. Heat Pump safeties need to be hard wired with the compressor’s binary

output. The control sequence is identical to the air-to-air heat pump.

Staged auxiliary heating

Auxiliary heating is controlled by the upper portion of the Heating Signal range.

The auxiliary heat signal ranges 0-100 as the Heating Signal ranges 65-100.

Auxiliary heating is staged ON for a percentage of each set Heating-Cycle

period [Hc] based on the value of the auxiliary heat signal. [Hc] operation is

locked out when the outside-air temperature is above the Auxiliary Heating

Lockout Temperature [hL]. Runtime is accumulated for auxiliary heating.

• AV-26 [Cc] AC-HP Compressor Cycle Time: (CYC) time in minutes

(factory default = 12 minutes)

• AV-27 [cc] AC-HP Compressor Minimum ON-OFF: (MON) and

(MOF) time in minutes (factory default = 3 minutes)

38

High and low refrigerant pressure cutouts must be separately provided,

preferably hard-wired, to stop compressor operation in the event of these

conditions. Outdoor coil defrost control and any provisions to allow oil sump

31-00098-01 © Ho neywell

Page 39

Installation and Operations Guide

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

heaters to be effective must also be included in the equipment manufacturer’s

controls or otherwise provided for.

Single-stage auxiliary heating

Auxiliary heat responds to the range of 65-100 of the Heating signal.

Staged heating timing

Cycle times and minimum on/off times need to be set for operation of the

electric heating stages. Staged heating will not run if either of the following two

values are zero.

• A V-28 [Hc] Heating Stages Cycle Time: (CYC) time in minutes (factory

default = 3 minutes)

• AV-29 [hc] Heating Stages Minimum ON-OFF: (MON) and (MOF )

time in minutes. (factory default = 1 minute)

Compressor and Heating-stages Binary Control

DDC cycles the output ON for a percentage of each cycle time (CYC), based on

a 0.0 to 100.0 analog input control signal. For example, if the control signal is

75.0, then the output will be ON only for the first 75% of the cycle time.

The minimum ON time (MON) and minimum OFF time (MOF) prevent short

cycling. The output turns ON only if the calculated ON time is greater than the

MON. If the output is ON, it remains ON until it has been ON for the calculated

ON time and the MON has expired. The output remains ON continuously if the

calculated OFF time is less than the MOF.

• Inputs must be positive numbers.

• Time resolution is 1 second

• CalculatedOnTime = CycleTime (Input/100.0)

• CalculatedOffTime = CycleTime minus CalculatedOnTime

Air stratification and humidity control in Unoccupied state (optional)

Set BV-53 active to enable additional humidity control during Unoccupied

Mode. A humidity trigger setpoint is entered as AV-30, with humidity dead band

entered as AV-31. When sensed humidity equals or exceeds humidity trigger

setpoint, the fan cycles ON/OFF at low speed until sensed humidity drops below

the trigger setpoint minus the dead band.

Example: If AV-30 is set for 75 and AV-31 is set for 5: The fan will cycle when

the space humidity is >= 75 and continue to cycle until the space humidity drops

below 70.

The fan cycles ON for AV-48 seconds (default 1800) and OFF for AV-47 seconds

(default 300) when stratification and humidity control is active.

© Honeywell 31-00098-01 39

Page 40

Installation and Operations Guide

BACnet FF

|

Ta bl e 7 Unoccupied air stratification and humidity controls

Enable RH Fan Circulation Cycle BV-53 Active Unoccupied state

Fan ON Cycle Time Low Speed AV-48 1800 Seconds

Fan OFF Cycle Time Low Speed AV-47 300 Seconds

Sensed Space Humidity %RH AV-105 %RH Humidity

Space Humidity %RH Setpoint AV-30 User Value Humi dity

Space Humidity %RH Deadband AV-31 User Value Humidity

Economizer sequence (optional)

The economizer logic is enabled when Economizer Damper Stroke Time [ES]

AV-63 is set to 5 seconds or above. If the economizer option will not be used,

[ES] AV-63 should be set to 0 (factory default); this will prevent the economizer

relays from clicking. If the analog modulating option is to be used, [ES] AV-63

should be set to 5. The economizer sequence requires that a supply air sensor be

wired to AI-2.

Point Value Units

As the Cooling signal varies between 0 and 30, the economizer command varies

between the current minimum position [AV-66] and full open position. When

either the Occupied command or the After-hours Timer is ON, the current

minimum position [AV-66] is set to the specified Economizer Minimum

Position; otherwise it is zero. The default minimum position is 20. The

Economizer Minimum Position is set to zero if the fan is OFF.

The economizer minimum position will only work when "Schedule Mode " is

configured as "Setpoint Mode". It will be forced to the current minimum position

when any of the following are true:

• Outside Air Temperature goes above the Economizer Lockout

• Supply Temperature goes below the Low Supply Temperature Limit

• the unit is in Heat Mode

The Economizer Damper Stroke Time [ES] is used in combination with the

current economizer commanded position to estimate the actual current position

of the economizer damper. A BMS is required to set the values for AV-60,

AV-66, and AV-67.

Analog modulating economizer

The economizer is controlled directly by the economizer command output on

AO-0.

Temperature [AV-67]

[AV-60]

3-point floating motor economizer

The economizer is controlled directly by the economizer command. As the

command signal increases, BO-4 is active, driving the economizer open. As the

command signal decreases, BO-5 is active, driving the economizer closed.

40

31-00098-01 © Ho neywell

Page 41

Installation and Operations Guide

Heat Pump Alarms

If the Supply Temperature (AI-2) drops below the Supply Air Low Temp Limit

[LL] for more than 20 seconds, the Lo Limit Alarm (BV-20) is triggered. The

alarm automatically resets when the Supply T emperature exceeds the Supply Air

Low Temp Limit [LL] by 7 degrees and the Supply Temperature remains above

the Supply Air Low Temp Limit [LL] for 10 minutes. The Supply Air Low T emp

Limit [LL] default is 40º F (5º C).

When condensate is sensed, e.g., BI-2 is shorted (active), AI-2 reads 572.

Compressor operation is locked out until the condensate alarm lock out clears.

Space Temperature Alarms

A Bad Space-Sensor Alarm is activated if the room-temperature sensor indicates

a temperature greater than 120°F/50°C or less than 40°F/5°C.

Runtimes

Separate runtimes are accumulated for the fan and the filter based on fan

operation. The runtimes can be reset independently in the event of filter

replacement. A filter alarm, BV-16, is triggered if the filter runtime exceeds the

filter-alarm setpoint. AV-86 will reset the runtime on the filter.

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

English/Metric units configuration

The display contains adjustment arrows to change the controller’s main display

for English “F” or Metric “C”. The controller internal units English or Metric are

set by BV-71. BV-71 is set to inactive (default) for English or active for Metric.

Selecting either adjustment arrow will update the display units F or C. Setting

BV-8 (Lock Display Units Swap) to active will display the opposite units as

indicated by BV-71 and will lock out changes to the display.

Figure 18 Display: Metric (C) or English (F); Fan Auto (Au) or Fan Manual (On)

Note BV-55 controls Fan Auto/Fan ON display. Setting BV-55 inactive hides

Fan Auto/Fan ON. Setting BV-55 active shows Fan Auto/Fan ON status. If

BV-55 is inactive, BV-58 inactive/active control by BMS toggles Fan

Auto/Fan/ON.

© Honeywell 31-00098-01 41

Page 42

Installation and Operations Guide

Ta bl e 8 Setup codes: [AP] 0 or [AP] 1

Code Object Default Options Units Notes

AP AV-49 Application selection 0-1 0-18

OE BV-2 Outputs enable OFF OFF/ON Set to ON to enable outputs

HC BV-21 Rev Vlv Action HP or

4PHTG

FC AV-17 Fan1=Cont 2=CycHtg

3=CycHtgClg

CC AV-26 AC-HP Compr Cycle Time 12 Min

C0 AV-27 AC-HP Compr Min ON 3 Min

CF AV-18 AC-HP Compr Min OFF 3 Min

hC AV-28 Heating Stages Cyc Time 12 Min

h0 AV-29 Heating Stages Min ON 3 Min

hF AV-80 Heating Stages Min OFF 3 Min

2C AV-37 2 Pos Valves Cyc Time 3 Min

2c AV-38 2 Pos Valves Min ON 1 Min

c5 AV-64 Clg or 2-pipe Valve Stroke

Time

h5 AV-65 Htg Valve Stroke Time 3 Sec Heating Valve Stroke Time:

2P AV-34 2PVlvMode 1=ON-OFF

2=ABOT 3=TMV

FA BV-55 Enable Fan CTL Display OFF OFF/ON

cL AV-70 Cooling Lockout Temp 55 Deg

BACnet FF

|

OFF OFF/ON Apps 0-3, 6-9 & 17.

1 1,2,3

3 Sec Cooling Valve Stroke Time:

2 1,2,3

Value<=3 disables 3-point floating

binary output

Value<=3 disables 3-point floating

binary output

hL AV-72 Heating Lockout Temp 62 Deg

P5 BV-47 Enable AI-0 Sensor OFF OFF/ON

5r BV-32 Enable Remote Space

Sensor

F1 AV-46 Auto Fan Start Demand % 20 % Fan demand is based on AV-0 or

F5 AV-5 Fan Stop Delay Seconds SP15 Sec

F2 AV-85 Medium Speed Fan Start SP40 % Do not set less than AV-46 + 5

F3 AV-89 High Speed Fan Start SP 70 % Do not set less than AV-85 + 5

uL BV-3 Rev Standby Logic BI-1 OFF OFF/ON

50 AV-19 Standby Htg Offset Deg

SP AV-90 Occupied Space Setpoint 70 70 Deg

HI AV-91 Setpoint High Limit 78 78 Deg

42

OFF OFF/ON

AV-1 % signal

31-00098-01 © Ho neywell

Page 43

Installation and Operations Guide

Ta bl e 8 Setup codes: [AP] 0 or [AP] 1

Code Object Default Options Units Notes

LO AV-92 Setpoint Low Limit 62 62 Deg

CO AV-93 Cooling Offset 2 2 Deg

HO AV-94 Heating Offset 1 1 Deg

UC AV-95 Unoccupied Clg Setpoint 85 85 Deg

UH AV-96 Unoccupied Htg Setpoint 55 55 Deg

AL AV-97 After Hours Limit 4 4 Hours

Ta bl e 9 Requires BMS to set

Code Point Value Default Options Units Notes

BV-102 Show SYSTEM

control

Heat Pumps: Apps 0 and 1 [AP] 0: Air-to-air heat pump and [AP] 1:

|

Active Inactive/Active A visible SYSTEM Block may or

may not be required with

schedules. SYSTEM Block “OFF”

overrides scheduled occupied

states to unoccupied.

AV-123 Schedule

Model

BV-12 Dehumidify

Mode On

BV-27 Heating

Lockout

BV-28 Cooling

Lockout

BV-31 WS HP Water

Loop OK

BV-53 Enable RH Fan

Circ Cycle

BV-71 English

(OFF)/Metric

(ON)

AV-20 Standby Delay

Seconds

BV-56 Enable BMS

Scheduling

BV-53 Enable RH%

Fan Circ Cycle

AV-30 Dehumidify

Setpoint

Trigger

0

Inactive Inactive/Active Enables dehumidification App 10

Inactive Inactive/Active

Inactive Inactive/Active

Active Inactive/Active BMS enable allows heat pumps to

OFF OFF/ON

OFF OFF/ON System level settings impact DDC

180 180 Sec