Page 1

31-00121-02

TB3026B Configuration

Wizard Guide - N4

CONFIGURATION GUIDE

JUNE 2018

Page 2

Page 3

BACnet FF Controller

Table of Contents

INTRODUCTION ..................................................................................................................................................................... 5

WEBStation-N4TM ................................................................................................................................................................ 5

Features ..................................................................................................................................................................... 5

TB3026B Configuration Wizard ........................................................................................................................................... 5

TB3026B Configuration Requirement .................................................................................................................................. 6

Organization of the Manual .................................................................................................................................................. 6

CONFIGURATION OF TB3026B AND TB3026B-W CONTROLLERS .................................................................................. 7

Installation ........................................................................................................................................................................... 7

Installation of WEBStation-N4TM Tool ............................................................................................................................. 7

Getting Started..................................................................................................................................................................... 8

Digital Signature ............................................................................................................................................................. 8

TB3026B Configuration Wizard Initial Setup .................................................................................................................12

Connecting to Platform ..............................................................................................................................................12

Adding New Station ...................................................................................................................................................12

Starting New Station .................................................................................................................................................14

Adding BACnet Network to Niagara Network ............................................................................................................16

Adding TB3026B Controller to the BACnet Network .................................................................................................18

TB3026B Configuration Wizard .....................................................................................................................................19

Field Description for TB3026B Configuration Wizard ....................................................................................................20

APPLICATIONS ................................................................................................................................................................... 21

Equipment Type................................................................................................................................................................. 21

AHU ...............................................................................................................................................................................22

General Display .........................................................................................................................................................23

Schedule Options ......................................................................................................................................................25

Zone Setpoints ..........................................................................................................................................................27

Control Settings .........................................................................................................................................................30

Fan / Humidity ...........................................................................................................................................................32

Economizer ...............................................................................................................................................................34

I/O Configurations .....................................................................................................................................................35

Air Source Heat Pump ...................................................................................................................................................37

General Display .........................................................................................................................................................38

Schedule Options ......................................................................................................................................................40

Zone Setpoints ..........................................................................................................................................................42

Control Settings .........................................................................................................................................................45

Fan / Humidity ...........................................................................................................................................................47

Economizer ...............................................................................................................................................................49

I/O Configurations .....................................................................................................................................................50

Water Source Heat Pump..............................................................................................................................................52

General Display .........................................................................................................................................................53

Schedule Options ......................................................................................................................................................55

Zone Setpoints ..........................................................................................................................................................57

Control Settings .........................................................................................................................................................60

Fan / Humidity ...........................................................................................................................................................62

Economizer ...............................................................................................................................................................64

I/O Configurations .....................................................................................................................................................65

Two Pipe Fan Coil Unit ..................................................................................................................................................67

General Display .........................................................................................................................................................69

Schedule Options ......................................................................................................................................................71

1 31-00121—02

Page 4

BACnet FF Controller

Zone Setpoints .......................................................................................................................................................... 73

Control Settings ........................................................................................................................................................ 76

Fan / Humidity ........................................................................................................................................................... 80

I/O Configurations ..................................................................................................................................................... 82

Four Pipe Fan Coil Unit ................................................................................................................................................. 85

General Display ........................................................................................................................................................ 87

Schedule Options...................................................................................................................................................... 89

Zone Setpoints .......................................................................................................................................................... 91

Control Settings ........................................................................................................................................................ 94

Fan / Humidity ........................................................................................................................................................... 97

Economizer ............................................................................................................................................................. 100

I/O Configurations ................................................................................................................................................... 101

ONLINE OPERATIONS ...................................................................................................................................................... 106

Download ........................................................................................................................................................................ 106

Upload ............................................................................................................................................................................. 106

Write Device Instance...................................................................................................................................................... 106

Sensor Calibration ........................................................................................................................................................... 107

Diagnostics ...................................................................................................................................................................... 108

Modulating Output Diagnostics ................................................................................................................................... 109

Binary Output Diagnostics ........................................................................................................................................... 109

Refresh ....................................................................................................................................................................... 109

Alarms ............................................................................................................................................................................. 110

Error ............................................................................................................................................................................ 110

Error Details ................................................................................................................................................................ 110

Value Limits ................................................................................................................................................................ 110

Current Value .............................................................................................................................................................. 110

Refresh alarm list ........................................................................................................................................................ 110

Auto Refresh / Update auto refresh rate ..................................................................................................................... 110

Time Sync ....................................................................................................................................................................... 111

Batch Operations ............................................................................................................................................................. 112

Download .................................................................................................................................................................... 113

Upload ......................................................................................................................................................................... 113

Set Outputs to Auto ..................................................................................................................................................... 113

HONEYWELL SOFTWARE END USER LICENSE AGREEMENT .................................................................................... 114

2 31-00121—02

Page 5

BACnet FF Controller

List of Figures

Figure 1: Installing WEBStation-N4

Figure 2: Installing WEBStation-N4TM (selecting installation location) ..................................................................................... 7

Figure 3: Installing Platform Daemon ...................................................................................................................................... 9

Figure 4: WEBStation-N4TM – Getting Started ........................................................................................................................10

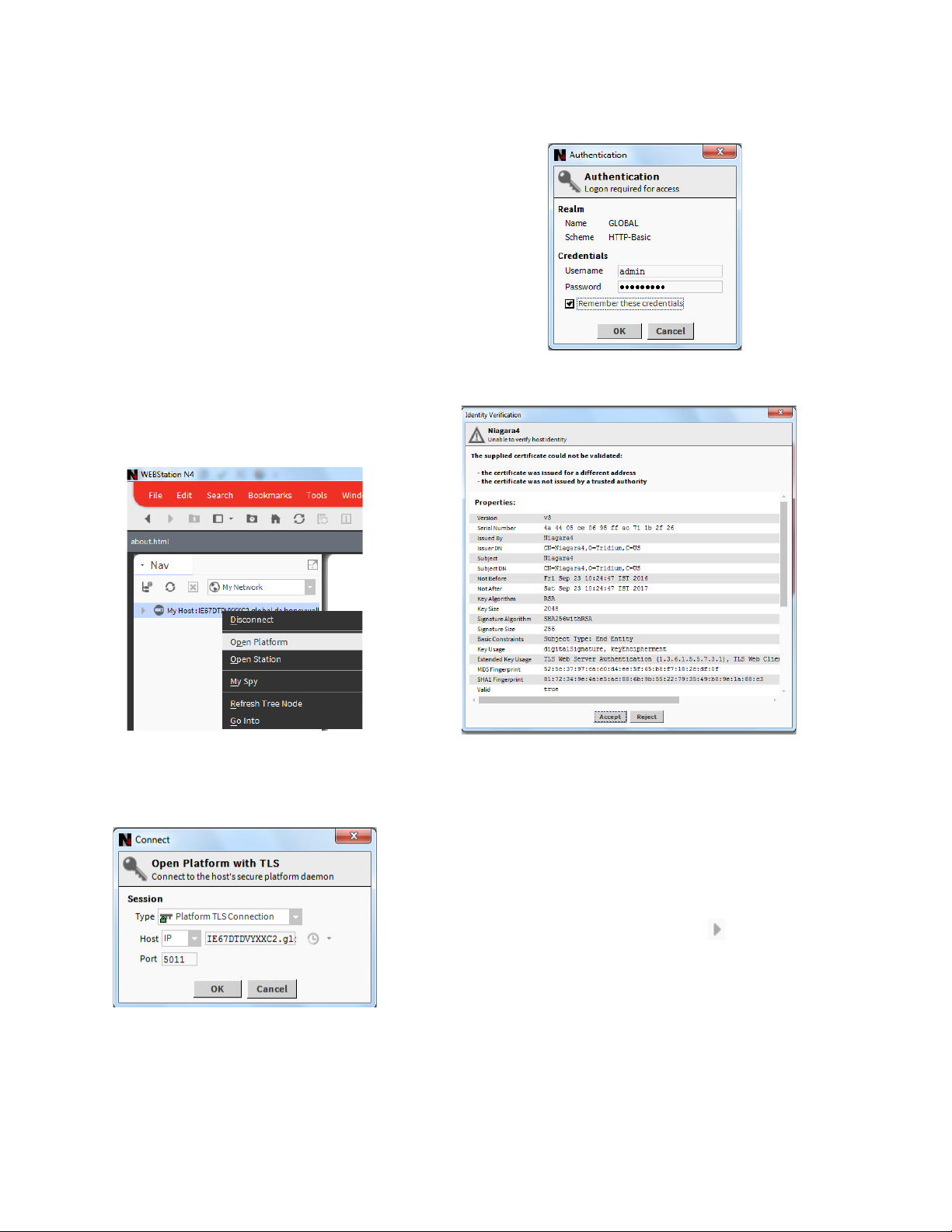

Figure 5: Open Platform .........................................................................................................................................................12

Figure 6: Connect Platform ....................................................................................................................................................12

Figure 7: Authentication during connecting Platform ..............................................................................................................12

Figure 8: Identity Verification during Connecting to Platform ..................................................................................................12

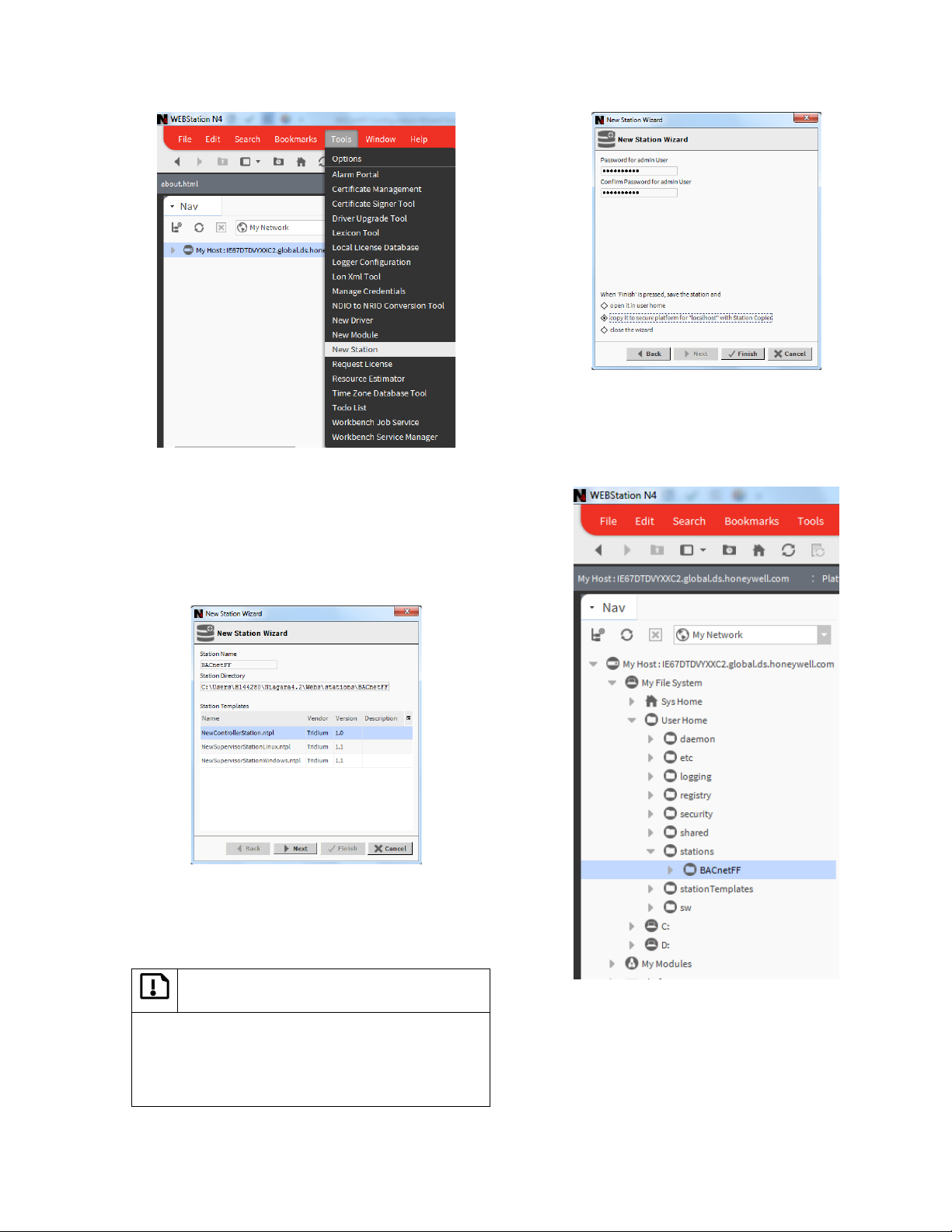

Figure 9: Adding New Station .................................................................................................................................................13

Figure 10: New Station Wizard Window .................................................................................................................................13

Figure 11: Entering Admin Password for New Station............................................................................................................13

Figure 12: Location of New Station (BACnetFF) ...................................................................................................................13

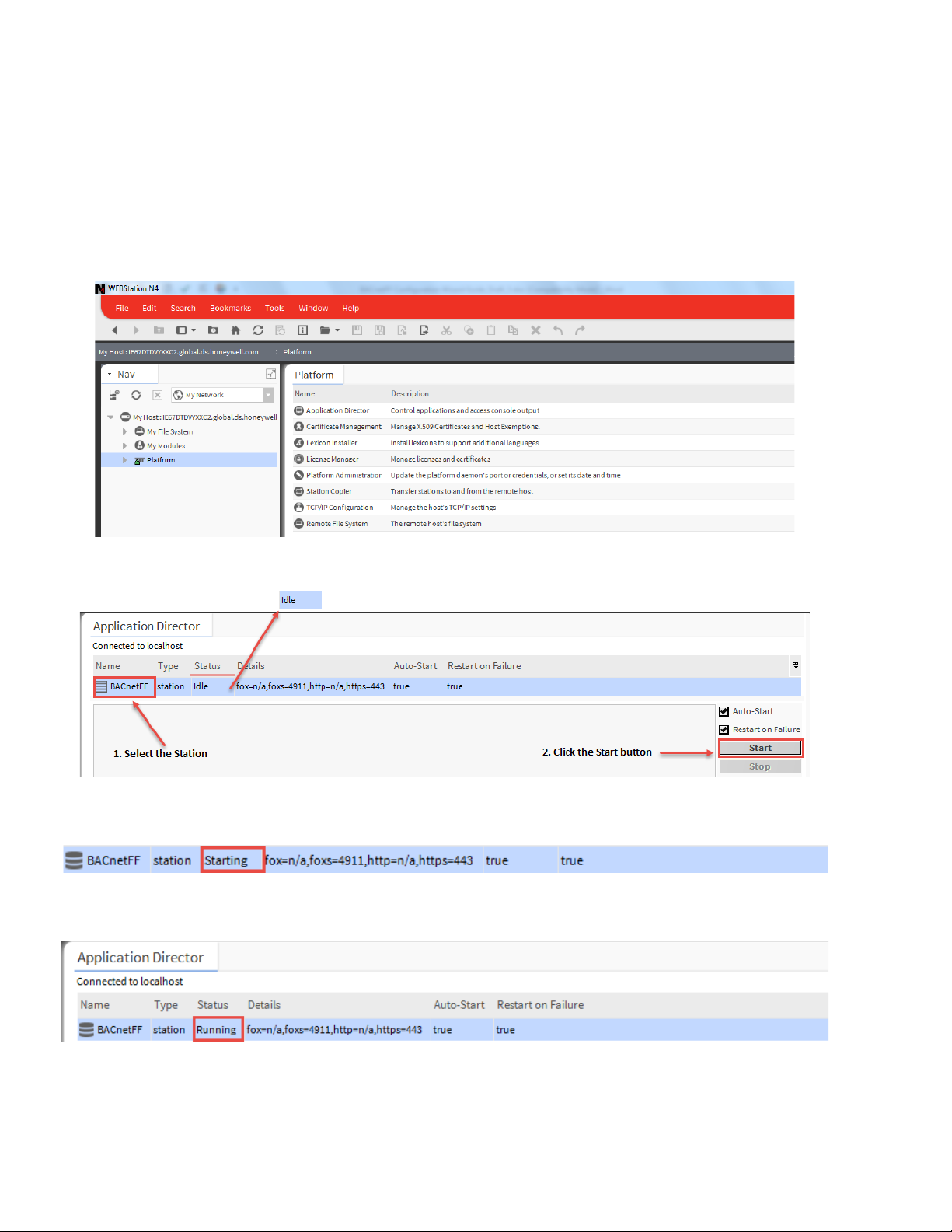

Figure 13: Application Director ...............................................................................................................................................14

Figure 14: Selecting the Station to Start .................................................................................................................................14

Figure 15: Starting the Station ................................................................................................................................................14

Figure 16: Started Station ......................................................................................................................................................14

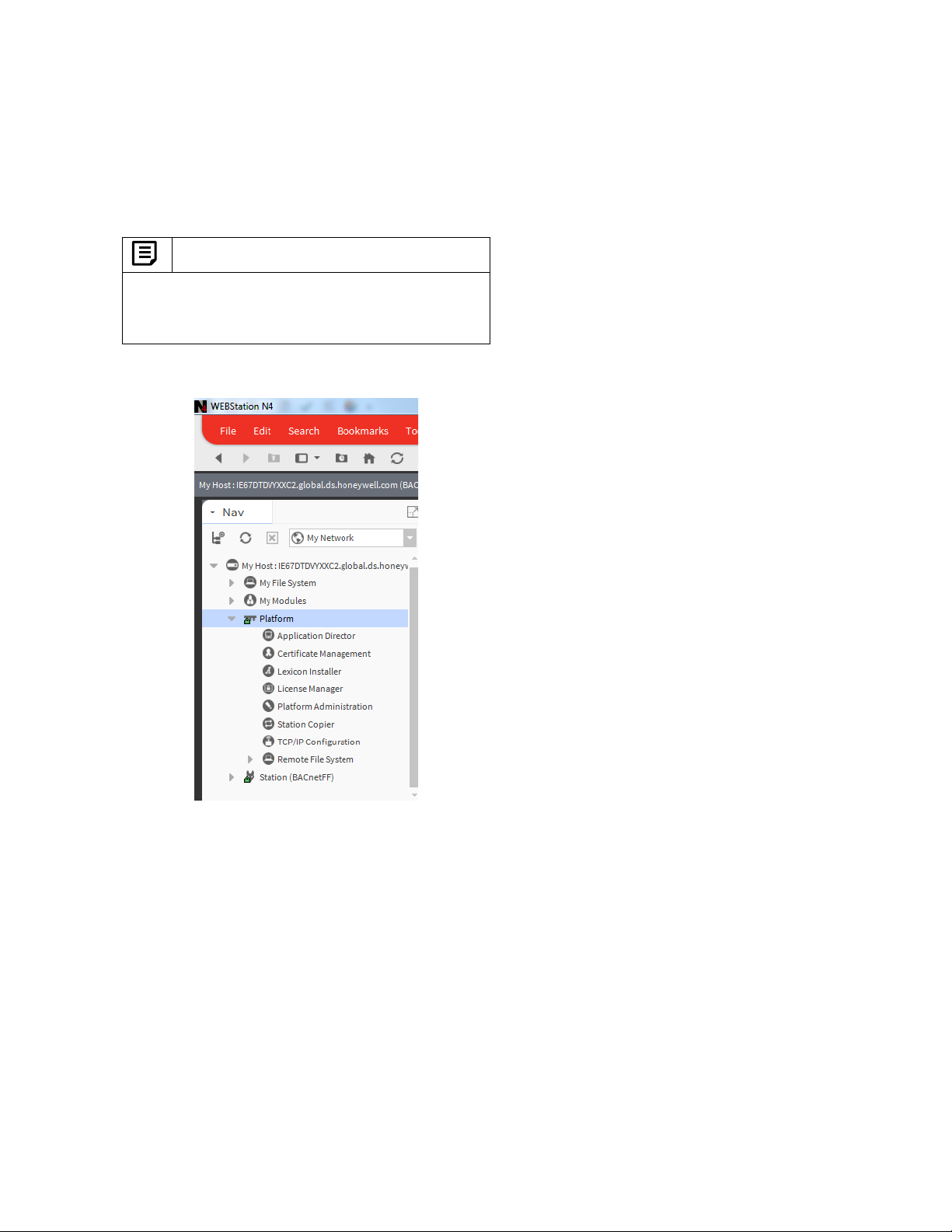

Figure 17: Newly added Station .............................................................................................................................................15

Figure 18: Adding BACnet Network........................................................................................................................................16

Figure 19: Selecting BACnet Network to add .........................................................................................................................16

Figure 20: Adding Specification to add BACnet Network .......................................................................................................17

Figure 21: Newly added BACnet Network ..............................................................................................................................17

Figure 22: Adding Palette .......................................................................................................................................................18

Figure 23: Opening Palette ....................................................................................................................................................18

Figure 24: Adding ‘honeywellTB3026BWizard’ to BACnet Network .......................................................................................18

Figure 25: BACnetFF in Palette TAB......................................................................................................................................18

Figure 26: Drag and drop BACnetFF on BacnetNetwork .......................................................................................................18

Figure 27: Naming Controller .................................................................................................................................................19

Figure 28: Location of Controller ............................................................................................................................................19

Figure 29: Opening TB3026B Configuration Wizard Screen ..................................................................................................20

Figure 30: Field description for TB3026B Configuration Wizard Screen ................................................................................20

Figure 31: Application Screen ................................................................................................................................................21

Figure 32: Equipment Type ....................................................................................................................................................21

Figure 33: AHU window ..........................................................................................................................................................22

Figure 34: General Display Screen (AHU) .............................................................................................................................23

Figure 35: Schedule Options Screen (AHU) ...........................................................................................................................25

Figure 36: Zone Setpoints Screen (Occupancy Mode)...........................................................................................................27

Figure 37: Zone Setpoint Screen (Setpoint Mode) .................................................................................................................29

Figure 38: Control Settings Screen (AHU) .............................................................................................................................30

Figure 39: Fan/Humidity Screen (AHU) ..................................................................................................................................32

Figure 40: Economizer Screen (AHU) ....................................................................................................................................34

Figure 41:I/O Configurations Screen (AHU) ...........................................................................................................................35

Figure 42: Terminal Assignment View (AHU) .........................................................................................................................36

Figure 43: Air Source Heat Pump Window .............................................................................................................................37

Figure 44: General Display Screen (Air Source Heat Pump) .................................................................................................38

Figure 45: Schedule Options Screen (Air Source Heat Pump) ...............................................................................................40

Figure 46: Zone Setpoints Screen (Occupancy Mode)...........................................................................................................42

Figure 47: Zone Setpoint Screen (Setpoint Mode) .................................................................................................................44

Figure 48: Control Settings Screen (Air Source Heat Pump) .................................................................................................45

Figure 49: Fan/Humidity Screen (Air Source Heat Pump) ......................................................................................................47

Figure 50: Economizer Screen (Air Source Heat Pump) ........................................................................................................49

Figure 51: I/O Configurations Screen (Air Source Heat Pump) ..............................................................................................50

TM

..................................................................................................................................... 7

31-00121—02 3

Page 6

BACnet FF Controller

Figure 52: Terminal Assignment View (Air Source Heat Pump) ............................................................................................. 50

Figure 53: Water Source Heat Pump Window ....................................................................................................................... 52

Figure 54: General Display Screen (Water Source Heat Pump) ............................................................................................ 53

Figure 55: Schedule Options Screen (Water Source Heat Pump) ......................................................................................... 55

Figure 56: Zone Setpoints Screen (Occupancy Mode) .......................................................................................................... 57

Figure 57: Zone Setpoint Screen (Setpoint Mode) ................................................................................................................. 59

Figure 58: Control Settings Screen (Water Source Heat Pump) ............................................................................................ 60

Figure 59: Fan/Humidity Screen (Water Source Heat Pump) ................................................................................................ 62

Figure 60: Economizer Screen (Water Source Heat Pump)................................................................................................... 64

Figure 61: I/O Configurations Screen (Water Source Heat Pump) ......................................................................................... 65

Figure 62: Terminal Assignment View (Water Source Heat Pump) ....................................................................................... 66

Figure 63: Two Pipe Fan Coil Unit Window............................................................................................................................ 67

Figure 64: General Display Screen (Two Pipe Fan Coil Unit) ................................................................................................ 69

Figure 65: Schedule Options Screen (Two Pipe Fan Coil Unit) ............................................................................................. 71

Figure 66: Zone Setpoints Screen (Occupancy Mode) .......................................................................................................... 73

Figure 67: Zone Setpoint Screen (Setpoint Mode) ................................................................................................................. 75

Figure 68: Control Settings Screen (Two Pipe Fan Coil Unit) ................................................................................................ 76

Figure 69: Fan/Humidity Screen (Two Pipe Fan Coil Unit) .................................................................................................... 80

Figure 70: I/O Configurations Screen (Two Pipe Fan Coil Unit) ............................................................................................. 82

Figure 71: Terminal Assignment View (Single Speed Fan) .................................................................................................... 82

Figure 72: Four Pipe Fan Coil Unit window ............................................................................................................................ 85

Figure 73: General Display Screen (Four Pipe Fan Coil Unit)................................................................................................ 87

Figure 74: Schedule Options Screen (Four Pipe Fan Coil Unit) ............................................................................................. 89

Figure 75: Zone Setpoints Screen (Occupancy Mode) .......................................................................................................... 91

Figure 76: Zone Setpoint Wizard Screen (Setpoint Mode) ..................................................................................................... 93

Figure 77: Control Settings Screen (Four Pipe Fan Coil Unit)................................................................................................ 94

Figure 78: Fan/Humidity Screen (Four Pipe Fan Coil Unit) .................................................................................................... 97

Figure 79: Economizer Screen (Four Pipe Fan Coil Unit) .................................................................................................... 100

Figure 80:I/O Configurations Screen (Four Pipe Fan Coil Unit) ........................................................................................... 101

Figure 81: Terminal Assignment View (Three Speed Fan) .................................................................................................. 101

Figure 82: Selecting ‘Download’ ........................................................................................................................................... 106

Figure 83: Selecting ‘Upload’ ............................................................................................................................................... 106

Figure 84: Write Device Instance ......................................................................................................................................... 106

Figure 85: Online Operations View ...................................................................................................................................... 106

Figure 86: Sensor Calibration .............................................................................................................................................. 107

Figure 87: Outputs Overridden Mode/Diagnostics ............................................................................................................... 108

Figure 88: Viewing Alarms ................................................................................................................................................... 110

Figure 89: Selecting ‘Honeywell Time Sync’ ........................................................................................................................ 111

Figure 90: Time Sync View .................................................................................................................................................. 111

Figure 91: Selecting ‘BACnet FF Batch Operations’ ............................................................................................................ 112

Figure 92: BACnet FF Batch Operations’ view ..................................................................................................................... 112

Figure 93: BACnet FF Batch Operations’ view while loading the Mode Status .................................................................... 113

4 31-00121—02

Page 7

BACnet FF Controller

INTRODUCTION

The BACnet Fixed Function (TB3026B) is a

communicating sensor/fixed application controller with a

built-in humidity sensor. The TB3026B-W is the wireless

version with an onboard wireless receiver for wireless

occupancy control.

It supports the following equipment types:

1. AHU

2. Air Source Heat Pump

3. Water Source Heat Pump

4. Two Pipe Fan Coil Unit

5. Four Pipe Fan Coil Unit

Each equipment type has other various configurable

settings, which provide multiple options and flexibility to the

user. Configuration of the TB3026B and TB3026B-W

controllers involves selection of the appropriate settings

from available options as per the application requirement.

It can be configured using the ‘TB3026B Configuration

Wizard’. This configuration wizard is developed under

WEBStation-N4

Framework® software. It utilizes BACnet

communication technology (MS/TP).

WEBStation-N4TM

The WEBStation-N4™, powered by the Niagara N4

Framework® is a flexible network server for all connected

WEBs-N4 controllers.

WEBStation-N4™ creates a powerful network environment

with comprehensive database management, alarm

management and messaging services.

WEBStation-N4™ hosts an application called ‘TB3026B

Configuration Wizard’, which provides an engineering

environment for configuration of TB3026B and TB3026B-W

controllers.

TM

software tool which uses the NiagaraN4

®

network

Features

• Provisioning of multi-controller systems (tools for

updating and installation of software modules).

• Central database storage for attached controllers.

• Archive destination/repository for log and alarm data.

• Central server of graphics and aggregated data (single

point of access to the system – one IP address).

• Platform for optional enterprise applications.

WEBStation-N4™ acts as a network server or a

‘Supervisor’ for all connected WEBs-N4™ Controllers. It

creates a network environment for the management of

these controllers, alarms and messaging services.

TB3026B Configuration Wizard

It is a special application developed in the WEBStation-N4

to configure the TB3026B and TB3026B-W controllers. All

configurable network variables of theTB3026B and

TB3026B-W controllers are accessible through this

application for configuration.

TB3026B Configuration Wizard provides a means to select

settings for all equipment types, control strategy and

parameters as per the application requirement.

The following operations can be performed using this

wizard:

1. Add a TB3026B controller on the BACnet network.

2. Configure and set the parameters as per the

application requirements.

3. Download and upload the configuration into the

selected TB3026B controller (Online Operation).

4. Set the time and date.

31-00121—02 5

Page 8

BACnet FF Controller

TB3026B Configuration

Requirement

TB3026B controller is configured using following:

1.

With WEBStation- N4 Software Tool

In the WEBStation-N4

Configuration Wizard application is integrated for TB3026B

and TB3026B-W controllers’ configuration.

• Configuration through PC

TB3026B controllers can be accessed with a personnel

computer with WEBStation-N4

Via BACnet converter, which connects a PC, TB3026B

controller can be accessed for configuring, uploading,

downloading operations.

• Configuration through WEBs Controller

If the TB3026B controller is on the BACnet network of

WEBs controller, it can be accessed through WEBs

controller using a PC with WEBStation-N4

When WEBs controller is already commissioned, then it

can be accessed through an IP address via Browser. All

required operations on the TB3026B controller can be

performed by accessing WEBs controller.

2. Through TB3026B touch screen

Configurable network parameters are also accessible

through the TB3026B touch screen. Access to the

configurable parameters is password protected with a

default password of 0000. For details refer to, ‘BACnet

Fixed Function System Engineering Guide, 31-00098.’

TM

software tool, the TB3026B

TM

software tool installed.

TM

tool installed.

Organization of the Manual

This manual is divided into two basic parts: Introduction

and Configuration.

The Introduction provides information for the TB3026B

configurable controllers, WEBStation-N4TM Software tool,

“TB3026B Configuration Wizard”, control application, and

abbreviations.

Configuration provides information for the engineering

about configurable TB3026B and TB3026B-W controllers’

different application types through “TB3026B Configuration

Wizard” using its various settings options.

6 31-00121—02

Page 9

CONFIGURATION OF

TB3026B AND TB3026B-W

CONTROLLERS

Installation

Before proceeding to the “TB3026B Configuration Wizard”,

WEBStation-N4

configuration wizard.

Installation of WEBStation-N4TM Tool

WEBStation-N4TM software is distributed via the web or a

DVD, and has the following minimum hardware

requirements:

Processor: Intel Pentium

Operating System:

32-bit: Microsoft Windows XP Professional, Windows 2003

or 2008 Server (if Microsoft IIS is disabled), Vista Business

or Windows 7

64-bit: Windows XP Professional, Windows 7

Browser: Microsoft IE versions 7, 8, 9, Google Chrome

version 15, and Mozilla Firefox version 8, 10, 12

Memory: 1 GB minimum, 2 GB or more recommended for

large systems, 8 GB or more recommended for the

windows 64-bit version

Hard Drive: 1 GB minimum, 5 GB for applications that

need more archiving capacity

Display: Video card and monitor capable of displaying

1024 x 768 pixel resolution or greater

Network Support: Ethernet adapter (10/100 Mb with

RJ-45 connector)

Modem: 56 KB minimum, full time high speed ISP

connection1111 recommended for remote site access (i.e.

T1, ADSL, cable modem).

These requirements can vary for the different versions of

WEBStation-N4

is added. For the latest product data, visit

http://

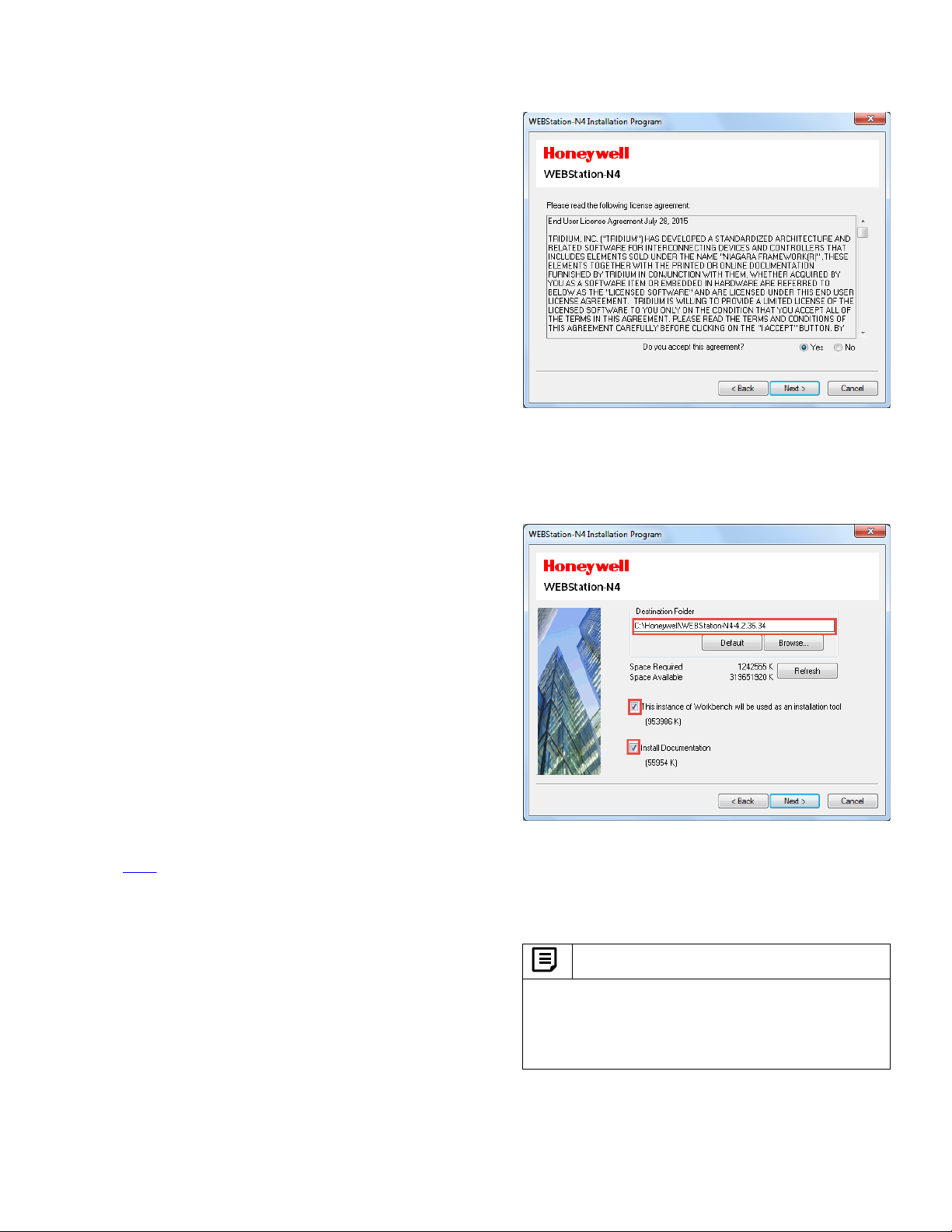

After selecting the setup for installation, proceed by

clicking ‘Next’ to accept the license agreement.

TM

should be installed as it hosts the

®

IV, 2 GHz or higher

TM

as support for newer operating systems

BACnet FF Controller

Figure 1: Installing WEBStation-N4TM

Select the installation location, (It will create a path in ‘C’

drive under ‘Honeywell’ folder by default)

TM

Figure 2: Installing WEBStation-N4

installation location)

Click ‘Next’ button to proceed after selecting appropriate

options. Wait until the installation gets finished.

Note:

(selecting

It is recommended to secure the WEBStation-N4 system

in order to make it resistant to the attacks.

Refer to the security documents available within

WEBStation-N4 software build to make WEBStation-N4

system secure.

31-00121—02 7

Page 10

BACnet FF Controller

Getting Started

Digital Signature

IMPORTANT

All the Honeywell WEBs software tools are now signed. Users can verify the signature using any OpenSSL tool.

Below are the steps to verify signature using OpenSSL community distribution.

Prerequisites:

• Download the Honeywell public key BuildingsCommonSupervisor.crt from location- same location as the

software release location

• Download the batch file “VerifyWEBsToolsSignature.bat” from location- same location as the software

elease location. This file has the commands to verify the module signature using the public key specified i

r

ep 1

St

• Download OPENSSL from this link- https://www.openssl.org/source/openssl-1.0.2o.tar.gz

• Extract the file using any ZIP utility to get the folder “openssl-1.0.2o”

• In the extracted folder find the file “openssl.cnf”

• Set Windows environment variable OPENSSL_CONF=<PATH TO openssl.cnf>, for example

OPENSSL_CONF=C:\openssl-1.0.2o\apps\openssl.cnf

Steps to verify the signature:

1. Place the files BuildingsCommonSupervisor.crt, VerifyWEBsToolsSignature.bat, WEBs tools modules and

signature file in the same location. For example: Following files are in one place

a. BuildingsCommonSupervisor.crt

b. VerifyWEBsToolsSignature.bat

c. honeywellSpyderTool.jar

d. honeywellSpyderTool.jar.sig

2. Open the command prompt and navigate to the location of the above files.

3. Execute the batch file VerifyWEBsToolsSignature.bat against a module for verifying its signature, for example

- C:\Spyder_RELEASE\ > VerifyWEBsToolsSignature.bat honeywellSpyderTool.jar

4. OpenSSL will verify this module’s signature and printout the below verification details:

n

5. If the Niagara module is compromised then user will get the below log, where verification has failed:

31-00121—02 8

Page 11

TB3026B Configuration Wizard is a user interface where a

user can set and adjust various types of parameters.

Important

BACnet FF Controller

Note:

Hash Value: Honeywell publishes the Hash Value with

the TB3026B Configuration Wizard module. It is

available as “honeywellTB3026BWizard_HashValue.txt”

with the released module.

The Hash Value generated at user’s end should match

the Hash Value published with the TB3026B

Configuration Wizard module. It is recommended to

perform this check in order to ensure the authenticity of

the TB3026B Configuration Wizard module.

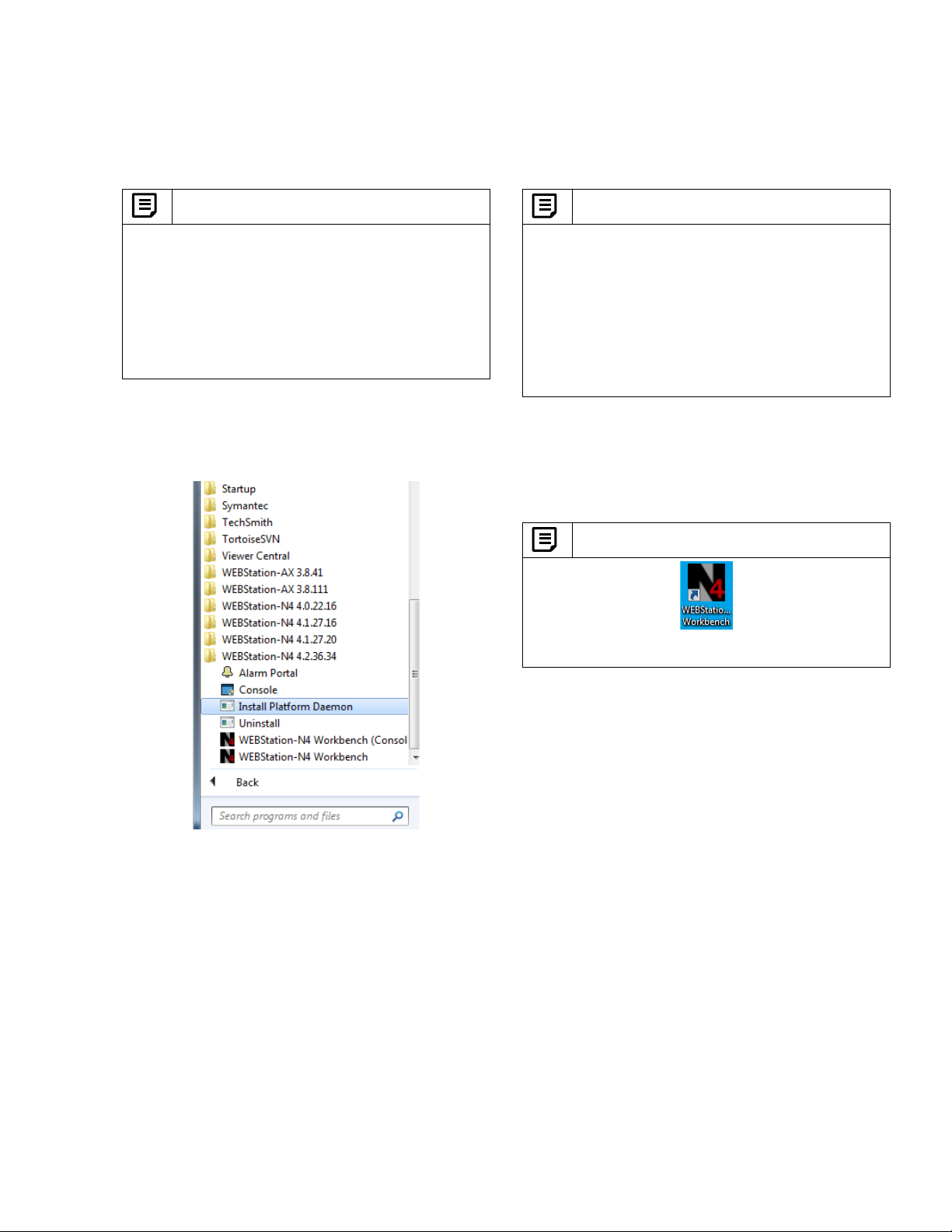

To start working with the configuration wizard, go to ‘Start’

menu, select ‘All Programs’, navigate to ‘WEBStation-N4

4.2.36.34’ folder and click on it. Click ‘Install Platform

Daemon’ as shown in Figure 3.

• If more than one version of WEBStation-N4 is

installed on the same PC, It is mandatory to install

Platform Daemon when switching from one version

of WEBStation-N4 to other.

It is not required to install Platform Daemon if the

same version of WEBStation-N4 needs to open

consecutively.

• If only single version of WEBStation-N4 is installed,

then it may not be required to install Platform

Daemon every time while opening WEBStation-N4.

After installing Platform Daemon completely, go to ‘Start’

menu again and select ‘All Programs, navigate to

‘WEBStation-N4 4.2.36.34’ folder and click on it. Click

‘WEBStation.’ It will open ‘WEBStation-N4’ window. Refer

to Figure 4.

Note:

‘WEBStation-N4’ can also be open by clicking an icon

named ‘WEBStation-N4 Workbench’ on the desktop

Figure 3: Installing Platform Daemon

31-00121—02 9

Page 12

BACnet FF Controller

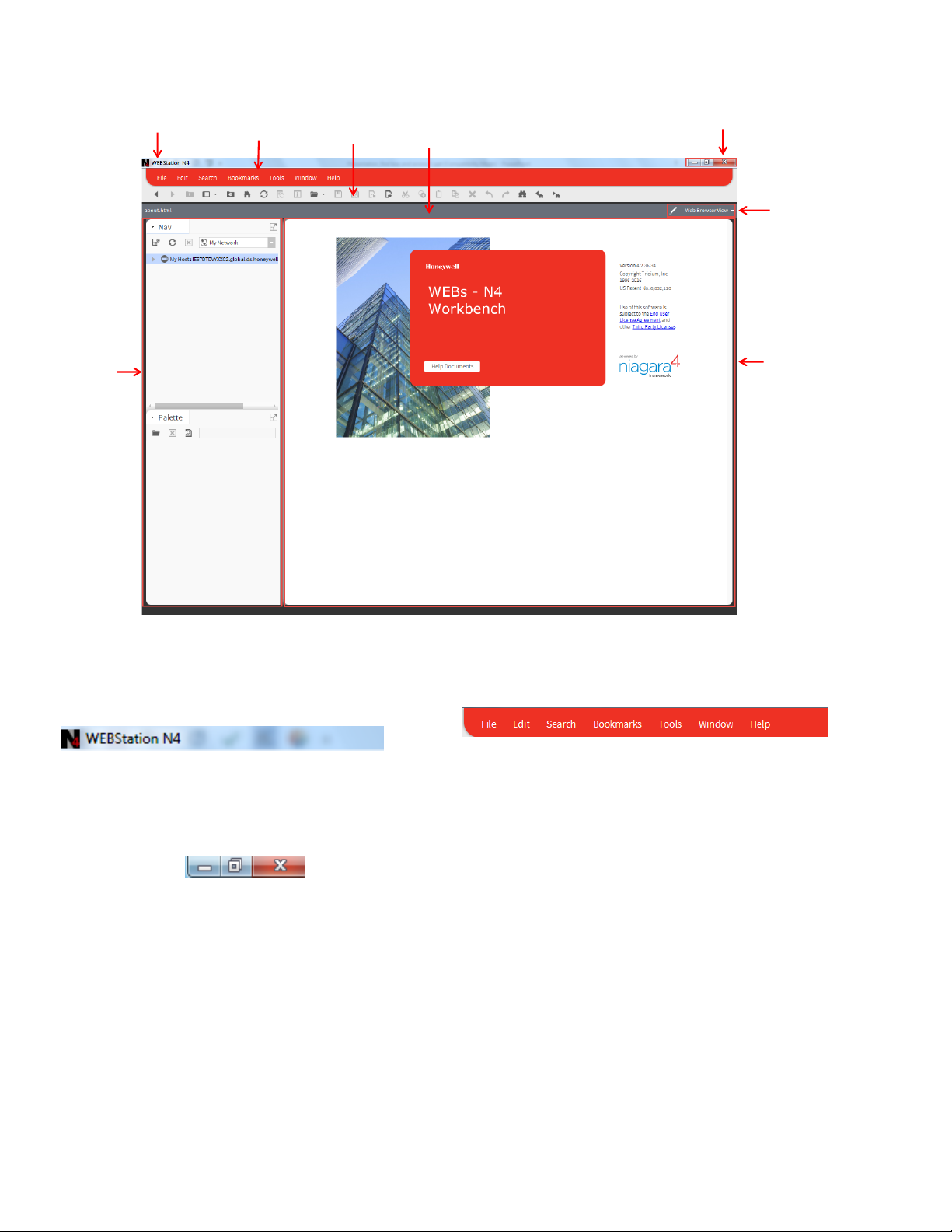

Title Bar

Menu Bar

Standard Toolbar

Path Bar

Controls

View Tab

Right Pane

Left Pane

Figure 4: WEBStation-N4TM – Getting Started

The field description for Figure 4is as follows:

1. Title Bar:

Top of the WEBStation interface is the Title bar. It displays

the title of the screen.

2. Controls

An application can be minimized, maximized and closed

with these controls.

3. Menu Bar

It displays heading for drop-down menus.

According to function, commands are group in to the menu

tabs. These are File, Edit, Search, Bookmarks, Tools,

Window, and Help.

I. File: A user can open, close and save the file,

directory, query, new tab, new window using File tab.

II. Edit: Cut, copy, paste, duplicate delete options are

available.

III. Search: A file can be searched and navigate from one

file to other file.

IV. Bookmarks: A user can add or manage bookmarks.

V. Tools: A user can maintain certificates, license,

migration and credential details.

VI. Window: A user can add/ hide Side Bar, Console

window, check Active Plug-in.

VII. Help: A user can get assist by clicking F1 or help tab.

10 31-00121—02

Page 13

BACnet FF Controller

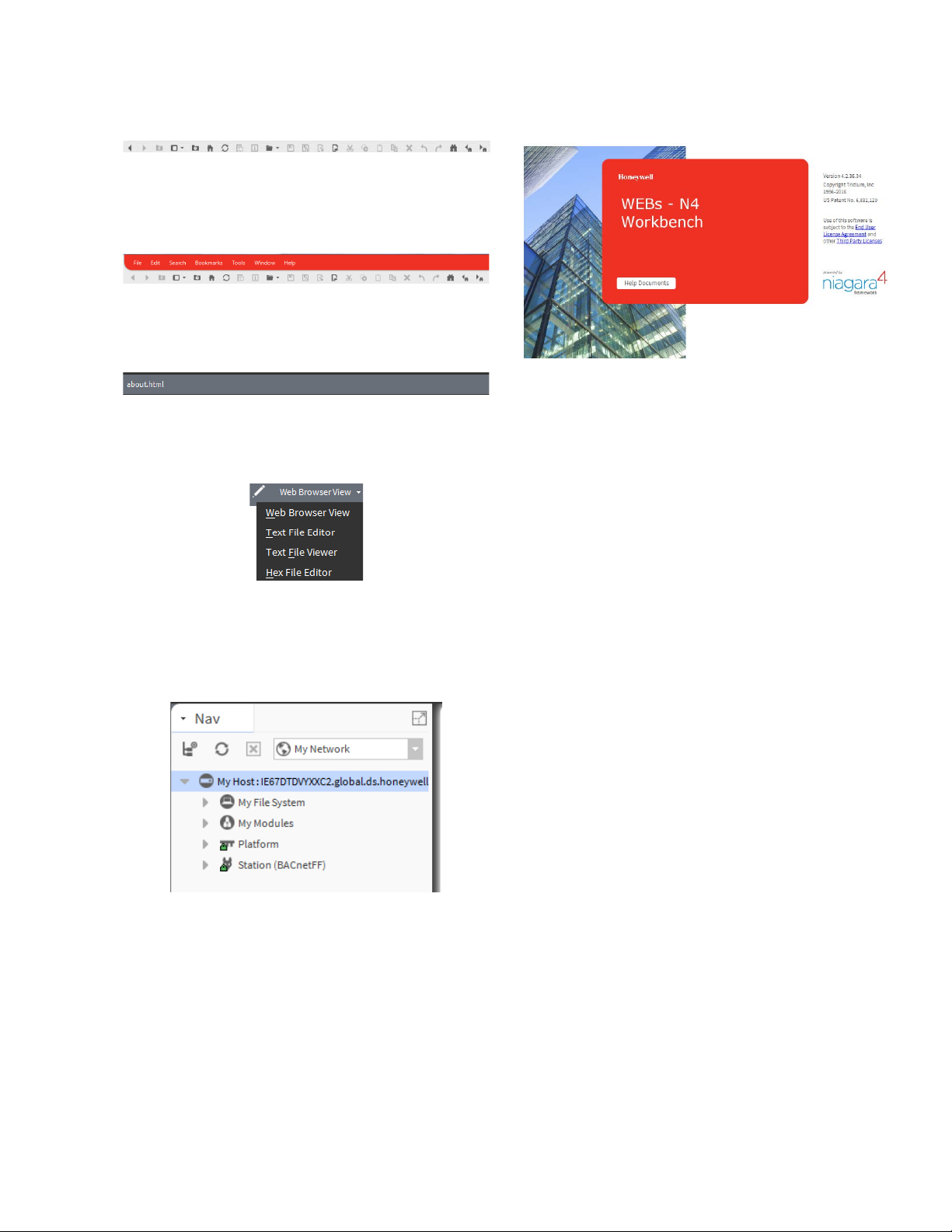

4. Standard Tool Bar

Various functions can be accessed using this tool bar. It

provides a quick shortcut to frequently used functions.

5. Ribbon

It includes menu bar and standard toolbar.

6. Path Bar

A path of a particular function can be tracked using this.

7. View Tab

9. Right Pane

Details about Version, License and Certificate are found

over here.

It is used to switch between various views, such as, Html

View, Text File Editor, Text File Viewer, and Hex File

Editor.

8. Left pane

Nav tree details can be viewed over here.

31-00121—02 11

Page 14

BACnet FF Controller

TB3026B Configuration Wizard Initial

Setup

The TB3026B Configuration Wizard’s user interface

window is obtained by following these steps:

1. Connecting to platform

2. Adding new station

3. Starting/Running new station

4. Adding a BACnet network

5. Adding TB3026B device to the BACnet network

Connecting to Platform

To perform various operations, it is necessary to connect

to the Platform initially.

To connect Platform, follow the process:

Navigate to ‘My Host: …’ in the Left pane, by right clicking

on it, select ‘Open Platform’. Refer to Figure 5.

Enter Username and Password and click ‘OK’

Figure 7: Authentication during connecting Platform

Figure 5: Open Platform

A window will pop up to connect to the Host’s secure

platform daemon. Click ‘OK’ to proceed.

Figure 6: Connect Platform

An Identity Verification window may pop up during the first

time configuration. Click ‘Accept’ to verify. (Refer to

Figure 8)

12 31-00121—02

Figure 8: Identity Verification during Connecting to

Platform

Adding New Station

The next stage is to add a new station under platform.

Different controllers can be added to the respective

network assigned to the station.

To add a new station:

• Navigate to the Platform by clicking sign of Host in

the left pane.

• Click ‘Tools’ tab on menu bar.

• Navigate to ‘New station’ and click on it.

Page 15

BACnet FF Controller

Figure 11: Entering Admin Password for New Station

Figure 9: Adding New Station

• After clicking ‘New Station’, it opens ‘New Station

Wizard, window. (Refer to Figure 10)

• Enter name in Station Name field. For example,

‘BACnetFF’ is added here. Station Directory displays a

path by default.

• Click ‘Next’

It creates a station at ‘My Host > My File System> User

Home > Stations > (created station)’. Refer to Figure 12.

• Click ‘Finish’ to complete action.

Figure 10: New Station Wizard Window

• Enter a password in the ‘Admin Password’ field. Enter

the same password in ‘Confirm Admin Password’ field.

Important:

Password must contain:

− at least 10 character(s)

− at least 1 digit(s)

− at least 1 lower case character(s)

− at least 1 upper case character(s)

31-00121—02 13

Figure 12: Location of New Station

(BACnetFF)

Page 16

BACnet FF Controller

Starting New Station

To start configuration of controller, it is necessary to start

the station. The following is the process to start a newly

added station:

Double click on ‘Platform’, it opens a screen as shown in

Figure 13.

Double click on ‘Application Director’ at the right pane.

(Refer to Figure 13).

Figure 13: Application Director

Select the newly created station (‘BACnetFF’ in this case)

by just clicking on it. Status for this station will be Idle at

this stage.

Click ‘Start’ button as shown in Figure 14. After clicking

‘Start’, the ‘Status’ of this station will change to ‘Starting’ as

shown in Figure 15.

Figure 14: Selecting the Station to Start

Figure 15: Starting the Station

Figure 16: Started Station

14 31-00121—02

Page 17

Once the station is started, its status will change to

‘Running’ (Refer to Figure 16).

Double click on the started station, a ‘verification window

will pop up as shown in Figure 8. Click ‘Accept’ to proceed.

It opens an authentication window. Enter username and

password. Click ‘OK’ to proceed.

Note:

Check ‘Remember these credentials’ box to remember

the username and passwords so that it will not be

required to enter it every time during opening the

station.

Check newly added station as shown in Figure 17.

BACnet FF Controller

Figure 17: Newly added Station

31-00121—02 15

Page 18

BACnet FF Controller

Adding BACnet Network to Niagara

Network

TB3026B controller works with BACnet network.

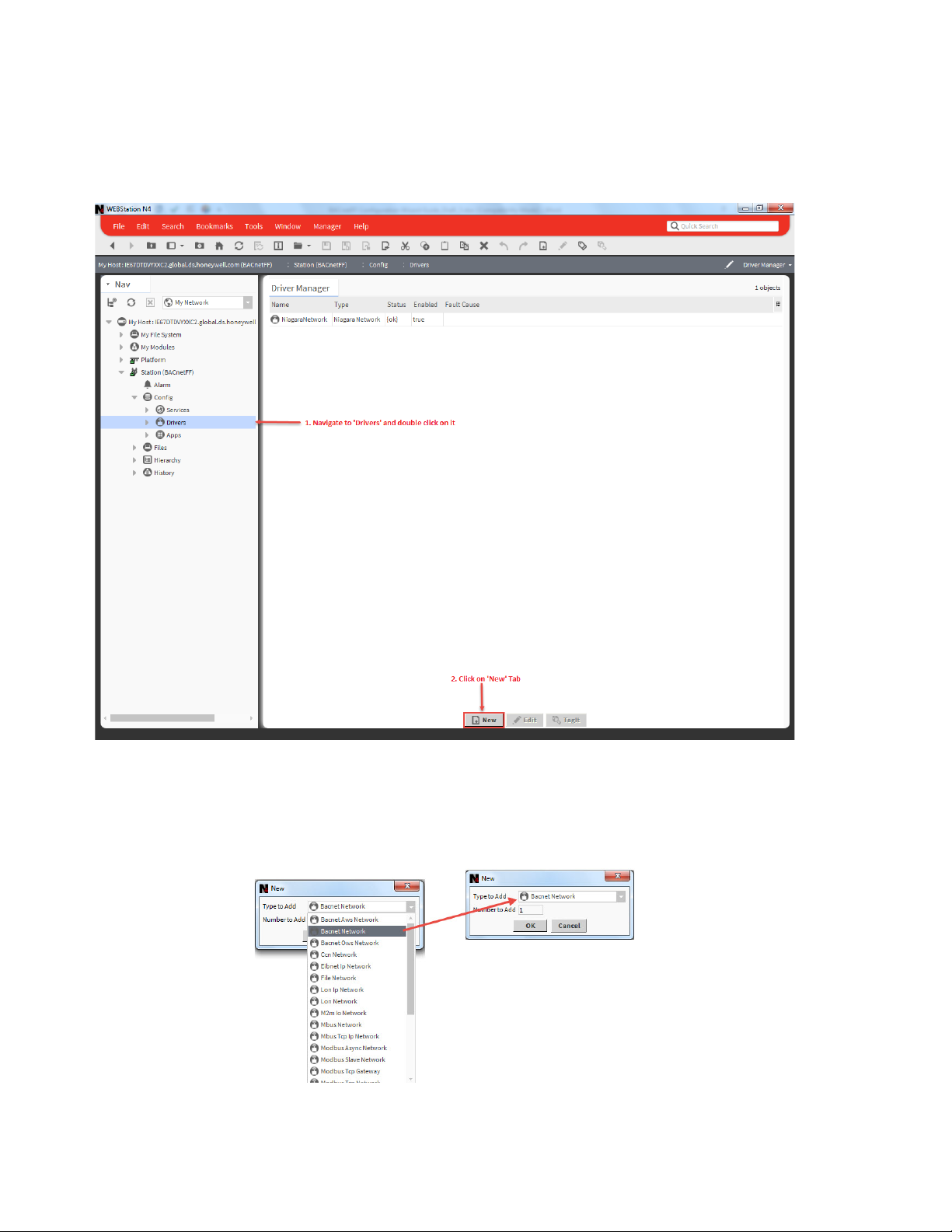

To add a BACnet network (Refer to Figure 18):

• Navigate to Drivers and double click on it.

• Click on ‘New’ tab

Figure 18: Adding BACnet Network

• A window will pop out as shown in Figure 19, asking

‘Type to Add’.

• Select ‘Bacnet Network’ from the drop down list.

Figure 19: Selecting BACnet Network to add

31-00121—02 16

Required number of networks can be added in

‘Number to Add’ field. (In this guide since only one

network is shown, Number is added as ‘1’)

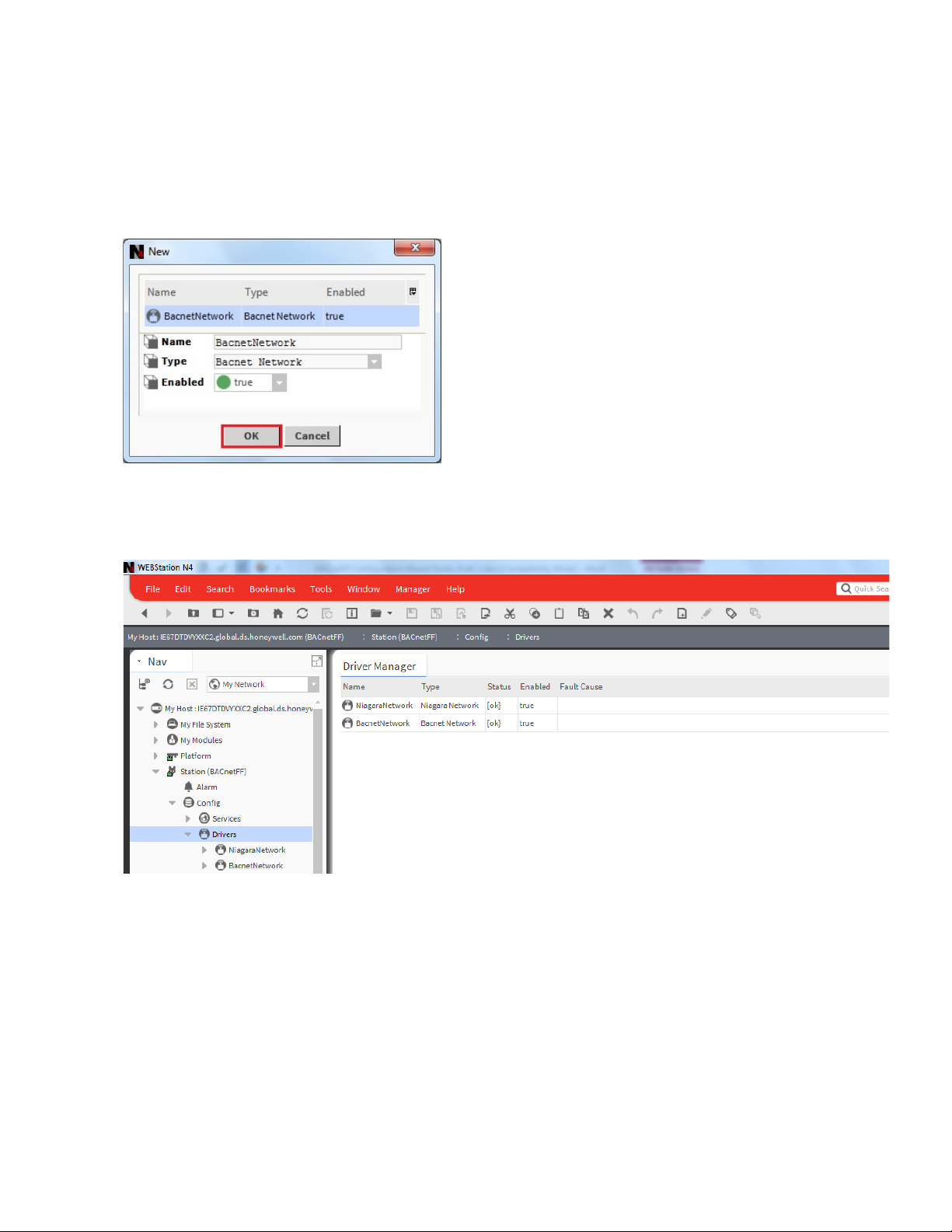

Page 19

• Click ‘OK’ to proceed.

• Next, a new window will appear, showing ‘Name’,

‘Type’ and ‘Enabled’(keep its value to ‘True’). Refer to

Figure 20.

• Click ‘OK’.

Figure 20: Adding Specification to add BACnet

Network

BACnet FF Controller

• A newly added ‘BacnetNetwork’ can be seen under

‘Device manager’ on the right pane highlighted in

Amber color as shown in Figure 21

(An amber colored background highlight appears, as

BacnetNetwork is offline. Background will turn white when

it is online.)

Figure 21: Newly added BACnet Network

31-00121—02 17

Page 20

BACnet FF Controller

Adding TB3026B Controller to the

BACnet Network

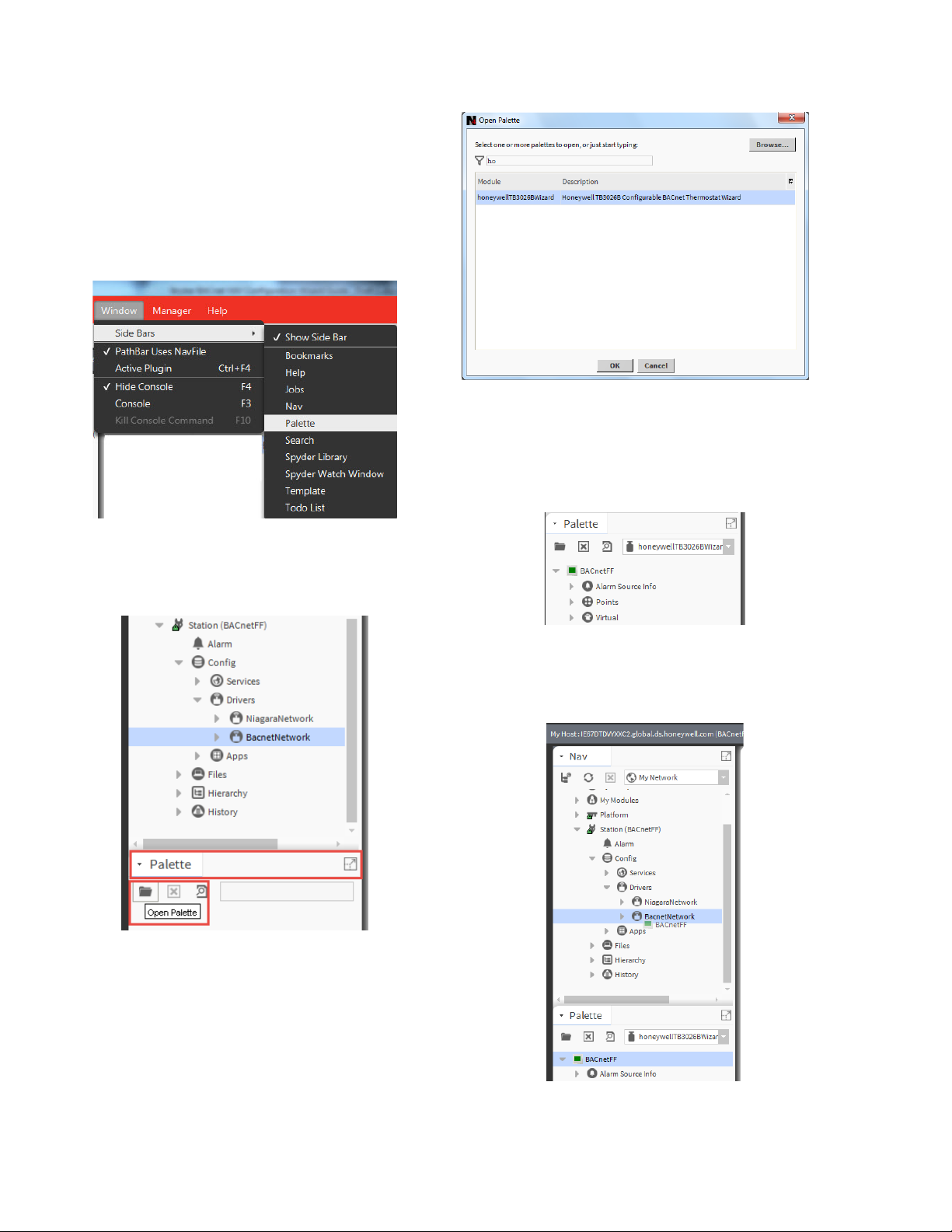

• After adding a Bacnet Network to the Drivers, the next

step is to add a TB3026B controller to the Bacnet

Network.

• Click on the ‘Window’ option in Menu bar; navigate to

‘Palette’ through sub menu of ‘Side Bars’.

(Refer to Figure 22).

Figure 24: Adding ‘honeywellTB3026BWizard’ to

BACnet Network

• After adding ‘honeywellTB3026BWizard’, it

reflects in the ‘Palette’ tab as ‘BACnetFF’ as seen

in Figure 25.

Figure 22: Adding Palette

• This will add a ‘Palette’ tab in the left pane. (Refer to

Figure 23). Click ‘Open Palette’ option.

Figure 23: Opening Palette

• An ‘Open Palette’ window will open. Find a module

named ‘honeywellTB3026BWizard’ as shown in

Figure 24, Select it and click ‘OK’ button to add into

the Palette.

Figure 25: BACnetFF in Palette TAB

• Drag ‘BACnetFF’ and Drop it on ‘BacnetNetwork’

added under created station. Refer to Figure 26.

Figure 26: Drag and drop BACnetFF on BacnetNetwork

18 31-00121—02

Page 21

BACnet FF Controller

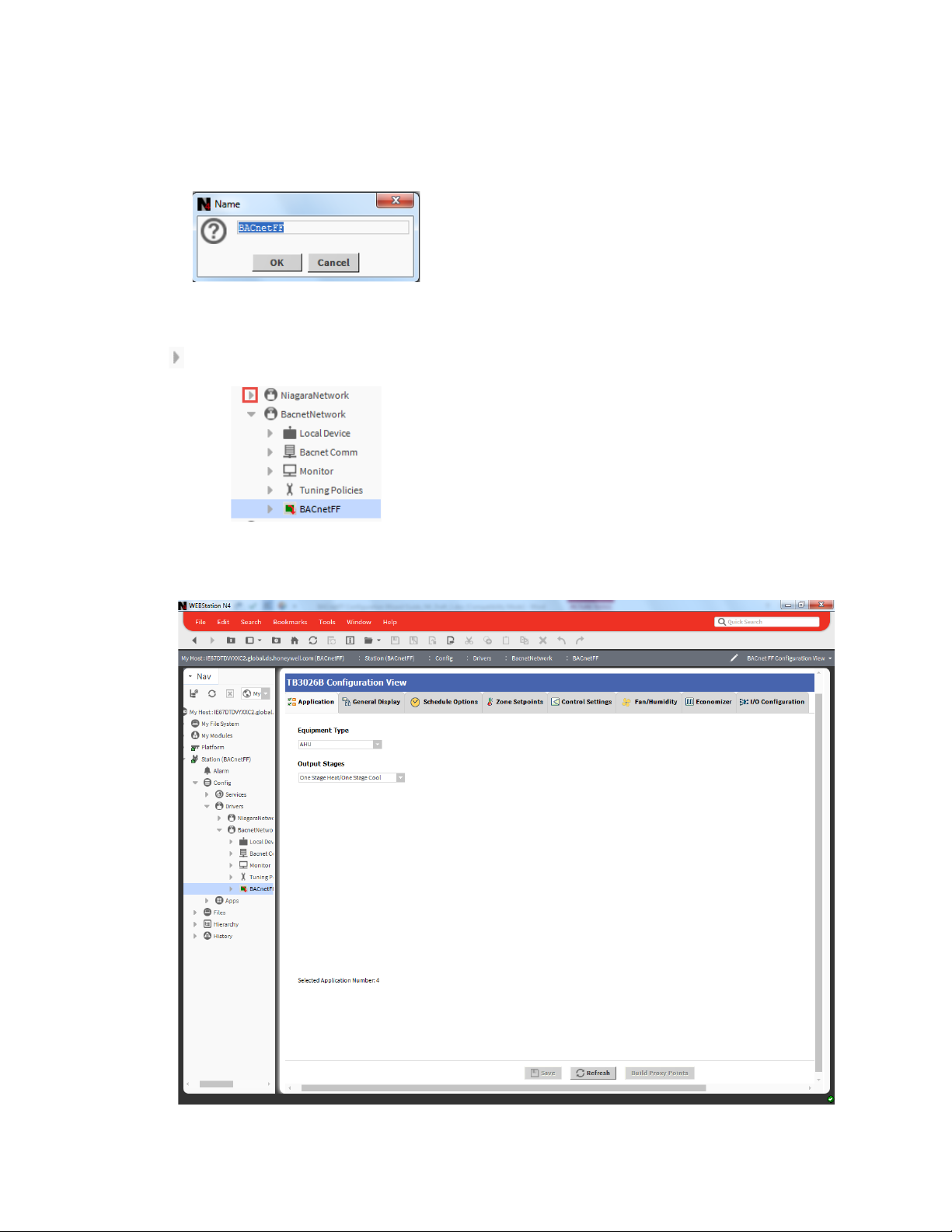

A window will pop up as ‘BACnetFF’ is dropped on

BacnetNetwork to name the controller. Enter the name

accordingly. In this guide, it is named as ‘BACnetFF’ as

shown in Figure 27.

Figure 27: Naming Controller

A newly added TB3026B controller can be seen by

clicking sign as shown in Figure 28.

Figure 28: Location of Controller

TB3026B Configuration Wizard

To start working with the TB3026B wizard, navigate to

Bacnet Network (Refer to Figure 28). Double click on

added controller (here, ‘BACnetFF’). It will open the

TB3026B Configuration Wizard window. .

31-00121—02 19

Page 22

BACnet FF Controller

Figure 29: Opening TB3026B Configuration Wizard Screen

Field Description for TB3026B Configuration Wizard

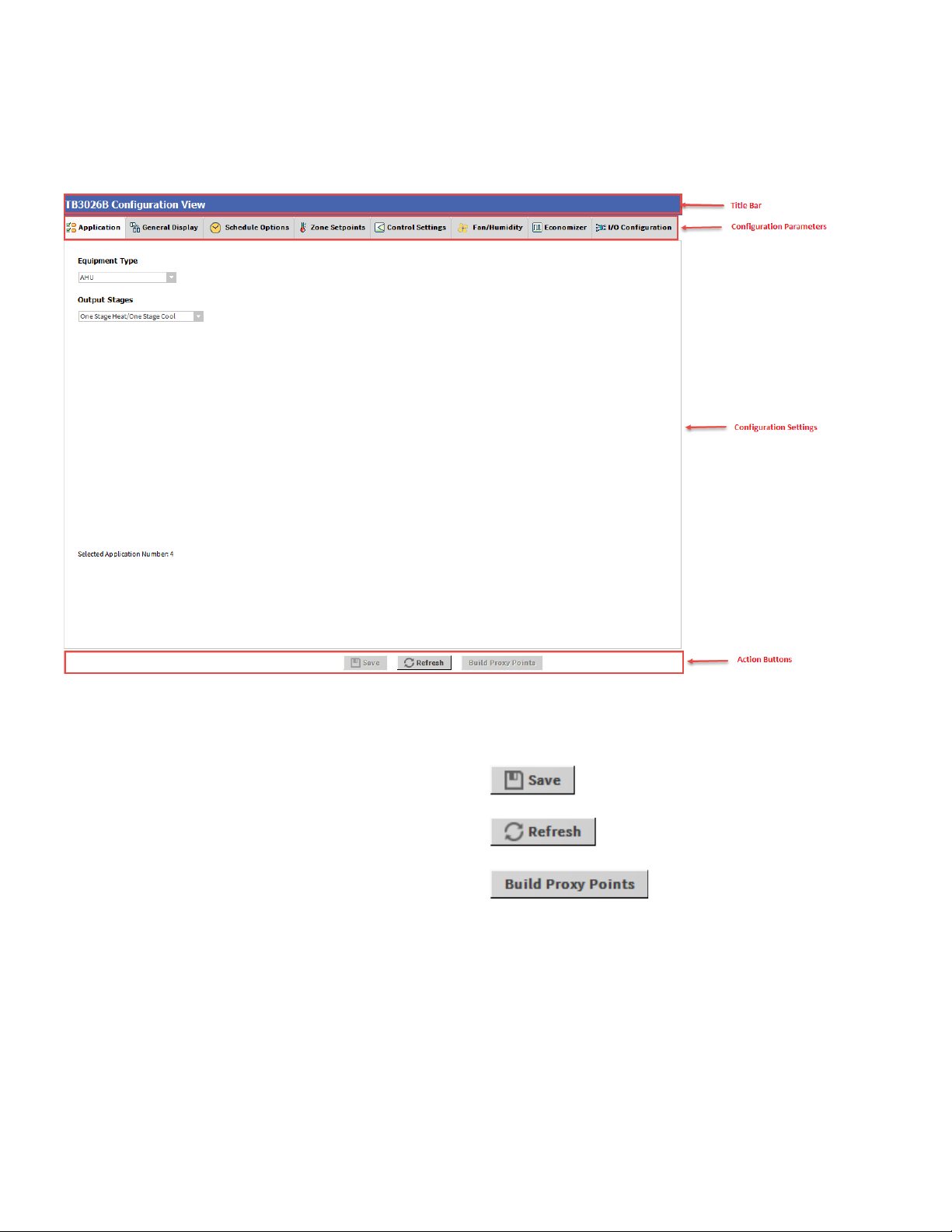

Figure 30: Field description for TB3026B Configuration Wizard Screen

1. Title Bar

It displays the name ‘TB3026B Configuration View’.

2. Configuration Parameters

It displays the list of setting buttons for various groups

of configuration parameters.

3. Configuration Settings

It displays Configuration settings as per the selected

group of parameters.

4. Action Buttons

It displays following buttons:

It is used to save the configuration

settings.

It is used to reset actions to its

default value.

It is used to generate proxy

points under TB3026B controller "points" folder for the

selected configuration.

20 31-00121—02

Page 23

APPLICATIONS

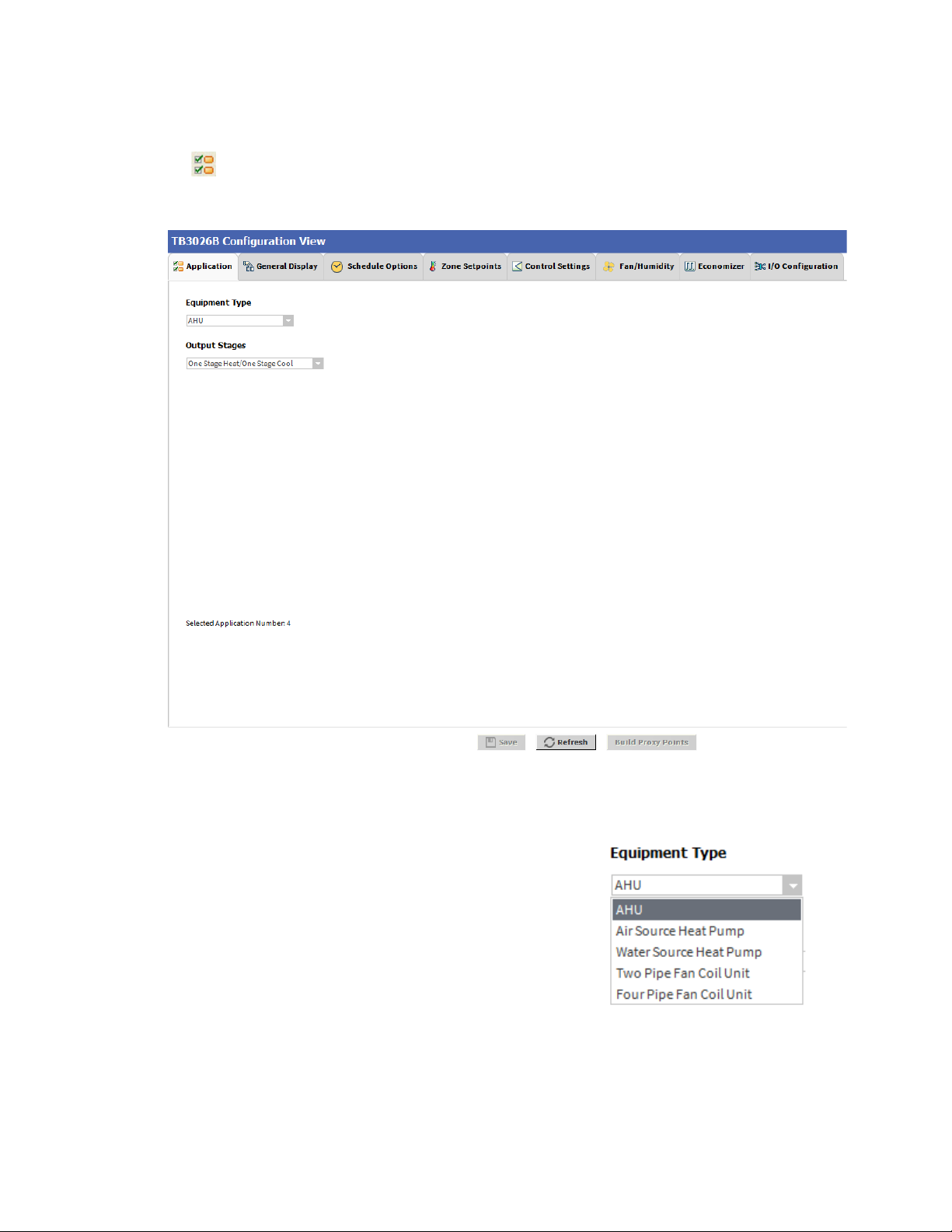

Application is the first tab of the Configuration Wizard.

The Application screen allows a user to select the required

Equipment Type.

BACnet FF Controller

Figure 31: Application Screen

Equipment Type

A user can select the required equipment type through this

option. This is a fundamental setting in a configuration as

selection of various other parameters from the different

settings depend on the Equipment Type.

A required Equipment Type can be selected from the

following:

1. AHU

2. Air Source Heat Pump

3. Water Source Heat Pump

4. Two Pipe Fan Coil Unit

5. Four Pipe Fan Coil Unit

31-00121—02 21

Figure 32: Equipment Type

Page 24

BACnet FF Controller

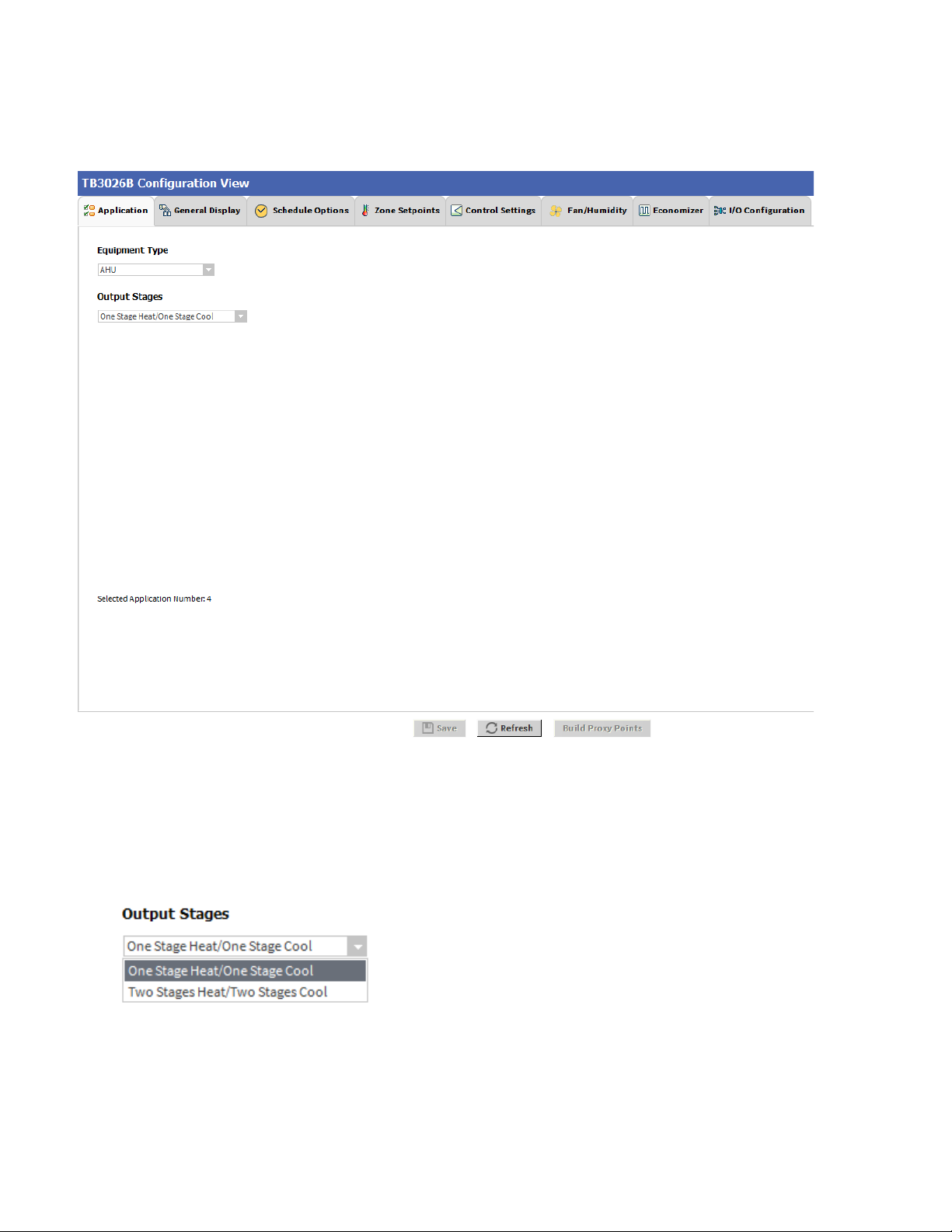

AHU

Figure 33: AHU window

Output Stages

Equipment Type ‘AHU’ consists of two types of ‘Output

Stages’

1. One Stage Heat/One Stage Cool

2. Two Stage Heat/Two Stage Cool

22 31-00121—02

One Stage Heat/One Stage Cool: Select this option if

One stage of cooling and one stage of Heating is required

in the application.

Two Stage Heat/Two Stage Cool: Select this option if

Two stages of cooling and two stages of Heating are

required in the application.

Page 25

BACnet FF Controller

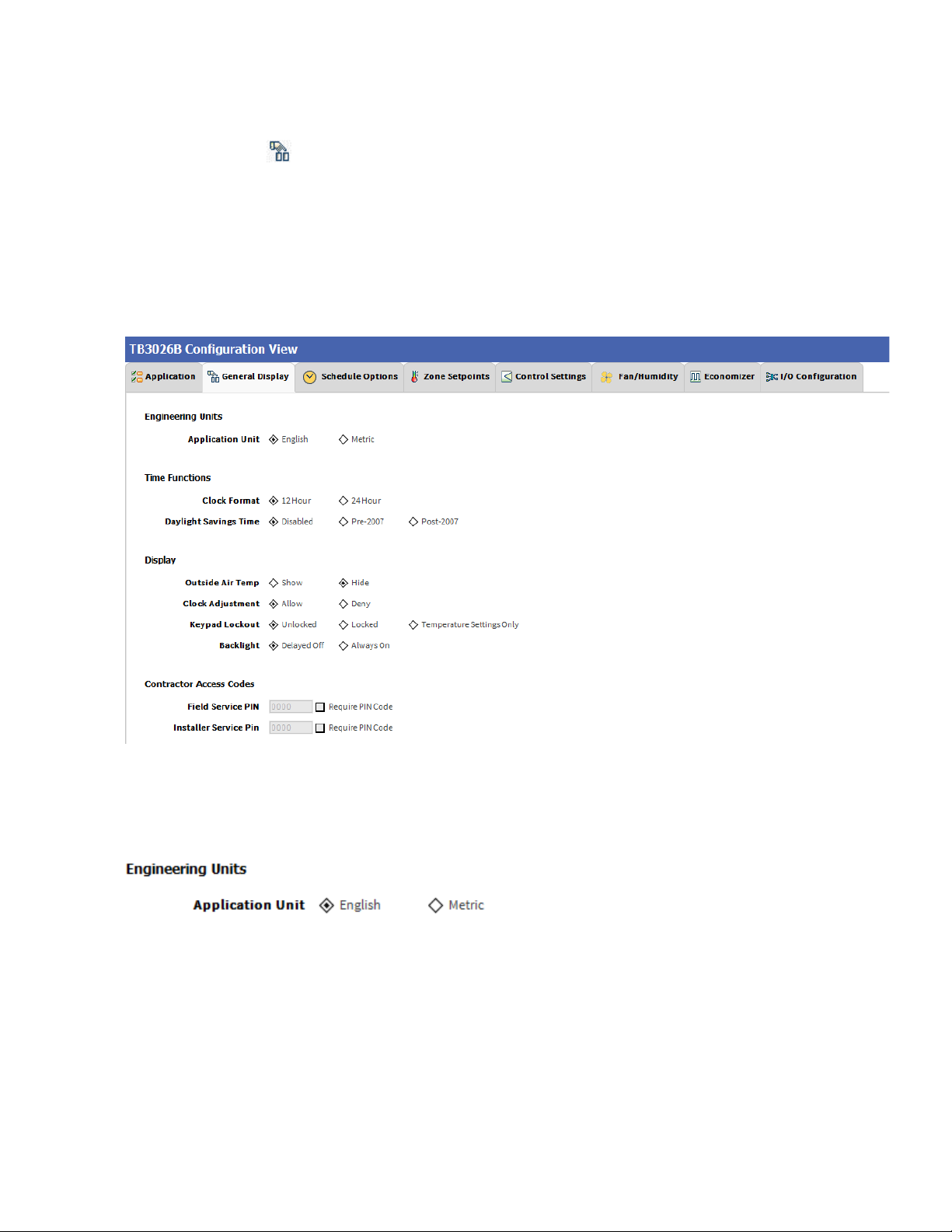

General Display

Click ‘General Display’ to view the general display

settings. The following parameters are used to configure

the controller’s display settings.

1. Engineering Units

2. Time Functions

3. Display

4. Contractor Access Codes

Figure 34: General Display Screen (AHU)

Engineering Units

Application Unit: The application units contain two

options to change the controller’s units. By default, the

controller’s application units are set to ‘English’. Application

Units can be changed to ‘English’ or ‘Metric’.

31-00121—02 23

Page 26

BACnet FF Controller

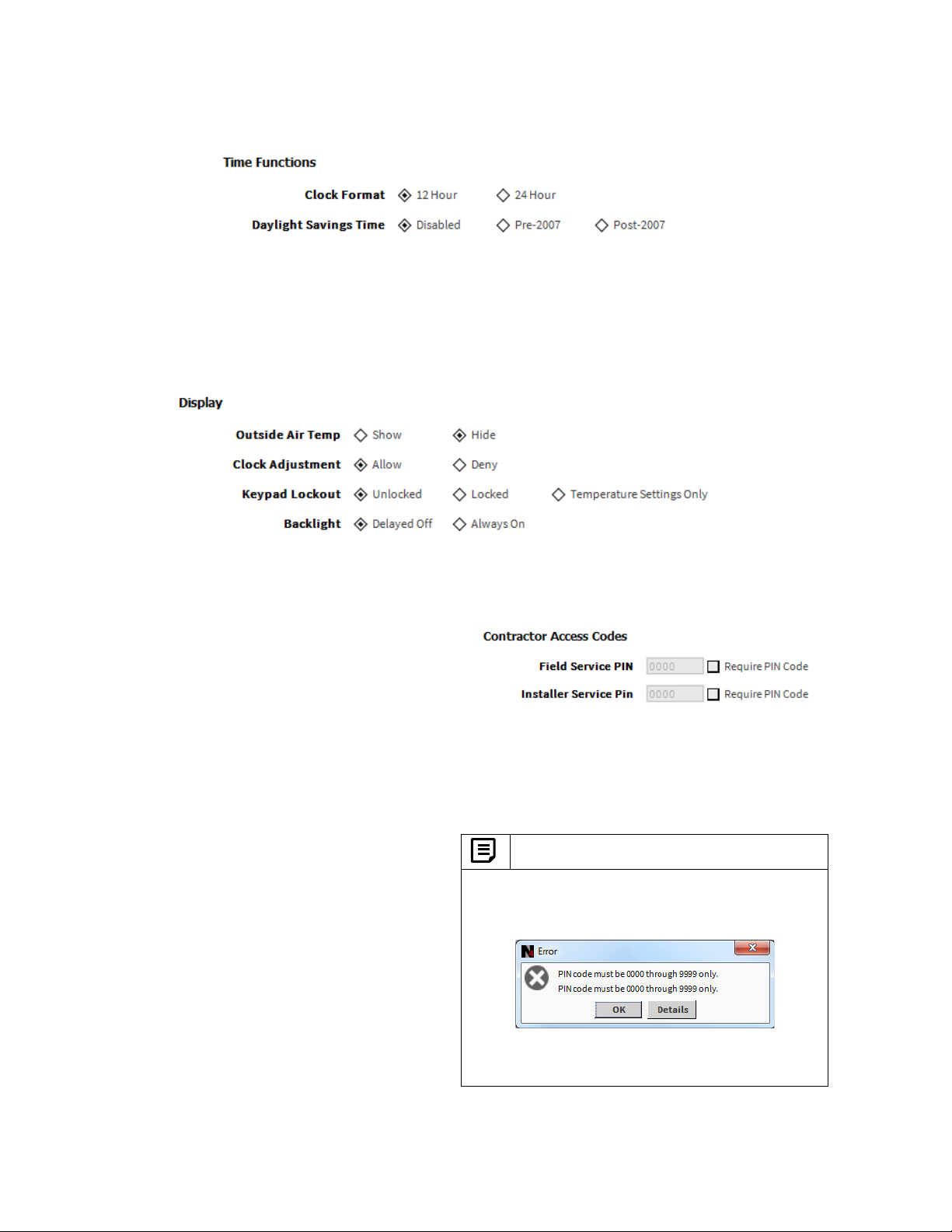

Time Function

Clock Format: A user can select a clock format as

12-hour format or 24-hour format.

Display

This feature allows a user to select the Display settings.

Outside Air Temp: A user has an option to hide/show an

outside air temperature.

Clock Adjustment: This option allows a user to

enable/disable the clock adjustment on the controller

display.

Keypad Lockout: This option allows a user to lock/unlock

the clock adjustment.

When an option, ‘Temperature Settings Only’ is selected, a

user can only set the temperature through keypad.

Backlight: A user can keep the backlight always on or set

to delayed off through this option.

Daylight Savings Time: This feature enables to select the

Daylight Savings Time settings. By default, Daylight

Savings Time is set to ‘Disabled’. Daylight Savings Time

can be changed to ‘Pre-2007’ or ‘Post-2007’.

Contractor Access Codes

An access to the controller can be restricted with the help

of Access Codes.

Field Service Pin and Installer Service Pin can be set.

These codes should be enabled to restrict an access to the

controller.

Note:

A user can set only numerical PIN code for ‘Field

Service Pin’ and ‘Installer Service Pin’. PIN codes

should be set within 0000 – 9999. The following Error

Window pops up if this field is left blank after selecting.

Note: When error message pops up, it displays the text

field twice in the error window.

24 31-00121—02

Page 27

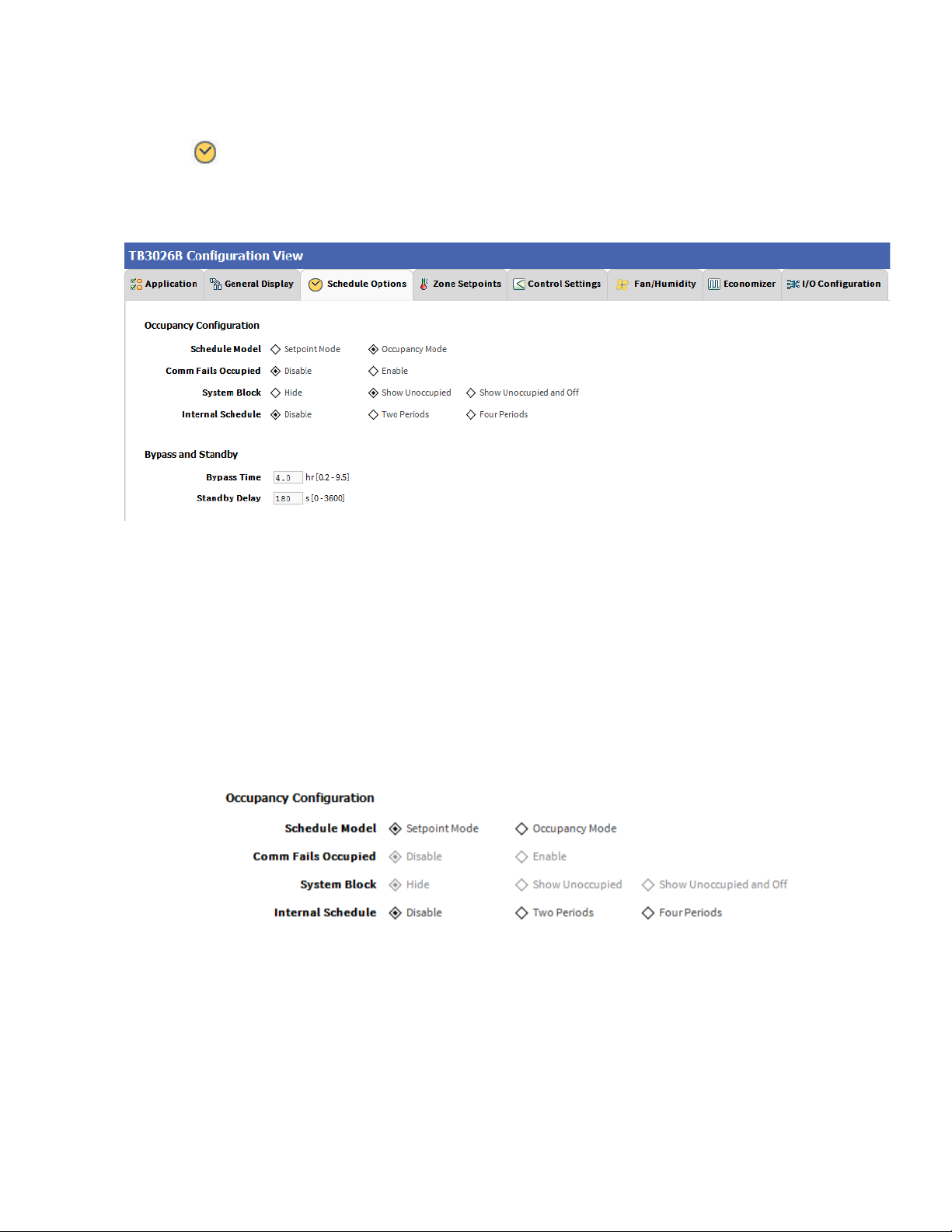

Schedule Options

‘Schedule’ tab displays Schedule options.

The following parameters are used to configure the

schedule options (i.e. Occupancy Configuration and

Bypass and Standby).

BACnet FF Controller

Figure 35: Schedule Options Screen (AHU)

Occupancy Configuration

Schedule Model: A user can set the device’s schedule

model as;

1. Setpoint Mode or

2. Occupancy Mode

Setpoint Mode: In setpoint mode, the controller logically

emulates residential thermostats. The space temperature

is controlled to "SP Mode Cooling SP" and "SP Mode

Heating SP". Each schedule period consists of a start time,

a heating setpoint, and a cooling setpoint.

Occupancy Mode: By default, ‘Schedule Model’ is in

‘Occupancy Mode’. The system will be switched to

‘Occupied Mode’ when the occupancy sensor detects

occupancy. Occupied Mode allows a user to configure

‘Comm Fails Occupied’, ‘System Block’ & ‘Internal

Schedule’ settings.

If a user selects ‘Setpoint Mode’ from the available

‘Schedule Model’, the fields for ‘Comm Fails Occupied’

and ‘System Block’ settings become disabled.

31-00121—02 25

Page 28

BACnet FF Controller

Comm Fails Occupied: It allows a user to switch the

system in Occupied Mode in case of MS/TP

communication failure. If the MS/TP communication fails,

the system enters into Occupied Mode when this option is

selected as ‘Enable’, otherwise the system remains in its

current state when this option is selected as ‘Disable’.

System Block: The System Block is hidden when the

schedule model is in ‘Setpoint Mode’. When the schedule

model is in ‘Occupancy Mode’, it allows a user to switch

between the available options. Selecting “Show

Unoccupied/Off” places the controller in unoccupied state.

Internal schedule: It can be configured in both Occupancy

Mode & Setpoint Mode. By default, ‘Internal Schedule’ is

‘Disable’.

If the internal schedule is ‘Disable’, a user can adjust the

setpoint (within setpoint limits).

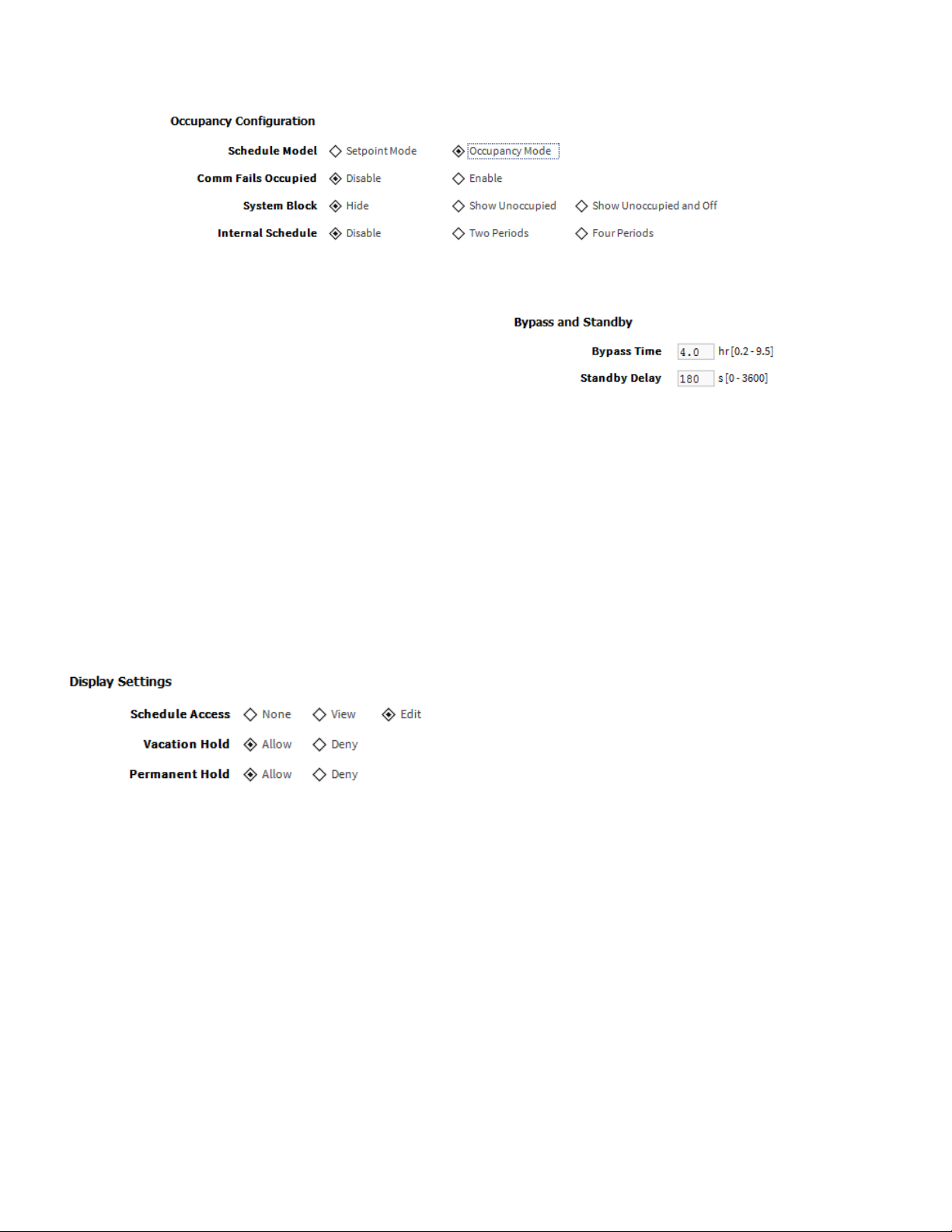

Display Settings

When a user selects, ‘Two Periods’ or ‘Four Periods’

options an additional ‘Display Settings’ appears as follows:

Bypass and Standby

Bypass Time: In the Unoccupied state, it forces the

controller into the occupied state for up to 4 hours (default

value). The override time limit is adjustable from a

minimum of 0.2 hours to a maximum of 9.5 hours.

Standby Delay: In Occupied Mode, if any window or door

is opened and closed with no motion detected after the

time mentioned for the Standby Delay, the room status

switches to Standby state. The default value is 180

seconds.

Schedule Access: When a user selects ‘Edit’, it allows a

user to view and edit the schedule and when a user selects

‘View’, it allows a user to view the schedule. When a user

selects ‘None’, it will not allow a user to view or edit the

schedule.

Vacation Hold: It allows/denies a user to override the

scheduled setpoint from TB3026B display to “Vacation

Hold”.

Permanent Hold: It allows/denies a user to override the

scheduled setpoint from TB3026B display to “Permanent

Hold”.

26 31-00121—02

Page 29

BACnet FF Controller

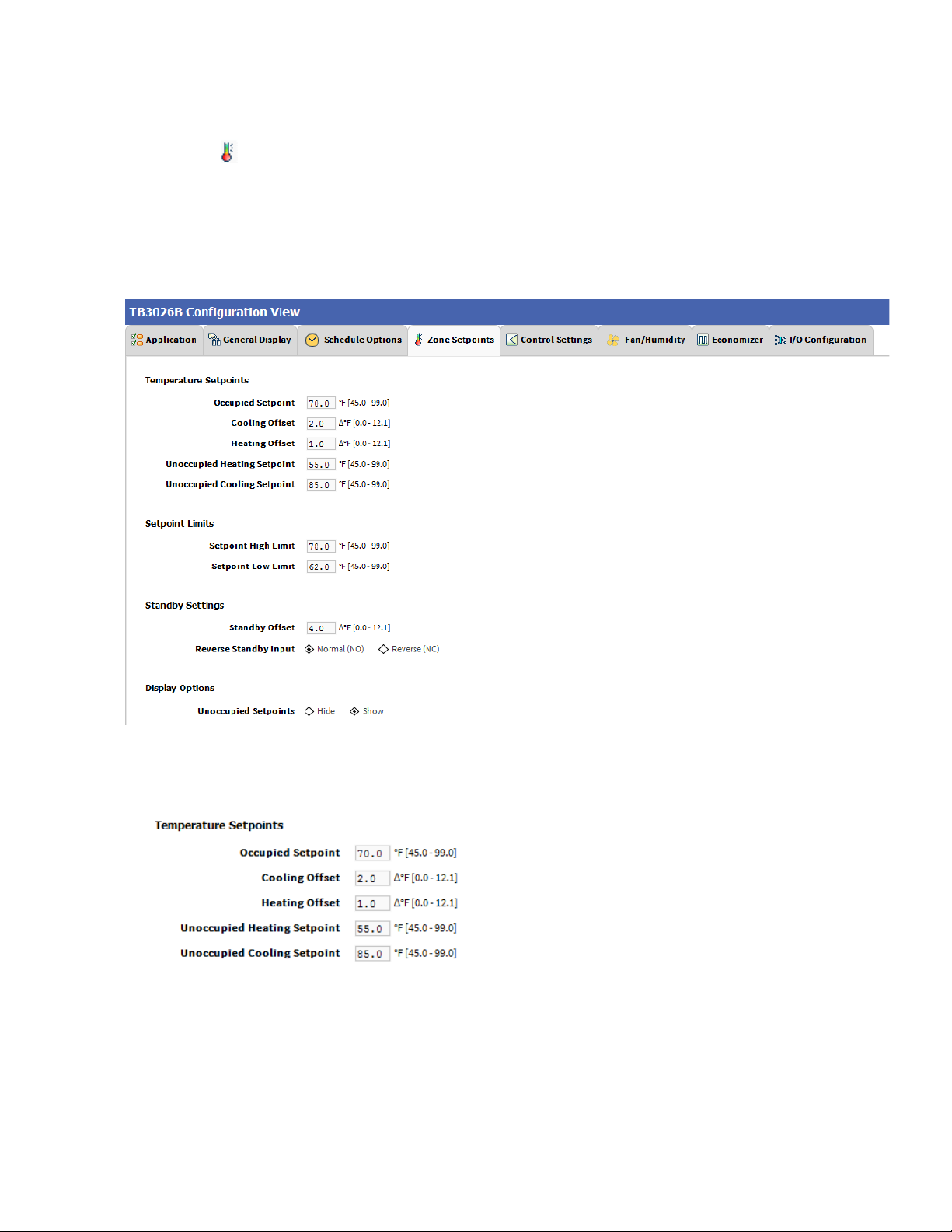

Zone Setpoints

Zone Setpoints , allows a user to set the following

parameters as per the requirement:

1. Temperature Setpoints

2. Setpoint Limits

3. Standby Settings

4. Display Options

Figure 36: Zone Setpoints Screen (Occupancy Mode)

Temperature Setpoints

Occupied Setpoint: It is a setpoint in Occupied Mode.

Enter the value within the range of 45 ºF to 99 ºF. The

default value is 70ºF.

Cooling Offset: In the Occupied state, the cooling setpoint

is calculated as cooling offset plus occupied setpoint. Enter

31-00121—02 27

the value within the range of 0ΔºF to 12.1ΔºF. The default

value is 2 ΔºF.

Heating Offset: In the Occupied state, the heating setpoint

is calculated as heating offset minus occupied setpoint.

Enter the value within the range of 0ΔºF to 12.1ΔºF. The

default value is 1 ΔºF.

Unoccupied Heating Setpoint: It is a setpoint for Heating

in Unoccupied mode. Enter the value within the range of

45 ºF to 99 ºF. The default value is 55 ºF.

Unoccupied Cooling Setpoint: It is a setpoint for Cooling

in Unoccupied mode. Enter the value within the range of

45 ºF to 99 ºF. The default value is 85 ºF.

Page 30

BACnet FF Controller

Setpoint Limits

Setpoint High Limit: A user can enter a Setpoint High

Limit in Occupied Mode within the range of 45 ºF to 99 ºF.

The default value is 78 ºF.

Setpoint Low Limit: A user can enter a Setpoint Low Limit

in Occupied Mode within the range of 45 ºF to 99 ºF. The

default value is 62 ºF.

Note:

1. Unoccupied Cooling Setpoint should always be set

GREATER than Unoccupied Heating Setpoint.

Following Error window appears if Unoccupied

Cooling Setpoint is set lower than Unoccupied

Heating Setpoint.

2. Setpoint High Limit should always be set

GREATER than Setpoint Low Limit.

Following Error window appears if Setpoint High

Limit is set lower than Setpoint low Limit.

Standby Settings

Standby state is a power-saving function of Occupancy

mode. It occurs when the space is scheduled as Occupied,

but sensors detect (When the Standby input is active)

there are no humans in the space.

Standby Offset: In this case, the Standby Offset relaxes

the occupied setpoints. The value of the Standby Offset

[SO] can be set between a minimum of 0ΔºF and a

maximum of 12.1ΔºF degrees. The default value is 4 ΔºF.

Reverse Standby Input: It allows a user to configure two

types of inputs, ‘Normally Open (NO)’ and ‘Normally Close

(NC)’.

28 31-00121—02

Page 31

BACnet FF Controller

Display Options

Unoccupied Setpoints: It allows a user to either ‘Hide’ or

‘Show’ the unoccupied setpoint.

When a user selects Schedule Mode under the ‘Schedule Options’ tab to ‘Setpoint Mode’, the ‘Zone Setpoints’

configuration window appears as follows:

Figure 37: Zone Setpoint Screen (Setpoint Mode)

31-00121—02 29

Page 32

Control Settings

‘Control Settings’ allows a user to configure following

settings:

1. Cooling PI Control

2. Heating PI Control

3. Compressor Settings

BACnet FF Controller

Figure 38: Control Settings Screen (AHU)

31-00121—02 30

Page 33

BACnet FF Controller

Cooling PI Control

Proportional Constant K

: A user can enter a value for Kp

p

within the range of 10 to 40. The default value is 20.

Integral Constant K

: A user can enter a value for Ki

i

within the range of 0.50 to 2. The default value is 1.

OAT Lockout Setpoint: Cooling PI control will lockout

when outside Temperature decreases below OAT

(Cooling) Lockout Setpoint. The default value is 55 ºF.

Heating PI Control

Proportional Constant K

: A user can enter a value for Kp

p

within the range of 10 to 40. The default value is 20.

Integral Constant K

: A user can enter a value for Ki

i

within the range of 0.50 to 2. The default value is 1.

OAT Lockout Setpoint: Heating PI control will lockout

when outside Temperature increases above OAT (Heating)

Lockout Setpoint. The default value is 62 ºF.

Compressor Settings

Cycle Time: The Compressor Cycle Time is adjustable, it

ranges from minimum of 8 minutes, and a maximum of 30

minutes. The default value is 20 minutes.

Minimum On/Off Time: It is a minimum time for the

compressor to stay On/Off. The default value is 3 minutes.

31-00121—02 31

Page 34

BACnet FF Controller

Fan / Humidity

‘Fan / Humidity’ allows a user to configure the

following settings:

1. Fan Operation

2. Humidity Control

3. Filter Alarm

Figure 39: Fan/Humidity Screen (AHU)

Fan Operation

Fan Mode Control: During Setpoint Mode and Occupancy

Mode, the fan can be configured to operate based on the

selected Fan Mode Control as describe below:

Auto: When this option is selected, Fan cycles ON when:

1. Cooling or heating is selected or

2. During Unoccupied mode only when called to run

by cooling or heating demand.

On: When this option is selected the fan runs continuously

for ventilation.

On Cool/Auto Heat: When this option is selected the fan

runs continuously in cooling mode. In heating mode the fan

cycles on only when the heating signal calls for the fan to

run.

32 31-00121—02

Page 35

BACnet FF Controller

Humidity Control

Fan Circulation Cycle: When a user selects the ‘Enable’

option from Fan Circulation Cycle, it allows a user to edit

the Trigger Setpoint, Reset Deadband, and Fan On/Off

Cycle Time.

Trigger Setpoint & Reset Deadband: When sensed

humidity equals or exceeds humidity trigger setpoint, the

fan cycles ON/OFF at low speed until sensed humidity

drops below the trigger setpoint minus the reset deadband.

Fan On Cycle Time: This field allows a user to enter a

time for fan ON cycle when stratification and humidity

control is active. The default value is 300 seconds.

Fan Off Cycle Time: This field allows a user to enter a

time for fan OFF cycle when stratification and humidity

control is active. The default value is 1800 seconds.

Filter Alarm

Runtime Hours: A filter alarm activates after the Runtime

Hours mentioned in this field. The default value is 3000

hours.

31-00121—02 33

Page 36

BACnet FF Controller

Economizer

Select Economizer from Configuration parameters. It

is used to configure the economizer settings in TB3026B

controller.

Figure 40: Economizer Screen (AHU)

Configuration

Minimum Position: When either the occupied command

or the After-hours Timer is ON, the current minimum

position is set to the specified Economizer Minimum

Position; otherwise, it is zero. The default minimum

position is 20%.

Outside Air Lockout: The economizer is forced to

Minimum position when Outside Air Temperature goes

above the Outside Air Lockout setpoint. The default value

is 68º F.

Supply Air Low Limit: The economizer is forced to

Minimum position when Supply Temperature goes below

the Supply Air Low Limit. The default value is 45º F.

34 31-00121—02

Page 37

BACnet FF Controller

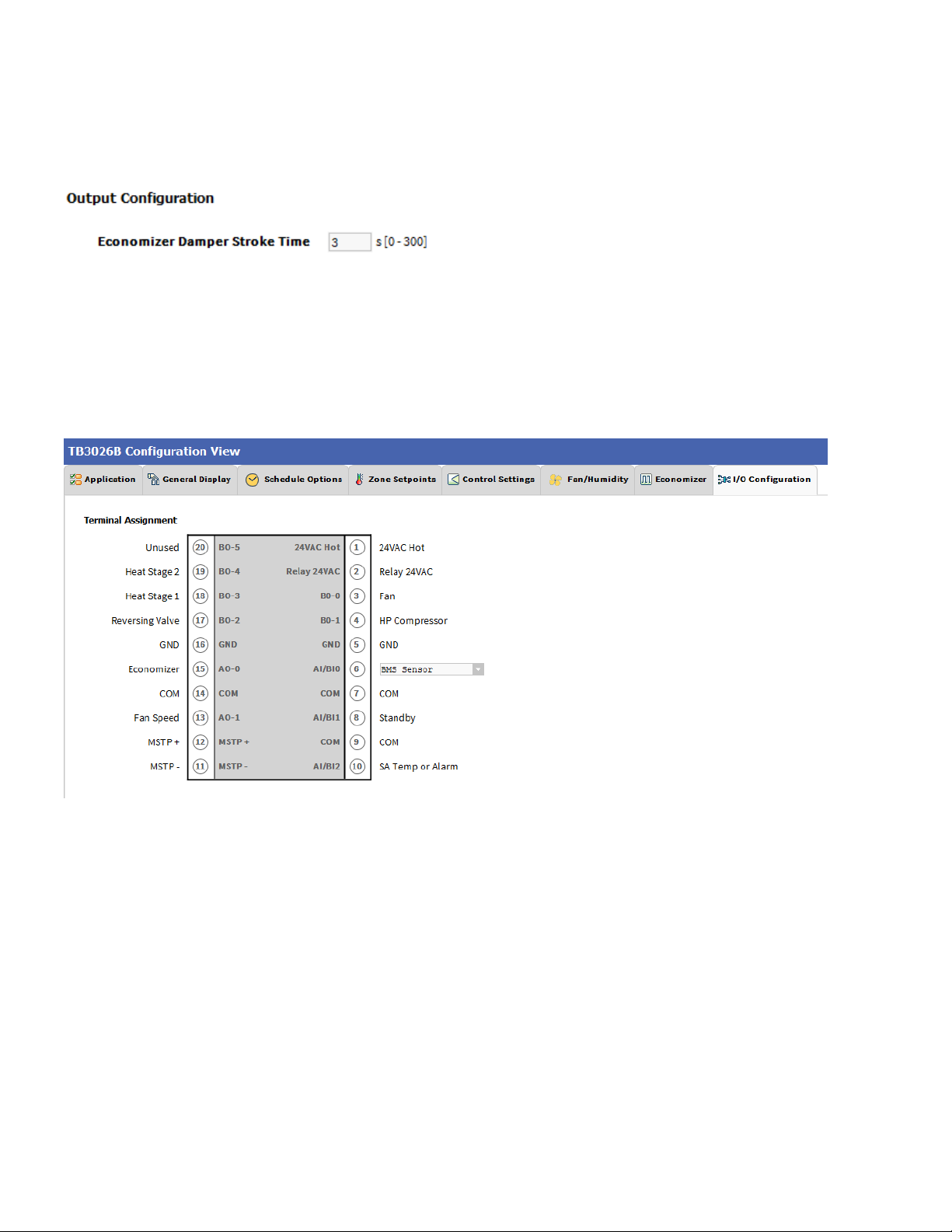

I/O Configurations

Select I/O Configurations from Configuration

parameters. This configuration is mainly used for Terminal

Assignment & Output Configuration.

Figure 41:I/O Configurations Screen (AHU)

Terminal Assignment

After completing the AHU configuration, selected inputs

and outputs get automatically assigned to the TB3026B

controller’s input and output terminals. However, a user

can assign the outputs as ‘Economizer Open’ &

‘Economizer Close ’to BO-4 & BO-5 and inputs as ‘BMS

Sensor’ or ‘Remote Space Temp’ or ‘Outdoor Air Temp’ to

AI/BI0 respectively.

31-00121—02 35

Page 38

BACnet FF Controller

Figure 42: Terminal Assignment View (AHU)

Output Configuration

When a user assigns the outputs, ‘Economizer Open’ and

‘Economizer Close’ to BO-4 and BO-5 respectively,

‘Economizer Damper Stroke Time’ can be mentioned in the

field ‘Output Configuration’. The default value is 3 seconds.

When ‘Output Stage’ is selected as ‘Two Stages Heat/Two Stages Cool’, the ‘Terminal Assignment’ view changes

as follows:

36 31-00121—02

Page 39

Air Source Heat Pump

BACnet FF Controller

Figure 43: Air Source Heat Pump Window

Output Stages

Equipment Type ‘Air Source Heat Pump’ consists of two

types of ‘Output Stages’. Required type of output stages

can be selected from the following available options:

One Compressor Stage and One Aux Heat Stage:

Select this option if One stage of compressor and one

stage of Auxiliary Heating is required in the application

31-00121—02 37

One Compressor Stage and Two Aux Heat Stage:

Select this option if Two stages of Compressors and Two

stages of Auxiliary Heating are required in the application

Fan Speeds

A user can select Two types of ‘Fan Speeds’ when the

output stage is configured as ‘One Compressor Stage and

One Aux Heat Stage’.

1. Single Speed Fan

2. Three Speed Fan

Page 40

BACnet FF Controller

General Display

Click ‘General Display’ to view the general display

settings. The following parameters are used to configure

the controller’s display settings.

1. Engineering Units

2. Time Functions

3. Display

4. Contractor Access Codes

Figure 44: General Display Screen (Air Source Heat Pump)

Engineering Units

Application Unit: The application units contain two

options to change the controller’s units. By default, the

controller’s application units are set to ‘English’. Application

units can be changed to ‘English’ or ‘Metric’.

38 31-00121—02

Page 41

Time Function

BACnet FF Controller

Clock Format: A user can select a clock format as

12-hour format or 24-hour format.

Display

This feature allows a user to select the Display settings.

Outside Air Temp: A user has an option to hide/show an

outside air temperature.

Clock Adjustment: This option allows a user to

enable/disable the clock adjustment on the controller

display.

Keypad Lockout: This option allows a user to lock/unlock

the clock adjustment.

When an option, ‘Temperature Settings Only’ is selected, a

user can only set the temperature through keypad.

Backlight: A user can keep the backlight always on or set

to delayed off through this option.

Daylight Savings Time: This feature enables to select the

Daylight Savings Time settings. By default, Daylight

Savings Time is set to ‘Disabled’. Daylight Savings Time

can be changed to ‘Pre-2007’ or ‘Post-2007’.

Contractor Access Codes

An access to the controller can be restricted with the help

of Access Codes.

Field Service Pin and Installer Service Pin can be set.

These codes should be enabled to restrict an access to the

controller.

Note:

A user can set only numerical PIN code for ‘Field

Service Pin’ and ‘Installer Service Pin’. PIN codes

should be set within 0000 – 9999. The following Error

Window pops up if this field is left blank after selecting.

31-00121—02 39

Page 42

BACnet FF Controller

Schedule Options

‘Schedule’ tab displays Schedule options.

The following parameters are used to configure the

schedule options (i.e. Occupancy Configuration and

Bypass and Standby)

Figure 45: Schedule Options Screen (Air Source Heat Pump)

Occupancy Configuration

Schedule Model: A user can set the device’s schedule

model as;

1. Setpoint Mode or

2. Occupancy Mode

Setpoint Mode: In setpoint mode, the controller logically

emulates residential thermostats. The space temperature

is controlled to "SP Mode Cooling SP" and "SP Mode

Heating SP". Each schedule period consists of a start time,

a heating setpoint, and a cooling setpoint.

Occupancy Mode: By default, ‘Schedule Model’ is in

‘Occupancy Mode’. The system will be switched to

‘Occupied Mode’ when the occupancy sensor detects

occupancy. Occupied Mode allows a user to configure

‘Comm Fails Occupied’, ‘System Block’ & ‘Internal

Schedule’ settings.

If a user selects ‘Setpoint Mode’ from the available

‘Schedule Model’, the fields for ‘Comm Fails Occupied’

and ‘System Block’ settings become disabled.

40 31-00121—02

Page 43

Comm Fails Occupied: It allows a user to switch the

system in Occupied Mode in case of MS/TP

communication failure. If the MS/TP communication fails,

the system enters into Occupied Mode when this option is

selected as ‘Enable’, otherwise the system remains in its

current state when this option is selected as ‘Disable’.

‘Enable’, and remains in its current state when this option

is selected as ‘Disable’.

System Block: The System Block is hidden when the

schedule model is in ‘Setpoint Mode’. When the schedule

model is in ‘Occupancy Mode’, it allows a user to switch

between the available options. Selecting “Show

Unoccupied/Off” places the controller in unoccupied state.

Internal schedule: It can be configured in both Occupancy

Mode & Setpoint Mode. By default, ‘Internal Schedule’ is

‘Disable’.

If the internal schedule is ‘Disable’, a user can adjust the

setpoint (within setpoint limits).

Display Settings

When a user selects, ‘Two Periods’ or ‘Four Periods’

options an additional ‘Display Settings’ appears as follows:

BACnet FF Controller

Bypass and Standby

Bypass Time: In the Unoccupied state, it forces the

controller into the occupied state for up to 4 hours (default

value). The override time limit is adjustable from a

minimum of 0.2 hours to a maximum of 9.5 hours.

Standby Delay: In Occupied Mode, if any window or door

is opened and closed with no motion detected after the

time mentioned for the Standby Delay, the room status

switches to Standby state. The default value is 180

seconds.

Schedule Access: When a user selects ‘Edit’, it allows a

user to view and edit the schedule and when a user selects

‘View’, it allows a user to view the schedule. When a user

selects ‘None’, it will not allow a user to view or edit the

schedule.

Vacation Hold: It allows/denies a user to override the

scheduled setpoint from TB3026B display to “Vacation

Hold”.

Permanent Hold: It allows/denies a user to override the

scheduled setpoint from TB3026B display to “Permanent

Hold”.

31-00121—02 41

Page 44

BACnet FF Controller

Zone Setpoints

Zone Setpoints , allows a user to set the following

parameters as per the requirement:

1. Temperature Setpoints

2. Setpoint Limits

3. Standby Settings

4. Display Options

Figure 46: Zone Setpoints Screen (Occupancy Mode)

Temperature Setpoints

Occupied Setpoint: It is a setpoint in Occupied Mode.

Enter the value within the range of 45 ºF to 99 ºF. The

default value is 70ºF.

Cooling Offset: In the Occupied state, the cooling setpoint

is calculated as cooling offset plus occupied setpoint. Enter

42 31-00121—02

the value within the range of 0ΔºF to 12.1ΔºF.The default

value is 2 ΔºF.

Heating Offset: In the Occupied state, the heating setpoint

is calculated as heating offset minus occupied setpoint.

Enter the value within the range of 0ΔºF to 12.1ΔºF. The

default value is 1 ΔºF.

Unoccupied Heating Setpoint: It is a setpoint for Heating

in Unoccupied mode. Enter the value within the range of

45 ºF to 99 ºF. The default value is 55 ºF.

Unoccupied Cooling Setpoint: It is a setpoint for Cooling

in Unoccupied mode. Enter the value within the range of

45ºF to 99ºF.The default value is 85 ºF.

Page 45

BACnet FF Controller

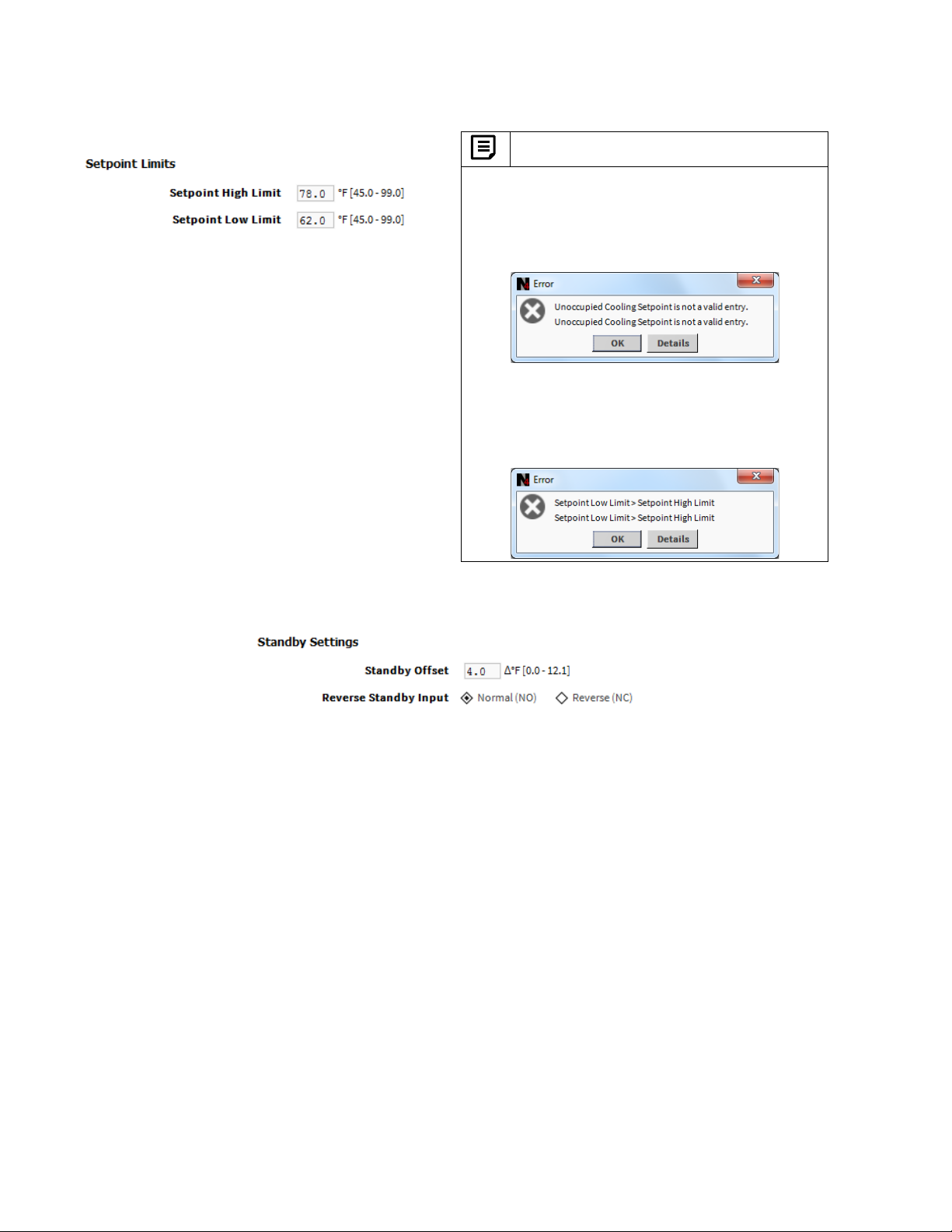

Setpoint Limits

Setpoint High Limit: A user can enter a Setpoint High

Limit in Occupied Mode within the range of 45 ºF to 99 ºF.

The default value is 78ºF.

Setpoint Low Limit: A user can enter a Setpoint Low Limit

in Occupied Mode within the range of 45 ºF to 99 ºF. The

default value is 62ºF.

Note:

1. Unoccupied Cooling Setpoint should always be set

GREATER than Unoccupied Heating Setpoint.

Following Error window appears if Unoccupied

Cooling Setpoint is set lower than Unoccupied

Heating Setpoint.

2. Setpoint High Limit should always be set

GREATER than Setpoint Low Limit.

Following Error window appears if Setpoint High

Limit is set lower than Setpoint low Limit.

Standby Settings

Standby state is a power-saving function of Occupancy

mode. It occurs when the space is scheduled as Occupied,

but sensors detect (When the Standby input is active)

there are no humans in the space.

Standby Offset: In this case, the Standby Offset relaxes

the occupied setpoints. The value of the Standby Offset

[SO] can be set between a minimum of 0ΔºF and a

maximum of 12.1ΔºF degrees. The default value is 4 ΔºF.

Reverse Standby Input: It allows a user to configure two

types of inputs, ‘Normally Open (NO)’ and ‘Normally Close

(NC)’.

31-00121—02 43

Page 46

BACnet FF Controller

Display Options

When a user selects Schedule Model under the ‘Schedule Options’ tab to ‘Setpoint Mode’, the ‘Zone Setpoints’

configuration window appears as follows:

Figure 47: Zone Setpoint Screen (Setpoint Mode)

Unoccupied Setpoints: It allows a user to either ‘Hide’ or

‘Show’ the unoccupied setpoint.

44 31-00121—02

Page 47

BACnet FF Controller

Control Settings

‘Control Settings’ allows a user to configure following

settings:

1. Cooling PI Control.

2. Heating PI Control.

3. Aux Staged Heating

4. Compressor Settings.

Figure 48: Control Settings Screen (Air Source Heat Pump)

31-00121—02 45

Page 48

BACnet FF Controller

Cooling PI Control

Proportional Constant K

: A user can enter a value for Kp

p

within the range of 10 to 40. The default value is 20.

Integral Constant K

: A user can enter a value for Ki

i

within the range of 0.50 to 2. The default value is 1.

OAT Lockout Setpoint: Cooling PI control will lockout

when outside Temperature increases above OAT (Cooling)

Lockout Setpoint. The default value is 55 ºF.

Aux Staged Heating

Heating PI Control

Proportional Constant K

: A user can enter a value for Kp

p

within the range of 10 to 40. The default value is 20.

Integral Constant K

: A user can enter a value for Ki

i