I

T991A REMOTE BULB

TEMPERATURE CONTROLLER

APPLICATION

The T991A Remote

used to sense water and air temperatures, and provides proportional control of a Series 90 (Modutrol*)

motor. Typically, Series SO motors are used with

linkages to operate valves or dampers in air cmditiming systems.

The TSSlA cm be used to replace the controliers

listed below:

INSTALLATION

NOTE:

by a quaiiCied service mm. Follov instruciions lunished by heating or cooling system manufacturer, if

available.

(ion on a blat surface where the ambient temper&e

does not exceed 125 F. When mounting on a hoi or

cold surface. mount the case on a wood board or

other insulating material. The 5-fool capillary tube

provides for remote mounting.

or FOR REPLACEMENT section.

FOR NEW INSTALLATION:

MOUNTTHE CONTHOLLER CASEmark three screw hole locations on mountinz surface,

then punch or drill holes.

the mounting screws furnished.

TO INSTALL SENSING BULB IN AIR DUCT:

temperature can circulate freely around ii. Avoid

mounting the bulb close to hot pipes, cooling coils,

and other places where air temperatures are not

representative.

No. 107324A (supplied).

Installation and service should be made only

Proceed lo Ihe FORK NEW INSTALLATION section

1. Remove cover. Using the case as a templa.te,

2. Fasten TSSlAsecurely lo mounting surfacewith

Locale

To support the bulb in Lhe duct, use Bulb Hoider

the sensing bulb where duct air of average

Bulb Temperature Controller is

TSSIA temperature settings sa,me

See

Table

1 for corresponding T9SlA

-

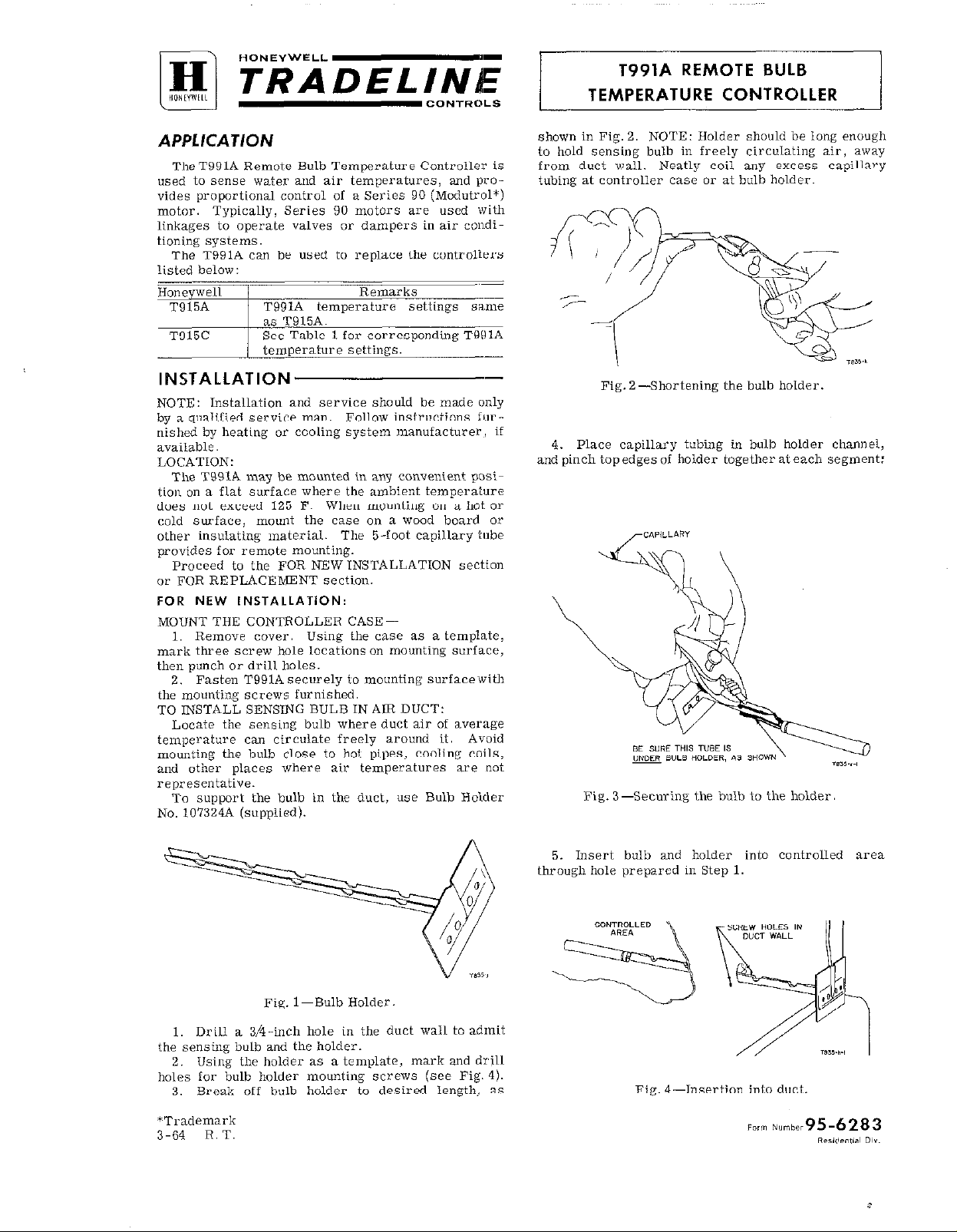

shown in Fig. 2.

to hold sensing bulb in freely circulaiing air, away

from duck wail. Neatly coil any excess capillary

tubing at controller case or at bulb holder.

Fig. 2Shortening Ihe bulb holder.

4. Place capillary tubing in bulb holder channel,

and pinch topedges of holder together aleach segment:

Fig. 3--Securing the bulb to the holder

NOTE:

Holder should be long enough

Fig. l-Bulb Holder,

1. Drill a 3/4-inch hole in the duct wall to admit

the sensing bulb and the holder.

2.

Using

holes for bulb holder mounting screws (see Fig. 4).

3.

*Trademark

3-64 R.T.

the holder as a template, mark and drill

Break off bulb holder to desired length, as

5. Insert bulb and holder into controlled area

through hole prepared in Step 1.

Fig. 4-Insertion into duct.

3

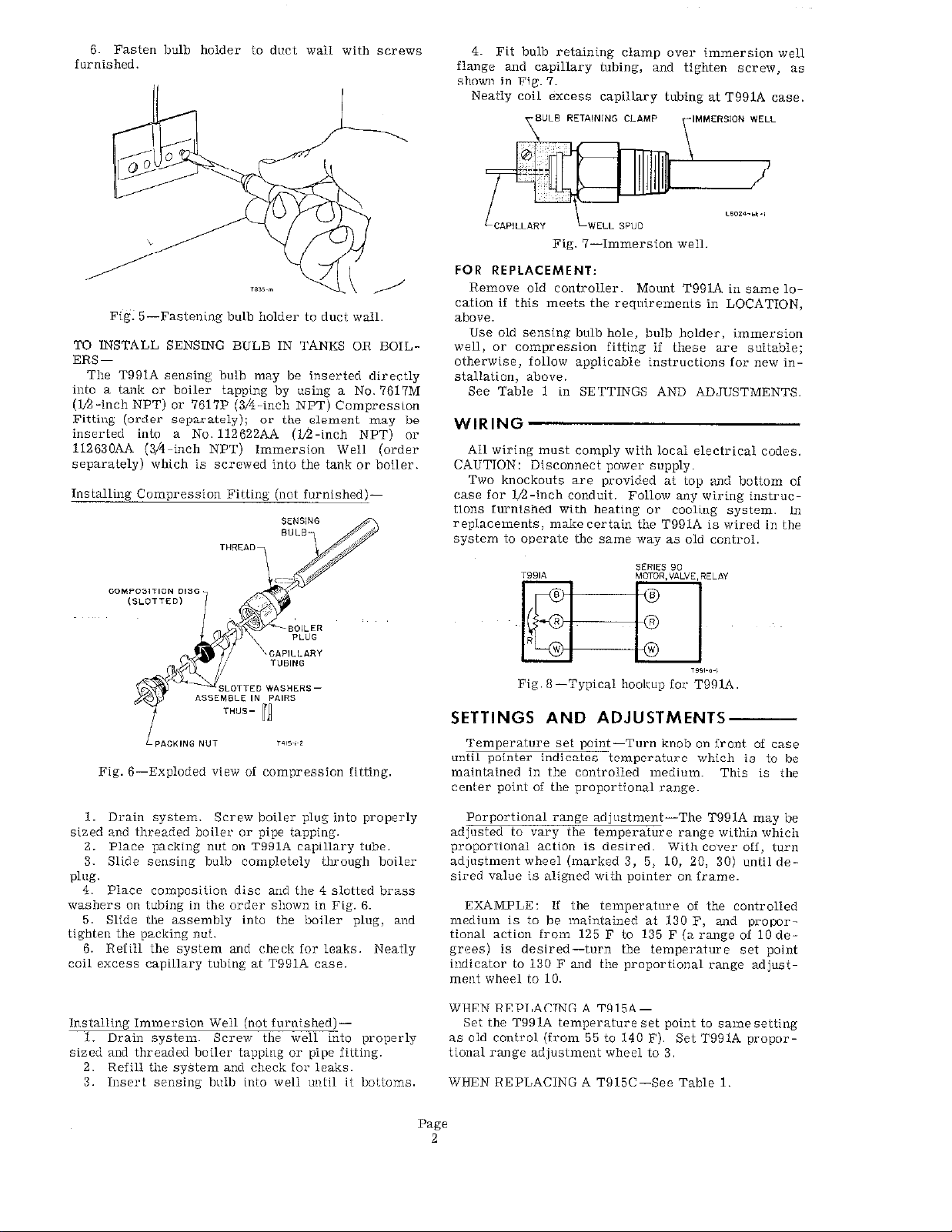

6. Fasten bulb holder to duct wall with screws 4. Fit bulb retaining clamp over immersion well

furnished.

flange and capillary tubing, and tighten screw, as

slhown in Fie. 7.

Neatly coil excess capillary tubing at T991A case.

8”s RETAlNlNG CLAMP pMERSI”N WELL

\

FOR REPLACEMENT:

Remove old controller. Moluit T991A in same lo-

cation if ihis meek the requirements in LOCATION,

FigI 5-Fastening bulb holder to duck wail above.

Use old sensing bulb hole, bulb holder, immersion

TO INSTALL SENSING BULB IN TANKS OR BOIL- well, or compression iitting if these are suitable;

ERS - otherwise, follow applicable instructions for new in-

The T991A sensing bulb may be inserted directly stallaiion, above.

into a tank or boiler tapping by “si”g a No. 7617M See Table 1 in SETTINGS AND ADJUSTMENTS.

(M-inch NPT) or 76172 (3kinch NPT) Compression

Fitting (order separately); or the element may be

inscried into a No. 112622AA (&‘-inch NPT) or

WIRING

112G30AA (3/4-inch NPT) Immersion Well (order All wiring must comply with local electrical codes.

separately) which is screwed into ihe ianlr or boiler.

CAUTION: Disconnect power supply.

Two knockouts are provided ai top and boliom of

Installing Compression Fitiing (not i”rnished)- ca.se for U-inch conduit. Follow any wiring instruc-

iions furnished with heaiing or cooling system. In

replacemenis, make certain the T991A is wired in the

system to operate the same way as old control.

Fig. 8-Typical hookup for T991A

SEtTTINGS AND ADJUSTMENTS

L

PPiCKlNGNUT

Fig. B-Exploded view of compression fitting,

1. Drain system. Screw boiler plug into properly Porportional range adjustmen-The T991A may be

sized and threaded boiler or pipe tapping.

2. Place packing nut 011 T99iA capillary lube.

3. Slide sensing bulb compieieiy tko”gh boiler adjustment wheel (marked 3, 5, 10, 20, 30) until de-

p,i,g.

4. Place composilion disc and the 4 slotted brass

washers

on

tubing in the order shown in Fig. 6.

5. Slide the assembly into the boiler plug, and medium is to be maintained ai 130 F, and propor-

tighte” the packing nul.

6. ReIill the sysiem and check for leaks. Neatly

coil cxccss capillary tubing at T991A case. inclicaior to 130 F and the proportional range adjust-

Inslalling Immersion Well (not furnished)-

1. Drain system. Screw the well into properly

sized and threaded boiler tappiq or pipe Eiiiing.

2. Refill the syShn and check for leaks.

3. Insert sensing b”ib into well wlil it bottoms. WHEN REPLACING A T915C-See Table 1.

,OiS~,~i

Temperaiure sel point-Turn knob on front of case

until pokier indicates temperaiure which is io be

maintained in the controlled medium This is the

center point Of the proportional range.

adjusted to vary the iemperaturc range within which

action

proporlionai

is desired. With cover off, lurn

sired value is aligned wiih p~inier on frame.

EXAMPLE: If the temperature of the controlled

tional action from 125 F to 135 F (a range of 10 degrees) is desired-turn ihe iemperature set point

ment wheel to 10.

WHEN REPLACBIG A T915A-

Set the T991A temperature set point to same seiiing

as Oid control (from 55 io 140 F). Set T991A propor-

tional range adjustmeni wheel to 3.

Page

2

-

T915C T915C Settings

Scale Temperature Porportional

Range

F

TABLE l-TRIAL SETTINGS FOR T991A WHEN REPLACING A T915C

set Point Range

Min.

Set T991A at same temperature Set T991A Proset point as T915C PLUS- portional range at

Corresponding Settings for T99lA:

Z-lb degrees (F) 5

I

t

Between 55

and90F

Between 115

and 140 F

Between 90

and 115 F

E

/

15 to 90 F

65 to 140 F

F

in.

A

Between 65

and 90 F

aThe Tradeline T991A proportional range is from 3 to 30 degrees F. If ihe application exceeds the

30.degree proportional range, then a T915C must be used or a repaired exchange T915C musi be ordered.

CHECKOUT

After mounting and wiring have been conipleted, let Constantly mo”es back and forth, widen the T991A

the controlled equipment operate until system temperature stabilizes (from 1 to 3 hours). Observe the the system is stable.

B

C

=I

n

G / 22 degrees (F)

I

-

IY oegrees ,j?)

motor action to see if ii stabilizes. If the motor shaft

proportional range (about 5 degrees ai a time) until

see note”

By using this Honeywell literature, you agree that Honeywell will have no liability for any damages arising out of your use or modification to, the

literature. You will defend and indemnify Honeywell, its affiliates and subsidiaries, from and against any liability, cost, or damages, including

attorneys’ fees, arising out of, or resulting from, any modification to the literature by you.

@, HONEYWELL . a . Minneapolis 8, Minnesota

.

Toronto 17. Ontario

Loading...

Loading...