STT700 SmartLine

Temperature Transmitter

User’s Manual

34-TT-25-17

Revision 6

November 2020

Honeywell Process Solutions

Copyrights, Notices and Trademarks

© Copyright 2020 by Honeywell, Inc.

Revision 6, November 2020

While the information in this document is presented in good faith and believed to be

accurate, Honeywell disclaims any implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in the written

agreement with and for its customers. In no event is Honeywell liable to anyone for any

indirect, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Honeywell, TDC 3000, SFC, SmartLine, PlantScape, Experion PKS, and TotalPlant are

registered trademarks of Honeywell International Inc. Other brand or product names are

trademarks of their respective owners.

Honeywell Process Solutions 1250 W Sam Houston Pkwy S

Houston, TX 77042

Revision 6 STT700 Temperature Transmitter User’s Manual Page ii

About This Manual

This manual is a detailed how to reference for installing, piping, wiring, configuring, starting up,

operating, maintaining, calibrating, and servicing Hone y w ell’s family of STT700 temperature

transmitters. Users who have a Honeywell STT700 SmartLine Temperature Transmitter

configured for HART protocol or Honeywell’s Digitally Enhanced (DE) are referred to the

STT700 SmartLine Series HART/DE Option User’s Manual, document number 34-TT-25-18.

The configuration of your transmitter depends on the mode of operation and the options selected

for it with respec t to operating controls, displays and mechanica l in s tal lation. This manual

provides detailed procedures to assist first-time users, and it further includes keystroke

summaries, where appropriate, as quick reference or refresh e rs f or experienced pe rsonnel.

To digitally integrate a transmitter with one of the following systems:

• For the Experion PKS, you will need to supplement the information in this document with the

data and procedures in the Experion Knowledge Builder.

• For Honeywell’s TotalPlant Solutions (TPS), you will need to supplement the information in this

document with the data in the PM/APM SmartLine Transmitter Integration Manua l, which is

supplied with the TDC 3000 book set. (TPS is the evolution of the TDC 3000).

Release Information:

STT700 SmartLine Temperature Transmitter User Manual, Document # 34-TT-25-17,

st

Rev.1 July 2017 1

Release

Rev.2 February 2018 FM Approval updates

Rev.3 October 2018 CCoE, NEPSI, SAEx approvals added.

Sensor Wiring Best Practice Recommendations added

Rev.4 December 2018 Voltage resistance chart updated. Dimensions added.

Rev.5 July 2019 Integral Meter, Head mount Enclosure and DE Start-up fix

Rev.6 November 2020 Host / Device nomonclature

Revision 6 STT700 Temperature Transmitter User’s Manual Page iii

United States and

Canada

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

Global Email

Support

Honeywell Process

Solutions

References

The following list identifies publications that may contain information relevant to the information

in this document.

• STT700 SmartLine Temperature Transmitter Quick Start Installation Guide, Document

# 34-TT-25-19

• STT700 SmartLine Temperature Transmitter HART/DE Option User’s Manual,

Document # 34-TT-25-18

• STT700 SmartLine Temperature Field Device Spec (HART), Document # 34-TT-00-05

• STT700 SmartLine Transmitter Safety manual Document # 34-TT-25-20

• MC Toolkit User Manual, MCT404, Document # 34-ST-25-50

• Engineering Meter (EU) User Guide, Document #34-ST-25-18

• STT700 Series Temperature, Transmitter, Agency IS Control Drawing #50133855

• Smart Field Communicator Model STS 103 Operating Guide, Document # 34-ST-11-14

(for use with STT700 DE only)

Patent Notice

The Honeywell STT700 SmartLine Temperature Transmitter family is covered by one or more of the

following U. S. Patents: 5,485,753; 5,811,690; 6,041,659; 6,055,633; 7,786,878; 8,073,098 ; and other

patents pending.

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, refer to the back page of this

manual or the appropriate Honeywell Solution Support web site:

Honeywell Corporate www.honeywell.com

Honeywell Process Solutions https://www.honeywellprocess.com

SmartLine Temperature https://www.honeywellprocess.com/smartline-temperature.aspx

Training Classes http://www.automationcollege.com

Telephone and Email Contacts

Area Organization Phone Number

Honeywell Inc.

Page iv STT700 Temperature Transmitter User’s Manual Revision 6

ask-ssc@honeywell.com

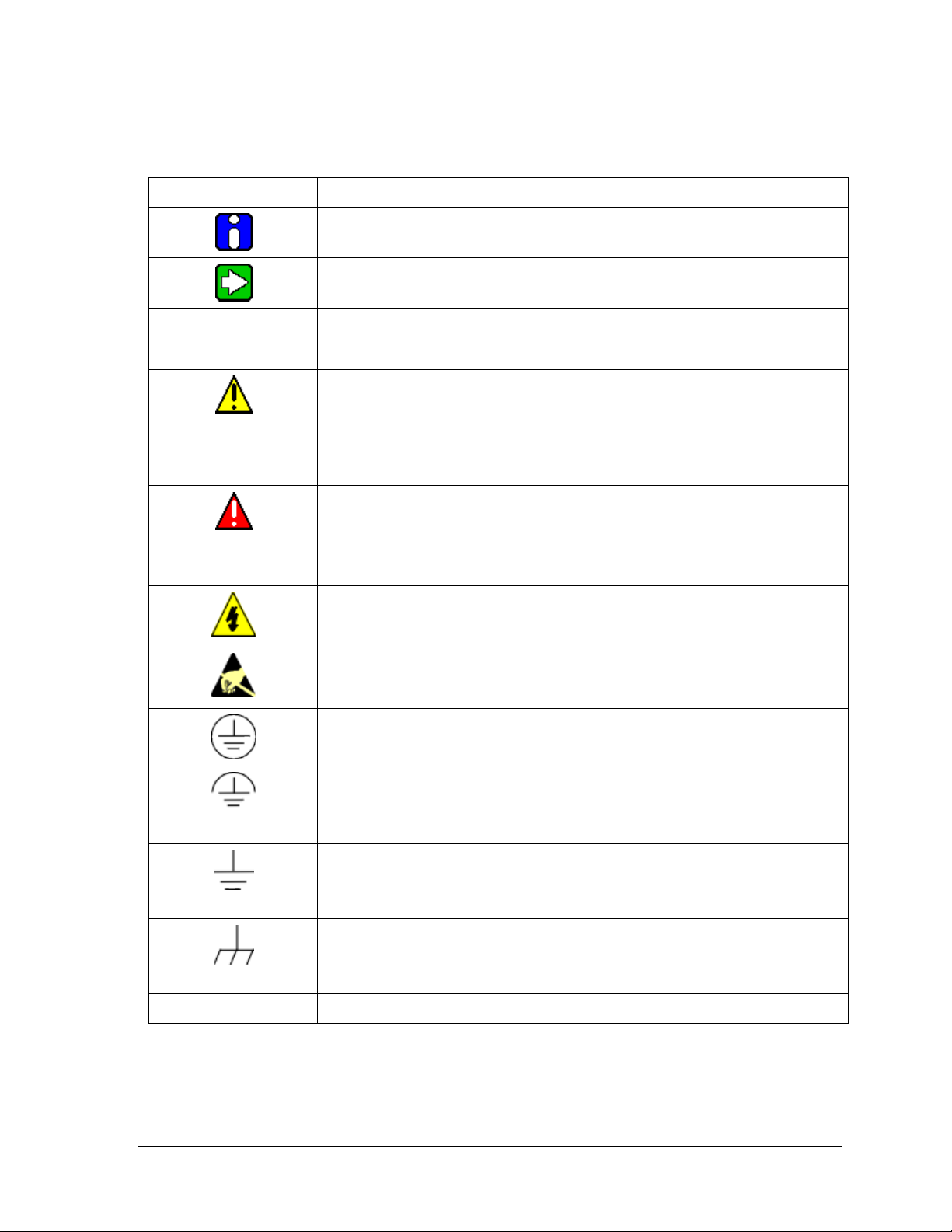

Symbol Descriptions and Definitions

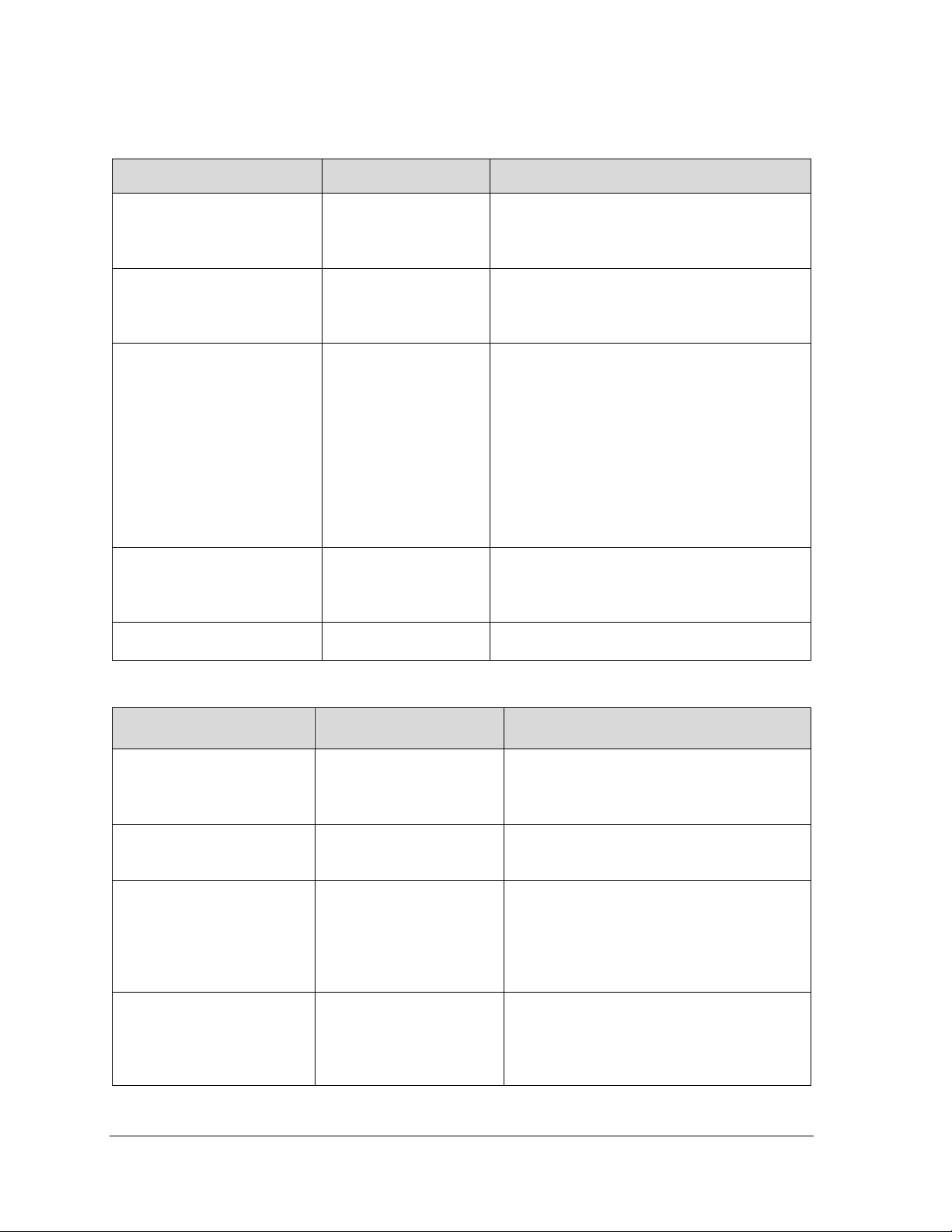

The symbols identified and defined in the following table may appear in this document.

Symbol Definition

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a

task.

CAUTION

Indicates a situation which, if not avoided, may result in equipment or work

(data) on the system being damaged or lost, or may result in the inability to

properly operate the process.

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

unsafe practices.

CAUTION symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in

the manual.

WARNING: Indicates a potentially hazardous situation, which, if not avoided,

could result in serious injury or death.

WARNING symbol on the equipment refers the user to the product manual

for additional information. The symbol appears next to required information

in the manual.

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 VDC

may be accessible.

ESD HAZARD: Danger of an electro-static discharge to which equipment may

be sensitive. Observe precautions for handling electrostatic sensitive

devices.

Protective Earth (PE) terminal: Provided for connection of the protective

earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noise

immunity improvement. NOTE: This connection shall be bonded to

Protective Earth at the source of supply in accordance with national local

electrical code requirements.

Earth Ground: Functional earth connection. NOTE: This connection shall be

continued

bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

Chassis Ground: Identifies a connection to the chassis or frame of the

equipment shall be bonded to Protective Earth at the source of supply in

accordance with national and local electrical code requirements.

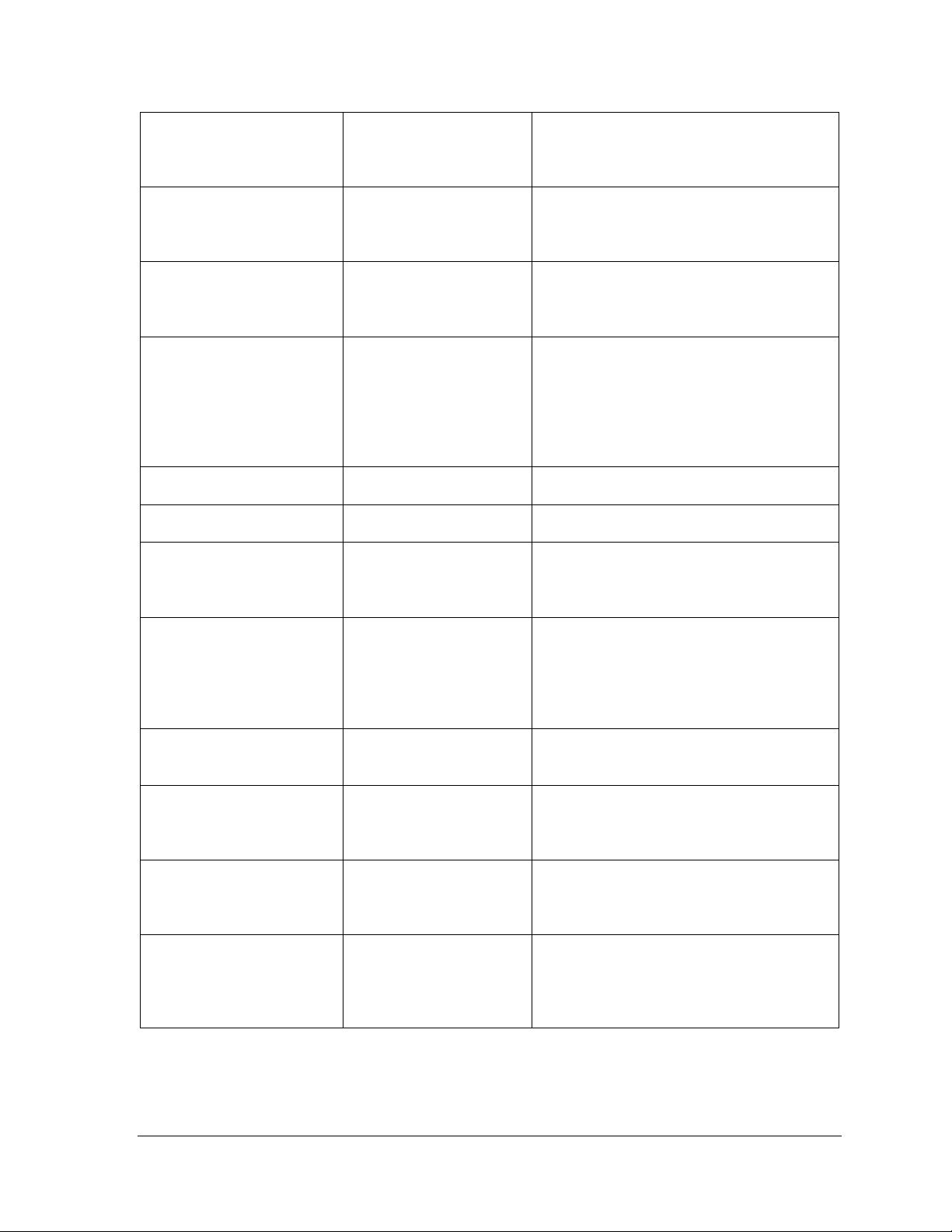

Revision 6 STT700 Temperature Transmitter User’s Manual Page v

Symbol

Description

The Factory Mutual® Approval mark means the equipment ha s been rigorou sly

tested and certified to be reliable.

The Canadian Standards mark means the equipment has been tested and meets

applicable standards for safety and/or performance.

The Ex mark means the equipment complies with the requirements of the

European standards that are harmonized with the 94/9/EC Directive (ATEX

Directive, named after the French "AT mospher e EXplosible").

Page vi STT700 Temperature Transmitter User’s Manual Revision 6

Contents

1. Introduction .................................................................................................................................... 1

Overview ................................................................................................................................ 1

Features and Options .............................................................................................................. 1

Physical Characteristics .................................................................................................. 2

Functional Characteristics .............................................................................................. 3

STT700 SmartLine Transmitter Nameplate ........................................................................... 3

Safety Certification Information ............................................................................................. 4

Transmitter Adjustments ........................................................................................................ 4

EU Meter Option – HART only ............................................................................................. 4

2. Application Design ......................................................................................................................... 5

Overview ................................................................................................................................ 5

Safety ...................................................................................................................................... 5

Accuracy ......................................................................................................................... 5

Diagnostic Messages ...................................................................................................... 5

3. Installation and Startup ................................................................................................................... 9

Installation Site Evaluation ..................................................................................................... 9

Honeywell MC To olkit........................................................................................................... 9

Mounting and Dimensions ................................................................................................... 10

DIN Rail Mounting ....................................................................................................... 10

Mounting Module in Housing ...................................................................................... 11

Dimensions ................................................................................................................... 13

Spring Loading ............................................................................................................. 15

Installation Procedure of Standard display for STT700: ...................................................... 16

Uninstalling/Installing Standard Display for external wiring ....................................... 16

Wiring a transmitter .............................................................................................................. 20

Loop Power Overview .................................................................................................. 20

Digital System Integration Information ........................................................................ 22

Wiring Variations ......................................................................................................... 22

Grounding and Lightning Protection ............................................................................ 23

Input Sensor Wiring ..................................................................................................... 23

Lightning Protector ....................................................................................................... 25

4. Startup .......................................................................................................................................... 29

Overview ...................................................................................................................... 29

Startup Tasks ................................................................................................................ 29

Output Check Procedures ............................................................................................. 29

Constant Current Source Mode Procedure ................................................................... 30

5. Operation ...................................................................................................................................... 32

Overview .............................................................................................................................. 32

Configuration Tools.............................................................................................................. 32

Smart Field Communicator (SFC) for DE Models ....................................................... 32

HART Communicator Model 375, 475 or MC Toolkit FDC for HART 7 Models .... 33

Revision 6 STT700 Temperature Transmitter User’s Manual Page vii

6. Maintenance ................................................................................................................................. 35

Overview .............................................................................................................................. 35

Preventive Maintenance Practices and Schedules ................................................................ 35

Troubleshooting ................................................................................................................... 35

Troubleshooting with SFC ........................................................................................... 35

Troubleshooting with HART communicator ............................................................... 37

Recommended Parts ............................................................................................................. 38

Wiring and Installation Drawings ........................................................................................ 41

Upgrading the firmware ....................................................................................................... 42

7. Calibration .................................................................................................................................... 46

Recommendations for transmitter Calibration ..................................................................... 46

Calibration Procedures ......................................................................................................... 46

Appendix A. PRODUCT CERTIFICATIONS .................................................................................... 47

Glossary ............................................................................................................................................... 62

List of Tables

Table 1 – Features and Options.............................................................................................................. 1

Table 2 – Available EU Meter Characteristics ...................................................................................... 4

Table 3 – STT700 Diagnostic Messag es ................................................................................................ 6

Table 4 – STT700 Standard Non-C ritical Diagno sti cs Mess ag es .......................................................... 6

Table 5 - Dimension table for use with Figure 6 and Figure 7 ............................................................ 12

Page viii STT700 Temperature Transmitter User’s Manual Revision 6

List of Figure s

Figure 1: STT700 Temperature Transmitter device with display module ............................................. 2

Figure 2 – STT700 HART (left) and DE (right) Transmitter module .................................................... 2

Figure 3 – Nameplate on the side of the transmitter............................................................................... 3

Figure 4 –STT700 Model Number Format ............................................................................................ 3

Figure 5 - DIN Rail Mounting .............................................................................................................. 10

Figure 6 - Wall Mounting Dimensions ................................................................................................. 11

Figure 7 - Pipe Mounting Dimensions ................................................................................................. 12

Figure 8 – STT700 transmitter module with lightning protection (top) and without (bottom) ............ 13

Figure 9: Housing cover and O-ring ..................................................................................................... 14

Figure 10 - Spring Loading and Sensor Assembly ............................................................................... 15

Figure 11: : Position of Standard display for external wiring ............................................................. 16

Figure 12: Assembly of Standard display with Bracket ....................................................................... 17

Figure 13: short cable and display assembly ....................................................................................... 17

Figure 14: Cable joint fixed in the bracket ........................................................................................... 18

Figure 15: Long cable connection with STT Module ........................................................................... 18

Figure 16: Positioning of Long cable in the IM Housing ..................................................................... 19

Figure 17: : Example of external wiring (Reference only) ................................................................... 19

Figure 18 – STT700 with HART Transmitter Operating Ranges ........................................................ 20

Figure 19– STT700 with DE Transmitter Operating Ranges ............................................................... 20

Figure 20 –STT700 module terminal connections ............................................................................... 21

Figure 21 – HART/DE Input Wiring Diagram for single sensor connection ....................................... 24

Figure 22 – Wiring Diagram for HART Dual Sensor Connections ..................................................... 24

Figure 23 – STT700 with Lightning Protector Dimensions ................................................................. 25

Figure 24 – Installation without EU Meter ........................................................................................... 26

Figure 25 – Installation with EU Meter ................................................................................................ 27

Figure 26 – Installation with Standard Display .................................................................................... 27

Figure 27 – Current Loop Test Connections ........................................................................................ 30

Figure 27: Housing with EU meter ...................................................................................................... 39

Figure 28: Housing without EU meter ................................................................................................. 39

Figure 29: HOUSING WITH STANDARD DISPLAY ....................................................................... 40

Figure 30: HOUSING WITHOUT STANDARD DISPLAY .............................................................. 40

Revision 6 STT700 Temperature Transmitter User’s Manual Page ix

HART version 7

Human-Machine Interface (HMI)

No Display

Standard Display

Calibration

Single

Approvals (See Appendix A for details.)

ATEX, CSA, FM, IECEx, CCoE, NEPSI, SAEx

Pipe mounting and wall mounting brackets in carbon

Integration Tools

DD or DTM Hosts such as Experion and FDM

Firmware Upgrade

SAT tool for firmware upgrade

1. Introduction

Overview

This section is an introduction to the physical and functional characteristics of Honeywell’s STT700

SmartLine Temperature Transmitter.

Features and Options

The STT700 SmartLine Temperature Transmitter is available in a variety of models for measuring

Thermocouples, RTD, Millivolts, and ohm sensor types. Table 1 lists the protocols, Human-Machine

Interface (HMI), materials, approv al s, and mounting bracket options for the STT700.

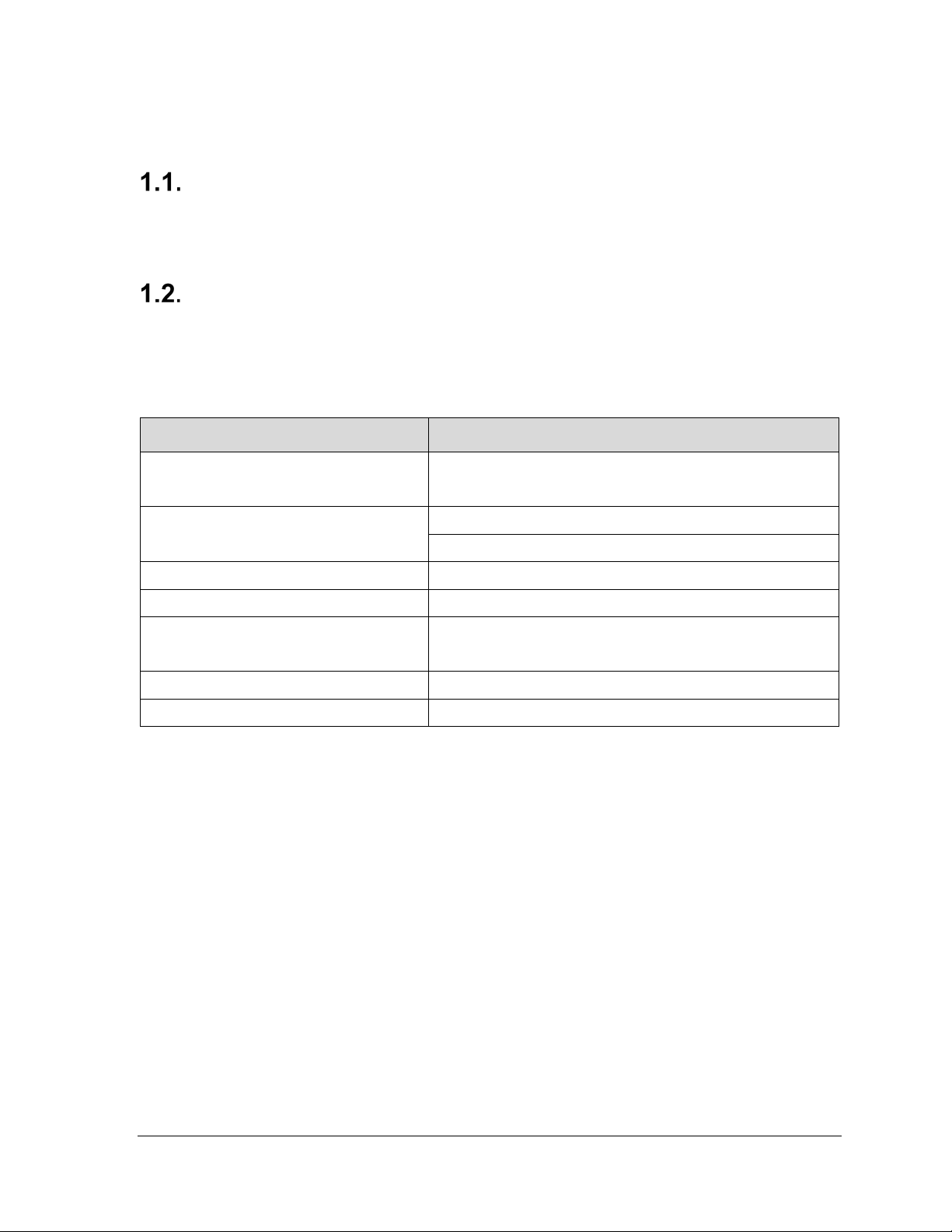

Table 1 – Features and Options

Feature/Option Standard/Available Options

Communication Protoco ls

Options

Mounting Brackets

Digitally Enhanced (DE)

steel and 316 stainless steel.

Revision 6 STT700 temperature transmitter User’s Manual Page 1

Physical Characteristics

As shown in Figure 1 and Figure 2, the STT700 is packaged in a single module. The elements in this

module are connected to the process sensors, measure the process variables, respond to setup

commands and execute the software and protocol for the different temperature measurement types.

Figure 1: STT700 Temperature Transmitter device with display module

Figure 2 – STT700 HART (left) and DE (right) Transmitter module

Page 2 STT700 Temperature Transmitter User’s Manual Revision 6

Key I II III IV V VI VII VIII

STT700 - _ _ - _ _ _ - _ _ _ _ _ _ - _ _ _ _ - _ _ _ - _ - _ _, _ _, _ _ - 00000

Functional Characteristics

The transmitter measures process temperature and outputs a signal proportional to the measured

process variable (PV). Available output communication protocols include 4 to 20mA, Honeywell

Digitally Enhanced (DE) and HART protocols.

In addition, a Honeywell Multi-Communication (MC) Toolkit (not supplied with the transmitter) can

facilitate setup and adjustment procedures in the case of HART and DE. Certain adjustments can be

made through an Experion Station or a Universal Station if the transmitter is digitally integrated with

Honeywell’s Experion or TPS/TDC 3000 control system for HART and DE transmitte rs.

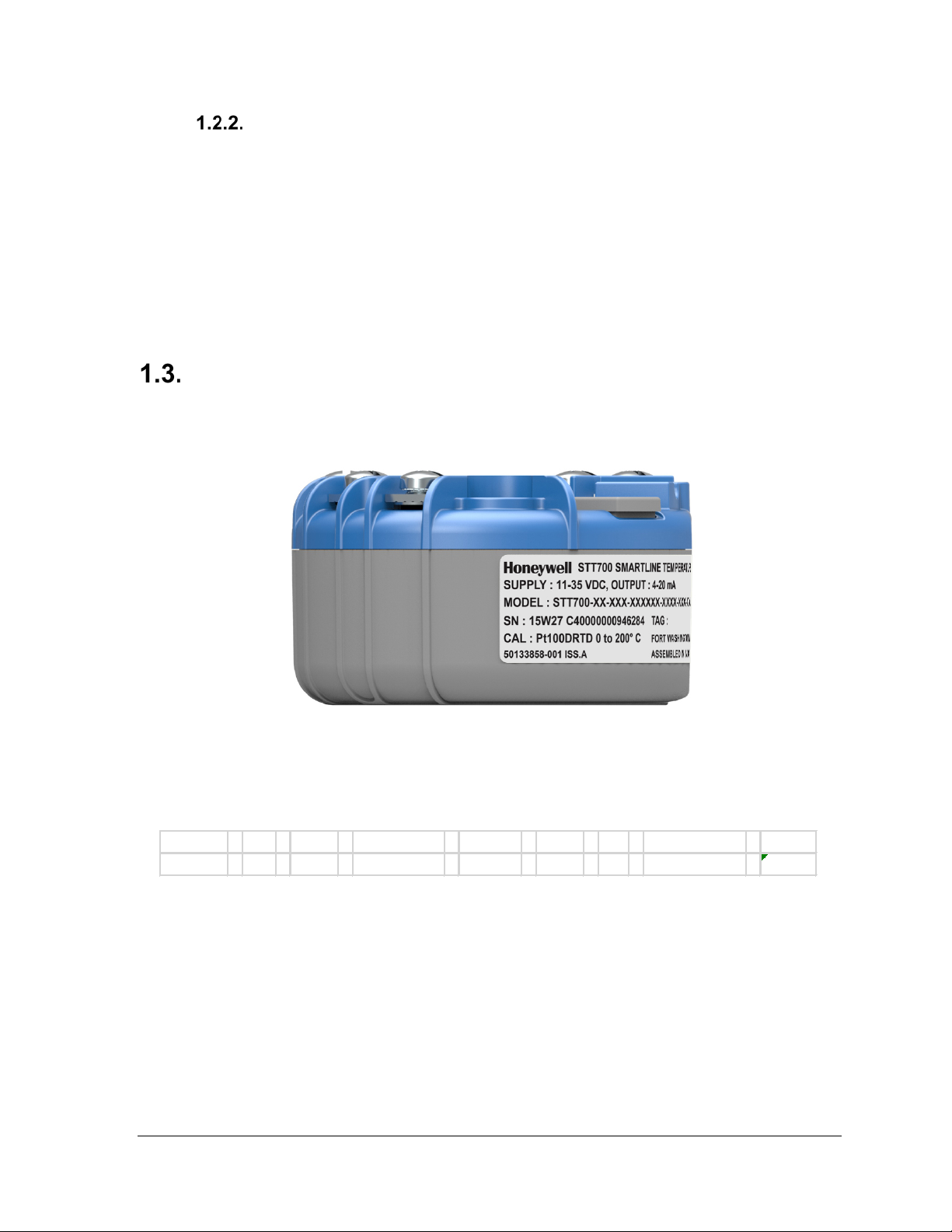

STT700 SmartLine Transmitter Nameplate

The transmitter nameplate mounted on the side of the transmitter (see Figure 3) lists its model

number, physical configuration, electronics options, accessories, certifications, and manufacturing

specialties.

Figure 3 – Nameplate on the side of the transmitter

Figure 4 is an example of a typical temperature transmitter nameplate. The model number format

consists of a Key Number with several table selections.

Figure 4 –STT700 Model Number Format

The transmitter type can be identified from the key number. The third letter in the Key number

represents this basic transmitter ty pe:

• T = Temperature

For a complete selection breakdown, refer to the appropriate Specification and Model Selection

Guide provided as a separate document.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 3

EU Meter

EU Meter

Safety Certification Information

The hazardous area approvals information is listed on the nameplate which, as shown in Figure 3, is

located at the bottom of the module.

The approvals nameplate contains information and service

marks that disclose the transmitter compliance information. Refer to Appendix A of this document for

safety certification requirements and details.

Transmitter Adjustments

For HART and DE you can use the Honeywell MC Toolkit or other third-party hand-held (for

HART) to make any adjustments to an STT700 SmartLine Temperatu re Transmitter.

Any HART 7.0 compliant PC host like Honeywell FDM can be used to configure the device.

Honeywell FDM can also configure the STT700 with DE protocol

Alternately, certain adjustments can be made through the Experion or Universal Station, if the

transmitter is digitally integrated with a Honeywell Experion or TPS system.

.

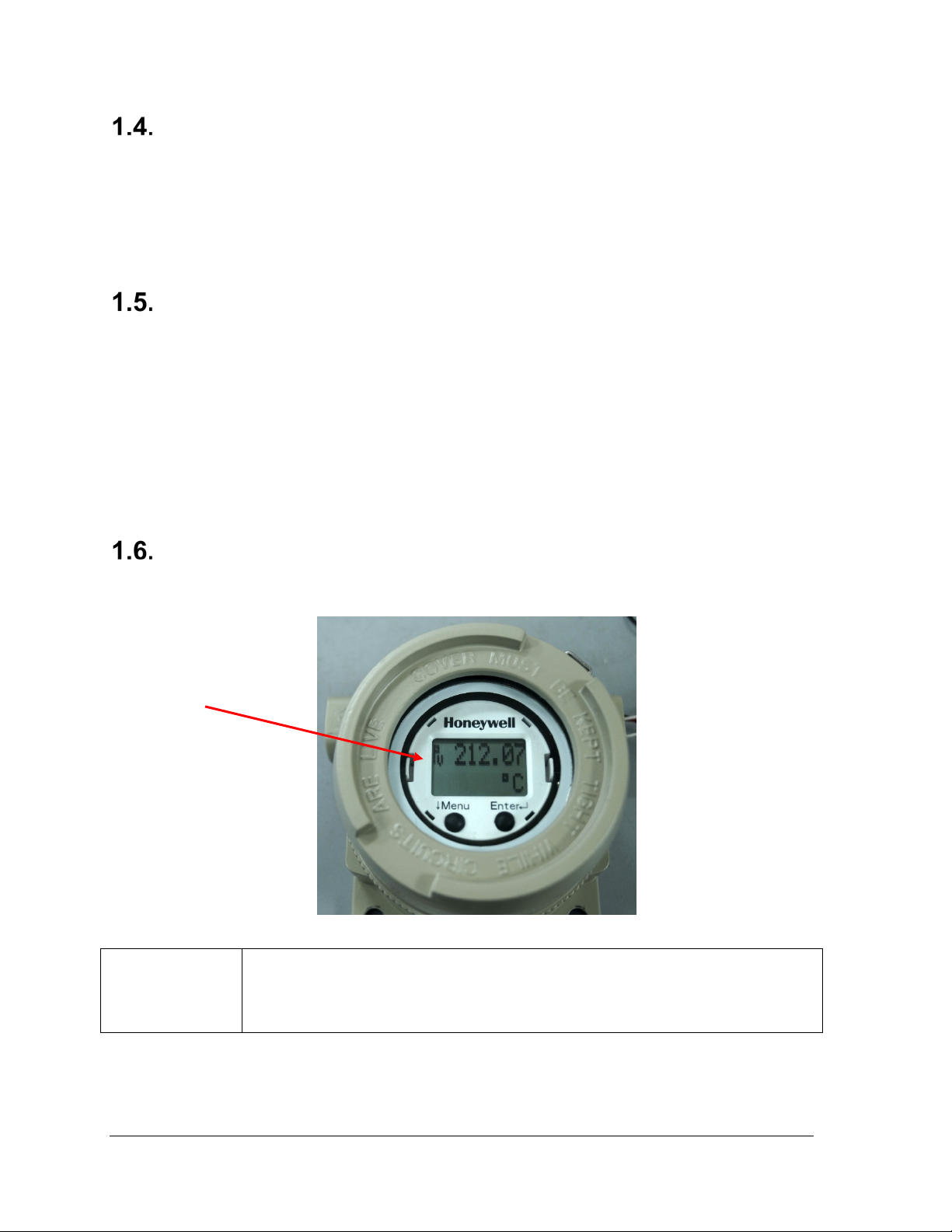

EU Meter Option – HART only

The STT700 SmartLine Temperature Transmitter can be supplied with the optional EU Meter, see Table 2.

inside housing

(HART only)

Table 2 – Available EU Meter Characteristics

• Compatibility for replacement of existing STT250 installations

o

• 360

• Standard units of measurement: °F, °C, °R, K, Ω, mV & %

rotation in 90o increments

Page 4 STT700 Temperature Transmitter User’s Manual Revision 6

2. Application Design

Overview

This section discusses the considerations involved with deploying a Honeywell STT700 SmartLine

Temperature Transmitter in a process system. The following areas are covered:

• Safety

• Input and output data

• Reliability

• Environm enta l limits

• Installation considerations

• Operation and maintenance

• Repair and replacement

Safety

Accuracy

The STT700 SmartLine Temperature Transmitter accurately measures the temperature of a process

and reports the measurement to a receiving device like a controller I/O module. Refer to STT700

Specification, 34-TT-03-19, for complete accuracy specifications.

Diagnostic Messages

The transmitter standard diagnostics are reported in the two basic categories: critical and non-critical

faults. Problems detected as critical diagnostics drive the analog output to the programmed burnout

level for HART and DE. Tables 3 and 4, below, list the diagnostics and how faults are handled by the

STT700 transmitter. Refer to the Troubleshooting section for further details.

Table 3 show specific diagnostics to the transmitter, exclusive of those associated with HART and

DE protocols. HART and DE diagnostic messages are listed and described in the STT700 SmartLine

Temperature Transmitte r HART/DE Option User Manual, document number 34-TT-25-18.

See Safety Integrity Level (SIL)

STT700 is intended to achieve sufficient integrity against systematic errors by the manufacturer’s

design. A Safety Instrumented Function (SIF) designed with this product must not be used at a SIL

level higher than the statement, without “prior use” justification by the end user or diverse technology

redundancy in the design. Refer to the STT700 Sa fety Manual, 34-TT-25-20, for additional

information. The DE variant of STT700 is not SIL certified.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 5

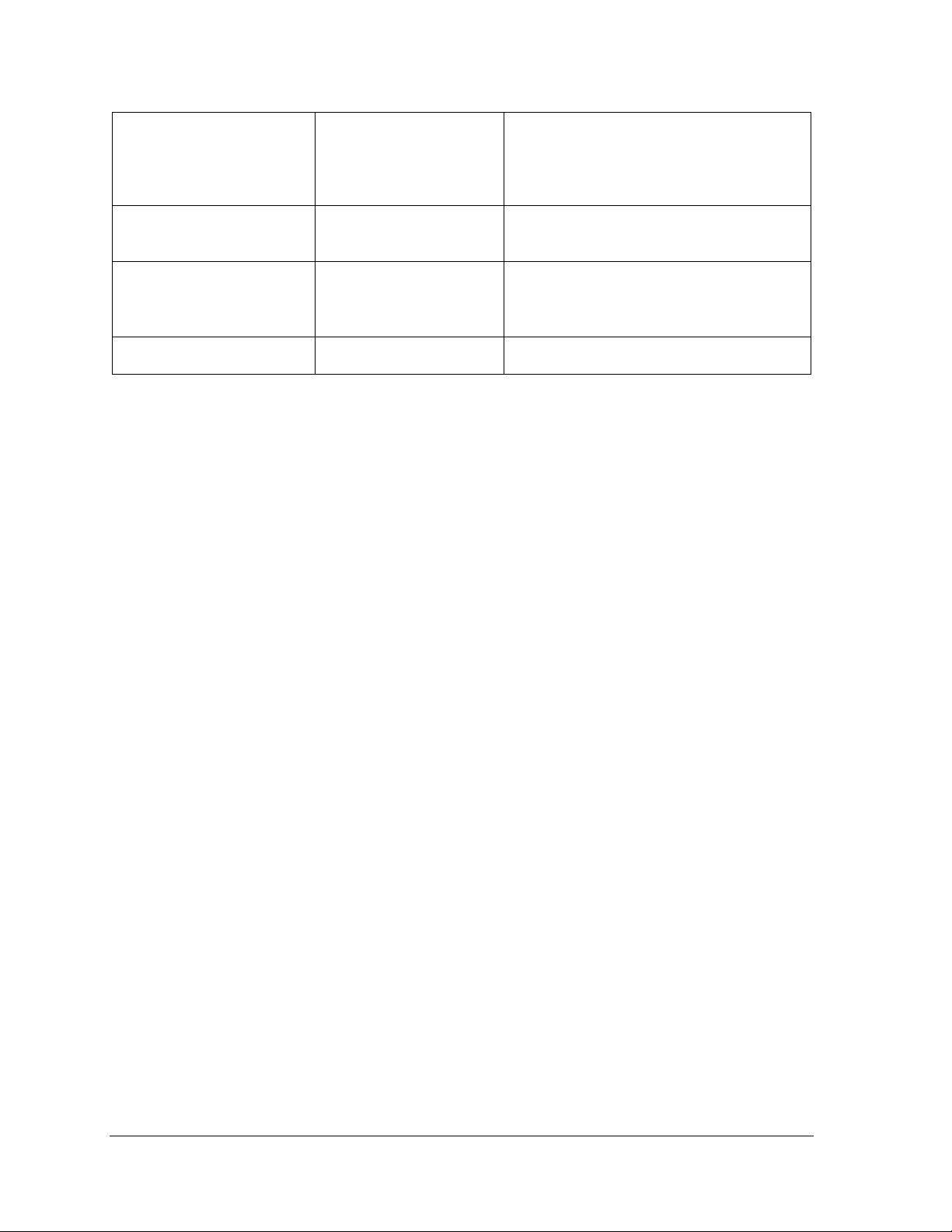

Critical Diagnostics (Failure

Conditions)

Description

Details

Elec. Mod. Diag Failure

Action: Reset the device. If the problem persists

Elec. Mod. DAC Failure

Action: Reset the device. If problem persist,

Sensor Input Failure

"Failure in sensing section. Any of the following

to see which of these conditions are set

Char/Cal Data Corrupt

Characterization / Calibrati on data is corru pted

cycle

Config Data corrupt

Action: Power cycle the device. If the problem

Description

Details

CT Out of Range

Core Temperature out of range (-36°C to

contact the vendor.

No Factory Calibration

Factory calibration data is

PV Out of Range

Loop PV is out of configured URV and LRV.

transmitter with one that has a wider range.

CJ Out of Limits SV Bad

Cold junction sensor

the range)

The ambient temperature measured is out of

temperature source.

Table 3 – STT700 Diagnostic Messages

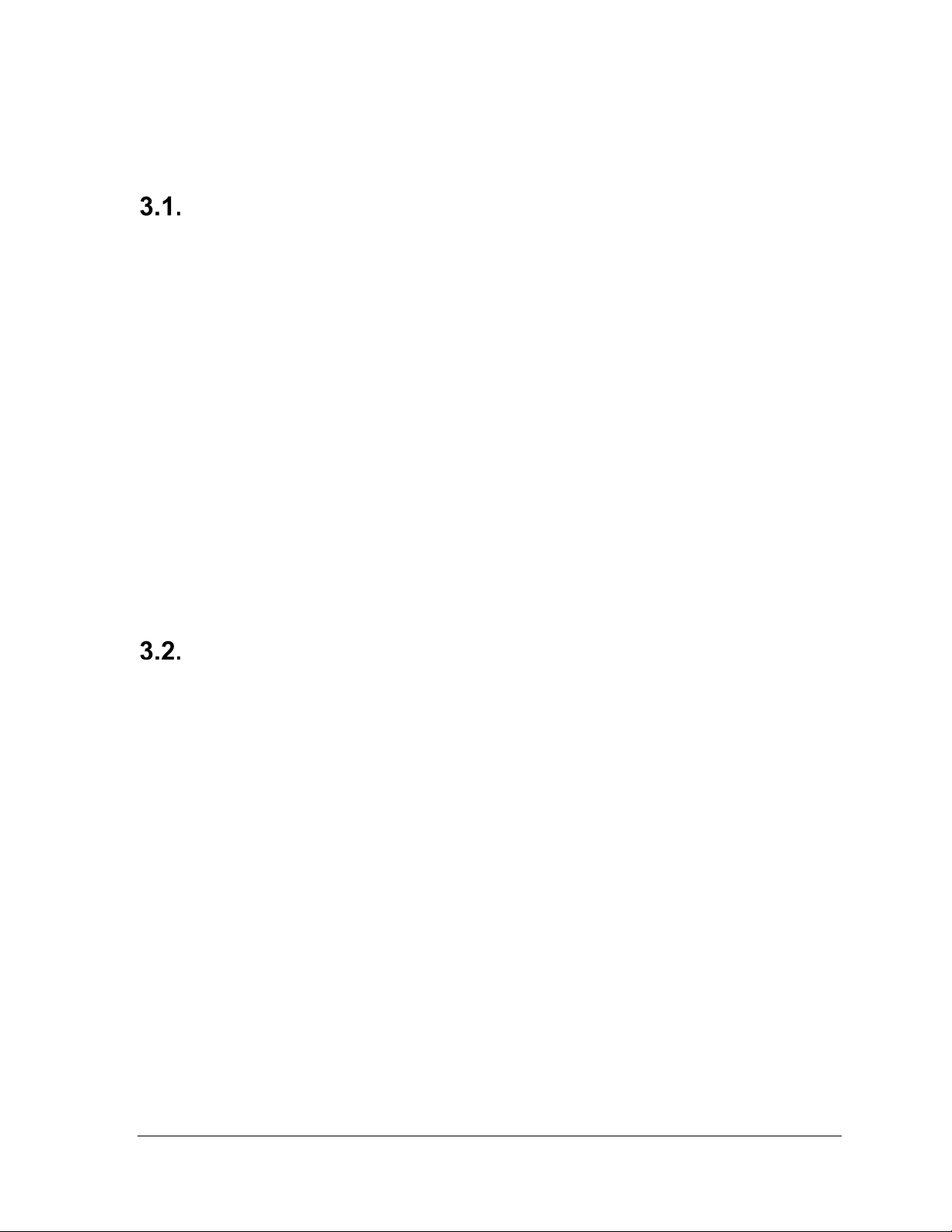

Table 4 – STT700 Standard Non-Critical Diagnostics Messages

Non-Critical Diagnostics

(Warning Conditions)

Diagnostics failure (like

ROM / RAM corrupt

etc.)

Failure related to DAC

which regulates 4-20mA

loop

Input sensor may be

open / short / out of

range

Factory calibration data

is corrupted

NVM data corrupted

replace the electronics module Note: Select

“Device Status - Additional Status” to see which

of these conditions are set.

replace the electronics module.

Note: Select “Device Status - Additional Status”

to see which of these conditions are set.

conditions can cause this failure:

1..Input 1 Fault

2. Input 2 Fault.

Check the sensor input connections.

3. Suspect Input.

Check sensor and connections. If the

connections are ok, and problem persists,

replace the electronics module board

Note: Select “Device Status - Additional Status”

or missing.

Replace device if error persists upon power

persists, replace the electronics module.

Page 6 STT700 Temperature Transmitter User’s Manual Revision 6

MCU temperature of the

device is out of range

not available, device is not

factory calibrated

Process value measured is

out of range

temperature or device

terminal temperature is out

of limits (-40°C to 85°C is

112.5°C).

If it is certain that the reading is in error, then

The transmitter has not been calibrated by the

factory. Contact the vendor.

Check your process temperature. Adapt the

span.

Check range and, if required, replace

the transmitter specifications

(-40°C to 85°C).

Take steps to isolate the device from the

Sensor1 excess LRV

Applied Input 1 value and

This non critical flag will be set when

Sensor1 excess

Applied Input 1 value and

This non critical flag will be set when

Suspect Input

MCU reference voltages

MCU reference voltages are beyond limits and

Fixed Current Mode

Output current is fixed and not varying as per

Input1 Fault

There is a problem with the Input 1 sensor.

Input2 Fault

There is a problem with the Input 2 sensor.

Verify sensor connections and configur atio n.

Analog Output Saturated

This status is set when loop

out of range)

Calculated analog output is either above or

Check the transmitter input.

Excess Delta Detect

This will be set when delta value exceeds

applicable delta limit

ADC Fault

ADC reference voltages

limits

Sensor2 excess LRV

Applied Input 2 value and

Sensor2 excess

Applied Input 2 value and

Input1 Out Of Range

Input 1 temperature is greater than Sensor 1

correct

URV correct

measured value differ by

more than 1.5% span at

low calibration point

measured value differ by

more than 1.5% span at

high calibration point

are beyond limits and

hence inputs measured

may not be correct

The 4-20mA loop is put in

fixed current mode and is

not following the PV value

Input1 may be open/short

Input2 may be open/short

current is set to out of 4-20

mA (generally when PV is

difference between applied Input 1 LRV value

and measured value exceeds 1.5% of span.

Perform Reset correct.

difference between applied Input 1 URV value

and measured value exceeds 1.5% of span

Perform Reset correct.

hence inputs measured may not be correct.

Replace the sensor based on Input 1, Input 2

measurement suspect.

input. Loop current mode is disabled or Loop

Test is active.

Enable loop current mode if it is disabled or

exit the Loop Test mode if active to return to

normal operation.

Verify sensor connections and configur atio n.

below the specified loop current limits. The

transmitter input is not in specified range.

Sensor 1 and Sensor 2

measured values differ by

more than a user defined

threshold

are beyond working correct

correct

URV correct

measured value differ by

more than 1.5% span at

low calibration point

measured value differ by

more than 1.5% span at

high calibration point

Measured value of Sensor1

is out of range

delta limit. When Exc ess Delta Alarm is

disabled and device is in non-redundant mode,

this status indicates that the difference

between two sensor inputs has crossed the

Controller ADC fault. Replace device if error

persists upon power cycle.

This will be set when difference between

applied Input 2 LRV value and measured

value exceeds 1.5% of span

This will be set when difference between

applied Input 2 URV value and measured

value exceeds 1.5% of span

URL or less than Sensor 1 LRL

Set when the input at first sensor is either

under range or over range

Revision 6 STT700 Temperature Transmitter User’s Manual Page 7

Input2 Out Of Range

Input 2 temperature is greater than Sensor 2

Watchdog reset

Watchdog has reset (it may

Supply Voltage Fault

This is set when one of the supply voltages

SIL Diagnostics

RAM / NVM database

corrupt

Advance diagnostics data is corrupte d. Pow er

cycle the device

Measured value of Sensor2

is out of range

be due to FW failure or HW

failure)

MCU or DAC reference

voltages are beyond limits

URL or less than Sensor 2 LRL.

Set when the input at second sensor is either

under range or over range

Controller Watchdog has reset

(DAC loop / MCU) in the device is outside its

specification limits. Check the trans mitt er

supply voltage

Page 8 STT700 Temperature Transmitter User’s Manual Revision 6

3. Installation and Startup

Installation Site Evaluation

Evaluate the site selected for the STT700 SmartLine transmitter instal lat ion w ith respect to the

process system design specifications and Honeywell’s published performance characteristics for your

particular model and sensor selection. Some parameters that you may want to include in your site

evaluation are:

• Environmental Conditions:

o Ambient temperature

o Relative humidity

• Potential Noise Sources:

o Radio frequency interference (RFI)

o Electromagnetic interference (EMI)

• Vibration Sources

o Pumps

o Motorized system devices (e.g., pumps)

o Valve cavitation

• Process Parameters

o Temperature

o Maximum sensor input ratings

Honeywell MC Toolkit

In preparation for post-installation processes, refer to the MC Toolkit User Manual (MCT404),

Document # 34-ST-25-50, for devic e operation and maintenance inform ation.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 9

Mounting and Dimensions

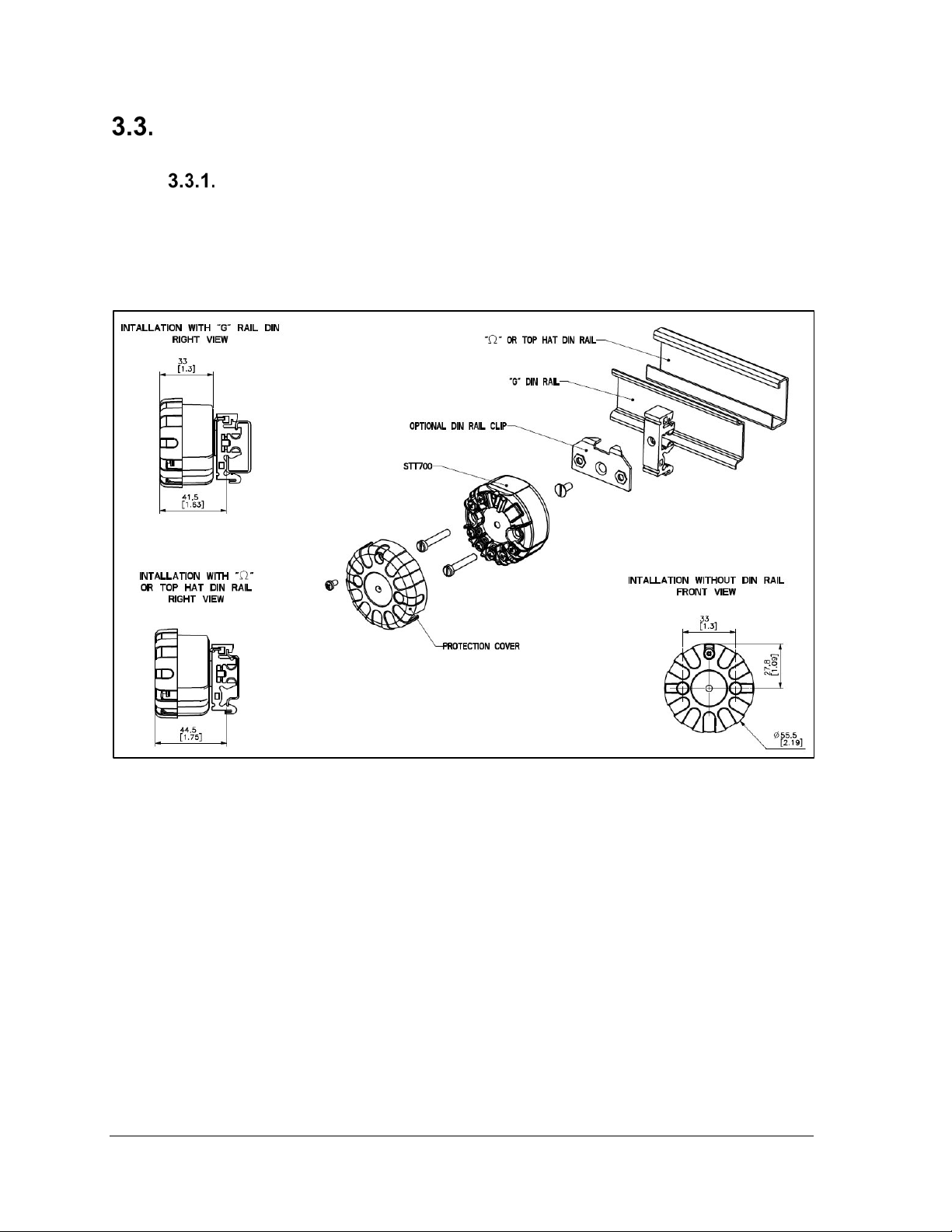

DIN Rail Mounting

If the STT700 is to be installed on DIN rail option then the main considerations are electrical

connections and mechanical fixing. Electrical connections are identical to the bench test instructions

except that thermocouple wire is likely to be used with thermocouples. Mechanical fixing of the

module is by means of the snap-in DIN rail clips which are screwed to the bottom lugs of the module.

Figure 5 - DIN Rail Mounting

The DIN rail needs to be connected to Earth Ground per Section 3.4 below. It is generally required

by regional wiring, safety and installation codes that these units be mounted in a suitable enclosure

such as a metal cabinet or box which is locally connected to Earth Ground.

Page 10 STT700 Temperature Transmitter User’s Manual Revision 6

TO THE AUTHORITY HAVING JURISDICTION FOR THE INSTALLATION.

Field Mount Housing with Meter

Field Mount Housing without Meter

without Meter

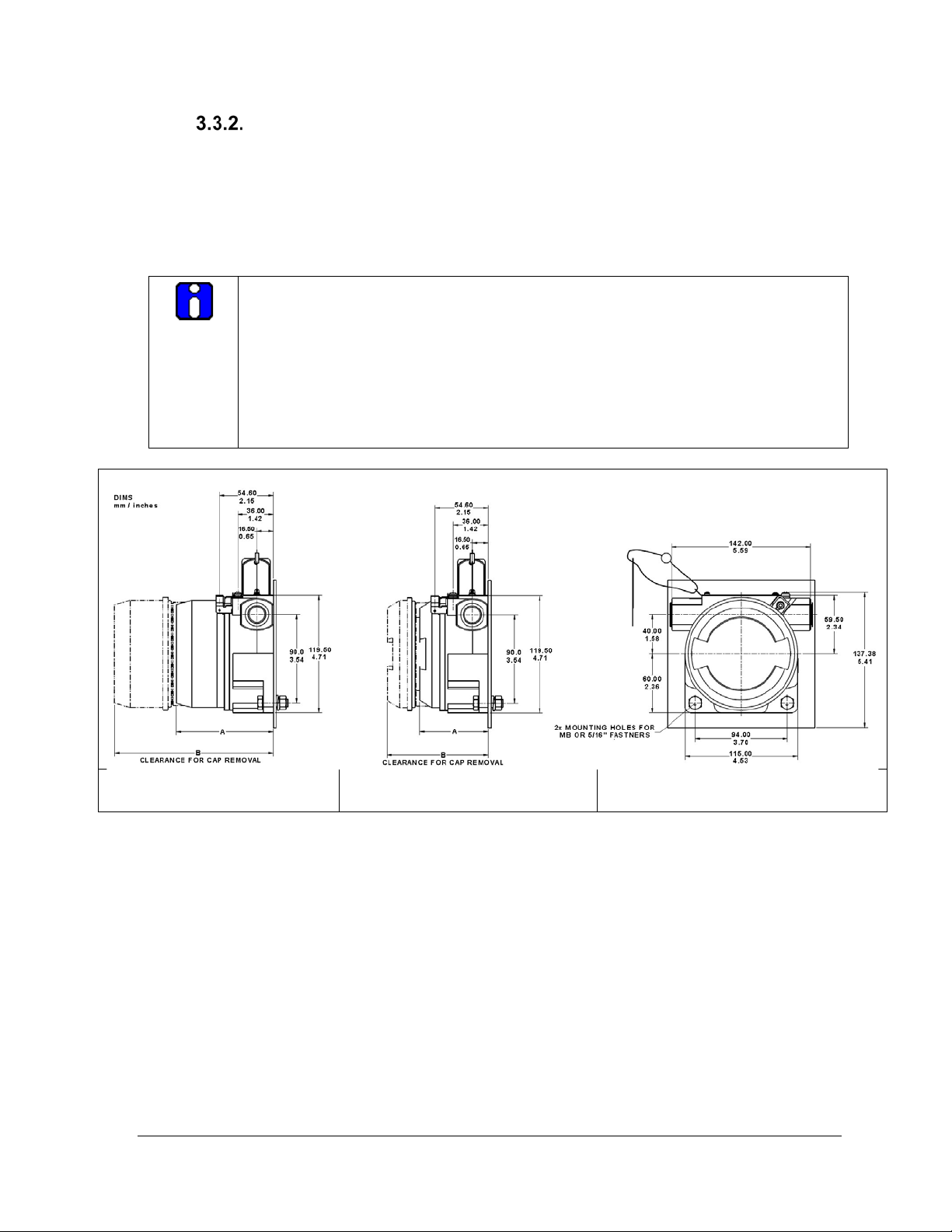

Mounting Module in Housing

The STT700 module can be installed in a variety of housings suitable for field mounting (2” or 50mm

pipe mount), direct head mounting, or wall mounting.

Ensure that the installation location is suitable for reliable transmitter operation (e.g. for high

temperature applications, a therm ow ell extens ion is rec om m en ded to minim iz e failure rates due to

high ambient temperatures near the tr ansmitter).

ATTENTION:

THIS PRODUCT IS SUPPLIED WITH PLASTIC DUST PLUGS IN THE

CONDUIT/CABLE GLAND ENTRIES. IT IS THE USER’S RESPONSIBILITY TO

PROVIDE CABLE GLANDS, ADAPTORS AND/OR BLANKING PLUGS SUITABLE

FOR THE ENVIRONMENT IN WHICH THIS PRODUCT IS INSTALLED. WHEN

INSTALLED IN A HAZARDOUS LOCATION THE CABLE GLANDS, ADAPTORS

AND/OR BLANKING P LU GS SHALL ADDITIO N ALL Y BE SU ITABLE FOR THE

HAZARDOUS LOCATION, THE PRODUCT CERTIFICATION AND ACCEPTABLE

Figure 6 - Wall Mounting Dimensions

Revision 6 STT700 Temperature Transmitter User’s Manual Page 11

Field Mount Housing with and

Field Mount Housing with Meter

Field Mount Housing without Meter

without Meter

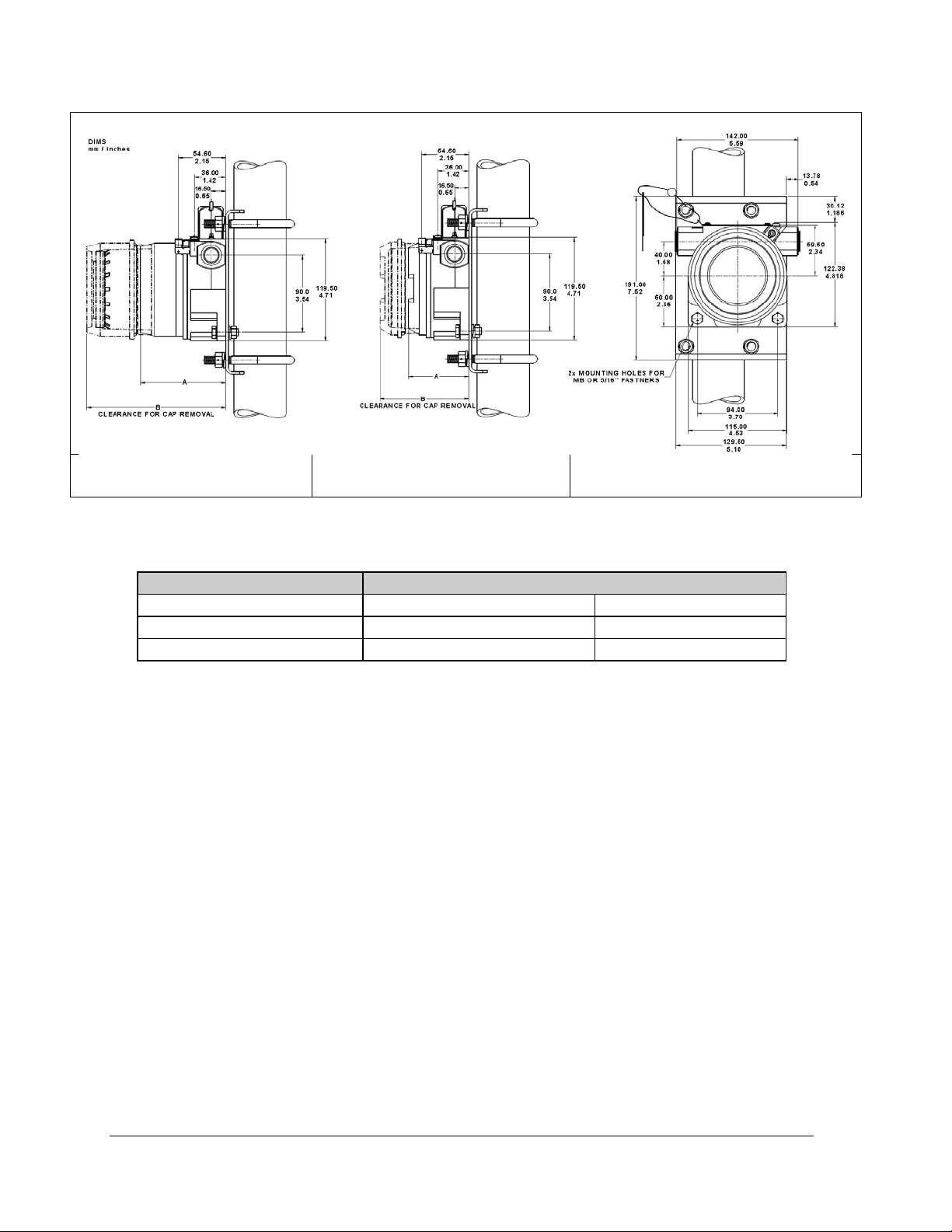

Dimensions

Aluminum (field mount housing)

A

B

Without integral meter

70 mm [2.76 inch]

120,8 mm [4.76 inch]

With integral meter

127 mm [5.00 inch]

210,8 mm [8.30 inch]

Field Mount Housing with and

Figure 7 - Pipe Mounting Dimensions

Table 5 - Dimension table for use with Figure 6 and Figure 7

Page 12 STT700 Temperature Transmitter User’s Manual Revision 6

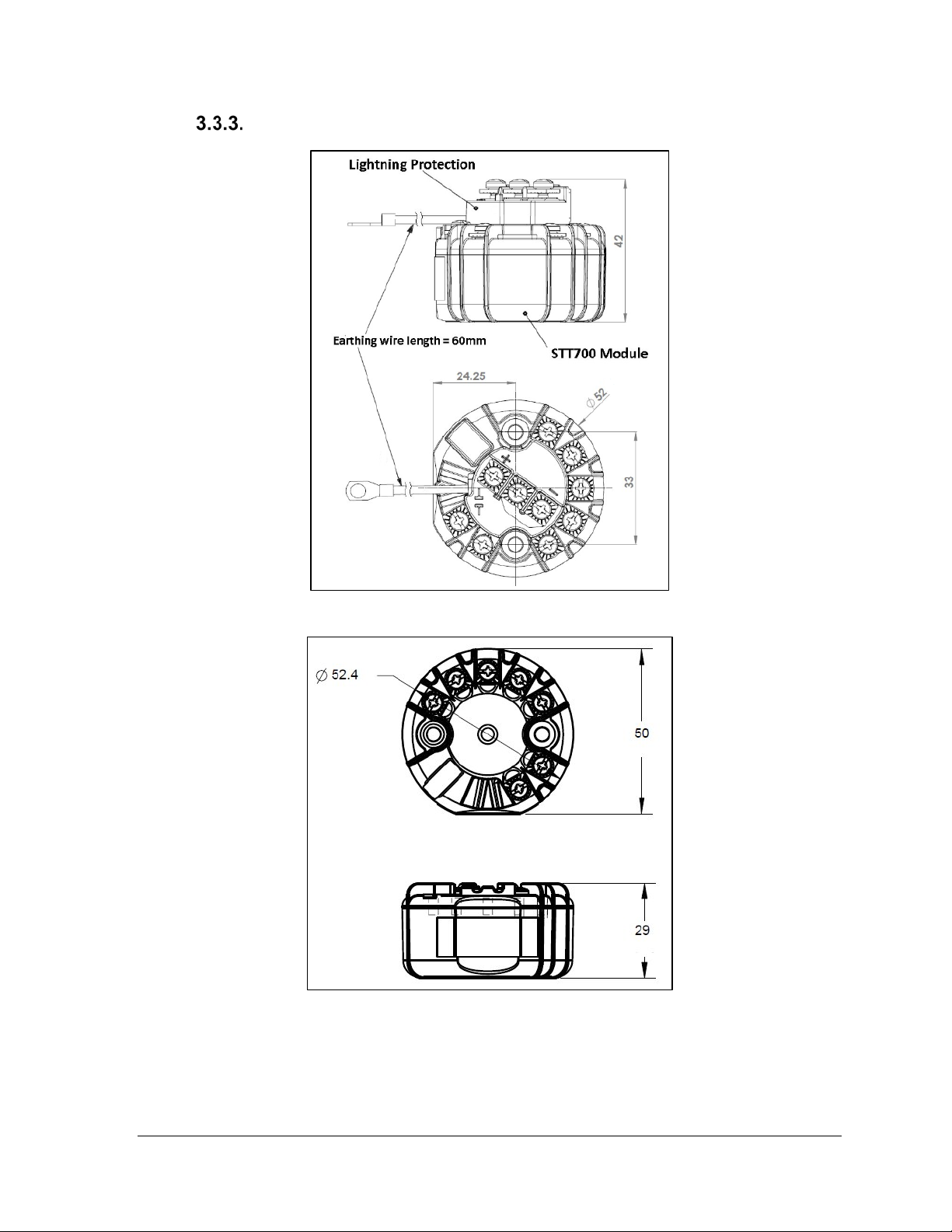

Dimensions

Figure 8 – STT700 transmitter module with lightni ng protection (top) and without (bottom)

Revision 6 STT700 Temperature Transmitter User’s Manual Page 13

3.3.3.1. Housing Cover and O Ring:

1. Review O-ring condition & replace, if damaged. New O-ring can be ordered

from spare parts list.

2. Apply O-ring lubricant to the end cap O-ring. Relax O-ring twists, if any.

3. Assemble housing cover with sufficient torque for securing against IP.

Figure 9: Housing cover and O-ring

Page 14 STT700 Temperature Transmitter User’s Manual Revision 6

Spring Loading

Figure 10 - Spring Loading and Sensor Assembly

Spring loading is available worldwide with direct head mounting. In North America, the spring

loading is typically included in the sensor/thermowell assembly and is available with all housings.

For non-North American spring loading as shown in Figure 9, simply include the springs under the 33

mm pitch mounting screws, pass the screws through the module and sensor mounting plate and snap

in the retaining circlip to the screws to hold the assembly together. Guide the sensor assembly through

the housing sensor entry and screw down the 33 mm screws until the limit is reached as the sensor

presses against the bottom of thermowell.

For wall or 2'' pipe mounting, the temperature sensor can be remote from the STT700 field mount

housing or integral to the housing. For remote installations, the sensor wiring should be run in

shielded, twisted pair wiring and connected via one of the housing wiring entries.

For explosion proof/flam eproof ins ta llat ions, ensure that the cable entries are fitted w ith flameproof

adaptors and that the wiring grade complies with local standards.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 15

For this item

Use this tool

M3 set screw for end cap removal

1.5 mm Allen key

Transmitter re-assembly

Parker Super O-ring lubricant or equivalent

Field upgrades

Pliers

Installation Procedure of Standard display for STT700:

Including removing brackets, housing, connection and wiring details

Tools required

Uninstalling/Installing Standard Display for external wiring

Step – 1: When installed as explosion-proof or flame-proof in a hazardous location, keep covers

tight while the transmitter is energized. Disconnect power to the transmitter in the non-hazardous area

prior to removing end caps for service.

When installed as non-incendive or non-sparking equipment in a hazardous location, disconnect

power to the transmitter in the non-hazardous area, or determine that the location is non-hazardous

before disconnecting or connecting the transmitter wires.

Unscrew 4-6 threads of the display bracket on both the sides. Hold the bracket at the right-hand side

(open hole side) and rotate in clock wise direction as shown in Figure 11.

Figure 11: : Position of Standard display for external wiring

Step – 2: Loosen the end cap screw lock and unscrew the end cap from the transm itter housing.

Page 16 STT700 Temperature Transmitter User’s Manual Revision 6

Black wire indication

first pin locatio n

Cable connection between Standard Display & STT Module:

Step – 3: Complete the cable connections between the standard display and STT module as follows.

a) Orient & Assemble the standard display module onto the bracket as shown in Figure

12. Align the display module with the slots in the bracket and push. Check if the

module is fitted properly into the bracket and is tight.

Figure 12: Assembly of Standard display with Bracket

b) Connect the shorter cable connector to the display module at the indicated location.

Ensure that the first pin of the cable connector (indicated with the black colored wire)

matches with the first pin of the display connector (indicated with white spot). Refer

Figure 13.

Figure 13: short cable and display assembly

Revision 6 STT700 Temperature Transmitter User’s Manual Page 17

Black wire of cable

c) Fix the cable joint by sliding it slowly into the slot provided in the bracket as shown

in the Figure 14.

Figure 14: Cable joint fixed in the bracket

Connect the longer cable connector to the STT module, keeping the black colored wire towards

the light protector module. Shown in Figure 15

Figure 15: Long cable connection with STT Module

Page 18 STT700 Temperature Transmitter User’s Manual Revision 6

Long cable – Extra length

Step – 4: Pull the longer cable away from the STT module and screw the display bracket assembly

with the stand offs. See Figure 16.

Figure 16: Positioning of Long cab le in the IM Housing

pulled away from bracket to

provide flexibility while

assembly/disassembly of

bracket

Step – 5 (Cable connection verification): Power ON the IM and wait for few seconds to check

if the display module is working. If the display is ON, then continue with step 6. Else recheck the

cable connections as described from step 3-4.

Step –6: Power OFF the IM.

Step –7: Apply Parker Super O-ring Lubricant or equivalent to the end cap O-ring before installing

the end cap. Reinstall the end cap and tighten the end cap locking screw.

Complete the required wiring connections to the STT Module following the routing as shown in the

example Figure 17 below and refer to the next section below for cable connections if required.

Figure 17: : Example of exter n al wiring (Reference only)

Revision 6 STT700 Temperature Transmitter User’s Manual Page 19

Wiring a transmitter

Please note the display module must be removed from support bracket to access the power

connections for HART or DE.

Loop Power Overview

The transmitter is designed to operate in a two-wire power/current loop with loop resistance and

power supply voltage within the HART or DE operating range shown in Figure 10 and Figure 11.

Figure 18 – STT700 with HART Transmitter Operating Ranges

Figure 19– STT700 with DE Transmitter Operating Ranges

Page 20 STT700 Temperature Transmitter User’s Manual Revision 6

Loop wiring is connected to the transmitter by simply attaching the positive (+) and negative (–) loop

wires to the positive (+) and negative (–) termina ls on the transmitter module terminal block. Route

the wires through the pre-moded channels on top of the terminal module. Connect the loop power

wiring shield to Earth Ground only at the power supply end.

Note that the STT700 transmitter features SmartLine’s Universal terminal wiring capability and thus

is not polarity-sensitive.

With the single input HART transmitter, four (4) terminal screws will be available on the top of the

module. When either the dual-input HART or the single input DE is suppli ed, five (5) termination

screws will be included.

Figure 20 –STT700 module terminal connections

This transmitter uses the two m o un ting screws to connec t it to Earth Ground. Grounding the

transmitter for proper operation is required, as doing so tends to minimize the possible effects of noise

on the output signal and affords protection against lightning and static discharge. An optional

lightning protection module is available for use in areas that are highly susceptible to lightning

strikes. As noted above, the loop power wiring shield should only be connected to Earth Ground at

the power supply end.

Wiring must comply with local codes, regulations and ordinances.

The current output signal will operate a floating or ground system.

If the signal appears noisy or erratic, it is recommended to ground the loop at the

negative terminal of the power supply.

Shielding should only be connected to ground at one point to avoid ground loops.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 21

For HART and DE, the transmitter is designed to operate in a two-wire power/current loop with loop

resistance and power supply voltage within the operating range; see Figure 18 and Figure 19. With an

optional remote meter, the voltage drop for this must be added to the basic power supply voltage

requirements, to determine the required transmitter voltage (V

(R

LOOP MAX

they will supply at least minimum transmitter voltage (V

). Additional consideration is required when selecting intrinsic safety barriers to ensure that

XMTR MIN

) and maximum loop resistance

XMTR

), including the required 250 ohms of

resistance (typic a lly within the barriers) needed for digital communications.

Transmitter loop parameters are as follows:

R

LOOP MAX

operation and is calculated as R

= maximum loop resistance (barriers plus wiring) that will allow proper transmitter

LOOP MAX

= (V

SUPPLY MIN

– V

XMTR MIN

- VSM) ÷ 21.8 mA.

In this calculation:

V

XMTR MIN

V

SM

= 10.8 V

= 2.3 V if using EU or Remote meter, 0V if not using EU or Remote meter

Note that V

should only be considered if an EU meter will be conn ec ted to the transmitter.

SM

The positive and negative loop wires are connected to the positive (+) and negative (–) terminals on

the STT700.

Barriers can be installed per Honeywell’s instructions for transmitters to be used in intrinsically safe

applications.

Note: Problems detected as non-critical diagnostics may affect performance without driving the

analog output to the programmed burnout level (for HART only). For DE, the burnout direction

needs to be selected in the hardware and this will be detected at power on time.

Digital System Integration Information

DE transmitters that are to be digitally integrated to Honeywell’s Total Plant Solution (TPS) system

will be connected to the temperature transmitter Interface Module in the Process Manager, Advanced

Process Manager or High Performance Process Manager through a Field Termination Assembly.

Details about the TPS system connections are given in the PM/APM SmartLine Transmitter

Integration Manual, PM12-410, which is part of the TDC 3000

X

system bookset.

When digitally integrating a transmitter in an Allen Bradley Programmable Logic Controller (PLC)

process system, the same Field Terminal Assembly (FTA) and wiring procedures used with

Honeywell’s TPS system are also used with the Allen-Bradley 1771 and 1746 platforms.

Wiring Variations

The above procedures are used to connect power to a transmitter. For loop wiring, sensor wiring and

external wiring, detailed drawings are provided for transmitter installat ion in no n -intrinsically safe

areas and for intrinsically safe loops in hazardous area locations.

If you are using the transmitter with Honeywel l’ s TPS sy stem , see PM/APM SmartLine Transmitter

Integration Manual, PM12-410, which is part of the TDC 3000

X

system bookset.

Page 22 STT700 Temperature Transmitter User’s Manual Revision 6

Grounding and Lightning Protection

Connect a wire from the mounting screws to Earth Ground to make the protection effective. Use size

14 AWG or 2.0mm

For ungrounded thermocouple, mV, RTD or ohm inputs, connect the input wiring shield(s) to the

same Earth Ground connection.

For grounded thermocouple inputs, connect the internal ground connection shown in Figure 12 to the

same Earth Ground as used by the thermocouple. For direct head mount housings, the ground

terminal may not exist and another means of direct ground connection will need to be devised. For

proper protection, the green ground wire must be securely connected to a local ground in as direct a

path as possible. As noted above, the loop power wiring shield should only be connected to Earth

Ground at the power supply end.

The tightening torque to be applied on the wire termination screws are to be

between 0.34 Nm (3 in-lbf) min to 0.56 Nm (5 in-lbf) max.

Shielded twisted pair cable gauge 18AWG-22AWG for the sensor connections and

22AWG – 14AWG for the loop power connections.

The tightening torque to be applied on the STT700 module mounting screws are to be

between 1.0 Nm (8.85 in-lbf) min to 1.35 Nm (12 in-lbf) max.

2

bare or green covered wire for this connection.

Input Sensor Wiring

3.5.5.1. Sensor Wiring Best Practice Recommendation:

• Sensor cable should be a shielded cable and the shield should be connected to protection earth

at the transmitter end. Refer Figure 12, STT700 module terminal connections for details of

grounding screw.

• Sensor lines should be isolated from high voltage lines and should not be routed in parallel

with high voltage lines.

• Sensor wires are designed to be routed through a controlled EMC environment. Possible

sources of surges shall be avoided.

• For any queries contact Honeywell Technical support team.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 23

Connect the input sensors as shown in figures below for RTD, thermocouple, mV and ohm

connections.

Figure 21 – HART/DE Input Wiring Diagram for single sensor connection

The single sensor connections can also be used on a dual input transmitter when a second input is not

required. In this case, it is recommended that the second input be configured to None in the software.

In case of RTD type being configured for 4-wire, the configuration for single input is automatically

done.

Figure 22 – Wiring Diagram for HART Dual Sensor Connections

Page 24 STT700 Temperature Transmitter User’s Manual Revision 6

Lightning Protector

The lightning protection device is designed to give the STT700 temperature transmitter maximum

protection against surges such as those generated by lightning strikes. It mounts on the top of the

STT700 transmitter module, providing easy field wiring and also protection for the EU meter if used.

The compact mounting allows the use of a variety of housings including the Honeywell explosion

proof field mount housing.

The device can be used in both intrinsic safety and flame/explosion proof applications.

Figure 23 – STT700 with Lightning Protector Dimensions

Revision 6 STT700 Temperature Transmitter User’s Manual Page 25

3.5.6.1. Installation

• If an EU meter is used, remove the shunt on the Lightning Protector. In all other cases, the

shunt must be present.

• Remove the cover/cap of the housing (if applicable). The device fits on the top of the

transmitter module terminal block and the transmitter output screws (+ and -) fix

mechanically the device.

• Attach the grounding wire to the ground screw in the housing. Connect a wire from the

transmitter enclosure to local Earth Ground. Use size 14 AWG or 2.0mm2 bare or green

covered wire.

• If an EU meter is used, wire according to Figure 24.

• Connect the 4 – 20mA loop to the + and – terminal screws of the surge protection and close

the cap of the housing.

Figure 24 – Installation without EU Meter

Page 26 STT700 Temperature Transmitter User’s Manual Revision 6

Figure 25 – Installation with EU Meter

Figure 26 – Installation with Standard Display

Revision 6 STT700 Temperature Transmitter User’s Manual Page 27

3.5.6.2. Maintenance

The unit is designed to give a long service life under normal industrial conditions. Howev er, if

exposed to a large number of high energy transients beyond the capability of the unit, the lig htning

protector may fail. The unit has been designed so that, under excessive surge conditions (more than

10 KA), the lightning protector should fail, thus protecting the transmitter.

If the unit has failed, it can be replaced in the field – the process for removal in the reserve of that

for installing the unit.

If a replacement is not immediately available, part number 50133588-501-501, it is possible to

bypass the unit by wiring directly to the transmitter; however, it should be remembered that, in this

case, the transmitter will be unprotected from surges.

Page 28 STT700 Temperature Transmitter User’s Manual Revision 6

4. Startup

Overview

This section identifies typical startup tasks the STT700 temperature transm it ter an d includes the

procedure for running an optional analog output check.

Startup Tasks

After completing the installation and configuration tasks for a transmitter, you are ready to startup the

process loop. Startup usually includes:

• Setting initial resistance, based on actual temperature (RTD sensor types only)

• Reading inputs and outputs

• Applying process inputs to the tra ns mitter.

You can also run an optional output check to wring out an analog loop and check out individual

Process Variable (PV) outputs in Digitally Enhanced (DE) mode before startup.

The actual steps in a startup procedure vary based on the type of transmitter and the measurement

application. In general, the procedures in this section are based on using Honeywell MC Toolkit, with

a HART or DE variant, to check the transmitter input and output under static process conditions, and

make adjustments as required initiating full operation with the running process.

Output Check Procedures

The Output Check comprises the following procedures:

• The Loop Test procedure checks for continuity and the condition of components in the output

current loop.

• The Trim DAC Current procedure calibrates the output of the Digital-to-Analog converter for

minimum (0%) and maximum (100%) values of 4 mA and 20 mA, respectively. This

procedure is used for transmitters operating online in analog mode to ensure proper operation

with associated circuit components (for example, wiring, power supply, control equipment).

Precision test equipment (an ammeter or a voltmeter in parallel with precision resistor) is

required for the Trim DAC Current procedure.

• The Apply Values procedure uses actual Process Variable (PV) input levels for calibrating

the range of a transmitter. The PV is carefully adjusted to stable minimum and maximum

levels, and the Lower Range Limit Value (LRV) and Upper Range Limit Value (URV) are

then set by commands from the MC Toolkit.

The transmitter does not measure the given PV input or update the PV output

while it operates in the Output mode.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 29

Constant Current Source Mode Procedure

Please note the display module must be removed from support bracket to access the power

connections for HART or DE connections in Figure 27. Refer to Uninstalling/Installing Standard

Display for external wiring on page 16

Figure 27 – Current Loop Test Connections

1. Refer to Figure 27 for test connections. Verify the integrity of electrical components in the output

current loop. Please note that the temperature transmitter is shown as STT700 device only for

ease of connections understanding.

2. Establish communication with the transmitter. For these procedures, the v alues of com ponents in

the current loop are not critical if they support reliable communication between the transmitter

and the MC Toolkit.

3. On the MC Toolkit, display the Output Calibration box.

4. In the Output Calibration box, select the Loop Test button; the LOOP TEST box will be

displayed.

5. Select the desired constant-level Output: 0 %, 100 %, or Other (any between 0 % - 100 %).

6. Select the Set button. A box will be displayed asking Are you sure you want to place the

transmitter in output mode?

Page 30 STT700 Temperature Transmitter User’s Manual Revision 6

With t he transmitter in Analog mode, you can observe the output on an

externally-connected meter or on a local meter.

7. Select the Yes button. Observe the output current at the percentage you selected in Step 5.

8. To view the monitor display, navigate back from the LOOP TEST display, and select the

MONITOR display. A Confirm popup will be displayed.

9. Select Yes to continue. This concludes the Startup procedure.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 31

5. Operation

Overview

The Operations section describes the internal operation of the STT700 transmitter and the operations

of the Smart Field Communicator and the HART communicator with the STT700. If an EU Meter is

installed, see the Engineering Unit Meter User Guide 34-ST-25-18 for additional information on

operations.

This transmitter is powered via the 2-wire, 4-20 mA signal connected to the + and - terminals on the

output side of the module.

Configuration Tools

Smart Field Communicator (SFC) for DE Models

As previously indicated, the SFC communicates by connecting across the 4-20 mA wiring. DE

communication is by 16 mA pulses which disturb the 4-20 mA output signal. When in analog mode,

ensure that receiving instruments are not on automatic control. The SFC does not feed 16 mA pulses

into the loop but instead merely uses the power on the 4-20 mA wires and switches it through a field

effect transistor output switch. The SFC alw ay s acts as a host and the transmitter as a device. When

the transmitter is operating in the digital DE mode, there is no wake-up pulse required and the SFC

communication does not disturb the PV signal. Consequently, there is no need to put the loop on

manual control when operating in the DE mode.

Supported Commands:

• Read/write ID (e.g. TID 250)

• Select a sensor type (e.g. Pt100)

• Enable/disable sensor break detection

• Set damping time (e.g. 0 second)

• Set LRV and URV

• Read URL (upper range limit), LRL (lower range limit) and span

• Read process value and cold junction value in engineering units

• Read output in % of span

• Read software version

• Read fail-safe direction configured by link

• Set/reset user calibration to specific sensor

• Set 0 and 100% output calibration

• Force output current

• Read/write scratch pad

• Select broadcast type 4 or 6 bytes (Digital DE only). 6 bytes broadcasts PV and transmitter

database while 4 bytes broadcasts PV only

• Enable/disable write protect

• Enable/disable latching. Latching means the alarm needs acknowledgment. Press "STATUS"

key to acknowledge the alarm. If latching is disabled, the transmitter will leave the alarm

mode as soon as the alarm cause disappears.

Page 32 STT700 Temperature Transmitter User’s Manual Revision 6

HART Communicator Model 375, 475 or MC Toolkit FDC for

HART 7 Models

Connect the HART communicator by attaching the leads in parallel with the input (24V) terminals of

the device. HART communication consists of a high frequency carrier superimposed onto the 4-20

mA signal. The HART transmitter transmits by modulating the 4-20 mA DC loop current with a 1

mA peak to peak (p-p) AC current signal.

Supported Commands

• Read/write ID

• Select Dual Mode TC/TC, RTD/RTD

• Select sensor type

• Select PV/SV units

• Select damping time

• Set LRV and URV

• Read URL and LRL

• Read analog output

• Read Sensor1 and Sensor2

• Read % Output

• Read Process Value (PV)

• Read Cold Junction (CJ) Value

• Read fail-safe direction

• Set 0% and 100% output calibration

• Force output current

• Enable/disable latching

• XS Delta detection ON/OFF

• Set Delta Alarm

• Read Delta

• Match PVs

• Read device status

• Set/clear write protect

• Select Loop Control Mode – Average, Difference, Sensor1, Sensor2, Redundant and Split-

Range

• Lock/Unlock device

• Read/Write Long tag

• Read/write message, descriptor, date

• Read/Write polling address

• Read/Write loop current mode

Revision 6 STT700 Temperature Transmitter User’s Manual Page 33

Advanced Diagnostics

• Read Install Date

• Write Install Date

• Read Calibration Date and Time

• Write Correct LRV Date and Time

• Write Correct URV Date and Time

• Read Time in service value

• Read first set of Error log data

• Read second set of Error log data

• Read Error Log option status

• Write Error Log option status

• Reset Error Log

• Read PV tracking data

• Read SV tracking data

• Write high and low alarm limits for PV and SV

• Reset tracking data

• Read power up count

• Reset power up count value

• Read device model number

• Read Sensor1 and Sensor2 limits

• Read middle range value (MRV)

• Write middle range value (MRV)

• Read Loop Control option value

• Write Loop Control option value

• Read hysteresis

• Write hysteresis value

• Read damping value for bump less transfer (applicable to Split Range option)

• Write damping value for bump less transfer (applicable to Split Range option)

Page 34 STT700 Temperature Transmitter User’s Manual Revision 6

DISPLAY

"INPUT OPEN" (with

its voltage operating area and

6. Maintenance

Overview

Maintenance of this transmitter is limited to ensuring that connections, seals and mounting hardware

are tight and secure. There are no moving parts or adjustments, thus, the only reason to open the

housing (where supplied) is to inspect for corrosion or conductive dust entry which could later affect

reliable operation.

WARNING:

Preventive Maintenance Practices and Schedules

This SmartLine transmitter does not require any specific maintenance at regularly scheduled intervals.

Please take appropriate steps to avoid ESD damage when handling

The transmitter module itself should NEVER be opened.

Troubleshooting

Troubleshooting with SFC

Troubleshooting the STT700 DE transmitter loop is greatly simplified by connecting the SFC in the

termination area near the receiving instrum ent. A lso co nnect a digital volt meter (DVM), at the

termination area for the receiving instrument, to confirm a similar signal is coming from the field and

power is available on the two wires of the 4-20 mA loop. This isolates the problem to either field loop

or receiving instrument/power supply/wiring/safety barriers etc. If the original symptom was an

unstable input, it could be a loose connection on the receiving side. Assuming the above confirms a

field loop problem, the likely causes and actions are given below.

For any step the first action is to hook up the SFC to the transmitter and press "ID", then "STATUS".

SYMPTOM SFC MESSAGE/

No input or low

input

High input

"INPUT OPEN" (with

downscale fail-safe)

"I/P OUT OF SPEC"

(indicates that the input is

below LRL)

"HI RES/LO VOLTS" which

indicates an open circuit

loop

upscale fail-safe)

POSSIBLE CAUSE CURE

Bad sensor wire

connection.

Incorrect operating voltage.

Bad sensor wire

connection.

Check out field wiring and

connections.

Ensure that the transmitter is

in its voltage operating area.

Verify that the 250 ohms

resistor is in loop.

Check field wiring and

connections for partial short

circuit.

Check that the transmitter is in

Revision 6 STT700 Temperature Transmitter User’s Manual Page 35

DISPLAY

"I/P OUT OF SPEC"

Incorrect operating voltage.

line resistance is not

"STATUS CHECK = O.K."

problem would give upscale

"STATUS CHECK = O.K."

INVALID

INVALID REQUEST

critical status

"USER CORR ACTIVE"

SYMPTOM SFC MESSAGE/

(indicates that the input is

above URL or below LRL)

Unstable onscale

input

Fail-safe output

signal

Incorrect output

signal with

simulating device

"

REQUEST" when

changing LRV or

URV

Nonmessage, without

# sign

Remember that successful communications with the transmitter result in many useful pieces of data. With the

initial I.D. response, the user can confirm that the:

1. Transmitter is powered

2. Line resistance is correct

Wires run to the correct unit. If not, the unit connected can be identified by the tag number.

since any identified

or downscale fail-safe.

"CRITICAL STATUS"

but does not correspond to

value set by simulating

device

"

"

POSSIBLE CAUSE CURE

excessive.

Bad sensor wire

connection.

Intermittent open circuit of

sensor.

Wiring disturbed by strong

electromagnetic

interference.

A fail-safe output signal

(critical status) can be

caused by several reasons.

The most common error is

changing the sensor wiring

after probe type selection or

after power-up.

If the LRV is changed, the

URV tries to change by the

same amount to maintain

the same SPAN. If this new

URV exceeds the URL then

this message appears.

Transmitter has been

trimmed for particular

sensor range. This can be

done by keying in

LRV/URV, CORRECT,

ENTER with exact LRV and

URV input values to enable

improved accuracy over the

specifications.

Check connection and wiring

for intermittent connections.

Check that sensor fault

detection is "ON", this allows

detection of a bad sensor.

Protect wiring by using

appropriate grounding,

shielding etc.

The SFC will indicate the

source of the problem by

displaying the appropriate

error message.

Check the appropriate sensor

wiring and power cycle when it

is correct.

Remember when changing

configuration to first connect

sensor wiring correctly, then

change configuration.

Reduce the URV or SPAN

before changing the LRV.

When performing a Reset

Correct command or a sensor

type change, the transmitter

will lose this sensor correction

and fall back to the original

factory calibration.

Page 36 STT700 Temperature Transmitter User’s Manual Revision 6

Configuration Corrupt.

Troubleshooting with HART communicator

Troubleshooting the STT700 HART transmitter loop is greatly simplified by connecting a HART

Communicator in the termination area near the receiving instrument. Also connect a digital volt

meter (DVM), at the termination area for the receiving instrument, to confirm a similar signal is

coming from the field and power is available on the two wires of the 4-20 mA loop. This isolates

the problem to either field loop or receiving instrument/power supply/wiring/safety barriers etc. If

the original symptom was an unstable input, it could be a loose connection on the receiving side.

Assuming the above confirms a field loop problem, the likely causes/actions are given below.

Condition Analysis Recommended Corrective Action

Diagnostics Failure.

A critical failure has been

detected on the HART

Electronics.

DAC Failure.

A critical failure has been

detected on the HART

Electronics.

Sensor Input Failure.

A critical failure has been

detected on the HART

Sensor Inputs.

Use a HART device

communicator to read the

detailed status information fro m

the transmitter. Refer to the

appropriate manual for more

details about the possible failure

causes.

Use a HART device

communicator to read the

detailed status informatio n from

the transmitter. Refer to the

appropriate manual for more

details about the possible failure

causes.

Use a HART device

communicator to read the

detailed status information fro m

the transmitter. Refer to the

appropriate manual for more

details about the possible failure

causes.

Power cycle the transmitter and if problem

persists replace the transmitter.

Power cycle the transmitter and if problem

persists replace the transmitter.

If detail status indicate input fault (open,

short...), correct the root error by checking

the input connection to the transmitter and

sensor type configuration.

If problem persists even after verifying the

input connection and sensor input type

configuration, replace the transmitter.

Power cycle the transmitter and if problem

persists replace the transmitter.

A critical failure has been

detected on the HART

Electronics.

Use a HART device

communicator to read the

detailed status information fro m

the transmitter. Refer to the

appropriate manual for more

details about the possible failure

causes.

For DE please refer to STT700 HART/DE option manual, #34-TT-25-18.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 37

GENERAL DESCRIPTION:

Reference

STT700 transmitter module device

Order from the Model

METERS

Replacement EU meter

51451985-501

Meter mounting bracket kit

46188056-502

HEAD MOUNT HOUSINGS (Cable/Conduit entry noted. All have

Aluminum head mount housing (M20)

46188452-501

Aluminum head mount housing (1/2"NPT)

46188452-502

Flame proof cast iron head mount housing (M20)

46188453-501

Flame proof cast iron head mount housing (1/2"NPT)

46188453-502

FIELD MOUNT HOUSINGS (All have ½” NPT sensor and

Field mount housing - Aluminum beige epox y -polyester hybrid painted

46188472-501

Field mount housing end cap - Aluminum beige epoxy

30752006-501

Field mount housing meter cap - Aluminum beige epoxy-polyester hybrid

30755956-501

Field mount housing - Aluminum beige epoxy painted

46188472-502

Field mount housing end cap - Aluminum beige epoxy painted

46188471-501

Field mount housing meter cap - Aluminum beige epoxy painted

46188471-502

Recomme nde d P arts

½” NPT sensor entry)

Selection Guide to include

options as required.

cable/conduit entries)

painted

Page 38 STT700 Temperature Transmitter User’s Manual Revision 6

Figure 28: Housing with EU meter

Figure 29: Housing without EU m eter

Revision 6 STT700 Temperature Transmitter User’s Manual Page 39

Figure 30: HOUSING WITH STANDARD DISPLAY

Figure 31: HOUSING WITHOUT STANDARD DISPLAY

Page 40 STT700 Temperature Transmitter User’s Manual Revision 6

MISCELLANEO US PARTS (TBC)

Adaptor plate to install module in field mount housing

46188423-501

Spring loading mounting set

46188416-501

DIN rail mounting (top hat/"Ω" or "G" rail)

51156364-501

Carbon steel mounting bracket for 2" pipe

30755905-501

Stainless steel mounting bracket for 2" pipe

30671907-501

1/2"NPT to M20 x 1.5 conduit adaptor (flameproof EEx d)

46188203-501

1/2"NPT Male to 3/4"NPT Female conduit adaptor

51196567-501

Transient protector (external to housing)

30755970-501

Stainless steel wired-on customer ID tag

50080380-501

Lightning Protector

50133588-501

Spring loading and sensor assembly

51307912-001

Pipe mounting dimensions for field mounting housing

46188468-201

Wall mounting dimensions for field mounting housing

46188467-201

DIN rail mounting for the STT700 transmitter module

51156364-501

(for use with field mount housing)

(for use with field mount Housing)

46188203-501

51196567-501

Wiring and Installation Drawings

Revision 6 STT700 Temperature Transmitter User’s Manual Page 41

Upgrading the firmware

To upgrade the firmware of the Remote Indicator, please use the SmartLine Anytime Tool (SAT).

See SmartLine Anytime Tool (SAT) User’s Guide, # 34-TT-25-12 to download the firmware Refer

Below link for more details

https://www.honeywellprocess.com/en-US/explore/products/instrumentation/transmitter-

configurationtools-and-accessories/Pages/field-instrumentation-configuration-and-support-files.aspx

and select the Software tab or

Firmware upgrade Tool for SmartLine devices to download the .zip file direcly

Firmware upgrade on STT700 R100 transmitters which has firmware version 1.000100.

1. Connect the SAT tool to STT700 device which has firmware version 1.000100 and open the SAT

tool application. You can find the SAT shortcut in the desktop or ‘Start->All Programs >Honeywell’ in the desktop taskbar. Then click the SAT shortcut to open it.

2. Click ‘Refresh’ button or ‘Next’ button in below Figure to detect modules automatically. All

connected modules and their firmware version, product type and module type should be displayed

but it will not display module information, you can see figure as below.

Page 42 STT700 Temperature Transmitter User’s Manual Revision 6

3. Double click on the empty module information. The “Firmware Upgrade” panel is displayed on

the right side of GUI as below

Revision 6 STT700 Temperature Transmitter User’s Manual Page 43

4. If your transmitter is HART module, then choose the module type as ‘HART

COMMUNICATION’ or if your transmitter is DE module then choose the module type as ‘DE

COMMUNICATION’.

5. Choose the correct firmware file from the dropdown list at right side of the GUI or click “+”

button to choose the firmware file from a PC file folder where the firmware files are stored.

Choose 50129929-701_R2.000000.hex for HART modules and choose 50129929702_R2.000000.hex for DE module.

6. User can download firmware by clicking the “Apply” button, as shown in the following:

Page 44 STT700 Temperature Transmitter User’s Manual Revision 6

7. The firmware will start downloading as below.

Revision 6 STT700 Temperature Transmitter User’s Manual Page 45

7. Calibration

Recomme nda ti ons for transmitter Calibration

The STT700 SmartLine Temperature Transmitter does not require periodic calibration to m ain t ain

accuracy. Typically, calibration of a process-connected transmitter will degrade, rather than augment

the capability of a smart transmitter. For this reason, it is recommended that a transmitter be removed

from service before calibrat ion. Moreover, calibration must be accomplished in a controlled,

laboratory-type environment, using certified precision equipment.

Calibration Procedures

For a transmitter operating in analog mode, you must calibrate its output signal measurement range

using any compatible hand-held communicator..

One calibration option is to use the Honeywell MC Toolkit (MCT). Refer to the MC Toolkit User

Manual, MCT404, Document # 34-ST-25-50

Calibration information and procedures for a transmitter operating in the HART/DE mode are

provided in the STT700 Series HART/DE Option User’s manual, document number 34-TT-25-18,

Section on “Calibration.”

Page 46 STT700 Temperature Transmitter User’s Manual Revision 6

Appendix A. PRODUCT CERTIFICATIONS