Honeywell Steam Humidifier Professional Installation Manual

69-2285-09

Steam Humidifier

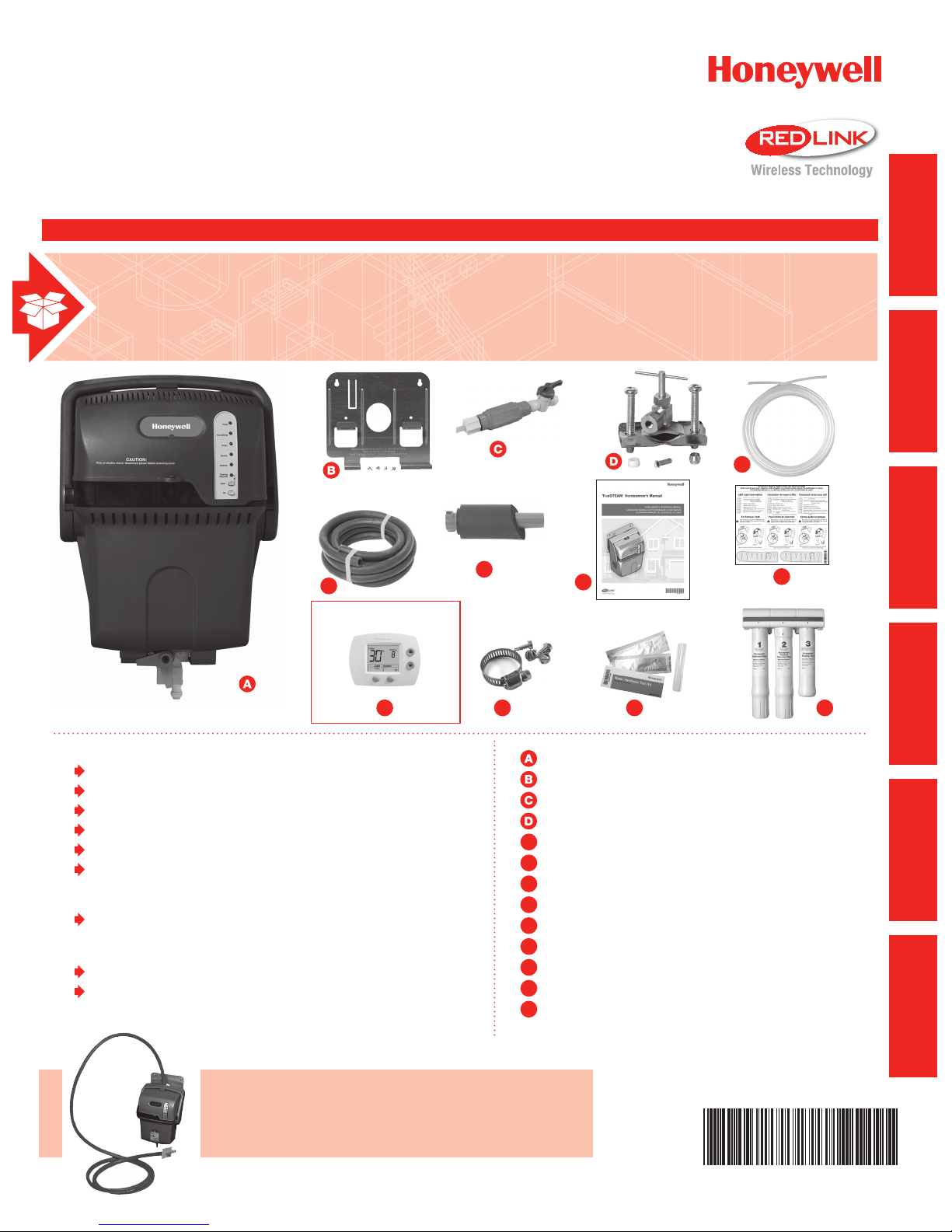

INCLUDED IN THIS HUMIDIFIER BOX

PROFESSIONAL INSTALLATION GUIDE

E

TM

STARTED

GETTING

MOUNTING PLUMBING WIRING APPENDICES

F

J3

Tools needed to install Steam Humidier

Wire cutter/stripper

1-3/4-in. diameter hole saw

1/8-in. drill bit

Standard screwdriver

18-gauge wire (up to 5 conductor)

Torx driver T-20 and T-30

Other Requirements

Steam Humidifier flushes water at or above 140°F (60°C).

Refer to local codes for proper draining practices

for hot water.

Condensate pump rating of 212°F (100°C) if used.

Drip pan with water sensor shut-off required underneath

Steam Humidifier if installed in or above finished space.

G

K L

E

F

G

H

I

J3

K

L

M

H

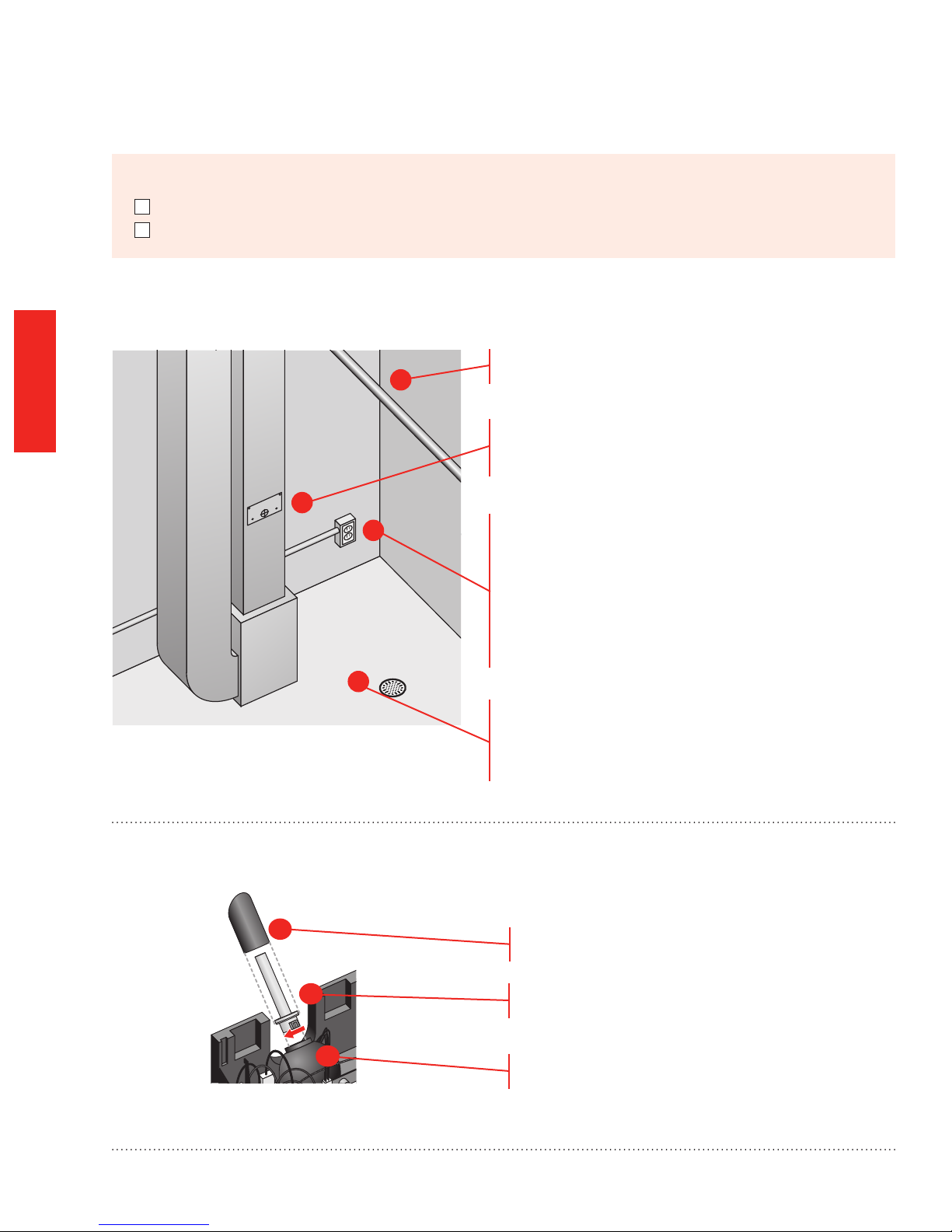

Steam Humidifier

Mounting bracket and hardware

Backflow preventer

Saddle valve

Water supply hose

Drain hose (10 feet)

Duct nozzle and gasket

Owner’s manual

Service label

HumidiPRO Digital Control

Hose clamp

Water Hardness Test Kit

RO Filter System

*RO Tank not needed with installation

I

M*

AND SERVICE

OPERATION

Remote installation requires separate purchase of the

Honeywell Remote Mounting Kit (#50024917)

Steam Humidier

Critical Installation Information ................................2

Water Quality and Hardness ...............................................2

Testing Water Quality and Interperting Results ....................2

Choosing the Filter ...............................................................2

Set the Automatic Flush Cycle Timing .................................3

Proper Sizing of a Steam Humidier Humidier ..................5

Steam Humidier Pre-Install Information .............................7

Safety Denitions and Precautions ..........................8

Safety Denitions ................................................................ 8

Safety Precautions .............................................................. 8

Setting Homeowner Expectations ............................9

Important Installation Requirements ......................10

Personal Safety .................................................................10

Mounting Location ............................................................10

Duct Nozzle ......................................................................10

Water Drainage .................................................................10

Choosing a Mounting Method .................................11

Which is right for you? .......................................................11

Duct Mounting ..........................................................12

STEP ONE: Select a Mounting Location ...........................12

STEP TWO: Connect the Duct Nozzle ...............................12

STEP THREE: Install Mounting Bracket to the Duct ..........13

STEP FOUR: Install Steam Humidier onto the

Mounting Bracket ...............................................................13

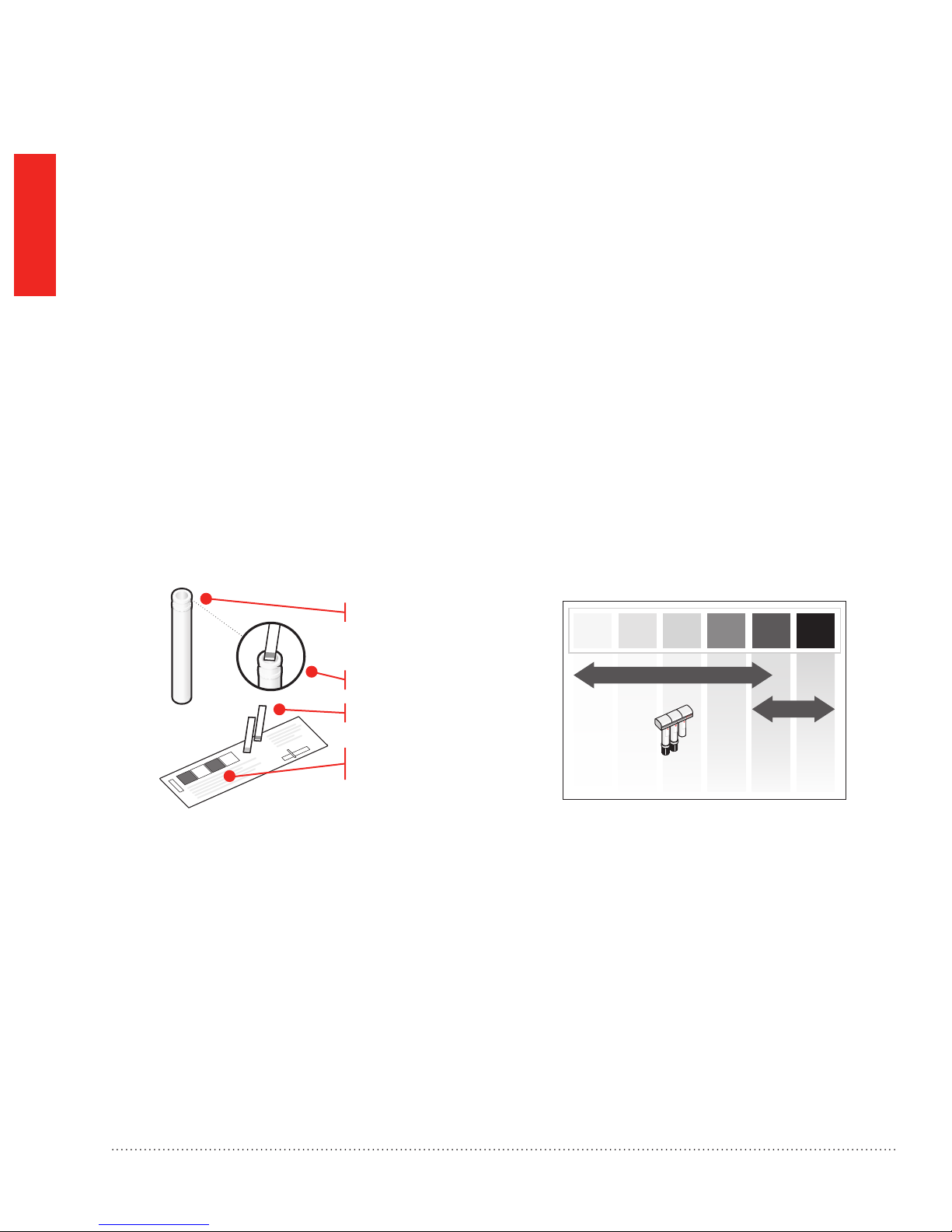

Reverse Osmosis Filter ...........................................24

Parts of the RO Filter .........................................................24

Setting up the RO Filter ....................................................25

Maintaining the RO Filter ..................................................26

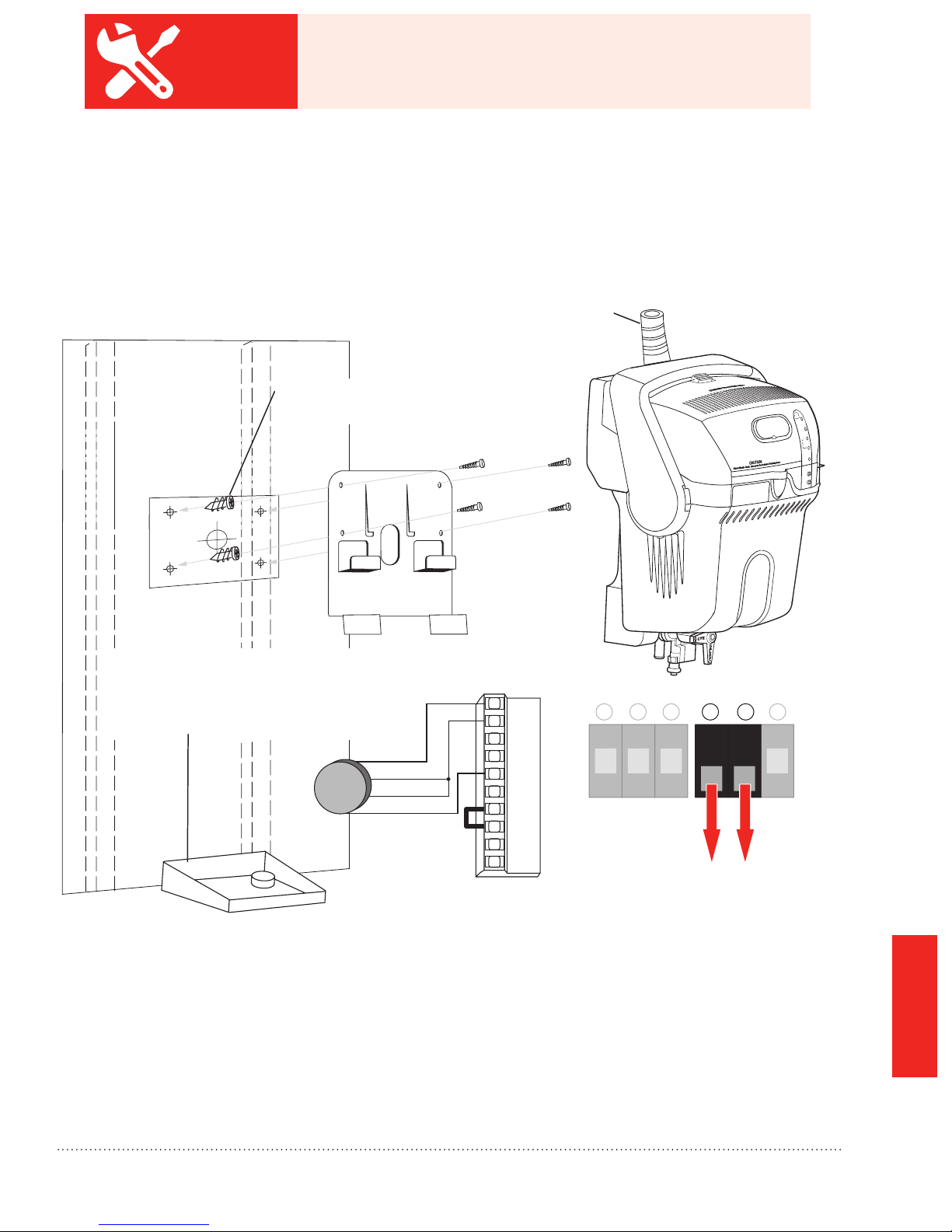

Before Wiring Steam Humier .................................27

Using the DIP Switches .....................................................27

STEP ONE: Remove the Steam Humidier Cover .............27

STEP TWO: Understand the DIP Switches........................27

Deciding on the Wiring Conguration ....................29

STEP ONE: Make Power Monitoring Decision ...................29

STEP TWO: Make System Fan Regulation Decision .........31

STEP THREE: Make Add-On Air Proving Decision ...........33

Using the Terminals ...........................................................34

Routing the Wires ..............................................................34

Using the Correct Control Diagram ........................35

Mounting the Outdoor Sensor ................................38

Startup and Checkout ..............................................43

Routine Maintenance ...............................................44

Automatic Cleaning Cycle ..................................................44

STEP ONE: Initiate a Flush Cycle .....................................44

STEP TWO: Remove the Water Tank .................................46

STEP THREE: Clean the Tank ...........................................47

STEP FOUR: Replace the Water Level Sensor .................47

STARTED

GETTING

MOUNTING PLUMBING WIRING APPENDICES

Water Supply and Drain Connections ....................14

STEP ONE: Connect the Cold Water Supply .....................14

STEP TWO: Tap into a Water Line .....................................14

STEP THREE: Connect Steam Humidier to the

Cold Water Pipe .................................................................15

STEP FOUR: Connect to the Water Drain .........................15

Water Level Sensor Troubleshooting Steps ...........48

Test Setup ..........................................................................48

Test Pins ............................................................................48

Testing for Shorts ...............................................................48

Good Water Sensor ...........................................................48

Bad Water Sensor ..............................................................48

STEP FIVE: Reinstall the Tank .........................................49

Other Plumbing Options ..........................................16

For All Options Shown: ......................................................16

Connect to Steam Humidier .............................................16

Remote Installation ..................................................19

Proper Hose Installation ..........................................21

Troubleshooting .......................................................50

A: Specications ......................................................54

B: Advanced Steam Humier Wiring ....................55

C: Parts List ..............................................................66

NEED HELP? For assistance with this product please visit http://yourhome.honeywell.com

?

or call Honeywell Customer Care toll-free at 1-800-468-1502.

Read and save these instructions.

® U.S. Registered Trademark. Patents pending. Copyright © 2014 Honeywell International Inc. All rights reserved.

AND SERVICE

OPERATION

Steam Humidier System 69-2285—09

1

GETTING

A

STARTED

Critical Installation Information

Water Quality and Hardness

Proper ltration is critical for the operation of the steam humidier. Failure to address water quality will lead to

increased maintenance requirements and possible failure of the steam humidier and its components. Be sure to

complete the following procedure well in advance of installation to ensure any additional costs are documented

and understood.

It is imperative to fully understand the quality and hardness of the water that will be used on each individual steam

humidier. Water quality and water hardness can vary greatly from home to home, and even between two homes

on the same street. Water test kits are included with every steam humidier and are also available for purchase

separately (50044721-001). Proper use of these kits will help determine which ltration option is right for each

particular installation.

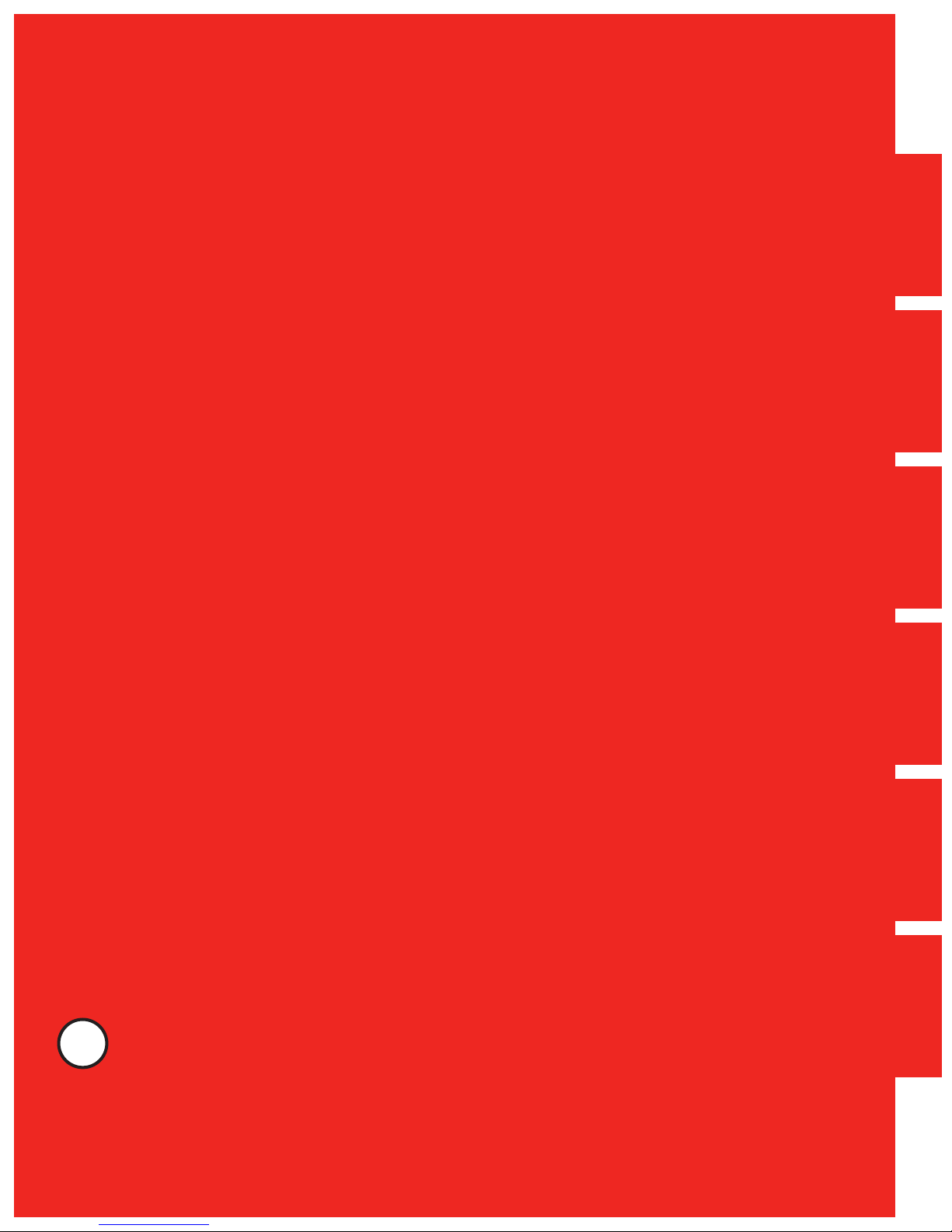

Testing Water Quality and Interpreting Results

• The color block will recommend the best water ltration method for the home.

• Water test strips will be green when new.

• Honeywell always recommends installing a reverse osmosis lter.

1

3

4

Fill the plastic tube with water directly from the

steam humidifier input water source.

Note: It is important to test the specific input to steam

humidifier, as it may differ from the faucet taps in the home.

2

Dip the colored end of one of the test strips into

the tube’s water for 3 seconds.

Remove the test strip. Do not shake the strip.

Wait 20 seconds and then match the test strip’s

color to the closest color block on the water

hardness scale.

Note: Strip color results are no longer valid after one minute.

Honeywell

Recommends

RANGE 1

RO Filter Part No.

HM600XROF1

RANGE 2

Water

Softener

MCR35268

Choosing the Filter

If the water tests in range 2 then the steam humidier will require the use of a whole-house water softener for

optimal performance. Failure to use softened water in this situation can potentially lead to drastically increased

maintenance requirements and premature failure of the steam humidier and its components. Water hardness in

this range negatively affects all facets of a home including shower heads, faucets, laundry machines (as well as

steam humidier).

2

Steam Humidier System 69-2285—09

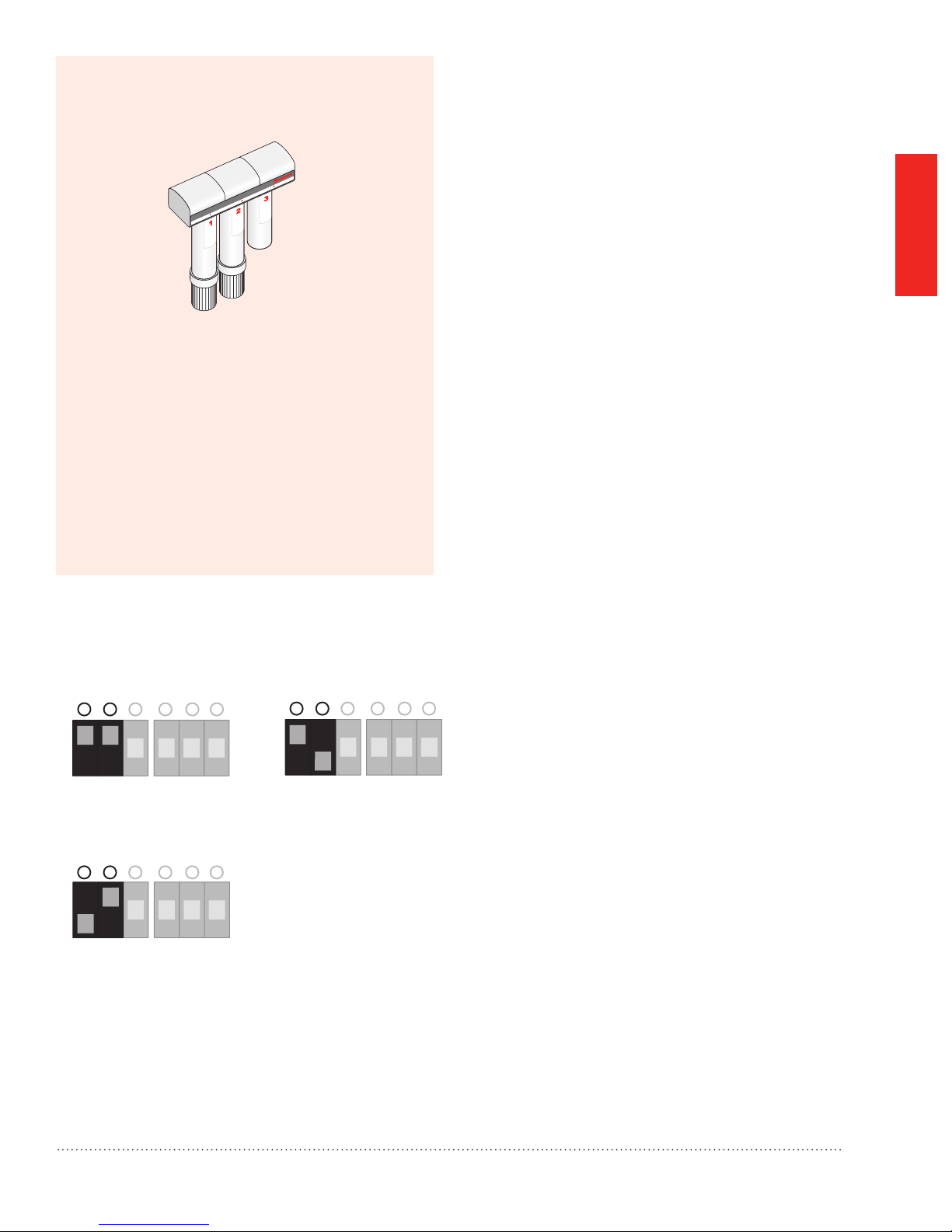

If water hardness is in range 1:

M29661

654321

On

Off

For water that is filtered through

the Honeywell RO Filter System.

(30 hour flush)

654321

65432

On

Off

1

654321

654321

On

Off

On

Of

For water that is filtered through

the Honeywell RO Filter System.

(30 hour flush)

For hard water without

a softener or filter.

(8 hour flush)

For water that is put through

a softener before

entering steam humidifier.

(20 hour flush)

On

Off

M29614A

Honeywell recommends using the RO Filtration

system

Proceed to “Water Supply and Drain

Connections” on page 14. See “Reverse

Osmosis Filter” on page 24 to install the lter.

STARTED

GETTING

Set the Automatic Flush Cycle Timing

On

Off

For water that is filtered through

the Honeywell RO Filter System.

f

For soft water without

(30 hour flush)

a softener or filter.

(12 hour flush)

On

Off

For water that is put through

654321

a softener before

entering steam humidifier.

(20 hour flush)

M29614A

654321

• Use DIP 1 and DIP 2 to congure how often steam

humidier will automatically ush the tank.

Timing for the automatic ush is based on hours of

active heating element time.

• The home’s water hardness determines how often

automatic ushing should be performed.

• The automatic ush timing can be changed any

time after installation by setting the DIP 1 and

DIP 2 positions, as shown at left. See “Automatic

Cleaning Cycle” on page 44 for a description of

the automatic ushing process.

Steam Humidier System 69-2285—09 3

GETTING

STARTED

Use Steam Humidier with water that is less than 1 grain

BEST

PRACTICE

per gallon hardness. A properly functioning water softener

will accomplish this.

While the steam humidier and its available ltration options help to address the issue of water quality and

hardness, homes with extreme hard water problems should consider using a whole house water softener as

the primary ltration device. Use of a whole house water softener will help protect the humidier from excessive

maintenance requirements as well as undue wear and tear in homes with hard water.

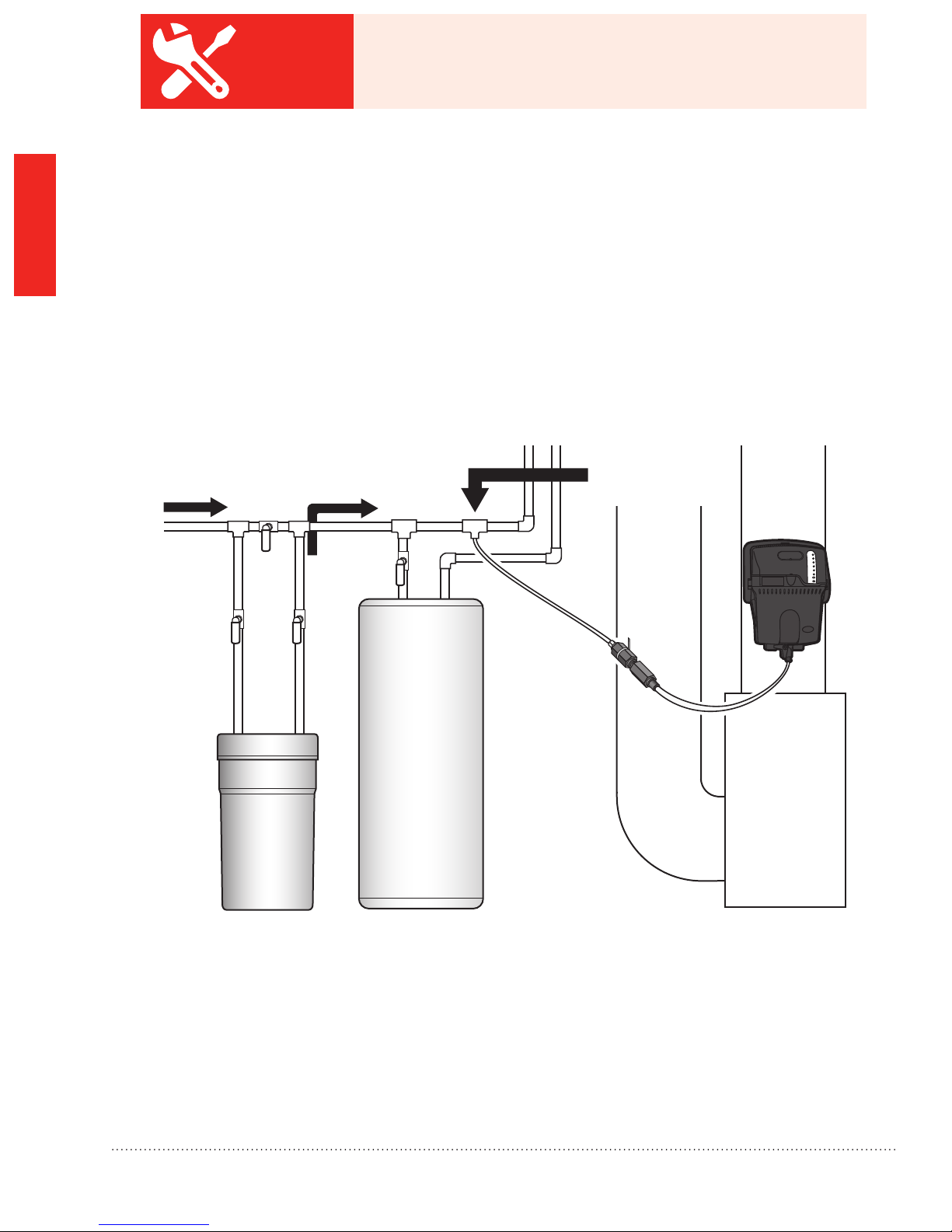

In applications with a water softener, it is critical for the steam humidier to draw its water supply from the cold

water line after the water softener.

Note: Be sure to check all local plumbing codes before beginning installation.

Steam humidifier draws water

Hard water source

Cold softened water

from cold water line after whole

house water softener

Water

Heater

Furnace

Water

Softener

M35265

4

Steam Humidier System 69-2285—09

Proper Sizing of a Steam Humidier

The Air-Conditioning, Heating and Refrigeration Institute (AHRI) has set guidelines for determining humidication

capacity requirements. The recommendation is based on the cubic footage (volume) and type of home

construction – assuming typical conditions. It is important to realize many homes will have humidication

requirements that differ from the guidelines depending on how the circumstances differ from standard conditions.

Factors that impact the amount of humidity needed:

• Geographic Area

• Elevation

• Ventilation type

• Number of people living in the home

• Ceiling height (i.e. cubic volume)

• Window type (i.e. structure type)

• Insulation type (i.e. structure type)

• Equipment type

Converting square footage to cubic volume requires multiplying the square footage by the ceiling height (i.e. 2000

square foot space with 10 foot ceilings is 20,000 cubic feet). In general, the higher the ceilings, the smaller the

square footage space each steam humidier will cover since it must humidify the additional air volume.

STARTED

GETTING

AHRI denes structure type as follows:

• Tight construction: Well insulated with vapor retarders, tight storm doors, windows with weather stripping,

dampered replace, and using ½ air change per hour of air inltration.

• Average construction: Insulated with vapor retarders, loose storm doors and windows, dampered replace

with 1 air change per hour of air ltration.

• Loose construction: Generally built before 1930 with little or no insulation, no storm doors, no insulated

windows, no weather stripping, no vapor retarders, undampered replace, and with 1-1/2 air changes per hour

of air inltration.

It is vital to take all of these factors into account when sizing a steam humidier for a particular home. Undersizing

the humidier will not only reduce the potential to meet the a desired humidity set point, it may also lead to

extensive system fan run time or higher operating costs as the system tries to deliver to the control’s setting. While

oversizing the humidier may lead to higher amp draw, the system run time will be less, which in some situations

may be less expensive at the bottom line.

Steam Humidier System 69-2285—09 5

GETTING

STARTED

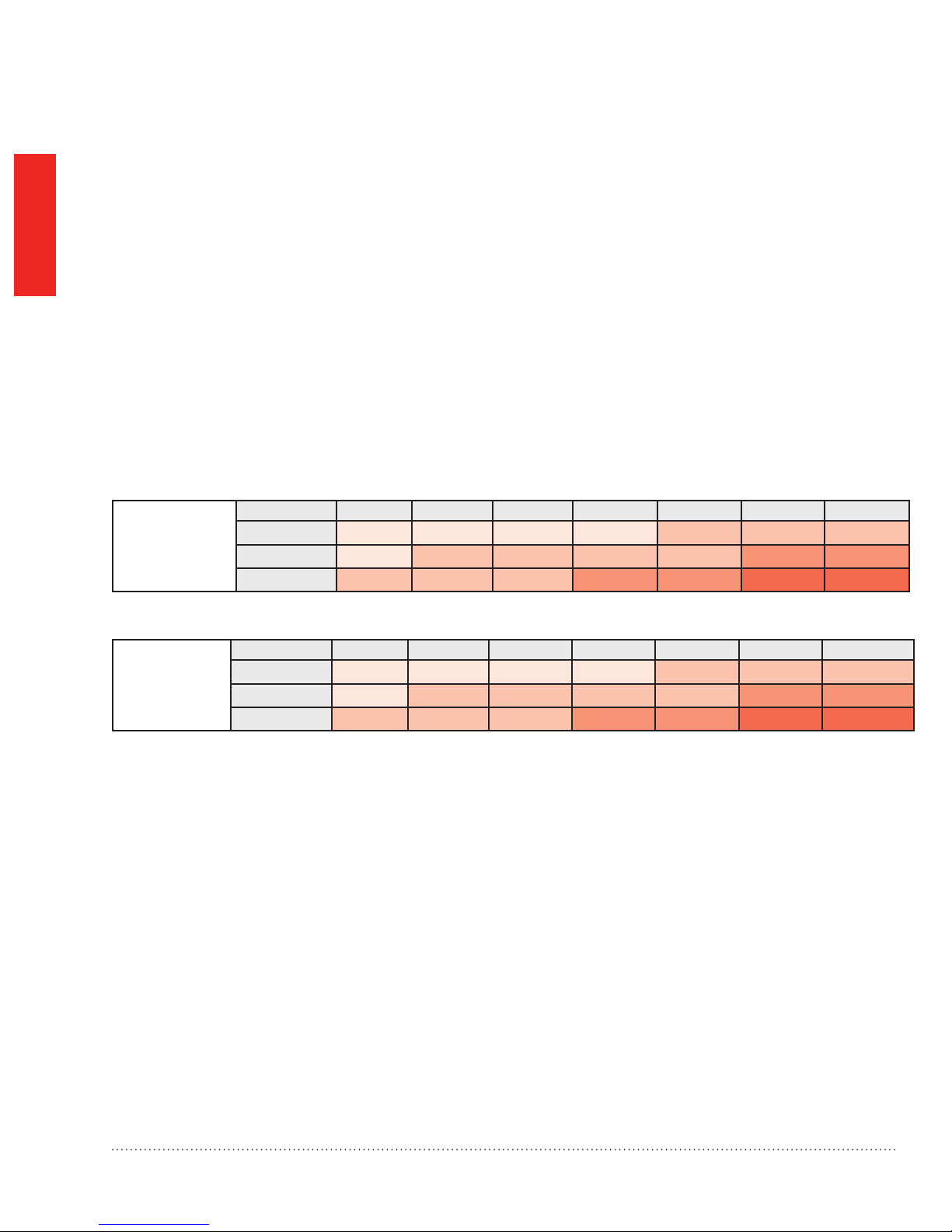

Proper Sizing of a Steam Humidier

Converting square footage to cubic volume requires multiplying the square footage by the ceiling height

(i.e. 2000 square foot space with 10 foot ceilings is 20,000 cubic feet). In general, the higher the ceilings, the

smaller the square footage space each Steam Humidier will cover since it must humidify the additional air

volume.

INCLUDE ALL SQUARE FOOTAGE OF THE HOME. FINISHED AND UNFINISHED.

Example 1: 2000 sq ft home: 8 ft ceilings = 16,000 cu ft. (2000 x 8)

Example 2: 2000 sq ft home: 10 ft ceilings = 20,000 cu ft. (2000 x 10)

Example 3: 2000 sq ft home: ½ with 8 ft ceilings, ½ with 12 ft ceilings. = 20,000 cu ft. ((1000 x 8) + (1000 x 12))

INCLUDING CEILING HEIGHT, FINISHED AND UNFINISHED SPACE WILL PROVIDE A MORE ACCURATE

SIZING FOR HUMIDIFICATION.

AHRI

Recommended

Humidity

(Gallons Per Day)

Recommended

Steam

Humidier

Construction Type 8,000 CU FT 12,000 CU FT 16,000 CU FT 20,000 CU FT 24,000 CU FT 28,000 CU FT 32,000 CU FT

Tight 3.3 4.3 5.4 7.5 9.6 11.7 16

Average 7.6 9.6 11.8 16 20.3 24.4 33

Loose 11.7 14.9 18.1 24.5 30.8 37.1 50

Construction Type 8,000 CU FT 12,000 CU FT 16,000 CU FT 20,000 CU FT 24,000 CU FT 28,000 CU FT 32,000 CU FT

Tight

Average

Loose

9 GPD 9 GPD 9 GPD 9 GPD 12 GPD 9 GPD X2 12 GPD X2

9 GPD 12 GPD 9 GPD X2 9 GPD X2 12 GPD X2 12 GPD X3 12 GPD X3

12 GPD 9 GPD X2 12 GPD X2 12 GPD X3 12 GPD X3 12 GPD X4 12 GPD X4

6

Steam Humidier System 69-2285—09

BEST

PRACTICE

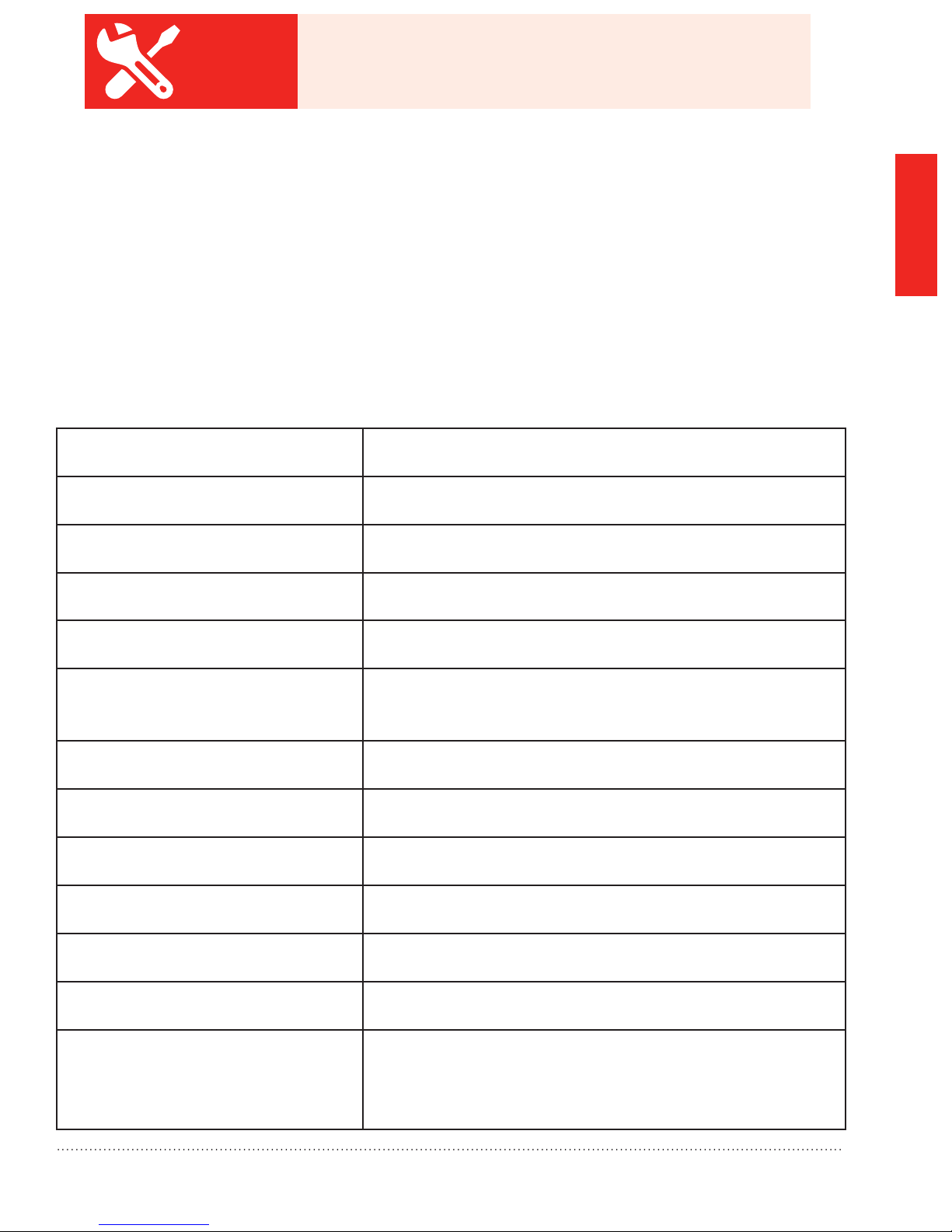

Complete this information sheet and leave on all jobsites

In the event that a service technician needs to call in to the steam humidier support techline, the following

information is typically required for the Honeywell tech support specialist to accurately evaluate each situation.

Failure to have this information ready may result in resolution delays or a potentially incomplete diagnosis.

Honeywell recommends completing the below questionnaire and leaving a copy

behind at the home along with the Steam Humidier installation guide with every steam

humidier installation.

Honeywell steam humidier techline: 800-814-9452

Steam Humidier Pre-Install Information

Model Number of Steam Humidier Unit

Date Code (xxxx)

Water Quality Test 1 2 3 (circle one)

Water Pressure Test (psi)

Flush Cycle Setting

DIP 1 OFF ON OFF ON (circle one)

DIP 2 OFF ON ON OFF (circle one)

STARTED

GETTING

Duct Static Pressure Test (in.wc.)

(Maximum static pressure is 0.5 in.wc.)

Condensate Pump or Drain Pump Drain (circle one)

If Drain - PVC or Standard PVC Standard N/A (circle one)

Supply Voltage to Unit (V)

Monitoring Air Flow/System Power/

None

Control - Wireless or Wired Wireless Wired (circle one)

Fan Control - Steam Humidier or

Controller

Other (any additional relevant

information)

DIP 4 ON OFF (circle one)

DIP 5 ON OFF (circle one)

Steam Humidier Controller (circle one)

Steam Humidier System 69-2285—09 7

GETTING

STARTED

Safety Denitions and Precautions

Safety Denitions

These safety terms identify information you must read.

CAUTION: Indicates a hazardous situation which, if not avoided, could cause bodily injury

or property damage.

WARNING: Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

Safety Precautions

Make sure you read and understand the following safety hazards before installing, using, or working

with the steam humidier:

• Do not direct the steam nozzle at people.

• Water inside tank can be very hot. Explain this to homeowner and emphasize the warning label

on steam humidier.

• Scalding danger from draining water. When the water tank drains, the water can be hot enough to cause

injury. Make sure the homeowner understands the danger of hot water and steam.

CAUTION: Voltage Hazard.

Can cause electrical shock or equipment damage.

Disconnect HVAC equipment before beginning installation.

WARNING: Electrocution, Heavy Equipment, and Water Hazard.

Can cause death, blindness, and water damage to home, and heating element failure.

CAUTION: Steam Condensation, Fire, and Freezing Water Hazard.

Can cause failure of fan or limit control or result in water damage to home.

8

Steam Humidier System 69-2285—09

Setting Homeowner Expectations

Make sure the homeowners know what to expect from their steam humidier. Discuss the following points with the

homeowners and answer any questions they have.

• Achieving Humidity Setpoint. It may take up to a week of continuous operation to achieve the humidity

setpoint. This depends on such factors as weather, size of home, furnishings in the home, and insulation.

• Plastic or Rubber Odor. At startup, it is normal to smell a slight plastic odor in the home. If the remote hose is

used, there may be a slight rubber odor. These odors will go away within a few days.

• Ideal Humidity. 35% – 45% relative humidity in typical winter weather is considered ideal by industry experts.

Homeowners can adjust to their own comfort or until there is condensation on the windows. Lower the setpoint

if condensation appears.

• Unit Not Humidifying. If steam humidier is not running but the humidity is below the setpoint, the humidity

control may have a frost protection setting. Steam humidier will not humidify while in a drain cycle mode.

STARTED

GETTING

• Setpoint Not Reached. If humidity doesn’t reach the setpoint, steam humidier may be undersized for the

home. This can be due to factors such as insulation, windows, and arid climate. Also, the outdoor temperature

may be too low to maintain the humidity level. Wait for the outdoor temperature to warm closer to 20°F (-6°C). If

the desired humidity is still not reached, then a larger capacity steam humidier may be needed.

• Home Ventilation. Excessive ventilation sends moist air outside and replaces it with dry air. This can make it

hard to maintain the humidity setpoint. If installing a ventilator, use a solution that retains moisture. An Energy

Recovery Ventilator (ERV) is recommended.

• Cleaning Required Light. If the Cleaning Required light is on, clean steam humidier using the steps found in

the “Routine Maintenance” section on page 44, or in the Homeowner’s Operating Manual. Steam Humidier

will continue to run normally while this light is on.

• Hard Water. The home’s water hardness determines how often steam humidier must be cleaned. A water

hardness test kit is provided with your steam humidier. It will help you determine the cleaning interval and

lter requirements for your steam humidier.

• Energy Consumption. There may be a slight increase in overall energy consumption when operating

any humidier. However, steam humidier will make the home feel warmer. This allows the homeowner to lower

the temperature setting on the thermostat. Every degree lower on the thermostat can save up to 3% on

heating costs.

Steam Humidier System 69-2285—09 9

GETTING

STARTED

Important Installation Requirements

Failure to comply with these requirements will result in voided warranty, improper installation, and

service callbacks.

Personal Safety

• Wear safety glasses while installing steam humidier.

• Do not cut into any air conditioning or electrical line.

• Follow professional safety standards and all local regulations.

Mounting Location

• Mount steam humidier in a level position to avoid water damage or heating element failure.

• Install steam humidier on the supply duct. Use the Remote Mounting Kit if duct mounting is not possible.

• Do not install steam humidier where the ambient temperature is lower than 34°F (1.1°C) or higher

than 104°F (40°C).

• Mounting area must be strong enough to support steam humidier’s weight when full of water (up to 15 lbs.).

• Choose a location that is well ventilated. Do not install steam humidier in completely enclosed spaces, such

as a cabinet or unventilated closet.

• Allow at least 1 foot clearance to ventilation holes in the steam humidier cover. Do not cover the holes.

Covering them can increase the temperature inside steam humidier and shorten its life.

• Do not mount directly to duct board. The remote mount nozzle attachment is allowed only with a Honeywell

duct board adapter kit. See “Appendix C: Parts List” on page 55.

• If used near a pool or spa, make sure steam humidier can not fall into the water or be splashed. Also, ensure

steam humidier is plugged into a ground fault interrupted (GFI) outlet.

10

Duct Nozzle

• Do not install the duct nozzle into a supply duct with static pressure exceeding 0.5 in. w.c.

• Do not install the duct nozzle through wooden sidewalls (e.g., oor joist).

• If the duct has exposed insulation on the interior, be sure the nozzle extends beyond the insulation. Clear away

excess insulation at the insertion point, or replace a section of insulated duct (approximately 6 in. x

6 in.) with rigid, non-insulated sheet metal.

• Allow at least 4 in. clearance between nozzle outlet and any interior duct to avoid water condensation.

• Mount steam humidier where the nozzle outlet has a minimum 24 in. of downstream open air space.

Water Drainage

• Consult local plumbing codes for drain size, material, and maximum temperature allowed.

Steam Humidier System 69-2285—09

Choosing a Mounting Method

Return

Supply

MCR29596

Supply

MCR35264

Before installing steam humidier in a home, you must decide which mounting method you want to use:

Which is right for you?

DUCT MOUNTING – if you can mount steam

humidier onto the supply duct of

the HVAC system:

The generated steam goes directly into the

supply duct.

This is the simplest type of installation, but

it requires that a suitable mounting location

can be found on the supply duct.

REMOTE MOUNTING – if a suitable

mounting location can not be found

on the supply duct:

The steam humidier can be mounted up to

20 feet away from the supply duct for

select models.

A remote hose must be installed to carry

steam from steam humidier to the supply

duct.

You will need to use a remote mounting kit

(see “Appendix C: Parts List” on page 66).

MOUNTING

This manual covers duct mounting of steam humidier. For Remote Mounting Instructions, see “Remote

Installation” on page 19 or “Document 69-2317” (included with Remote Mounting Kit).

Before proceeding:

I have decided to use: Duct Mounting Remote Mounting

Steam Humidier System 69-2285—09 11

Duct Mounting

M29598

M29599

Before beginning Duct Mounting:

I have conrmed local codes for proper draining practices for hot water

I have chosen an installation location that meets the requirements on page 10

Follow these steps to mount steam humidier directly to the supply duct of the homeowner’s HVAC equipment.

STEP ONE: Select a Mounting Location

Choose a location that has access to a cold

1

water supply pipe.

MOUNTING

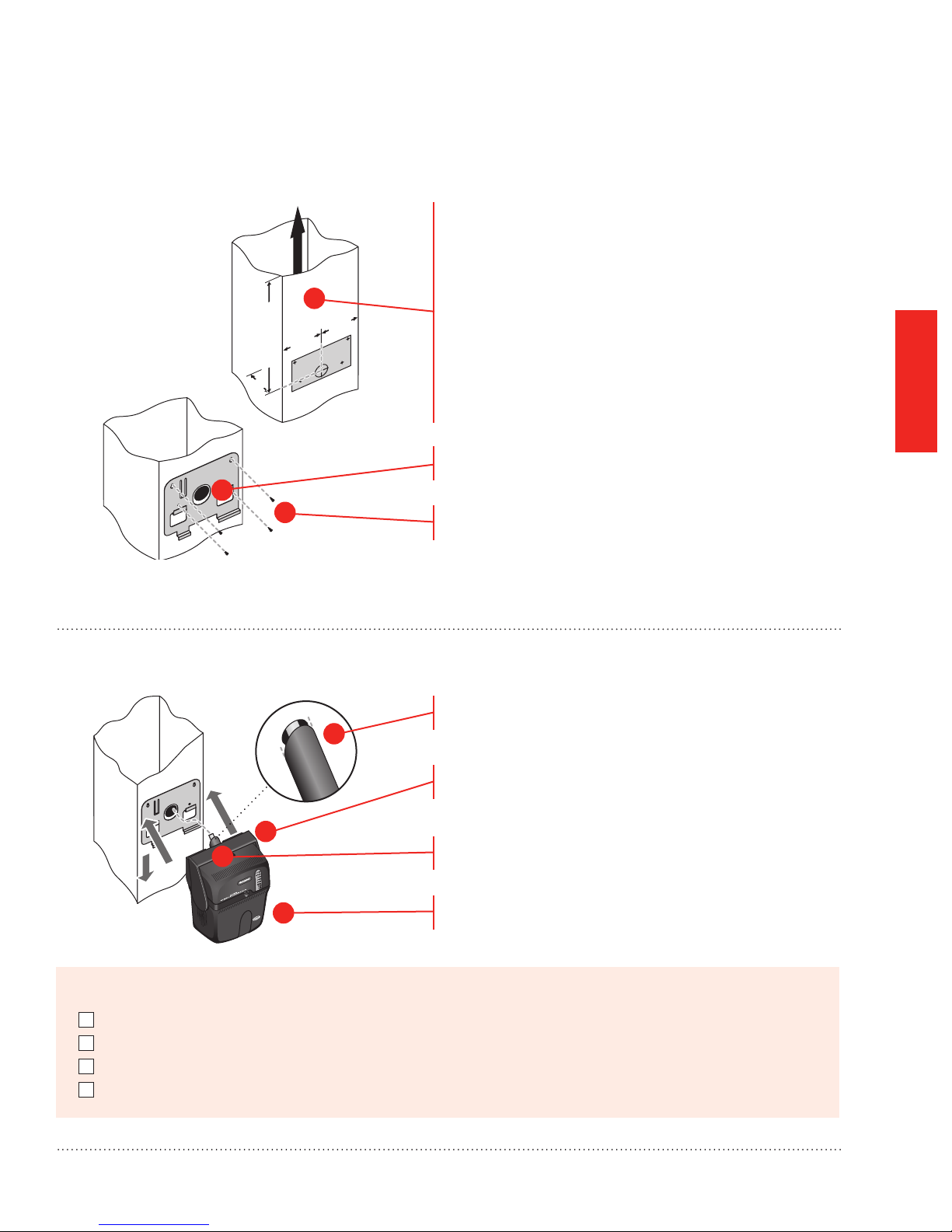

STEP TWO: Connect the Duct Nozzle

Select a vertical or horizontal surface on the HVAC

supply duct, with adequate clearances, where steam

humidier can be mounted.

2

3

Make sure there is a 120 VAC electrical outlet

rated for the steam humidier being installed.

Steam Humidier Required Minimum

Circuit Capacity:

HM609 10 Amps

HM612 12 Amps

4

Ensure the location is near a drain with a high-

temperature water rating. Consult local plumbing

codes for proper drainage. If no main oor drain

is available, see “Other Plumbing Options” on page

16.

1

2

12

Slide the foam gasket over the nozzle.

Make sure the o-ring gasket is properly seated

in the groove.

3

Insert the duct nozzle into steam humidier. Twist

clockwise to ensure a tight seal.

Steam Humidier System 69-2285—09

STEP THREE: Install Mounting Bracket to the Duct

M29600

Position the template on the supply duct:

• Make sure the template is level and in the desired

position on the duct.

• Ensure proper clearances from A-coil.

• Make sure the duct nozzle will have proper

clearances from duct walls.

• Minimum 4-inch clearance from nozzle outlet to any

duct wall.

• Minimum 24 inches of downstream open duct air

space. (Needed to prevent water condensation.)

Drill the 1-3/4 inch hole.

Secure the mounting bracket to the duct, using four

self-drilling sheet metal screws provided.

2

12”

(min)

4”

Flow

1

4”4”

3

MOUNTING

STEP FOUR: Install Steam Humidier onto the Mounting Bracket

Make sure the foam gasket is positioned correctly over

1

2

3

4

M29601A

Before proceeding to Plumbing:

I selected a duct mounting location

I connected the duct nozzle

I installed the mounting bracket to the duct

I installed the steam humidier onto the mounting bracket

the nozzle.

Lift steam humidier into place against the mounting

bracket. Insert the nozzle directly into the duct hole.

Check the foam gasket – it must form a tight seal in

the duct hole.

Push down to secure steam humidier to the bracket

arms.

Steam Humidier System 69-2285—09 13

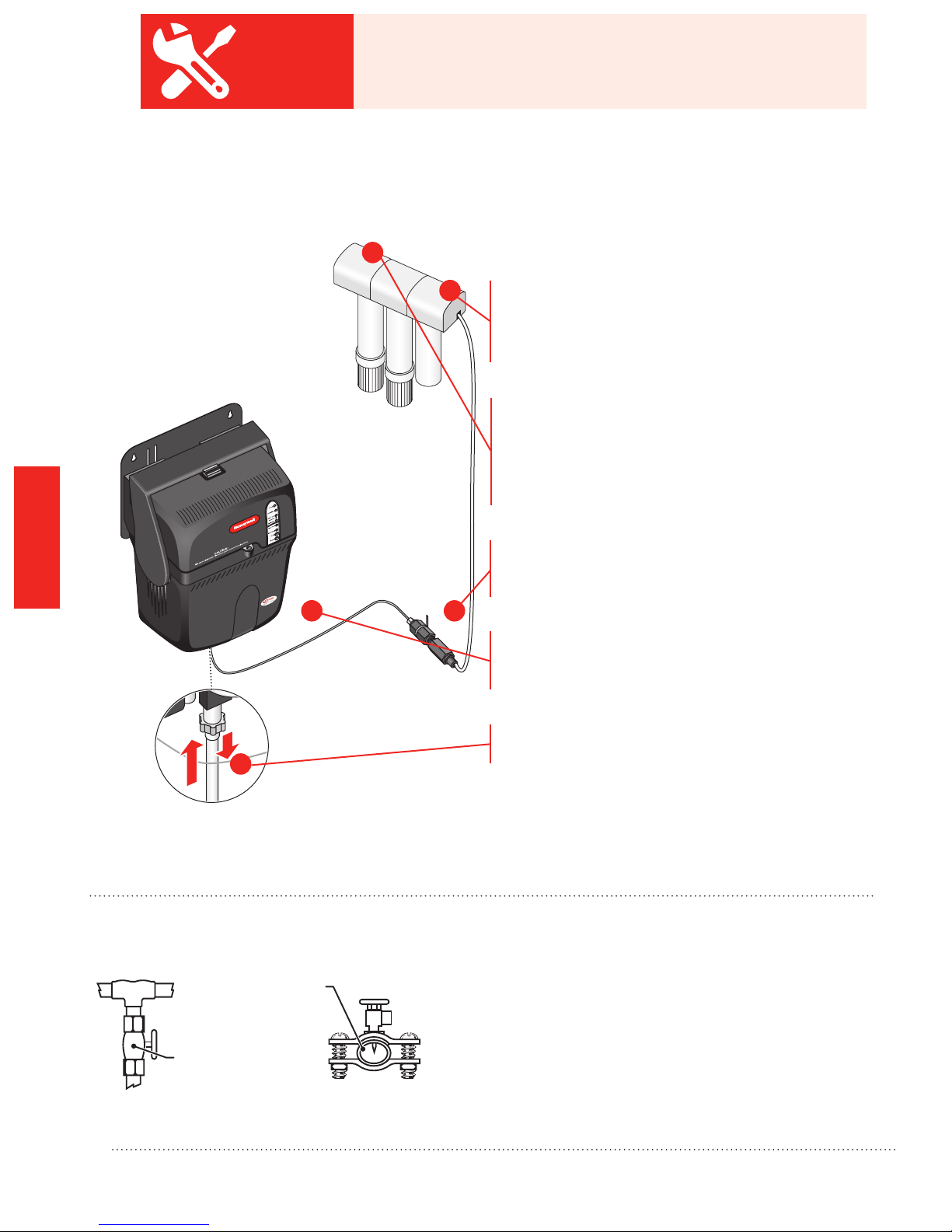

MCR35266

BEST

PRACTICE

Use a manual shutoff valve when tapping into a water line.

Water Supply and Drain Connections

STEP ONE: Connect the Cold Water Supply

2

Do not use hot water supply. Cold water is required

to cool boiling water to safe draining temperatures.

PLUMBING

1

Insert one end of the water line into the water lter

or reverse osmosis kit. Use the 1/4-inch plastic

water line provided or a 1/4-inch copper water line.

Apply a modest pull to ensure a tight t.

Use clamps or ties to secure the water lter in a

location that allows for removing and replacing it in

the future. Honeywell recommends changing the

water lter or RO canisters 1 & 2 annually, or as

needed based on water conditions.

Install the provided backow preventer, as required

by code. See “Reverse Osmosis Filter” if using the

Reverse Osmosis Filter.

4

3

Cut the water line so it is long enough to reach

from the water lter to the supply tting on the

bottom of the steam humidier.

Insert the water line into the steam humidier

5

supply tting.

STEP TWO: Tap into a Water Line

Water Supply

Line

Manual Shutoff

Valve

T-fitting

14

Note: Failure to check for a tight t with plastic water line

could result in the line coming loose in the future. Apply

modest pull to ensure water line is properly seated and

secure.

• Consult local codes for proper plumbing.

• Use the saddle valve provided or a T-tting and

manual shutoff valve to tap into a cold water

line.

• Refer to the literature included with the valve

you chose and the local plumbing codes. Use

proper technique for the valve.

Saddle Valve

M29605

Steam Humidier System 69-2285—09

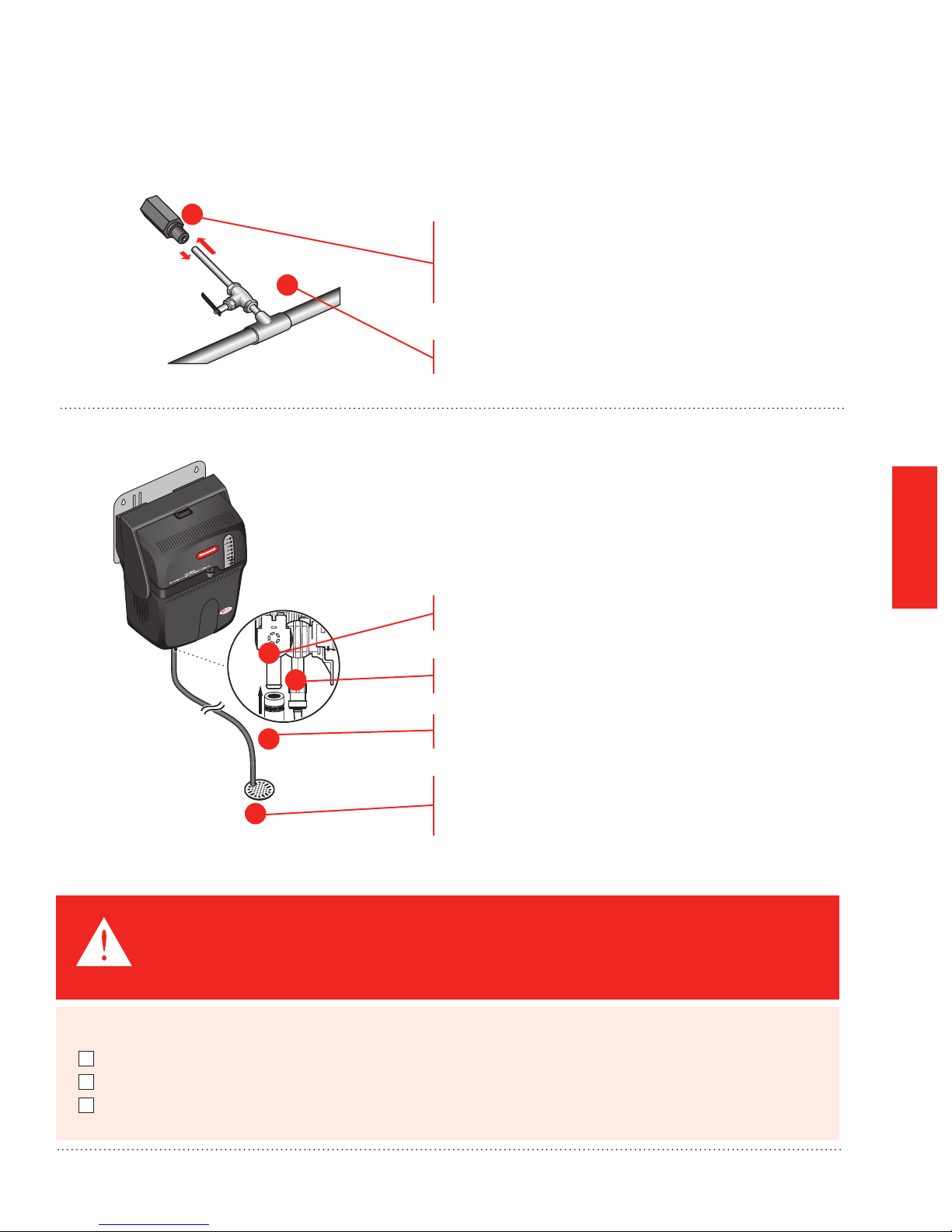

STEP THREE: Connect Steam Humidier to the Cold Water Pipe

MCR32901

1

Connect one end of the remaining length of water

line to the backow preventer. Apply a modest pull

2

to ensure a tight t. See “Reverse Osmosis Filter” on

page 24 if using the Reverse Osmosis Filter.

Connect the other end of this line to the saddle valve

or T-tting and manual shutoff valve.

STEP FOUR: Connect to the Water Drain

• Consult and follow local plumbing codes for drain

pipe size and maximum temperature requirement.

• The ideal installation is directly to the main oor

drain using the rubber hose provided.

• If direct oor drain access is not available, see

“Other Plumbing Options” on page 16.

Connect the 1/2-inch drain hose provided to the drain

tting on the bottom of the steam humidier.

PLUMBING

1

2

3

MCR29607

4

CAUTION: Scalding Hazard.

During operation, hot water may exit drain and can cause burns from scalding.

Make sure the hose is securely connected to the drain.

Before proceeding to Wiring:

I have conrmed minimum required circuit capacity

I have connected the water supply using cold water

I have installed the drain connection

Use the hose clamp provided to secure the drain hose

to the barbed tting.

Route the drain hose to the oor drain. The hose must

have a continuous downward slope.

Direct the hose outlet into the oor drain. Secure

the hose to reduce the risk of hot water pooling

or splashing.

Note: Some building codes require an air gap between

discharge hose and oor drain.

Steam Humidier System 69-2285—09 15

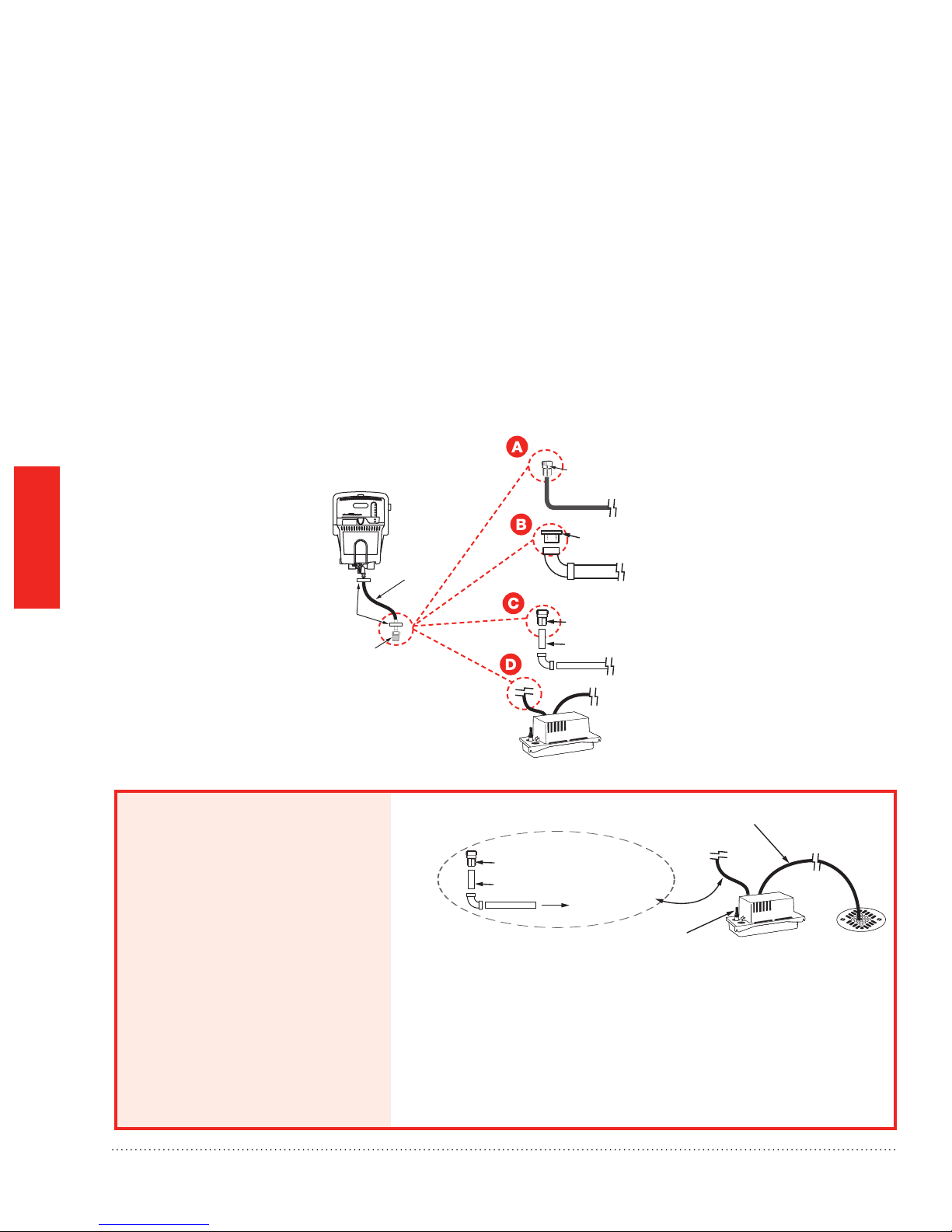

Other Plumbing Options

1/2 IN. BARB X 3/4 IN. MNPT

3/8-IN. TUBING

M28713A

The following diagrams are for applications where standard draining to a oor drain is not available.Choose the

plumbing option that suits your installation. Use A, B, C, or D based on type of pipe or condensate pump. Consult

and follow local plumbing codes in addition to these instructions.

For All Options Shown:

PLUMBING

• Support rubber hose every 6 in.

• PVC must be schedule 40 or higher rating.

Connect to Steam Humidifier

Common to all plumbing options.

SEAL ALL CONNECTIONS FROM

SOLENOID VALVE TO DRAIN STACK

FLEXIBLE

HOSE

HOSE

CLAMPS

212°F RATED PUMP

HOSE FROM

STEAM

HUMIDIFIER

• All plastic pipe joints are welded.

• Drain into a P-trap that will remain wetted at all

times.

3/4 IN. FNPT X SWEAT

3/4 IN. COPPER PIPE

3/4 IN. FNPT X

1-1/2 IN. PVC

1-1/2 IN. (MINIMUM) PVC PIPE

3/4 IN. FNPT X 3/4 IN. CPVC

3/4 IN. CPVC PIPE

3/8-IN. TUBING

RATED AT 212°F

MCR28678

Option 1: Plumbing

to drain with

condensate pump.

16

RATED AT 212°F

ALTERNATIVE

3/4 IN. FNPT X 3/4 IN. CPVC

3/4 IN. CPVC PIPE

TO PUMP

HOSE CLAMPS AT

ALL CONNECTIONS

HOSE FROM

STEAM HUMIDIFIER

• Use Hartell A3X-115 condensate pump or equivalent

(212°F temperature rating, > 1 GPM pump flow rate).

• Pump must be powered when Steam Humidifier is operating.

• Use a pump with a built-in overflow sensor or install the pump

in a drip pan with wet switch wired to turn off Steam Humidifier.

Steam Humidier System 69-2285—09

M28679

3/4 IN. FNPT X 1-1/2 IN. PVC

3/8 IN. BARB X 3/4 IN. MNPT

SIZE TO FIT PUMP OUTPUT

Option 2: Plumbing to a dedicated trap.

1-1/2 IN. (MINIMUM)

PVC PIPE

STAINLESS STEEL

SLOTTED BAND

COUPLING SIZED TO

FIT PIPE (COPPER,

PVC, CPVC

SIZE TO FIT PUMP OUTPUT

3/4 IN. MNPT X SWEAT

3/4 IN. FNPT X 1-1/2 IN. PVC

1-1/2 IN. (MINIMUM) PVC PIPE

1-1/2 IN. PVC

3/4 IN. MNPT X 3/4 IN. CPVC

3/4 IN. FNPT X 1-1/2 IN. PVC

HOSE CLAMP

1-1/2 IN. MINIMUM TRAP

(OR SIZE PER LOCAL CODE)

VENTED PER

LOCAL CODE

ALL PLASTIC PIPE

JOINTS ARE WELDED

Option 3: Plumbing to sink with a dedicated trap.

PLUMBING

3/4 IN. MNPT X SWEAT

3/4 IN. FNPT X 1-1/2 IN. PVC

1-1/2 IN. PVC

3/4 IN. MNPT X 3/4 IN. CPVC

3/4 IN. FNPT X 1-1/2 IN. PVC

HOSE CLAMP

3/8 IN. BARB X 3/4 IN. MNPT

3/4 IN. FNPT X 1-1/2 IN. PVC

)

WELD

ALTERNATIVE

THIS CONFIGURATION ALLOWS FOR

REMOVAL OF THE TRAP

1-1/2 IN. PVC

ALL CONNECTIONS FROM

SOLENOID VALVE TO

DRAIN TRAP ARE SEALED

SINK

WELD

WELD

THREADS

ALL PLASTIC PIPE UNDER

SINK 1-1/2 IN. MINIMUM PVC

COUPLING

WELD

WYE

THREADS

M28681

Steam Humidier System 69-2285—09 17

3/4 IN. MNPT X SWEAT

.

STAINLESS STEEL

SLOTTED BAND

COUPLING SIZED TO

FIT PIPE (COPPER,

PVC, CPVC)

Option 4: Plumbing to sink trap.

PLUMBING

3/4 IN. FNPT X 1-1/2 IN. PVC

1-1/2 IN. (MINIMUM)

PVC PIPE

1-1/2 IN. PVC

3/4 IN. MNPT X 3/4 IN. CPVC

3/4 IN. FNPT X 1-1/2 IN. PVC

HOSE CLAMP

3/8 IN. BARB X 3/4 IN. MNPT

3/4 IN. FNPT X 1-1/2 IN. PVC

SIZE TO FIT PUMP OUTPUT

1-1/2 IN. PVC

ALL CONNECTIONS FROM

SOLENOID VALVE TO

DRAIN TRAP ARE SEALED

SINK

WELD

WELD

ALTERNATIVE

THIS CONFIGURATION ALLOWS FOR

REMOVAL OF THE TRAP

COUPLING

1-1/2 IN.

PVC TEE

WELD

THREADS

1-1/2 IN

PVC

M28680

18

Steam Humidier System 69-2285—09

If humidier is in nished space, always install a drip pan

MCR28708

BEST

PRACTICE

with wet switch. Honeywell recommends Diversitech WS-1

(wiring shown here).

Remote Installation

Use remote installation when no suitable duct mounting location can be found on the homeowner’s

HVAC system. For detailed instructions on remote installation, see the steam humidier Remote Mount Kit

Installation Instructions (69-2317).

Always pitch the remote Adapter Nozzle upwards

Use provided anchors if mounting

to drywall or plaster

If humidifier is in finished space, always

install a drip pan with wet switch.

Honeywell recommends Diversitech WS-1

(wiring shown here.)

RED

BLACK

GREEN

ORANGE

STEAM

HUMIDIFIER

TERMINAL

24V

24V

HUM

HUM

C

GT

R

RT

GF

EXT

On

Off

1

65432

APPENDICES

Steam Humidier System 69-2285—09

19

BEST

Cut a slit in the insulation half way

around the hose

Minimum

pitch

per

Nozzle

PRACTICE

.

Always inspect the hose installation after at least 1 hour of

steam production to conrm that there are no sags in the

hose or leaks at the connection points.

at upward pitch.

upward

of 2 inches

foot.

Avoid sharp kinks and

prevent bends.

Minimum of

6 inches

of straight

vertical rise.

12 inches

Do not cut into the

rubber steam hose.

3 inches minimum clearance from nozzle

outlet to duct.

1-3/4 inch hole

Clamp

On straight runs, use perforated angle

iron. Otherwise, secure hose every 12 inches

using provided hooks.

Clearance hole for hose and insulation.

Seal off unconditioned space with

Clamp

grommet (not provided) or caulk.

Always install nozzle so the

outlet is pointed up.

Do not route the steam

hose through the hole

in the mounting plate.

On straight runs, use

perforated angle iron.

Otherwise, support

hose every 12 inches

using provided hooks.

24 inches open air downstream.

If hose slopes downhill…

Downward slope can not be more than

3 feet below humidifier steam outlet.

Provide a 212°F rated Te e at the

lowest point. Do not use plastic Te e.

Minimum 6 inches

Minimum 2 inches

Insert the hose clamp into

the slit and hook it onto the

rubber hose.

Hose clamps at

every connection.

Minimum upward

pitch of 2 inches

per foot.

Nozzle at

Clamps

upward pitch.

APPENDICES

20

Always consult and follow local

plumbing codes for drain pipe

size and maximum temperature

requirement.

Water in elbow.

Note: Some building codes require

an air gap between discharge hose

and floor drain.

M29636

Steam Humidier System 69-2285—09

Loading...

Loading...