Honeywell STD730, STD770, STG730, STG740, STG770 User Manual

...

ST 700

SmartLine Pressure Transmitters

User’s Manual

34-ST-25-44

Revision 2.0

May 2013

Honeywell Process Solutions

Page ii ST 700 SmartLine Pressure Transmitters User’s Manual Revision 2.0

Copyrights, Notices and Trademarks

© Copyright 2013 by Honeywell, Inc.

Revision 2, May 2013

While the information in this document is presented in good faith and believed to be

accurate, Honeywell disclaims any implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in the written

agreement with and for its customers. In no event is Honeywell liable to anyone for any

indirect, special, or consequential damages. The information and specifications in this

document are subject to change without notice.

Honeywell, TDC 3000, SFC, Smartline, PlantScape, Experion PKS, and TotalPlant are

registered trademarks of Honeywell International Inc. Other brand or product names are

trademarks of their respective owners.

Honeywell Process Solutions

1860 Rose Garden Lane

Phoenix, AZ 85027

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page iii

About This Manual

This manual is a detailed how to reference for installing, piping, wiring, configuring, starting up,

operating, maintaining, calibrating, and servicing Honeywell’s family of ST 700 SmartLine

Pressure Transmitters. Users who have a Honeywell ST 700 SmartLine Pressure Transmitter

configured for HART protocol or Honeywell’s Digitally Enhanced (DE) are referred to the ST

700 Series HART/DE Option User’s Manual, document number 34-ST-25-47. Users who have a

Honeywell ST 700 SmartLine Pressure Transmitter configured for Fieldbus operation are referred

to the ST 700 Series Fieldbus Option User’s Manual, document number (34-ST-25-48).

The configuration of your Transmitter depends on the mode of operation and the options selected

for it with respect to operating controls, displays and mechanical installation. This manual

provides detailed procedures to assist first-time users, and it further includes keystroke

summaries, where appropriate, as quick reference or refreshers for experienced personnel.

To digitally integrate a Transmitter with one of the following systems:

• For the Experion PKS, you will need to supplement the information in this document with the

data and procedures in the Experion Knowledge Builder.

• For Honeywell’s TotalPlant Solutions (TPS), you will need to supplement the information in

this document with the data in the PM/APM SmartLine Transmitter Integration Manual,

which is supplied with the TDC 3000 book set. (TPS is the evolution of the TDC 3000).

Release Information

ST 700 SmartLine Pressure Transmitter User Manual, Document # 34-ST-25-44,

Revision 1.0, February, 2013

Revision 2.0, May, 2013 – Updates to Parts list, Explosionproof Seal class, Fail Safe and Comms

Module procedures.

References

The following list identifies publications that may contain information relevant to the information

in this document.

SmartLine Pressure Transmitter Quick Start Installation Guide, Document # 34-ST-25-36

ST 800 & ST 700 Pressure Transmitter with HART Safety Manual, # 34-ST-25-37

ST 700 SmartLine Pressure Transmitter HART/DE Option User’s Manual, Document

# 34-ST-25-47

ST 700 FF Transmitter with FOUNDATION Fieldbus Option Installation & Device Reference

Guide, Document # 34-ST-25-48

MC Tookit User Manual, for 400 or later, Document # 34-ST-25-20

PM/APM Smartline Transmitter Integration Manual, Document # PM 12-410

ST 800 & ST 700 Series Pressure, Analog, HART and DE Communications form, Honeywell

drawing 50049892

Smart Field Communicator Model STS 103 Operating Guide, Document # 34-ST-11-14

Page iv ST 700 SmartLine Pressure Transmitters User’s Manual Revision 2.0

Patent Notice

The Honeywell ST 700 SmartLine Pressure Transmitter family is covered by one or more of the

following U. S. Patents: 5,485,753; 5,811,690; 6,041,659; 6,055,633; 7,786,878; 8,073,098; and other

patents pending.

Support and Contact Information

For Europe, Asia Pacific, North and South America contact details, refer to the back page of this

manual or the appropriate Honeywell Solution Support web site:

Honeywell Corporate www.honeywellprocess.com

Honeywell Process Solutions www.honeywellprocess.com/pressue-transmitters/

Training Classes http://www.automationccollege.com

Telephone and Email Contacts

Area Organization Phone Number

United States and

Canada

Global Email

Support

Honeywell Inc.

Honeywell Process

Solutions

1-800-343-0228 Customer Service

1-800-423-9883 Global Technical Support

ask-ssc@honeywell.com

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page v

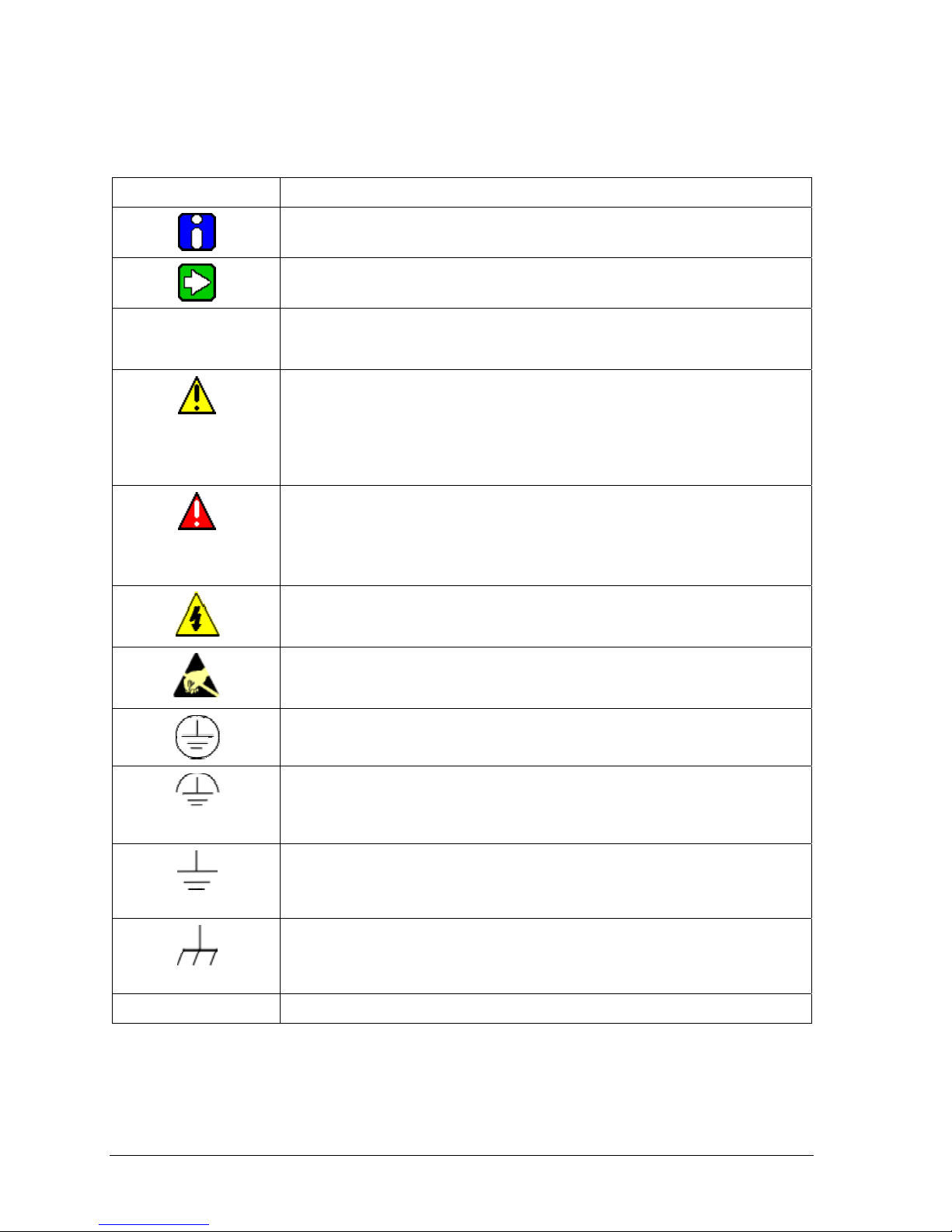

Symbol Descriptions and Definitions

The symbols identified and defined in the following table may appear in this document.

Symbol Definition

CAUTION

ATTENTION: Identifies information that requires special consideration.

TIP: Identifies advice or hints for the user, often in terms of performing a

Indicates a situation which, if not avoided, may result in equipment or work

(data) on the system being damaged or lost, or may result in the inability to

CAUTION: Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

CAUTION symbol on the equipment refers the user to the product manual for

additional information. The symbol appears next to required information in

WARNING: Indicates a potentially hazardous situation, which, if not avoided,

WARNING symbol on the equipment refers the user to the product manual

for additional information. The symbol appears next to required information

WARNING, Risk of electrical shock: Potential shock hazard where

HAZARDOUS LIVE voltages greater than 30 Vrms, 42.4 Vpeak, or 60 VDC

ESD HAZARD: Danger of an electro-static discharge to which equ i pment may

be sensitive. Observe precautions for handling electrostatic sensitive

Protective Earth (PE) terminal: Provided for connection of the protective

earth (green or green/yellow) supply system conductor.

Functional earth terminal: Used for non-safety purposes such as noise

immunity improvement. NOTE: This connection shall be bonded to

Protective Earth at the source of supply in accordance with national local

Earth Ground: Functional earth connection. NOTE: This connection shall be

bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

properly operate the process.

could result in serious injury or death.

may be accessible.

electrical code requirements.

task.

unsafe practices.

the manual.

in the manual.

devices.

Chassis Ground: Identifies a connection to the chassis or frame of the

continued

equipment shall be bonded to Protective Earth at the source of supply in

Page vi ST 700 SmartLine Pressure Transmitters User’s Manual Revision 2.0

accordance with national and local electrical code requirements.

Symbol Description

®

The Factory Mutual

tested and certified to be reliable.

The Canadian Standards mark means the equipment has been tested and meets

applicable standards for safety and/or performance.

The Ex mark means the equipment complies with the requirements of the

European standards that are harmonised with the 94/9/EC Directive (ATEX

Directive, named after the French "ATmosphere EXplosible").

Approval mark means the equipment has been rigorously

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page vii

Contents

1 Introduction .................................................................................................................................... 1

1.1 Overview ................................................................................................................................ 1

1.2 Features and Options .............................................................................................................. 1

1.2.1 Physical Characteristics ................................................................................................. 1

1.2.2 Functional Characteristics .............................................................................................. 2

1.3 ST 700 Transmitter Nameplate .............................................................................................. 3

1.4 Safety Certification Information ............................................................................................ 3

1.5 Transmitter Adjustments ........................................................................................................ 3

1.6 Display Options ..................................................................................................................... 4

1.7 Optional 3-Button Assembly ................................................................................................. 4

2 Application Design ........................................................................................................................ 5

2.1 Overview ................................................................................................................................ 5

2.1.1 Accuracy ........................................................................................................................ 5

2.1.2 Diagnostic Messages ...................................................................................................... 5

2.2 Safety ..................................................................................................................................... 6

2.2.1 Safety Integrity Level (SIL) ........................................................................................... 6

3 Installation and Startup .................................................................................................................. 7

3.1 Installation Site Evaluation .................................................................................................... 7

3.2 Honeywell MC Toolkit .......................................................................................................... 7

3.3 Display Installation Precautions ............................................................................................. 7

3.4 Mounting ST 700 SmartLine Pressure Transmitters .............................................................. 8

3.4.1 Summary ........................................................................................................................ 8

3.4.2 Mounting Di

3.4.3 Bracket Mounting Procedure ......................................................................................... 9

3.4.4 Mounting Transmitters with Small Absolute or Differential Pressure Spans .............. 11

3.4.5 Flange Mounting .......................................................................................................... 12

3.4.6 Remote Diaphragm Seal Mounting Information .......................................................... 13

3.5 Piping the ST 700 Transmitter ............................................................................................. 14

3.5.1 Piping Arrangements .................................................................................................... 14

3.5.2 Suggestions for Transmitter Location .......................................................................... 15

3.5.3 General Piping Guidelines ........................................................................................... 15

3.5.4 Procedure to Install Flange Adapters ........................................................................... 15

3.6 Wiring a Transmitter ............................................................................................................ 16

3.6.1 Overview ...................................................................................................................... 16

3.6.2 Digital System Integration Information ....................................................................... 18

3.6.3 Wiring Variations ......................................................................................................... 18

3.6.4 Wiring Procedure ......................................................................................................... 18

3.6.5 Lightning Protection .................................................................................................... 18

3.6.6 Supply Voltage Limiting Requirements ....................................................................... 18

3.6.7 Process Sealing ............................................................................................................ 19

3.6.8 Explosion-Proof Conduit Seal ..................................................................................... 19

3.7 Startup .................................................................................................................................. 19

3.7.1 Overview ...................................................................................................................... 19

3.7.2 Startup Tasks ................................................................................................................ 19

3.7.3 Output Check Procedures ............................................................................................. 20

3.7.4 Constant Current Source Mode Procedure

mensions

.................................................................................................... 8

...................................................................

20

Page viii ST 700 SmartLine Pressure Transmitters User’s Manual Revision 2.0

4 Operation ...................................................................................................................................... 22

4.1 Overview .............................................................................................................................. 22

4.2 Three-Button Operation ........................................................................................................ 22

4.2.1 The Basic Display Menu .............................................................................................. 23

4.2.2 Data Entry ..................................................................................................................... 27

4.2.3 Editing a Numeric value ............................................................................................... 27

4.2.4 Selecting a new setting from a list of choices .............................................................. 27

4.3 Three Button Operation with no Display Installed ............................................................... 28

4.3.1 Zero Adjustment ........................................................................................................... 28

4.3.2 Span Adjustment .......................................................................................................... 28

4.4 Changing the Default Failsafe Direction .............................................................................. 28

4.4.1 DE and Analog Differences .......................................................................................... 28

4.4.2 Procedure to Establish Failsafe Operation .................................................................... 29

4.5 Monitoring the Basic Display ............................................................................................... 32

4.5.1 Basic Display ................................................................................................................ 32

5 Maintenance ................................................................................................................................. 33

5.1 Overview .............................................................................................................................. 33

5.2 Preventive Maintenance Practices and Schedules ................................................................ 33

5.3 Inspecting and Cleaning Barrier Diaphragms ...................................................................... 33

5.4 Replacing the Communication Module ................................................................................ 36

5.5 Replacing the Meter Body .................................................................................................... 38

6 Calibration .................................................................................................................................... 42

6.1 Recommendations for Transmitter Calibration .................................................................... 42

6.2 Calibration Procedures

7 Troubleshoot

7.1 Overview .............................................................................................................................. 43

7.2 Critical Diagnostics Screens ................................................................................................. 43

7.2.1 Fault Conditions and Recommended Corrective Actions ............................................ 43

8 Parts List ....................................................................................................................................... 44

8 Parts List ....................................................................................................................................... 44

8.1 Overview .............................................................................................................................. 44

Appendix A. PRODUCT CERTIFICATIONS .................................................................................... 56

Index ..................................................................................................................................................... 68

ing ............................................................................................................................ 43

......................................................................................................... 42

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page ix

List of Figures

Figure 1 – ST 700 Major Assemblies .................................................................................................... 2

Figure 2 – Electronics Housing Components ........................................................................................ 2

Figure 3 –Typical ST 700 Name Plate ................................................................................................... 3

Figure 4 – Typical Bracket Mounted and Flange Mounted Installations ............................................... 8

Figure 5 – Angle Mounting Bracket Secured to a Horizontal or Vertical Pipe ..................................... 9

Figure 6 – Inline Model Mounted to an Optional Bracket ................................................................... 10

Figure 7 – Rotating the Electronics Housing ....................................................................................... 10

Figure 8 – Using a Spirit Balance to Level a Transmitter .................................................................... 11

Figure 9 – Tank-Flange Mounted Transmitter ..................................................................................... 12

Figure 10 – Representative Remote Diaphragm Seal Transmitter Installation .................................... 13

Figure 11 – Typical 3-Valve Manifold with Blow-Down Piping ........................................................ 14

Figure 12 – Flange Adapter Removal and Replacement ..................................................................... 16

Figure 13 – Transmitter Operating Ranges .......................................................................................... 16

Figure 14 – Transmitter 3-Screw Terminal Board and Grounding Screw ........................................... 17

Figure 15 – Current Loop Test Connections ........................................................................................ 20

Figure 16 – Three-Button Option ......................................................................................................... 22

Figure 17 – Locating the Failsafe and Write Protect Jumpers ............................................................. 29

Figure 18 – Basic Display with Process Variable Format ................................................................... 32

Figure 19 – DP Transmitter Head Disassembly ................................................................................... 34

Figure 20 – Head Bolt Tightening Sequence ....................................................................................... 35

Figure 21 – PWA Replacement ........................................................................................................... 36

Figure 22 – Disassembly for Meter Body Replacement ...................................................................... 38

Figure 23 – Hardware Location to Remove the Meter Assembly ....................................................... 39

Figure 24 – Meter Body Reassembly ................................................................................................... 40

Figure 25 – Head Bolt Tightening Sequence ....................................................................................... 40

Figure 26 – Angle and Flat Bracket Parts ............................................................................................ 45

Figure 27 – Electronic Housing, Display End ..................................................................................... 47

Figure 28 – Electronic Housing, Terminal Block End ......................................................................... 48

Figure 29 – Transmitter Major Assemblies ......................................................................................... 49

Figure 30 - ST 700 Models STD710, 720, 730, & 770 ........................................................................ 51

Figure 31 – STG730, 740, 770, and STA722, 740 Transmitter Body (Ref.) ....................................... 53

Figure 32 – Inline Gauge and Inline Atmospheric Meter Body Bodies ............................................... 53

Page x ST 700 SmartLine Pressure Transmitters User’ s Manual Revision 2.0

List of Tables

Table 1 – Features and Options .............................................................................................................. 1

Table 2 – Available Display Characteristics .......................................................................................... 4

Table 3 – ST 700 Standard Diagnostics Messages ................................................................................. 5

Table 4 - Mounting Bracket procedure ..................................................................................................... 9

Table 5 – Flange Mounting Guidelines ................................................................................................ 13

Table 6 – Remote Diaphragm Mounting Details .................................................................................. 13

Table 7 – Suggested Connection Locations ......................................................................................... 15

Table 8 – Three-Button Option Functions ............................................................................................ 23

Table 9 – The Basic Display Menus ..................................................................................................... 23

Table 10 – Three-Button Data Entry .................................................................................................... 27

Table 11 – Hart and DE Failsafe and Write Protect Jumpers ............................................................... 30

Table 12 – Fieldbus Simulation and Write Protect Jumpers ................................................................ 30

Table 13 – Head Bolt Torque Values ................................................................................................... 35

Table 14 – Fault Conditions and Recommended Corrective Actions. ................................................. 43

Table 15 – Summary List of Recommended Spare Parts ..................................................................... 44

Table 16 – Angle and Flat Bracket Parts .............................................................................................. 4

Table 17 – Tr

Table 18 – S

Table 19 - I Parts for STG730, 740, 770 and STA722, 740 Transmitter Body .................................... 5

Table 20 - Inline Gauge and Inline Atmospheric Meter Body Parts .................................................... 53

Table 21 – Flange-Mounted Meter Body Parts (Ref Figure 32) .......................................................... 54

ansmitter Major Assemblies ........................................................................................... 4

T 700 Models STD710, 720, 730, 770 & STG774 (Ref. Figure 29) .............................. 50

6

7

2

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page xi

Page xii ST 700 SmartLine Pressure Transmitters User’s Manual Revision 2.0

1 Introduction

1.1 Overview

This section is an introduction to the physical and functional characteristics Honeywell’s family of

ST 700 SmartLine Pressure Transmitters.

1.2 Features and Options

The ST 700 SmartLine Pressure Transmitter is available in a variety of models for measuring

Differential Pressure (DP), Gauge Pressure (GP), and Absolute Pressure (AP). Table 1 lists the

protocols, human interface (HMI), materials, approvals, and mounting bracket options for the ST 700.

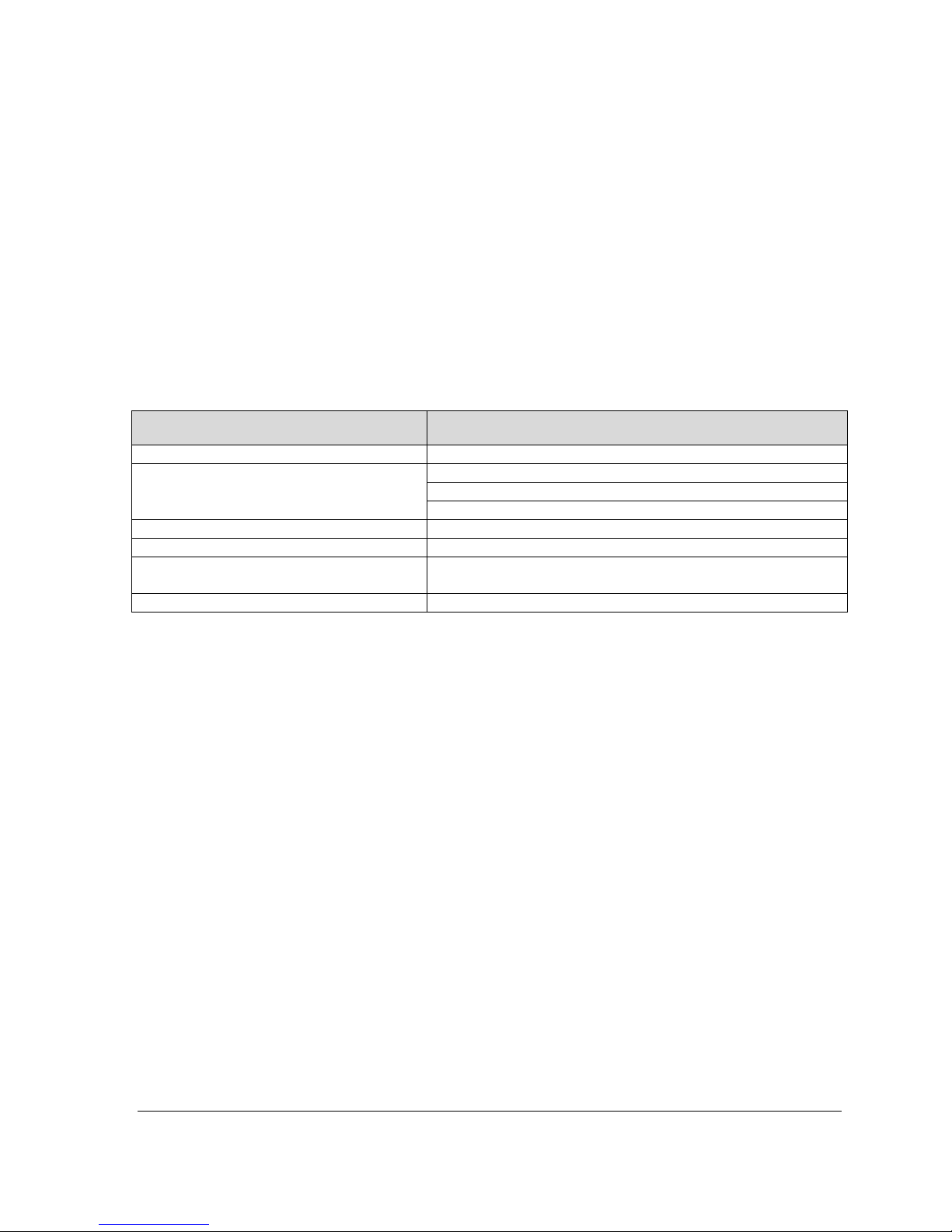

Table 1 – Features and Options

Feature/Option Standard/Available Options

Communication Protocols HART version 7, Digitally Enhanced (DE), Fieldbus

Human-Machine Interface (HMI)

Options (Basic Display)

Calibration Single

Approvals (See Appendix C for details.) ATEX, CSA, FM, IECx, NEPSI

Mounting Brackets Angle/flat carbon steel/304 and 316 stainless steel, Marine

Integration Tools Experion

Basic Digital Display

Three-button programming (optional)

Basic display language: English only

304 stainless steel

1.2.1 Physical Characteristics

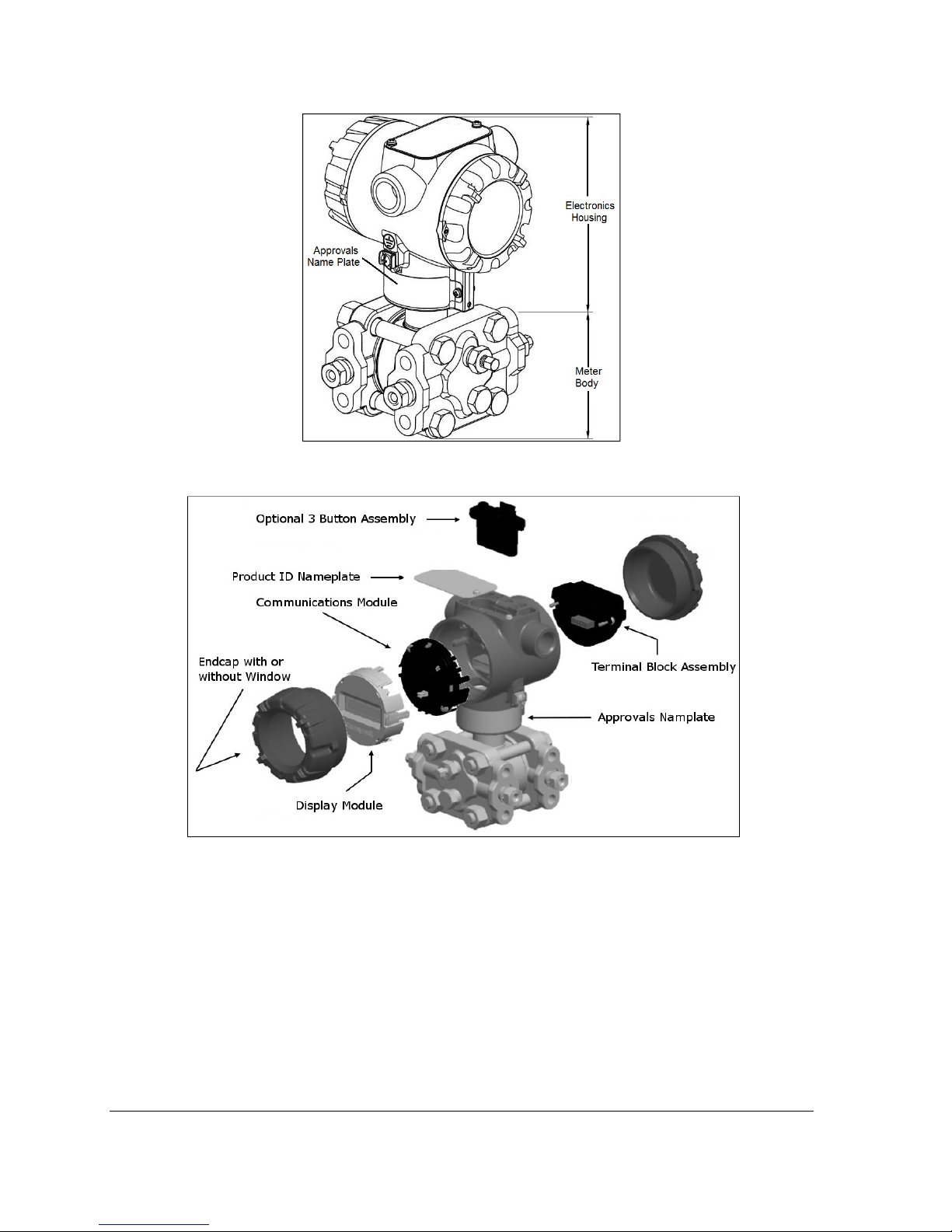

As shown in Figure 1, the ST 700 is packaged in two major assemblies: the Electronics Housing and

the Meter Body. The elements in the Electronic Housing respond to setup commands and execute the

software and protocol for the different pressure measurement types. Figure 2 shows the assemblies in

the Electronics Housing with available options.

The Meter Body provides connection to a process system. Several physical interface configurations

are available, as determined by the mounting and mechanical connections, all of which are described

in the “Installation” section of this manual.

Page iii ST 800 SmartLine Pressure Transmitters User’s Manual Revision 1.0

Figure 1 – ST 700 Major Assemblies

Figure 2 – Electronics Housing Components

1.2.2 Functional Characteristics

Functionally, the Transmitter can measure process pressure and provides a proportional analog 4 to

20 mA output to the measured process variable (PV). Available output communication protocols

include Honeywell Digitally Enhanced (DE), HART, and FOUNDATION Fieldbus.

An optional 3-button assembly is available to set up and make adjustments to the Transmitter. In

addition, a Honeywell Multi-Communication (MC) Toolkit (not supplied with the Transmitter) can

facilitate setup and adjustment procedures. Certain adjustments can be made through an Experion

Station or a Universal Station if the Transmitter is digitally integrated with Honeywell’s Experion or

TPS/TDC 3000 control system.

Page 72 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 1.0

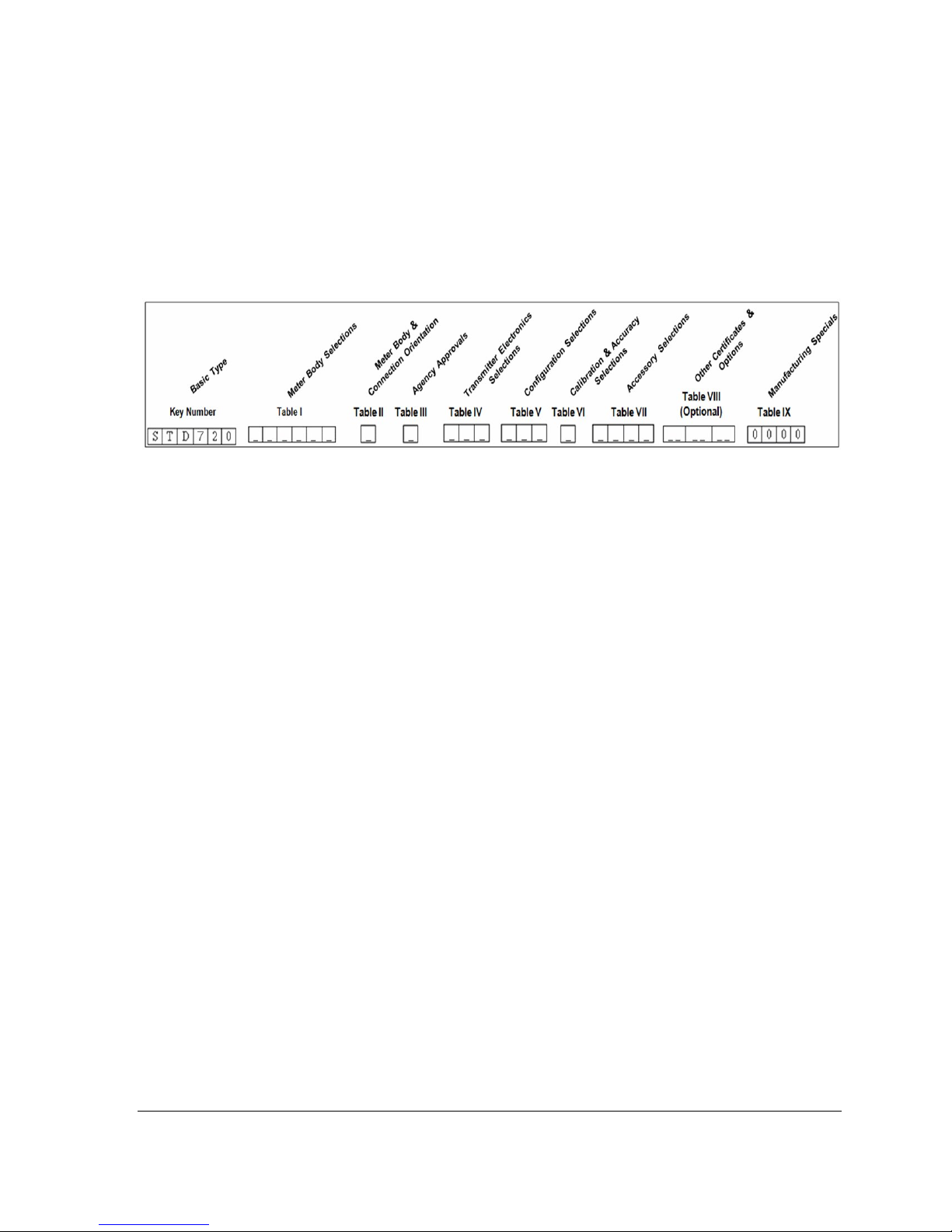

1.3 ST 700 Transmitter Nameplate

The Transmitter nameplate mounted on the bottom of the electronics housing (see Figure 1) lists its

model number, physical configuration, electronics options, accessories, certifications, and

manufacturing specialties. Figure 3 is an example of a typical Gauge Pressure (GP) or Atmospheric

Pressure (AP) Transmitter name plate. The model number format consists of a Key Number with

several table selections. The Differential Pressure (DP), Absolute Pressure (AP), and Gauge Pressure

(GP) name plates are essentially the same. However, the DP provides one additional entry (7 vs. 6) in

the Meter Body Selections (Table I) to accommodate the static pressure rating.

Figure 3 –Typical ST 700 Name Plate

You can readily identify the series and basic Transmitter type from the third and fourth digits in the

key number. The letter in the third digit represents one of these basic transmitter types:

• A = Absolute Pressure • D = Differential Pressure • F = Flange Mounted

• G = Gauge Pressure • R = Remote Seals

For a complete selection breakdown, refer to the appropriate Specification and Model Selection

Guide provided as a separate document.

1.4 Safety Certification Information

An “approvals” name plate is located on the bottom of the Electronics Assembly; see Figure 1for

exact location. The approvals name plate contains information and service marks that disclose the

Transmitter compliance information. Refer to Appendix C of this document for safety certification

requirements and details.

1.5 Transmitter Adjustments

Zero and Span adjustments are possible in ST 700 SmartLine Pressure Transmitters with the optional

three-button assembly located at the top of the Electronic Housing (see Figure 2).

You can also use the Honeywell MC Toolkit or other third-party hand-held zero to make any

adjustments to an ST 700 SmartLine Pressure Transmitter. Alternately, certain adjustments can be

made through the Experion or Universal Station, if the Transmitter is digitally integrated with a

Honeywell Experion or TPS system.

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page 3

1.6 Display Options

The ST 700 SmartLine Pressure Transmitter with Basic Display.

Table 2 – Available Display Characteristics

Basic Display

• Suitable for basic process needs

• 360

• 2 lines, 16 characters

• Standard units-of-measurement: Pa, KPa, MPa, KGcm2, TORR, ATM, inH2O,

• Diagnostic messaging

• Square root output indications

o

rotation in 90o Increments

mH2O, bar, mbar, inHg, FTH2O, mmH2O, MMHG, & PSI

1.7 Optional 3-Button Assembly

The optional 3-Button Assembly provides the following features and capabilities:

• Increment, decrement, and enter key functions.

• With the menu-driven display:

o Comprehensive on-screen menu for navigation.

o Transmitter configuration.

o Transmitter calibration

o Display configuration.

o Set zero and span parameters.

Page 72 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 1.0

2 Application Design

2.1 Overview

This section discusses the considerations involved with deploying a Honeywell ST 700 SmartLine

Pressure Transmitter in a process system. The following areas are covered:

• Safety

• Input and output data

• Reliability

• Environmental limits

• Installation considerations

• Operation and maintenance\

• Repair and replacement

2.1.1 Accuracy

The ST 700 SmartLine Pressure Transmitter (Transmitter) measures the gauge, differential, or

absolute pressure of a process and reports the measurement to a receiving device. Measurements are

accurate up to 0.05 of the calibrated span.

2.1.2 Diagnostic Messages

Transmitter standard diagnostics are reported in the two basic categories listed in Table 3. Problems

detected as critical diagnostics drive the analog output to the programmed burnout level. Problems

detected as non-critical diagnostics may affect performance without driving the analog output to the

programmed burnout level. Informational messages (not listed in Table 3) report various Transmitter

status or setting conditions. The messages listed in Table 3 are specific to the Transmitter, exclusive

of those associated with HART and DE protocols. HART and DE diagnostic messages are listed and

described in the ST 700 SmartLine Pressure Transmitter HART/DE Option User Manual, document

number 34-ST-25-47.

Table 3 – ST 700 Standard Diagnostics Messages

Critical Diagnostics

(Failure Conditions)

Sensor Comm Timeout

Meter Body Critical Failure

Electronic Module Diag Failure

Config Data Corrupt

Meter Body NVM Corrupt

Electronic Module DAC Failure

No DAC Compensation

No Factory Calibration

PV Out of Range

Fixed Current Mode

Sensor Over Temperature

Meter Body Excess Correct

No DAC Compensation

No Factory Calibration

Local Display

Low Supply Voltage

Non-Critical Diagnostics (Warning Conditions)

No DAC Calibration

Tamper Alarm

Meter Body Unreliable Comm

Loop Current Noise

AO Out of Range

URV Set Error – Span Config

Button

LRV Set Error – Span Config

Button

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page 5

2.2 Safety

2.2.1 Safety Integrity Level (SIL)

The ST 700 is intended to achieve sufficient integrity against systematic errors by the manufacturer’s

design. A Safety Instrumented Function (SIF) designed with this product must not be used at a SIL

level higher than the statement, without “prior use” justification by the end user or diverse technology

redundancy in the design. Refer to the Honeywell SmartLine Safety Manual, 34-ST-25-37, for

additional information.

Page 72 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 1.0

3 Installation and Startup

3.1 Installation Site Evaluation

Evaluate the site selected for the ST 700 Transmitter installation with respect to the process system

design specifications and Honeywell’s published performance characteristics for your particular

model. Some parameters that you may want to include in your site evaluation are:

• Environmental Conditions:

o Ambient Temperature

o Relative Humidity

• Potential Noise Sources:

o Radio Frequency Interference (RFI)

o Electromagnetic Interference (EMI)

• Vibration Sources

o Pumps

o Motorized System Devices (e.g., pumps)

o Valve Cavitation

• Process Parameters

o Temperature

o Maximum Pressure Rating

3.2 Honeywell MC Toolkit

In preparation for post-installation processes, refer to the MC Tookit User Manual, Document # 34-

ST-25-20, for battery conditioning and device operation and maintenance information.

3.3 Display Installation Precautions

Temperature extremes can affect display quality. The display can become unreadable at temperature

extremes; however, this is only a temporary condition. The display will again be readable when

temperatures return to within operable limits.

The display update rate may increase at cold temperature extremes, but as with readability, normal

updating resumes when temperatures are within limits for full operability.

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page 7

3.4 Mounting ST 700 SmartLine Pressure Transmitters

3.4.1 Summary

Transmitter models, except flush mounts and those with integral flanges, can be attached to a twoinch (50 millimeter) vertical or horizontal pipe using Honeywell’s optional angle or flat mounting

bracket; alternately you can use your own bracket. Flush-mount models are attached directly to a

process pipe or tank by a one-inch weld nipple. Models with integral flanges are supported by the

flange connection.

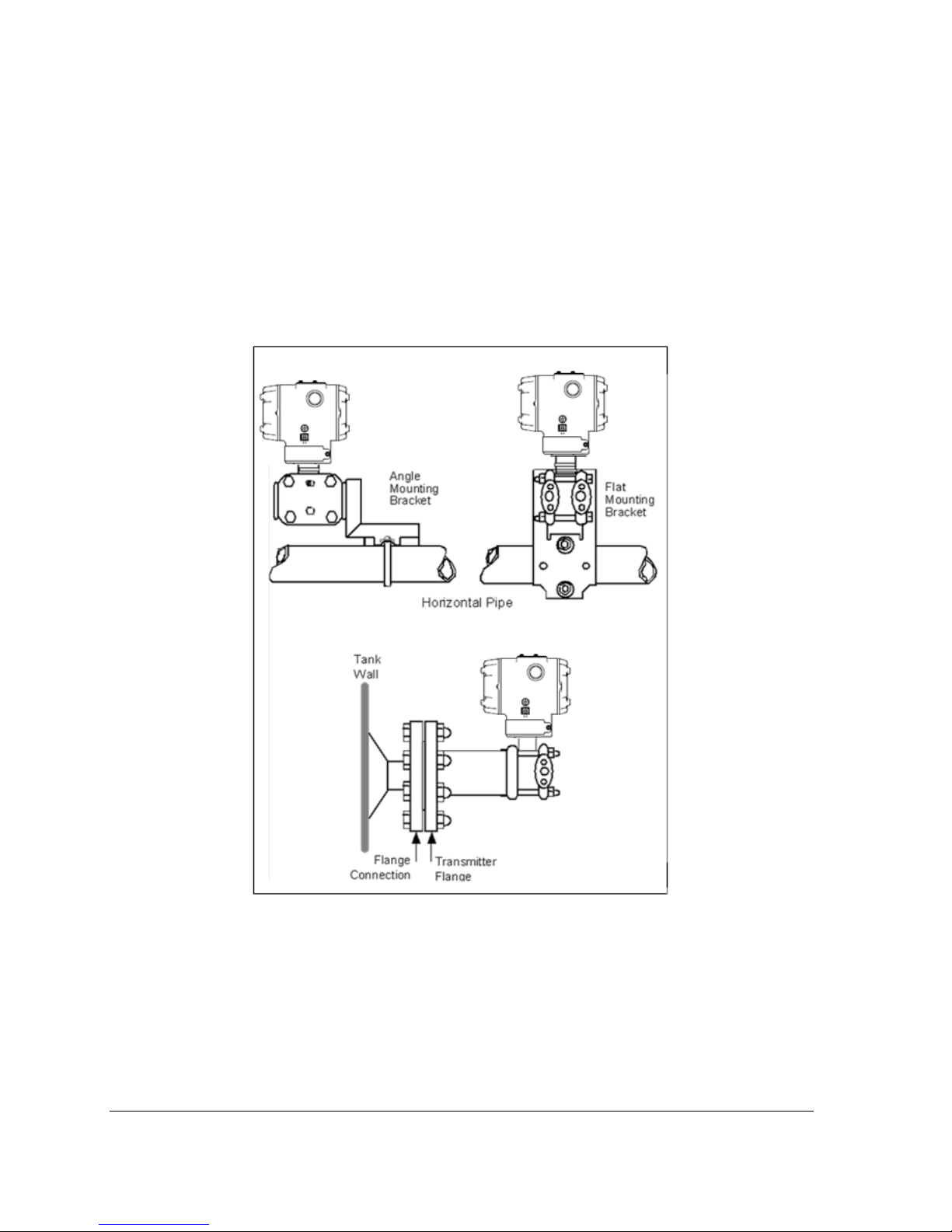

Figure 4 shows typical bracket-mounted and flange-mounted transmitter installations.

Figure 4 – Typical Bracket Mounted and Flange Mounted Installations

3.4.2 Mounting Dimensions

Refer to Honeywell drawing number 50049930 (Dual Head), 50049931 (In-Line), 50049932 (Flange

Mount) 50049933 (Extended Flange), and 50049934 (Remote Seal) for detailed dimensions.

Abbreviated overall dimensions are also shown on the Specification Sheets for the transmitter

models. This section assumes that the mounting dimensions have already been taken into account and

the mounting area can accommodate the Transmitter.

Page 72 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 1.0

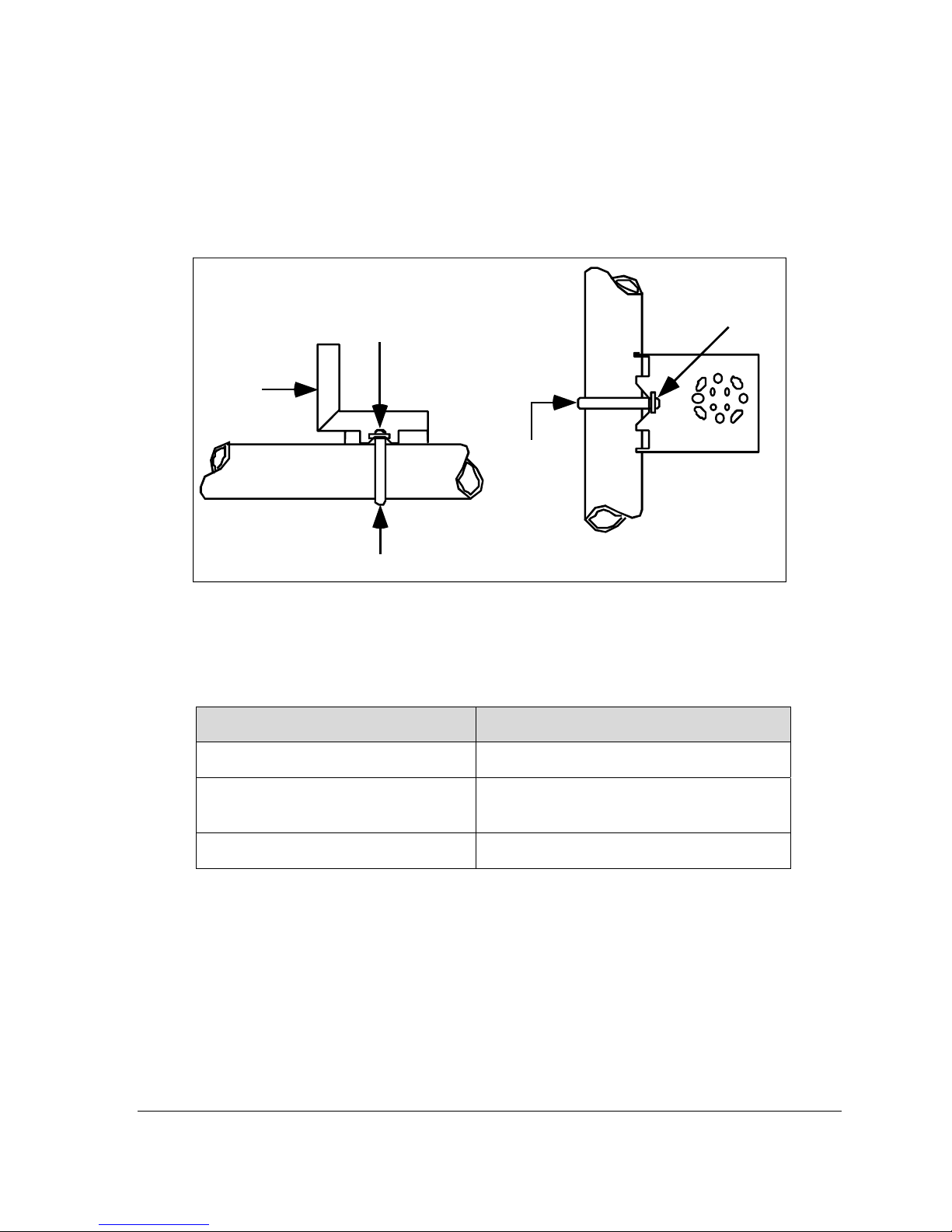

3.4.3 Bracket Mounting Procedure

If you are using an optional bracket, start with Step 1. For an existing bracket, start with Step 2.

1. Refer to Figure 5. Position the bracket on a 2-inch (50.8 mm) horizontal or vertical pipe, and

install a “U” bolt around the pipe and through the holes in the bracket. Secure the bracket

with the nuts and lock washers provided.

Nuts and

Lockwashers

Mounting

Bracket

U-Bolt

Nuts and

Lockwashers

Mounting

Bracket

Horizontal Pipe

Vertical P ipe

U-Bolt

Figure 5 – Angle Mounting Bracket Secured to a Horizontal or Vertical Pipe

2. Align the appropriate mounting holes in the Transmitter with the holes in the bracket. Use the

bolts and washers provided to secure the Transmitter to the bracket; see the following

variations.

Table 4 Mounting Bracket procedure

Transmitter Type Use Hardware

DP with double-ended process heads

and/or remote seals

In-line GP and AP (STGxxL and

STAxxL)

Dual-head GP and AP

EXAMPLE: Inline model mounted to an optional angle bracket. See Figure 6.

Alternate mounting holes in the ends of the

heads

The smaller “U” bolt provided to attach the

meter body to the bracket. See the

following example.

Mounting holes in the end of the process

head.

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page 9

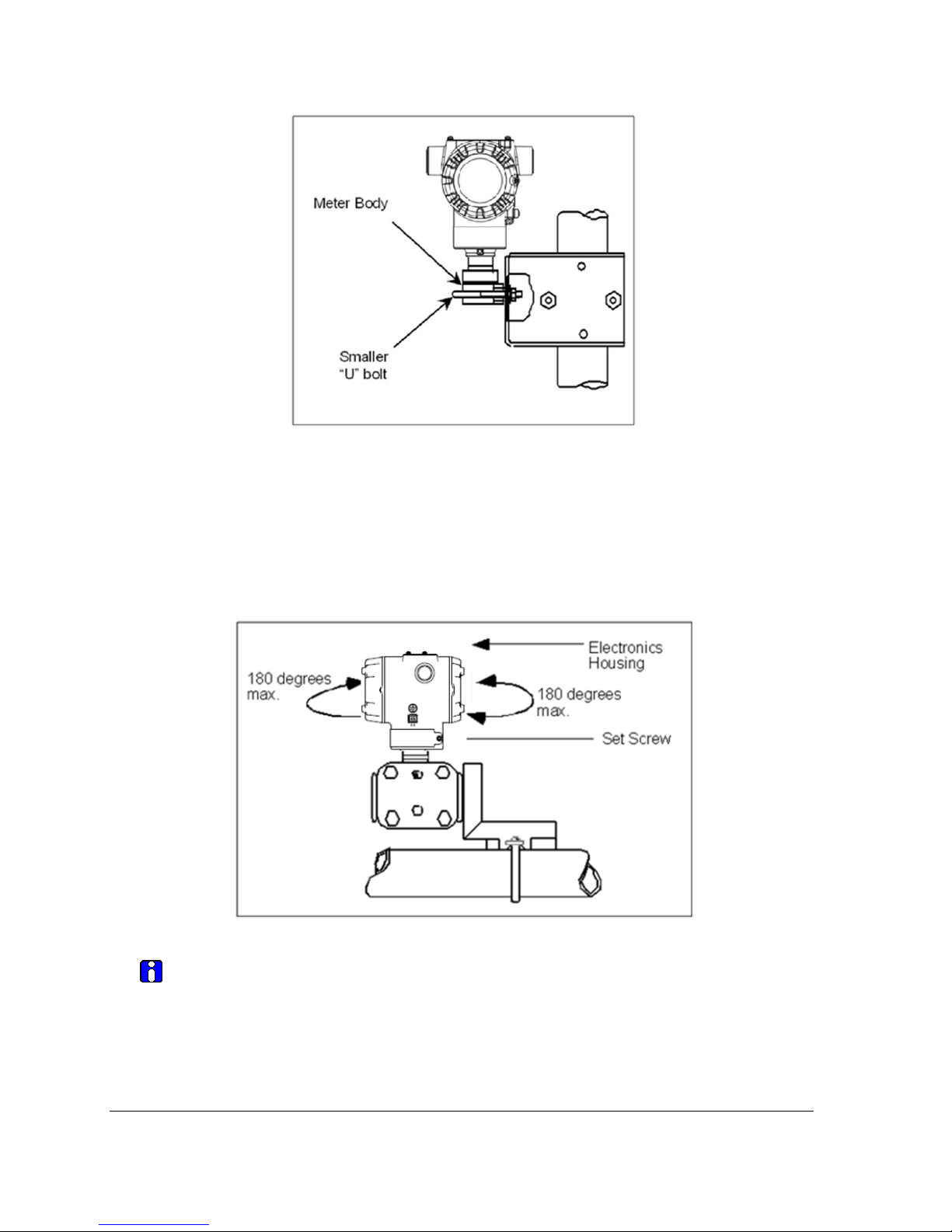

Figure 6 – Inline Model Mounted to an Optional Bracket

3. Loosen the set screw on the outside neck of the Transmitter one (1) full turn.

4. Rotate the Electronics housing a maximum of 180

o

left or right from the center to the position

you require, and tighten the set screw 8.9 to 9.7 pound-inches (1.40 to 1.68 Newton meters),

using a 4mm metric socket head wrench. See the following example and Figure 7.

EXAMPLE: Rotating the Electronics Housing

Figure 7 – Rotating the Electronics Housing

The mounting position of absolute pressure models STA822, STA82L, or a draft

range model STD810 is critical as the Transmitter spans become smaller.

A maximum zero shift of 2.5 mmHg for an Absolute Transmitter or 1.5 inches of

water (inH

that is rotated 90

O) for a Draft Range Transmitter can result from a mounting position

2

o

from the vertical. A typical zero-shift of 0.12 mmHg or 0.20 inH2O

can occur for a five (5)-degree rotation from the vertical.

Page 72 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 1.0

3.4.4 Mounting Transmitters with Small Absolute or Differential Pressure

Spans

To minimize positional effects on calibration (zero shift), take the appropriate

mounting precautions for the respective Transmitter model. For a model STA722 or

STA72L, ensure that the Transmitter is vertical when mounting it. You do this by

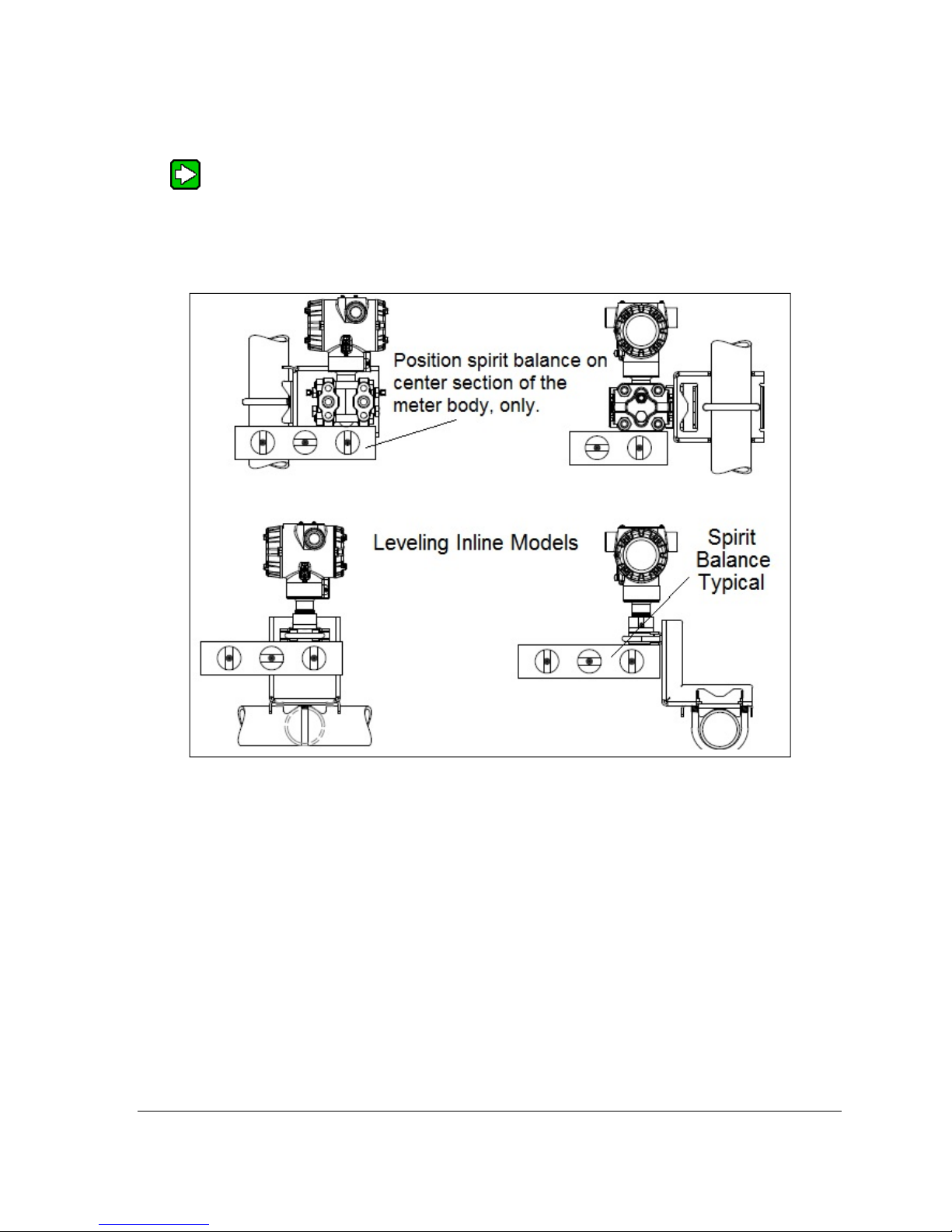

leveling the Transmitter side-to-side and front-to-back. Figure 8 shows how to level

a Transmitter using a spirit level.

Figure 8 – Using a Spirit Balance to Level a Transmitter

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page 11

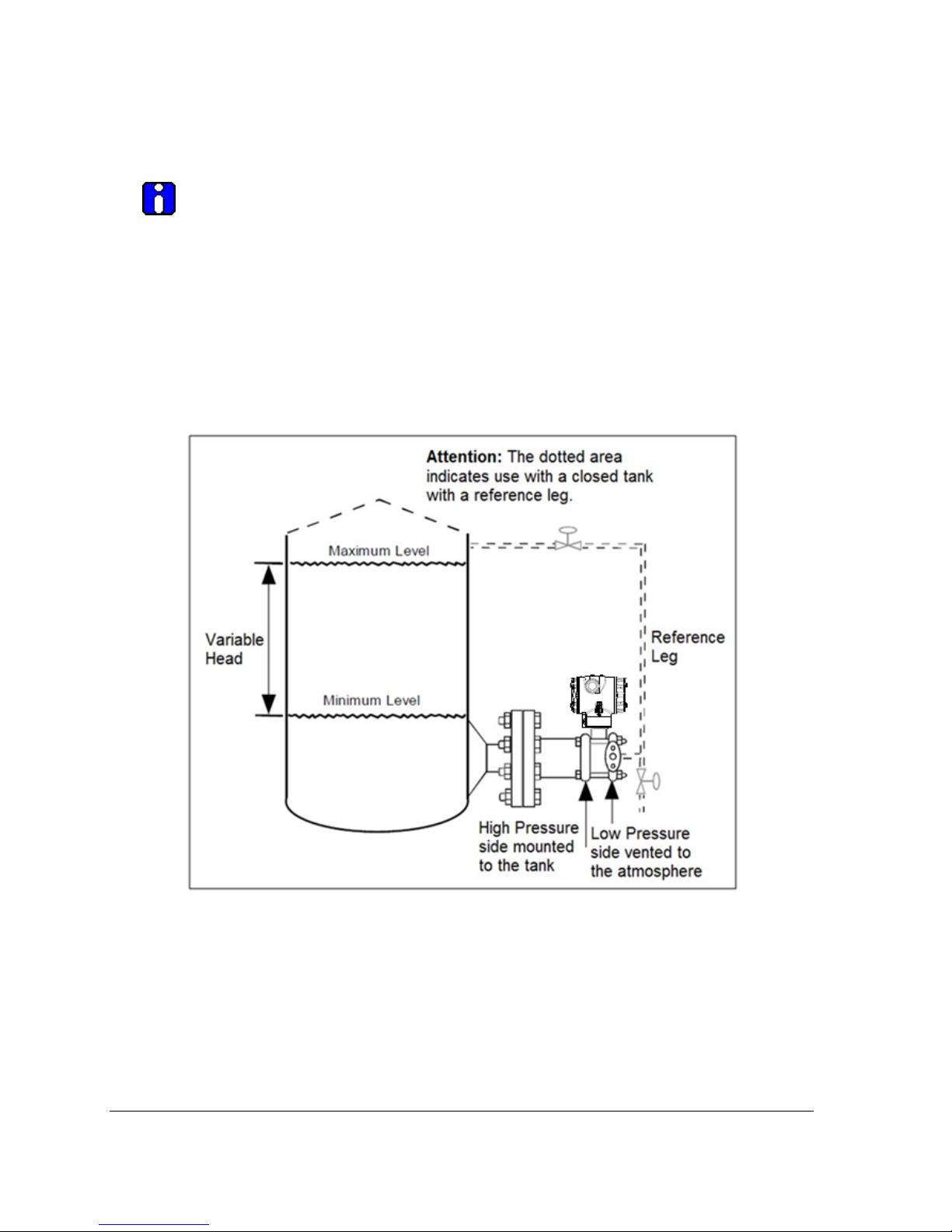

3.4.5 Flange Mounting

Figure 9 shows a typical tank-flange mount installation, with the Transmitter flange mounted to the

pipe on the wall of the tank.

On insulated tanks, remove enough insulaiton to accommodate the flange

extension.

When flange-mounting to a tank, note the following:

• The End User is responsible for providing a flange gasket and mounting hardware suitable for

the Transmitter service conditions.

• To avoid degrading performance in flush-mounted flanged Transmitters, exercise care to

ensure that the internal diameter of the flange gasket does not obstruct the sensing diaphragm.

• To prevent performance degradation in extended-mount flanged Transmitters, ensure that

sufficient clearance exists in front of the sensing diaphragm body.

Figure 9 – Tank-Flange Mounted Transmitter

Page 72 ST 700 SmartLine Pressure Transmitters User’s Manual Revision 1.0

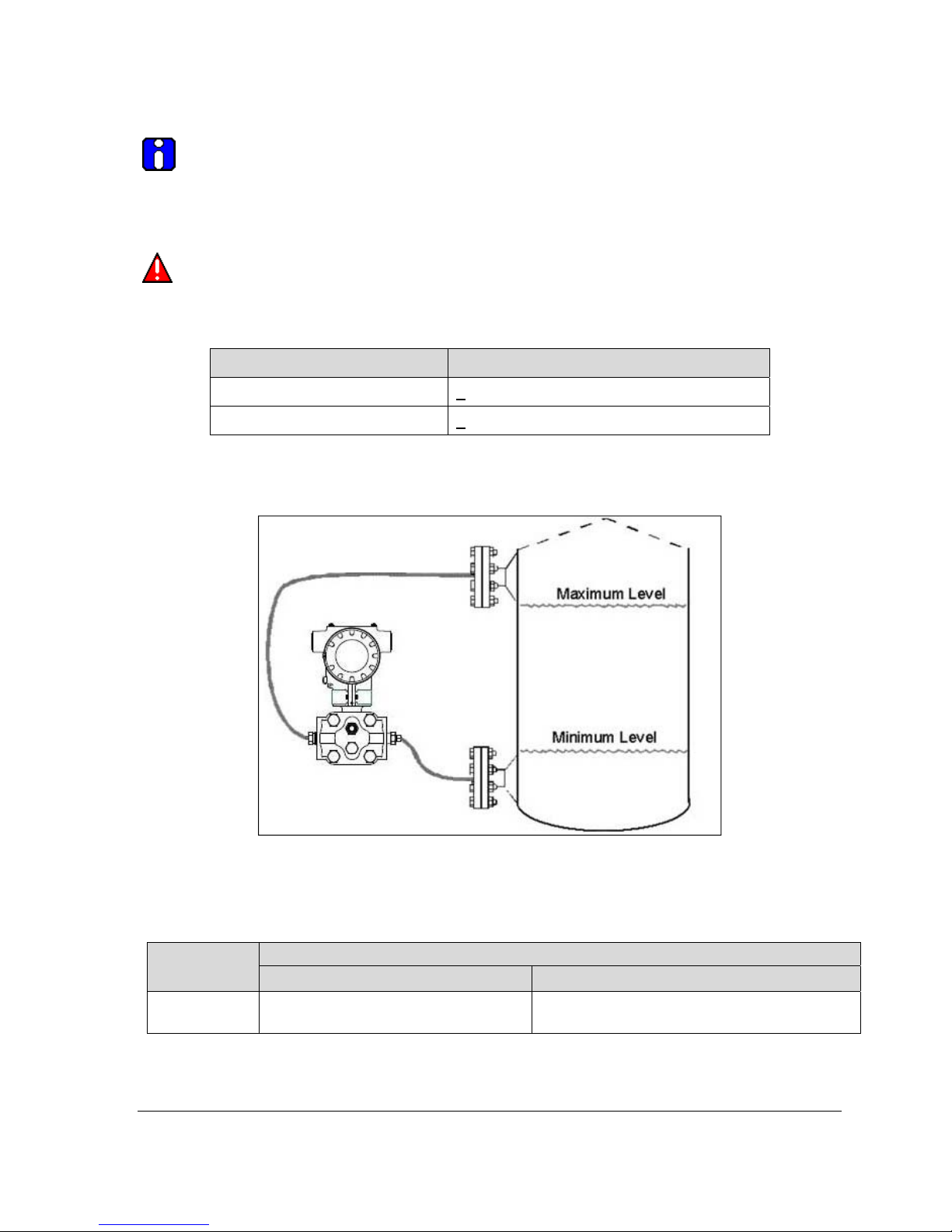

3.4.6 Remote Diaphragm Seal Mounting Information

The combination of tank vacuum and high pressure capillary head effect should not

exceed nine (9) psi (300 mmHg) absolute. For insulated tanks, be sure to remove enough

insulation to accommodate the flange extension. The end user is responsible for supplying a

flange gasket and mounting hardware suitable for the service condition of the Transmitter.

Mount the Transmitter flanges within the limits in Table 5 for the fill fluid in the capillary

tubes, with a tank at one (1) atmosphere.

Table 5 – Flange Mounting Guidelines

Fill Fluid Mount the Flange…

Silicone 200 Oil <22 feet (6.7 meters) below the Transmitter

Chlorotrifluorethylene (CTFE) <11 feet (3.4 meters) below the Transmitter

Refer to for a representative remote diaphragm seal installation. Mount the Transmitter at a remote

distance determined by the length of the capillary tubing.

Figure 10 – Representative Remote Diaphragm Seal Transmitter Installation

Depending on Transmitter model, connect the remote seal to the tank according to Table 6.

Transmitter

Model

STR73D

Transmitter High Pressure (HP) Side

to tank wall lower flange mounting.

Revision 2.0 ST 700 Smart Pressure Transmitter User’s Manual Page 13

Table 6 – Remote Diaphragm Mounting Details

Connect the Remote Seal on ….

Variable Head Fixed or Constant Head

Transmitter Low Pressure (LP) side to tank

wall upper flange.

Loading...

Loading...