Honeywell SmartDrive Compact User Manual

Ho

Honeywell

Complete User Manual

SmartDrive Compact

Constan and variable torque

Variable Frequency Drives

for Induction motors

Subject to changes without notice

Honeywell 1

User’s Manual

Index

1. SAFETY ..........................................................................................3

1.1 Warnings ................................................................................3

1.2 Safety instructions .................................................................. 5

1.3 Grounding and earth fault protection......................................5

1.4 Before running the motor........................................................6

2. RECEIPT OF DELIVERY ................................................................ 7

2.1 Type designation code ........................................................... 7

2.2 Storage................................................................................... 7

2.3 Maintenance........................................................................... 7

2.4 Warranty................................................................................. 8

3. INSTALLATION ..............................................................................9

3.1 Mechanical installation ........................................................... 9

3.1.1 SmartDrive Compact dimensions ................................10

3.1.2 Cooling......................................................................... 10

3.1.3 EMC-levels...................................................................11

3.1.4 Changing the EMC protection class.............................12

3.2 Cabling and connections ........................................................13

3.2.1 Power cabling .............................................................. 13

3.2.2 Control cabling .............................................................14

3.2.3 Cable and fuse specifications ...................................... 16

3.2.4 General cabling rules ...................................................17

3.2.5 Stripping lengths of motor and mains cables...............18

3.2.6 Cable installation and the UL standards ......................18

3.2.7 Cable and motor insulation checks ..............................19

4. COMMISSIONING........................................................................... 20

4.1 Commissioning steps of SmartDrive Compact....................... 20

5. FAULT TRACING ........................................................................... 22

6. SMARTDRIVE COMPACT CONTROL CONNECTIONS ...............25

6.1 Introduction.............................................................................25

6.2 Control I/O ..............................................................................26

7. CONTROL PANEL..........................................................................27

7.1 General...................................................................................27

7.2 Display....................................................................................27

7.3 Keypad ...................................................................................28

7.4 Navigation on the SmartDrive Compact control panel ...........29

7.4.1 Main menu ...................................................................29

7.4.2 Reference menu .......................................................... 30

7.4.3 Monitoring menu ..........................................................30

2 Honeywell

7.4.4 Parameter menu...........................................................32

7.4.5 Fault history menu ........................................................33

8. PARAMETERS................................................................................34

8.1 Quick setup parameters (Virtual menu, shows when par. 3.1 = 1)

..............................................................................................35

8.2 Motor settings (Control panel: Menu PAR -> P1) ...................37

8.3 Start/stop setup (Control panel: Menu PAR -> P2).................38

8.4 Frequency references (Control panel: Menu PAR -> P3).......38

8.5 Ramps and brakes setup (Control panel: Menu PAR -> P4)..39

8.6 Digital inputs (Control panel: Menu PAR -> P5) .....................39

8.7 Analogue inputs (Control panel: Menu PAR -> P6)................40

8.8 Digital and analogue outputs (Control panel: Menu PAR -> P7)

..............................................................................................41

8.9 Protections (Control panel: Menu PAR -> P9)........................42

8.10 Autorestart parameters (Control panel: Menu PAR -> P10).42

8.11 PI control parameters (Control panel: Menu PAR -> P12) ...43

8.12 Easy usage menu (Control panel: Menu PAR -> P0)..........44

8.13 System parameters ..............................................................44

9. PARAMETER DESCRIPTIONS ......................................................46

9.1 Motor settings (Control panel: Menu PAR -> P1) ...................46

9.2 Start/Stop setup (Control panel: Menu PAR -> P2)................50

9.3 Frequency references (Control panel: Menu PAR -> P3).......53

9.4 Ramps & brakes setup (Control panel: Menu PAR -> P4) .....54

9.5 Digital inputs (Control panel: Menu PAR -> P5) .....................58

9.6 Analoque inputs (Control panel: Menu PAR -> P6)................59

9.7 Digital and analoque outputs (Control panel: Menu PAR -> P7)

..............................................................................................59

9.8 Motor thermal protection (parameters 9.7 - 9.10)...................60

9.9 Autorestart parameters (Control panel: Menu PAR -> P10)..63

9.10 PI control parameters (Control panel: Menu PAR -> P12) ...63

9.11 Easy usage menu (Control panel: Menu PAR -> P9)...........65

9.12 Fieldbus parameters (Control panel: Menu PAR -> S2).......66

9.12.1 Modbus process data .................................................67

10. TECHNICAL DATA .......................................................................70

10.1 SmartDrive Compact technical data .....................................70

10.2 Power ratings........................................................................72

10.2.1 SmartDrive Compact - Mains voltage 208 - 240 V.....72

10.2.2 SmartDrive Compact - Mains voltage 380 - 480 V.....73

Honeywell Safety 3

ONLY A COMPETENT ELECTRICIAN IS ALLOWED TO

CARRY OUT THE ELECTRICAL INSTALLATION!

1. SAFETY

This manual contains clearly marked cautions and warnings which are intended for

your personal safety and to avoid any unintentional damage to the product or connected appliances.

Please read the information included in cautions and warnings carefully:

= Dangerous voltage

Risk of death or severe injury

= General warning

Risk of damage to the product or connected appliances

1.1 WARNINGS

The components of the power unit of the inverter are live when

SmartDrive Compact is connected to mains potential. Coming into

contact with this voltage is extremely dangerous and may cause

1

death or severe injury. The control unit is isolated from the mains

potential.

The motor terminals U, V, W (T1, T2, T3) and the possible brake

resistor terminals -/+ are live when inverter is connected to mains,

2

even if the motor is not running.

The control I/O-terminals are isolated from the mains potential.

However, the relay output terminals may have a dangerous control

3

voltage present even when inverter is disconnected from mains.

The earth leakage current of SmartDrive Compact inverters

exceeds 3.5mA AC. According to standard EN61800-5-1, a rein-

4

forced protective ground connection must be ensured.

If the inverter is used as a part of a machine, the machine manufacturer is responsible for providing the machine with a main

5

switch (EN 60204-1).

1

1

4 Safety Honeywell

If SmartDrive Compact is disconnected from mains while running

the motor, it remains live if the motor is energized by the process.

In this case the motor functions as a generator feeding energy to

6

the inverter.

After disconnecting the inverter from the mains, wait until the fan

stops and the indicators on the display go out. Wait 5 more min-

7

utes before doing any work on power connections.

Honeywell Safety 5

1.2 SAFETY INSTRUCTIONS

The SmartDrive Compact inverter has been designed for fixed

1

installations only.

Do not perform any measurements when the inverter is connected

2

to the mains.

Do not perform any voltage withstand tests on any part of Smart-

3

Drive Compact. The product safety is fully tested at factory.

Prior to measurements on the motor or the motor cable, disconnect

4

the motor cable from the inverter.

Do not open the cover of SmartDrive Compact. Static voltage discharge from your fingers may damage the components. Opening

5

the cover may also damage the device. If the cover of SmartDrive

Compact is opened, warranty becomes void.

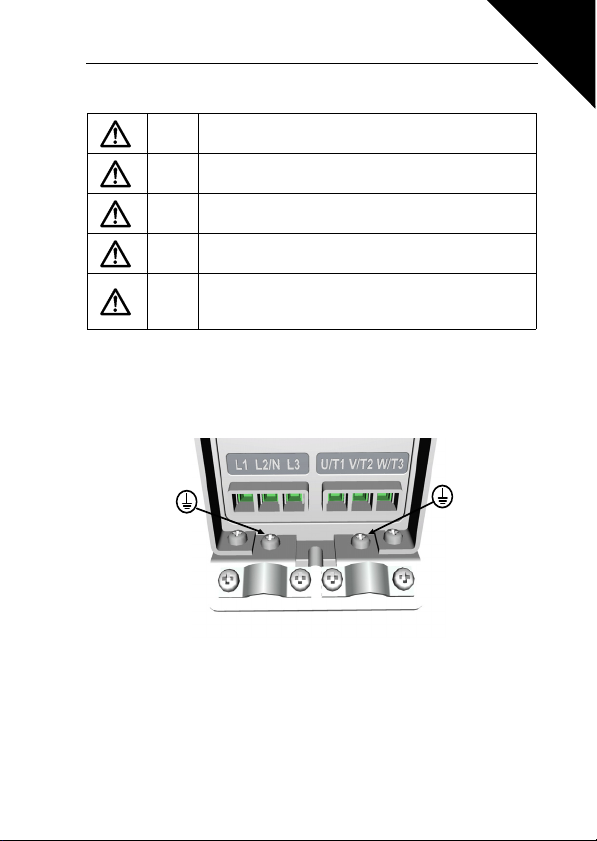

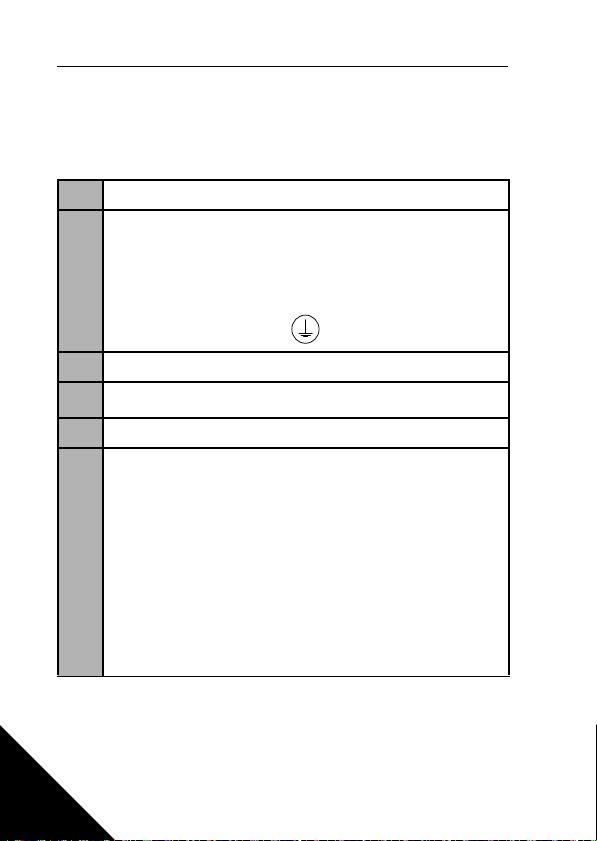

1.3 GROUNDING AND EARTH FAULT PROTECTION

The SmartDrive Compact inverter must always be earthed with an grounding conductor connected to the grounding terminal. See figure below:

1

• The earth fault protection inside the inverter protects only the con-

verter itself against earth faults.

• If fault current protective switches are used they must be tested

with the drive with earth fault currents that are possible to arise in

fault situations.

1

6 Safety Honeywell

1.4 BEFORE RUNNING THE MOTOR

Checklist:

Before starting the motor, check that the motor is mounted

properly and ensure that the machine connected to the motor

allows the motor to be started.

Set the maximum motor speed (frequency) according to the

motor and the machine connected to it.

Before reversing the motor shaft rotation direction make sure

that this can be done safely.

Make sure that no power correction capacitors are connected

to the motor cable.

Honeywell Receipt of Delivery 7

COMP400-1P1-20

Product range:

COMP = SmartDrive Compact

Nominal voltage:

230 = 208-240 Vac (1~ input, 3~ output)

400 = 380-500 Vac

Nominal power:

P75 = 0.75 kW

1P1 = 1.1 kW

Etc.

Enclosure class:

20 = IP20

COMP400-1P1-20

Product range:

COMP = SmartDrive Compact

Nominal voltage:

230 = 208-240 Vac (1~ input, 3~ output)

400 = 380-500 Vac

Nominal power:

P75 = 0.75 kW

1P1 = 1.1 kW

Etc.

Enclosure class:

20 = IP20

2. RECEIPT OF DELIVERY

After unpacking the product, check that no signs of transport damages are to be

found on the product and that the delivery is complete (compare the type designation

of the product to the code below).

Should the drive have been damaged during the shipping, please contact primarily

the cargo insurance company or the carrier.

If the delivery does not correspond to your order, contact the supplier immediately.

2.1 TYPE DESIGNATION CODE

Figure 2.1: SmartDrive Compact type designation code

2.2 STORAGE

If the inverter is to be kept in store before use make sure that the ambient conditions

are acceptable:

Storing temperature-40…+70°C

Relative humidity < 95%, no condensation

2.3 MAINTENANCE

In normal operating conditions, SmartDrive Compact inverters are maintenancefree.

2

8 Receipt of Delivery Honeywell

2.4 WARRANTY

Honeywell’s time of warranty is 30 months from the delivery or 24 months from the

commissioning whichever expires first (General Conditions NL92/Orgalime S92 ).

2

Honeywell Installation 9

MI2-3MI1

=M 4

=M 5

12

3. INSTALLATION

3.1 MECHANICAL INSTALLATION

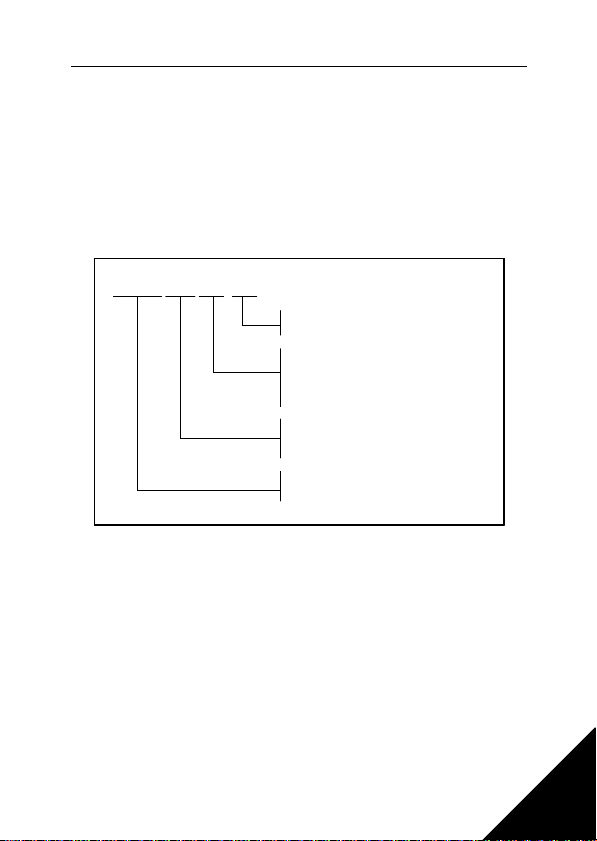

There are two possible ways to mount SmartDrive Compact in the wall; either screw

or DIN-rail mounting. The mounting dimensions are given on the back of the drive

and on the following page.

Figure 3.1: Screw mounting

3

Figure 3.2: DIN-rail mounting

3

W1

W2

W3

H1

H2D1H3

D2

10 Installation Honeywell

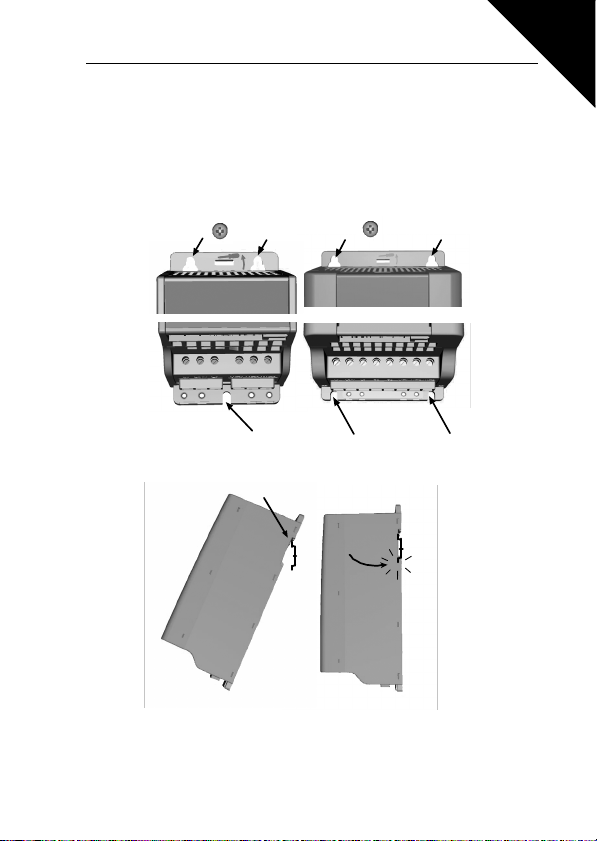

3.1.1 SmartDrive Compact dimensions

Figure 3.3: SmartDrive Compact dimensions, MI1-MI3

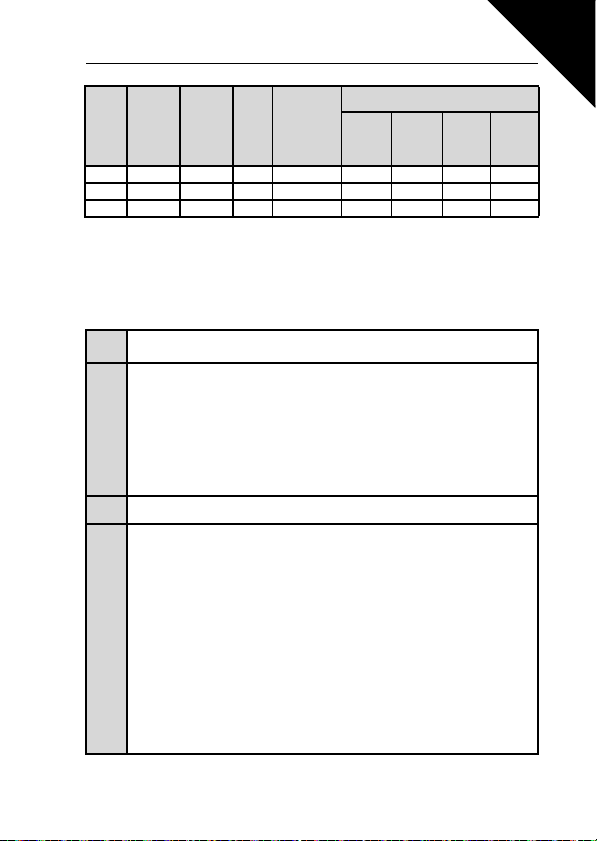

Typ e H1 H2 H3 W1 W2 W3 D1 D2

MI1 156,5 147 137,3 65,5 37,8 4,5 98,5 7

MI2 195 183 170 90 62,5 5,5 101,5 7

MI3 262,5 252,3 241,3 100 75 5,5 108,5 7

Table 3.1 : SmartDrive Compact dimensions in millimetres

3.1.2 Cooling

Forced air flow cooling is used in all SmartDrive Compact drives.

Enough free space shall be left above and below the inverter to ensure sufficient air

circulation and cooling. You will find the required dimensions for free space in the table below:

Honeywell Installation 11

A

B

Typ e Dimensions (mm)

AB

MI1 100 50

MI2 100 50

MI3 100 50

Table 3.2 : Dimensions required for cooling

3

Typ e

MI1 10

MI2 10

MI3 30

Table 3.3 : Required cooling air

Note! Side-to-side installation allowed only if the ambient temperature is below 40

degrees Celsius.

Cooling air required (m3/h)

3.1.3 EMC-levels

SmartDrive Compact inverters are divided into three classes according to the level

of electromagnetic disturbances emitted, the requirements of a power system network and the installation environment (see below). The EMC class of each product

is defined in the type designation code.

Category C1 (Honeywell EMC class C): Inverters of this class comply with the requirements of category C1 of the product standard EN 61800-3 (2004). Category C1

ensures the best EMC characteristics and it includes converters the rated voltage of

which is less than 1000V and which are intended for use in the 1st environment. This

EMC class is meant for highly sensitive areas and can be sometimes required in installations in e.g. hospitals or airport control towers.

NOTE: The requirements of class C1 are fulfilled only as far as the conducted emissions are concerned with an external EMC-filter.

Category C2 (Honeywell EMC class H): All Honeywell SmartDrive Compact inverters comply with the requirements of category C2 of the product standard EN 618003 (2004). Category C2 includes converters in fixed installations and the rated voltage

of which is less than 1000V. The class H inverters can be used both in the 1st and

the 2nd environment. This category fulfills the requirements with normal installations

in buildings.

3

12 Installation Honeywell

IT networks (Honeywell EMC class T): Inverters of this class fulfil the product

standard EN 61800-3 (2004) if intended to be used in IT systems. In IT systems, the

networks are isolated from earth, or connected to earth through high impedance to

achieve a low leakage current. NOTE: if inverters are used with other supplies, no

EMC requirements are complied with. SmartDrive Compact inverters can be easily

modified to the requirements of the T-class. This class is very typical requirement

also in installations in ships.

Environments in product standard EN 61800-3 (2004)

First environment: Environment that includes domestic premises. It also includes

establishments directly connect ed without intermediate transformers to a low-voltage

power supply network which supplies buildings used for domestic purposes.

NOTE: houses, apartments, commercial premises or offices in a residential building

are examples of first environment locations.

Second environment: Environment that includes all establishments other than

those directly connected to a low-voltage power supply network which supplies buildings used for domestic purposes.

NOTE: industrial areas, technical areas of any building fed from a dedicated transformer are examples of second environment locations.

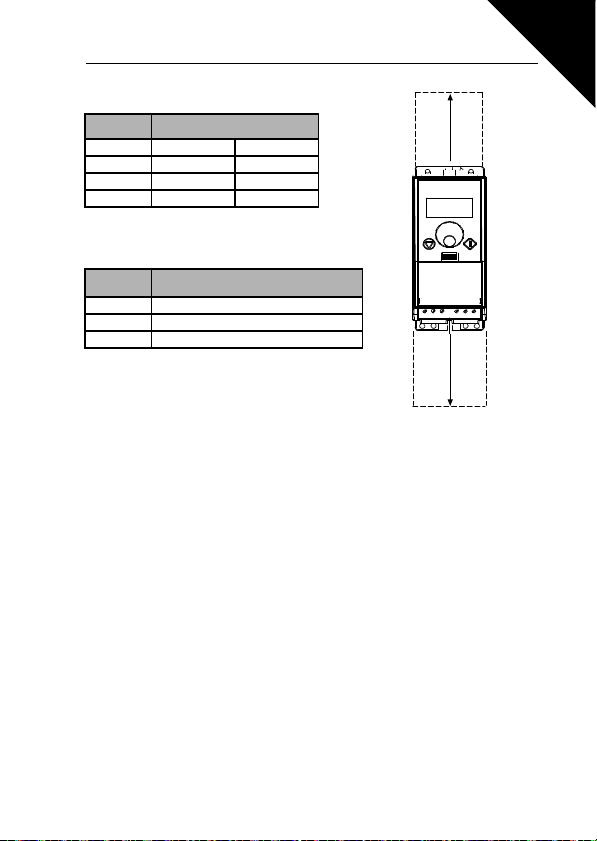

3.1.4 Changing the EMC protection class

The EMC protection class of SmartDrive Compact inverters can be changed from

class H by removing the EMC-capacitor disconnecting screw, see figure below.

Note! Do not attempt to change the EMC level back to class H. Even if the proce-

dure above is reversed, the inverter will no longer fulfil the EMC requirements of

class H!

Honeywell Installation 13

3.2 CABLING AND CONNECTIONS

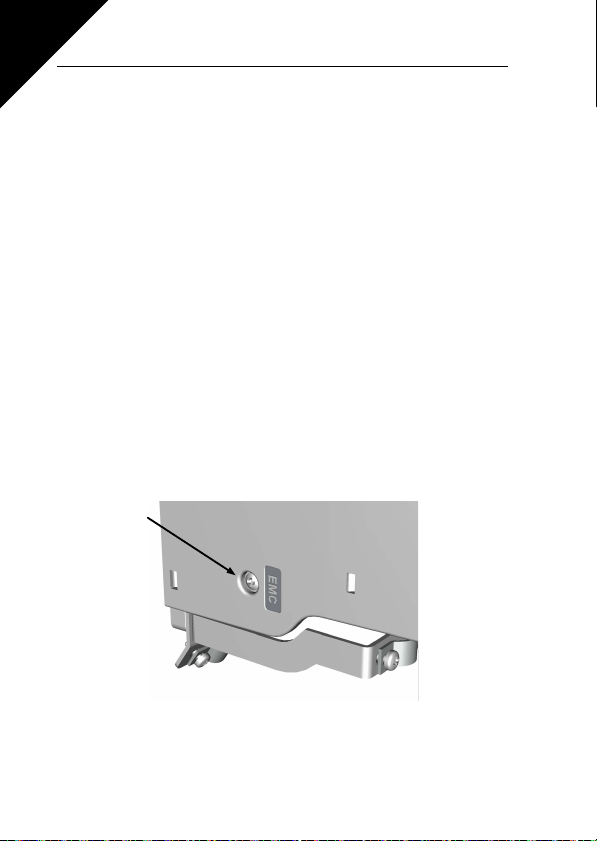

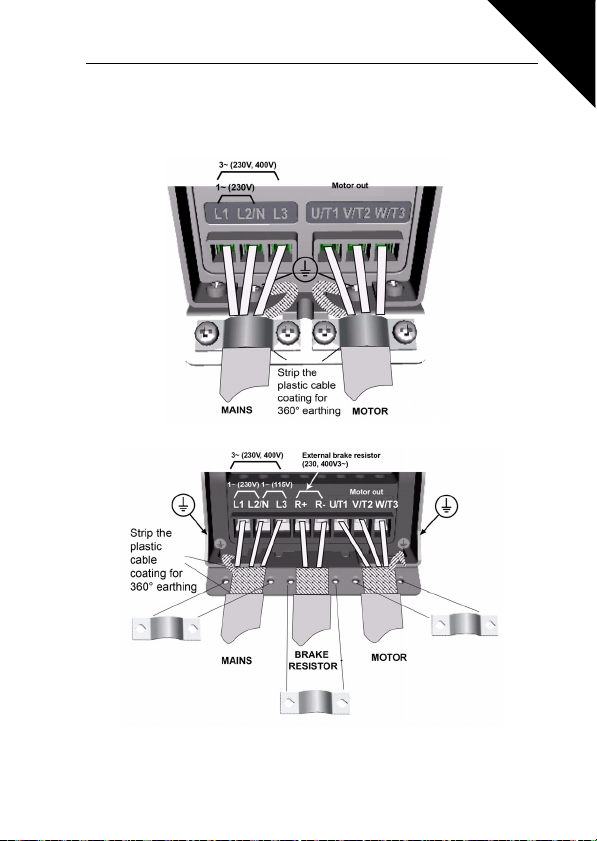

3.2.1 Power cabling

Note! Tightening torque for power cables is 0.5 - 0.6 Nm

Figure 3.4: SmartDrive Compact power connections, MI1

3

Figure 3.5: SmartDrive Compact power connections, MI2 - MI3

3

14 Installation Honeywell

3.2.2 Control cabling

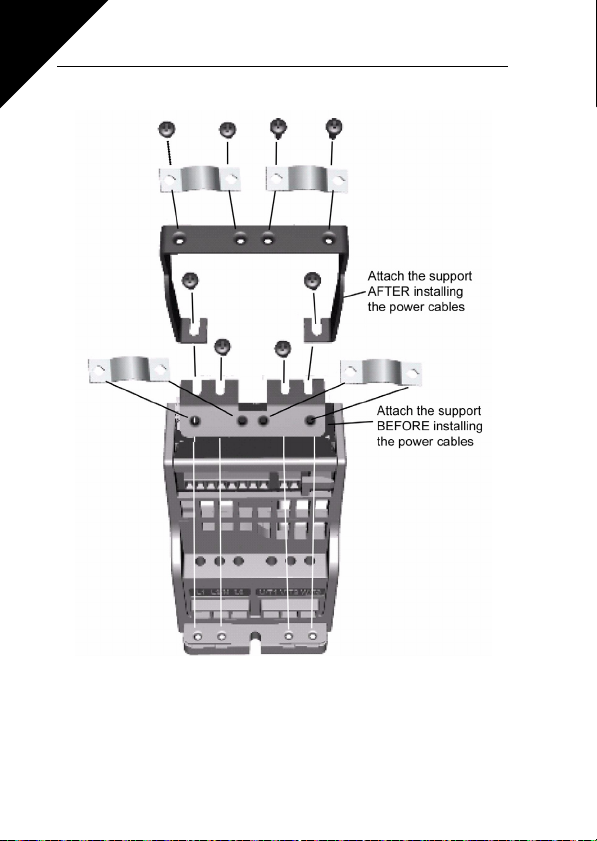

Figure 3.6: Mount the PE- plate and control cable support

Honeywell Installation 15

Strip the p lastic

cable coating for

360

°

Control cable

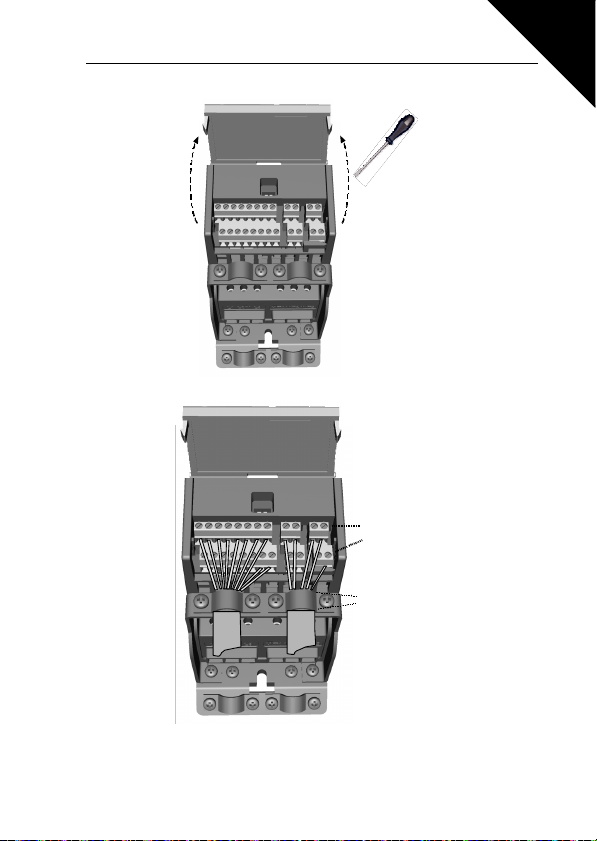

tightening

torque: 0.4 Nm

grounding

Figure 3.7: Open the cover

3

Figure 3.8: Install the control cables. See Chapter 6.2

3

16 Installation Honeywell

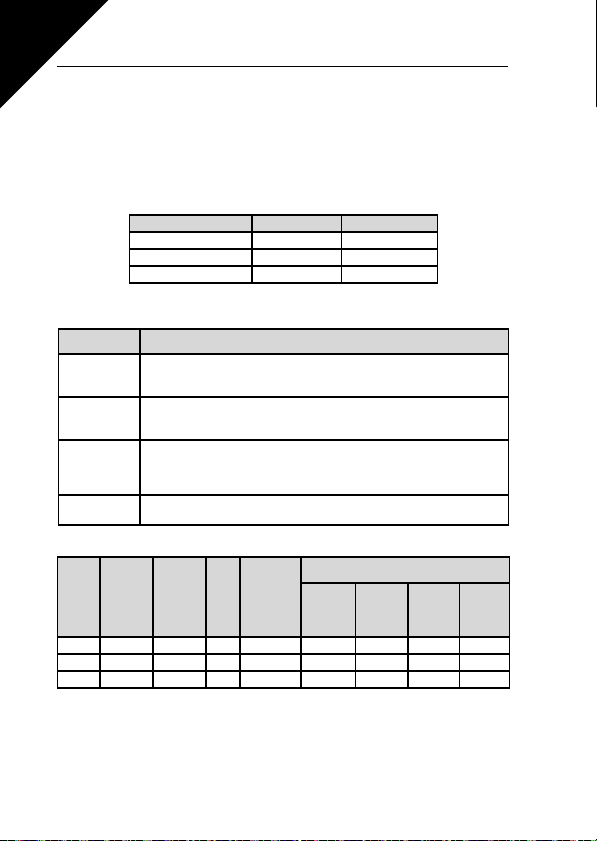

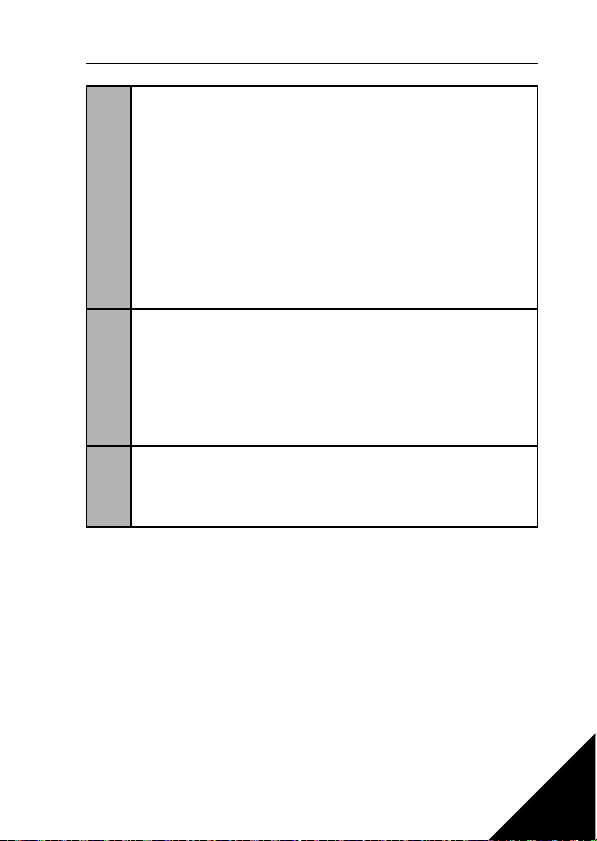

3.2.3 Cable and fuse specifications

Use cables with heat resistance of at least +70 C. The cables and the fuses must be

dimensioned according to the tables below. Installation of cables according to UL

regulations is presented in Chapter 3.2.6.

The fuses function also as cable overload protection.

These instructions apply only to cases with one motor and one cable connection from

the inverter to the motor. In any other case, ask the factory for more information.

EMC class Level H (C2) Level C (C1)

Mains cable types 1 1

Motor cable types 3 3

Control cable types 4 4

Table 3.4 : Cable types required to meet standards. EMC levels are

described in Chapter 3.1.3.

Cable type Description

Power cable intended for fixed installation and the specific mains voltage.

Shielded cable not required.

1

(NKCABLES/MCMK or similar recommended)

Power cable equipped with concentric protection wire and intended for the

specific mains voltage.

2

(NKCABLES /MCMK or similar recommended).

Power cable equipped with compact low-impedance shield and intended

for the specific mains voltage.

3

(NKCABLES /MCCMK, SAB/ÖZCUY-J or similar recommended).

*360º grounding of both motor and FC connection r equired to meet the standard

Screened cable equipped with compact low-impedance shield (NKCA-

4

Table 3.5 : Cable type descriptions

BLES /Jamak, SAB/ÖZCuY-O or similar).

Fuse

[A]

Mains

cable

Cu [mm2]

I

Frame Type

MI1 P25-P75 1.7-3.7 10 2*1.5+1.5 1.5-4 1.5-4 0.5-1.5 0.5-1.5

MI2 1P1-1P5 4.8-7.0 20 2*2.5+2.5 1.5-4 1.5-4 0.5-1.5 0.5-1.5

MI3 2P2 9.6 32 2*6+6 1.5-6 1.5-6 0.5-1.5 0.5-1.5

[A]

N

Terminal cable size (min/max)

Main

Earth

terminal

2

[mm

]

Control

terminal

2

[mm

]

terminal

2

[mm

]

Table 3.6 : Cable and fuse sizes for SmartDrive Compact, 208 - 240V

Relay

terminal

2

[mm

]

Honeywell Installation 17

3

Terminal cable size (min/max)

Main

Earth

terminal

2

[mm

]

Control

terminal

2

[mm

]

terminal

2

[mm

]

Relay

terminal

[mm

Fuse

[A]

Mains

cable

Cu [mm2]

I

Frame Ty pe

MI1 P37-1P1 1.9-3.3 6 3*1.5+1.5 1.5-4 1.5-4 0.5-1.5 0.5-1.5

MI2 1P5-2P2 4.3-5.6 10 3*1.5+1.5 1.5-4 1.5-4 0.5-1.5 0.5-1.5

MI3 3P0-5P5 7.6-12 20 3*2.5+2.5 1.5-6 1.5-6 0.5-1.5 0.5-1.5

[A]

N

Table 3.7 : Cable and fuse sizes for SmartDrive Compact, 380 - 480V

Note! To fulfil standard EN61800-5-1, the protective conductor should be at least

10mm2 Cu or 16mm Al. Another possibility is to use an additional protective con-

ductor of at least the same size as the original one.

3.2.4 General cabling rules

Before starting the installation, check that none of the components of the inverter

1

is live.

Place the motor cables sufficiently far from other cables:

• Avoid placing the motor cables in long parallel lines with other cables

• If the motor cable runs in parallel with other cables, the minimum distance

between the motor cable and other cables is

2

3

4

0,3 m.

• The given distance also applies between the motor cables and signal cables

of other systems.

• The maximum length of the motor cables is 30 m

• The motor cables should cross other cables at an angle of 90 degrees.

If cable insulation checks are needed, see Chapter 3.2.7.

Connecting the cables:

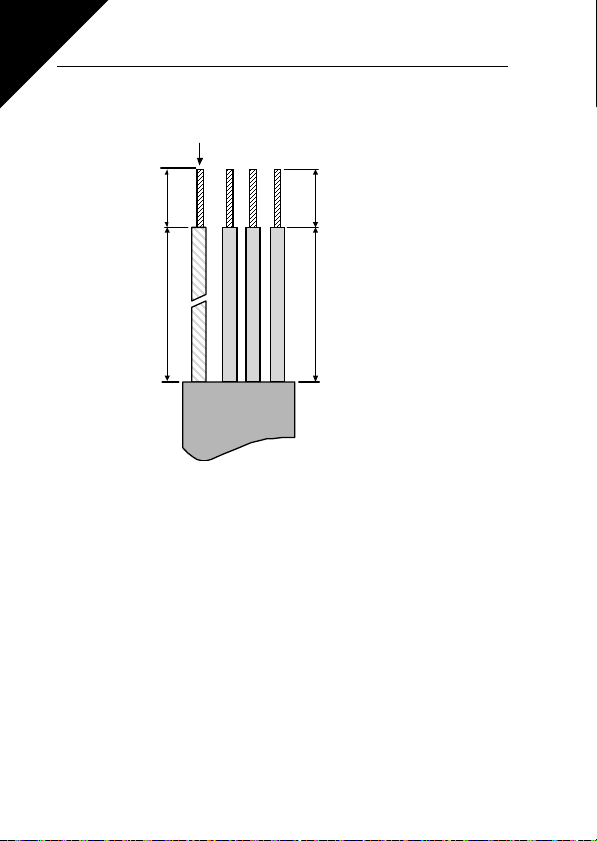

• Strip the motor and mains cables as advised in Figure 3.9.

• Connect the mains, motor and control cables into their respective terminals,

see Figures 3.4 - 3.8.

• Note the tightening torques of power cables and control cables given in

page 13 and page 15.

• For information on cable installation according to UL regulations see Chapter

3.2.6 .

• Make sure that the control cable wires do not come in contact with the electronic components of the unit

• If an external brake resistor (option) is used, connect its cable to the appropriate terminal.

• Check the connection of the earth cable to the motor and the inverter terminals marked with

• Connect the separate shield of the motor cable to the earth plate of the

inverter, motor and the supply centre

2

]

3

20 mm

35 mm

8 mm

Earth conduct or

8 mm

18 Installation Honeywell

3.2.5 Stripping lengths of motor and mains cables

Figure 3.9: Stripping of cables

Note! Strip also the plastic cover of the cables for 360 degree grounding. See Figures 3.4, 3.5 and 3.8.

3.2.6 Cable installation and the UL standards

To meet the UL (Underwriters Laboratories) regulations, a UL-approved copper cable with a minimum heat-resistance of +60/75 0C must be used.

Honeywell Installation 19

3.2.7 Cable and motor insulation checks

These checks can be performed as follows if motor or cable insulations are suspected to be faulty.

1. Motor cable insulation checks

Disconnect the motor cable from terminals U/T1, V/T2 and W/T3 of the inverter and

from the motor. Measure the insulation resistance of the motor cable between each

phase conductor as well as between each phase conductor and the protective

ground conductor.

The insulation resistance must be >1MOhm.

2. Mains cable insulation checks

Disconnect the mains cable from terminals L1, L2/N and L3 of the inverter and from

the mains. Measure the insulation resistance of the mains cable between each phase

conductor as well as between each phase conductor and the protective ground conductor.The insulation resistance must be >1MOhm.

3. Motor insulation checks

Disconnect the motor cable from the motor and open the bridging connections in the

motor connection box. Measure the insulation resistance of each motor winding. The

measurement voltage must equal at least the motor nominal voltage but not exceed

1000 V. The insulation resistance must be >1MOhm.

3

20 Commissioning Honeywell

4. COMMISSIONING

Before commissioning, note the warnings and instructions listed in

Chapter 1!

4.1 COMMISSIONING STEPS OF SMARTDRIVE COMPACT

Read carefully the safety instructions in Chapter 1 and follow them.

1

After the installation, make sure that:

• both the inverter and the motor are grounded

• the mains and motor cables comply with the requirements given in Chapter

3.2.3.

2

3

4

5

6

• the control cables are located as far as possible from the power cables

(see Chapter, step 2) and the shields of the shielded cables are connected

to protective earth.

Check the quality and quantity of cooling air (Chapter 3.1.2).

Check that all Start/Stop switches connected to the I/O terminals are in Stop-

position.

Connect the inverter to mains.

Run the Start Up Wizard (The Wizard is explained fully in chapter 9.11)

1. Activate the wizard by pressing STOP for 5 seconds

2. Tune the motor nominal speed

3. Tune the motor nominal current

4. Select the mode (0 = basic, 1 = Fan, 2 = Pump, 3 = Conveyor)

Or if the setting is done manually set the parameters of group 1 according to the

requirements of your application. At least the following parameters should be set:

• motor nominal voltage (par. 1.1)

• motor nominal frequency (par. 1.2)

• motor nominal speed (par. 1.3)

• motor nominal current (par. 1.4)

You will find the values needed for the parameters on the motor rating plate.

4

Honeywell Commissioning 21

Perform test run without motor. Perform either Test A or Test B:

A) Control from the I/O terminals:

• Turn the Start/Stop switch to ON position.

• Change the frequency reference (potentiometer).

• Check in the Monitoring Menu that the value of Output frequency changes

according to the change of frequency reference.

• Turn the Start/Stop switch to OFF position.

7

B) Control from the keypad:

• Move to keypad control by pressing the navigation wheel for 5 seconds.

You can also select the keypad as the control place with par. 2.1.

• Push the Start button on the keypad.

• Check in the Monitoring Menu that the value of Output frequency changes

according to the change of frequency reference.

• Push the Stop button on the keypad.

Run the no-load tests without the motor being connected to the process, if possible. If this is not possible, secure the safety of each test prior to running it. Inform

your co-workers of the tests.

• Switch off the supply voltage and wait up until the drive has stopped.

• Connect the motor cable to the motor and to the motor cable terminals of

8

9

the inverter.

• See to that all Start/Stop switches are in Stop positions.

• Switch the mains ON.

• Repeat test 7A or 7B.

Connect the motor to the process (if the no-load test was run without the motor

being connected).

• Before running the tests, make sure that this can be done safely.

• Inform your co-workers of the tests.

• Repeat test 7A or 7B.

4

5

F1 02

Fault code (02 = overvoltage)

Fault ordinal number (F1 = latest fault)

22 Fault Tracing Honeywell

5. FAULT TRACING

When a fault is detected by the inverter control electronics, the drive is stopped and

the symbol F together with the ordinal number of the fault and the fault code appear

on the display in the following format, e.g:

The fault can be reset by pressing the Stop button on the control keypad or via the I/

O terminal or fieldbus. The faults with time labels are stored in the Fault history menu

which can be browsed. The different fault codes, their causes and correcting actions

are presented in the table below.:

Fault

Fault name Possible cause Correcting actions

code

Overcurrent

1

Overvoltage

2

Earth fault

3

System fault

8

Undervoltage

9

Table 5.1 : Fault codes

Inverter has detected too high a

current (>4*I

The DC-link voltage has

exceeded the internal safety limit:

Current measurement has

detected extra leakage current at

start:

The DC-link voltage has

exceeded the internal safety limit:

) in the motor cable:

N

• Sudden heavy load increase

• Short circuit in motor cables

• Unsuitable motor

• Too short a deceleration time

• High overvoltage spikes in

mains

• Insulation failure in cables or

motor

• Component failure

• Faulty operation

• Most probable cause: too low

a supply voltage

• Inverter internal fault

• Power outages

Check loading.

Check motor size.

Check cables.

Increase the deceleration

time (P.4.3).

Check motor cables and

motor.

Reset the fault and restart.

Should the fault recur, contact technical support.

In case of temporary supply

voltage break reset the fault

and restart the inverter.

Check the supply voltage. If

it is adequate, an internal

failure has occurred.

Contact technical support.

Loading...

Loading...