Sieger Sensepoint

LEL Combustible Sensor

Operating Instructions

Issue 01 12/2005

H_MAN0590_V1

2106M0518

© 2005 Honeywell Analytics

11068

Find out more

www.honeywellanalytics.com

Customer business centre

Europe and the rest of the world

Honeywell Analytics AG

Wilstrasse 11-U11

CH-8610 Uster

Switzerland

Tel: +41 (0)44 943 4300

Fax: +41 (0)44 943 4398

sales@zelana.co.uk

Customer business center

A

mericas

Honeywell Analytics Distribution, Inc.

400 Sawgrass Corporate Pkwy

Suite 100

Sunrise, FL 33325

USA

Tel: +1 954 514 2700

Toll free: +1 800 538 0363

Fax: +1 954 514 2784

sales@zelana.com

www.honeywell.com

Please Note:

While every effort has been made to ensure

accuracy in this publication, no responsibility

can be accepted for errors or omissions.

Data may change, as well as legislation, and you

are strongly advised to obtain copies of the most

recently issued regulations, standards, and guidelines.

This publication is not intended to form the

basis of a contract.

© 2005 Honeywell Analytics

SENSEPOINT

MAN0513 .P65 Issu e 06 - 04/99

2106M 0501

SensePoi nt LEL

Combusti ble Sensor

1. INTRODU CTION

SensePo int is a sealed disp osable sens or for the detection

of fla mmable gases and is des igned for us e with an

approve d junction box.

It emp loys a cat alytic pelli stor sensor device whi ch is used

as par t of a br idge measuri ng circuit.

Sensepo int is cer tified for hazardous areas to E N50018

and is protected against wate r and dust ingress to IP66/67.

The se nsor is ava ilable in M 20, M25, M2 6 or 3/4 N PT

thread versions. All accept accessories from the specified

range.

2. ASSOCIA TED DOCUMENTATI ON

2106M05 02 SensePo int Techn ical Hand book.

Refer to the rele vant control system man ual for co nnection

informa tion.

1. INT RODUCTION & 2 . ASSOCIATED DOCUMENTATION

CONTEN TS

1. INTRODU CTION ......................................................2

2. ASSOCIA TED DOCUMENTATI ON......................... 2

3. SAFETY ....................................................................

3

3.1 Warn ings ........................................................... 3

3.2 Cautio ns............................................................. 3

4. OPERATION S ..........................................................

4

4.1 Instal lation ......................................................... 4

4.2 Calib ration ......................................................... 5

4.3 Fault finding .......................................................9

5. MAINTENANC E..................................................... 1 0

5.1 Changin g filters ................................................. 9

Appendi x A - Spe cifications ....................... 11

Appendi x B - Glo ssary ............................... 12

Appendi x C - Main features ....................... 1 3

Appendi x D - Spar e parts ........................... 14

1 2

11

12

13 14

APPENDI X C - MAIN FEATUR ESAPPENDI X A - SPECIFICATION S APPENDI X D - SPARE PARTSAPPENDI X B - GLOSSARY

Operati ng temperat ure range:

-55°C to +80°C (see certifi cation).

Operati ng humidity range:

20% to 90% RH con tinuous.

10% to 99% RH int ermittent - non condens ing.

Operati ng pressur e range:

90 to 110 k Pa.

Warm u p time:

no gre ater than 1 0 minutes.

Voltage range:

2.9 V t o 3.5 V brid ge (at 200mA ).

Power c onsumption:

700mW .

Signal output:

mV brid ge.

Calibra tion flow rate:

recomme nded between 1 and 1.5 l /min.

Poison ing:

the se nsing element s may becom e inactive after

extensi ve exposure to silic ones, haloge nated

hydroca rbons, heavy metals or sulphur co mpounds.

Expecte d operating life:

5 year s.

IP rat ing:

IP65 s tandard; IP6 6/67 with weather prot ection.

Certif ication:

Ex II 2G EExd IIC T 6 -55 to +55° C.

Ex II 2G EExd IIC T 5 -55 to +70° C.

Ex II 2G EExd IIC T 4 -55 to +80° C.

BAS98AT EX2156X.

UL app roved via IEC 79 (pen ding).

This p roduct compl ies with t he relevant CE standar ds

concern ing performa nce: EMC to BS EN50081 parts 1 & 2,

BS EN50 082 parts 1 & 2 and EN 50054.

Explosi ve gas atm osphere:

a mi xture in air of combustib le materia ls in the form of gas

vapour or mi st in which, a fter igni tion, com bustion spreads

through out the unc onsumed mixt ure.

Lower explosive li mit (LEL):

the vo lume of co mbustible ga s or vapou r in air below which

an exp losive gas a tmosphere wil l not be f ormed.

Exd:

flame proof or explosion proof withi n the confines of European

standar ds EN5 0014 and EN 50018. An e nclosure that can

wit hstan d the press ure d evelo ped d uring the inte rnal

expl osion o f an ex plosiv e mixtu re and whic h preve nts

transmi ssion of the explosion to t he explo sive at mosphere

surroun ding the enclosure.

Exe:

increas ed safety within the confines of European standards

EN50014 and EN5 0019 appli ed to e lectrical apparatus that

does no t produce a rcs or spark s in normal service, in which

additio nal measures are app lied so as to give incre ased

securit y against the possibi lity of e xcessive te mperatures.

PPS:

polymer pol yphenylene sulphi de, suitable for use in most

chem ical e nviron ments ( eg aci ds, al dehydes , keto nes,

alkalies , petroleum , aromatic hydrocarbo ns, alcohols, ethers,

esters and mos t chlorina ted hydrocarbons ). Avoid immersion

in so lvents for extended periods. F or further details contact

Zellweg er Analyti cs Ltd.

Sensor ....................................................... 2106B12 00 (M20)

Sensor ....................................................... 2106B12 01 (M25)

Sensor ....................................................... 2106B12 02 (M26)

Sensor ....................................................... 2106B12 04(3/4 NPT )

Weather protec tion ................................... 02000-A-16 40

Sensor filter ............................................... 00780-F -0018

Flow housing ............................................. 02000-A -1645

Collect ing cone ......................................... 0 2000-A-1642

Junctio n box (std) ..................................... 00780- A-0100

High te mperature ju nction box ................. 555-0 90-038

High t emperature weather pro tection ...... 00780-A-0 076

To reo rder a comp lete new se nsor, see th e label on the

product leads, or contact Z ellweger An alytics Ltd .

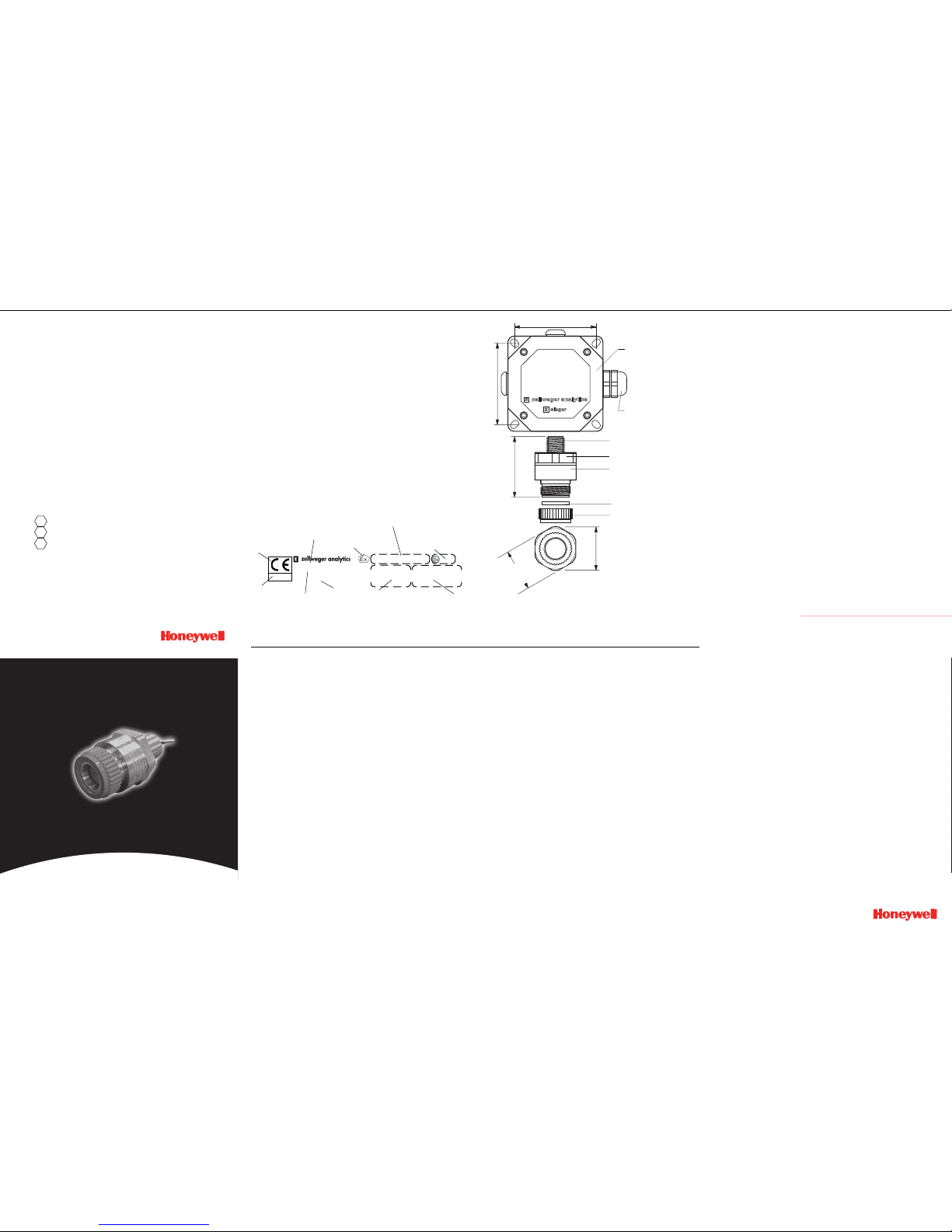

103mm

Standard Zellweger

Analytic s junction box

threads availa ble:

M20; M25; M26 ; 3/4” NPT.

SensePoi nt Combustible Gas

Sensor 0-100% LEL

Weight - 1 90g

Filter

Plastic retainer

103mm

74mm

56mm

52mm

(across flats)

Exe/Exd gland

operating instructions

Poole Dorset

SensePoint

static ri sk - read manual

EEx d IIC T6 Tamb -55 +55

o

C

EEx d IIC T5 Tamb -55 +70oC

EEx d IIC T4 Tamb -55 +80

o

C

0600

Bas98ATE X2156X II 2G

manufactur er’s

trademar k &

address

CE mark conforms to all

applicabl e

European

directives

product name

test house

trademark

certific ation code

as EN50014 1992

certific ation number

certifie d ambient

temperature

range

explosion

protecti on mark

and equipmen t

group & categ ory

ident.number

of ATEX

notified

body

caution

Certifi cation label as defined in directiv e 94/9/EC

This publication is not intended to form the basis of a contract, and the company reserved the right to

amend the design and specification of the instruments without notice.

MIDDLE EAST

Zellweger Analytics

Middle East Regional Office

PO Box 52196

Karama-Bur Dubai UAE

Tel: (971) 4 360940

Fax: (971) 4 345802

NETHERLANDS

Imbema Analytics BV

Maurisstraat 1-7

Postbus 160

2000 AD Haarlem

Netherlands

Tel: (31) 23 517 2424

Fax: (31) 23 5318040

FRANCE

Zellweger Analytics SA

33 rue de Ballon

ZI des Richardets

F-93165 Noisy le Grand

Cedex

France

Tel: (33) 01 48 15 80 80

Fax: (33) 01 48 15 80 00

GERMANY

Zellweger Analytics GmbH

Sollner Strasse 65b

D-81479 Munchen

Germany

Tel: (49) 89 791 920

Fax: (49) 89 791 9243

ITALY

Zellweger Analytics srl

Via F. Primaticcio 168

1-20147 Milano

Italy

Tel: (39) 48300436

Fax: (39) 48302314

UNITED KINGDOM

Zellweger Analytics Ltd

Parsonage Road

Takeley

Bishop’s Stortford

Herts

CM22 6PU, U.K.

Tel: (44) 1279 870182

Fax: (44) 1279 870377

SINGAPORE

Zellweger Analytics Ltd

Asia Pacific Regional Office

30, Tech Park Crescent

Singapore 638102

Tel: (65) 862 7701

Fax: (65) 862 3858

SPAIN

Zellweger Analytics SA

Avda Remolar 31

08820 EI Prat de LIobregrat

Barcelona

Spain

Tel: (34) 3 379 9611

Fax: (34) 3 379 8551

USA

Zellweger Analytics Inc

(Sieger Division)

405 Barclay Blvd

Lincolnshire

Illinois 60069,USA

Tel: (1) 847 913 0015

Fax: (1) 847 634 1371

E-mail: sieger@zelana.com

INTERNATIONAL HQ

Zellweger Analytics Ltd

Hatch Pond House

4 Stinsford Road

Nuffield Estate

Poole

Dorset

BH17 0RZ, UK

Tel: (44)1202 676161

Fax: (44)1202 678011

E-mail: postmaster@

zellweger-analytics.co.uk

Ser.No./ Year of manufacture

3

5.1 CHA NGING FILTERS

- Remo ve the grey plastic re tainer or a ccessory.

- Remo ve the old filter and replace wit h a fresh filter.

- Repl ace the gr ey plastic retainer o r accessory.

5. MAINTE NANCE

4 5

4. OPER ATIONS

Table 2: Meter Settings

* Rating of Gas to be Detected

* Calibration

Gas 8* 7* 6* 5* 4* 3* 2* 1*

8* 50 62 76 95 - - - -

7* 40 50 61 76 96 - - -

6* 33 41 50 62 78 98 - -

5* 26 33 40 50 63 79 100 -

4* 21 26 32 40 50 63 80 -

3* - 21 26 32 40 50 64 81

2* - - - 25 3 1 39 50 64

1* - - - - 25 31 39 50

Note: The se settings must only be used wi th a calibr ation

gas co ncentration of 50% LEL.

Cross Calibration example:

The target gas to be de tected is B utane. The calibration

gas av ailable is Methane (5 0% LEL).

Look up the st ar rating f or each gas (Table 1) :

Butane 4*, Methane 6*

Chec k the meter settings f or 50% LEL calibration gas

(Table 2).

The control car d meter sho uld therefor e be set t o 78%

to giv e an accura te reading f or Butane, using 50% L EL

Methane as a cal ibration ga s.

4.3 F AULT FINDING

Sensor reads non ze ro all the ti me:

- gas co uld be pres ent, ensure there is no combusti ble

gas in the atmosph ere.

Sensor reads non zer o when no ga s is present:

- adjust the zero of the control system.

Sensor reads low w hen gas is a pplied:

- adjust the span of the control system.

Sensor reads high when gas is applied:

- adjust the span of the control system.

Sensor reads zero when gas is applied:

- check the wiring.

- check t hat the dus t protection cap has be en removed.

- check that the si nter is not obstructed .

- replace the senso r if poiso ning is su spected.

Table 3: Meter Mu ltiplication Factors

Unit calibrated Unit used to detect

To Detect 8* 7* 6* 5* 4* 3* 2* 1*

8* 1.00 1.24 1.52 1 .89 2.37 2.98 3.78 4.83

7* 0.81 1.00 1.23 1 .53 1.92 2.40 3.05 3.90

6* 0.66 0.81 1.00 1 .24 1.56 1.96 2.49 3.17

5* 0.53 0.66 0.80 1 .00 1.25 1.58 2.00 2.55

4* 0.42 0.52 0.64 0 .80 1.00 1.26 1.60 2.03

3* 0.34 0.42 0.51 0 .64 0.80 1.00 1.27 1.62

2* 0.26 0.33 0.40 0 .50 0.63 0.79 1.00 1.28

1* 0.21 0.26 0.32 0 .39 0.49 0.62 0.78 1.00

4. OPER ATIONS

4. OPER ATIONS

Grey plasti c retainer

Filter

Main body of se nsor

4.1 IN STALLATION

The Se nsePoint mu st be fitt ed into a suitably a pproved Exe

or Exd junctio n b ox fitted with a suitably app roved cable

gland. This should b e correctly i nstalled befo re use. Cabli ng

should be multi core, thre e wire m inimum, of conductor size

2.5 mm

2

max.

The sensor sh ould be fitted into a threaded hole wi thin the

junctio n box and loc ked in place with a lock n ut. Ensure th at

junctio n box threa d is compat ible with s ensor thread .

The se nsor should be install ed in a l ocation free from dire ct

heat sources . It shoul d be fitte d suc h th at it eith er po ints

downwar ds or horizonta lly. It is not rec ommended that th e

sensor points up wards. See the techni cal handbo ok for

install ation in forced a ir conditi ons.

Wiring connections are:-

4. OPER ATIONS 4. OPER ATIONS

3.1 WARNINGS

This apparatus is not suit able for use in

oxygen enriched a tmospheres ( >21%V/V).

Oxygen deficient atmosphe res (<10% V/V)

may sup press sensor output.

Refer to loc al or nat ional reg ulati ons

relativ e to insta llation at the site.

Operator should be fully awar e of the action

to be taken if the gas concentration exceeds

an ala rm level.

Sense Poin t sh ould be pro tect ed fr om

mec hanic al im pact. Inst allat ion sh ould

conside r not only th e best placing for gas

leakage related to potential l eak points,

gas charac teristics and venti lation, but also

where t he potential of mechani cal damage

is min imized or a voided.

3.2 CAUTIONS

Atmo sph eres a bove 1 00% L EL ma y

suppres s the sens or reading.

Do n ot m odi fy o r al ter t he s ens or

co nstr ucti on as es sent ial sa fety

require ments may be invalida ted.

Install using certified Exe or Ex d junc tion

box, c onnectors a nd glanding .

Dispose of in accordance with local disposal

reg ulat ions . Mat eria ls u sed -Fo rtro n®

(PPS- Polyphenyle ne Sulphid e).

3. SAF ETY

4.2 CA LIBRATION

Pri or to cal ibrati on, a llow the sen sor to warm up f or

approxi mately 10 mi nutes. Re-cal ibration shou ld only be

attempt ed by qua lified ser vice person nel.

First zero the contro l system with no gas present on the

sensor. If com bustible gas is suspected to be in the vicinity of

SensePoint, flow clean air over the sensor using a flow housing

(see below) .

Fit a flow hou sing and connect a cylinder o f either air, for a

zero, or a know n concent ration of gas in air, at appr oximately

the alarm point (e. g. 50% LEL), to the flo w housing. Pass th e

gas thr ough the flo w housing at a flow rate of approxima tely

1 l to 1 .5 l per minut e. Allow the sensor to stabilis e. When

gassing with air, ad just the cont rol card to i ndicate zero. For

span, the contr ol c ard should be adjusted to indicat e th e

concent ration o f the target gas be ing appl ied. Rem ove the

flow h ousing and the gas sup ply.

Sensors should be calibrated at concentra tions representative

of those to be measured . It is alw ays recommended that

SensePo int is cali brated with the target gas it is to detect. I f

this i s not poss ible, then cross cali bration can be used.

For ca libration in fast f low condi tions see the te chnical

handbo ok.

4.3 CR OSS CALIBRATIO N PROCEDURE

When the Sense Point sens or is t o be c alibrated with a gas

which i s different t o the gas/va pour to be de tected, the

followi ng cross calibration procedure should be followed.

Table 1 l ists gases acco rding to the rea ction they prod uce at

the detecto r. A n ei ght star (8*) gas produces the highes t

output while a one star (1*) g as produces the lowest o utput.

(These are not a pplicable a t ppm leve ls.)

4. OPER ATIONS

To calibr ate the SensePo int sensor, obta in the star ratin g for

both the te st gas and t he gas to be detected from table 1.

These value s m ay then be used in table 2 to obtain the

require d meter setting whe n a 50% LEL test gas is appl ied to

the de tector.

If a sensor is to be used to detect a gas other than that for

which it wa s calibrated, the re quired correction fac tor may be

obtained from tab le 3. The meter reading should be mul tiplied

by this n umber in order to obtain the true gas concentration.

IMPORTA NT

Si nce combustibl e sensors requir e oxygen for corr ect

operati on, a mixture of gas in air sh ould be used for

calibra tion pu rposes.

As suming an average sens or performance, the sensitivi ty

informa tion in tables 1 to 3 is norm ally accurate to ± 20%.

Table 1: Star R ating of Ga sses

7 8 9 10

6

Gas Star Rating

Acetone 4*

Ammonia 7*

Benzene 3*

Butane 4*

Diethyl ether 4*

Ethane 6*

Ethanol 5*

Ethyl acetate 3*

Ethylene 5*

Gas Star Rating

Hexane 3*

Hydrogen 6*

Methane 6*

Octane 3*

Propan-2-ol 4*

Propane 5*

Styrene 2*

Tetra hydrafuran 4*

Xylene 2*

The uni t requires 200mA curre nt with a n ominal 3V s upply.

Install ation and service are to be pe rformed b y a qu alified

in stal lati on eng ine er w ith th e po wer to the se nsor

discon nected.

SENSITIVE

(S)

NON

SENSITIVE

(NS)

COMMON

(01)

SPARE

BROWN BLUE WHITE

SENSOR

Thank you for reading this data sheet.

For pricing or for further information, please contact us at our UK Office, using the details

below.

UK Office

Keison Products,

P.O. Box 2124, Chelmsford, Essex, CM1 3UP, England.

Tel: +44 (0)330 088 0560

Fax: +44 (0)1245 808399

Email: sales@keison.co.uk

Please note - Product designs and specifications are subject to change without notice. The user is responsible for determining the

suitability of this product.

Loading...

Loading...