Honeywell SI06042, SI04022, SI012000 Product Data

31-00028-02

Sylk™ I/O Devices

PRODUCT DATA

APPLICATION

The Sylk IO devices are part of the Spyder family. The three

IO devices are designed to seamlessly integrate with

Spyder with relay controllers using only Sylk™ for

communication. These devices expand the footprint of a

single Spyder, increasing the controller's ability to be

applied in applications that require a large amount of

physical I/O. The Sylk IO devices are programmable using

existing Spyder wire sheets through the Niagara

Framework® software. Since the Sylk IO devices are

extensions of the Spyder LON and Spyder BACnet

controllers, the same Spyder feature will be leveraged in

the WebPro workbench tool and the WEBs-AX JACE

controller. To utilize the Sylk IO devices, the Spyder with

Relay models, PUL6438SR (for LON) or PUB6438SR (for

BACnet), need to be selected.

The Sylk IO devices are intended for use in HVAC

applications that require a programmable controller

where the IO count is more than the full sized Spyder point

count. All devices provide flexible, universal inputs for

external sensors while SIO6042 and SIO4022 provide a

combination of analog and digital outputs.

FEATURES

•Ex

pands a single Spyder controller's IO count by 8-1

IO per device.

• Up to three devices for Lon Spyders and up to two

devices for BACnet Spyders can be applied.

• Communicates through Sylk™ bus freeing up IO for

more applications.

• Program logic resides in a single controller and uses

the existing Spyder wire sheet.

• Programming is built directly into the Spyder tool.

• Installation can be done locally or remotely.

• Field configurable and programmable for control,

input, and output functions using the Niagara

Framework® software.

• All wiring connections are made to removable

terminal blocks to simplify device installation and

replacement.

• The device housing is UL plenum rated.

Contents

Description ............................................................................................ 2

Specifications ...................................................................................... 2

Installation ............................................................................................ 2

Checkout ................................................................................................ 9

Device Replacement ........................................................................ 10

2

SYLK™ I/O DEVICES

WARNING

DESCRIPTION

The Sylk IO devices are available in three models, as

described in Table 1.

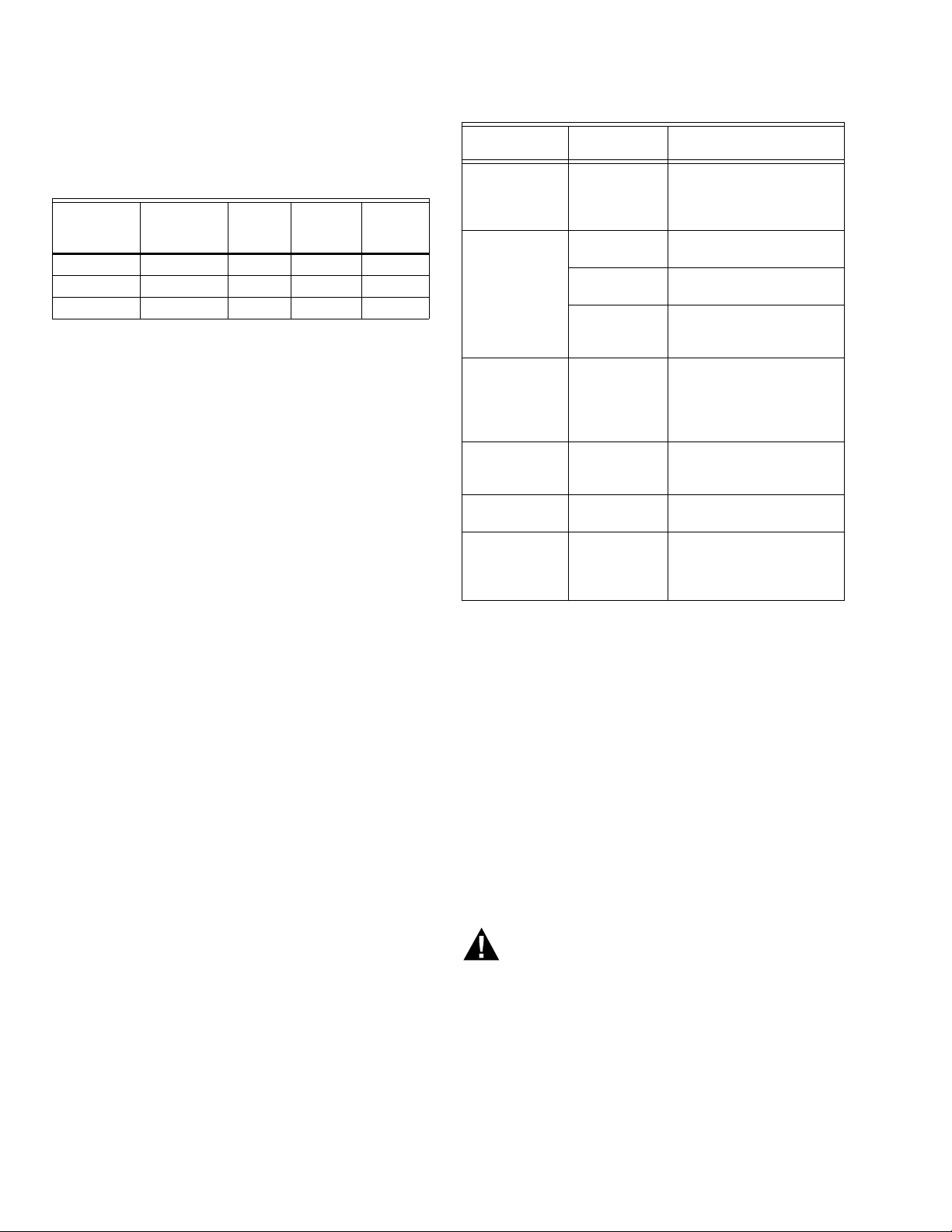

Table 1. Device Configurations.

UI

(Universal

Devices

SI06042 6 0 4 2

SI04022 4 0 2 2

SI012000 12 0 0 0

Each device is programmable because the user chooses

which function blocks to use and how to connect them. It

is configurable because each function block has userdefined behavior.

Input)

DI

(Digital

Input)

AO

(Analog

Output)

DO

(Digital

Output)

SPECIFICATIONS

General Specifications

Electrical

Rated Voltage: 20-30 Vac; 50/60 Hz

Power Consumption:

100 VA for Sylk IO device and all connected loads

Sylk IO Device Only Load (Excluding Digital Triac Out-

puts): 3 VA maximum (SIO12000), 4 VA maximum

(SIO4022), 5 VA maximum (SIO6042)

Environmental

Operating & Storage Temperature Ambient Rating:

Minimum -40° F (-40° C); Maximum 150° F (65.5° C)

Relative Humidity: 5% to 95% non-condensing

Digital Triac Output (DO) Circuits

Voltage Rating: 20 to 30 Vac @ 50/60Hz

Current Rating: 25 mA to 500 mA continuous, and

800 mA (AC rms) for 60 milliseconds

Analog Output (AO) Circuits

Analog outputs can be individually configured for current

or voltage.

ANALOG CURRENT OUTPUTS:

Current Output Range: 4.0 to 20.0 mA

Output Load Resistance: 550 Ohms maximum

Table 2. Universal Input Circuit Specifications.

Input

Type

Room/Zone

Discharge Air

Outdoor Air

Tem per ature

Outdoor Air

Tem per ature

TR23

Setpoint

Potentiometer

Resistive Input Generic 100 Ohms

Voltage

Input

Discrete Input Dry Contact

a

C7031G and C7041F are recommended for use with

these controllers, due to improved resolution and accuracy when compared to the PT1000.

Sensor

Type

20K Ohm

NTC

C7031G

C7041F

PT1000

(IEC751

3850)

500 Ohm

to

10,500 Ohm

Tra nsduc er,

Controller

closure

a

a

Operating

Range

-40° F to 199° F

(-40° C to 93° C)

-40° to 120°F

(-40° to 49°C)

-40° to 250°F

(-40° to 121°C)

-40° F to 199° F

(-40° C to 93° C)

-4° DDC to 4° DDC

(-8° DDF to 7° DDF)

or

50° F to 90° F

(10° C to 32° C)

to

100K Ohms

0 - 10 Vdc

Open Circuit ≥

3000Ohms

Closed Circuit <

3000Ohms

BEFORE INSTALLATION

The device is available in three models (see Table 1).

Review the power, input, and output specifications on

page 2 before installing the device.

— Hardware driven by Triac outputs must have a

minimum current draw, when energized, of 25 mA and a

maximum current draw of 500 mA.

— Hardware driven by the analog current outputs must

have a maximum resistance of 550 Ohms, resulting in a

maximum voltage of 11 volts when driven at 20 mA. If

resistance exceeds 550 Ohms, voltages up to 18 Vdc

are possible at the analog output terminal.

ANALOG VOLTAGE OUTPUTS:

Voltage Output Range: 0 to 10.0 Vdc

Maximum Output Current: 10.0 mA

Analog outputs may be configured as digital outputs and

operate as follows:

– False (0%) produces 0 Vdc, (0 mA)

– True (100%) produces the maximum 11 Vdc, (22 mA)

Universal Input (UI) Circuits

See Table 2 for the UI circuit specifications.

31-00028—02 2

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

or making wiring connections to prevent electrical

shock or equipment damage.

INSTALLATION

The device must be mounted in a position that allows

clearance for wiring, servicing, and removal.

SYLK™ I/O DEVICES

M35144

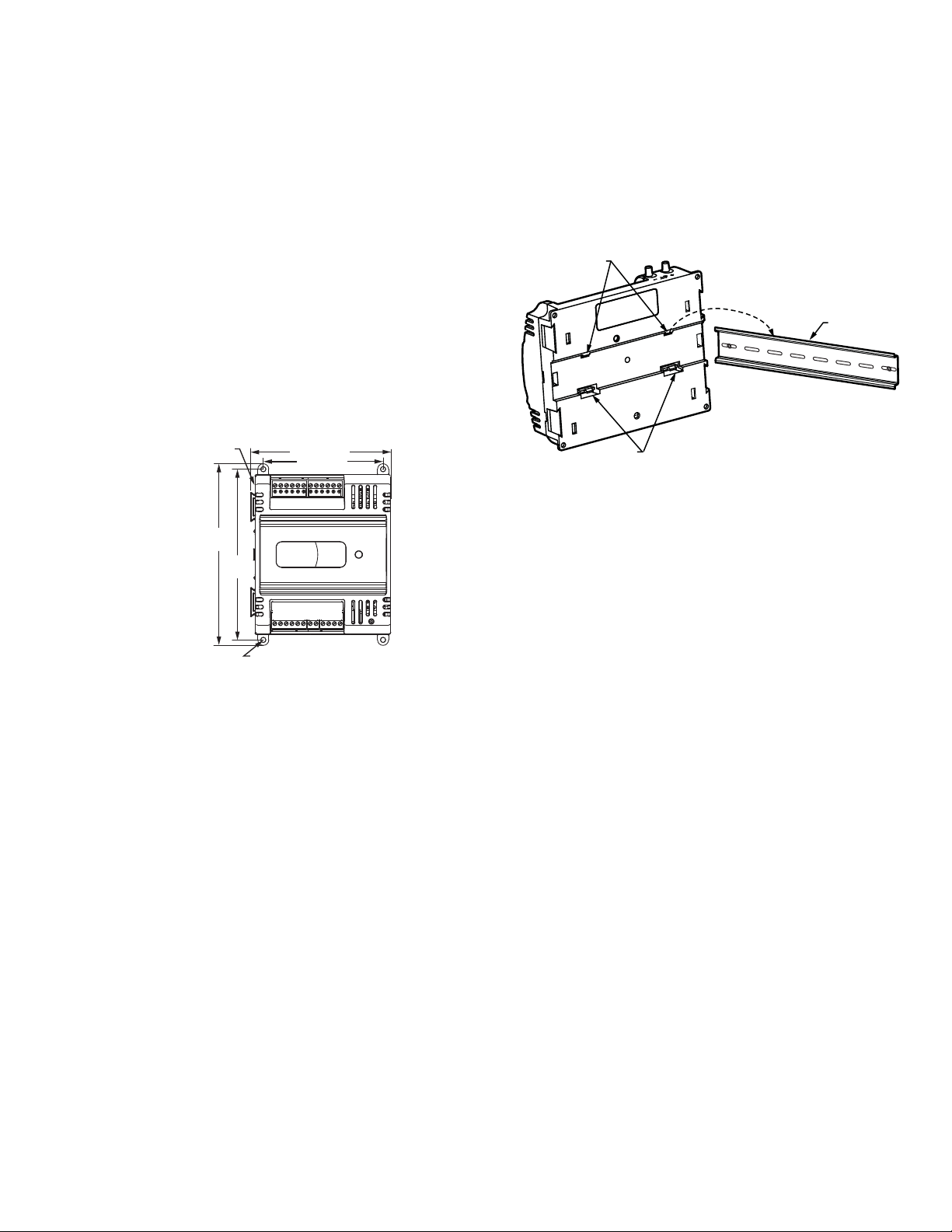

NOTE: DEVICE CAN BE MOUNTED IN ANY ORIENTATION.

3/16 (4.5) PANEL MOUNTING HOLE (4X)

1 1 1 1 1 1 1 2 2 2 2 2

3 4 5 6 7 8 9 0 1 2 3 4

1 1

1 2 3 4 5 6 7 8 9 0 1 2

DEPTH IS

2-1/ 4 (57)

4-13/16 (122)

4-1/8 (105)

6-1/4

(159)

5-7/8

(149)

DIN RAIL

TOP TABS

BOTTOM FLEX

CONNECTORS

M16815

The device may be mounted in any orientation.

IMPORTANT

Avoid mounting in areas where acid fumes or other

deteriorating vapors can attack the metal parts of

the controller, or in areas where escaping gas or

other explosive vapors are present. See Fig. 1 for

mounting dimensions.

Mount Device

NOTE: The device may be wired before mounting to a

panel or DIN rail.

Terminal blocks are used to make all wiring connections to

the device. Attach all wiring to the appropriate terminal

blocks (see “Wiring” on page 5).

See Fig. 1 for panel mounting dimensions. See Fig. 2 on

page 3 for DIN rail mounting.

Fig. 1. Device dimensions in in (mm).

Panel Mounting

The device enclosure is constructed of a plastic base plate

and a plastic factory-snap-on cover.

NOTE: The device is designed so that the cover does not

The device mounts using four screws inserted through the

corners of the base plate. Fasten securely with four No. 6

or No. 8 machine or sheet metal screws.

The device can be mounted in any orientation. Ventilation

openings are designed into the cover to allow proper heat

dissipation, regardless of the mounting orientation.

DIN Rail Mounting

To mount the SIO12000, SIO4022, or SIO6042 device on a

DIN rail [standard EN50022; 1-3/8 in. x 9/32 in. (7.5 mm x

35 mm)], refer to Fig. 2 and perform the following steps:

need to be removed from the base plate for either

mounting or wiring.

1. Holding the device with its top tilted in towards the

DIN rail, hook the two top tabs on the back of the

device onto the top of the DIN rail.

2. Push down and in to snap the two bottom flex connectors of the device onto the DIN rail.

IMPORTANT

To remove the device from the DIN rail, perform

the following:

1. Push straight up from the bottom to release the

top tabs.

2. Rotate the top of the device out towards you and

pull the controller down and away from the DIN rail

to release the bottom flex connectors.

Fig. 2. Controller DIN rail mounting

(models SIO12000, SIO4022, and SIO6042).

Power

Before wiring the controller and device, determine the

input and output device requirements for each controller

and device used in the system. Select input and output

devices compatible with the controller, device, and the

application. Consider the operating range, wiring

requirements, and the environment conditions when

selecting input/output devices. When selecting actuators

for modulating applications consider using floating

control. In direct digital control applications, floating

actuators will generally provide control action equal to or

better than an analog input actuator for lower cost.

Determine the location of controllers, sensors, actuators

and other input/output devices and create wiring diagrams.

The application engineer must review the control job

requirements. This includes the sequences of operation

for the controller, and for the system as a whole. Usually,

there are variables that must be passed between

controllers that are required for optimum system-wide

operation. Typical examples are the TOD, Occ/Unocc

signal, the outdoor air temperature, the demand limit

control signal, and the smoke control mode signal.

It is important to understand these interrelationships

early in the job engineering process, to ensure proper

implementation when configuring the controllers.

Power Budget

A power budget must be calculated for each device to

determine the required transformer size for proper

operation. A power budget is simply the summing of the

maximum power draw ratings (in VA) of all the devices to

be controlled. This includes the controller itself and any

devices powered from the controller, such as equipment

actuators (ML6161 or other motors) and various

contactors and transducers.

3 31-00028—02

SYLK™ I/O DEVICES

IMPORTANT

• If a controller is used on Heating and Cooling

Equipment (UL 1995, U.S. only) and transformer

primary power is more than 150 volts, connect the

transformer secondary common to earth ground

(see Fig. 5 on page 6).

• When multiple controllers operate from a single

transformer, connect the same side of the transformer secondary to the same power input terminal in each device. The earth ground terminal

(terminal 3) must be connected to a verified earth

ground for each controller in the group (see Fig. 6

on page 7).

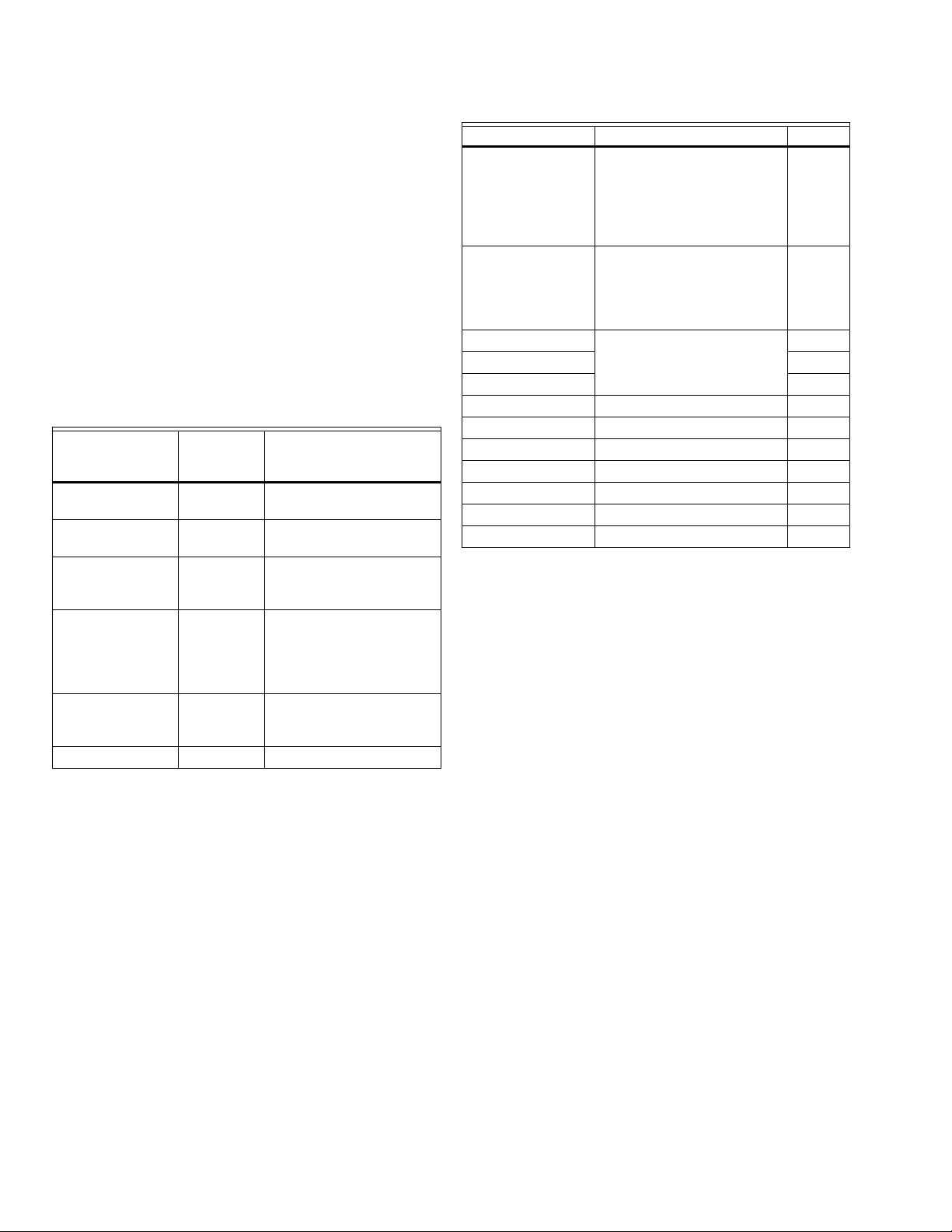

POWER BUDGET CALCULATION EXAMPLE

Table 3 is an example of a power budget calculation for

typical Spyder LON controller and Sylk IO devices. While

the example is shown for only these models, the process is

applicable for all controller and device configurations.

Table 3. Power budget calculation example.

VA

Informatio

Device

nObtained From

PUL6438SR 5.0 Spyder LON Product Data

Sheet

SIO6042

R8242A

Contactor fan

rating

5.0

21.0

a

See “Specifications” on

page 2.

TRADELINE

®

Catalog

inrush rating

D/X Stages 0.0 For example, assume

cooling stage outputs are

wired into a compressor

control circuit and have

no impact on the budget.

M6410A Steam

Heating Coil

Valve

0.7

TRADELINE® Catalog,

0.32A 24 Vac

TOTAL 31.7

a

Excludes the use of digital Triac outputs.

The system example above requires 31.7 VA of peak power.

Therefore, a 100 VA AT92A transformer could be used to

power one controller and device of this type. Because the

total peak power is less than 33 VA, this same transformer

could be used to power this configuration and meet NEC

Class 2 restrictions (no greater than 100 VA).

See Fig. 4–Fig. 6 beginning on page 6 for illustrations of

controller power wiring. See Table 4 for VA ratings of

various devices.

Table 4. VA ratings for transformer sizing.

Device Description VA

PVL0000AS,

PVL4022AS, and

Controller and Actuator

a

9.0

PVL6436AS

controllers and

Series 60 Floating

Damper Actuator

PUL1012S,

PUL4024S,

Controller

a

5.0

PUL6438S,

PVL4024NS, or

PVL6438NS

SIO12000

IO Device

a

3.0

SIO4022 4.0

SIO642 5.0

ML684 Versadrive Valve Actuator 12.0

ML6161 Damper Actuator, 35 lb-in. 2.2

ML6185

Damper Actuator SR 50 lb-in

12.0

ML6464 Damper Actuator, 66 lb-in. 3.0

ML6474 Damper Actuator, 132 lb-in. 3.0

R6410A Valve Actuator 0.7

R8242A Contactor 21.0

a

When used, each digital Triac output can add an addi-

tional 22 VA (peak) and 12 VA long-term.

For contactors and similar devices, the in-rush power ratings

should be used as the worst case values when performing

power budget calculations. Also, the application engineer

must consider the possible combinations of simultaneously

energized outputs and calculate the VA ratings accordingly.

The worst case, which uses the largest possible VA load,

should be determined when sizing the transformer.

Each device requires 24 Vac power from an energy-limited

Class II power source. To conform to Class II restrictions

(U.S. only), transformers must not be larger than 100 VA. A

single transformer can power more than one device.

GUIDELINES FOR POWER WIRING ARE AS FOLLOWS:

— For multiple devices operating from a single trans-

former, the same side of the transformer secondary

must be connected to the same power input terminal in each device. The earth ground terminal must

be connected to a verified earth ground for each

device in the group (see Fig. 6 on page 7). Device

configurations are not necessarily limited to three

devices, but the total power draw, including accessories, cannot exceed 100 VA when powered by the

same transformer (U.S. only).

— See Fig. 5 on page 6 for device power wiring used in

UL 1995 equipment (U.S. only).

— Many devices require all loads to be powered by the

same transformer that powers the device.

— Keep the earth ground connection wire run as short

as possible (refer to Fig. 4–Fig. 6 beginning on

page 6).

— Do not connect earth ground to the device’s digital

or analog ground terminals (refer to Fig. 4 and

Fig. 6).

— Unswitched 24 Vac power wiring can be run in the

same conduit as the L

ONWORKS® Bus cable.

31-00028—02 4

Loading...

Loading...