Page 1

S9360A, S9361A, S9370A, S9371A

Integrated Boiler Controllers

INSTALLATION INSTRUCTIONS

SPECIFICATIONS

IMPORTANT:

The specifications given in this publication do

not include normal manufacturing tolerances.

Therefore, an individual unit may not match the

listed specifications exactly. Also, this product is

tested and calibrated under closely controlled

conditions, and some minor differences in

performance can be expected if those

conditions are changed.

Model Numbers

APPLICATION

These integrated boiler control modules provide ignition

sequence, flame monitoring and safety shutoff for either

intermittent pilot spark ignition or direct hot surface

ignition heating systems. They also provide limit rated

water temperature control and display interface capability

for either “on-board” or remote user interface

applications.

• S9360A—Spark Ignition, Intermittent Pilot, Remote

Display.

• S9361A—Spark Ignition, Intermittent Pilot, “On board”

Display.

• S9370A—Hot Surface Ignition, Remote Display.

• S9371A—Hot Surface Ignition, “On board” Display.

• Enabled with EnviraCOM™ communication capability

to support remote monitoring and diagnostics.

• Limit-rated Temperature Sensing Probe.

• One or Two Sensor Models.

S—Switching Control

93—Integrated Hydronic Control Platform

6—Spark Ignition

7—Hot Surface Ignition

0—Remote Display Required

1—Integrated On-Board Display

A—Boiler Control

B—Water Heater Control

C—Pool Heater Control

1—No Circulator

2—On/Off Circulator

S9360A1000

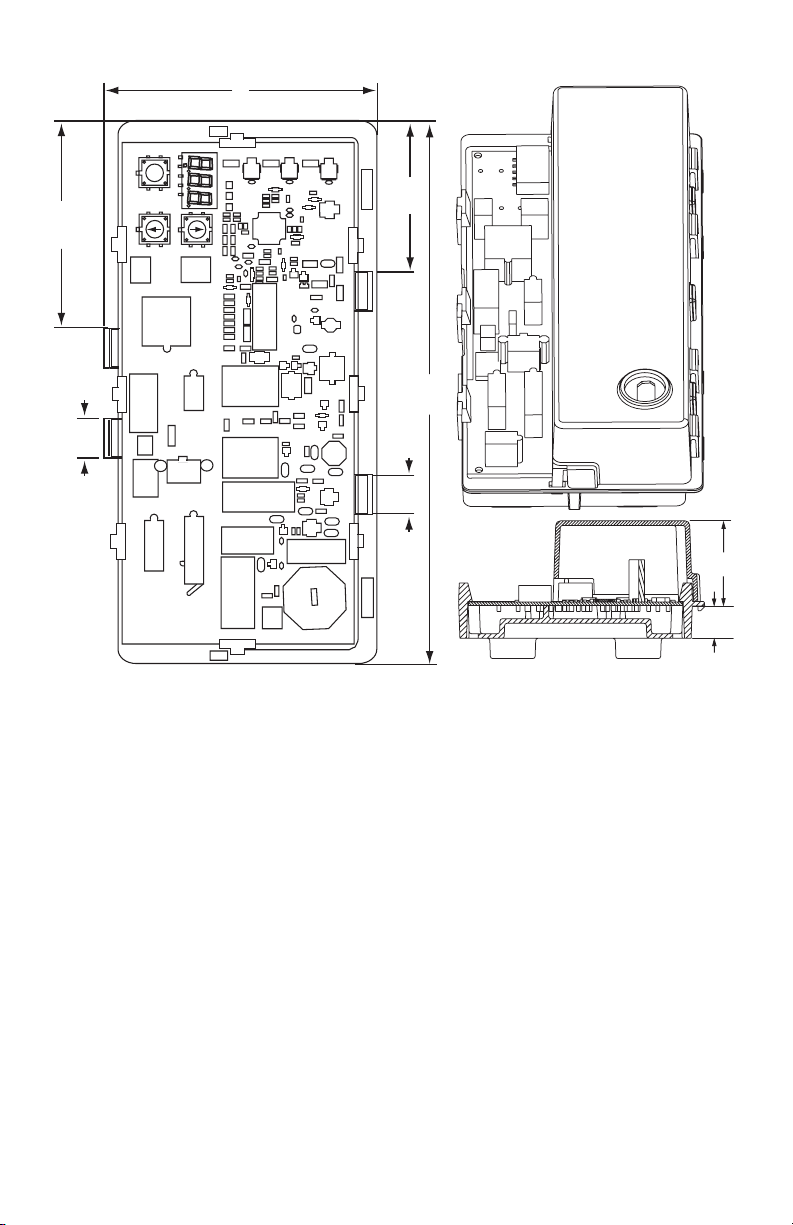

Dimensions:

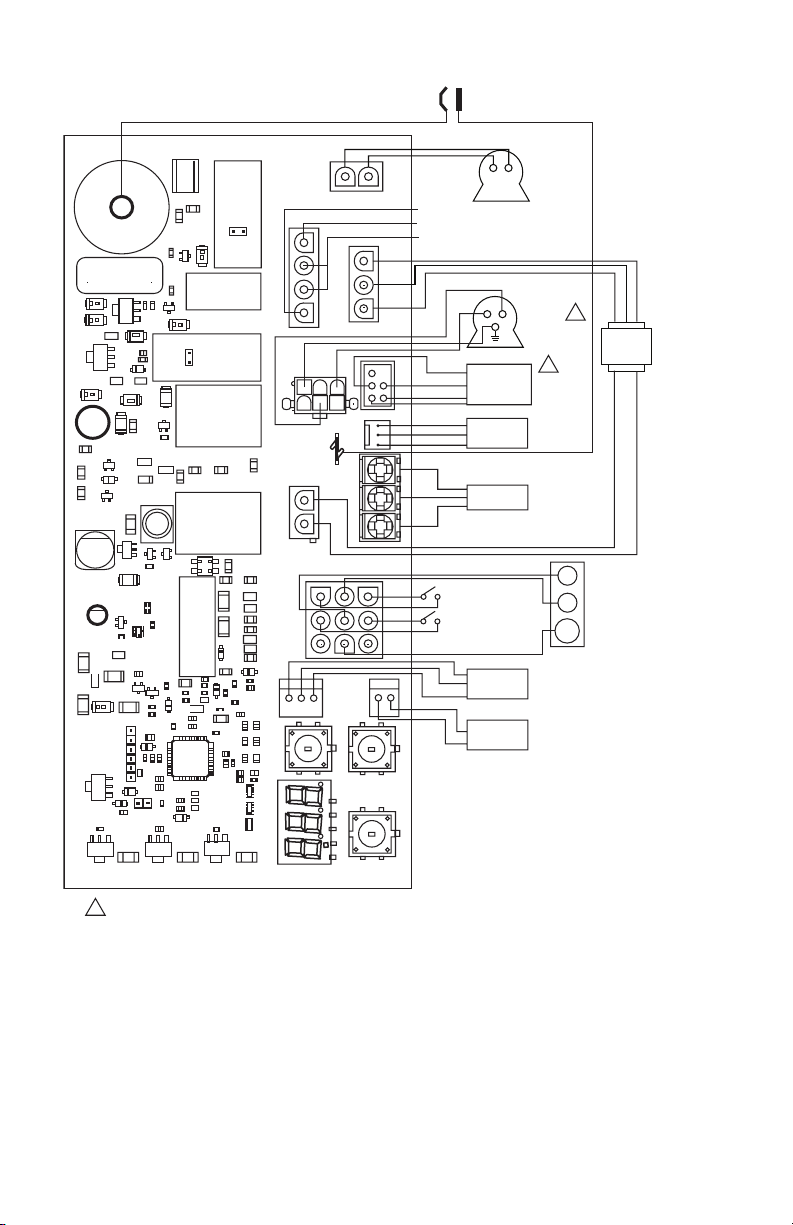

See Fig. 1.

69-2076-01

Page 2

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

111

I

2 x 84.5

2 x 15

Fig. 1. S936X Integrated Boiler Controller, dimensions in in. (mm).

Electrical Ratings:

Line Voltage: 120 Vac, 60 Hz (220 Vac, 50 Hz on specific

model numbers).

Transformer:

Nominal 24 Vac (maximum 30 Vac, minimum 18 Vac).

5.0 VA plus external loads (gas valve, vent damper, etc.)

On/Off Circulator:

Full Load: 7.4A at 120 Vac (0.75 to 0.8 power factor

[PF]). (220 Vac TBD.)

Locked Rotor: 44.4A at 120 Vac (0.4 to 0.5 PF). (220

Vac TBD.)

Inducer (Optional):

Full Load: 6A at 120 Vac (0.75 to 0.8 PF). (220 Vac

TBD.)

Locked Rotor: 17.48A at 120 Vac (0.4 to 0.5 PF). (220

Vac TBD.)

Vent Damper (Optional):

Full Load: 0.5A at 24 Vac.

In Rush: 1A at 24 Vac.

Main Valve:

Full Load: 2A at 24 Vac (0.5 to 0.6 PF).

In Rush: 6A at 24 Vac (0.5 to 0.6 PF)

Pilot Valve (Optional):

Full Load: 2A at 24 Vac (0.5 to 0.6 PF)

In Rush: 6A at 24 Vac (0.5 to 0.6 PF).

Hot Surface Igniter (HSI) (Optional):

2 x 61

220.5

2 x 15

1-3/8

(35)

5/8

(16)

M24217

Full Load: 4.5A at 120 Vac.

Warm-up Time:

18 seconds for first trial for ignition; this varies by

model, as does the time for the second trial for ignition (recommended for Norton igniter model 201 or

270 or equivalent)

Ambient Ratings:

Humidity: 0 to 95 percent relative humidity,

noncondensing.

Operating Ambient Temperature: -30°F to +150°F.

Shipping Ambient Temperature: -40°F to +175°F.

Flame Monitoring (May vary by model):

Flame Establishing Period (FEP): Maximum 2 seconds.

Flame Failure Response Time (FFRT):

Maximum: 2 seconds @ 1 µA.

Flame Stabilization Time: 4 seconds. Time from ignit-

ing the main burner and detecting loss of flame (the

flame current is allowed to be under the flame lost

threshold for this time while waiting for burner to

stabilize).

Flame Lost Threshold: 0.23 µA.

Ignition Cables:

Use cable types recommended in Table 1.

69-2076—01 2

Page 3

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

Table 1. Recommended Ignition Cables.

Cable Type

UL Style

3217

UL Style

3257

Transformer Requirement:

Add current ratings of module, pilot valve, main valve,

vent damper and any other components of the control

system to determine transformer size requirement.

Approvals:

Varies with control model.

ANSI Z21.20 Automatic Gas Ignition Systems and

Components.

ANSI Z21.23 Gas Appliance Thermostats.

EN298: Automatic Gas Burner Control Systems

ANSI Z21.87: Automatic Gas Shutoff Devices for Hot

Water Supply Systems.

UL353 Limit Controls.

Vol tag e

Rating (rms)

10,000 150 302

10,000 250 484

Temperature Rating

°C °F

PLANNING THE INSTALLATION

Automatic Ignition Control domestic and commercial

boiler systems are used on a wide variety of equipment.

Some of these applications may make heavy demands on

the controls, either because of frequent cycling, or

because of moisture, corrosive chemicals, dust or

excessive heat in the environment. In these situations,

special steps may be required to prevent nuisance

shutdowns and premature control failures. These

applications require Honeywell Engineering review;

contact your Honeywell Sales Representative for

assistance.

Frequent Cycling

These controls are designed for use on domestic and

commercial boiler systems that typically cycle less than

10,000 cycles per year. In an application with significantly

greater cycling rates, we recommend monthly checkout

because the controls may wear out more quickly.

High Humidity or Dripping Water

Over time, dripping water or high ambient humidity can

create unwanted electrical paths on the module circuit

board, causing the module to fail. Never install an

appliance where water can drip on the controls.

In addition, high ambient humidity can cause the control

to corrode and finally fail.

Where the appliance may be installed in a humid

atmosphere, make sure air circulation around the module

and gas control is adequate to prevent condensation. It is

also important to regularly check out the system. A NEMA

4 enclosure may be needed.

Corrosive Chemicals

Corrosive chemicals can also attack the module and gas

control and eventually cause a failure. Where chemicals

may be used routinely for cleaning, make sure the

cleaning solution cannot reach the controls. Where

chemicals are likely to be suspended in the air, as in some

industrial and agricultural applications, protect the module

from exposure with a NEMA 4 enclosure.

Dust or Grease Accumulation

Heavy accumulation of dust or grease may cause the

controls to malfunction. Where dust or grease may be a

problem, provide covers for the module and gas control

that limit environmental contamination. A NEMA 4

enclosure is recommended for the module.

Heat

The controls can be damaged by excessively high

temperatures. Make sure the maximum ambient

temperature at the control locations will not exceed the

rating of the control. If the appliance normally operates at

very high temperatures, insulation, shielding, and air

circulation may be necessary to protect the controls.

Proper insulation or shielding should b provided by the

appliance manufacturer; make sure adequate air

circulation is maintained when the appliance is installed.

INSTALLATION AND CHECKOUT

Water or Steam Cleaning

Once a module or gas control has been wet, it may

operate unreliably and must be replaced. If the appliance

is likely to be cleaned with water or steam, the controls

and associated wiring should be covered so that water or

steam cannot reach them. The controls should be high

enough above the bottom of the cabinet so they will not

be subjected to flooding or splashing during normal

cleaning procedures. If necessary, shield the controls to

protect them from splashing water. A NEMA 4 enclosure

is recommended.

When Installing This Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure they are suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

3 69-2076—01

Page 4

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. The module can malfunction if it gets wet,

leading to accumulation of explosive gas.

• Never install where water can flood, drip or

condense on module.

• Never try to use a module that has been

wet—replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not vent upward naturally.

• Do not light pilot or operate electric switches,

lights, or appliances until you are sure the

appliance area is free of gas.

3. If a new gas control is to be installed, turn off

gas supply before starting installation. Conduct

Gas Leak Test according to gas control

manufacturer instructions after the gas control

is installed.

4. If module must be mounted near moisture or

water, provide suitable waterproof enclosure.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

to prevent electrical shock or equipment damage.

Perform Preinstallation Safety Inspection

The preinstallation checks described in ANSI Standard

Z21.71 must be done before a replacement module is

installed. If a condition which could result in unsafe

operation is detected, the appliance should be shut off

and the owner advised of the unsafe condition. Any

potentially unsafe condition must be corrected before

proceeding with the installation.

Maintenance Requirements in Severe

Environments

Regular preventive maintenance is important in any

application, but especially so in commercial, agricultural,

and industrial applications, because:

1. In such applications, particularly commercial, the

equipment can operate 100,000 to 200,000 cycles

per year. Such heavy cycling can wear out the gas

control in one to two years. A normal boiler application, for which the controls were intended, typically

operate fewer than 10,000 cycles per year.

2. Exposure to water, dirt, chemicals, and heat can

damage the module or the gas control and shut

down the control system. A NEMA 4 enclosure can

reduce exposure to environmental contaminants.

The maintenance program should include regular

checkout of the system as outlined under Checkout.

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to take the module apart or to

clean it. Improper reassembly and cleaning may

cause unreliable operation, leading to an

accumulation of explosive gas.

Maintenance frequency must be determined individually

for each application. Some considerations are:

Cycling frequency. Appliances that may cycle more than

10,000 times annually should be checked monthly.

Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before the

next use.

Consequence of unexpected shutdown. Where the cost of

an unexpected shutdown would be high, the system

should be checked more often.

Dusty, wet, or corrosive environment. Since these

environments can cause the controls to deteriorate more

rapidly, the system should be checked more often.

Any control should be replaced if it does not perform

properly on checkout or troubleshooting. In addition,

replace any module if it is wet or looks like it ever has

been wet. Protective enclosures as outlined under

Planning the Installation are recommended regardless of

checkout frequency.

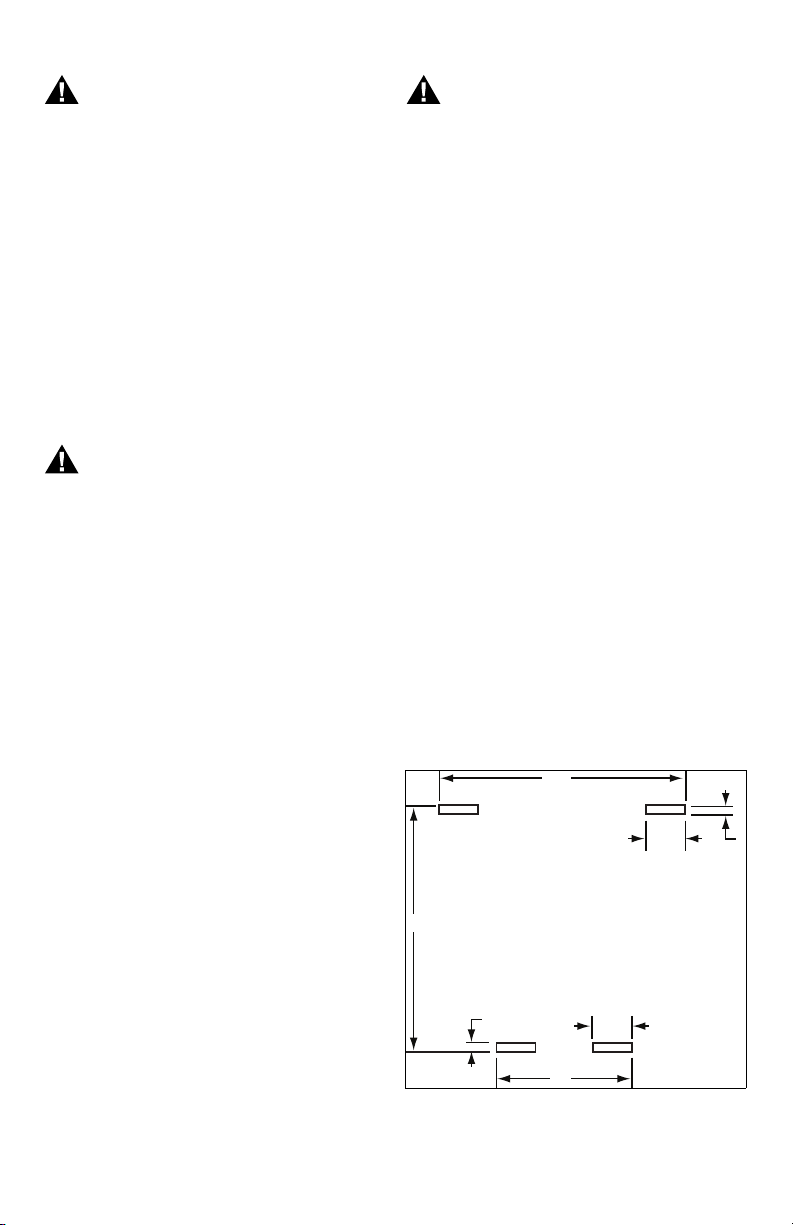

Mount Module

Select a location close enough to the burner to allow a

short (3 ft. [0.9 m] maximum), direct cable route to the

igniter. Ambient temperature at the module must be within

the range listed under Specifications. The module must

be protected from water, moisture, corrosive chemicals

and excessive dust and grease. Refer to Fig. 2 and 3 for

recommended slot/hole pattern in appliance.

99.5

16

100

4

16

4

69-2076—01 4

55

Fig. 2. Recommended slot/hole pattern in appliance

(in mm).

M24198

Page 5

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

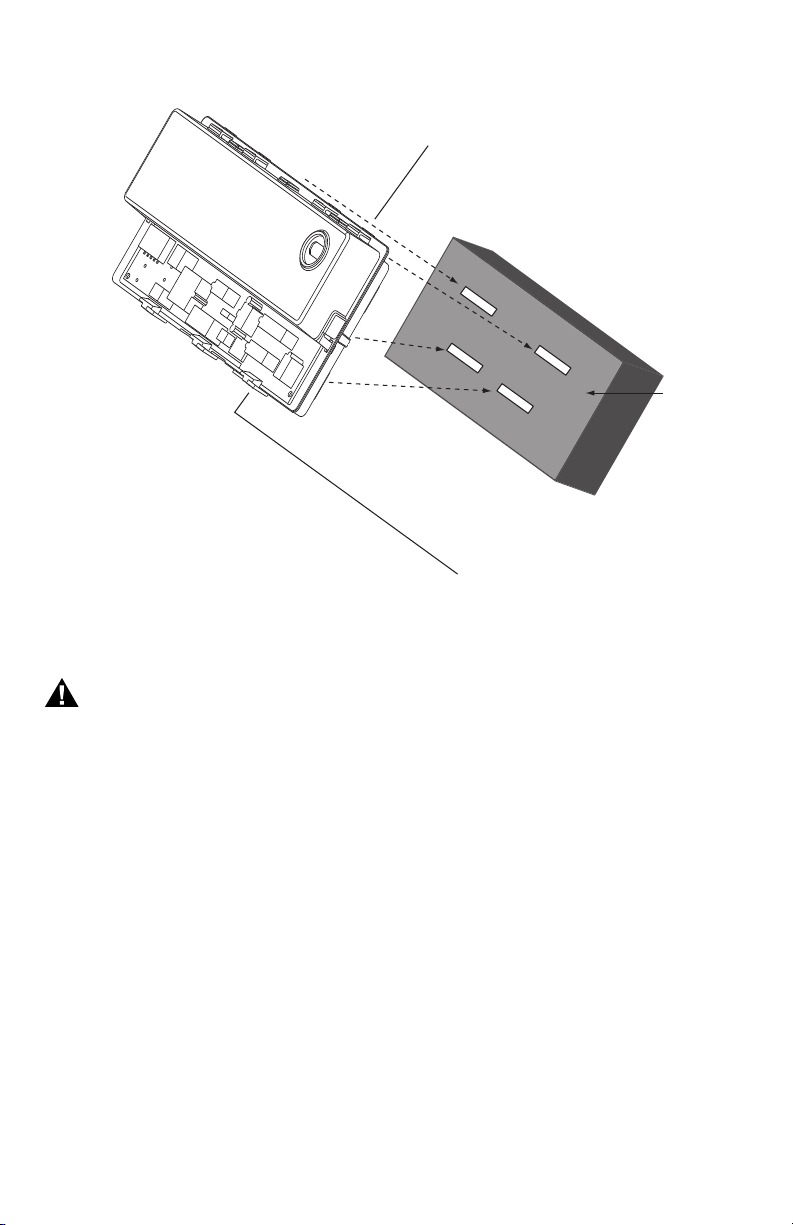

WATER

HEATER

M24229

Fig. 3. Align module with slots in control box.

CONTROL

BOX

Wire the System

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect the power supply before making wiring

connections to prevent electrical shock or

equipment damage.

Check the wiring diagram furnished by the appliance

manufacturer for circuits differing from the wiring hookup

shown in Fig. 4 and 5. Carefully follow any special

instructions affecting the general procedures outlined

below.

IMPORTANT

1. All wiring must comply with applicable local

electrical codes and ordinances.

2. When installing a hot surface igniter, the

leadwires should be kept as short as possible

and should not be allowed to rest against

grounded metal surfaces.

3. A common ground is required for the S93XX and

the main burner. The 24V “secondary” plug internally grounds one side of the transformer. Any

auxiliary controls or limits must not be in the

grounded leg. In addition, the appliance should

be earth-grounded.

4. Make sure the transformer has adequate VA.

The ignition module requires at least 0.2A at 24

Vac. Add the current draws of all other devices in

the control circuit, including the gas control, and

multiply by 24 to determine the total VA

requirements of these components. Add this

total to 5.0 VA (for the module). The result is the

minimum transformer VA rating. Use a Class II

transformer if replacement is required.

5. Check that L1 (hot) and L2 (neutral) are wired to

the proper terminals.

Connect Ignition Cable (S936XAXXXX)

Use Honeywell ignition cable or construct an ignition

cable that conforms to suitable national standards, such

as Underwriters Laboratories Inc. See Specifications

section. To construct a cable, fit one end (the module end)

with 1/4 in. connector receptacle and the other with a

connector to match the pilot assembly. Protect both ends

with insulated boots.

5 69-2076—01

Page 6

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

NOTE: Cable length must be 36 in. (0.9 m) or less. The

cable must not be in continuous contact with a

metal surface or spark voltage will be greatly

reduced. Use ceramic or plastic standoff

insulators as required.

1. Connect one end of the cable to the male

quick-connect SPARK terminal on the module.

2. Connect the other end of the cable to the igniter or

igniter-sensor stud on the pilot burner/ignitersensor.

Connect Vent Damper (Vent Damper Models)

A vent damper can be used with modules provided with a

vent damper plug connector. The Molex

simplifies wiring connections.

To connect the vent damper, follow the wiring diagrams

supplied with the vent damper for typical connections.

®

plug provided

Connect Remaining Module Connectors

Connect remaining system components to the ignition

module terminals as shown in the appropriate wiring

diagrams, Fig. 4 and 5.

Connect Igniter (HSI Models)

Prepare wiring harness:

1. Use wire suitable for the temperatures near the HSI

igniter.

2. Use wire suitable for the voltage ratings of the

specific igniter.

3. Attach connector per Table 4, HSI Specific

Connectors.

Connect Gas Control

Use No. 18 AWG solid or stranded wire. Connect to gas

control terminals as shown in wiring diagrams, using

terminals appropriate to the gas control.

Ground Control System

The igniter, flame sensor and module must share a

common ground with the main burner. Use AWM

insulated wire with a minimum rating of 105°C (221°F) for

Table 2. Specific Ignition Timings.

No. of

Model Ignition Type Draft Type

S9360A Intermittent

S9360A Intermittent

S9370A Direct Hot

a

Ignition Activation Period is the time that the hot surface igniter remains powered after the gas valve opens.

b

Purge Timing specified in seconds.

Pilot - Spark

Pilot - Spark

Surface

Induced 3 Separate 1 hour N/A 15 5

Atmospheric 3 Separate 1 hour N/A 1 5

Induced 3 Separate 1 hour 2.5 5 15

Ignition

Trials

the ground wire; asbestos insulation is not acceptable. If

necessary, use a shield to protect the wire from radiant

heat generated by the burner.

The burner serves as the common grounding area. If

there is not a good metal-to-metal contact between the

burner and ground, run a lead from the burner to ground.

NOTE: “Earth” ground is not required.

S937XA Hot Surface Ignition Versions

These models provide operating control of a direct ignition

system using a hot surface igniter. Additional components

required to complete the system must be ordered

separately. They include:

• Dual Valve Combination Gas Control: Any direct

ignition gas control with 2.0A maximum main valve

rating. VR8205, VR845, VR854, VR8450, or VR8540

recommended.

• Hot Surface Igniter: Norton Model 201 or 271 or

equivalent.

NOTE: If igniter other than Norton Model 201 or 271 is

used, the igniter must meet the following

minimum specifications, required over the life of

the igniter:

1. Igniter must reach 1000°C (1832°F) within 34

seconds with 102 Vac applied.

2. Igniter must maintain at least 500 megohms

insulation resistance between the igniter

leadwires and the igniter mounting bracket.

3. Igniter current draw at 132 Vac must not

Sensor: Separate sensor required. Honeywell Q354

recommended.

Igniter Wiring: Provide wiring harness to suit application.

• Leadwires: No. 18 AWG, stranded copper with 105°C

• Terminals: Insulated. See Table 4 for HSI specific

Transformer: Add current ratings of module, gas control,

vent damper and any other components of the control

system to determine transformer size requirements.

Igniter/

Sensor

Typ e

exceed 5 A.

rated, 1/16 in. AWM insulation.

connectors.

Automatic

Restart

Time

Ignition

Activation

a

Period

Prepurge

Timing

b

Postpurge

b

Timing

69-2076—01 6

Page 7

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

GND

SPARK

IGNITER

L1

L2

GND

FLAME

SENSE

DAMPER

ENVIRACOM

DIAGNOSTIC

ENVIRACOM

DISPLAY

PRESSURE SWITCH

LIMIT SWITCH

CIRCULATOR

INDUCER

1

1

24 VAC

TRANSFORMER

MV

GAS

CONTROL

PV

PV/

MV

1

OPTIONAL DEPENDING ON CONFIGURATION

SENSOR 1

SENSOR 2

M24216

Fig. 4. Spark Ignition Wiring (S936X).

7 69-2076—01

Page 8

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

GND

HOT SURFACE

IGNITER

L2

GND

L1

ENVIRACOM

DIAGNOSTIC

ENVIRACOM

DISPLAY

PRESSURE SWITCH

LIMIT SWITCH

CIRCULATOR

INDUCER

FLAME

SENSE

MV

MV

GAS

CONTROL

24 VAC

TRANSFORMER

Fig. 5. Hot Surface Ignition Wiring (S937X).

Common Connectors

Table 3. Connectors Common to Both Spark-to-Pilot and Hot Surface Ignition Options.

Connection/Color Pin Mating Plug Description

Flame Sense 1 of 1 3/16 in. female quick-

Sensor 1/White 1 of 3

2 of 3 Sensor Common

3 of 3 NTC 1-2

Sensor 2a/White

1 of 2

2 of 2

69-2076—01 8

connect

Molex

Molex® 43061-0002

SENSOR 1

SENSOR 2

®

43061-0003

M24218

Connection to Flame

Rod

NTC 1-1

NTC Temperature

Sensor

Page 9

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

Table 3. Connectors Common to Both Spark-to-Pilot and Hot Surface Ignition Options. (Continued)

Connection/Color Pin Mating Plug Description

EnviraCOM/Black 1 of 3 Stripped Bare Wire ECOM Data “1”

2 of 3 ECOM R “2”

3 of 3 ECOM C “3”

EnviraCOM Diag/

White

1 of 3 “Pen” Diagnostic Tool

2 of 3 ECOM R “2”

with 0.1 in. spacing

ECOM Data “1”

3 of 3 ECOM C “3”

Transformer Primary/

White

1 of 3

Molex

®

50-81-1030

2 of 3 Earth Ground

L1

3 of 3 Neutral

Transformer

Secondary/White

“Control”/White 1 of 9

1 of 2

Molex® 50-81-1020

24 Vac Input

2 of 2 Earth Ground

Molex® 50-81-1090 Pressure Switch

2 of 9

3 of 9

Pilot Valve

Pressure Switch

a

a

a

4 of 9 AC N.C. Switch

5 of 9 Main Valve

6 of 9 AC N.C. Switch

7 of 9 N.C.

8 of 9 MV/PV (Valve

Common)

9 of 9 N.C.

a

Indicates optional connection based on configuration.

HSI Model Specific Connectors

In addition to the common connectors listed above, Table 4 identifies connectors available on the HSI model board

assemblies.

Connection Pin Mating Plug Description

a

On/Off Circulator

/White

Line Voltage Input/Red 1 of 3

Induced Draft Blower (Combustion Air)/Red 1 of 4

HSI/Red 1 of 2

a

Indicates optional connection based on configuration.

Table 4. HSI Model Specific Connectors.

1 of 4

Molex® 50-84-1061

2 of 4 Earth Ground

3 of 4 Neutral

4 of 4 Neutral

Molex® 50-84-1031

2 of 3 Earth Ground

3 of 3 Neutral

Molex® 50-84-1041

2 of 4 Earth Ground

3 of 4 Neutral

4 of 4 Neutral

Molex® 50-84-1021

2 of 2 Flame Sense/(N) Relay Out

L1 Relay Out

L1

L1 Relay Out

L1 Relay Out

9 69-2076—01

Page 10

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

Table 5. Spark Model Specific Connectors.

Connection Pin Mating Plug Description

Line Voltage Input/White 1 of 4

2 of 4 Earth Ground

3 of 4 Earth Ground

4 of 4 Neutral

Induced Draft Blower (Combustion Aira)/White

Vent Dampera/White

Spark Rod 1 of 1 1/4 in. female quick-

a

On/Off Circulator

a

Indicates optional connections based on configuration.

/Red

Line In pin 02-08-2004

Transformer Primary socket 02-08-1002

Transformer Secondary socket 02-08-1002

Circulator pin 02-08-2004

Damper pin 03-06-2103

Inducer socket 39-00-0039

Control socket 02-08-1002

Sensor 1 socket 08-50-0106

Sensor 2 socket 08-50-0106

E-COM Diagnostic socket 08-50-0114

1 of 6

2 of 6 N/C

3 of 6 Neutral

4 of 6 N/C

5 of 6 L1 Relay Out

6 of 6 N/C

1 of 6 24 Vac

2 of 6 Damper E.S.

3 of 6 24V Common if

4 of 6 24V Common

5 of 6 Damper Activation

6 of 6 N/C

1 of 2

2 of 2 Neutral

Table 6. Pin Configuration.

Wire Harness Housing Pin Configuration

Pin/Socket Molex

®

50-81-1040

Molex

Molex® 39-01-2060

connect

Molex® 50-84-1021

®

Number

L1

Earth Ground

Feedback

damper connected

Connection to Spark

Rod

L1 Relay Out

Temperature Control

Temperature control setpoint on the module can be

adjusted as described in the following sections. Some

modules with temperature control also include a threedigit display on the printed circuit board to facilitate

adjustments and troubleshooting.

For modules that do not include temperature control on

the module refer to the Honeywell Installation Instructions

for the specific interface module or the appliance

manufacturer’s instructions. A separate automatic gas

shutoff device is not required in a system that uses this

control to meet requirements for CSA International ANSI

Z21.87 and UL 353.

69-2076—01 10

The overall range of the setpoint is model-dependent but

is within 130°F to 240°F (54°C to 116°C). Select devices

may have different ranges.

Adjusting Settings or Models with “OnBoard” Display

To discourage unauthorized changing of settings, a

procedure to enter the adjustment mode is required. To

enter the adjustment mode, press the UP, DOWN, and I

buttons (see Fig. 1) simultaneously for three seconds.

Press and release the I button until the parameter

requiring adjustment is displayed:

Page 11

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

Displ

“SP_” Setpoint.

“Df_” Setpoint Differential (select models).

“°F_” Degrees Fahrenheit

Then press the UP or DOWN button until the parameter

has reached the desired value. After 60 seconds without

any button inputs, the control will automatically return to

the READ mode.

Display

In the RUN mode, status items and parameters are

viewable. For example, to display setpoint, the control will

flash “sp” (setpoint) followed by the temperature (i.e.,

135), followed by °F or °C.

To read settings, press and release the I key to find the

parameter of interest. For example, press and release I

until setpoint (sp) is displayed, followed by a three-digit

number, i.e., 220, followed by °F or °C. Pressing the I

button again will display the (S1T) Sensor 1 Temperature

followed by a three-digit number and the corresponding

degree designator. See Display Readout, Fig. 6.

ay

Text Description

sta

Current State

Sensor 1 Temperature

s1t

s2t

Sensor 2 Temperature*

Setpoint

sp

Setpoint Differentialdff

Heat Request Statushr

Error Codeerr

Flame Currentfla

Degrees Fahrenheit F

Degrees Celsius C

uA

Micro Amps

Fig. 6. Display readout definitions.

Shows

M24052

LOCATION AND MOUNTING

Sensing Bulb(s)

The water heater manufacturer usually provides a tapping

for the sensing bulb at a point where average water

temperature can be measured. Some water heaters use

two (2) sensors, one limit rated near the center or bottom

of the tank, the other non-limit rated near the top. See Fig.

7. Follow the heater manufacturer instructions.

The sensing bulb can be installed in an immersion well.

Wells and fittings must be ordered separately. See 68-

0040.

When an immersion well is used, the sensor should fit

snugly and should touch the bottom of the well for best

temperature response. Use heat-conductive compound

(Honeywell part no. 107408) to fill the space between the

bulb and the well to improve heat transfer characteristics

(optional). Make sure the sensor is held firmly in the well.

Remote Display

For units that use a remote display, refer to I&I sheet for

SD7000A.

WIRING

IMPORTANT:

For maximum trouble free operation, run the

sensor leadwires separately from any other current-carrying wires.

All wiring must comply with local codes and ordinances.

Disconnect power supply before beginning wiring.

Connect according to water heater manufacturer

instructions.

INDUCER

MOTOR

(OPTIONAL)

INLET

LIMIT

SENSOR

SUPPLY

PUMP

Boiler Temperature Controller

When the water temperature reaches setpoint, the

controller ends the heating cycle. When the water

temperature drops below the setpoint minus the

differential, the control restarts a heat cycle to re-heat the

tank of water.

If the water temperature exceeds the max allowed

temperature, the control enters a manual reset lockout

state. For models that have reset capability, press any onboard button (when present), cycle power, or use the

remote display to reset.

CHECKOUT

Put the system into operation and observe operation

through at least one complete cycle to make sure that the

controller operates properly. See Troubleshooting section

to assist in determining system operation.

INTEGRATED

BOILER

CONTROL

MAIN

BURNER

PILOT

M27076

Fig. 7. Typical location of limit function sensor and

11 69-2076—01

control module.

Page 12

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

Mounting Sensor and Thermowell

The remote upper temperature sensor is installed in an

immersion well (Fig. 8) that extends into the supply water

side of the boiler.

Immersion Well Fitting

The immersion well must snugly fit the sensing bulb for

good thermal response. Install as follows:

1. Use tapping provided by tank manufacturer, if pos-

sible, or select an area where typical water temperature is best measured.

2. If tank is filled, drain to below point where bulb will

be installed.

3. Screw well into tank.

4. Insert bulb into well, pushing wires until bulb bot-

toms in well.

5. Attach mounting clamp end of well spud.

6. With mounting clamp attached to well spud (make

sure jaws of clamp hook over ridge at end of spud,

as shown at points A in Fig. 8), adjust sensing leadwire to fit through mounting clamp groove, as

shown at point B in Fig. 8.

7. Tighten draw nut until mounting clamp is firmly

attached to well spud and wires are held securely in

place.

CAUTION

Do not secure draw nut so tightly that

mounting clamp collapses tubing.

SENSOR WIRES

Fig. 8. Immersion well fitting for sensor.

Wiring

Disconnect power supply before installation to prevent

electrical shock or equipment damage. All wiring must

comply with local codes and ordinances regarding wire

size, type of insulation, enclosure, etc.

BOILER

IMMERSION

WELL

HEAT-CONDUCTIVE COMPOUND

(OPTIONAL)

SENSOR

M23086A

OPERATION AND CHECKOUT

Operation

The S9360A, S9361A, S9370A and S9371A continuously

monitor the temperature of the boiler water and enable or

disable the burner based on this temperature data. In

general, when a “Call for Heat” occurs, the ignition portion

of the control module proceeds through the steps

necessary to start the burner and heats the water in the

boiler until the setpoint temperature is achieved. At this

point the burner is de-activated, the ignition module

completes the heating cycle, returns to idle and waits for

the temperature to drop again. The circulator is turned on

throughout the “Call for Heat.”

See Fig. 9 for a graphical representation of a simple

control cycle. Note that the setpoint differential may vary

based on OS number.

High Limit Controller

All models include a 3-wire temperature sensor interface,

“Sensor 1,” which is utilized for High Limit functionality in

addition to the thermostatic control of the water heater

burner. If the temperature sensor ever indicates a

temperature above the maximum limit then the control

enters over temperature mode. In over temperature mode

no heating will occur.

200°F (93.3°C)

SETPOINT

15°F (8°C)

DIFFERENTIAL

70°F (21°C)

Fig. 9. Basic control algorithm example.

GAS VALVE OFF

GAS VALVE ON

M27000

69-2076—01 12

Page 13

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

TIME OUT

IGNITION

SEQUENCE

IDLE

ALL OUTPUTS OFF

WATER TEMPERATURE LOW AND THERMOSTAT ACTIVE

WATER TEMP.

HIGH OR CALL

FOR HEAT LOST

A

CHECK LEAKAGE/

SET FLAME BIAS

BIAS DONE

WAIT LIMIT

SWITCH CLOSE

LIMIT SWITCH CLOSE

CHECK DAMPER/

PRESSURE SWITCH

OPEN

SWITCH OPEN

DRIVE DAMPER/

INDUCER WAIT FOR

SWITCH CLOSE

SWITCH OPEN

PREPURGE

TIME OUT

SPARK

TURN PILOT VALVE ON

FLAME SENSED

PROVE FLAME

STOP SPARKING

FLAME PROVED

FLAME STABILIZATION

TURN MAIN VALVE ON

TIME OUT

RUN

SWITCH CLOSE

LIMIT SWITCH

OPEN

FLAME DEB ON

FLAME DEB OFF

TIME OUT

DAMPER/

PRESSURE

SWITCH OPEN

FLAME LOST

TIME OUT OR

MANUAL RESET

CHECK FLAME

PRE-TRIAL

RETRY DELAY

B

CIRCULATOR

CONTROL

IDLE

ALL OUTPUTS OFF

THERMOSTAT CALL FOR HEAT ACTIVE

CIRCULATOR ON

THERMOSTAT CALL FOR HEAT LOST

CIRCULATOR OFF

TIME OUT

RECYCLE DELAY

SOFT LOCKOUT

TIME OUT

TIME OUT

A

A

TIME OUT

WATER TEMPERATURE HIGH OR THERMOSTAT CALL FOR HEAT LOST

B

POSTPURGE

FLAME DEB ON

FLAME DEB OFF

Fig. 10. Operating Sequence.

CHECK FLAME

POST-TRIAL

M27073

13 69-2076—01

Page 14

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

TROUBLESHOOTING

IMPORTANT

1. The following service procedures are provided

as a general guide. Follow appliance manufacturer’s service instructions if available.

2. On lockout and retry models, meter readings

between gas control and ignition module must

be taken within the trial for ignition period. Once

the ignition module shuts off, lockout models

must be reset through the key buttons and display. On retry models, wait for retry or reset at

the thermostat.

3. If any component does not function properly,

make sure it is correctly installed and wired

before replacing it.

4. The ignition module cannot be repaired. If it malfunctions, it must be replaced.

5. Only trained, experienced service technicians

should service ignition systems.

Perform the checkout as the first step in troubleshooting.

Then check the appropriate troubleshooting guide and the

schematic diagram to pinpoint the cause of the problem. If

troubleshooting indicates an ignition problem, see Ignition

System Checks below to isolate and correct the problem.

Following troubleshooting, perform the checkout

procedure again to be sure system is operating normally.

Intermittent Pilot

Ignition System Checks

STEP 1: Check ignition cable.

Make sure:

• Ignition cable does not run in contact with any metal

surfaces.

• Ignition cable is no more than 36 in. [0.9 m] long.

• Connections to the ignition module and to the igniter or

igniter-sensor are clean and tight.

• Ignition cable provides good electrical continuity.

STEP 2: Check ignition system grounding. Nuisance

shutdowns are often caused by a poor or erratic ground.

• A common ground, usually supplied by the pilot burner

bracket, is required for the module and the pilot burner/

igniter sensor.

— Check for good metal-to-metal contact between

the pilot burner bracket and the main burner.

— Check the ground lead from the GND(BURNER)

terminal on the module to the pilot burner. Make

sure connections are clean and tight. If the wire is

damaged or deteriorated, replace it with No. 14-18

gauge, moisture-resistant, thermoplastic insulated wire with 105° C [221° F] minimum rating.

—Check the ceramic flame rod insulator for

cracks or evidence of exposure to extreme

heat, which can permit leakage to ground.

Replace pilot burner/igniter-sensor and provide shield if necessary.

—If flame rod or bracket are bent out of position,

STEP 3: Check spark ignition circuit.

restore to correct position.

• Disconnect the ignition cable at the SPARK terminal on

the module.

WARNING

The ignition circuit generates over 10,000 volts

and electrical shock can result.

Energize the module and listen for the audible sparking

noise. When operating normally, there should be a

buzzing noise that turns on and off twice per second for a

duration of 1–7 seconds, depending on the model.

STEP 4: Check pilot and main burner lightoff.

• Set the system to call for heat by turning the

thermostat above room temperature.

• Watch the pilot burner during the ignition sequence.

See if:

— Ignition spark continues after the pilot is lit.

— The pilot lights and the spark stops, but main

burner does not light.

• If so, ensure adequate flame current as follows.

— Turn off furnace at circuit breaker or fuse box.

— Clean the flame rod with emery cloth.

— Make sure electrical connections are clean and

tight. Replace damaged wire with moisture-resistant No. 18 wire rated for continuous duty up to

105° C [221° F].

— Check for cracked ceramic insulator, which can

cause short to ground, and replace igniter-sensor

if necessary.

— At the gas valve, disconnect main valve wire from

the MV terminal.

— Turn on power and set thermostat to call for heat.

The pilot should light but the main burner will

remain off because the main valve actuator is disconnected.

— Check the pilot flame. Make sure it is blue, steady

and envelops 3/8 to 1/2 in. [10 to 13 mm] of the

flame rod. See Fig. 11 for possible flame problems

and their causes.

— If necessary, adjust pilot flame by turning the pilot

adjustment screw on the gas control clockwise to

decrease or counterclockwise to increase pilot

flame. Following adjustment, always replace pilot

adjustment cover screw and tighten firmly to

assure proper gas control operation.

— Set temperature below room setpoint to end call

for heat.

• Recheck ignition sequence as follows.

— Reconnect main valve wire.

— Adjust thermostat above room temperature.

— Watch ignition sequence at burner.

— If spark still doesn’t stop after pilot lights, replace

module.

— If main burner doesn’t light or if main burner lights

but system locks out, check module, ground wire

and gas control as described in appropriate troubleshooting chart.

Troubleshooting Error Codes

The integrated boiler control uses advanced diagnostic

capability to assist in troubleshooting error conditions.

The following table shows the codes that could arise on

the remote or integrated display during a fault.

Suggestions are provided in Table 7 for servicing these

potential errors.

69-2076—01 14

Page 15

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

Table 7. Error Codes.

Segment

Display Definition

Pressure Switch failed to open (contacts stuck closed).

Flame sensed out of normal sequence (before opening gas valve or after

closing gas valve).

Flame sensed during prepurge (before gas valve signaled opened).

Flame sensed during postpurge (before gas valve signaled closed).

Pressure Switch failed to close (contacts stuck open).

Sensor 2 Error. Temperature sensor or interface failure (open or short

connection) or failure of A/D conversion (invalid offset).

Sensor 1 Error. Temperature sensor or interface failure (open or short

connection, increased connection resistance, dual sensor mismatch) or

failure of A/D conversion (invalid offset or gain, too many failures during

A/D conversion).

Atmospheric Damper End Switch failed to close (end switch contacts stuck

open).

Atmospheric Damper End Switch failed to open (end switch contacts stuck

closed).

Flame Rod shorted to burner ground.

AC line frequency error—signal is too noisy or frequency is incorrect.

Line voltage error—voltage out of spec high or low.

Line voltage unstable—possibly too many heavy loads switching on and

off cause erratic supply voltage.

Soft Lockout—maximum number of retries exceeded.

Soft Lockout—maximum number of recycles exceeded.

Soft Lockout—electronics failure. Caused by general electronics failure

such as relay open or shorted contacts, flame sensing circuit error, or A to

D error.

Over temperature error. Sensors measured temperature in excess of ECO

limit.

15 69-2076—01

Page 16

S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

APPEARANCE

SMALL BLUE FLAME

LAZY YELLOW FLAME

WAVING BLUE FLAME

NOISY LIFTING

BLOWING FLAME

HARD SHARP FLAME

CAUSE

CHECK FOR LACK OF GAS FROM:

• CLOGGED ORIFICE FILTER

• CLOGGED PILOT FILTER

• LOW GAS SUPPLY PRESSURE

• PILOT ADJUSTMENT AT MINIMUM

CHECK FOR LACK OF AIR FROM:

• DIRTY ORIFICE

• DIRTY LINT SCREEN, IF USED

• DIRTY PRIMARY AIR OPENING,

IF THERE IS ONE

• PILOT ADJUSTMENT AT MINIMUM

CHECK FOR:

• EXCESSIVE DRAFT AT PILOT

LOCATION

• RECIRCULATING PRODUCTS

OF COMBUSTION

CHECK FOR:

• HIGH GAS PRESSURE

THIS FLAME IS CHARACTERISTIC

OF MANUFACTURED GAS

CHECK FOR:

• HIGH GAS PRESSURE

• ORIFICE TOO SMALL

M3272A

Fig. 11. Examples of unsatisfactory pilot flames.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2007 Honeywell International Inc.

69-2076—01 M.S. 10-07

Loading...

Loading...