Page 1

™

SL AT E

Sub-Base Module

R8001S9001

INSTALLATION INSTRUCTIONS

Page 2

Scan for more information

Page 3

Application

SLATE™ brings configurable safety and programmable logic

together into one single platform. The platform can easily be

customized for almost any requirement or application–offering

virtually limitless development opportunities with far less

complexity.

The R8001S9001 SLATE Sub-Base Module provides the ability

for the SLATE system to be mounted via DIN Rail in a panel. All

SLATE modules need this sub-base except for the SLATE Base

Module.

Features

• Quick-mount to standard DIN-Rail

• Locking mechanism

• Provides bus connectivity to all modules

• Connections for remote mounted flame amplifiers (remote bus)

and remote pushbutton reset

Specifications

Electrical Ratings:

Voltage and Frequency (from the Base): 18 VDC (± 1 VDC)

Maximum Total Connected Load: 2.5A

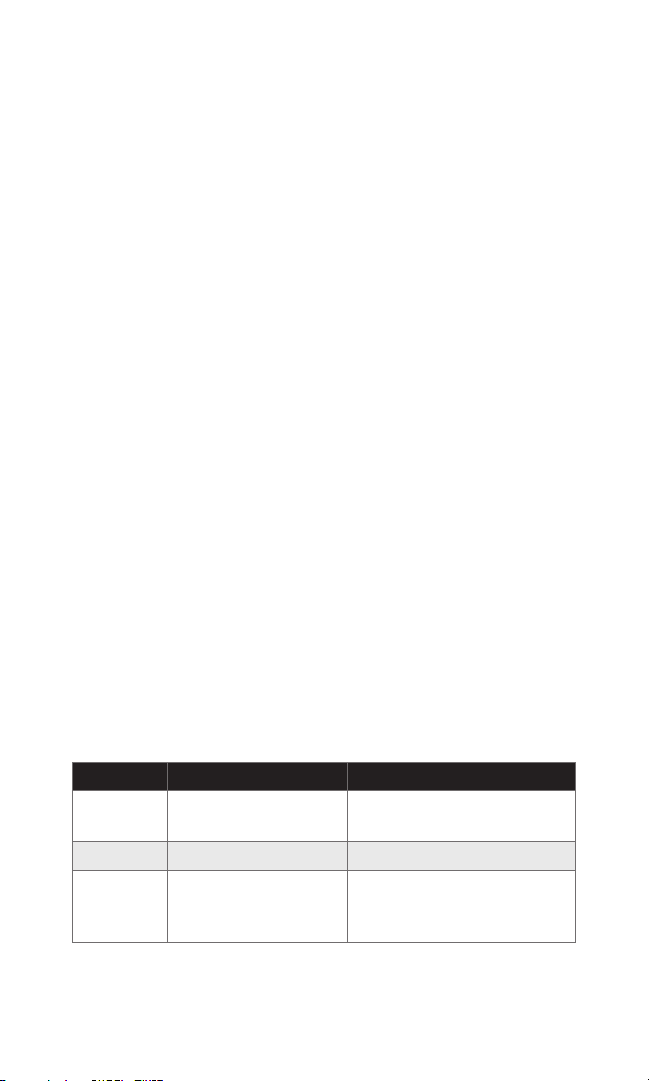

Terminal Ratings: See Table 1

Terminal Description Rating

1 18 V Power 2.5 A max including

modules

2 18 V Ground ---

3 Remote Reset

(Burner Control and

Limit modules only)

SLATE™ Sub-Base Module 3

R8001S9001

Connect to Terminal 2 (18

V Ground) via external

pushbutton

Page 4

Terminal Description Rating

4 B (Remote Bus

RS485)

5 A (Remote Bus

RS485)

Table 1. Terminal Ratings.

Used for Remote mounted ame ampliers

Used for Remote mounted ame ampliers

Environmental Ratings

Ambient Temperature:

Operating: -20°F to +150°F (-29°C to +66°C).

Shipping: -40°F to +150°F (-40°C to +66°C)

Humidity: 95% continuous, noncondensing.

Vibration: 0.5G environment

Dimensions: See Fig. 1.

Weight: 5 oz (136 g)

Approvals

Underwriters Laboratories Inc. Listed, File: MP286

IRI acceptable.

Federal Communications Commission: Part 15, Class A

Emissions.

Mounting

DIN Rail (See Fig. 3)

Required Components

R8001A1001 SLATE Base Module

Any other SLATE modules

Optional 5-position terminal block for remote flame amplifier or

remote reset button connections (Phoenix Contact p/n 1754504

or equivalent). See Fig. 2.

4 32-00025—01

Page 5

Fig. 1.

Dimensions in in. (mm).

2-21/32 (67)

3-13/32 (86)

7-3/32

(180)

1-5/32

(29)

M35384

SLATE™ Sub-Base Module 5

R8001S9001

Page 6

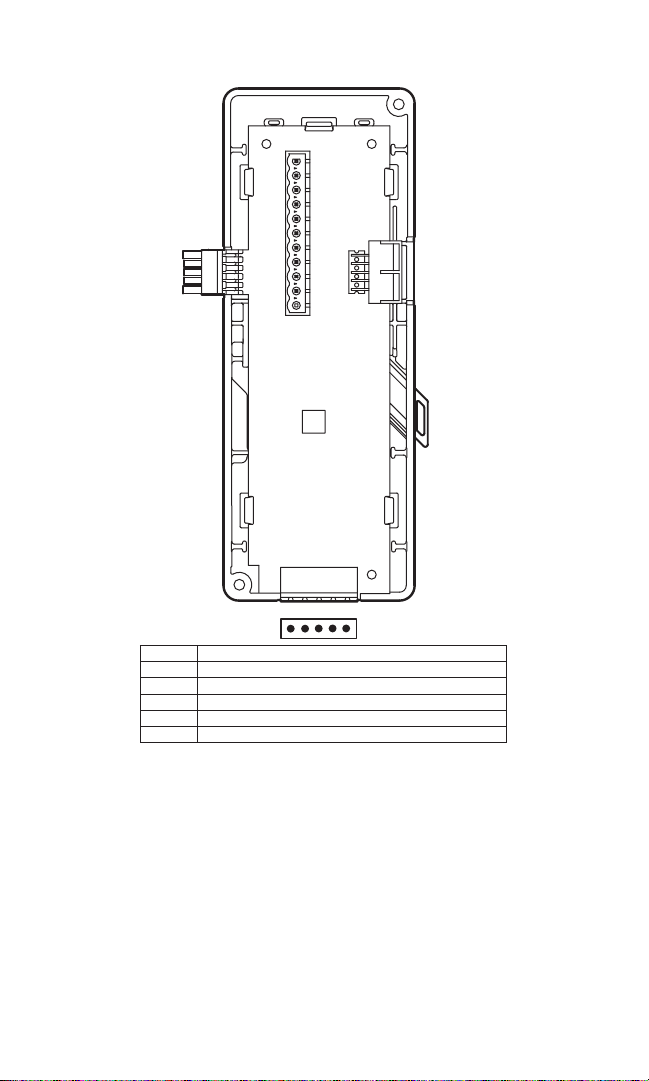

4 5

3

2

1

TERMINAL

Fig. 2.

Sub-base module wiring terminals.

18V POWER

1

2

18V GROUND

3

REMOTE RESET (BURNER CONTROL AN D LIMIT MODULES ONLY)

B (REMOTE BUS RS485)

4

A (REMOTE BUS RS485)

5

DESCRIPTION

M35430

6 32-00025—01

Page 7

Installation

WARNING

Fire or Explosion Hazard Can cause severe injury,

death, or property damage.

Verification of safety requirements must be performed

each time a control is installed on a burner to prevent

possible hazardous burner operation.

When Installing This Product

1. Read these instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the product

to make sure the product is suitable for your application.

Mounting

1. The sub-base module can be mounted on type C 20 DIN rail.

2. Mount the sub-base module first. The sub-base has locking

mechanisms on both sides of the module. Pull to unlock

position. See Fig. 3.

SLATE™ Sub-Base Module 7

R8001S9001

Page 8

Fig. 3.

M35378

UNLOCKED FROM DIN RAIL

LOCKED ONTO DIN RAIL

Sub-base locking mechanisms.

3. Slide sub-base on the DIN rail and lock into place.

4. When securing subsequent sub-base modules make sure

communication ports are aligned and locked into place. See

Fig. 4.

Fig. 4.

Connecting additional sub-base modules.

8 32-00025—01

M35386

Page 9

5. After securing the sub-base module, snap the SLATE module

into place and secure the module to the sub-base using

screws (included with SLATE module).

Wiring

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment damage.

1. Disconnect the power supply before beginning installation to

prevent electrical shock and equipment damage. More than

one power supply disconnect can be involved.

2. Wiring must comply with all applicable codes, ordinances and

regulations. See Fig. 2.

3. Wiring must comply with NEC Class 1 (Line Voltage) wiring.

Application Recommended Wire

Size

Communication

Lines

Other terminals 18 AWG wire insulat-

Table 2. Recommended Wire Sizes and Part Numbers.

IMPORTANT

This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with these

instructions, may cause interference for radio communications.

It has been tested and found to comply with the limits of a Class

A computing device of part 15 of FCC rules, which are designed

to provide reasonable protection against such interference

SLATE™ Sub-Base Module 9

R8001S9001

22 AWG two-wire

twisted pair with

ground, or ve-wire.

ed for voltages and

temperatures for given

application.

Recommended

Part Numbers

Belden 8723

shielded cable

or equivalent.

TTW60C,

THW75C,

THHN90C

Page 10

when operated in a commercial environment. Operation of this

equipment in a residential area may cause interference; in which

case, the user, at their own expense, may be required to take

whatever measures are required to correct this interference.

1. This digital apparatus does not exceed the Class A limits for

radio noise, set out in the Radio Interfeence Regulations of

the Canadian Department of Communications.

2. Cable shield must be terminated to ground at both ends. If

shielded cable is NOT used, use three-wire twisted cable.

Recommended Grounding Practices

Use an Earth ground or a signal ground as described below.

Earth Ground (Base, Rectification Flame Amp

Module, Other Modules Optional)

1. Use to provide a connection between the base and the

control panel of the equipment. Earth ground must be capable

of conducting enough current to blow the breaker in the event

of an internal short circuit.

2. Use wide straps or brackets to provide minimum length,

maximum surface area ground conductors. If a leadwire is

required, use 14 AWG copper wire.

3. Verify that mechanically tightened joints along the ground path

are free of nonconductive coatings and protected against

corrosion on mating surfaces.

Signal ground

Note the 18 V system ground is not electrically connected

to earth ground. Follow local codes and appliance

recommendations to determine if this should be connected to

earth ground.

Recommended Routing of Leadwires

• Do not run high voltage ignition transformer wires in the same

conduit with the flame detector or data lines.

• Do not route flame detector or data lines in conduit with line

voltage circuits.

10 32-00025—01

Page 11

• Enclose flame detector leadwires without armor cable in metal

cable or conduit.

• Follow directions in flame detector instructions.

Be sure loads do not exceed the terminal ratings. Refer to the

labels or terminal ratings in Table 1.

The SLATE system must be mounted in an electrical enclosure.

When mounting in an electrical enclosure, provide adequate

clearance for servicing, installation, and removal of SLATE

modules.

Maximum Wire Length

• The maximum leadwire length is 300 feet to terminal inputs

(Control, Running/Lockout Interlock)

• For remote reset leadwires, maximum length to remote

pushbutton is 1000 feet.

• For remote bus data lines, maximum cable length depends on

the number of modules connected, the noise conditions, and

the cable used. The maximum of all interconnecting wires is

4000 feet.

SLATE™ Sub-Base Module 11

R8001S9001

Page 12

For more information and detailed instructions on the SLATE display

32-00025-01

please refer to the SLATE User Guide document located on our

website at http://combustion.honeywell.com/SLATE

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark.

© 2014 Honeywell International Inc.

32-00025—01 M.S. 11-14

Printed in U.S.A.

Loading...

Loading...