Page 1

32M-06009-06

SLATE™ Low Torque Actuator

SLATE Commercial Model

Series

FOR COMMERCIAL AND INDUSTRIAL MODELS

R8001M1050, R8001M1150, R8001M4050, R8001M4150

INSTALLATION INSTRUCTIONS

FEATURES AND BENEFITS

• Offered in two different configuration options:

— NEMA 1 rated, operating in a temperature

range of -18 to 158 °F (-28 to 70 °C) with

450 positions over a 90° span

— NEMA 4 rated, operating in a temperature

range of -40 to 158 °F (-40 to 70 °C) with

900 positions over a 90° span

• Field-reversible clockwise and counterclockwise

rotation operation.

• Internal temperature, valve status, health

diagnostics, and error codes reporting.

• Robust, heavy-duty construction, continuous

duty cycle-rated.

• Closed loop position control via Modbus RS-485

communications as an input to the SLATE Fuel

Air Ratio Module, part R8001C6001.

• Dual 1/2-in knockout conduit connections.

• 1/2-in keyed output shaft with a 1/8-in square

key.

APPLICATION

SLATE brings configurable safety and programmable

logic together into one single platform. The SLATE

program can easily be customized for almost any

application—offering virtually limitless development

opportunities with far less complexity.

• Die-cast aluminum base with high-impact

resistant, reinforced plastic cover.

• Meets UL353 Safety for Limit Controls.

• Meets UL1998 when used with R8001C6001

SLATE Fuel Air Ratio Module.

The SLATE Low Torque Actuator series includes

commercial- and industrial-grade 1/4-turn actuators

available in 50 and 150 in/lb models with highly

repeatable position accuracy designed specifically to

integrate with the SLATE system. This series is well

suited for the precise control of air and gas flow and

can operate in a wide range of temperatures and

environmental conditions.

SLATE™ Low Torque Actuator can be easily mounted

to the following valves using the mounting kits noted

below. These kits can be ordered via

www.customer.honeywell.com.

• Maxon CV Valve Series (1/2"–2")

mounting kit #50123928-001

• Honeywell V51E Valve Series (1-1/2"–2")

mounting kit #50124386-001 and mounting kit

#32003396-001

• Honeywell V51E Valve Series (2-1/2"–4")

mounting kit #50124386-001 and mounting kit

#32003396-002

• Honeywell V5197A Valve Series (3/4"–3")

mounting kit #50124386-001

APPROVALS

Underwriters

Laboratories

CE 2009/142/EC: Gas Appliance

Meets UL353 Safety for Limit

Controls.

Meets UL1998 when used with

R8001C6001 SLATE Fuel Air Ratio

Module.

Directive

(EN 12067-2:2004, EN298-2012)

Page 2

SLATE™ LOW TORQUE ACTUATOR SERIES

SPECIFICATIONS

Supply Voltage (Peak Current):

DC model: 24VDC +10/-20%

Power:

50 in/lb: 10 Watts maximum

150 in/lb: 25 Watts maximum

Rotation: Max span: 90° usable

Resolution:

Commercial: 450 positions (0.2° resolution)

Industrial: 900 positions (0.1° resolution)

Control Deadband:

Commercial: ±0.2 degrees

Industrial ±0.1 degrees

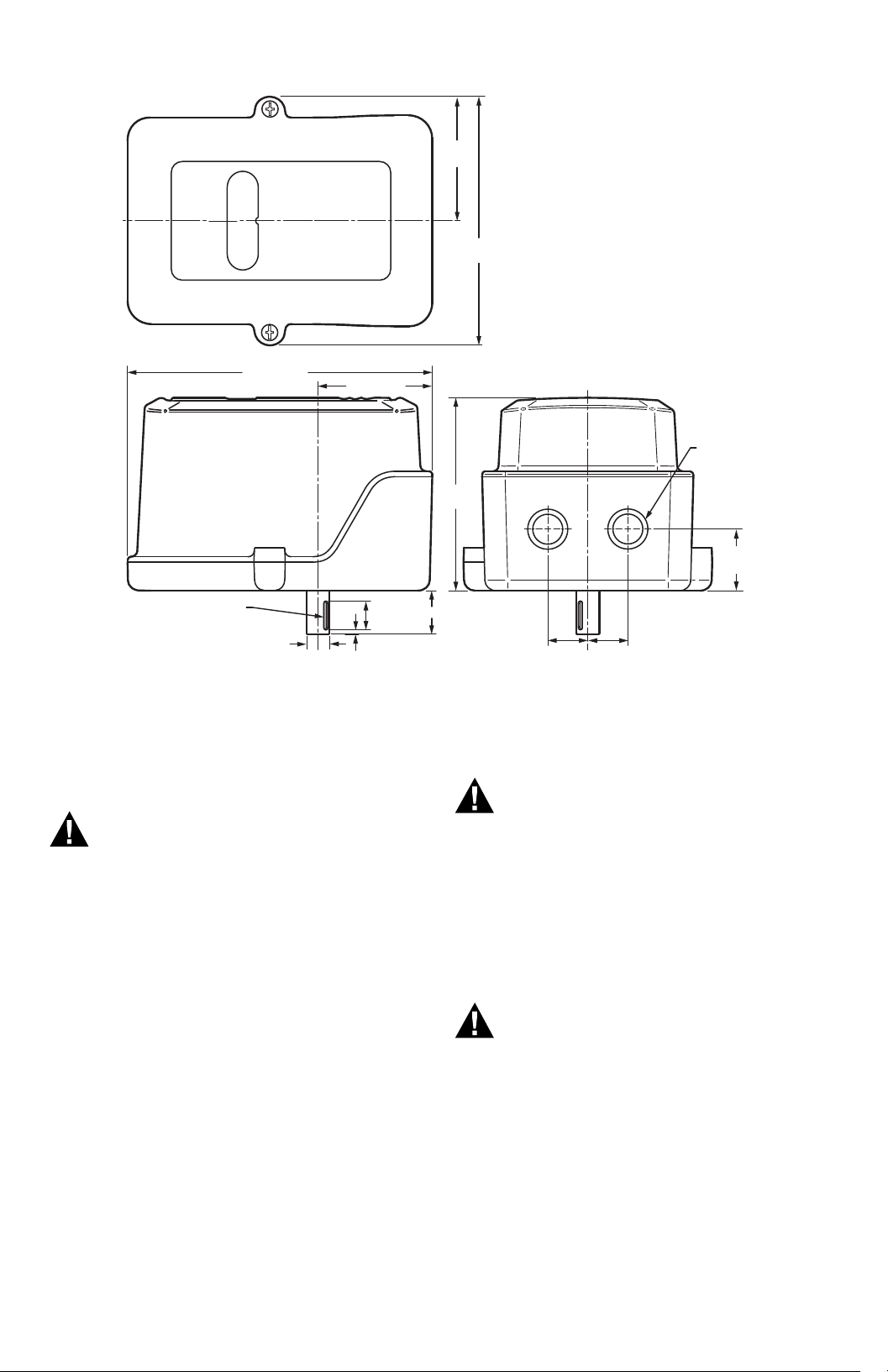

Dimensions in in (mm): 6-11/16 x 5-29/64 x 5-

29/64

(170 x 138 x 138); See Fig. 1

Weight: 3 Lbs. (1.4 Kg)

Operating Temperature:

-28 to +70 °C (-18 to +158 °F) for commercial models; -40 to +70 °C (-40 to +158 °F) for industrial

models

Storage Temperature: -40 to +80 °C (-40°F to

+176°F)

Vibration: Honeywell V2 test specification; 3 axes

tested as follows:

2-Hour Performance/Resonant Detection Sweep:

Vibration sinusoidal: 5 Hz - 30 Hz;

Amplitude: 0.012mil pk/pk75 mm

Vibration sinusoidal: 30 Hz – 300 Hz at 0.6G

Endurance: 1.1G for 2 hours at resonant frequencies

EMC: EN61000-6-1/2/3 (See Safety and Agency

Approval Requirements), FCC Part 15, Level A

EN55022, Level A

Enclosure:

NEMA1 (commercial models)

NEMA 4 (industrial models)

Models:

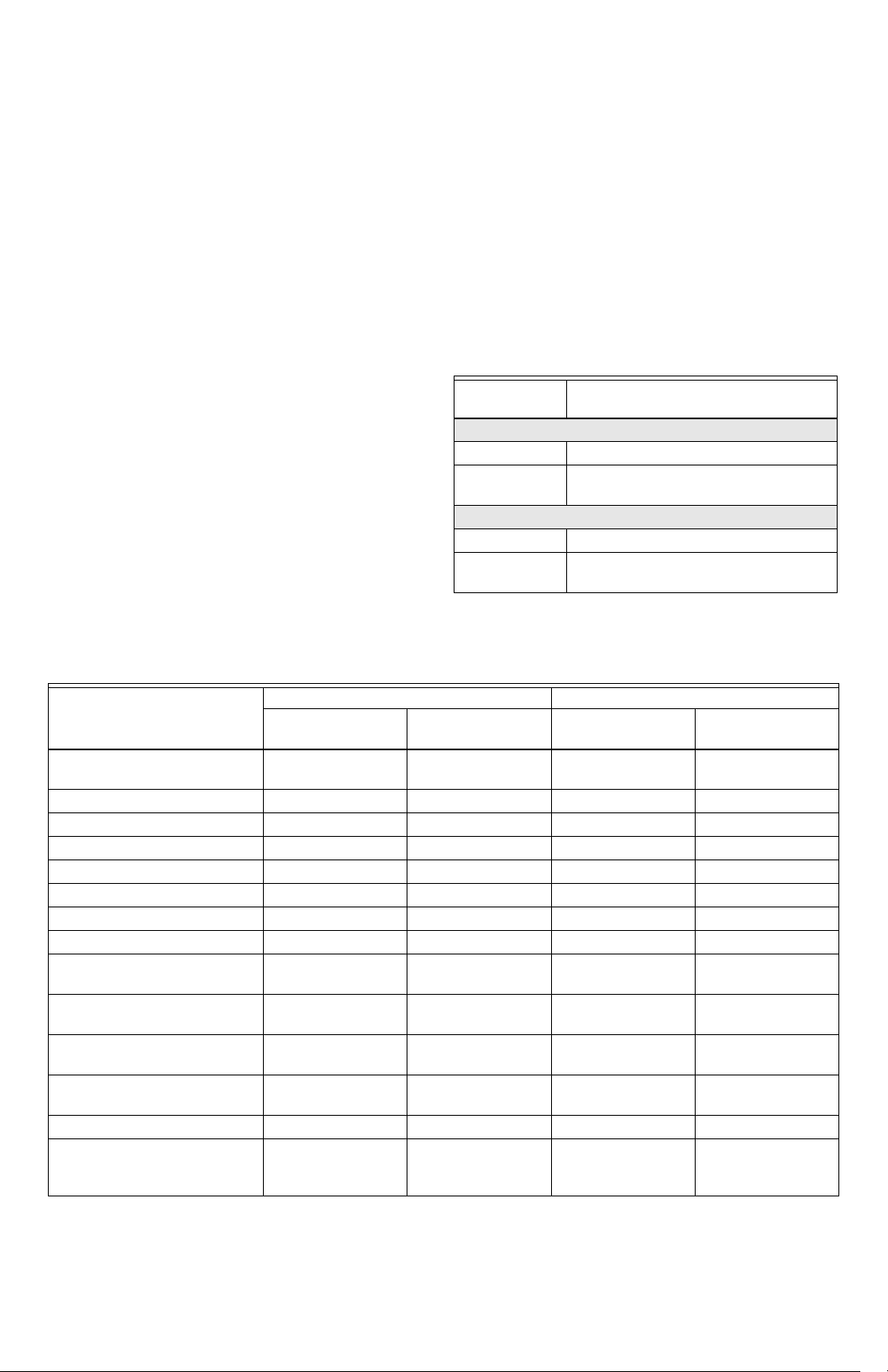

Model

Number Description

Commercial

R8001M1050 50 in/lb Actuator NEMA 1 Enclosure

R8001M1150 150 in/lb Actuator NEMA 1

Enclosure

Industrial

R8001M4050 50 in/lb Actuator NEMA 4 Enclosure

R8001M4150 150 in/lb Actuator NEMA 4

Enclosure

Relative Humidity:

0 to 99% non condensing (for commercial models)

Table 1. Model Specifications.

Commercial Model Industrial Model

50 in-lb

Actuator Options/Specs

Communication RS-485 non-

Fault Annunciation Generic Alarm Generic Alarm Yes Yes

Enhanced Data Logging None None Yes Yes

Resolution .2 Degree .2 Degree .1 Degree .1 Degree

Repeatability .2 Degree .2 Degree .1 Degree .1 Degree

Duty Cycle (Act Availability) 100% 100% 100% 100%

Opening Span 90 Degrees 90 Degrees 90 Degrees 90 Degrees

90 Degree Travel Time 30 sec 30 sec 15 sec max 15 sec max

Minimum Operating

Tem per ature

Maximum Operating

Tem per ature

Temp Sensor Yes; Alarm Only Yes; Alarm Only Yes; Alarm and

Output 1/2-in Keyed

Keyed Connection 1/8-in Square Key 1/8-in Square Key 1/8-in Square Key 1/8-in Square Key

Conduit Connections 1/2-in Conduit

R8001M1050

isolated

-28 °C (-18 °F) -28 °C (-18 °F) -40 °C (-40 °F) -40 °C (-40 °F)

70 °C (158 °F) 70 °C (158 °F) 70 °C (158 °F) 70 °C (158 °F)

Output Shaft

Knockouts (2)

(Shipped Closed)

150 in-lb

R8001M1150

RS-485 nonisolated

1/2-in Keyed

Output Shaft

1/2-in Conduit

Knockouts (2)

(Shipped Closed)

50 in-lb

R8001M4050

RS-485 Isolated RS-485 Isolated

Real Time Data

1/2-in Keyed

Output Shaft

1/2-in Conduit

Knockouts (2)

(Shipped Closed)

150 in-lb

R8001M4150

Yes; Alarm and

Real Time Data

1/2-in Keyed

Output Shaft

1/2-in Conduit

Knockouts (2)

(Shipped Closed)

32M-06009—06 2

Page 3

SLATE™ LOW TORQUE ACTUATOR SERIES

WARNING

WARNING

WARNING

M35299

(2) Ø 7/8 (22)

KNOCKOUTS

FOR 1/2”

CONDUIT

ENTRANCE

KEYWAY FOR

1/8” SQ. X 1/2” LG. KEY

6-11/16 (170)

2-47/64

(69)

5-29/64

(138)

2-33/64 (64)

Ø 1/2 (13)

3/32 (3)

5/8 (16)

61/64 (24)

5-29/64

(138)

7/8 (22)

7/8 (22)

1-11/32

(34)

Fig. 1. Dimensions in in (mm).

INSTALLATION INSTRUCTIONS

Read Carefully

Please read the operating and mounting

instructions before using the equipment.

Install the equipment in compliance with the

prevailing regulations.

Bedrijfs- en montagehandleiding voor gebruik

goed lezen! Apparaat moet volgens de

geldende voorschriften worden geïnstalleerd.

Lire les instructions de montage et de service

avant utilisation! L’appareil doit

imperativement être installé selon les

règlementations en vigueur.

Betriebs- und Montageanleitung vor Gebrauch

lesen! Gerät muß nach den geltenden

Vorschriften installiert werden.

NOTICE

Language translations for this document are available

at www.customer.honeywell.com.

Safety requirements

Safety Notice

The SLATE Actuator has been independently

evaluated by Underwriters Laboratories to

provide position feedback to the SLATE Fuel Air

Ratio Module. The safety of the overall system

is ultimately the responsibility of: 1) The

upstream safety control that commands and

monitors the SLATE Actuator, and 2) the

trained commissioning engineer that

configures the unit for system operation.

Safety Hazard

Before operating this product, check all

specifications and safety requirements to

ensure the product is suitable and safe for the

intended application. In addition, read all

installation, commissioning, and operating

instructions. The SLATE Actuator must be set

up and maintained in the field by qualified

personnel. If the equipment is used in a

manner not specified, the protection provided

by the equipment may be impaired.

3 32M-06009—06

Page 4

SLATE™ LOW TORQUE ACTUATOR SERIES

WARNING

WARNING

2X 3-1/2 (89)

M35300

1-1/8

(28)

THREADED FOR

M6 x 1 (25) x 1/2 (12)

FASTENER

O 1/4 (6) X 17/64 (7)

DEEP FOR OPTIONAL

DOWEL PIN

1-1/8

(28)

1-1/8

(28)

1 (25)

1 (25)

2X 1-3/8

(35)

2X 1-3/8

(35)

M35301

0° IF ROTATION IS SET TO CCW

90° IF ROTATION IS SET TO CW

5° SPAN

ADJUSTMENT

RANGE

(ADDITIONAL

TRAVEL)

5° SPAN

ADJUSTMENT

RANGE

(ADDITIONAL

TRAVEL)

90° IF ROTATION IS SET TO CCW

0° IF ROTATION IS SET TO CW

SHAFT KEY

INDICATES

ROTATIONAL

POSITION

Mounting

The actuator assembly may be installed in any

orientation.

Keep Free of Dust and Water

• Maintain the integrity of the enclosure by

using NEMA 4X rated dust- and water-tight

electrical connectors.

• Use cable-sealing grips and strain-relief

loops for any cord or cable.

• Plug unused conduit holes. Use internal

sealing materials on all conduit connections.

Moisture can have a harmful effect on device

internals if permitted to enter through wiring

connectors.

• Ensure that the device connection is not at a

low point of the conduit to avoid

condensation run-off into the housing;

install a drip loop if necessary.

• All cover screws should be tightened to the

specified torque. See Fig. 4.

• Cover screws should be checked periodically

to ensure adequate sealing protection.

If you are mounting the SLATE™ Low Torque Actuator

using third party valves, it is important to follow the

following assembly instructions:

1. Ensure that the SLATE™ Low Torque actuator

has sufficient torque for the valve's required

break-away torque. Also consider the line

pressure when making this calculation.

2. Turn off the fuel supply upstream from the

applicable valve.

3. Remove all external hardware from the third

party valve.

4. The SLATE actuator's shaft is ½-in. diameter

with a 1/8-in. square key. For a smaller 3/8-in.

valve shaft you must insert an adapter so that

the two shafts are concentrically aligned, ensure

that the set screws solidly contact both shafts.

5. If the bracket assembly permits, attach the

coupling to the valve and the actuator first,

ensuring exact alignment. After the coupling is

tightened, assemble and tighten the mounting

brackets. Do not tighten the mounting brackets

first.

6. Observe the actuator while it travels over its

entire range and ensure smooth operation. If

sticking/binding is observed, or if Slate reports

actuator error codes, the actuator shaft is not

properly aligned and must be re-adjusted.

Ensure the media temperature cannot exceed the

valve or actuator ratings. Use a coupling with thermal

breaks if required. If the possibility exists for radiant

heating (such as a furnace application), install a

thermal barrier.

Ensure that pipe and ductwork are free of debris that

could impair valve function.

See Fig. 2 for the locations of the mounting holes. The

mounting holes are threaded for M6 x 1 x 1/2-in

(12mm) fasteners.

Fig. 2. Mounting holes.

Note the quadrant of the keyway and rotation

direction. See Fig. 3.

Fig. 3. Actuator rotation direction.

NOTE: The SLATE Actuator ships CCW as default.

Electrical installation

Electrical Shock Hazard.

Can cause severe injury, death or equipment

damage.

Disconnect the power supply before beginning

installation to prevent electrical shock and

equipment damage. More than one power

supply disconnect can be involved.

Wiring terminals

Fig. 4 indicates each wiring terminal and Table 2

identifies each terminal’s signal type and function.

32M-06009—06 4

Page 5

Fig. 4. Wiring terminals.

WARNING

Com

(c) (b) (a)*

* AS PER THE LABEL ON

THE FUEL AIR RATIO MODULE

–

+

MODBUS

RS-485

V+ V-

24V DC

POWER

CHASSIS

ALL

SHIELDS

TO

CHASSIS

TORQUE COVER SCREWS: 16-18 IN LBS.

MINIMUM WIRE TEMPERATURE RATING: 90˚C (194˚F)

M35302

To access the field wiring compartment for power and

signal connections:

1. Remove the 2 screws and cover from the top of

the actuator housing.

2. Pass all customer-supplied wires into the enclo-

sure through the 2 conduit hubs.

SLATE™ LOW TORQUE ACTUATOR SERIES

4. In addition to a grounded conduit, the use of

shielded, twisted-pair cable is strongly recommended for DC power and signal wires. The

shield drain wires should be landed to chassis/earth on both ends of the cable, but ONLY if

a conduit is also grounded on both ends. In other

cases, earth the shields at actuator end only.

Input power

IMPORTANT

Use DC power only.

Use cable rated for the temperatures and voltages

required by the application. Use a gauge of wire to

minimize voltage loss (droop) over long cable runs,

especially at full current load. Ensure that voltage

specifications are met under all conditions.

See Table 2.

A fuse or breaker should be installed at the power

source. If the power supply is not factory-supplied, a

SELV (Safety Extra Low Voltage) rated supply with

regulated output must be provided.

Communication (Modbus over RS-485)

Use appropriate communication cable. A network will

consist of a customer’s Modbus master (with

termination) and one or more actuator slaves. See

SLATE documentation for wiring specifics.

Equipment Damage

To ensure physical protection as well as

electromagnetic immunity, the use of flexible,

sunlight-resistant, jacketed, metallic, watertight conduit is required. The conduit should be

connected to earth ground on both ends.

3. One or both conduit holes may be used when

wiring an actuator.

NOTE: On commercial models only:

Do not wire the non-isolated common

terminal to the Slate system; leave it

unconnected. Instead, wire the 24V- of the

actuator supply to Pin 2 of the Slate

Sub-Base. If all actuators share the same

supply, only one connection is needed.

Network layouts should be arranged so that

branch/homerun length does not exceed 300 feet for

commercial actuators, or 2000 feet for industrial

actuators.

5 32M-06009—06

Page 6

SLATE™ LOW TORQUE ACTUATOR SERIES

Table 2. Wiring Terminal Identification.

Type Terminal Description Wiring

PE (Protective Earth) Chassis

ground screw

Chassis connection for mains

power and shield/drain wires

Follow local codes for safety earth

installation. See Electrical installation

section for shield drain installation

instructions.

DC power terminals 24V+ 24VDC positive terminal Shielded twisted pair cable is

24V- 24VDC negative terminal

recommended. A replaceable 2A fuse

is provided on all actuators. Use a

slow blow fuse if additional external

fusing is desired. Required gauges

are:

Up to 80 ft: 24 AWG

Up to 120 ft: 22 AWG

Up to 500 ft: 16 AWG

Up to 800 ft: 14 AWG

Up to 1200 ft: 12 AWG

Low voltage

communication

(Modbus over RS-485)

Industrial models only:

R8001M4050,

R8001M4150

Low voltage

communication

(Modbus over RS-485)

Commercial models

only:

RS485 In+ Isolated RS-485: positive Shielded twisted pair cable with a

RS485 In- Isolated RS-485: negative

RS485COM Isolated RS-485: common

NOTE: Must be connected for

reliable performance.

RS485 In+ Non-isolated RS-485: positive

RS485 In- Non-isolated RS-485: negative

separate common wire is

recommended. See Electrical

installation section for length

limitations. Use 12–24 AWG wire.

NOTE: Shield should be tied to chas-

sis at Actuator side; do not

connect at SLATE (controller) side.

RS485COM Non-isolated RS-485: common

See note

1

R8001M1050,

R8001M1150

1

Do not wire the non-isolated common terminal to the Slate system; leave it unconnected. Instead, wire the

24V- of the actuator supply to Pin 2 of the Slate Sub-Base. If all actuators share the same supply, only one connection is needed.

32M-06009—06 6

Page 7

SLATE™ LOW TORQUE ACTUATOR SERIES

CAUTION

OPERATING INSTRUCTIONS

The SLATE Actuator is designed specifically for the

SLATE Fuel Air Ratio Module. For actuator operation

and programming information, see the SLATE Fuel Air

Ratio Module document 32-00006 and other SLATE

system documentation (Base Module document 3200005, and System Checkout guide 32-00016).

Read instructions carefully.

Read the instruction manual carefully before

initiating the start-up and adjustment

procedure. Verify that all of the equipment

associated with and necessary to the safe

operation of the system has been installed

correctly, that all pre-commissioning checks

have been carried out successfully and that all

safety-related aspects of the installation are

properly addressed.

Overview

SLATE Actuator provides multiple methods for

actuator commissioning, precise closed-loop valve or

damper position control, and health monitoring.

• Position can be commanded via Modbus using the

SLATE Fuel Air Ratio Module.

• Commissioning is accomplished through the

SLATE Fuel Air Ratio Module.

TROUBLESHOOTING

If the two shafts are not perfectly and concentrically

aligned, additional binding and torque will be

introduced into the assembly causing error codes to

be sent from the SLATE actuator to the SLATE Fuel Air

Ratio Module resulting in an inability to properly

commission the system. If you are receiving actuator

error codes either on the SLATE main module or in the

error code register, check the mounting brackets and

coupling's alignment and make necessary

adjustments.

Alarm and lockout event reporting

SLATE alarm and lockout codes are accessed through

the SLATE Fuel Air Ratio Module or using the SLATE

touchscreen display. See documents 32-00013 and

32-00006 for more information.

The Low-Torque Actuators also display status

messages through LED blinks. The LED is on the PCB

inside the unit. These can be used for troubleshooting

purposes.

The cover of the Low-Torque Actuators must be

removed to see the two LEDs:

• Green LED: displays status, including alarm codes

• Yellow LED: displays communication activity

(on RS-485, bus is working and actuator is

communicating with SLATE system)

The normal and error codes are shown in Table 3.

Table 3. Alarm LED Codes.

LED code Error Characteristic Action

Continuous Blinking Normal State – Ready to operate None.

1 Out of range – Actuator is out of

normal operating quadrant

2 Not calibrated – Actuator not

(Factory) calibrated

3 Low Voltage Check actuator input voltage.

4 High Temperature Reduce ambient temperature; shield actuator from

5 Mechanical binding, electrical

shorts, or internal electronics

fault.

5 or Dark Plus

Continuous Reset

Lockout Check power; replace actuator.

Command actuator to normal operational range.

Factory calibration data lost; replace actuator.

heat sources.

C

heck all cables and electrical connections;

check for debris or water on electronics;

check for mechanical binding or slipping;

if persistent, replace actuator.

Insure that the shaft key is located in the proper

quadrant (refer to FIG.3). If the shaft key is not

located in this quadrant, manually move the shaft key

to the location per the illustration. Take caution to not

damage the shaft while moving it back into the

functioning quadrant.

7 32M-06009—06

Page 8

SLATE™ LOW TORQUE ACTUATOR SERIES

Table 4 shows information about Lockout conditions

Table 4. Lockout Conditions.

Lockout Code Lockout Characteristic Comments

1 RAM Test of internal memory failed

2 RAM DMA Test of internal memory failed

3 Flash Memory Program corruption

4 Watchdog Startup Internal watchdog unit failure

5 Safety Variables Safety data corruption

6 Stack Overflow Program execution error

7 System Tick Program execution error

8 Main Loop Program execution error

9 Processor Fault Instruction test failure

10 Processor Fault – Memory RAM/ROM failure

Table 5. China RoHS

Hazardous Substances

繢橲銘

撲譾匱

(PBDE)

Polybromin

ated

Diphenyl

Ethers

(PBDE)

叛屛齟

Component Name

(Pb)

Lead (Pb)

蟍 (Hg)

Mercury

(Hg)

(Cd)

Cadmium

(Cd)

堘叝

(Cr6+)

Chromium

VI

Compounds

(Cr6+)

撲譾

(PBB)

Polybromin

ated

Biphenyls

(PBB)

擒逥蝜酆辏怺硸

Electronic Valve

Actuator

XXXXXX

纤聒哚砗 SJ/T 11364 馲橁奕瞱

This table is prepared in accordance with the provisions of SJ/T 11364.

O: 鸒繢橲銘憆叛瘽繢憰绝篰劣馲岍憰憆 GB/T 26572 橁馲螞参割瞱

Indicates that said hazardous substance contained in all of the homogeneous materials for this part is

below the limit requirement of GB/T 26572.

X: 鸒繢橲銘欱憆叛馲羢剥憰绝篰劣馲岍壿 GB/T 26572 橁馲螞瞱

Indicates that said hazardous substance contained in all of the homogeneous materials for this part is

above the limit requirement of GB/T 26572.

纡夨堅堺馲堥厫叛馵剴岍叡呤壿螞馲奕咨霶銘瞱

All other components, not listed in the table, do not contain restricted substances above the threshold level

For More Information

The Honeywell Thermal Solutions family of products includes

Honeywell Combustion Safety, Eclipse, Exothermics, Hauck,

Kromschröder and Maxon. To learn more about our products,

visit ThermalSolutions.honeywell.com or contact your

Honeywell Sales Engineer.

Honeywell Process Solutions

Honeywell Thermal Solutions (HTS)

1250 West Sam Houston Parkway

South Houston, TX 77042

ThermalSolutions.honeywell

® U.S. Registered Trademark

© 2019 Honeywell International Inc.

32M-06009—06 M.S. Rev. 05-19

Printed in United States

Loading...

Loading...