Page 1

SL AT E

™

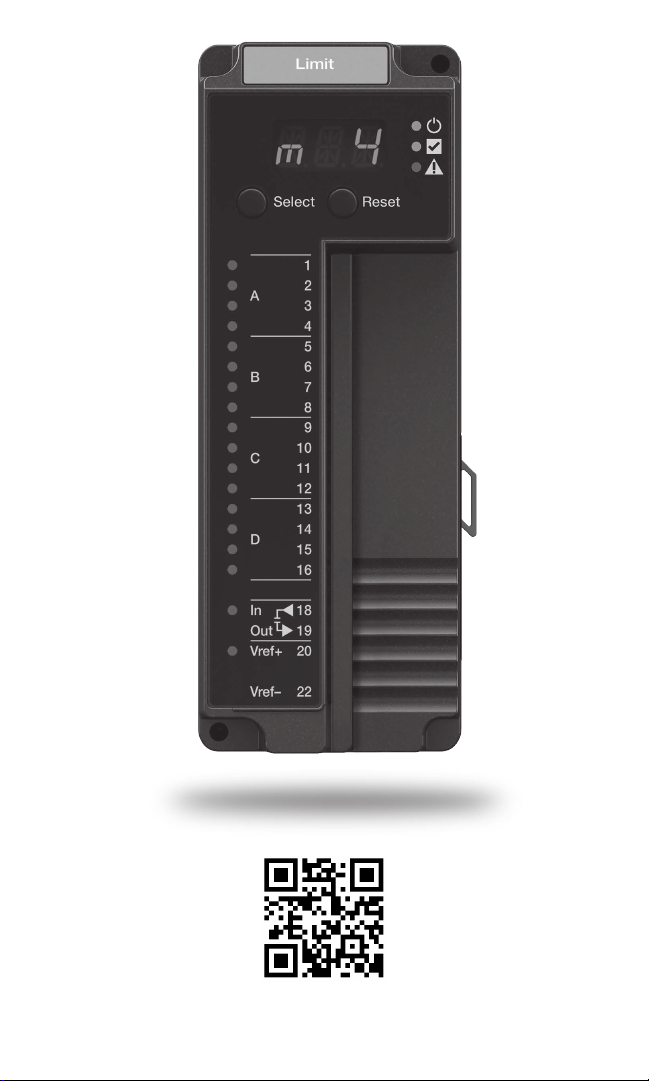

Limit Control Module

R8001L8001

INSTALLATION INSTRUCTIONS

Page 2

Scan for more information

Page 3

Application

SLATE™ brings configurable safety and programmable logic

together into one single platform. The platform can easily be

customized for almost any requirement or application–offering

virtually limitless development opportunities with far less

complexity.

The R8001L8001 SLATE Limit Control Module is part of the

SLATE Combustions System. The SLATE Limit Control Module

provides the ability to bring in any type of analog signal and

create limits on either pressure or temperature without needing a

UDC Controller.

Features

• 12 limit blocks with each block monitoring any sensor or pair

of sensors

• One limit module for multiple burner controls

• 4 sensors available for Limit Block use (2 sets of redundant

safety inputs)

• Unused Analog Cells available for general purpose I/O

configuration

• Redundant limit relay output

Specifications

Electrical Ratings:

See Table 3–Table 7.

Environmental Ratings

Ambient Temperature:

Operating: -20°F to +150°F (-29°C to +66°C).

Shipping: -40°F to +150°F (-40°C to +66°C).

Humidity: 95% continuous, noncondensing.

Vibration: 0.5G environment

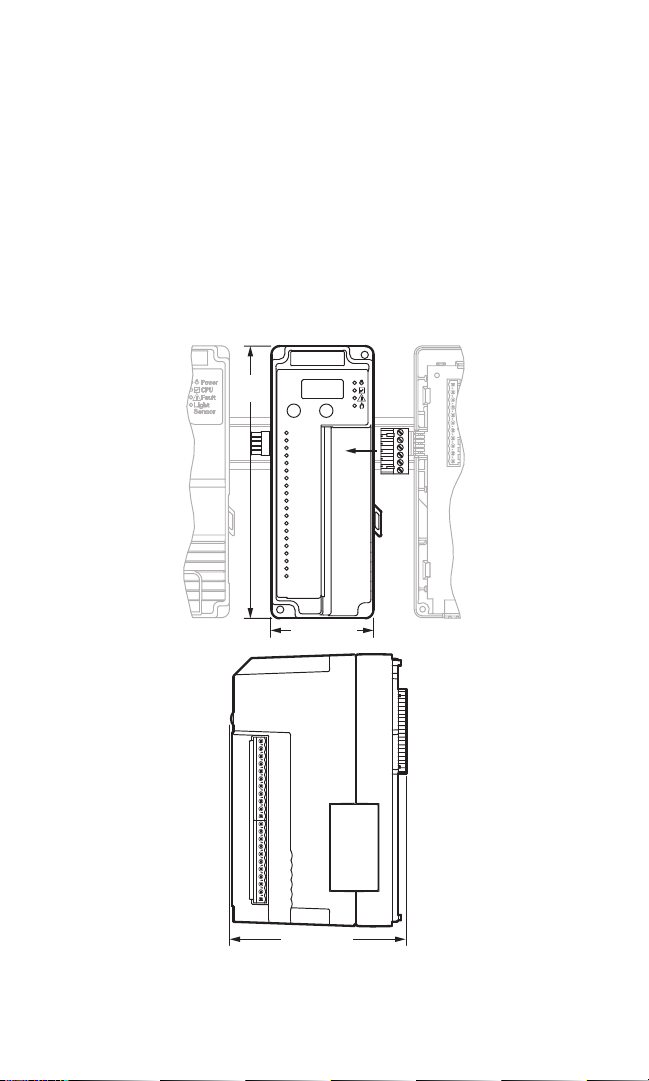

Dimensions: See Fig. 1

: 2 lb 1 oz (0.94 Kg)

Weight

SLATE™ LIMIT CONTROL MODULE 3

R8001L8001

Page 4

Approvals

M35382

Underwriters Laboratories Inc. Listed, File: MP268

IRI Acceptable

Federal Communications Commission: Part 15, Class A

Must be mounted inside a grounded metal enclosure.

Mounting

DIN Rail (See Fig. 2)

Required Components

R8001A1001 SLATE Base Controller

R8001S9001 SLATE Sub-Base Module

R8001B2001 SLATE Burner Control Module

7-3/32

(181)

2-11/16 (68)

4-19/32 (117)

Fig. 1.

Dimensions in in. (mm).

4 32-00007—03

Page 5

LED Array

There are four LEDs on the front of the Limit Control Module

that provides quick identification of the system status and any

problems that might occur. The status is broadcast to other

modules on the platform bus in case they are affected by the

inoperable modules.

The LEDs on the module are for the sensors, the inputs and

outputs, and for the Reference V.

Terminals 18 and 19 are the limit contacts.

Terminals 20 and 22 are reference voltage terminals to indicate to

the Limit Module what reference voltage it’s operating at.

LED Color Description

Power

CPU

Fault

Table 1. LED Descriptions.

No light System does not have power

Green System has power

Red No wire sheet or problem with the

wire sheet

Green Running

Red Fault

No light Running

LED Display

The SLATE system modules have a seven-segment, threeposition LED display used for indicating the module number of

the SLATE system. The LED colors indicate the terminal state as

shown in Table 2.

Color Description

Green Terminal is on

Red Fault

No light Not in use

Table 2. Terminal LED Meanings.

SLATE™ LIMIT CONTROL MODULE 5

R8001L8001

Page 6

Select and Reset Buttons

The SLATE system modules have a Select and Reset buttons

located on the front of the module and beneath the segment

display. The Reset button is used to clear a lockout and reset the

module. The Select button is used to scroll through the segment

display information.

Installation

WARNING

Fire or Explosion Hazard

Can cause severe injury, death, or property damage.

Verification of safety requirements must be performed

each time a control is installed on a burner to prevent

possible hazardous burner operation.

When Installing This Product

1. Read these instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the product

to make sure the product is suitable for your application.

3. After installation is complete, check out the product operation

as provided in these instructions.

4. The SLATE module must be mounted in an electrical

enclosure with adequate clearance for servicing, installation

and removal of modules.

6 32-00007—03

Page 7

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment damage.

1. Disconnect the power supply before beginning installation to

prevent electrical shock and equipment damage. More than

one power supply disconnect can be involved.

M35383

Fig. 2.

Installing the Limit Control Module on the Sub-Base Module.

2. Wiring must comply with all applicable codes, ordinances and

regulations.

3. Wiring must comply with NEC Class 1 (Line Voltage) wiring.

SLATE™ LIMIT CONTROL MODULE 7

R8001L8001

Page 8

IMPORTANT

1. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with these instructions, may cause interference for radio

communications. It has been tested and found to comply

with the limits of a Class A computing device of part 15

of FCC rules, which are designed to provide reasonable

protection against such interference when operated in a

commercial environment. Operation of this equipment in a

residential area may cause interference; in which case, the

user, at their own expense, may be required to take whatever

measures are required to correct this interference.

2. This digital apparatus does not exceed the Class A limits for

radio noise, set out in the Radio Interfeence Regulations of

the Canadian Department of Communications.

3. For combination gas-oil burner applications, a double pole,

double throw (dpdt) fuel select switch is required.

4. Cable shield must be terminated to ground at both ends. If

shielded cable is NOT used, use three-wire twisted cable.

Wiring

WARNING

Electrical Shock Hazard.

Can cause severe injury, death, or equipment

damage.

Disconnect the power supply from the main disconnect

before beginning installation to prevent electrical shock

and equipment damage. More than one disconnect can

be required.

8 32-00007—03

Page 9

M35285

LIMIT MODULE

4 SENSORS

12 LIMIT BLOCKS

2 DUAL LIMITS

SAFETY RELAY

A

UNIVERSAL

LOW VOLTAGE

CELL

1

2

+

_

3

4

SAFETY

RELAY

LOAD

RELAY

Wiring diagram for Limit Control Module.

Fig. 3.

B

UNIVERSAL

LOW VOLTAGE

CELL

C

UNIVERSAL

LOW VOLTAGE

CELL

D

UNIVERSAL

LOW VOLTAGE

CELL

BIAS

5

6

+

_

7

8

9

10

+

_

11

12

13

14

+

_

15

16

FROM

17

POWER

18

TO

19

LOADS

20

VREF+

21

22

VREF–

SLATE™ LIMIT CONTROL MODULE 9

R8001L8001

Page 10

Terminal Description Rating

1 Cell A (T1) See Table 4–7 for conguration options

2 Cell A (T2) See Table 4–7 for conguration options

3 Cell A (T3) See Table 4–7 for conguration options

4 Cell A (T4) See Table 4–7 for conguration options

5 Cell B (T5) See Table 4–7 for conguration options

6 Cell B (T6) See Table 4–7 for conguration options

7 Cell B (T7) See Table 4–7 for conguration options

8 Cell B (T8) See Table 4–7 for conguration options

9 Cell C (T9) See Table 4–7 for conguration options

10 Cell C (T10) See Table 4–7 for conguration options

11 Cell C (T11) See Table 4–7 for conguration options

12 Cell C (T12) See Table 4–7 for conguration options

13 Cell D (T13) See Table 4–7 for conguration options

14 Cell D (T14) See Table 4–7 for conguration options

15 Cell D (T15) See Table 4–7 for conguration options

16 Cell D (T16) See Table 4–7 for conguration options

17 Unused ---

18 Safety Relay

(dry contacts)

9.8 FLA, 58.8 LRA @ 120VAC,

4A (0.5 PF), 20A inrush @ 240VAC,

2A cont, 10A inrush @ 24VDC

19 Safety Relay

(see Terminal 18 above)

(dry contacts)

20 Vref+ 24VDC (0.1mA),

24VAC (0.1mA),

85-264VAC (0.2mA)

21 Unused ---

22 Vref- (see Terminal 20 above)

Table 3. Terminal Ratings.

Note: only one conguration option per cell is allowed for cells

congured as a Limit Block.

10 32-00007—03

Page 11

Basic Functions Min Typical Max Units

In Range 0.0 - 15.0 VDC

Resolution

- 2.43 - mV DC

Null -25.0 - 25.0 mV DC

Accuracy -25.0 - 25.0 mV DC Whichever is

Voltage

Out Range 0.0 - 15.0 VDC

-1.0 - 1.0 %

greater

Resolution - 4.0 - mV DC

Null 100.0 - 100.0 mV DC

Accuracy -50.0 - 50.0 mV DC Whichever is

T1

-1.5 - 1.5 %

In Range 0.0 - 25.0 mA DC

greater

a

Resolution - 7.4 - uA DC

Null -0.5 - 0.5 mA DC

Accuracy -1.5 - 1.5 % 0 to 25 mA

Current

b

Range 0.0 - 25.0 mA DC Max Load =

Out

Resolution

- 4.0 - mA Ω

500 Ω

Null -0.5 - 0.5 mA DC

Accuracy -300.0 - 300.0 uA DC 0 to 25 mA

-50.0 - 50.0 uA DC 4 to 20 mA

In Amplitude 0.0 - 15.0 VDC

Trip Point - 3.0 - VDC Comparator

T2 Voltage

Hysteresis

Resolution

- 0.25 - VDC

- 0.37 - mV DC

Only

Null -25.0 - 25.0 mV DC

Accuracy -25.0 - 25.0 mV DC

In Range 0.0 - 15.0 VDC

Voltage

T3

Current

Resolution

Null -25.0 - 25.0 mV DC

Accuracy -25.0 - 25.0 mV DC

In Range 0.2 - 25.0 mA DC

Resolution - 3.7 - uA DC

Null -0.5 - 0.5 mA DC

- 0.37 - mV DC

Accuracy -1.5 1.5 % 0 to 25 mA

a

T1 input terminal is held at constant 2.5VDC over allowable current

range.

b

Accuracy specification given is for 100 Ω load. Resolution specification

can be converted to mA by dividing out load.

Table 4. Specifications for Basic Cell Functions.

Specifications based on worst case over ambient temperatures.

SLATE™ LIMIT CONTROL MODULE 11

R8001L8001

Page 12

Complex Functions Min Typical Max Units

Thermocouple

T2 & T3Type J Range -200.0 1025.0 °C

Resolution - 0.1 - °C

Accuracy -5.0 - 5.0 °C

Type K Range -150.0 - 1000.0 °C

Resolution - 0.1 - °C

Accuracy -5.0 - 5.0 °C

T3 &

T4

RTD

Type PT100

a

Range -135.0 - 250.0 °C 3 wire, 100 Ω

Resolution - 0.5 - °C

Accuracy -2.0 - 2.0 °C

Type PT1000 Range -135.0 - 250.0 °C 3 wire, 1000 Ω

Resolution 0.5 °C

Accuracy -2.0 - 2.0 °C

NTC

T3 & T4Type 10K Range

b

- 175.0 °C T4 rated to 0 °C

-40.0

Resolution - 0.1 - °C

c

Accuracy

-2.0 - 2.0 °C -40 °C to 25 °C

-1.0 - 1.0 °C 25 °C to 125 °C

-1.5 - 1.5 %

-3.0 - 3.0 °C 125 °C to 175 °C

a

Shielded cable required for reliable operation in noisy environment.

b

NTC on terminal T4 is rated down to 0 °C.

c

Temperatures refer to sense range.

Table 5. Specifications Cell Complex Functions.

12 32-00007—03

Page 13

Frequency / PWM

Functions

PWM Out

T1 Amplitude 5.0 - 10.0 VDC Low output state = 0V

Frequency 100.0 - 1000.0 Hz

Duty Cycle 2.0 - 98.0 %DC Allowable output %DC

Resolution - 1.0 - %

Accuracy -0.5 - 0.5 %DC 10V amplitude

Frequency In

T2 Amplitude 5.0

Range 2.0 - 1000.0 Hz

Min. “on” pulse width

(low %DC)

Min. “off” pulse width

(high %DC)

Duty

Cycle

Resolution

Accuracy -5.0 - 0.0 % Whichever is greater

PWM In

T2 Amplitude 5.0

Frequency 125.0 - 500.0 Hz

Min. “on” pulse width

(low %DC)

Min. “off” pulse width

(high %DC)

Duty

Cycle

Resolution

Accuracy 125 Hz -1.5

Table 6. Specifications for Cell Frequency Functions.

2 – 100 Hz2.0 - 98.0 %DC 10V amplitude

1000 Hz 5.0

125 – 500 Hz5.0

500 Hz -7.5

Min Typical Max Units

10.0 15.0 VDC

- 50.0 - usec 10V amplitude

- 130.0 - usec 10V amplitude

- 85.0 %DC 10V amplitude

- 1.0 - Hz

-1.0 - 0.0 Hz

10.0 15.0 VDC

- 50 - usec 10V amplitude

- 130 - usec 10V amplitude

- 90.0 %DC 10V amplitude

- 1.0 %DC

- 1.5 %DC 10V amplitude

- 7.5 %DC 10V amplitude

SLATE™ LIMIT CONTROL MODULE 13

R8001L8001

Page 14

Configuration Min Optimum Range for Performance Max

Thermocouple J -50°C

K -50°C

RTD -135°C

NTC 25°C

Current Out 4 mA

Voltage: In / Out 2 V

Table 7. Suggested Sensor Selection based on Application.

1025°C ± 4 °C

1000°C ± 4 °C

250°C ± 2 °C

125°C ± 1°C

20 mA ± .05 mA

10 V 0.3 %,

typical

Application Recommended Wire

Size

Line voltage

terminals

14, 16 or 18 AWG copper conductor, 600 volt

insulation, moisture-re-

Recommended

Part Numbers

TTW60C,

THW75C,

THHN90C

sistant wire.

Other terminals

18 AWG wire insulated for voltages and

temperatures for given

TTW60C,

THW75C,

THHN90C

application.

Table 8. Recommended Wire Sizes and Part Numbers.

Recommended Grounding Practices

Use an Earth ground or a signal ground as described below.

Earth ground (Base, Rectification Flame Amp Module,

other modules optional)

1. Use to provide a connection between the base and the

control panel of the equipment. Earth ground must be capable

of conducting enough current to blow the breaker in the event

of an internal short circuit.

2. Use wide straps or brackets to provide minimum length,

maximum surface area ground conductors. If a leadwire is

required, use 14 AWG copper wire.

14 32-00007—03

Page 15

3. Make sure that mechanically tightened joints along the ground

path are free of nonconductive coatings and protected against

corrosion on mating surfaces.

Signal ground

Note the 18V system ground is not electrically connected to earth

ground. Follow local codes and appliance recommendations to

determine if this should be connected to earth ground.

Be sure loads do not exceed the terminal ratings. Refer to the

labels or terminal ratings in Table 2.

The SLATE system must be mounted in an electrical enclosure.

When mounting in an electrical enclosure, provide adequate

clearance for servicing, installation and removal of SLATE

modules.

The maximum leadwire length is 300 feet to terminal inputs

(Control, Running/Lockout Interlock).

SLATE™ LIMIT CONTROL MODULE 15

R8001L8001

Page 16

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark.

© 2014 Honeywell International Inc.

32-00007—03 M.S. Rev. 12-14

Printed in U.S.A.

For more information and detailed instructions on the R8001L8001

and the entire SLATE system please refer to the SLATE User Guide

located on our website at http://combustion.honeywell.com/SLATE

32-00007-03

Loading...

Loading...