Page 1

™

SL AT E

Fuel Air Ratio Module

R8001C6001

INSTALLATION INSTRUCTIONS

Page 2

Scan for more information

Page 3

Application

SLATE™ brings configurable safety and programmable logic

together into one single platform. The platform can easily be

customized for almost any requirement or application–offering

virtually limitless development opportunities with far less

complexity.

The R8001C6001 Fuel Air Ratio module uses the latest

technology to control up to 4 SLATE actuators and/or 2 Variable

Frequency Drives. The Fuel Air Ratio Control module controls the

relationship between fuel, airflow and flue gas recirculation on a

power burner.

Features

Within the SLATE system, the fuel air ratio module provides:

• Air-fuel ratio control for up to 4 actuators

• Drive 2 Variable Frequency Drives (VFDs)

• RS-485 Modbus communications to communicate to the

actuators and receive feedback

• SLATE actuator torque sizes:

– 50 in/lb (NEMA 1 and NEMA 4)

– 150 in/lb (NEMA 1 and NEMA 4)

– 300 in/lb (NEMA 4)

– 900 in/lb (NEMA 4)

• Up to 24 points

• Field configurable

• Automated actuator endpoint seeking process

• UL Recognized and NFPA acceptable

• Password protected

• Fault information

• Status of four actuator channels

• Unused VFD terminals (Analog Cells) available for general

purpose I/O configuration

• Flue Gas Recirculation (FGR)

• Trim

• Dual Fuel

SLATE™ FUEL AIR RATIO MODULE 3

R8001C6001

Page 4

Safety Features

• Class C operating software system

• Fail-safe feedback

• Curve verification algorithms

• Password protected

• Built in self test

• No slope constraints that would limit the steepness of the

curve

• Component anti-swap protection

• Off curve checking algorithm

Specifications

Electrical Ratings

Voltage and Frequency: See Tables 1–5.

Environmental Ratings:

Ambient Temperature:

Operating: -20°F to +150°F (-29°C to +66°C).

Shipping: -40°F to +150°F (-40°C to +66°C).

Humidity: 95% continuous, noncondensing.

Vibration: 0.5G environment

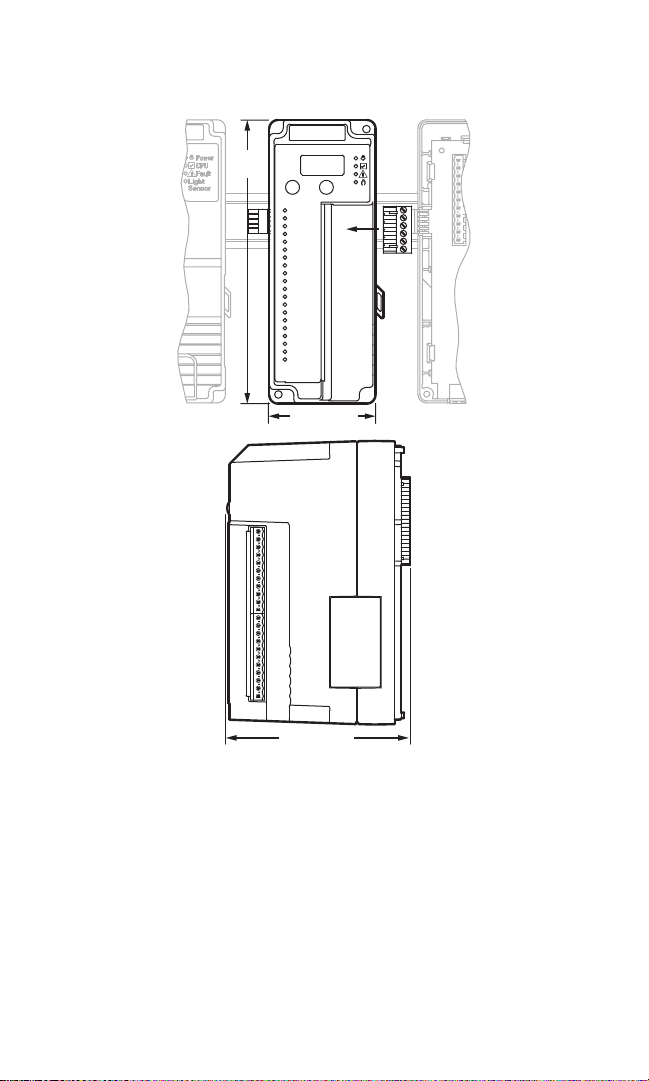

Dimensions: See Fig. 1.

Weight: 13.6 oz (0.39 Kg)

Approvals

Underwriters Laboratories Inc. Listed, File: MP268

Factory Mutual

IRI Acceptable

Federal Communications Commission: Part 15, Class A

Must be mounted inside a grounded metal enclosure.

Mounting: DIN Rail (See Fig. 2)

Required Components

R8001A1001 SLATE Base Module

R8001S9001 Sub-Base Module

4 32-00006—03

Page 5

R8001B2001 SLATE Burner Control Module

7-3/32

(181)

2-11/16 (68)

Fig. 1.

Dimensions in in. (mm).

4-19/32 (117)

M35382

Principal Technical Features

The R8001C6001 fuel air ratio module monitors and controls the

air-fuel ratio for combustion applications.

SLATE™ FUEL AIR RATIO MODULE 5

R8001C6001

Page 6

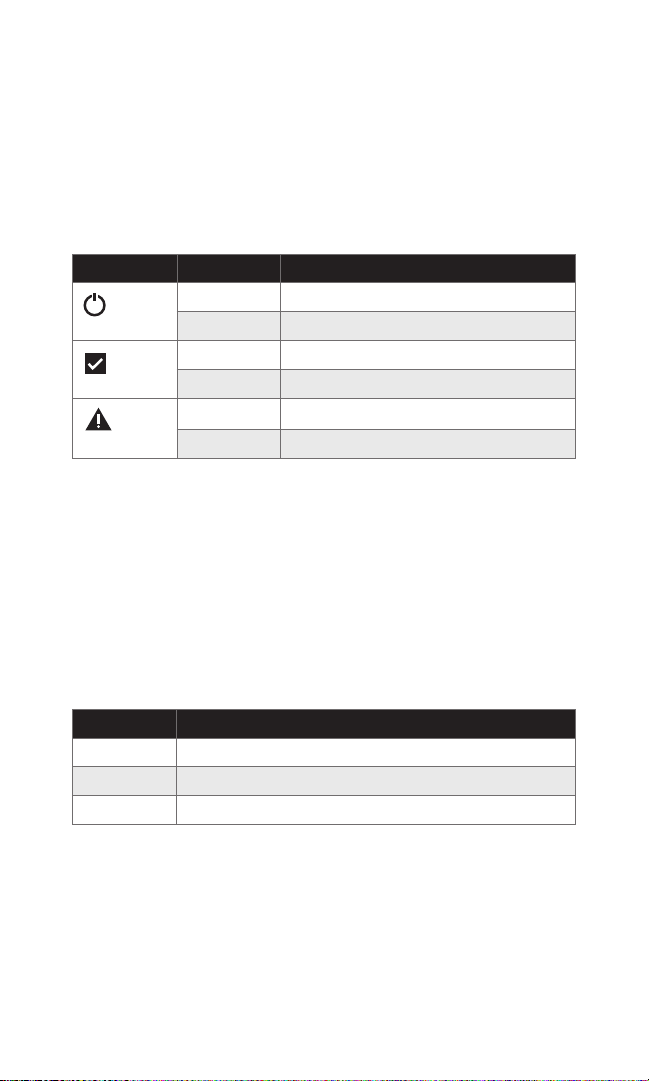

LED Array

There are three LEDs on the front of the Fuel Air Ratio module

that provide quick identification of the system status and any

problems that might occur. The status is broadcast to other

modules on the platform bus in case they are affected by the

inoperable modules. See Table 1 for descriptions.

LED Color Description

Power

CPU

Fault

Table 1. LED Descriptions.

No light System does not have power

Green System has power

Red No valid conguration

Green Running

Red Fault

No light No fault

LED Displays

The SLATE system modules have three-character LED displays

used for indicating the module number of the SLATE system.

They also have three-position LED colors to indicate terminal

states as shown in Table 2.

Color Description

Green Terminal is ON or is Normal

Red Fault

No light Terminal is OFF or Not in use

Table 2. Terminal LED Meanings.

6 32-00006—03

Page 7

Select and Reset Buttons

The SLATE system modules have Select and Reset buttons

located on the front of the module and beneath the segment

display. The Reset button is used to clear a lockout and reset the

module. The Select button is used to scroll through the segment

display information.

Installation

WARNING

Fire or Explosion Hazard

Can cause severe injury, death, or property damage.

Verification of safety requirements must be performed

each time a control is installed on a burner to prevent

possible hazardous burner operation.

When Installing This Product

1. Read these instructions carefully. Failure to follow them could

damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the product

to make sure the product is suitable for your application.

3. After installation is complete, check out the product operation

as provided in these instructions.

4. The SLATE module must be mounted in an electrical

enclosure with adequate clearance for servicing, installation

and removal of modules.

SLATE™ FUEL AIR RATIO MODULE 7

R8001C6001

Page 8

Wiring

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or equipment damage.

1. Disconnect the power supply before beginning installation to

prevent electrical shock and equipment damage. More than

one power supply disconnect can be involved.

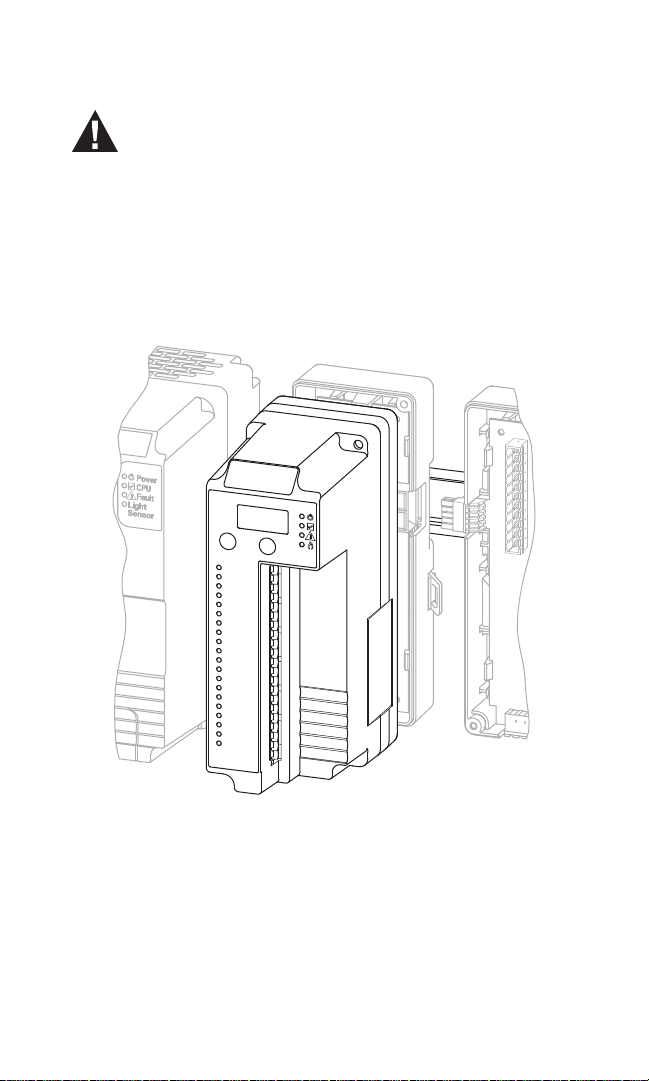

M35383

Fig. 2.

Installing the Fuel Air Ratio Module on the Sub-Base Module.

2. Wiring must comply with all applicable codes, ordinances and

regulations.

3. Wiring must comply with NEC Class 1 (Line Voltage) wiring.

8 32-00006—03

Page 9

IMPORTANT

1. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with these instructions, may cause interference for radio

communications. It has been tested and found to comply

with the limits of a Class A computing device of part 15

of FCC rules, which are designed to provide reasonable

protection against such interference when operated in a

commercial environment. Operation of this equipment in a

residential area may cause interference; in which case, the

user, at their own expense, may be required to take whatever

measures are required to correct this interference.

2. This digital apparatus does not exceed the Class A limits for

radio noise, set out in the Radio Interference Regulations of

the Canadian Department of Communications.

3. Cable shield must be terminated to ground at both ends. If

shielded cable is NOT used, use three-wire twisted cable.

WARNING

Fire or Explosion Hazard

Can cause severe injury, death, or property damage.

Disconnect the power supply from the main disconnect

before beginning installation to prevent electrical shock

and equipment damage. More than one disconnect can

be required.

SLATE™ FUEL AIR RATIO MODULE 9

R8001C6001

Page 10

FUEL AIR MODULE

4 ACTUATORS

2 VFD (OR LOW V

INPUT/OUTPUT)

UNIVERSAL

LOW VOLTAGE

CELL

UNIVERSAL

LOW VOLTAGE

CELL

ACTUATOR 1

ACTUATOR 2

ACTUATOR 3

ACTUATOR 4

VFD1

VFD2

RS-485

RS-485

RS-485

RS-485

1

2

+

_

3

4

5

6

+

_

7

8

A

9

B

10

C

11

A

12

B

13

C

14

A

15

B

16

C

17

A

18

B

19

C

20

M35284

Fig. 3.

Wiring diagram for Fuel Air Ratio Module.

10 32-00006—03

Page 11

Terminal Description Rating

1 VFD1 - Cell A (T1) See Tables 2-5 for congu-

ration options

2 VFD1 - Cell A (T2) See Tables 2-5 for congu-

ration options

3 VFD1 - Cell A (T3) See Tables 2-5 for congu-

ration options

4 VFD1 - Cell A (T4) See Tables 2-5 for congu-

ration options

5 VFD2 - Cell B (T1) See Tables 2-5 for congu-

ration options

6 VFD2 - Cell B (T2) See Tables 2-5 for congu-

ration options

7 VFD2 - Cell B (T3) See Tables 2-5 for congu-

ration options

8 VFD2 - Cell B (T4) See Tables 2-5 for congu-

ration options

9 A1 - A (RS485) ---

10 A1 - B (RS485) ---

11 A1 - C (GND) ---

12 A2 - A (RS485) ---

13 A2 - B (RS485) ---

14 A2 - C (GND) ---

15 A3 - A (RS485) ---

16 A3 - B (RS485) ---

17 A3 - C (GND) ---

18 A4 - A (RS485) ---

19 A4 - B (RS485) ---

20 A4 - C (GND) ---

21 Unused ---

22 Unused ---

Table 3. Terminal Ratings.

SLATE™ FUEL AIR RATIO MODULE 11

R8001C6001

Page 12

Terminal Functions Min Typical Max Units

T1 Voltage In Range 0.0 - 15.0 VDC Rin=1MOhm

Resolution - 2.43 - mV DC

Null -25.0 - 25.0 mV DC

Accuracy -25.0 - 25.0 mV DC Whichever is

c

-1.0 - 1.0 %

Range 0.0 - 15.0 VDC 10KOhm load

Out

greater

Resolution - 4.0 - mV DC

Null 100.0 - 100.0 mV DC

Accuracy -50.0 - 50.0 mV DC Whichever is

-1.5 - 1.5 %

Current In Range 0.0 - 25.0 mA DC

greater

a

Resolution - 7.4 - uA DC

Null -0.5 - 0.5 mA DC

Accuracy -1.5 - 1.5 % 0 to 25 mA

b,c

Range 0.0 - 25.0 mA DC Max Load =

Out

Resolution - 4.0 - mA Ω

500 Ω

Null -0.5 - 0.5 mA DC

Accuracy -300.0 - 300.0 uA DC 0 to 25 mA

-50 - 50 uA DC 4 to 20 mA

T2 Voltage In Amplitude 0.0 - 15.0 VDC

Trip Point - 3.0 - VDC Comparator

Hysteresis - 0.25 - VDC

Only

Resolution - 0.37 - mV DC

Null -25.0 - 25.0 mV DC

Accuracy -25.0 - 25.0 mV DC

T3 Voltage In Range 0.0 - 15.0 VDC

Resolution - 0.37 - mV DC

Null -25.0 - 25.0 mV DC

Accuracy -25.0 - 25.0 mV DC

Current In Range 0.2 - 25.0 mA DC

Resolution - 3.7 - uA DC

Null -0.5 - 0.5 mA DC

Accuracy -1.5 - 1.5 % 0 to 25 mA

a

T1 input terminal is held at constant 2.5VDC over allowable current

range.

b

Accuracy specification given is for 100 Ω load. Resolution specification

can be converted to mA by dividing out load.

c

Imax=25mA for Vout<10V

Imax=20mA for 10V<Vout<15V

Table 4. Specifications for Basic Cell Functions.

12 32-00006—03

Page 13

Specifications based on worst case over ambient temperatures.

Complex Functions Min Typical Max Units

Thermocouple

T2 & T3Type J Range -200.0 1025.0 °C

Resolution - 0.1 - °C

Accuracy -5.0 - 5.0 °C

Type K Range -150.0 - 1000.0 °C

Resolution - 0.1 - °C

Accuracy -5.0 - 5.0 °C

RTD

T2 &

Type PT100

T3 &

T4

Type PT1000 Range -135.0 - 250.0 °C 3 wire, 1000 Ω

NTC

T1-

Type 10K Range -40.0b- 175.0 °C T4 rated to 0 °C

T3,

T1T4

T1-

Type 12K Range -20.0 - 125.0 °C T4 rated to 0 °C

T3,

T1T4

T1-

Type 20K Range -25.0 - 150.0 °C T4 rated to 0 °C

T3,

T1T4

a

Shielded cable required for reliable operation in noisy environment.

b

NTC on terminal T4 is rated down to 0 °C.

c

Temperatures refer to sense range.

Table 5. Specifications Cell Complex Functions.

a

Range -135.0 - 250.0 °C 3 wire, 100 Ω

Resolution - 0.5 - °C

Accuracy -2.0 - 2.0 °C

Resolution 0.5 °C

Accuracy -2.0 - 2.0 °C

Resolution - 0.1 - °C

Accuracyc-2.0 - 2.0 °C -40 °C to 25 °C

-1.0 - 1.0 °C 25 °C to 125 °C

-1.5 - 1.5 %

-3.0 - 3.0 °C 125 °C to 175 °C

Resolution - 0.1 - °C

Accuracyc-2.0 - 2.0 °C -20 °C to 30 °C

-1.0 - 1.0 °C 30 °C to 120 °C

-1.5 - 1.5 %

-3.0 - 3.0 °C 120 °C to 125 °C

Resolution - 0.1 - °C

Accuracyc-2.0 - 2.0 °C -25 °C to 50 °C

-1.0 - 1.0 °C 50 °C to 135 °C

-1.5 - 1.5 %

-3.0 - 3.0 °C 135 °C to 150 °C

SLATE™ FUEL AIR RATIO MODULE 13

R8001C6001

Page 14

Frequency / PWM

Min Typical Max Units

Functions

PWM Out

T1 Amplitude 5.0 - 10.0 VDC Low output state = 0V

Frequency 100.0 - 1000.0 Hz

Duty Cycle 2.0 - 98.0 %DC 0-100% output allowed

Resolution - 1.0 - %

Accuracy -0.5 - 0.5 %DC 10V amplitude

Frequency In

T2-T4Amplitude 5.0 10.0 15.0 VDC

Range 2.0 - 1000.0 Hz

Min. “on” pulse

- 50.0 - usec 10V amplitude

width (low %DC)

Min. “off” pulse

- 130.0 - usec 10V amplitude

width (high %DC)

Duty

2 – 100 Hz2.0 - 98.0 %DC 10V amplitude

Cycle

1000 Hz 5.0 - 85.0 %DC 10V amplitude

Resolution - 1.0 - Hz

Accuracy -5.0 - 0.0 % Whichever is greater

-1.0 - 0.0 Hz

PWM In

T2-T4Amplitude

a

5.0 10.0 15.0 VDC

Frequency 125.0 - 500.0 Hz

Min. “on” pulse

- 50.0 - usec 10V amplitude

width (low %DC)

Min. “off” pulse

- 130.0 - usec 10V amplitude

width (high %DC)

Duty

Cycle

125 –

500 Hz

5.0 - 90.0 %DC 10V amplitude

Resolution - 1.0 %DC

Accuracy 125 Hz -1.5 - 1.5 %DC 10V amplitude

500 Hz -7.5 - 7.5 %DC 10V amplitude

a

Trip points = 3.0V +/- 0.25V

Hysteresis Voltage = 0.5V

Table 6. Specifications for Cell Frequency Functions.

14 32-00006—03

Page 15

Configuration Min Optimum Range for Performance Max

Thermocouple J -50°C

K -50°C

RTD -135°C

NTC 25°C

Current Out 4 mA

Voltage: In / Out 2 V

Table 7. Suggested Sensor Selection Based on Application.

1025°C ± 4 °C

1000°C ± 4 °C

250°C ± 2 °C

125°C ± 1°C

20 mA ± .05 mA

10 V 0.3 %,

typical

Application Recommended Wire

Size

Communication

Lines

22 AWG two-wire

twisted pair with ground,

or five-wire.

Other terminals 18 AWG wire insulated

for voltages and

temperatures for given

Recommended

Part Numbers

Belden 8723

shielded cable or

equivalent.

TTW60C,

THW75C,

THHN90C

application.

Table 8. Recommended Wire Sizes and Part Numbers.

Resistance to Temperature Conversion Tables

Below are the lookup tables for various types of SLATE sensors.

Linear interpolation is used for values that are between the points

that are shown.

10K NTC

Ohms Degrees C

100.000 228.199

120.000 214.979

144.000 202.439

172.800 190.526

207.360 179.195

248.832 168.404

SLATE™ FUEL AIR RATIO MODULE 15

R8001C6001

Page 16

298.598 158.116

358.318 148.295

429.982 138.912

619.174 121.345

891.610 105.213

1283.918 90.347

1848.843 76.605

2662.333 63.862

3833.760 52.015

5520.614 40.972

7949.685 30.653

11447.546 20.990

19781.359 7.594

34182.189 -4.636

59066.823 -15.846

102067.470 -26.159

176372.588 -35.678

304771.832 -44.491

12K NTC

Ohms Degrees C

494.600 124.750

560.400 119.750

726.000 109.750

952.300 99.750

1266.000 89.750

1707.000 79.750

2337.000 69.750

3252.000 59.750

4607.000 49.750

16 32-00006—03

Page 17

6652.000 39.750

9804.000 29.750

12000.000 24.750

14770.000 19.750

22800.000 9.750

36130.000 -0.250

58880.000 -10.250

98970.000 -20.250

20K NTC

Ohms Degrees C

372.200 150.000

555.080 133.250

842.660 117.050

1301.180 101.450

2047.500 86.400

3284.380 71.900

5378.420 57.850

8996.680 44.250

15345.520 31.150

26744.880 18.500

47748.920 6.250

87148.340 -5.550

163394.900 -17.000

260844.260 -25.000

SLATE™ FUEL AIR RATIO MODULE 17

R8001C6001

Page 18

100 ohm RTD

Ohms Degrees C

18.526 -200.250

50.064 -125.250

88.223 -30.250

132.801 84.750

174.010 194.750

213.822 304.750

250.520 409.750

280.962 499.750

1000 ohm RTD

Ohms Degrees C

185.26 -200.250

500.64 -125.250

882.23 -30.250

1328.01 84.750

1740.10 194.750

2138.22 304.750

2505.20 409.750

2809.62 499.750

1000 ohm Balco RTD

Ohms Degrees C

779.000 -40.000

864.700 -15.000

956.900 10.000

1044.400 32.200

1148.900 57.200

1247.300 79.400

1350.900 101.700

1418.200 115.600

18 32-00006—03

Page 19

Type J thermocouple

microVolts Degrees C

-8000.000 -205.214

-7600.000 -187.611

-7100.000 -169.194

-6300.000 -144.092

-5200.000 -114.127

-3800.000 -80.349

-1900.000 -38.715

-700.000 13.754

4600.000 87.675

12600.000 232.778

28400.000 517.923

33600.000 608.497

38300.000 686.565

44300.000 781.520

51600.000 895.549

56800.000 980.638

59500.000 1026.230

Type K thermocouple

microVolts Degrees C

-5000.000 -153.736

-4400.000 -129.609

-3600.000 -101.517

-2600.000 -70.403

-1200.000 -31.171

-700.000 17.529

6500.000 159.027

11300.000 278.023

17500.000 426.066

29000.000 696.902

34500.000 829.998

39500.000 954.713

41600.000 1008.307

SLATE™ FUEL AIR RATIO MODULE 19

R8001C6001

Page 20

Type T thermocouple

microVolts Degrees C

-5000.000 -166.012

-4200.000 -130.434

-3100.000 -89.867

-1600.000 -43.103

500.000 13.280

3100.000 74.769

6500.000 146.427

10900.000 230.361

16500.000 328.408

20800.000 399.315

Recommended Grounding Practices

Use an Earth ground or a signal ground as described below.

Earth ground (Base, Rectification Flame Amp

Module, other modules optional)

1. Use to provide a connection between the base and the

control panel of the equipment. Earth ground must be capable

of conducting enough current to blow the breaker in the event

of an internal short circuit.

2. Use wide straps or brackets to provide minimum length,

maximum surface area ground conductors. If a leadwire is

required, use 14 AWG copper wire.

3. Make sure that mechanically tightened joints along the ground

path are free of nonconductive coatings and protected against

corrosion on mating surfaces.

Signal ground

Note the 18V system ground is not electrically connected to earth

ground. Follow local codes and appliance recommendations to

determine if this should be connected to earth ground.

20 32-00006—03

Page 21

Recommended wire routing of leadwires

Do not run high voltage ignition transformer wires in the same

conduit with the flame detector or data lines.

Be sure loads do not exceed the terminal ratings. Refer to the

labels or terminal ratings in Table 3.

The SLATE system must be mounted in an electrical enclosure.

When mounting in an electrical enclosure, provide adequate

clearance for servicing, installation and removal of SLATE

modules.

Maximum wire length:

• The maximum leadwire length is 300 feet to terminal inputs

(Control, Running/Lockout Interlock)

• For Remote Bus data lines, maximum cable length depends on

the number of modules connected, the noise conditions and

the cable used. The maximum of all interconnecting wires is

4000 feet.

SLATE™ FUEL AIR RATIO MODULE 21

R8001C6001

Page 22

22 32-00006—03

Page 23

SLATE™ FUEL AIR RATIO MODULE 23

R8001C6001

Page 24

For more information and detailed instructions on the R8001C6001

32-00006-03

and the entire SLATE system please refer to the SLATE User Guide

located on our website at http://combustion.honeywell.com/SLATE

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark.

© 2015 Honeywell International Inc.

32-00006—03 M.S. Rev. 05-15

Printed in U.S.A.

Loading...

Loading...