Page 1

Q7751A Routers

DESCRIPTION

The Q7751A Router doubles the bus length and the number

of nodes on the L

ONWORKS

Q7751A2010 has an FTT-10 transceiver and is used on

L

ONWORKS networks with the Excel 10 series 2000 family of

controllers. The Q7751A1012 has a TP-78 transceiver and is

used on L

ONWORKS networks with the Excel 10 VAV1 series

1000 controllers.

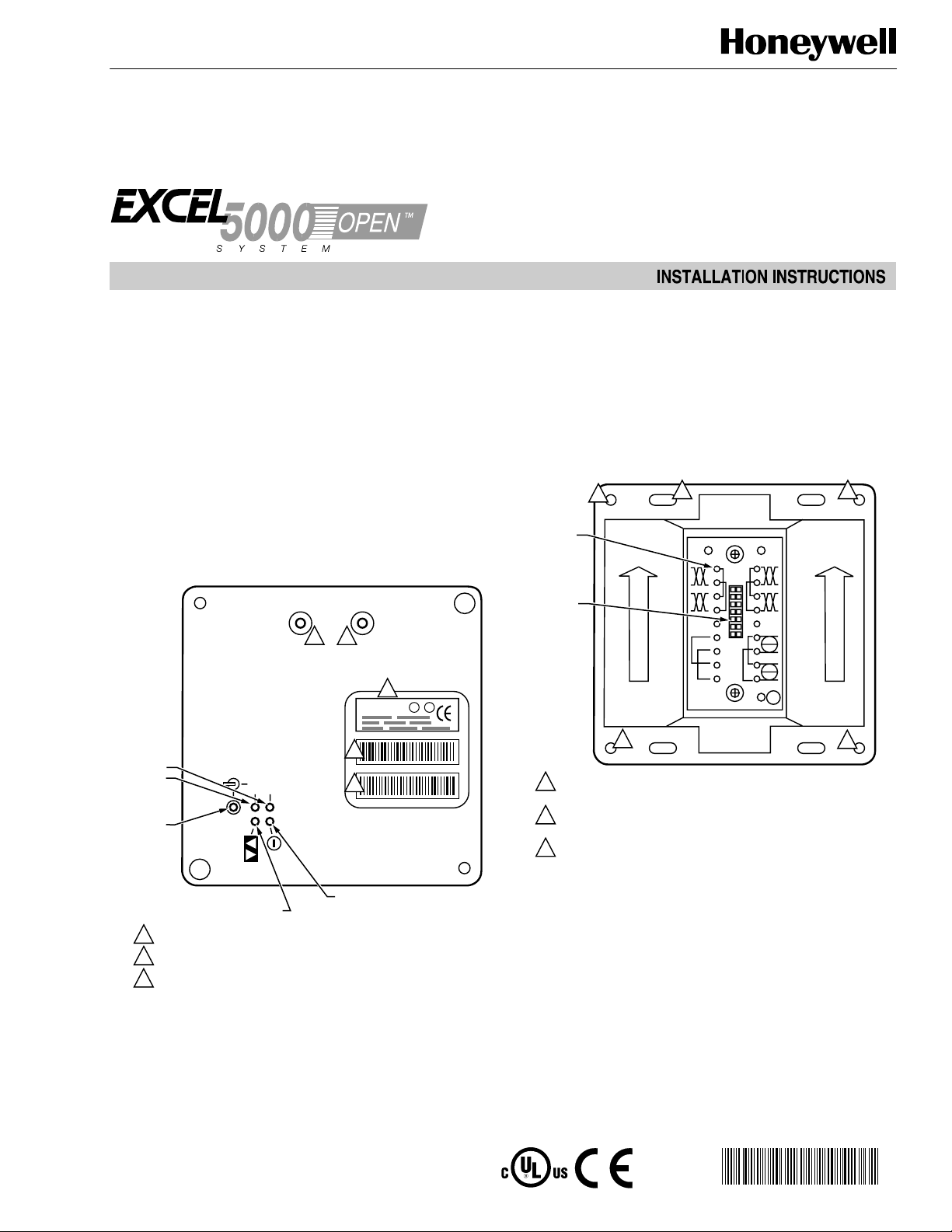

The Q7751A is a two-piece design allowing pre-wiring and

cable testing prior to installing the router. The front panel

includes a printed circuit board (PCB) with active electronics.

It also has a service switch and two service LEDs; a

combination power/wink LED, an activity LED and two

network connectors. See Fig. 1 for front panel view.

®

(E-Bus) network. The

BA

1

1

2

ULU

LPR-10

L

The router is installed in a Type 2 base plate. Wiring

connections are presented in Table 1. Specifications for the

router are shown in Table 2. Network and power are

connected to screw terminals located on a Type 2 base plate.

The router is plugged into the base plate. No wiring is ever

connected directly to the router. A writing space is provided

on the back of the base plate for recording the date of

installation and other important information. See Fig. 2 for

front view of base plate. See Fig. 3 for rear view of base

plate.

2

TEST

POINTS

1

3

BA

INTERFACE

CONNECTOR

2

SERVICE

LEDs

CHANNEL A

CHANNEL B

SERVICE

SWITCH

PACKET ACTIVITY LED ROUTER

TRANSFERRING PACKETS: FLASHING

1

OUTLET ACCESS JACKS; USE FOR ACCESS TO L

2

ROUTER INTERFACE MODEL AND SOFTWARE REVISION NUMBERS.

PEEL-OFF CODE 39 FORMAT BAR CODE OF ROUTER INTERFACE

3

®

Neuron

CHIP ID NUMBER.

B

A

3

3

POWER LED:

POWER ON: ILLUMINATED

CONTINUOUSLY

ONWORKS

BUS.

Fig. 1. Q7751A Router front plate.

®U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • All Rights Reserved

M16383

2

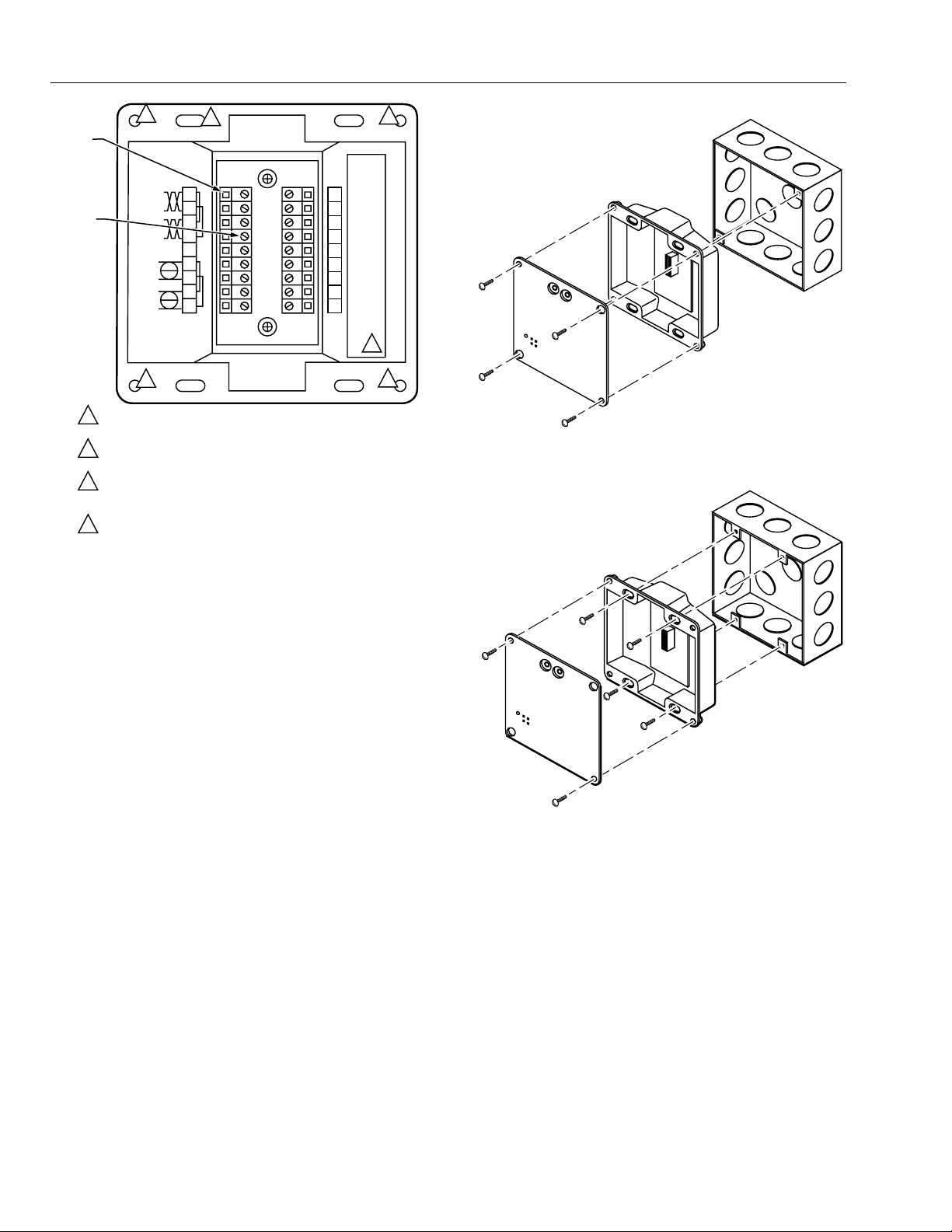

1

THREADED SCREW HOLES FOR ATTACHING ROUTER INTERFACE TO

BASE PLATE. USE 8-32, 3/8 IN. SCREW, Echelon 205-0130-01 OR EQUAL.

0.230 IN. HOLES FOR ATTACHING BASE PLATE TO ELECTRICAL BACK

2

BOX OR SUB-PANEL.

0.180 X 0.280 IN. HOLE FOR THE ATTACHING BASE PLATE TO

3

ELECTRICAL BACK BOX OR SUB-PANEL. USE 6-32, FLAT-HEAD,

3/8 IN. MINIMUM SCREW.

1

M16381

Fig. 2. Q7751A front view of base plate.

95- 7510- 3

Page 2

Q7751A ROUTERS

WIRE

ENTRY

TERMINAL

SCREW,

TIGHTENING

TORQUE 4

LBS. IN.

1

2

3

4

1

2

THREADED SCREW HOLES FOR ATTACHING ROUTER INTERFACE TO

BASE PLATE. USE 8-32, 3/8 IN. SCREW, Echelon 205-0130-01 OR EQUAL.

0.230 IN. HOLES FOR ATTACHING BASE PLATE TO ELECTRICAL BACK

BOX OR SUB-PANEL.

0.180 X 0.280 IN. HOLE FOR THE ATTACHING BASE PLATE TO

ELECTRICAL BACK BOX OR SUB-PANEL. USE 6-32, FLAT-HEAD,

3/8 IN. MINIMUM SCREW.

WRITING SPACE FOR INSTALLER. USE FINE POINT

SANFORD SHARPIE MODEL 30001 OR EQUAL.

3

1

23456789

11 12 13 14 15 16 17 18

10

2

4

1

M16382

Fig. 3. Q7751A rear view of base plate.

The Type 2 base plate is keyed to prevent accidental

insertion of an incorrect module. The router is attached to

the base plate with two 8-32 x 3/8 in. screws (provided).

The Type 2 base plate mounts to either a suitable U.S. four

in. square, two in. deep (10.16 cm x 5.08 cm) electrical

box, U.S. double gang electrical box or an IP-65 (NEMA 4)

enclosure. See Fig. 4 and 5.

4 IN. SQUARE

ELECTRICAL

BOX

BASE PLATE

ROUTER MODULE

M16384

Fig 4. Four in. square, two in. deep electrical box

mounting configuration.

DOUBLE GANG

ELECTRICAL BOX

BASE PLATE

ROUTER MODULE

Fig 5. Double gang two in. deep electrical box

mounting configuration.

95-7511—2 2

M16385

Page 3

Q7751A ROUTERS

Table 1. Router Wiring Connections.

Screw Terminal Wiring Connection

1 and 2 Incoming network wiring, polarity insensitive; CHANNEL A.

3 and 4 Outgoing network wiring, polarity-insensitive; CHANNEL A.

5 and 14 Cable shields; terminals 5 and 14 are internally connected.

6 and 7 Incoming power wiring 16 to 30 Vac or Vdc at 2.0 VA, polarity-insensitive. If using dc power, maintain

continuity of the power polarity throughout the network. Terminals 6 and 8 should be the same polarity.

Terminals 7 and 9 should be the same polarity.

10 and 12 Unused

Jumpered together internally; can be used to land extra wires.

11 and 13 Jumpered together internally; can be used to land extra wires.

15 and 16 Incoming network wiring, polarity insensitive; CHANNEL B.

17 and 18 Outgoing network wiring, polarity-insensitive; CHANNEL B.

Table 2. Router Specifications.

Function Description

Processor Two Echelon Neuron® 3150 chips. 10 Mhz.

Service function Recessed service switch, service LED. Dual tear-off bar code Neuron® ID self-adhesive tag for application

to redline drawings in the field.

Transceiver type Depends on model. FTT-10 for Q7751A2010

TP-78 for Q7751A1012

Network connector Ten orange screw terminals, non-removable, wire clamp style. Supports 12 to 24 AWG (4 to 0.27 mm2)

wire, shielded or unshielded daisy-chained cable. Two phone plug connectors are front panel accessible;

one per channel.

Input power 16 to 30 Vac or Vdc at 2.0 VA, internally isolated power supply.

Power connector Four black screw terminals, non-removable, wire clamp style. Supports 12 to 24 AWG (4 to 0.27 mm2)

daisy-chained wire.

Mounting Use with suitable back plate. Electrical box type or wall/35 mm DIN type.

Temperature -40 to +185oF (-40 to +85oC) operating and non-operating.

Humidity 10 to 95% RH at 122oF (50oC).

EMI FCC A, CE Mark

Safety agency UL 916

INSTALLING THE ROUTER

Install the router using the following steps:

1. Make sure the Type 2 base plate is correctly wired,

installed, and fastened to the electrical enclosure.

2. Check for continuity on all network and power wiring.

3. Make sure all network channels are terminated with

the correct number and type of terminator. Either one

or two terminator(s) can be installed in unused screw

terminals at the end of a network run.

4. Insert the router into the Type 2 base plate.

a. Align the network access jacks on the router

with the arrowhead on the Type 2 base plate

(the arrow should point toward the jacks).

b. Firmly press router into the base plate to make

sure the module is properly seated in its base

plate connector.

NOTE: The router can be hot plugged. There is no

need to disconnect power when installing

the module. If power is present, the Power

LED lights. If power is not present, the

Power LED is off.

5. Screw the two 8-32 x 3/8 in, (9.5 mm) screws into the

threaded inserts in the base plate.

6. Configure the router as described in the appropriate

software user guide.

7. See Troubleshooting section if necessary.

3 95-7510—3

Page 4

Q7751A ROUTERS

TROUBLESHOOTING

Table 3 contains common troubleshooting symptoms and

possible reasons and actions for repair.

Table 3. Troubleshooting symptoms and solutions.

Symptom Diagnosis

Power LED lit This is the normal LED state with node powered.

Power LED unlit Power supply that provides power to the module has lost primary power. Check power supply

outlet for power.

Power wiring not correctly connected to module. Use a meter to check for power on base plate

power terminals.

Input voltage is too low due to excessive load on the power supply that provides power to the

module because of excessively long cabling or power wiring that is shorted. Use a meter to

check for the correct voltage level on the base plate power terminals. Correct wiring length if too

long. Repair or replace faulty power cable.

Service LED unlit This is the normal state of the LED for a configured module.

Service LED flashing The module is not configured. This is the normal state for a new module. Commission the

module using the software tool.

No network communications Network wiring not connected correctly to the module.

Network cabling shorted, open, or otherwise damaged. Use continuity tester to check cabling.

Router(s) on network are not commissioned or powered.

Incorrect router channel type installed on channel.

Erratic or improper network

communications

Network wiring not securely connected to base plate terminals. The optimum tightening torque

for a base plate screw terminal is 4 lb/in. (0.5N/m) maximum.

Module not properly seated in the base plate. Make sure the module is pressed firmly into the

base plate and secured with fixing screws.

Use E-Bus Wiring Guidelines, form 74-2865.

Improper network cabling. In some cases, it is possible to correct network communications by

installing the Q7740A or Q7740B repeater in series with the network cabling. In other cases, the

cabling must be replaced with an approved cable.

Too many nodes on a channel. See the appropriate software user guide for channel limitations.

Controllers or devices are connected to the wrong channel of a router. Make sure the correct

types of controllers or devices are connected to the two router channels.

L

ONWORKS® is a registered trademark of Echelon® Corporation.

Home and Building Control Home and Building Control Home and Building Control Products

Honeywell Inc. Honeywell Limited-Honeywell Limitee Honeywell AG

Honeywell Plaza 155 Gordon Baker Road Böblinger Straße 17

P.O. Box 524 North York Ontario D-71101 Schönaich

Minneapolis, MN 55408-0524 M2H 3N7 Phone (49-7031) 637-01

Fax (49-7031) 637-493

95-7510—3 J.D. Rev. 5-99

Printed in U.S.A. on recycled

paper containing at least 10%

post-consumer paper fibers.

www.honeywell.com

Loading...

Loading...