Honeywell T7200D, T7200E, T7300F, Q7300, T7300D Product Data

...

T7200D,E, T7300D,E,F and Q7300

63-4355-2

Series 2000 Programmable Commercial

Thermostats and Subbases

PRODUCT DATA

• Automatic or manual changeover models available.

• Universal Versaguard™ Thermostat guards available.

• Convenient overrides allow temporary setpoint changes.

• Keypad lockout available.

T7200D,E Thermostats

• Use on single-stage conventional (T7200D) or heat

pump (T7200E) applications.

T7300D,E Thermostats:

• Use on multistage conventional (T7300D) or heat

pump (T7300E) applications.

• Models available with remote sensor capability.

T7300F Thermostats:

• Use on single-stage or multistage system in

conventional or heat pump applications.

• Auxiliary contacts on Q7300 can be used to interface

with C7400/W7459 Economizer System for total

integration of rooftop control.

• Remote temperature sensors available f or use with

all models.

• Different levels of keypad lockout available.

APPLICATION

The T7200, T7300 Thermostats and Q7300 Subbases control

24 Vac commercial single zone heating, ventilating and air

conditioning (HVAC) equipment. In addition, the Q7300H

Communicating Subbase can communicate schedule

information and system instructions to other devices in a

LonWorks® network.

FEATURES

All Models:

• 7-day programming.

• Two Occupied and two Unoccupied periods per day.

• Individual heat and cool setpoints available for

Occupied and Unoccupied periods.

• Proportional plus Integral (P+I) control eliminates

temperature fluctuations.

• Intelligent Recovery® control automatically optimizes

equipment start times based on building load.

• Intelligent Fan™ feature energizes fan continuously in

the Occupied periods. Fan can also be configured for

conventional heat or electric heat fan operation.

Q7300 Subbase:

• Use with T7300D,E,F Thermostats.

• Auxiliary contacts can be used to interface with

C7400/W7459 Economizer System for total

integration of rooftop control.

• When used with the T7300F (revision 3 or later), the

Q7300H communicates with other network devices.

Contents

Application........................................................................... 1

Features .............................................................................. 1

Specifications ...................................................................... 2

Ordering Information ........................................................... 2

Installation ........................................................................... 5

Wiring Subbase or Wallplate............................................... 7

Settings ............................................................................... 9

Installer Setup ..................................................................... 10

Installer System Test ........................................................... 14

Programming....................................................................... 16

Operation ............................................................................ 20

General Operation Information............................................ 22

Troubleshooting Guide ........................................................ 23

Cross Reference ................................................................. 25

Wiring Diagrams.................................................................. 33

LonWorks® is a registered trademark of Echelon Corporation.

® U.S. Registered Trademark

Copyright © 1999 Honeywell Inc. • • All Rights Reserved

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

SPECIFICATIONS

T7200/T7300 Thermostats:

T7200 and T7300 Thermostats provide features listed in

Table 1.

IMPORTANT

The specifications given in this publication do not

include normal manufacturing tolerances. Therefore,

Q7300 Subbases:

Q7300 Subbases provide features listed in Table 2.

this unit might not exactly match the listed

specifications. This product is tested and calibrated

under closely controlled conditions, and some minor

differences in performance can be expected if those

conditions are changed.

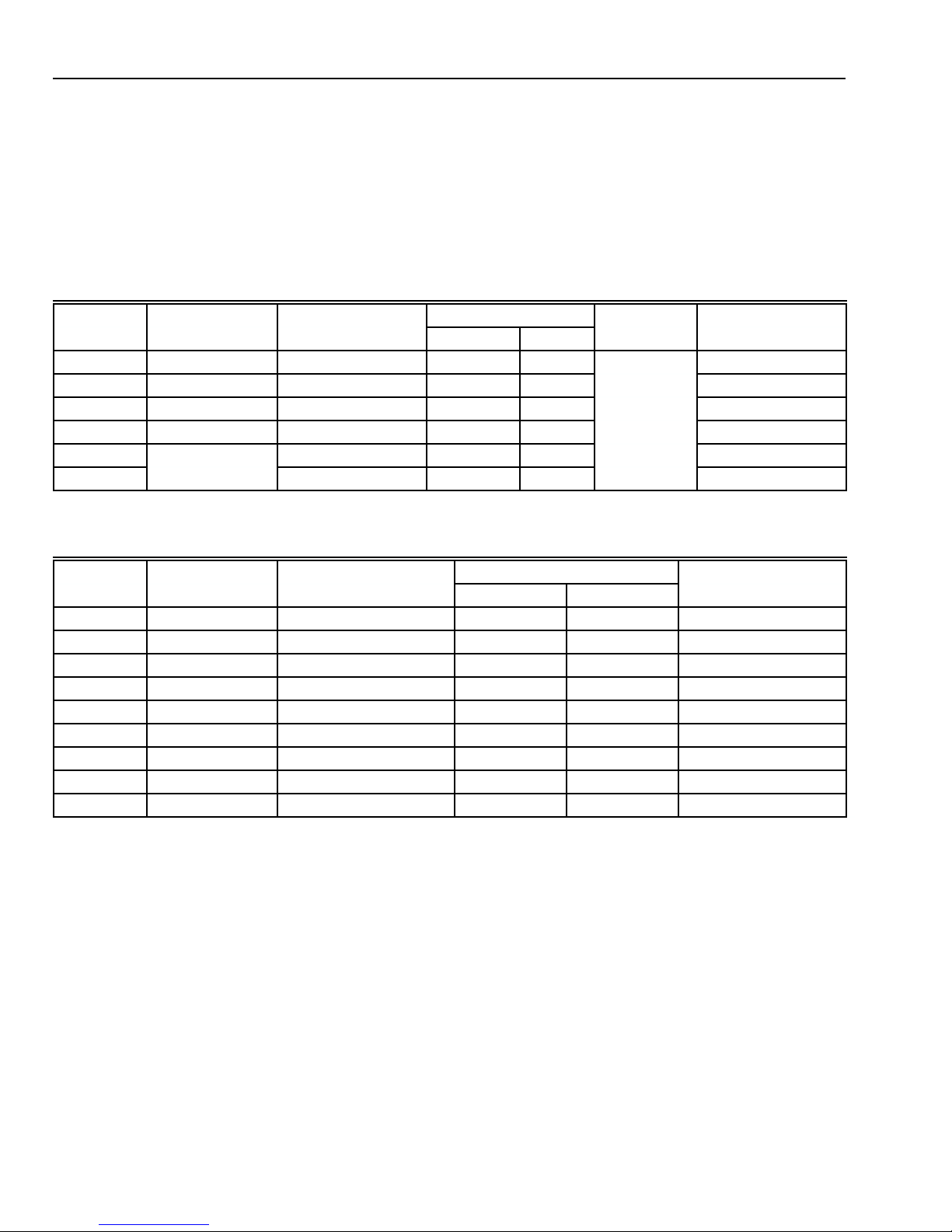

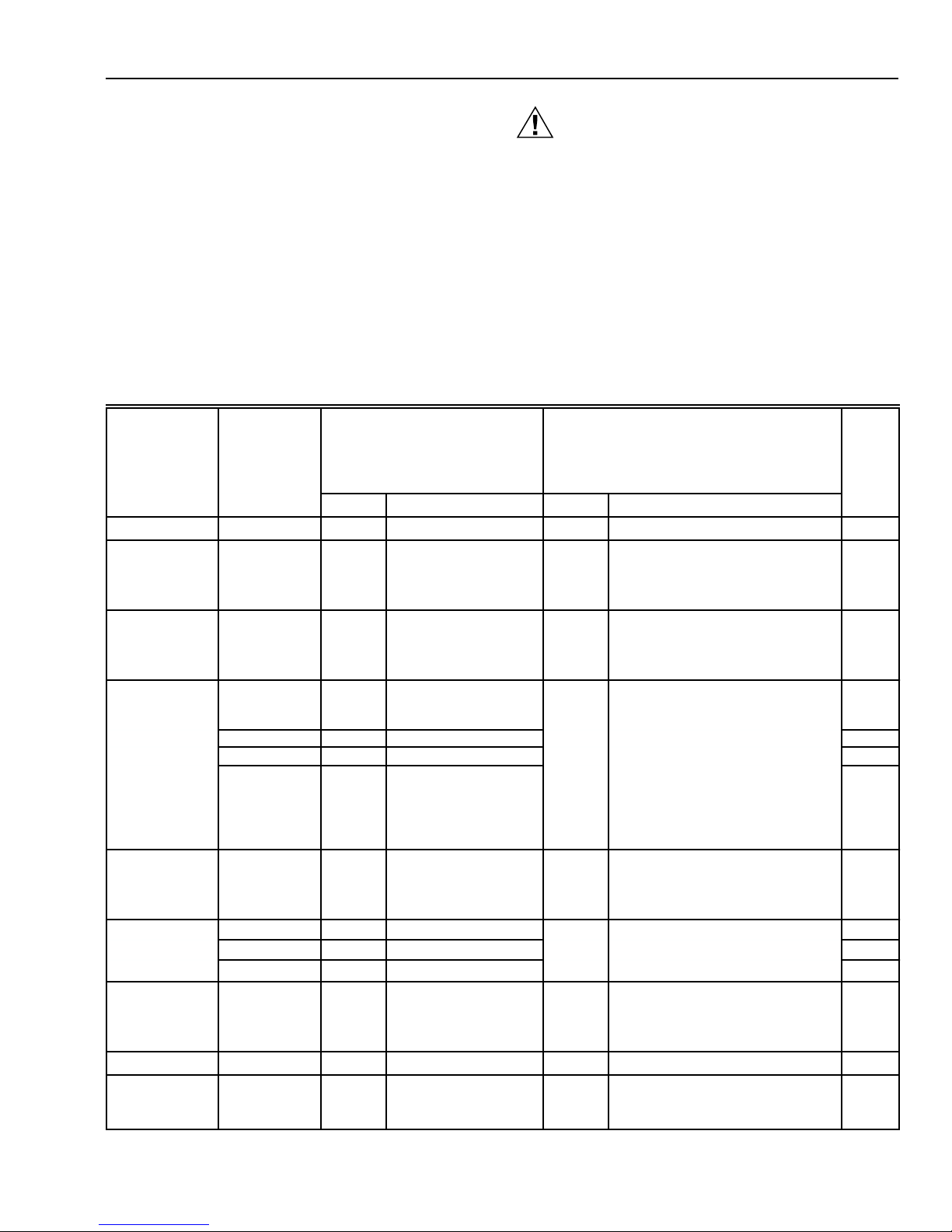

Table 1. T7200 and T7300 Thermostat Features.

Maximum Stages

Model Applications Subbase Required Heat Cool ChangeoverbHookup Drawing No.

T7200D Conventional None

T7200E Heat Pump None

a

a

11

11

Automatic

or Manual

19

20

T7300D Conventional Q7300A, G, L 3 3 21-22, 27, 33-34

T7300E Heat Pump Q7300C, D 3 2 23–26

T7300F

T7300F

a

Wallplate provided.

b

Configured in Installer Setup.

Conventional or

Heat Pump

Q7300A, C, D, G, L 3 3 21-27, 33-34

Q7300H — — 28-31

Table 2. Q7300 Subbase Features.

a

Drawing No.

Model Applications Thermostat

Q7300A

Q7300C

Q7300D

Q7300G

Q7300H

Q7300H

b

b

c

d

Conventional T7300D, F 2 2 21-22

b

Heat Pump T7300E, F 3 2 23–25

Heat Pump T7300E, F 3 2 26

b

Conventional T7300D, F 3 3 27

Heat Pump T7300F 3 2 28

Heat Pump T7300F 3 2 29

Required

Maximum Stages

Heat Cool Hookup

Q7300H Conventional T7300F 3 3 30

Q7300H Conventional T7300F 2 1 31

Q7300L Conventional

a

Wallplate only.

b

All subbases are down selectable and can be configured to

control fewer stages than the maximum allowed.

e

T7300D, F 2 1 33-34

c

With O/B terminals.

d

Without O/B terminals.

e

Used with ML7984 Actuator and V5011 or V5013 Valve.

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Home and Building Control Sales Office (check white pages of your phone directory).

2. Home and Building Control Customer Logistics

Honeywell Inc., 1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386 (612) 951-1000

In Canada—Honeywell Limited/Honeywell Limitée, 155 Gordon Baker Road, North York, Ontario M2H 3N7.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-4355—2 2

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

Electrical Ratings:

24 Vac, 50/60 Hz.

20 to 30 Vac, 50/60 Hz.

Batteries:

No batteries required.

Auxiliary Heat and Emergency Heat Indication:

Thermostat display indicates when Auxiliary Heat or

Emergency Heat are activated.

Loss of Power:

The thermostat will maintain programmed times and

temperatures for the life of the product. The clock and day

information is retained for a minimum of two hours.

Light Emitting Diodes (LEDs):

Two user-defined LEDs (not available on Q7300H).

Two defined (CHECK and MAINTENANCE) LEDs on select

models.

Two additional LEDs available on select models.

System Current Draw:

6 VA maximum at 30 Vac, 50/60 Hz.

Output Relay Draw:

See T able 3.

Table 3. Maximum Amps at 30 Vac.

Relay Running (A) Inrush (A)

Fan 1.6 3.5

Heat (all stages) 1.6 3.5

Cool (all stages) 1.6 7.5

Auxiliary (Economizer) 1.6 3.5

Temperature:

Ratings:

Operating Ambient: 40°F to 110°F (4°C to 43°C).

Shipping: -30°F to +150°F (-34°C to +65°C).

Display Accuracy: ±1°F (±0.5°C).

Setpoint:

Range: 45°F to 95°F (7°C to 35°C).

Deadband: 2°F (1°C).

Default Settings: see Table 4.

Table 4. Default Setpoints.

Control Occupied Unoccupied

Heating 70°F (20°C) 55°F (13°C)

Cooling 78°F (25.5°C) 90°F (32°C)

Table 5. T emperature Offset.

Temperature Range 18 AWG 20 AWG 22 AWG

50-90°F -0.4°F -0.7°F -1.0°F

10-32°C -0.3°C -0.4°C -0.6°C

Minimum Stage Operation Time:

Minimum On (Heat and Cool): factory setting 2 minutes;

option 0 minutes.

Minimum Off (Cool and Heat Pump): factory setting

4 minutes; option 0, 1, 3, 5 minutes.

Humidity Ratings:

5% to 90% RH, noncondensing.

Clock Accuracy:

+1 minute per month.

Finish:

Taupe color.

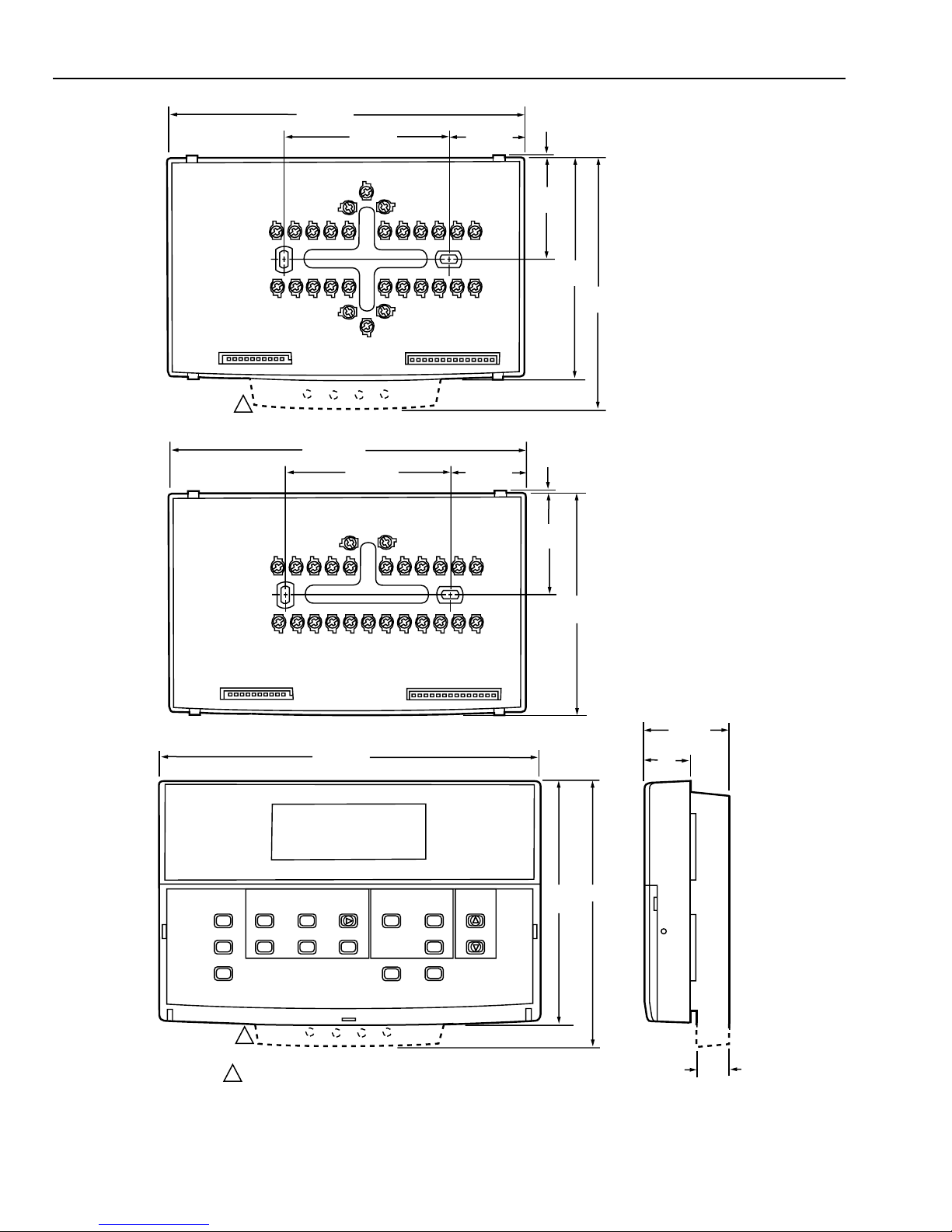

Dimensions:

See Fig. 1.

Mounting Means:

T7200 Thermostat mounts on a wallplate. The T7300 Thermostat mounts on a Q7300 Subbase. The wallplate and

subbase mount horizontally on a wall or outlet box with two

no. 6 x 32 screws (included).

Accessories:

C7150B1004 Discharge Air Sensor (form 63-2072).

C7400 Enthalpy Sensor (form 63-2140).

M7415 Damper Actuator (form 63-2100).

ML7984 Valve Actuator (form 95C-10753).

Q7760A Serial LonTalk® Adapter

R8222 Switching Relay (form 60-2056).

T675A Temperature Control (form 60-2200).

T7022A1010 Remote Temperature Sensor (form 60-0247).

T7047C Remote Temperature Sensor (form 62-3050).

T7047G Remote Temperature Sensor (form 62-3050).

T7147A Remote Temperature Sensor and Override Module

(form 62-3049).

W859F Packaged Economizer (form 63-2476).

W950A System Supervisor (form 60-2351).

W7459 Economizer Logic Module (form 63-2141).

W6210/W7210 Economizer (form 63-2528).

Approvals:

European Community Mark (CE) Listed.

Q7300H only: LonMark® Functional Profile No. 8060,

Thermostat Object (type 09).

Remote Sensor Wiring Temperature Offset:

Temperature offset occurs with 500 ft (157m) to 1000 ft (305m)

of 2-wire cable. See T able 5.

RECYCLING NOTICE

If this control is replacing a control that contains

mercury in a sealed tube, do

control in the trash.

Contact your local waste management authority for

instructions regarding recycling and the proper

disposal of the old thermostat.

not

place your old

63-4355—23

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

6-3/4 (172)

3-1/4 (82)

1-3/8 (35)

1/16 (2)

1-7/8

(47)

4-1/8

(105)

4-3/4

(121)

1

Q7300A,C,D,G,L

6-11/16 (170)

3-3/16 (77)

1-3/8 (35)

1/16 (2)

1-7/8

(47)

M16292

Q7300H

7-5/16 (186)

Run

Program

Temporary

Occupied

Continous

Unoccupied

Occupied

Start Time

Set Current

Day/Time

Set Program

Unoccupied

Start Time

Clear

Start Time

Day

Copy

Set Temperature

Occupied

Temp

System

Unoccupied

Temp

Heat/Cool

Settings

Fan

1

T7200D,E; T7300D,E,F

1 T7200 WALLPLATE DOES NOT HAVE THE LED EXTENSION

Fig. 1. Dimensions of T7200, T7300 and Q7300 in in. (mm).

Change

Time/Temp

4-5/8

(117)

4-1/8

(105)

5 (127)

7/8

(22)

1-11/16

(43)

9/16

(14)

63-4355—2 4

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

INSTALLATION

Q7300 Subbase with Remote-Mounted

Temperature Sensor(s)

When Installing this Product…

1. Read these instructions carefully. Failure to follow the

instructions can damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After completing installation, use these instructions to

check out the product operation.

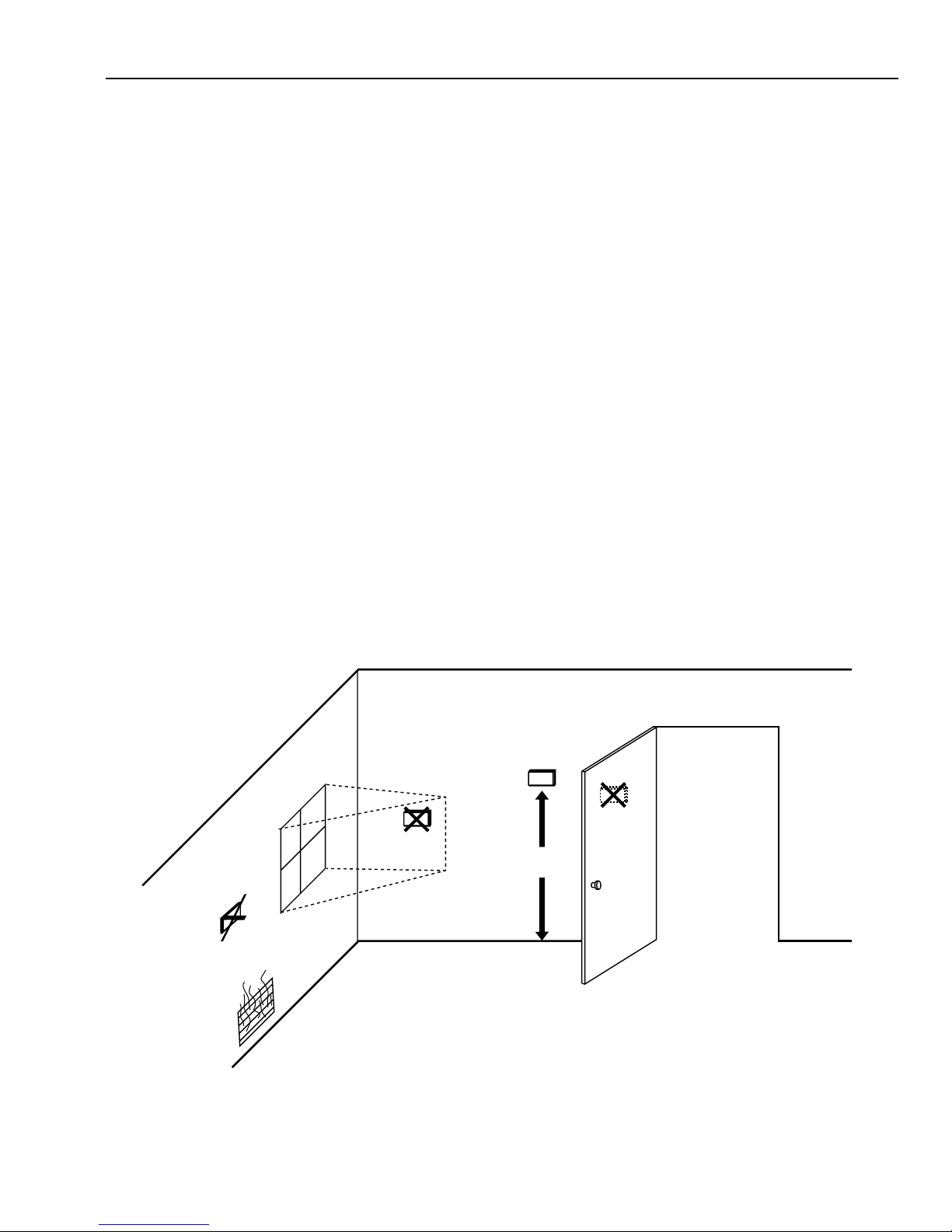

If only the remote-mounted temperature sensor(s) is used to

sense and control room temperature, then install the

thermostat in an area that is accessible for setting and

adjusting the temperature and settings.

If both the subbase and remote-mounted temperature

sensor(s) are used to sense and control room temperature,

then install the subbase about 5 ft above the floor in an area

with good air circulation.

Install the remote-mounted sensor(s) about 5 ft (1.5m) above

the floor in an area with good air circulation at average

temperature. See Fig. 2.

Location

T7200 Wallplate or Q7300 Subbase without RemoteMounted Temperature Sensor

Install the thermostat about 5 ft (1.5m) above the floor in an

area with good air circulation at average temperature. See

Fig. 2.

Do not install the thermostat where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

behind the thermostat.

Do not mount the sensor(s) where it can be affected by:

— drafts, or dead spots behind doors and in corners.

— hot or cold air from ducts.

— radiant heat from sun or appliances.

— concealed pipes and chimneys.

— unheated (uncooled) areas such as an outside wall

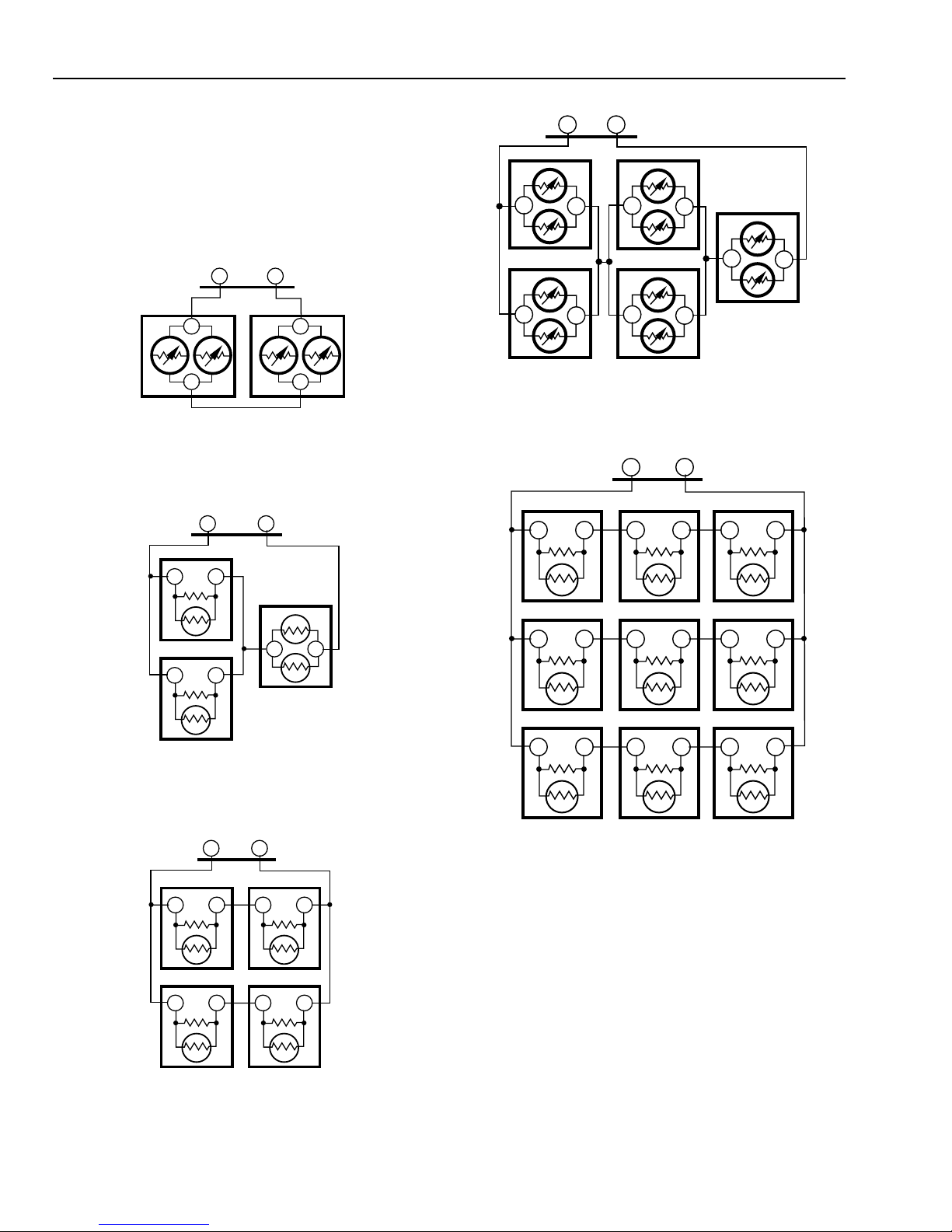

If more than one remote sensor are required, they must be

arranged in a temperature averaging network consisting of

two, three, four, five or nine sensors. See Fig. 3 through 7.

NOTES:

— When sensor averaging, the T7147A can be substituted

— Up to four T7147As can be used in parallel to place the

behind the thermostat.

for the T7047C. The T7147A includes OVERRIDE and

WARMER/COOLER keys.

thermostat in Temporary Occupied.

NO

Fig. 2. Typical location of thermostat or remote-mounted sensor.

NO

YES

5 FEET

(1.5 METERS)

NO

M4823A

63-4355—25

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

IMPORT ANT

To avoid electrical interference, which can cause

erratic performances, keep wiring runs as short as

possible and do not run thermostat wires adjacent to

the line voltage electrical distribution systems. Use

shielded cable (Belden type 8762 or equivalent for

2-wire and Belden type 8772 or equivalent for 3-wire).

The cable shield must be grounded only at the

controlled equipment case.

Fig. 3. Two T7047G Sensors providing

SUBBASE

TT

T7047GT7047G

T

T

T

T

M4838

temperature averaging network for

T7300/Q7300 Thermostat/Subbase.

SUBBASE

TT

T7047C

TT

T7047G

SUBBASE

TT

T7047G

T

T7047G

T

T7047G

T

T

T

T7047G

T

T

T7047G

T

Fig. 6. Five T7047G Sensors providing

temperature averaging network for

T7300/Q7300 Thermostat/Subbase.

SUBBASE

TT

T7047C

TT

T7047C

T7047C

TT

T7047C

T7047C

T7047C

T

TT

T

M4841

T7047C

TT

TT

M4839

Fig. 4. Two T7047C Sensors and one T7047G Sensor

providing temperature averaging network for

T7300/Q7300 Thermostat/Subbase.

SUBBASE

TT

T7047C

TT

T7047C

TT

T7047C

TT

T7047C

TT

M4840

Fig. 5. Four T7047C Sensors providing

temperature averaging network for

T7300/Q7300 Thermostat/Subbase.

TT

T7047C

TT

TT

T7047C

TT

TT

T7047C

TT

M4842

Fig. 7. Nine T7047C Sensors providing temperature

averaging network for T7300/Q7300 Thermostat/Subbase.

NOTE: When thermostat is configured for temperature

averaging network (remote and internal sensing), the

internal sensor has 50% authority of the averaged

temperature.

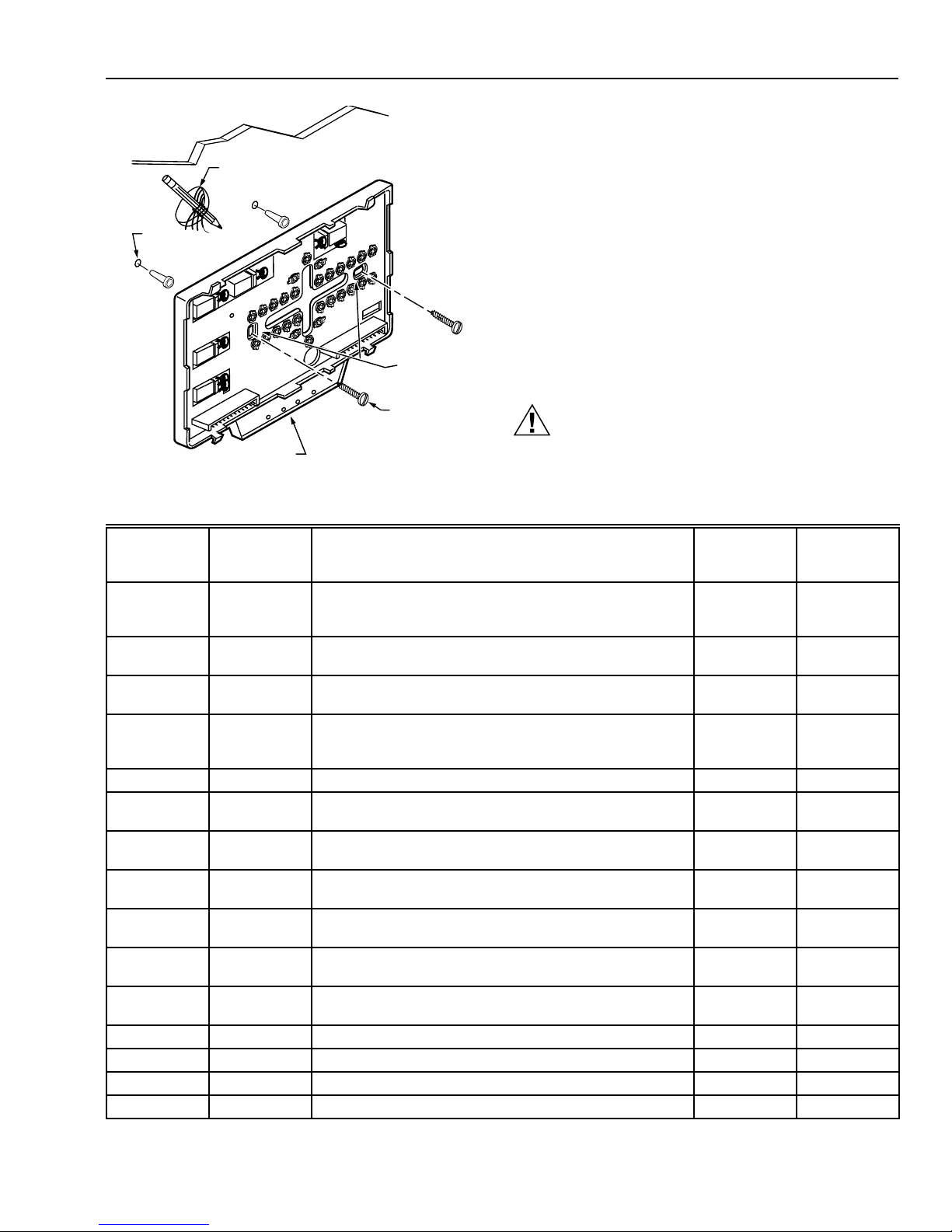

Mounting Subbase or Wallplate

The subbase or wallplate mounts horizontally on the wall or a

2 in. x 4 in. wiring box. Position the subbase or wallplate

horizontally on the wall or on a 2 in. x 4 in. wiring box.

1. Position and level the subbase or wallplate (for

appearance only). The thermostat functions properly

even when not level.

2. Use a pencil to mark the mounting holes. See Fig. 8.

63-4355—2 6

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

3. Remove the subbase or wallplate from the wall and drill

two 3/16 inch holes in the wall (if drywall) as marked.

For firmer material such as plaster or wood, drill two

7/32 inch holes. Gently tap anchors (provided) into the

drilled holes until flush with the wall.

WIRES

THROUGH WALL

WALL

4. Position the subbase or wallplate over the holes, pulling

wires through the wiring opening.

5. Loosely insert the mounting screws into the holes.

WALL

ANCHORS

(2)

6. Tighten mounting screws.

WIRING SUBBASE OR WALLPLATE

All wiring must comply with local electrical codes and

ordinances. Follow equipment manufacturer wiring

MOUNTING

HOLES

MOUNTING

SCREWS

LEDS

Fig. 8. Mounting subbase or wallplate.

M10237

instructions when available. Refer to Fig. 19 through 32 for

typical hookups. A letter code is located near each terminal

for identification. Refer to Table 6 for terminal designations.

CAUTION

Electrical Shock Hazard.

Power supply can cause electrical shock.

Disconnect power before beginning installation.

Table 6. Terminal Designations and Descriptions.

Standard

Terminal

Designations

A1

Alternate

Terminal

Designations Typical Connection Function

A2

a

Dry auxiliary contacts for economizer control; A1 is

Output Dry contact

Terminal

Type

normally open during Unoccupied periods and closed

during Occupied periods.

A1, A2 — Damper control relay (Q7300L only). Input, Output 24V powered

contact

A2

A1

a

Dry auxiliary contacts for economizer control (A2 is

Input Dry contact

common).

A3 — Dry auxiliary contacts for economizer control; A3 is

Output Dry contact

normally open during Occupied periods and closed during

Unoccupied periods.

AS, AS — C7150B Discharge Air Sensor connection. Input —

B — Heating changeover valve. Output 24V powered

contact

C1, C2, C3,

— Communication input for T7147. Input Low power

C4, C5

E K Emergency heat relay. Output 24V powered

contact

EB, EB

—

Q7300H LonWorks® bus connection to LonWorks®

network.

Input, Output Communi -

cations

G F Fan relay. Output 24V powered

contact

O R Cooling changeover valve. Output 24V powered

contact

R V 24V system transformer. Input —

RC — 24V cooling transformer. Input —

RH — 24V heating transformer. Input —

T, T — Remote sensor input for T7047 or T7147. Input —

a

Some OEM models reverse the economizer terminal designations A1 and A2.

(continued)

63-4355—27

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

Table 6. Terminal Designations (continued).

Standard

Terminal

Designations

W1 H1, R3 Stage 1 heating relay (Q7300A, G, H) or auxiliary heat

W2 H2, R4, W3, Y Stage 2 heating relay. Output 24V powered

W3 — Stage 3 heating relay. Output 24V powered

X

X1, X3 A, A1, A2, C,

X4 — LED common. Annunciation —

Y 1 C1, M, Y Stage 1 compressor contactor (Q7300C, D, H). Output 24V powered

Y1, Y RS, M

Y 2 C 2 Stage 2 cooling compressor (conventional).

Y 3 — Stage 3 cooling compressor. Output 24V powered

BM —

FC —

GH —

GL —

P1, P2 —

RM —

— C, H, L HSII Control Panel. — —

— O Momentary circuit changeover. — —

— P Defrost. — —

— R1, R2 Low- and high-speed fan relays. — —

— T External temperature readout, T-relay; outdoor thermistor. — —

a

Some OEM models reverse the economizer terminal designations A1 and A2.

b

Some OEM models label the terminal for transformer common B.

c

Only applies to Q7300H2037 model.

Alternate

Terminal

Designations Typical Connection Function

Output 24V powered

relay (Q7300C, D, H).

b

B

, C, X1, X2

Common. Input

User defined Light Emiting Diodes (LEDs). Annunciation —

L, X, Z

Stage 1 cooling compressor (Q7300A, G, H

c

, L).

Output 24V powered

Output 24V powered

Stage 2 compressor contactor (heat pump).

ML7984 Actuator connection (Q7300H

c

, L only); no call

Output —

for heat, valve closed; call for stage 1 heat, valve

approximately one-half open; call for stage 2 heat, valve

fully open.

Fan control transformer (Q7300H

High-speed fan output (Q7300H

c

, L only).

c

, L only); activate during

Input —

Output 24V powered

calls for cooling.

Low-speed fan output (Q7300H

c

, L only); activated on

Output 24V powered

calls for heat and fan On selection.

Pump interlock relay (Q7300H

c

, L only); operates

Input, Output 24V powered

circulator pump in hydronic heat or energizes

conventional heat system.

ML7984A Actuator connection (Q7300H

c

, L only); no call

Output —

for heat, valve closed; call for stage 1 heat, valve

approximately one-half open; call for stage 2 heat, valve

fully open.

Terminal

Type

contact

contact

contact

contact

contact

contact

contact

contact

contact

contact

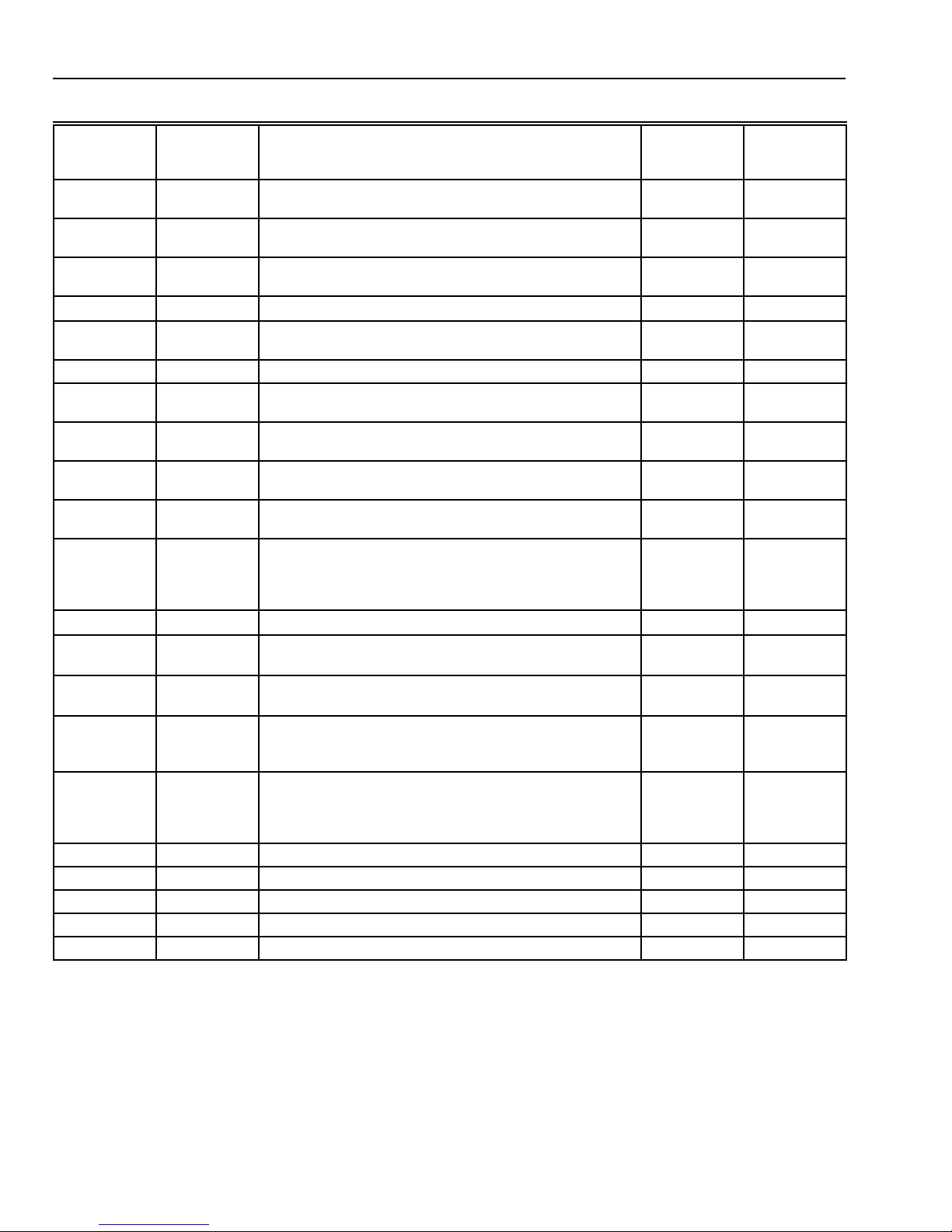

1. Loosen the terminal screws on the subbase or wallplate

and connect the system wires. See Fig. 9.

IMPORTANT

Use 18-gauge, solid-conductor color-coded

thermostat cable for proper wiring. If using

18- gauge stranded wire, no more than ten wires

can be used. Do not use larger than 18-gauge wire.

63-4355—2 8

2. Securely tighten each terminal screw.

3. Push excess wire back into the hole.

4. Plug the hole with nonflammable insulation to prevent

drafts from affecting the thermostat.

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

SETTINGS

Using Thermostat Keys

The thermostat keys are used to:

• set current time and day,

• program times and setpoints for heating and cooling,

• override the program temperatures,

• display present setting,

• set system and fan operation,

• configure Installer Setup,

• check Installer System Test.

FOR STRAIGHT

FOR WRAPAROUND

INSERTION STRIP

7/16 IN. (11 MM).

Fig. 9. Proper wiring technique.

INSERTION STRIP

5/16 IN. (8 MM).

M4826

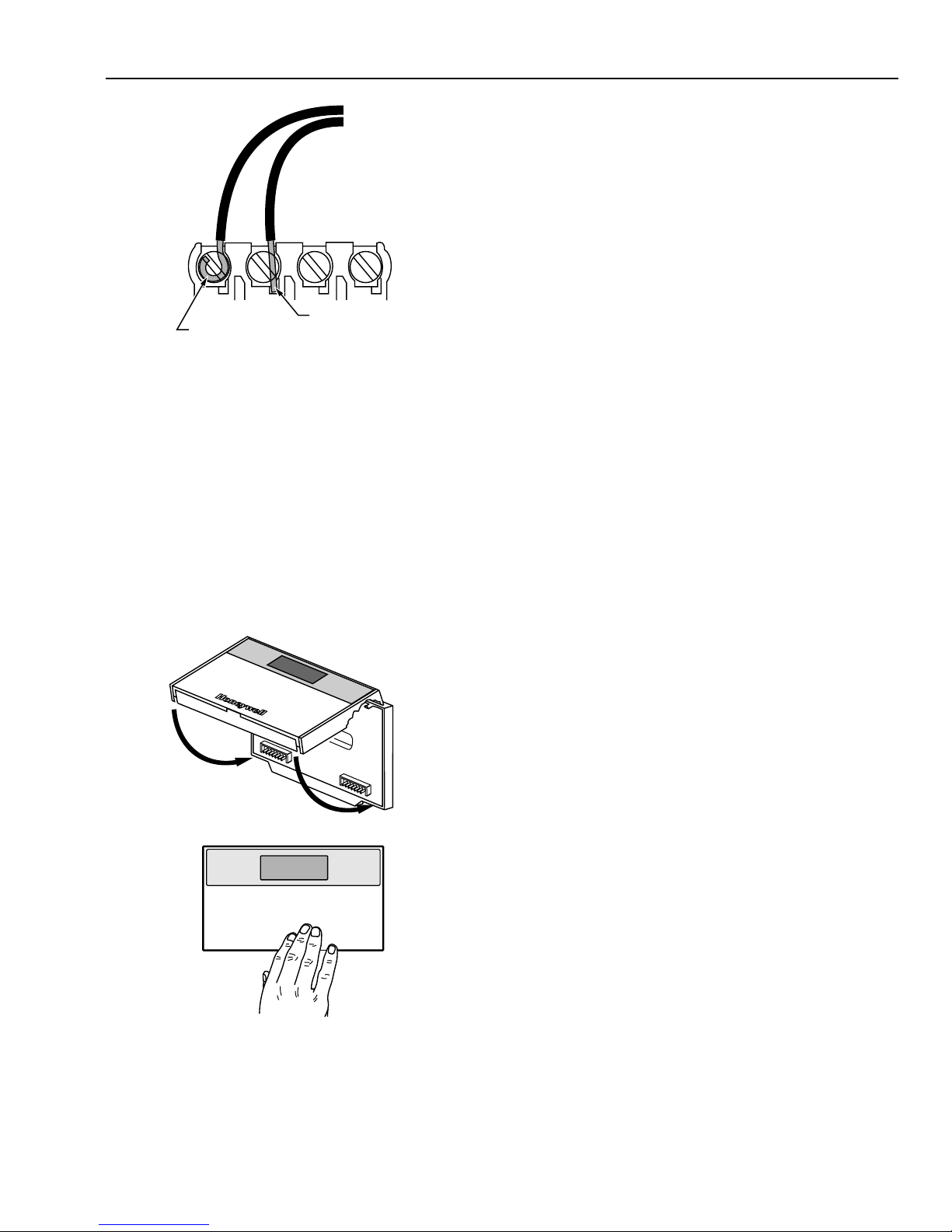

Mounting Thermostat on Subbase or

Wallplate

The thermostat mounts on the subbase or wallplate after they

are installed.

1. Engage the tabs at the top of the thermostat and

subbase or wallplate. See Fig. 10.

2. Press the lower edge of the case to latch.

NOTE: To remove the thermostat from the wall, first pull out

at the bottom of the thermostat; then remove the top.

A. ENGAGE TABS AT TOP OF THERMOSTAT AND SUBBASE OR WALLPLATE.

See Fig. 11 for key information.

Setting System and Fan (select models)

The system default setting is Heat. The fan default is set so

the fan operates continuously in Occupied periods,

Unoccupied period recovery times and with the heating and

cooling equipment in Unoccupied periods. Use the System

and Fan keys to change the settings. Fan and system

operation are configured in the Installer Setup options.

The system settings are:

Em Heat (T7200E, T7300/Q7300C,D,H): Emergency heat

relay is on continuously. Thermostat cycles highest stage

of heat. Cooling system is off. Compressor is de-energized.

Heat: Thermostat controls the heating.

Off: Both the heating and cooling are off.

Cool: Thermostat controls the cooling.

Auto: Thermostat automatically changes between heating

and cooling depending on the indoor temperature.

The fan settings are:

On: Fan operates continuously in occupied period.

Auto: Equipment controls the fan in the Unoccupied

periods. The Intelligent Fan™ operation (Installer Setup

number 17) offers three choices for the fan operation in

Occupied periods:

— fan turns on only when there is a call for heating or

cooling.

— fan operates continuously in Occupied periods.

— fan is on continuously in Occupied periods and

Unoccupied period recovery times.

B. PRESS LOWER EDGE OF CASE TO LATCH.

Fig. 10. Mounting thermostat on subbase or wallplate.

Setting Temperature

Refer to Table 7 for the default temperature setpoints. See

Programming section for complete instructions on changing

the setpoints.

M4824A

63-4355—29

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

ENTER OCCUPIED

PROGRAM MODE

RETURNS TO

NORMAL

OPERATIONS

SET OVERRIDE

TEMPERATURE

OFFSET AND

ACTIVATE

TEMPORARY

OVERRIDE

ENTER HOLD MODE

Run

Program

Temporary

Occupied

Continuous

Unoccupied

SET CURRENT

DAY AND TIME

CLEAR PROGRAM PERIOD

Fig. 11. Thermostat key locations and descriptions.

ENTER UNOCCUPIED

PROGRAM MODE

SET CURRENT DAY OR

PROGRAM DAY

AM

Mon

Occupied

System Fan

Heat

Set Program Set Temperature Change

Occupied

Start Time

Set Current

Day/Time

Unoccupied

Start Time Day

Clear

Start Time

Copy

COPY ONE

PROGRAMMED DAY

TO ANOTHER DAY

SET OCCUPIED

TEMPERATURE

SETPOINTS

Room

Auto

Occupied

Temp

System Fan

SELECT

SYSTEM

OPERATION

Unoccupied

Temp

Heat/Cool

Settings

Time/Temp

SELECT FAN

OPERATION

SET UNOCCUPIED TEMPERATURE

SETPOINTS AND SCROLLS

THROUGH INSTALLER SETUP

AND SYSTEM TEST

INCREASE

TEMPERATURE

OR TIME SETTING

DECREASE

TEMPERATURE

OR TIME SETTING

CHANGE BETWEEN HEATING

AND COOLING SETPOINTS

AND SCROLLS BACKWARDS

THROUGH INSTALLER SETUP

NUMBERS AND SYSTEM TEST

M10233A

Table 7. Default Temperature Setpoints.

Control Occupied Unoccupied

Heating 70°F (20°C) 55°F (13°C)

Cooling 78°F (25.5°C) 90°F (32°C)

INSTALLER SETUP

NOTE: For most applications, the thermostat factory

settings do not need to be changed. Review the

factory settings in Table 8 and if no changes are

necessary, go to the Installer System Test section.

The Installer Setup is used by the installer to customize the

thermostat to specific systems. Installer Setups are listed in

Table 8. The table includes all the configuration options

available.

A combination of key presses are required to use the Installer

Setup feature.

— To enter the Installer Setup, press and hold the Heat/Cool

Settings key and both the increase ▲ ▲ and ▼ ▼ decrease

keys until the first number is displa yed. All display

segments appear for approximately three seconds before

the number is displayed. See Fig. 12 and 13.

Set Program

Start Time

Em Ht

Aux Ht

Comm

Mon

TueWedThuFriSatSun

Un

Occupied 12 Override

Set Day/Time

AM

PM

System Fan

Cool

Off Auto

Heat

Em

Temporary Setting Enrg

Heat

Recovery

In

Lo

Med

Hi

Wait

Cool

Auto

Room

%Humid

Remote

Only

On

Sav

Duct

Auto

M4916

Fig. 12. LED display of all segments.

MODE NUMBER

DISPLAY

(COLUMN 2

OF TABLE 8)

FACTORY SETTING

OR OTHER CHOICE

DISPLAY (COLUMN 3

OR 5 OF TABLE 8)

M10227

Fig. 13. Installer Setup number and setting display.

63-4355—2 10

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

— To advance to the next Installer Setup number, press the

Unoccupied T emp ke y .

— To return to an Installer Setup number, press the Heat/

Cool Settings key.

— To change a setting, use the increase ▲ ▲ or ▼ ▼ decrease

key.

— To exit the Installer Setup, press the Run Program key.

The Installer Setup is automatically exited if no key

presses are made for four minutes.

CAUTION

Possible Equipment Damage.

Fan must be running when system is operating.

Heat pump and electric heat systems must be

configured correctly in Installer Setup 2 to prevent

equipment damage caused by the system running

without the fan.

NOTE: Be sure to set the thermostat time after exiting the

Installer Setup.

Installer Setup numbers are listed in Table 8.

IMPORTANT

Only configurable numbers are shown on the device.

Example: If the thermostat does not have a system

key, Installer Setup number 12 will not be displayed.

Review Table 8 factory settings and mark any

desired changes in the Actual Setting column. When

the Installer Setup is complete, review the settings to

confirm that they match the system.

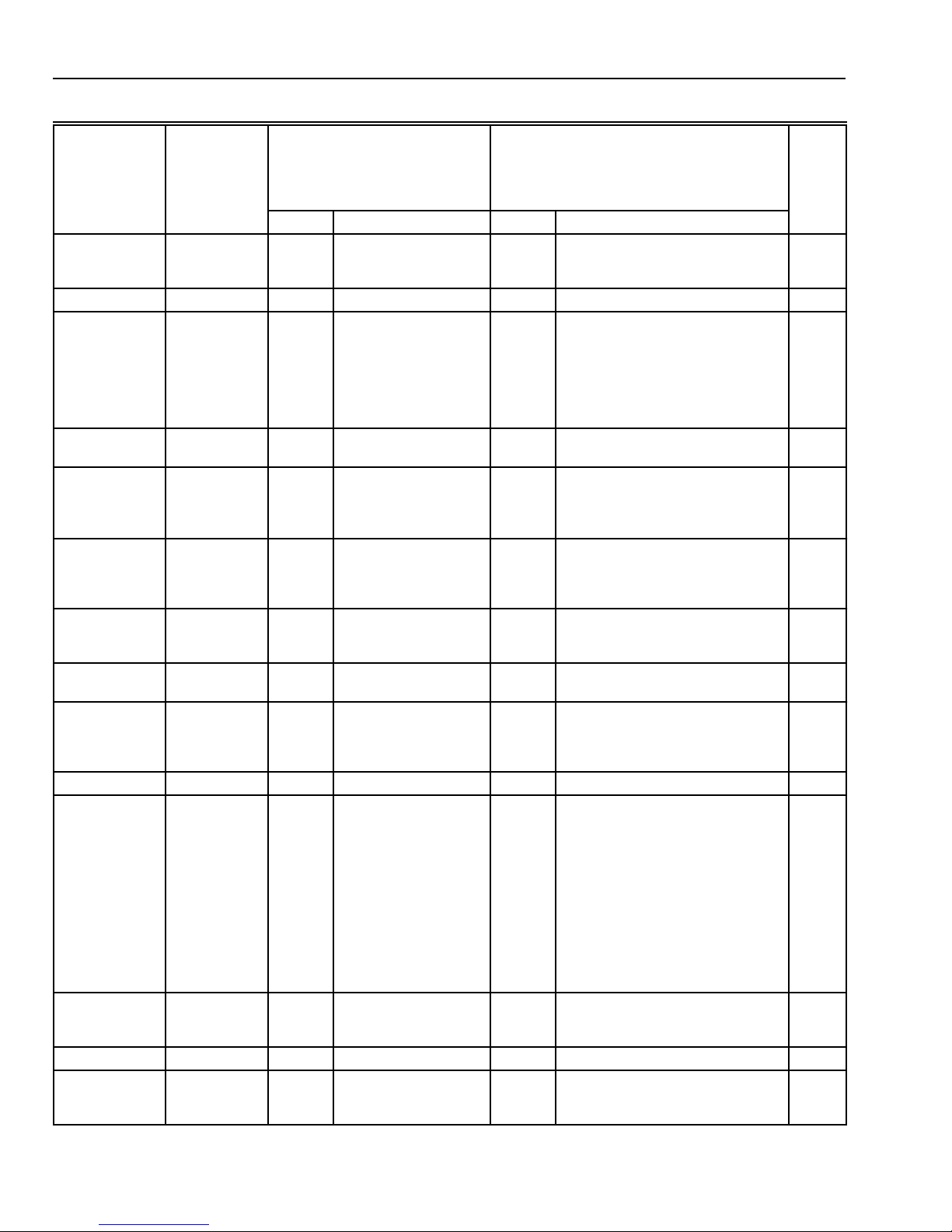

Table 8. Thermostat Installer Setup Options.

Installer

Setup Number

(Press

Unoccupied

Temp key

a

to change)

2 0 Conventional

3 Depends

4 4 Stage 1—4 cph. 3, 6, 8 or

5 4 Stage 2—4 cph.

6 4 Stage 3—4 cph.

7 4 Emergency heat relay

8 Depends

9 4 Stage 1—4 cph. 3 3—3 cph.

10 4 Stage 2—4 cph.

11 4 Stage 3—4 cph.

12 Depends

14 0 Temperature is

Display Description Display Description

subbase

subbase

on model

Select

Not used 1 — — — — —

Fan operation

Output stages

of heating

Heating cycle

rate

Output stages

of cooling

Cooling cycle

rate

System setting

adjustment

(models with

System key)

Not used 13 — — — — —

Degree

temperature

display

a

Number 2 must be set to 1 to extend fan operation.

Factory Setting

applications where

equipment controls fan

operation in heat mode.

Stages of heat. 0, 1, 2,

on

is on continuously.

Highest stage of heat

cycles at 4 cph

(Q7300C or D only).

Stages of cooling. 0, 1, 2

on

System selection. 0, 1 or 2 0—System setting key is

displayed in °F.

(Press ▲ or ▼ key to change)

1 Electric heat applications where

or 3

9

or 3

1 Temperature is displayed in °C.

Other Choices

Actual

Setting

thermostat controls fan operation in

heat mode.

0—No heating.

1—One stage of heat.

2—Two stages of heat.

3—Three stages of heat.

3—3 cph used for hot water

systems or high efficiency

furnaces.

6—6 cph used for conventional

systems.

8—8 cph used for conventional

systems.

9—9 cph used for electric heat

systems.

0—No cooling.

1—One stage of cool.

2—Two stages of cool.

3—Three stages of cool.

operational.

1—Auto setting is disabled.

2—Auto only setting.

(continued)

63-4355—211

T7200D ,E, T7300D,E,F AND Q7300 SERIES 2000 PROGRAMMABLE COMMERCIAL THERMOSTATS AND SUBBASES

Table 8. Thermostat Installer Setup Options

(Continued).

Installer

Setup Number

Select

Displaying

temperature

(Press

Unoccupied

Temp key

to change)

Display Description Display Description

Factory Setting

15 0 Temperature is

displayed.

(Press ▲ or ▼ key to change)

1 Temperature is not displayed.

Other Choices

Actual

Setting

(T7300F only).

Clock format. 16 0 12-hour clock format. 1 24-hour clock format.

Intelligent Fan™

operation.

17 2 Fan operates con-

tinuously in Occupied

and recovery modes.

Fan operates with call

for heating or cooling in

Unoccupied mode.

0 or 1 0—Fan only operates with calls for

heating or cooling in Occupied

and Unoccupied modes.

1—Fan operates continuously in

Occupied mode. Fan operates

with calls for heating or cooling

in Unoccupied mode.

Auxiliary contact

operation.

Extended fan

operation in

a

heating

18 0 0—Time of day

contact.

19 0 No extended fan

operation after the call

for heat ends.

0 or 1 1—Economizer contacts. —

1 Fan operation is extended

90 seconds after the call for

heat ends.

(T7300F only).

Extended fan

operation in

cooling (T7300

20 0 No extended fan

operation after the call

for cool ends.

1 Fan operation is extended

90 seconds after the call for

cool ends.

only).

Fan key adjust-

ment (models

21 0 Fan setting key is

operational.

1 Fan setting key is Auto only.

with Fan key).

Remote sensing. 22 0 Remote sensing not

1 Remote sensing activated.

activated.

Temperature

averaging

network

b

(T7300

23 0 Temperature averaging

disabled.

1 Temperature averaging between

local sensor and remote sensor(s)

activated.

only).

Not used. 24 — — — — —

Keypad lockout

level (keypad

lockout is

enabled and

disabled by DIP

switch 1 on

back of

thermostat).

25 0 No lockout. 1 or 2 1—Lockout all keys on thermostat

except system and fan settings,

temporary setpoint, clock and

day adjustments, increase ▲ and

▼ decrease keys.

2— Lockout all keys except Set

Current Day/Time, increase ▲

and decrease ▼ keys.

3—Lockout all keys except

Temporary Occupied and Set

Current Day/Time (for clock, day

adjustment).

Duration of

temporary

override.

26 3 3—Three hour

override.

1, 8 or 12 1—One hour override.

8—Eight hour override.

12—Twelve hour override.

Not used. 27 thru 29 — — — — —

Deadband

(T7300F only).

b

Number 22 must be set to 1 and remote sensor(s) must be installed.

30 2 Heating and cooling

setpoints can be set no

closer than 2°F (1.1°C).

3 thru 10 Heating and cooling setpoints can

be set no closer than the chosen

value.

(continued)

63-4355—2 12

Loading...

Loading...