Page 1

PolyGard is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

PolyGard2 Multi Gas Controller MGC2-K

Controller for Analog Sensors / Honeywell Sensors

User Manual

Version 26.03 2020 en

Page 2

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 2

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

1 Intended Use .......................................................................................................... 4

2 Functional Description ......................................................................................... 4

2.1 General ................................................................................................................................... 4

3 Installation ............................................................................................................. 5

3.1 Mounting Instructions .............................................................................................................. 5

3.2 Installation Work ..................................................................................................................... 5

4 Electrical Connection ........................................................................................... 6

4.1 Wiring ...................................................................................................................................... 6

4.2 Wiring Diagrams ..................................................................................................................... 7

5 Intended Use for the Display Unit ........................................................................ 8

6 Description ............................................................................................................ 8

7 Operation ............................................................................................................... 8

7.1 Function of the Keys and LEDs on the Keypad ...................................................................... 8

7.2 Setting / Changing of Parameters and Set Points .................................................................. 9

7.3 Code Levels ............................................................................................................................ 9

8 Menu Overview .................................................................................................... 10

8.1 Fault Management ................................................................................................................ 12

8.1.1 Error Memory .................................................................................................................... 12

8.1.2 System Messages and System Errors .............................................................................. 12

8.2 Alarm Status ......................................................................................................................... 13

8.3 Relay Status .......................................................................................................................... 13

8.4 Menu Measuring Values ....................................................................................................... 14

8.5 Display Parameters .............................................................................................................. 14

8.5.1 Software Version ............................................................................................................... 14

8.5.2 Language .......................................................................................................................... 15

8.5.3 Service Phone Number ..................................................................................................... 15

8.5.4 Customer Password .......................................................................................................... 15

8.5.5 Error Time Delay ............................................................................................................... 15

8.5.6 LCD Function .................................................................................................................... 16

8.6 Menu Relay Parameters ....................................................................................................... 16

8.6.1 Relay Mode ....................................................................................................................... 16

8.6.2 Relay Operation Mode ...................................................................................................... 16

8.6.3 Relay Function Static / Flashing........................................................................................ 17

8.6.4 Alarm Quantity................................................................................................................... 17

8.6.5 Horn Function .................................................................................................................... 17

8.6.6 External Override .............................................................................................................. 18

8.6.7 Delay Mode of Alarm Relay .............................................................................................. 19

8.6.8 Assignment to Fault .......................................................................................................... 19

8.6.9 Assignment to Maintenance Message .............................................................................. 19

8.7 MP Parameters ..................................................................................................................... 20

8.7.1 Activate – Deactivate MP .................................................................................................. 20

8.7.2 Selection of Gas Type and Measuring Range .................................................................. 20

8.7.3 Alarm Thresholds / Hysteresis .......................................................................................... 23

8.7.4 Delay for Alarm ON and/or OFF........................................................................................ 24

8.7.5 Average Overlay ............................................................................................................... 24

8.7.6 Latching Mode Assigned to Alarm .................................................................................... 24

8.7.7 MP Fault Assigned to Alarm .............................................................................................. 25

Page 3

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 3

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.7.8 Alarm Assigned to Alarm Relay ........................................................................................ 25

8.7.9 MP Assigned to Analog Output ......................................................................................... 25

8.8 Menu System Parameters .................................................................................................... 26

8.8.1 System Information ........................................................................................................... 26

8.8.2 Maintenance Interval ......................................................................................................... 26

8.8.3 Average Function .............................................................................................................. 26

8.8.4 Power On Time ................................................................................................................. 27

8.8.5 Deadband .......................................................................................................................... 27

8.8.6 AO Function ...................................................................................................................... 28

8.8.7 Relay Multiplication ........................................................................................................... 29

8.9 Operating Data...................................................................................................................... 30

8.10 Test Function for Relays ....................................................................................................... 31

8.11 Test Function for Analog Output ........................................................................................... 32

8.12 Calibration ............................................................................................................................. 33

8.12.1 Zero Calibration of Analog Output..................................................................................... 34

8.12.2 Calibration of the Digital Sensors ...................................................................................... 34

8.12.3 Credit Menu ....................................................................................................................... 34

8.13 Setting RS-485 Address ....................................................................................................... 34

9 Commissioning ................................................................................................... 35

9.1 General Notes ....................................................................................................................... 35

9.2 Visual Inspection ................................................................................................................... 35

9.3 Selection Gas Type with Unit ................................................................................................ 35

10 Configuration and Parameter Cards .................................................................. 36

10.1 Configuration Card System Parameters ............................................................................... 36

10.2 Configuration Card Alarm Relays / Signal Outputs .............................................................. 36

10.3 Configuration Card MC2 of Analog Measuring Points .......................................................... 37

11 Routine Maintenance and Scheduled Testing .................................................. 38

11.1 Routine Maintenance ............................................................................................................ 38

11.2 Routine Testing ..................................................................................................................... 38

12 Technical Data MGC2 ......................................................................................... 39

13 EC – Declaration of Conformity ......................................................................... 40

14 Part Disposal ....................................................................................................... 41

15 Notes and General Information .......................................................................... 41

15.1 Installers’ Responsibilities ..................................................................................................... 41

15.2 Disclaimer ............................................................................................................................. 41

15.3 Warranty ............................................................................................................................... 42

15.4 Copyright Notice ................................................................................................................... 42

Page 4

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 4

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

1 Intended Use

The PolyGard2 MGC2 is designed for detection and warning detection of toxic, combustible or dangerous

atmosphere in many commercial and industrial applications.

The intended sites are all areas being directly connected to the public low voltage supply, e.g. residential,

commercial and industrial ranges as well as small enterprises (according to EN50 082).

The PolyGard2 Multi Gas Controller MGC2 must not be used in potentially explosive atmospheres. The

sensor must only be employed in areas within the environmental conditions specified in the Technical Data.

2 Functional Description

2.1 General

The Multi-Gas-Controller is designed for the connection of max. three analog sensors with 4-20 mA signal and

eight Honeywell sensors.

The controller monitors the measured values and activates the alarm relays if the set local alarm thresholds for

pre-alarm and main alert have been exceeded or if there are the alarm messages coming from the eight digital

sensors via RS-485 communication.

The SIL 2 compliant self-monitoring function in the MGC2 activates the fault message in case of an internal

error as well as in case of a fault at the 4-20 mA input / output current signals or if there is a communication

error to the digital sensors.

Other options such as three-color status LED, warning buzzer, digital input for acknowledgment or test function

ensure proper adaptation to the wide range of applications in gas detection technology.

Page 5

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 5

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

3 Installation

Electronics can be destroyed by electrostatic discharge (ESD). Therefore, the installation work

should be done only by persons connected to ground, e. g. with a wrist strap connected to ground

or by standing on a conductive floor (acc. to DIN EN 100015).

3.1 Mounting Instructions

When choosing the mounting site please pay attention to the following:

• Choose mounting location of the sensor according to the local regulations.

• Mount the sensor at a location with minimum vibration and minimum variation in temperature (avoid

direct sunlight).

• Avoid locations where water, oil etc. may influence proper operation and where mechanical damage

might be possible.

• Provide adequate space around the sensor for maintenance and calibration work.

• Observe possible local instructions.

3.2 Installation Work

Assembly work must only be carried out under gas-free conditions.

Do not drill holes in the housing. Use only the providing know-outs.

• Open housing cover.

• Break out the required pre-embossed knockouts on the housing for cable glands and Sensor

Cartridge.

• Cables are introduced from above.

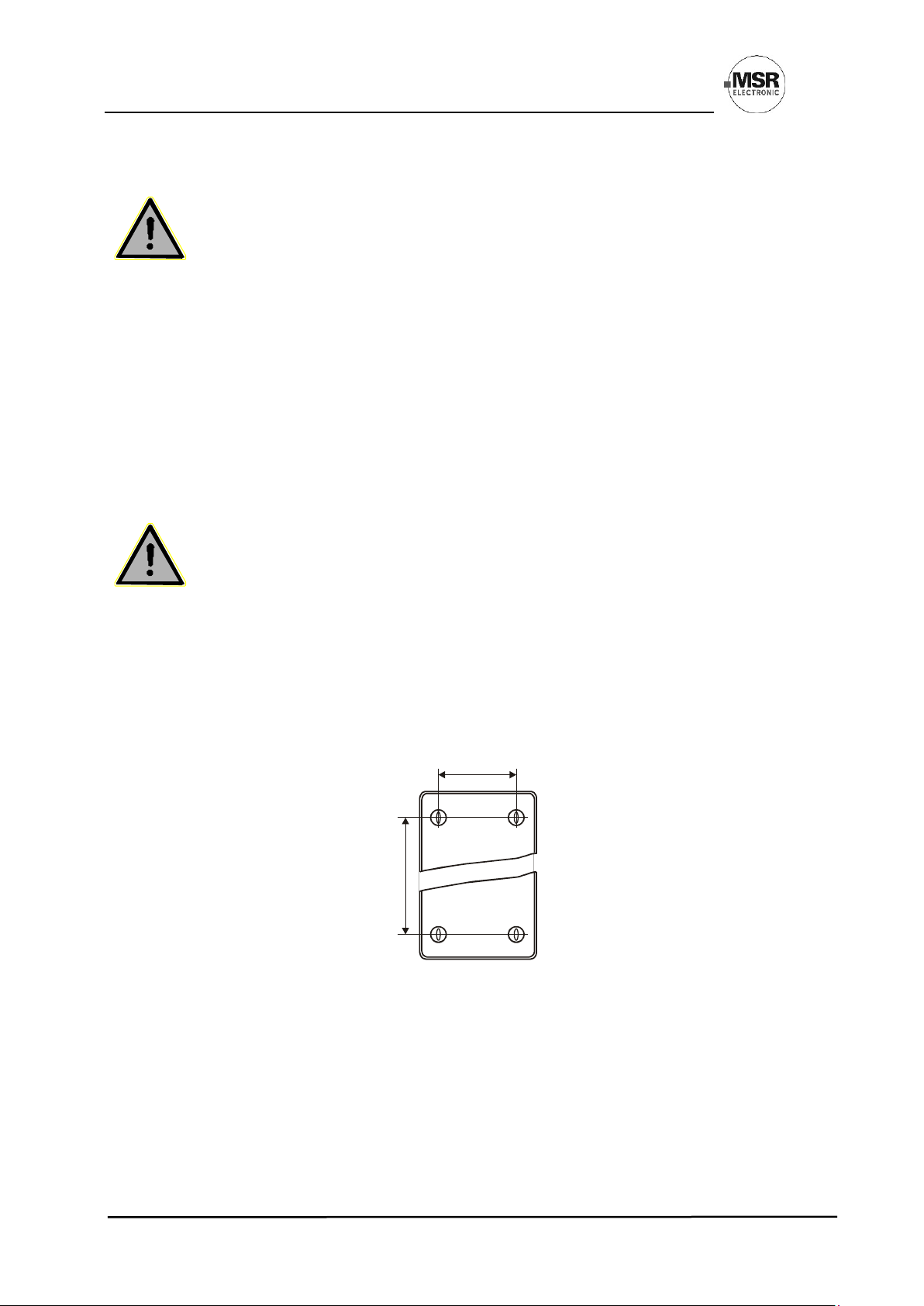

• The MGC2 Controller is fixed to the wall through the four marked mounting points at the back side of

the housing. These mounting points are accessible after opening the housing. See figure below.

• The dimensions XX depend on the type and can be read on the back of the housing, it is115 mm.

• The mounting points are covered by closing the cover at the end of the assembly.

• Close the cover.

Installation of Controller:

XX

XX

Page 6

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 6

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

4 Electrical Connection

Assembly work must only be carried out under gas-free conditions!

Consider static electricity instructions (ESD)!

4.1 Wiring

• The technical requirements and regulations for wiring, electrical safety, as well as project specific and

environmental and local conditions etc. must be observed when mounting.

• We recommend the following cable types1:

Europe USA / Canada

Power supply 230 V NYM-J 3 x 1.5 mm

2

14 AWG / 300 V

Alarm message 230 V (also possible together with power supply) NYM-J X x 1.5 mm

2

14 AWG / 300 V

Signal message, bus connection, warning devices 24 V J-Y(St)Y 2x2 x 0.8 mm2 min. 300 V

Possibly connected external analog transmitters J-Y(St)Y 2x2 x 0.8 mm

2

min. 300 V

1

The recommendation does not consider local conditions such as fire protection etc.

• Use copper conductors only for the terminal is only for connection to copper wire.

• Avoid any influence of external interferences by using shielded cables for the bus line, but do not

connect the shield.

• Remove the cable isolation as short as possible. It is important to ensure that bare wires, e.g. wire

shields do not come into contact with the mounted PCB (risk of short-circuit).

• Low voltage wire and mains connected wire must be fixed separately by cable ties or similar, to secure

against looseness.

• Analog sensors are connected directly to the spring type terminals of the module. The correct polarity

must be observed.

• The alarm signals are available as voltage-free change-over contacts. If required, the voltage supply is

available at the terminal L.

The exact position of the terminals for the sensors and alarm relays is shown in the connection diagrams.

Page 7

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 7

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

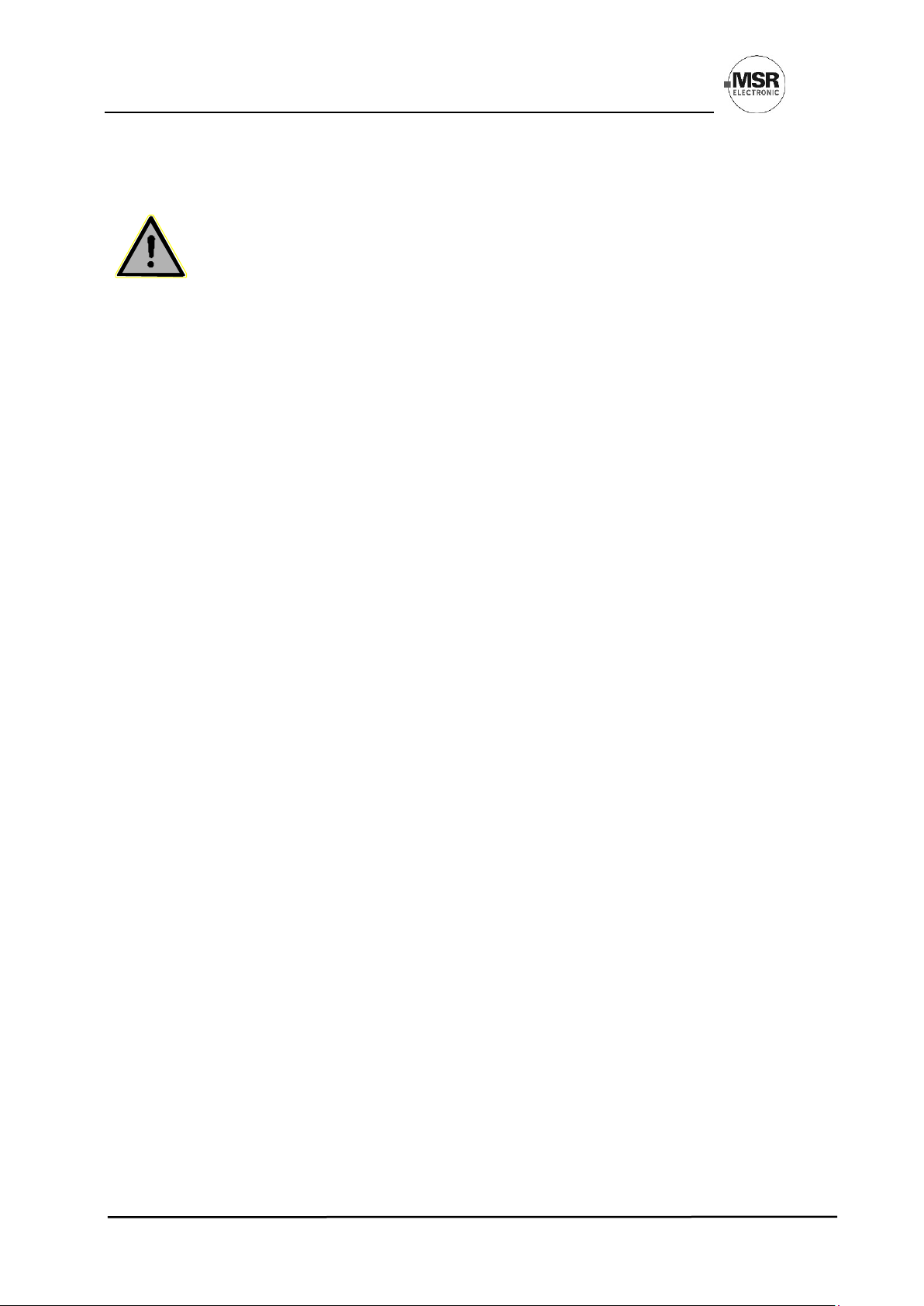

4.2 Wiring Diagrams

Wiring Diagram Example

+24 V

GND

NC

X2 X3 X41 1 12 2 23 3 3

Multi Gas Controller MGC2 24 VDC

Bus_A

Bus_B

4 - 20 mA

GND

Field Bus Analog

Input

Digital

Output

1 13 32 24 4 5 6 7

X12

X13

BUS_A

24 VDC

AI_01

AI_02

AI_03

GND

Beacon

Horn

AO_01

BUS_B

GND

Analog

Output

24 VDC

24 VDC

24 VDC

GND

GND

GND

4-20mA

4-20mA

4-20mA

1 1 12 2 23 3 3

X1 23 1

Power Supply

24 VDC

Relay

Alarm 1

Relay

Alarm 2

Relay

Fault

Relay Voltage

Max. 230

Relay drawn de-energized

Relays Mode = Energized (Alarm ON = Relay OFF)

Digital

Input

DI_1

DI_2

1 2 3

Digital

Input

GND

X11

Page 8

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 8

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

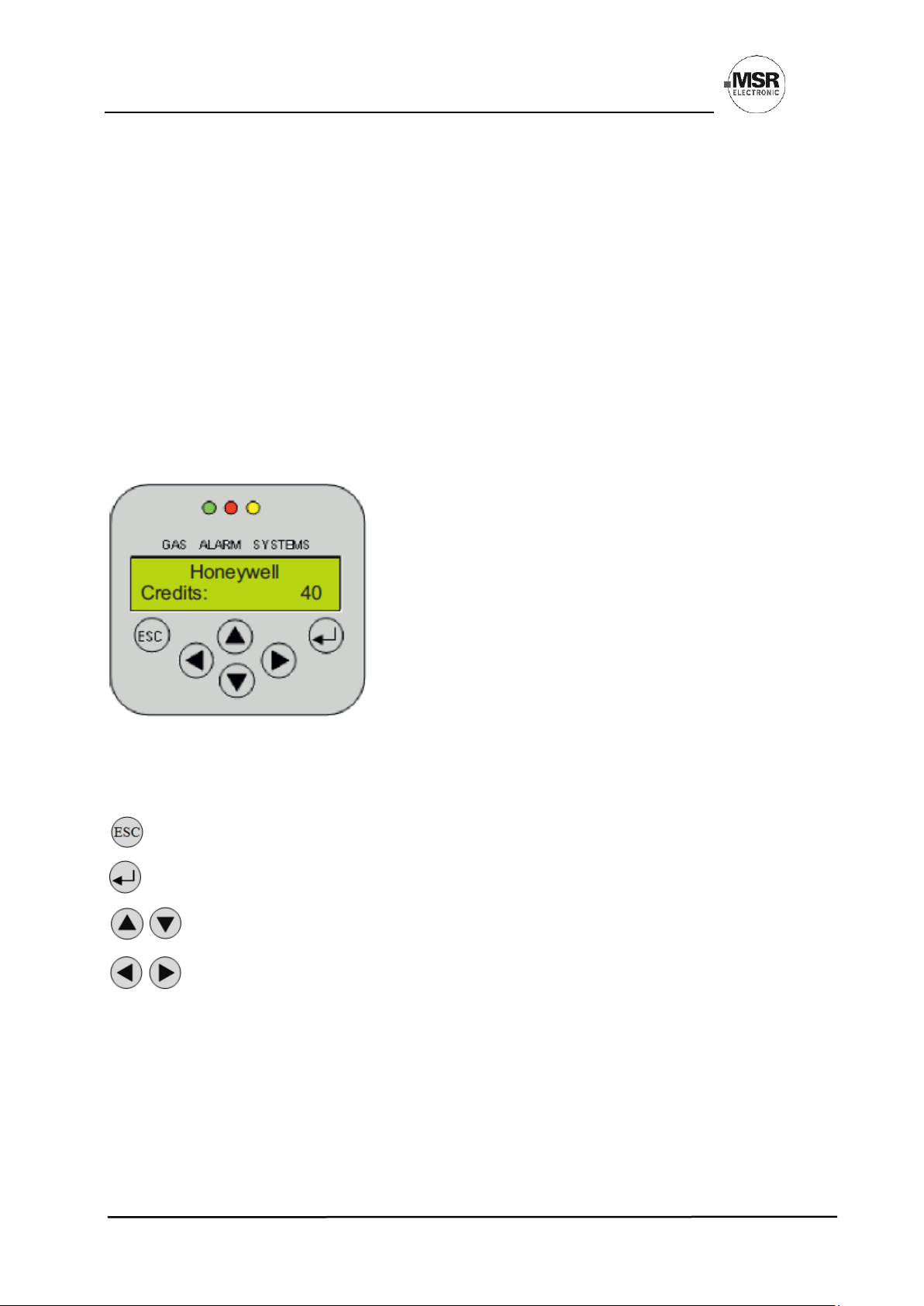

Display Unit for Series MGC2-K

5 Intended Use for the Display Unit

The display is used as visual indication, operating, commissioning and calibration unit for gas detecting and

measuring instruments of the series PolyGard®2 (PG2).

6 Description

The parameters, gas types, units, etc. specified in the description are only examples.

7 Operation

The complete configuration and service are made via operating keys in combination with the LCD display

screen. Security is provided via four password levels against unauthorized intervention

Version for PG2 series

Operation via 6 buttons

7.1 Function of the Keys and LEDs on the Keypad

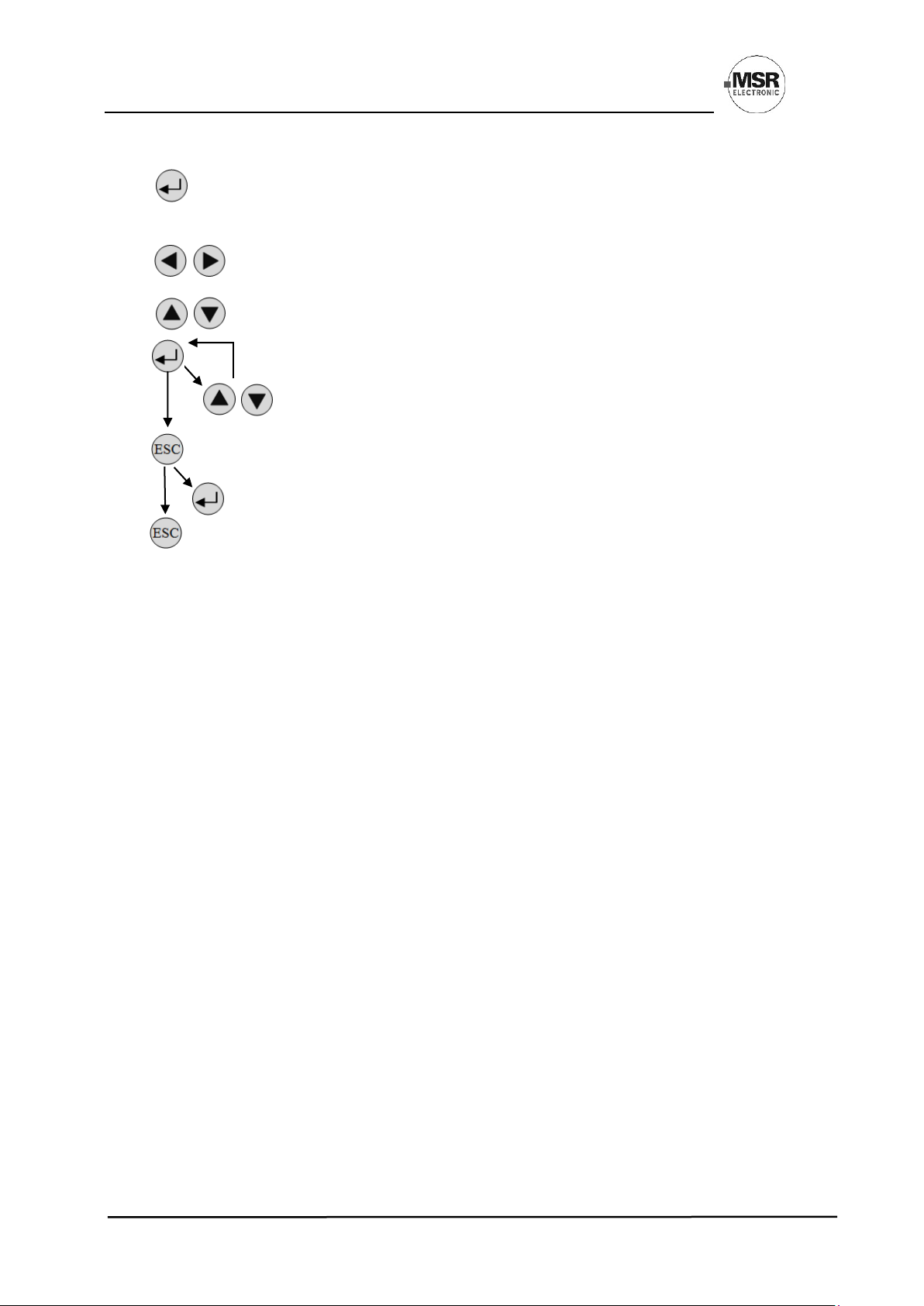

Exits programming, returns to the previous menu level.

Enters sub menus, saves parameter settings.

Scrolls up & down within a menu, changes a value.

Changes cursor position.

The status LEDs indicate the operating state.

Green: Continuous: = Normal operation

Flashing: = Maintenance message

Yellow: Continuous: = Failure

Slowly flashing: = Warming-up

Fast flashing: = Special mode

Red: =Alarm

The backlight of the display changes from green to red when an alarm is active.

Page 9

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 9

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

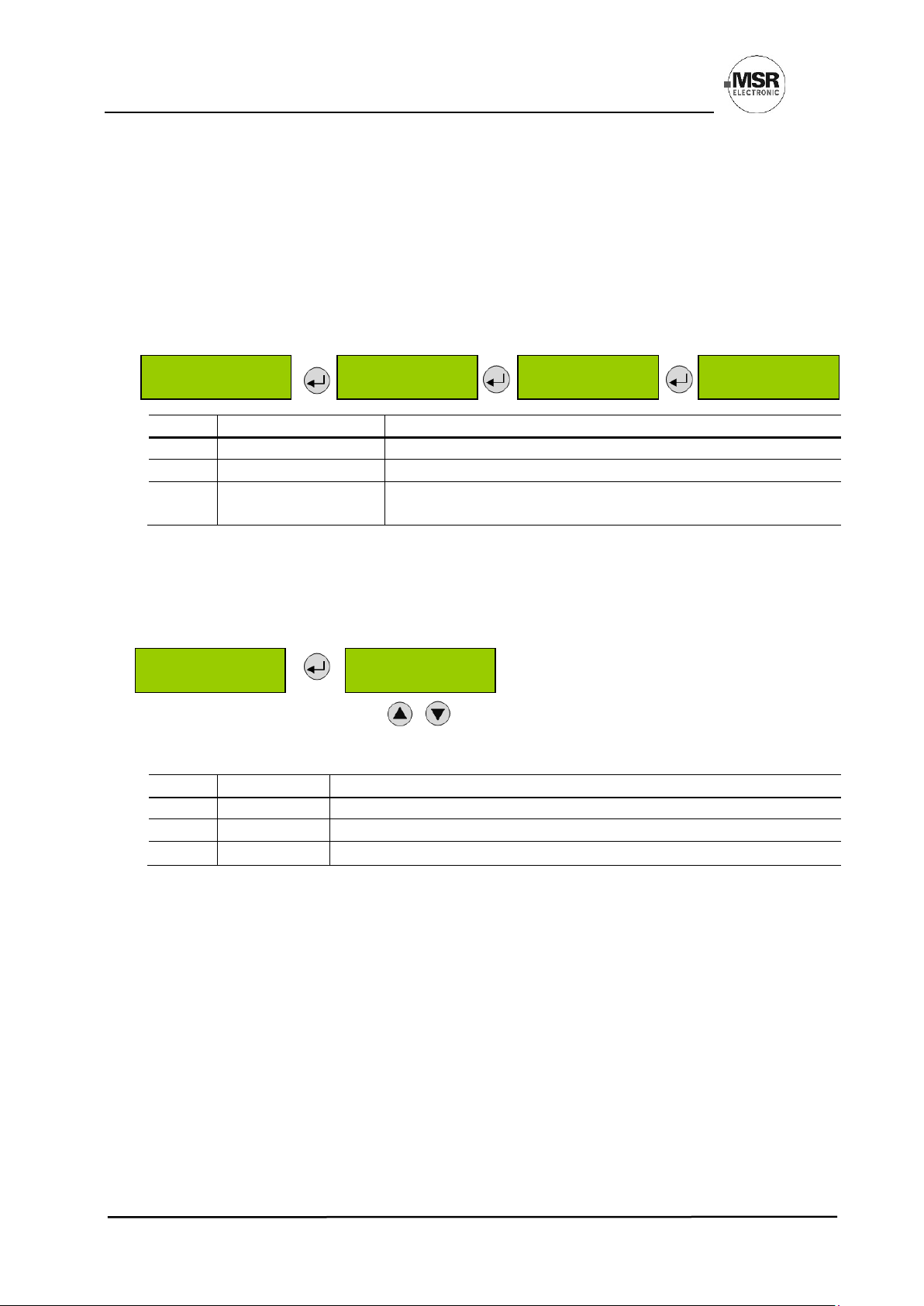

7.2 Setting / Changing of Parameters and Set Points

Open desired menu window.

Code input field opens automatically, if required.

After input of valid code, the cursor jumps onto the first position segment to be changed.

Push the cursor onto the position segment, which has to be changed.

Set the desired parameter / set point with the keys.

Input of value finished.

Change further parameters in the same menu.

Save the changed value?

YES, and back to higher menu level.

NO, (previous value isn’t overwritten) and back to higher menu level.

7.3 Code Levels

All inputs and changes are protected by a four-digit numeric code (= password) against unauthorized

intervention according to the regulations of all national and international standards for gas warning systems.

The menu windows of status messages and measuring values are visible without entering a code.

The access to a code level is cancelled if no button is pushed within 15 minutes or if there is no data

communication between display and basic board.

The code levels are classified in order of priority: Priority 1 has top priority.

Priority 1: (code not changeable)

Code level priority 1 is intended for the service technician of the installer to change parameters and set-points.

This password allows working on all settings. For opening the parameter menus, you must first activate the

service mode after code release.

Priority 2: (code not changeable)

This functionality isn’t available.

Priority 3: (customer password is settable)

Customer password is inactive in delivery state and is activated by entering a value. Same behaviour as priority

1 password, only changing the customer password is not possible.

Normally the code is only known by the service technician who has last changed it since it can be changed

individually via priority 1.

Priority 4: (password 1234) (code not changeable)

Code level priority 4 allows the operator after activation of the operation mode “Service Mode” to read all

parameters as well as all test functions of the alarm relays, analog outputs and LCD.

- Manual test function of the alarm relays (functional test of the connected actuators),

- Manual test function of the analog outputs (functional test of the connected actuators),

- Manual test function of the LCD (functional test of the LCD display and the LEDs).

Page 10

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 10

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

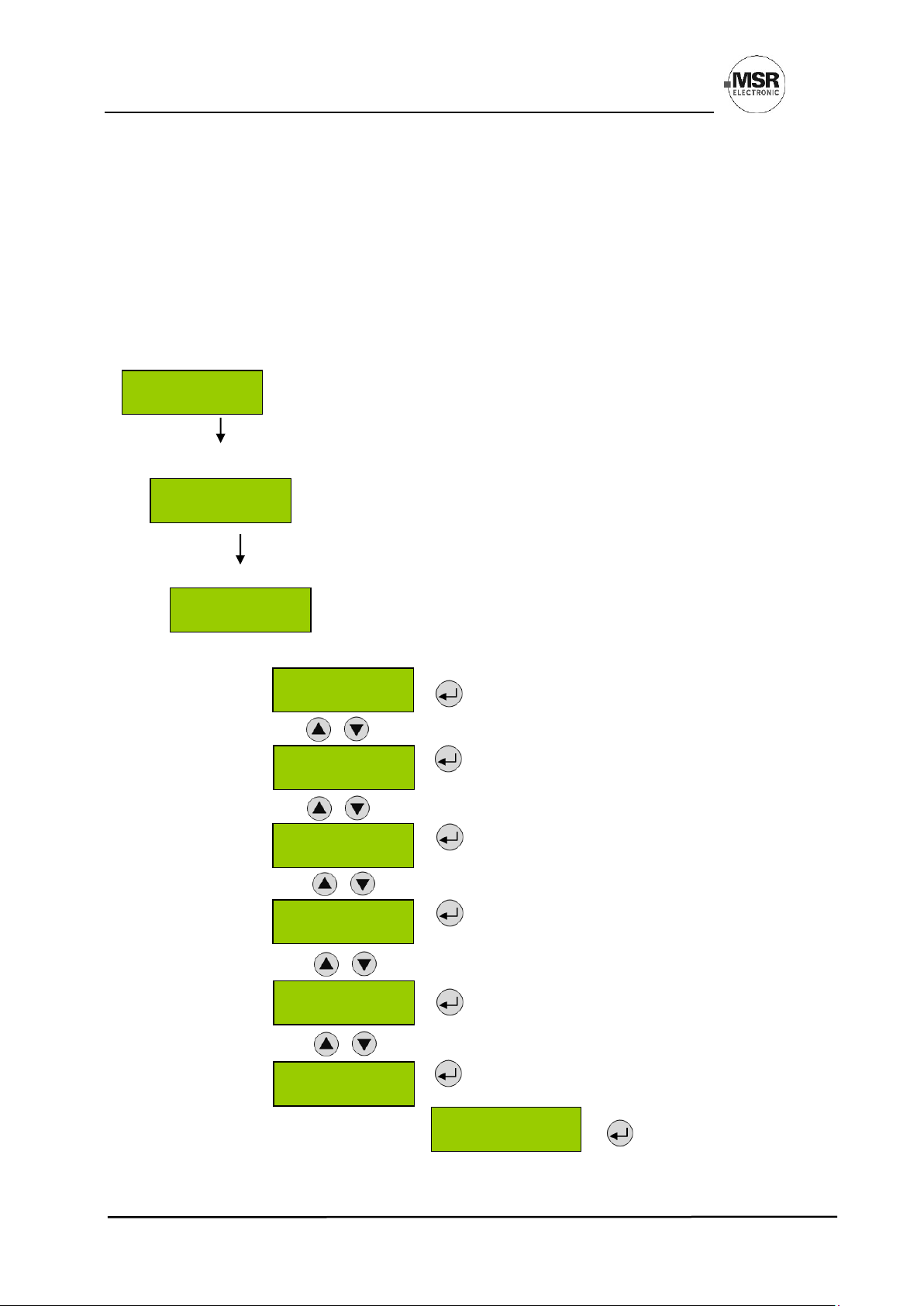

8 Menu Overview

Menu operation is done via a clear, intuitive and logical menu structure. The operating menu contains the

following levels:

• Starting menu with indication of the device type if no MP (Measuring Point) is registered. Otherwise

scrolling display of the gas concentrations of all registered sensors in 5-second intervals. If alarms are

active, only the values of the sensors currently in alarm status will be displayed.

• Main menu

• Submenu 1 to 3

Power On Time of the basic device

Second counter counts down, when communication between display <> basic

device is OK. In case of communication error, the count-down will stop.

Seconds indicator = 0

MGC2-K = Multi Gas Controller Kompakt

After about 5 seconds

“Warn-up Time” is displayed. As soon as the sensor warm-up period has

expired, the measured value is displayed = measuring mode.

Starting menu Main menu Submenu 1

Reading and acknowledgement of errors

See from point 8.1

Display of the alarm status of active alarms

See from point 8.2

Display of the relay status

See from point 8.3

Display of measuring values

See from point 8.4

General display parameters without safety relations

See from point 8.5

Reading and change of the relay, measuring point

and system parameters as well as test and calibration

functions

D1 CH4 % LEL

Warm-up Time

System Errors

Alarm Status

Relay

Status

Measuring Values

Display

Parameter

Power On Time

19s

Honeywell

MGC2-K

Installation &

Calibration

Service Mode

OFF

Page 11

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 11

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

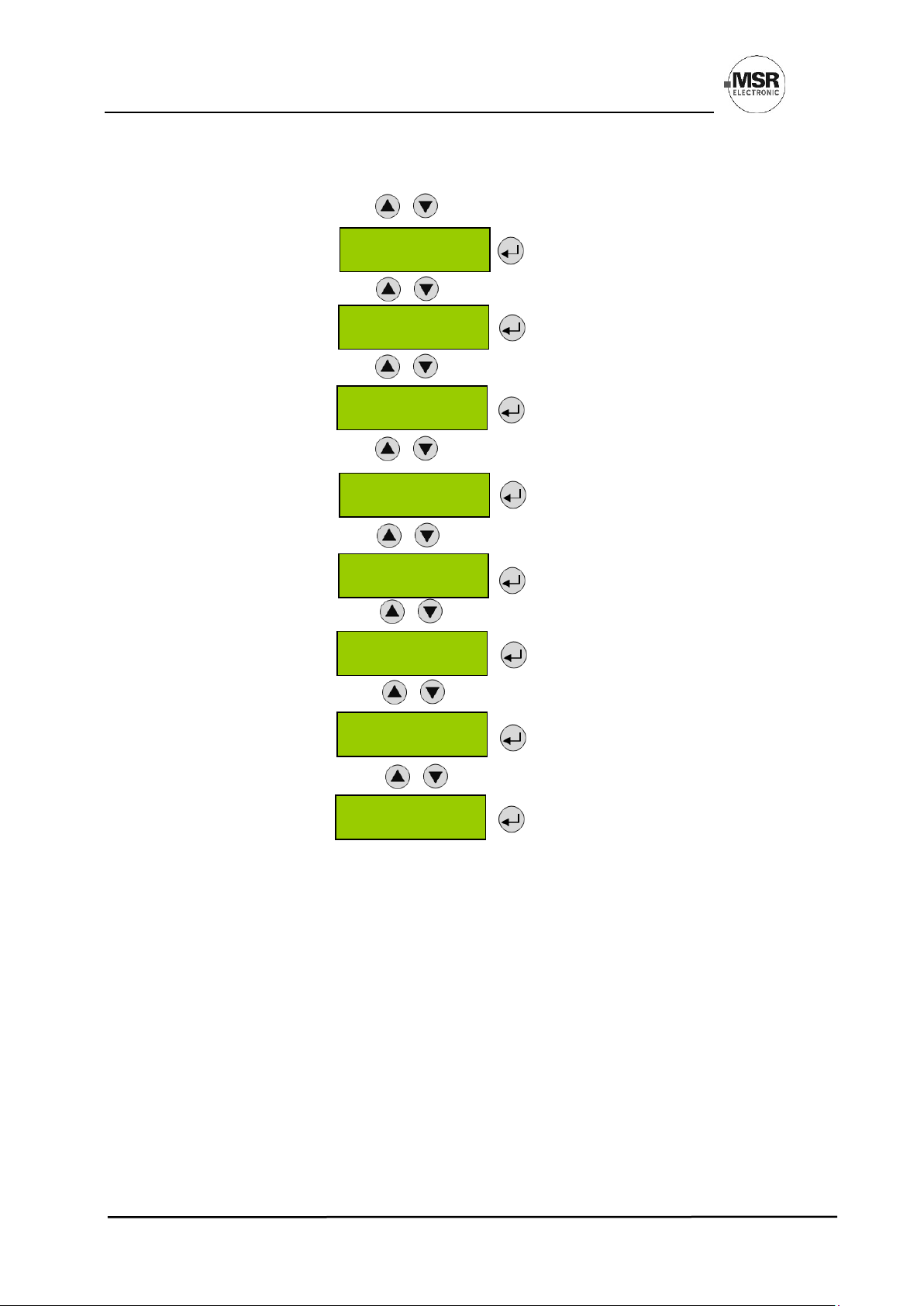

The following menu items are only accessible in Service ON mode (password protected)

!! Service ON = Special mode = Fault message is active!!

See from point 8.6

See from point 8.7

See from point 8.8

See from point 8.9

See from point 8.10

See from point 8.11

See from point 8.12

See from point 8.13

Relay Parameter

MP Parameter

System Parameter

Operating Data

Addressing

Calibration

Relay

Test Function

Analog Outputs

Test Function

Page 12

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 12

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

MP 1 Comm.Error

1 1T 2h 6‘

8.1 Fault Management

A pending fault activates the yellow LED (Fault).

The integrated fault management records the first 50 occurred faults with time

stamps in the menu “System Errors”. The timestamp shows the days, hours and

minutes that have elapsed since the fault has occurred.

Additionally, a record of the faults occurs in the “Error memory”, which can only be read and deleted by the

service technician (code level 1 (3)).

8.1.1 Error Memory

The menu “Error Memory” in the main menu “System Errors” can only be opened via the code level priority 1.

In the error memory, the first 50 faults that have occurred and have already been acknowledged in the menu

“Error Status” are listed for the service technician in a power failure safe way.

Attention:

This memory should always be read during maintenance, relevant faults should be tracked and entered

in the service logbook, and finally the memory should be emptied.

8.1.2 System Messages and System Errors

The warning device includes a diagnostic module for the continuous monitoring of the relevant functions and

parameters as well as a processor-independent watchdog. These features set the device into the safe mode

"Fault" in case of an internal or external error. The following table shows all possible errors, possible causes,

the related troubleshooting and the resulting device status.

Once the cause has been eliminated, the warning device restarts with the diagnostic mode on its own. It isn’t

necessary to acknowledge the error message. In the event of an error, the error is output as plain text in the

version with display instead of the measured value and in the Error status menu. In case of two or more errors,

the value is output with a cumulative, bit-coded error code.

Error Type

Cause

Remedy

Fault

Relay

Analog

Output

Centr.

Bus

Display

Error Code

Text Mess.

Error messages from MGC2

DP1-

Sensor element defective

Replace

sensor

Error

< 2 mA

Error

code is

sent

0x8 001 h

Sensor

Temperature < -25 °C > +60 °C

Ambient temp.

Temp.!

Error

< 2 mA

Error

code is

sent

0x8 002 h

Overtemp.

Internal

Replace device

Measured value processing

0x8 002 h

ADC error

RAM / ROM / µC error

0x8 008 h

CPU error

EEPROM error

0x8 010 h

EE error

No response alarm relay

0x8 020 h

I/O error

Deviation of analog output signal

< 5 % >

Short-circuit or

Interruption at the

analog output

Check wiring /

load

Error

X mA

0x8 020 h

I/O error

Internal

Replace device

Communication error to sensor

Sensor head not

fitted correctly

Check

Error

< 2 mA

0x9 000 h

Comm. error

Internal

Replace

Sensor

Hardware Watch Dog triggered

Internal, < system

voltage, µC defect.

Replace device

Error

< 1 mA

Comm.

STOP

Reset

Reset

Operating voltage limits exceeded

too high / too low

External

Check voltage

Error

< 2 mA

Comm.

STOP

0x8 008 h

Tension

Internal

Replace device

Maintenance due

Maintenance date

reached

Perform

maintenance

No effect

0x8 080 h*

Maintenance

Page 13

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 13

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

AP 1

’’A1

AP 1

Reset?

Check if no

Gas present?

8.2 Alarm Status

Display of the currently pending alarms in plain text in the order of their arrival. Only those measuring points

are displayed, where at least one alarm is active.

Alarms in latching mode and the overrange message can be acknowledged in this menu (only possible if the

alarm isn’t active any more).

Alarm 1 and Alarm 2 are evaluated both by the sensor (alarm bit transmitted by communication) and by the

locally set thresholds.

Symbol

Description

Function

AP 1

Measuring Point No.

Analog measuring point 1 = 1 - 3, where an alarm is pending

DP 4

Measuring Point No.

Digital measuring point 4 = 4 - 11, where an alarm is pending

‘A1

‘‘A1

Alarm status

‘A1 = Alarm 1 active

‘‘A1 = Alarm 1 in latching mode, can be acknowledged

8.3 Relay Status

Reading of the current status of alarm relays.

The actual relay status is displayed, depending on the relay mode (energized <> de-energized).

Selection of the alarm relay 1 – 5

Selection of the next alarm relay

Symbol

Description

Function

1

Alarm Relay

Alarm relay = 1 - 5

OFF

Relay Status

Deenergized

ON

Relay Status

Energized

Alarm Status

Relay

Status

Relay 1

Status OFF

Page 14

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 14

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

Measuring Values

D 4 CH4 % LEL

A ! 51.0 I

8.4 Menu Measuring Values

In this menu, the display shows the measuring value with gas type and unit. If the alarm evaluation is defined

via the average, the display additionally shows the average value (A) to the left of the current value (C).

Selection of the next measuring point

Symbol

Description

Function

A 11

Meas. Point No.

Analog measuring point 1 to 3

D 41

Meas. Point No.

Digital measuring point 4 to 11

CH4

Gas type

Display of gas type (must comply with gas type of sensor head)

% LEL

Gas unit

Unit (depending on gas type)

51,0 C

48,0 A

Measured value

C = Current measured value (current value) of the gas concentration

A = Arithmetic average of the gas concentr. (only if average is active)

A!

Alarm indication

At least one alarm has been released at this MP.

#

Maint. info

Sensor head: maintenance due (maintenance date exceeded)

Comm. err.

Fault MP

Communication error, sensor head <> I/O board

Underrange

Meas. range

monitoring

Meas. signal < admissible range (< zero point – 6 %)

Overrange2

Meas. signal > admissible range (> full scale value + 6 %)

Run-in

Run-in time

Warm-up of the sensor active

1

Display of the address number the measuring range is registered under in the Modbus

2

Acknowledgement in the menu Alarm Status

8.5 Display Parameters

In the menu Display Parameters, you can find the general, non-safety related parameters of the display. These

parameters can be changed in operating mode.

8.5.1 Software Version

Software version of the display and of the basic board

Symbol

Description

Function

XXXXX

YYYYY

Software Version of the displays

Software Version of the basic board

XXXXX Software Version

YYYYY Software Version

Software Version

XXXXX - YYYYY

Display

Parameters

Page 15

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 15

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

Change Customer

Password ****

8.5.2 Language

Selection of the menu language (only code level 1 and 3)

Symbol

Description

Default

Function

English

Language

German

German

English

USA English

French

Italian

8.5.3 Service Phone Number

The service phone no. can be individually defined.

Symbol

Description

Default

Function

00800…

Phone No.

Definition of the individual service phone no.

8.5.4 Customer Password

Storage of an individual customer password on the display for changing the parameters. See 7.3 Code level

Priority 3. Changing the password only via access of the code level 1.

8.5.5 Error Time Delay

Symbol

Description

Default

Function

s

Delay

120s

Definition of a delay time after a communication error Display

<> Basic Board has occurred (only fault indication on the

display, no effect on the function or outputs)

Service TEL:

0080081819691

Error Delay

0s

Language

English

Page 16

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 16

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.5.6 LCD Function

Testing the LCD hardware. Back-light is active for about 2 secs. The backlight is yellow. (Green and red are

activated at the same time). All segments are active on LCD.

The following area is only accessible if the service is set to "ON".

• With code priority 4 for reading the parameters

• With code priority 1 or 3 for changing the parameters.

8.6 Menu Relay Parameters

Reading and changing of the parameters separately for each alarm relay.

8.6.1 Relay Mode

Selection of alarm relay 1 - 5

The fault relay is listed as relay 3 and can be registered here as an

additional alarm relay. This registration has no influence on the

function as fault relay.

The relay switches off in addition when the assigned alarm is

active.

Symbol

Description

Default

Function

Used

Mode

Used

Used

Not Used

= Relay is registered and can be assigned to

an alarm

= Relay isn’t registered

8.6.2 Relay Operation Mode

Relay 3:

The parameter setting “Energized” cannot be changed.

The terms energized / de-energized come from the terms “energized / de-energized to trip” principle used for

safety circuits. The terms refer to the activation of the relay coil, not to the relay contacts (as they are executed

as changeover contacts and available in both principles).

The LEDs at the modules show the state in analogy. (LED off -> relay coil current-free)

Symbol

Description

Default

Function

Deenerg.

Mode

Deenerg.

De-energ.

Energ.

= Alarm OFF= Relay (and LED) current-free

Alarm ON = Relay (and LED) energized

= Alarm OFF = Relay (and LED) permanently energized

Alarm ON = Relay (and LED) current-free

Relay Mode

Used

Relay Parameters

Relay 1

Used

Operation Mode

Energized

LCD Function

check?

Installation &

Calibration

Service

OFF

Page 17

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 17

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.6.3 Relay Function Static / Flashing

Relay 3:

The parameter setting “No” (cannot be changed).

The function "Flashing" offers a connection option for warning devices to improve visibility. The frequency is

about 1 second with an impulse / pause rate of 1:1.

If “Flashing” is set, the output circuit mustn’t be used as a safe output any more.

The combination of relay mode energized with flashing operation makes no sense and is therefore suppressed.

Symbol

Description

Default

Function

No

Function

No

Yes

No

= Relay function flashing in case of alarm

= Relay function static in case of alarm

8.6.4 Alarm Quantity

In some applications it is necessary that the relay switches only at the nth alarm. Here you can set the number

of active alarms necessary for relay tripping. For safety related applications, the relay must always switch on

the first alarm.

Symbol

Description

Default

Function

1

No. of Alarms

1

1 = Number of pending alarms for triggering the alarm relay

8.6.5 Horn Function

Relay 3:

The parameter setting cannot be changed.

The horn function of the alarm relay is activated if at least one of the two parameters (time or assignment to

digital input) is set. The horn function retains its functionality even for alarms in latching mode.

This feature is not allowed for safety-related alarm messages because the output is resettable.

Symbol

Description

Default

Function

Recurrence

Mode

No

No = Automatic reset of the relay after time has expired.

Yes = Recurrence function

Time

0

Enter time for automatic reset function or recurrence function in s

0 = No reset function

DI 0

0 – 2 = Assignment, which digital input resets the relay

Horn function resettable:

The activated horn can be reset with this function.

The following possibilities to acknowledge are available for the alarm relay as horn relay:

• By pressing the left button (ESC). Only available in starting menu.

• Automatic reset at the end of the preset time (active, if value > 0).

• By an external pushbutton (assignment of the appropriate digital input DI 1-n).

Due to fixed polling cycles, external buttons must be pressed for a few seconds before the reaction occurs.

Flashing

No

Time- Recurr.- DI

0s No 0

Alarm Quantity

1

Page 18

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 18

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

After successful acknowledgment the horn remains permanently reset until all assigned alarms for this relay

function are inactive again. Only then it is triggered anew in case of an alarm.

Acknowledge the horn relay

Alarm 4

Relay 4

Gas concentration higher lower than threshold

Acknowledging

signal

On

Of

On

Off

On

Off

Time

Reset command by timer, external push-button or one of the operating keys.

Recurrence of the horn relay

After an alarm has been triggered, the horn will remain active until a reset action is done. After

acknowledgment of the horn relay (via a button or externally via digital input) a timer starts. When this time has

run out and the alarm is still acting, the relay is set again. This process is repeated endlessly as long as the

associated alarm remains active.

Alarm 4

Relay 4

Gas concentration higher lower than threshold

Acknowledging-

signal

On

Off

On

Off

On

Off

Time Time

Reset command by external push-button or one of the operating keys.

8.6.6 External Override

Relay 3:

The parameter setting cannot be changed.

Symbol

Description

Default

Function

DI 0

External ON

0

As long as DI 1-X is closed, relay switches ON

DI 0

External OFF

0

As long as DI 1- X is closed, relay switches OFF.

Manual operation of the alarm relays via DI does not start the "special mode", as this is a deliberate and

configured functionality. The use of the override should be used with caution, particularly the function "External

OFF".

Assignment of a digital input (DI) for the external alarm relay switching on/off.

This function has priority to gas alarm.

If External ON and External OFF are configured to the same relay and both are active at the same time, so in

this state, the External OFF command has priority. In this mode, too, the relay works respecting the parameter

settings "Static / Flashing" and "Energized / De-energized".

External function

DI 0 DI 0

Page 19

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 19

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.6.7 Delay Mode of Alarm Relay

.

Relay 3:

The parameter setting cannot be changed.

Definition of the time for switch-on and switch-off delay of the alarm relays.

Symbol

Description

Default

Function

0 sec.

Switch-ON

Delay Time

0

≥ 1: Alarm relay is only activated at the end of the defined time.

0 = No delay

0 sec.

Switch-OFF

Delay Time

0

≥ 1: Alarm relay is only deactivated at the end of the defined time.

0 = No delay

8.6.8 Assignment to Fault

Relay 3:

The parameter setting cannot be changed.

In case of a device fault the alarm, relay is triggered in addition.

This relay output must not be used as a safe error output.

Symbol

Description

Default

Function

No

No assignment

No

Alarm relay is not activated in case of a device fault.

Yes

Assignment to

fault

Yes

Alarm relay is activated in case of a device fault.

8.6.9 Assignment to Maintenance Message

In case of a pending maintenance, the alarm relay is triggered in addition.

Symbol

Description

Default

Function

No

No assignment

No

Alarm relay is not activated in case of a maintenance message.

Yes

Assignment to

maintenance

Yes

Alarm relay is activated in case of a maintenance message.

On Delay Time

0 s

Off Delay Time

0 s

Maintenance→ Active

No

Fault→ Active

No

Page 20

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 20

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.7 MP Parameters

This menu allows the parameters for each sensor (MP) to be reviewed or changed. A code level 1 password is

required.

Selection of measuring point (1 – X)

8.7.1 Activate – Deactivate MP

Every sensor needs to be active at the controller. After activation sensor signal will be displayed at the

controller. Existing alarms and faults are cleared with deactivation of the sensor.

Analog input signals are reserved for MP1 to MP3. Up to eight further Honeywell bus sensors can be

connected, here the address assignment starts with 4 and ends with 11.

Attention: The deactivated sensor does not cause a fault message.

Symbol

Description

Default

Function

active

n. active

MP Mode

not active

active = Measuring point activated in the controller.

not active = Measuring point not activated in the controller.

8.7.2 Selection of Gas Type and Measuring Range

Menu only displayed if a Freon group is selected as the gas

type. In the second line then the actual Freon name is

entered. These Freons are listed in the following table under

the Freon groups in the column FORMULA

Symbol

Description

Default

Function

CH4

Formula of

Gas Type

----

Formula (gas type)

%LEL

Unit of Gas

Type

----

Unit

100

Measuring

Range

----

Set measuring range (must correspond with the sensor head).

The gas type to be monitored and the range are set in the two menus.

Ensure the controller setting is meeting the sensor setting.

Select the gas type; then the associated unit will appear on the right next to it.

The indication of measured values, alarm thresholds and hysteresis depends on the measuring range. If the

measuring range is <10, there are three, if <100, there are two, if <1000, there is one decimal place. If => 1000,

the display is without decimal place. The resolution and accuracy of the calculation is not affected by the

different measuring ranges.

Please refer to the Honeywell sensor datasheets and sensor settings for the correct range. Please refer also

the Honeywell Sensepoint XCL and Sensepoint XRL datasheet.

MP Parameter

MP 1

active

MP Mode

active

Gas/Unit

CH4 % LEL

Measuring Range

100 % LEL

FRXX Mixture Type

RYYYYY

Page 21

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 21

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

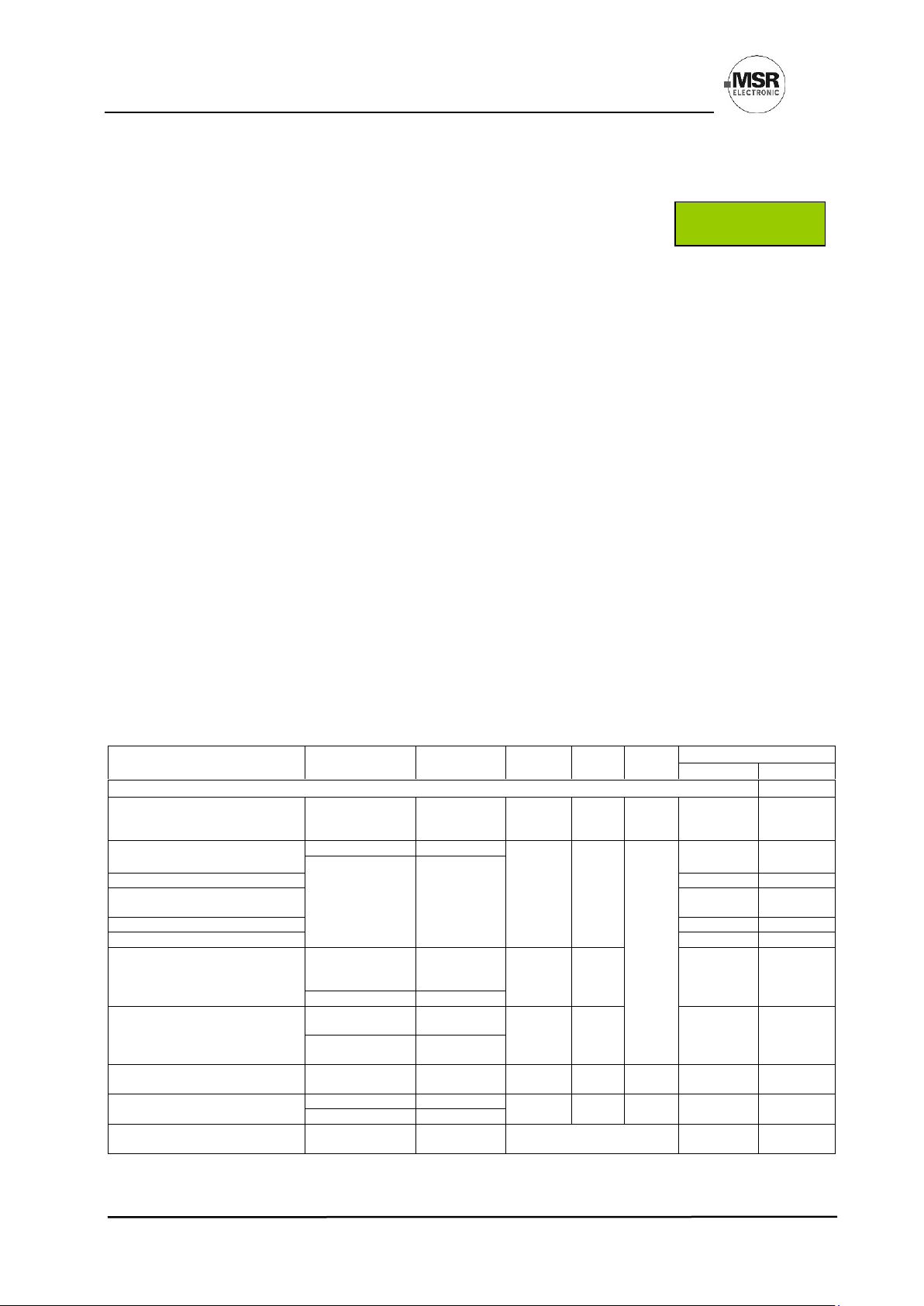

Table for example. The measuring range is configurable for each Gas Type (from 1 to 20000).

Gas Type

Formula

Meas. Range1

Unit

Carbon monoxide

CO

0-300

ppm

Nitrogen dioxide

NO2

0-30

ppm

Nitrogen monoxide

NO

0-100

ppm

Oxygen

O2

0-25

% Vol

Ammonia

NH3

0-300

ppm

Carbon dioxide

CO2

0-2000

ppm

Carbon dioxide

CO2

0-5

% Vol

Methane

CH4

0-100

% LEL

IR-Methane

CH4

0-100

% Vol

Propane

C3H8

0-100

% LEL

IR-Propane

C3H8

0-100

% Vol

Hydrogen

H2

0-100

% LEL

Ammonia

NH3

0-100

% LEL

Acetone

(CH3)2CO

0-100

% LEL

Benzene

C6H6

0-100

% LEL

Ethyl alcohol

C2H6O

0-100

% LEL

Ethyl acetate

CH3COOC2H5

0-100

% LEL

Ethylene

C2H4

0-100

% LEL

n-Butane

C4H10

0-100

% LEL

n-Heptane

C7H16

0-100

% LEL

n-Hexane

C6H14

0-100

% LEL

Isopropyl alcohol

(CH3)2CHOH

0-100

% LEL

JP8

JP8

0-100

% LEL

Methanol

CH3OH

0-100

% LEL

Methyl ethyl ketone MEK

C4H8O

0-100

% LEL

n-Octane

C8H18

0-100

% LEL

n-Pentane

C5H12

0-100

% LEL

Toluene

C7H8

0-100

% LEL

Butyl acetate

C6H12O2

0-100

% LEL

Cyclohexane

C6H12

0-100

% LEL

Cyclopentane

C5H10

0-100

% LEL

Ethane

C2H6

0-100

% LEL

Isobutanol / Isobutyl alcohol

C2H6 O2

0-100

% LEL

Methyl acetate

C3H6O2

0-100

% LEL

Nonane

C9H20

0-100

% LEL

LPG

LPG

0-100

% LEL

Petrol Vapours

Petrol

0-100

% LEL

Styrene

C8H8

0-100

% LEL

Xylene

C8H10

0-100

% LEL

Propane

C3H8

0-20000

ppm

Butadiene

C4H6

0-100

% LEL

Acetylene

C2H2

0-100

% LEL

VOC

VOC

0-2000

ppm

Xylene

C8H10

0-300

ppm

Sulphur hexafluoride

SF6

0-1000

ppm

Ethylene oxide

C2H4O

0-10

ppm

Bromine

Br2

0-2

ppm

Hydrogen fluoride

HF

0-10

ppm

Nitrous oxide

N2O

0-2000

ppm

Hydrogen cyanide

HCN

0-100

ppm

Formaldehyde

CH2O

0-10

ppm

Hydrogen chloride

HCL

0-20

ppm

Silane

SiH4

0-50

ppm

Ethylene

C2H4

0-1000

ppm

Ozone

O3

0-200

ppm

Chlorine

CL2

0-20

ppm

Page 22

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 22

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

Sulphur dioxide

SO2

0-100

ppm

Hydrogen sulphide

H2S

0-200

ppm

Fluorine

F2

0-2

ppm

Phosphine

PH3

0-5

ppm

Hydrogen

H2

0-1000

ppm

Chlorine dioxide

ClO2

0-12

ppm

Phosgene

COCl2

0-12

ppm

FR01

R12

20 - 2000

ppm

FR02

R23

R508b

20 - 2000

ppm

FR03

R1234yf

R452a

R513a

R454b

R454c

R455a

R1234ze

20 - 2000

ppm

FR04

R123

R1233zd

20 - 2000

ppm

FR05

R11

20 - 2000

ppm

FR06

R22

R401a

R401b

R402a

R402b

R403a

R408a

R409a

R411a

20 - 2000

ppm

FR07

R134a

R407a

R407f

R416a

R417a

R422a

R422d

R427a

E437a

R438a

R449a

R450a

20 - 2000

ppm

FR08

R32

R125

R143a

R404a

R407c

R410a

R434a

R448a

R542b

R507a

20 - 2000

ppm

Arsenic hydride

AsH3

0 -12

ppm

Temp

Temp

°C

Temp

Temp

°F

Humidity

Hum.

% RH

Pressure

Press

mbar

TOX

TOX ppm

Comb.

Comb

% LEL

External

External

%

Digital3

Digital

%

1 Different measuring ranges are possible, but not listed here.

2 The use with the measuring range value: 1 results in a binary value output of the values 0 or 1

Page 23

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 23

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.7.3 Alarm Thresholds / Hysteresis

For each measuring point four alarm thresholds are available for free definition. If the gas concentration is

higher than the set alarm threshold, the associated alarm is activated. If the gas concentration falls below the

alarm threshold minus the hysteresis the alarm is reset again. In the mode “Alarm at falling” the corresponding

alarm is set in case of falling below the set alarm threshold and reset again when exceeding the threshold plus

hysteresis.

The presentation of the alarm thresholds depends on the set measuring range: See chapter Gas Type and

Measuring Range.

The alarm thresholds are freely selectable in the range from 0 to 100 % of the measuring range.

The alarm threshold is only stored, if the value is ≥ than the lower alarm threshold

Unused alarm thresholds have to be defined with 0, in order to avoid undesired alarms.

Higher-level alarms automatically activate the lower-level alarms.

Lowest hysteresis: 3 % of the lowest alarm threshold

Highest hysteresis: 50 % of the lowest alarm threshold

Symbol

Description

Default

Function

C

Evaluation

C

C = Alarm evaluation with current value of MP

A = Alarm evaluation with average value of MP

10 %

LEL

Threshold 1

Threshold 2

Threshold 3

Threshold 4

Hysteresis

XX

XX

XX

XX

XX

Gas concentration > Threshold 1 = Alarm 1

Gas concentration > Threshold 2 = Alarm 2

Gas concentration > Threshold 3 = Alarm 3

Gas concentration > Threshold 4 = Alarm 4

Gas concentration < (Threshold X –Hysteresis) = Alarm X OFF

= Alarm release at increasing concentrations

= Alarm release at falling concentrations

Alarm Threshold 1

C 10.0 % LEL ↗

Alarm Threshold 2

C 20.0 % LEL ↗

Alarm Threshold 3

C 0.0 % LEL ↗

Alarm Threshold 4

C 0.0 % LEL ↗

Hysteresis

1.0 % LEL

Page 24

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 24

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.7.4 Delay for Alarm ON and/or OFF

Symbol

Description

Default

Function

0 s

Delay

Alarm

0 sec.

Gas concentration > alarm threshold + set time = Alarm ON

Gas concentration < alarm threshold – hysteresis + set time =

Alarm OFF

Function only active in Actual Value Mode.

8.7.5 Average Overlay

The function of the average overlay is only active for the gas type CO. The alarm evaluation of the operation

mode “Average” is overridden by the current value, if this one exceeds the alarm threshold and delay time

defined in the menu "System Parameters AV Overlay". The overlay is delayed by the time factor entered in the

local menu.

Symbol

Description

Default

Function

No

Overlay of alarm

release by

current value

No

No = Average overlay not active.

Yes = Average overlay active

8.7.6 Latching Mode Assigned to Alarm

Note: SBH means Latching

In this menu you can assign the latching mode to each alarm.

Symbol

Description

Default

Function

Alarm

Indication of the alarms 1 to 4; under each alarm you can activate

the latching with 1.

SBH

Assignment of

latching

function

yes/no

0 0 0 0

0 = no latching; alarm resets automatically if

gas concentration again < alarm threshold minus hysteresis

1 = latching; alarm remains active, if gas concentration < alarm

threshold minus hysteresis, until reset by the operator.

The acknowledgment of an alarm in latching mode is carried out in the menu Alarm status. See chapter 4.2.

Delay ON time

0 s

Delay OFF time

0 s

AV - Overlay

No

Alarm - 1234

SBH - 0100

Page 25

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 25

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.7.7 MP Fault Assigned to Alarm

In this menu you can define, which alarms should be activated by a fault at the measuring point. If the fault is

cleared, the alarm is automatically reset.

Symbol

Description

Default

Function

Alarm

Indication of the alarms 1 to 4; you can define with 1 for each

alarm that the alarm should be activated in case of MP fault.

Fault

Assignment of

MP fault to

alarm

0 0 0 0

0 = Alarm isn’t activated in case of MP fault.

1 = Alarm is activated in case of MP fault.

8.7.8 Alarm Assigned to Alarm Relay

Each of the four alarms can be assigned to any alarm relay 1 – 5 registered in the menu Relay Parameters by

entering the relay address right under the alarm. One alarm relay can be assigned to multiple alarms. Unused

alarms aren’t assigned.

The fault relay can also be used for alarm message (address 3). The relay has to be registered in the menu

Relay Parameters. The fault message function, however, remains unaffected.

Symbol

Description

Default

Function

Alarm

A1 A2 A3 A4

Presentation of the alarms 1 to 4; you can assign an alarm relay to

each alarm by setting a relay address.

Assignment of

alarm relay

A1 = X

A2 = X

A3 = X

A4 = X

X = Assignment of an alarm relay (relay address) to an alarm

8.7.9 MP Assigned to Analog Output

The measuring signal can be assigned to an analog output by entering the address of the analog output

instead of x. The analog output is configured in the menu System Parameters, AO Function.

Symbol

Description

Default

Function

X

Address AO

X = Assignment of an analog output by entering the AO address

Alarm - 1234

Fault - 0100

A1 A2 A3 A4

1 0 0 0

Analog Output

x

Page 26

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 26

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.8 Menu System Parameters

8.8.1 System Information

Symbol

Description

Default

Function

XXXX

Serial Number

Serial number (factory set)

XX.XX.XX

Date of Production

Date of production (factory set)

8.8.2 Maintenance Interval

Input of the maintenance interval in days. If you enter < 10 days, the function is not active

The maintenance interval can be set on the basic unit for maintenance information on the connected analog

inputs. If the maintenance interval is active, the accumulated maintenance message can only be acknowledged

by a calibration (at the analog input or at the head).

Symbol

Description

Default

Function

XXXX

Days

0

Maintenance interval (range: 10 - 2480 days)

8.8.3 Average Function

In the menu “Average Time” you can define the time base for the calculation of the arithmetic average value

(30 measurements within the time base). This average value can be used for alarm evaluation as an alternative

to the current value. The selection which value should be used for evaluation is defined separately for each

alarm in the menu “Alarm Threshold X”. In the average mode, the average value is indicated in the menu

“Measuring Values” next to the current value.

The alarm evaluation of the operating mode “Average Value” is overlaid by the current value, when the current

value exceeds the alarm threshold defined in the menu “AV-Overlay”. The overlay is delayed by the time factor

defined in this menu. The average overlay function is only available for the gas type CO.

System Parameters

Serial Number

XXXX

Mainten. Interval

XXXX Days

Date Manufacture

XX.XX.XX

Average Time

XXXX Sec.

AV - Overlay

0 s 0 ppm

Page 27

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 27

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

Symbol

Description

Default

Function

XXXX

Seconds

900

Time base for average calculation (range: 0 – 9999 sec.)

0 s

Seconds

120

Delay time in case of overlay by the current value (range: 0 – 9999

sec.)

0 ppm

Alarm

Threshold

100

Alarm threshold that triggers the overlay by the current value

(range: 0 – 999 ppm)

8.8.4 Power On Time

Gas sensors need a warm-up time, until the chemical process of the sensor reaches stable conditions. During

this running-in period the sensor signal can lead to an unwanted triggering of a pseudo alarm. Therefore, the

Power On time is started at each basic unit and each sensor head after power-on or voltage recovery. While

this time is running out, the device is in special mode and doesn’t activate alarms. The Power On time appears

in the starting menu. During this phase the sensor head transmits "Warm-up time" instead of the measured

value.

The Power On Time of the individual components may be different. Only when the longest time has expired,

the system starts the measuring operation.

Symbol

Description

Default

Function

XX

Seconds

30

Power On time (range: 0 – 999 sec.)

8.8.5 Deadband

The unwanted noise of the measured value around the zero point, caused by the basic drift of the sensor, can

be suppressed by activating a deadband with a range of 0% to 15% of the measuring range depending on

device.

If the measured value is within the set % value, the display shows 0. Natural zero-point fluctuations of sensors

downwards or upwards can thus be suppressed in the display. Default setting 0 means deadband deactivated.

The suppression also affects the analog output, because the measured value must not assume a different

display depending on the output.

When opening the calibration mode, the deadband function switches off automatically.

Power On Time

30 s

Deadband

0 %

Page 28

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 28

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.8.6 AO Function

This menu is for the configuration of the analog output.

After registration, each analog output checks the current signal for plausibility. Signal deviations of more than

5% from the nominal value will generate an error message (causes: short circuit or interruption of cable,

actuator not connected).

The steepness of the current signal can be adjusted in the range of 10 to 100% in case of local control.

If several measuring points are assigned, you can define whether the minimum, the maximum or the average

of all the assigned signals is output. It is likewise possible to define which signal of the measuring points

(source) is output.

If the 4 - 20 mA signal is used as a safe signal (SIL level), the following mandatory parameters must be

used:

Selection of analog signal: 100: 100 % gas signal = 20 mA (standard signal)

Selection source: CF: Source current value signal with fault message

Selection of operating mode: Max: Output of the maximum value of the assigned MP

Symbol

Description

Default

Function

Analog

Output 1

Selection of

channel

Selection of the analog output 1 - X

0

10-100 %

Selection of

output signal

100 %

0 = Analog output is not used, no monitoring of the feedback

≥ 10 = Local control and definition of the signal slope

10 = 10 % gas signal = 20mA (high sensitivity)

100 = 100 % gas signal = 20mA (standard signal)

C

Selection of

source

A

C = Source is current value

A = Source is average value

CF = Source is current value and additional fault message at AO

AF = Source is average value and additional fault message at AO

Max.

Selection of

mode

Max.

Min. = Displays the minimum value of all assigned MP

Max. = Displays the maximum value of all assigned MP

Average = Displays the average value of all assigned MP

Note: If you use more than one oxygen sensor, please do not use the mA output function; please

use only the relay functionality.

AO Function

Analog Output 1

100 % C Max.

Page 29

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 29

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.8.7 Relay Multiplication

With the relay multiplication table, it is possible to assign an additional alarm relay to an alarm. This

corresponds in the end to one multiplication of the source alarm situation per entry.

The additional relay follows the alarm status of the source but uses its own relay parameters to allow

different needs of the doubled relay. So, the source relay can be configured, for example, as safety

function in de-energized mode, but the doubled relay can be declared with flashing function or as horn

function.

There is a maximum of two entries for IN relays and OUT relays. Thus, it is possible to expand one relay

to two others or to double max. two relays.

In the column IN (source), you can set the relay assigned to an alarm in the menu MP Parameter.

In the column OUT (target), you can enter the relay needed in addition.

Note:

Manual intervention in the menu Relay Status or override in external ON or OFF by external DI do not

count as alarm status, so they do only affect the IN relay. If this is also desired for the OUT relays, it has

to be configured separately for each OUT relay.

Number

Description

Default Status

Function

0-5

IN AR Relay

0

0 = Function off

X = Relay X should be multiplied (information source).

0-5

OUT AR Relay

0

0 = Function off

X = Relay X (target) should switch together with IN relay.

Example:

2 relay contacts are needed with the same effect as relay 3, (see assignment of the relays in chapter MP

Parameters.)

Entry: 1: IN AR3 OUT AR4

Entry: 2: IN AR3 OUT AR5

If relay 3 is activated via an alarm, the relays AR3, AR4 and AR5 will switch at the same time.

R-Multiplication

In Out

1: R 0 R 0

IN OUT

2: AR 3 AR 5.

IN OUT

1: AR 3 AR 4.

Page 30

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 30

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.9 Operating Data

This menu is for retrieving relevant operational data of the sensor head and the basic unit. No changes or

modifications are possible.

Serial number of the device

Date of production of the device

Current days of operation

Display of the lowest temperature

detected at the device

Value is updated on new devices only after

a few days (initial value = 70°C)

Display of the highest temperature

detected at the device

Value is updated on new devices only after

a few days (initial value = -35°C)

Display of the zero offset of

analog output 1

(internal value)

Selection of analog input

The operating data for analog input

refer to the 4 – 20 mA signal!

Number of calibrations

performed

Current zero offset and gain

Serial Number

XXXX

Max. Temperature

31 °C

Operating Days

X Days

Date Manufacture

XX.XX.XX

Min. Temperature

25 °C

Analog Output 1

Offset 295

Analog Input ……X

Number of Calibr.

1

Zero Gain

xxxxx yyyyy

Operating Data

Page 31

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 31

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

Sensitivity of the analog sensor at the

last calibration compared to

new sensor (only for analog sensors)

Display of the days differing from

the nominal maintenance date

(fixed value)

Days of operation since the last

calibration (fixed value)

Currently remaining days until

next maintenance date

(down counter)

Maximum measured current

value of the sensor head

8.10 Test Function for Relays

In this menu, the alarm relays can be manually turned on and off in order to test their function.

This menu is only available in special mode.

The manual operation takes priority over activation by a gas alarm. However, the external activation of the

alarm relays via a digital input takes priority over the manual test function.

The test mode simulates an alarm for the relay and the relay accepts the alarm status. The test function is

deleted by selecting "Automatic" or by exiting the Special Mode.

The testing is possible via code level 1, 3 and 4.

Selection of the relay 1 - 5

Selection of further

relays

Sensitivity

100%

Maintenance Days

Last xxx

Days of operation

Last xxx

Maintenance Days

Currently xxx

Max. Current Value

0

Relay

Test Function

Relay X

Status OFF

Relay 1

Alarm manual ON

Relay 1

Alarm manual OFF

Relay 1

Automatic

Page 32

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 32

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

Symbol

Description

Default

Function

Status

Relay No. X

X = 1 – 5 Select the relay

OFF

Relay Status

OFF

Status OFF

Status ON

= Relay off (no gas alarm)

= Relay on (alarm)

Alarm

manual ON

Test of the

alarm

message

Autom

Alarm manual ON

Alarm manual OFF

Automatic

= Relay manually set in alarm status

= Relay manually set in “no alarm“ status

= Reset of manual intervention, relay

in automatic mode

8.11 Test Function for Analog Output

In this menu, you can define a desired value in mA for the analog output in order to test its function. This value

is then directly available at the output.

This menu is only available in special mode.

The manual operation has priority over the activation by the gas concentration.

The testing is possible via code level 1, 3 and 4.

When the menu is exited, the actual current signal is immediately output again, the entry field shows 0.

The test function is only possible for an active analog output.

On the left you can see the current set-point

as calculated from the gas concentration.

Enter the required current under “Set Value”,

e.g. 12 mA

The set value is accepted as set-point

(by displaying it on the left)

and is physically output.

Analog Output

Test Function

AO 1 Preset

4.02 mA 0.00 mA

AO 1 Set Value

12.00 mA 12.00 mA

AO 1 Set Value

4.02 mA 12.00 mA

Page 33

User Manual - PolyGard®2

Multi-Gas-Controller MGC2-K Honeywell

Page 33

PolyGard® is a registered trademark of MSR GAMGC2-K_E_0320

Phone 0049(0)8531/9004-0 Fax: 0049(0)8531/9004-54 Specification subject to change without notice

MSR-Electronic GmbH, Bgm.-Schoenbauer-Str. 13, D 94060 Pocking www:msr-electronic.de Made in Germany

8.12 Calibration

On this page there is the menu overview of the calibration. The calibration description can be found on the

following pages.

Zero calibration

Selection of the measuring

point to be calibrated

Set the test gas concentraion