Page 1

PCR-300

PCR-300 RC

Installation and Operating

Instructions

Electronic refrigeration control

EB-PCR-04 EN1H-1924GE23 R1207

Page 2

2

TABLE OF CONTENTS

11 Unpacking the unit and conditions of use

3

12 General instructions 3

13 Use and function 3

3.1 Use for the purpose intended 3

3.2 Function 4

14 Safety 4

4.1 Sources of danger 4

4.2 Safety precautions 5

15 Installation and commissioning 5

5.1 Mechanical installation 5

5.2 Electrical installation 6

5.3 Setting the DIP switch for the emergency setpoint and

clock back-up battery 8

16 Operating of the controller 9

6.1 Switching on the operating voltage 9

6.2 Display 9

6.3 Key functions 10

6.4 Adjusting the cold store temperature 11

6.5 Changing the cold store temperature difference, defrost cycle,

and alarm temperature 11

6.6 Setting the time (PCR-300RC only) 11

6.7 Manual defrost 12

17 Programming 13

7.1 Input parameters and ranges 13

7.2 Sensor calibration (parameters E 15 and E 16) 15

18 Maintenance 16

19 Alarm messages 16

10 Problem solving 17

11 Conditions of warranty 17

12 Technical data 18

Page 3

3

1 Unpacking the unit and conditions of use

Before and when unpacking the unit, make a visual inspection to

identify any possible damage which may have occurred during

transportation. Please look for loose parts, dents, scratches, etc.

Report any damage immediately to the freight company. (Please see

“Conditions if damage has occurred”.) In other cases, the latest edition

of the “General conditions for the supply of goods and services” issued

by the ZVEI (German Central Association for the Electrotechnical

Industry) shall apply.

Before disposing of the packaging, please check it for loose functional

parts and information leaflets.

So that we can process warranty claims, please give an exact

description of the defect (with a photograph, if appropriate) and state

the model designation of the unit.

Please keep these operating instructions at the place where the

equipment is used.

2 General instructions

Work on the electrical devices and switching equipment may only be

carried out by appropriately qualified personnel. The relevant safety

and environmental regulations must be followed.

FLICA equipment is free from PCBs, PCTs, asbestos, formaldehyde,

cadmium and water-repelling substances.

The design of the equipment has taken into account the Standards EN

50081-1,2 (emitted interference), EN 50082-1 (immunity to

interference), EN 60335-1 (electrical safety),

IEC 695-2-1 to -2-3 (fire resistance, glow-wire test).

Safety tests have been performed in the factory on all equipment in

accordance with EN 60335-1

(DIN VDE 0700 T500).

3 Use and Function

3.1 Use for the purpose intended

I This controller is designed to control ambient and media

temperatures in cold stores and refrigeration systems and to

control existing defrost equipment for one refrigeration circuit in

each case.

Page 4

I The controller must not be used as a safety cut-out device or excess

temperature limiter.

If the controller is used for purposes other than those stated

here, it shall not be considered to be use for the purpose

intended.

I Only connect sensors supplied with the unit. If a replacement sen-

sor is required, only use sensors of the same type (part no. H61007).

I The controller is not intended for use in vehicles because the

possible operating voltage ranges, interference level and

environmental operating conditions exceed the limits for which the

controller can be used.

I Please take the application limits into account

(see Technical Data, chapter 12).

3.2 Function

The PCR-300 is a microprocessor-controlled cold store control for

refrigeration and deepfreeze systems with a modular housing for

installation on 35 mm standard rails.

I Compressor control (dependent upon cold store

temperature) with delayed start-up.

I Evaporator fan control

u Fan either in combination with compressor or

u operating continuously or

u switched via the evaporator thermostat.

I Defrost control limited thermostatically,

either for electrical heating or hot-gas defrosting

I Alarm output.

Defrosting is initiated via programmable intervals of time, max. 24/day.

The PCR-300 RC is provided with a real-time clock with a

back-up battery for defrost control. A maximum of six times per day

can be programmed.

4 Safety

4.1 Sources of danger

I Caution - Mains voltage.

I Never expose the unit to water or moisture. Risk of malfunction

and short circuit. Only use the unit when it is adjusted to normal

ambient temperature (+15 to +30 °C). Extreme changes in

temperature in combination with high atmospheric humidity may

lead to the formation of condensed water.

I Even if the control-circuit voltage is switched off, high voltage may

still be applied to the unit. For this reason, isolate all electric

circuits before starting any service work.

4

Page 5

I Never expose the unit to excessive heat, dust and vibrations. Avoid

knocks and pressure loads. If the housing is damaged, there is a risk

of an electric shock causing death or injury.

I If the unit cannot be operated without the risk of danger, it must

be taken out of service and precautions taken so that it cannot be

switched on again unintentionally.

This applies, in particular, if:

u The housing has damage which is visible,

u the unit is no longer operational or

u it has been stored for a long time in unfavourable conditions.

I The unit must not be opened. If it is thought that the unit may be

defective, send it back to the dealer or manufacturer with a precise

description of the fault.

4.2 Safety precautions

I All electromagnetic loads (solenoid valves, contactors, alarm horns,

motors) should be interference suppressed directly at the coil with

RC elements.

I Please note the maximum contact rating of the relays and

terminals.

If this is not observed, there is a risk that the contacts may pit or

stick, with the result that the refrigeration system will not operate

correctly and the refrigerated items may be damaged.

I Sensor leads are to be routed separately from mains voltage wires.

The clearance should be at least 5 cm.

I Sensor leads must not be routed in multiple cables with other leads

carrying mains voltage, otherwise the system may malfunction.

I Tighten the terminals carefully; excessive strain will result in

damage to the controller.

I PCR-300RC: Set DIP switch 2 to “off” if the controller is going to

be out of service for more than 3 months and when the controller

is shipped. This is to prevent damage occurring to the back-up

battery.

5 Installation and commissioning

5.1 Mechanical installation

I 4 Din standard modular housings to be mounted on a

standard rail:

5

Page 6

6

a) housing with 2 mounting tabs:

open out the lateral mounting tabs; clip the unit on the 35 mm rail

and press tabs in again.

b) housings with 1 mounting tab:

put housing on the upper 35 mm rail. Clip the unit on the 35 mm

rail, lower tab clips on the rail automatically. To remove the unit

from the rail press in lower mounting tab with a screw driver, lift

unit.

I Mounting of sensor:

I Use a cable clamp to secure sensor T1 in a suitable position.

I Secure evaporator sensor T2 in the evaporator fin core at the point

where it is suspected icing is the greatest. It is advisable to use a

point in the lower third of the finned evaporator.

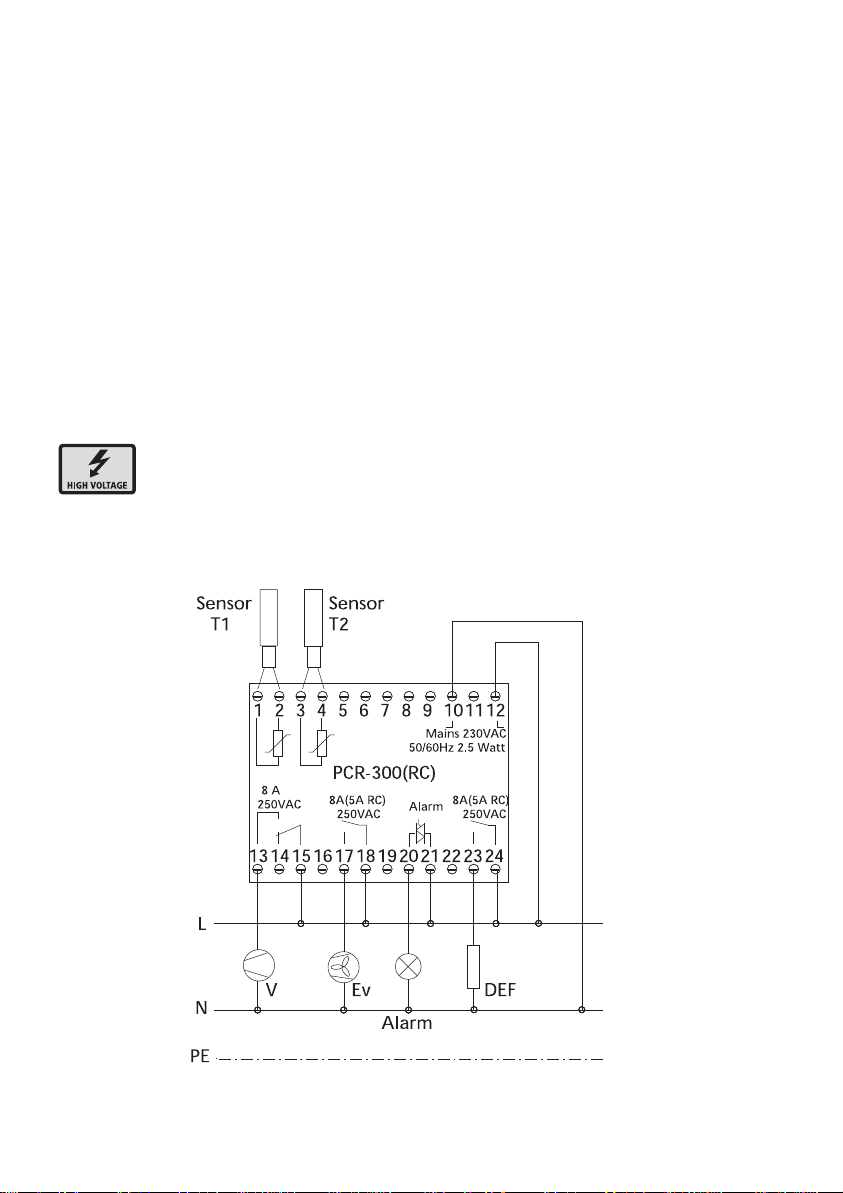

5.2 Electrical installation

☛ CAUTION: The mains voltage and system frequency must be the same

as the nominal values on the device’s rating plate.

Work on electrical systems must be performed by qualified personnel.

Relevant local safety regulations must be observed.

Wiring diagram:

Page 7

7

Terminal: Description:

1 - 2 T1 = Cold store sensor

3 - 4 T2 = Evaporator sensor

10 - 12 Mains = Power supply

13 - 15 V = Compressor contactor (cooling)

17 - 18 Ev = Evaporator fan (contactor)

20 - 21 Alarm = Remote alarm indicator; indicator lamp or

contactor (with RC-element)

23 - 24 Def = Defrost heating

(contactor) or hot gas valve

☛ The unit is equipped with an opto-decoupled electronic

alarm output.

Take note of the alarm output limit values.

I Supply voltage: Max. 250 V AC.

I Minimum load: 40 mA

I Maximum load: 80 mA

I If an inductive load (contactor or horn) is connected, connect

an RC element directly at its coil.

☛ Instructions:

I Pay attention to the contact loading of the relay

(8A / 5A resistive load, 2A / 1A inductive load). As a general rule,

contactors are recommended.

I The maximum tested sensor cable length is 50 m, with a minimum

cross section of 2 x 0.75 mm

2

. Solder the extension cable to the

sensor cable to prevent contact resistances.

I It is advisable to use shielded sensor extension cables.

All shields must be routed at the side of the controller to one

earth/protective potential. The extension cable shield must not be

connected on the sensor side, otherwise bonding currents may

occur via the shielding.

I The controllers are designed respecting the highest degree of

immunity to interference. If the local interference level exceeds the

immunity data might get lost (AL1 in display) and the controller

switches to the preprogrammed setting values. This is not a

mulfunction of the controller. In such cases the means to suppress

interference have to be improved (RC-elements, shielded lines).

Page 8

8

5.3 Setting the DIP switch for the emergency setpoint and the

clock back-up battery

Carefully lift the housing cover off the side, using your fingers.

I Selection of the emergency setpoint for the cold store

temperature:

This will be activated if the data in the memory is lost and alarm

AL1 is activated. This sets all program parameters to the preset

value. The cold store temperature setpoint can be preset to +4 °C

or –18 °C, as desired. This ensures that chilling systems with

temperatures above zero do not freeze and deepfreeze

installations do not thaw.

DIP switch 1 (left), Pos.: off (bottom): Setpoint value at +4 °C for

emergency operation.

Advisable for chilled storage

(= Preset value).

Pos.: on (top): Setpoint value at –18 °C for

emergency operation.

Advisable for deepfreezers.

For PCR-300 RC only:

The back-up battery must be switched on when the controller is started

up so that the real-time clock keeps operating if there is a power failure.

Activation of the back-up battery:

DIP switch 2 (right), Pos.: off (bottom): Battery switched off when

controller is stored or in transit. (The battery is

switched off when the controller is delivered;

exhaustive discharge monitoring).

Pos.: on (top): Battery activated.

Page 9

☛ Note: It takes approximately 24 hours for the battery to achieve its

full back-up capacity.

The battery will provide cover for a power failure of approximately

1 month.

6 Operation of the controller

Front view of controller:

6.1 Switching on the operating voltage

The controller is started by means of a control switch provided by the

customer.

The first time the controller is started, pre-programmed setting values

are used which at later point can be adapted for individual

requirements.

If alarm “AL 2” (temperature in refrigerated chamber too high

or too low) is displayed when the controller is switched on, this

can be cleared by pressing the key.

6.2 Display

During normal operation the current cold store temperature is

displayed. It is measured with cold store sensor T1.

In the event of an alarm, the most recent alarm message (e.g. AL1)

and the cold store temperature are displayed alternately.

9

Page 10

Three spot indicators show the switching status of the relays during

operation:

Pos. 1: On : Compressor relay on.

Off: Compressor relay off.

Flashes: Compressor start-up

delay E05 active.

Pos. 2: On : Evaporator fan relay on.

Off: Evaporator fan relay off.

Pos. 3: On : Defrost relay on.

Off: Defrost relay off.

Flashes: Drain time E09 is running.

6.3 Key functions

☛ Never operate the keys with sharp objects

(screwdriver or similar).

Display of setpoint Press and hold down key.

temperature

Clear alarm Press key.

messages (If the sensor is faulty, switch

mains voltage ON/OFF.)

Evaporator Press and keys in sequence

temperature and hold both down.

display

Manual defrost Press key for 5 secs.

initiation

Display of time Press and keys in

until the next sequence and hold both down.

defrost (Display in hours and minutes.)

Display limit Press key.

value for excess

temperature alarm

(cold store sensor T1)

I Change input values by using the and keys with

the key pressed down.

I Input parameters, e.g. the switching difference, are indicated by

“E” and a 2-digit number, e.g. “E01”.

I The input parameters are grouped together in two programming

levels.

10

Page 11

11

u Access the first programming level by pressing

the and keys at the same time for 5 seconds.

u Then use the and keys to access the parameters

to be changed.

u Access the second programming level by pressing

the and and keys simultaneously

for 5 seconds.

I To exit from the programming levels and save the data, press

the key after the last input parameter. If no key is pressed in

either of the programming levels for 10 minutes, this mode will be

exited without the data being saved.

I Do not display altered parameter data before saving the data, as it

would be reversed to its original value in the process.

6.4 Setting the cold store temperature

Press and hold down the key. Adjust the setpoint for

the value in question using the or key.

Adjustment is possible within the limits of the input parameters E12

and E13.

The factory setting is +4 °C.

6.5 Changing the cold store temperature difference,

defrost cycle and alarm tempera-ture

Access to the first programming level:

I Press and hold down the and keys at the same time for

approx. 5 seconds (E01 appears in the display for

PCR-300 and E00 for PCR-300RC)

I Setting: Press and hold down the key. Adjust the setpoint value

to the desired figure using the or key.

Input parameters and input ranges:

Display Setting range Preset

E00 Time, for PCR-300RC only 0.00 to 23.5, 12’0

see section 6.6

E01 Cold store temp. difference 1 to 20 K 2 K

E02 Time between 2 defrost cycles 1 to 24 h 8 hours

E03 Alarm temperature difference –50 K to +50 K 20 K

Page 12

If the set temperature difference E03 is negative, an alarm is given

if it is too cold in the refrigerated area,

e.g. E03 = –10 K, cold store setpoint = –18 °C

➝ alarm at –28 °C in refrigerated area.

If the set temperature difference E03 is positive, the alarm is given

if it is too warm in the refrigerated area,

e.g. E03 = +10 K, cold store setpoint value = –18 °C

➝ alarm at –8 °C in the refrigerated area.

Attention: any change of the cold store setpoint valve changes also

the alarm temperature.

If E03 is set to 0, no alarm will be given.

PCR-300RC only:

E2’1 1st defrost time

–––

(none), 00.1 to 23.5 hours

–––

(none)

E2’2 2st defrost time

–––

(none), 00.1 to 23.5 hours 01’0 hours

E2’3 3st defrost time

–––

(none), 00.1 to 23.5 hours 07’0 hours

E2’4 4st defrost time

–––

(none), 00.1 to 23.5 hours 13’0 hours

E2’5 5st defrost time

–––

(none), 00.1 to 23.5 hours 19’0 hours

E2’6 6st defrost time

–––

(none), 00.1 to 23.5 hours

–––

(none)

The time is entered in increments

of 10 minutes in each case.

Caution: The times must be entered

in ascending order.

Exiting programming mode: Press the key after the last level has

been entered.

6.6 Setting the time (PCR-300RC only)

I Press and hold down the and keys at the same time for

approx. 5 seconds to access the first programming level

(Display: E00).

I Setting: Press and hold down the key and change

the time to the current time using the or key

(increments of 10 minutes).

Display Setting range Preset

E00 Time 00.0 to 23.5 hours 12’0 hours

Exiting programming mode:

Press the key several times.

12

Page 13

6.7 Manual defrosting

Press and hold down the key for 5 seconds.

The manual defrosting process will be initiated.

7 Programming

Access to the second programming level:

I Press and hold down the , and keys at the same time for

approx. 5 seconds

(Display: E01 for PCR-300, E00 for PCR-300RC).

I Use or key to select parameters.

I Setting: Press and hold down the key. Adjust the setpoint value

to the desired figure using the or key.

I Do not display altered parameter data before saving the data, as it

would be reversed to its original value in the process.

7.1 Input parameters and input ranges

Parameter in Display Setting range Preset

( or ) ( and or )

E00 Time, only for PCR-300RC 00.0 to 23.5 hours 12’0 hours

E01 Cold store temp. difference 1 to 20 K 2 K

E02 Time between 2 defrost cycles 1 to 24 hours 8 h

☛ Once the controller has been switched on, defrosting occurs

for the first time at the end of the first time interval.

☛ After defrosting has been initiated manually, the next time

defrosting takes place is after a complete time interval has

elapsed.

☛ If the time interval between two defrost cycles is changed

when the system is in operation, the new time interval will

not be applied until after the next time defrosting has

occurred.

For PCR-300RC only:

E2’1 1st defrost time

–––

(none), 00.1 to 23.5 hours

–––

(none)

E2’2 2st defrost time

–––

(none), 00.1 to 23.5 hours 01’0 hours

E2’3 3st defrost time

–––

(none), 00.1 to 23.5 hours 07’0 hours

E2’4 4st defrost time

–––

(none), 00.1 to 23.5 hours 13’0 hours

E2’5 5st defrost time

–––

(none), 00.1 to 23.5 hours 19’0 hours

E2’6 6st defrost time

–––

(none), 00.1 to 23.5 hours

–––

(none)

13

Page 14

14

The time is entered in increments

of 10 minutes in each case .

Important: The times must be entered

in ascending order.

E03 Alarm temperature difference –50 K to + 50 K 20 K

E04 Delay time – Alarm 0 to 99 mins. 10 mins.

E05 Compressor start-up delay 0 to 15 mins. 5 mins.

E06 Defrost type 1 or 2 1

1 = Electrical (compressor off)

2 = Hot gas (compressor on)

E07 Defrost limit temperature 0 to 50 °C 8 °C

E08 Defrost time limit 1 to 99 mins. 25 mins.

E09 Drainage time, evaporator 0 to 99 mins. 3 mins.

E10 Time delay, fan 0 to 500 secs. 30 secs.

E11 Evaporator fan control 1,2 or 3 1

1 = Fan with compressor.

2 = Continuous fan operation, except during defrosting.

3 = Fan run-on. If there is an undershoot in the cold

store temperature, the fan is switched on by

evaporator sensor T2. The fan is switched off again

once the desired cold store temperature is

attained or exceeded.

E12 Minimum permissible –55 °C to E13 –55 °C

cold store temp.

E13 Maximum permissible E12 to +50 °C +50 °C

cold store temp.

E14 Display during defrosting 1,2 or 3 1

1 = “dEF” in display.

2 = Current cold store temperature in display.

3 = Retaining temperature in display when defrosting

is initiated until the current cold store temperature

reaches the retained value again. This is for a maximum of 15 minutes after the end of defrosting.

( Evaporator drainage time E09 and time delay fan E10 are not

respected at hot gas defrost mode E06 = 2.

Page 15

15

E15 Sensor calibration T1 –5 to +5 K 0 K

(cold store)

E16 Sensor calibration T2 –5 to +5 K 0 K

(evaporator)

E17 Operation of 0 = Relay de-energizes 2

compressor relay 1 = Relay is permaif cold store sensor T1 nently engergized

is defective 2 = Alternately ener-

gized/de-energized according to

time set in E18

and E19.

E18 “On” time at E17 1 to 99 mins. 15 mins.

E19 “Off” time at E17 1 to 99 mins. 15 mins.

To exit from the programming mode:

Press the key after inputting the last level.

7.2 Sensor calibration (parameters E15 and E16)

The cold store and evaporator sensors can be calibrated.

Note: An additional resistance of 7

q in each case,

caused by the extension of the sensor cable,

results in a change in the temperature display by

+1K.

How to proceed: Measure the temperature at the sensor concerned

with a calibrated thermometer or submerge the

sensor in well mixed iced water (0 °C).

Compare the measured temperature with the

temperature displayed on the unit display.

If the measured temperature is lower than the

one displayed, set the negative difference as the

programming value

(e.g. - 2 K).

If the measured temperature is higher than the

one displayed, set the positive difference as the

programming value

(e.g. 2 K).

The temperature display is then corrected by the

set value.

Page 16

16

8 Maintenance

The controller does not require any maintenance. It does not have any

fuses so, if brief voltage spikes occur, the refrigeration system will not

stop operating for a prolonged period. Once the disturbance has

passed, the controller will automatically start up again.

Cleaning the housing: Only a dry anti-static cloth may be used to wipe

clean all plastic parts. Do not use water or cleaning agents containing

solvents!

9 Alarm messages

If an alarm occurs, the alarm output will be activated and on the

display a code will alternate with the cold store temperature.

Display Meaning

AL1 Program memory data loss.

The preset values will be used as an emergency program.

The setpoint value will be set to +4 or –18 °C,

depending on the selection of DIP switch 1.

AL2 Limit value (=setpoint value +E03) at sensor T1

exceeded and delay time E04 elapsed.

AL3 The sonsor temperature at sensor T1 is above

50 °C or below –55 °C.

AL4 The specified setpoint value is outside

the limits E12 and E13

AL5 Cold store temperature sensor T1 – short

circuit or break in wiring. Compressor switches

as a function of parameter E17.

AL6 Evaporator temperature sensor T2 – short

circuit or break in wiring.

Safety times are used, for the fan run-on function

the fan is controlled with the compressor by the

evaporator fan control E11 automatically

switching from 3 to 1.

☛ After sensor T2 has been repaired,

E11 must be reset manually from 1 to 3.

AL7 For PCR-300RC only: Real-time clock faulty,

switching over to interval defrosting (interval = 4 hours)!

Page 17

Clearing alarm:

Press the key.

All alarm messages, with the exception of AL2, are also reset by

switching off the operating voltage. AL2 can only be reset using

the key.

10 Problem solving

Fault Cause Remedy

Evaporator fan does not Evaporator Refit

switch on during sensor T2 has sensor.

cooling when the fallen out of

programmed setting the fins.

of parameter E11

is set to position 3

(fan run-on).

For PCR-300RC only: Back-up battery Switch on

The real-time clock is switched off. back-up

stops or indicates the battery

wrong time in the event see

of a power failure. Section 5.3.

11 Warranty conditions

I Warranty is provided for a period of 12 months, starting at the

date the item was delivered. Proof of this should be furnished in

the form of a delivery note or invoice.

I All functional faults caused by poor workmanship or faulty

materials will be repaired free of charge during the warranty

period.

I More extensive claims, in particular for consequential damage, are

excluded

I Damage or malfunctioning caused by the equipment

being handled incorrectly or by non-compliance with the operating

instructions shall not be covered by the warranty.

The warranty shall be invalidated if any work is carried out

on the appliance.

17

Page 18

18

12 Technical data

Mains voltage/frequency 230 V AC ± 10% / 50/60 Hz

Rated wattage 2.5 watts

Display 3-digit, 7-segment, red LED, 14.2 mm

Resolution 1 K

Measuring range –55 to +50 °C

Outputs 1 relay with changeover contact, 8 A,

230 V AC, resistive load, (cooling).

1 relay with N.O. contact, 8 A

(5A PCR-300RC), 230 V AC,

resistive load, (defrost heating).

1 relay with N.O. contact, 8 A (5A -PCR-300RC),

230 V AC, resistive load (fan control).

Control response Two-step

Alarm output Opto bidirectional triode thyristor, 250 V AC,

max. load 80mA

Display accuracy ± 0.5K internal, ± 1 digit, at 25 °C

Operating conditions 0 °C to 50 °C, 30 to 85 % R.H., excluding dew

Storage temperature –20 °C to +80 °C

Data back-up Non-volatile memory (EEPROM)

Clock: Back-up battery, approx. 1 month

power reserve (PCR-300 RC only)

Emergency setpoint DIP switch under display cover

selection (off = +4 °C / on = –18 °C)

Sensor type PTC

– Number 2 sensors

T1 = Control signal to compressor relay

T2 = Control signal to defrost limitation and

fan control

– Cable length 2.5 m

– Range where cable –30 °C to +80 °C not fixed

can be used: –40 °C to +80 °C fixed

– Accuracy ± 2 %

Housing L x W x H = 85 x 70 x 61 mm,

ABS plastic, self-extinguishing (UL 94 V0)

Protective rating Housing: IP 20, front panel: IP 52

Class of protection 2

Terminals 250V / 10 A screw-type terminal strips,

with wire protection,

tightening torque 0.6 Nm

Max. core cross section 1.5 mm

2

Weight Approx. 420 g (inc. 2 sensors).

Only operate the unit in dry places.

Errors in the technical data are excepted. We reserve the right to make changes without prior notice.

Page 19

19

EC Declaration of Conformity

as defined in the

EMC Directives 89/336/EEC

and the

EC Low Voltage Directives 73/23/EEC

Product: FLICA, electronic coldstore control

Model designation: PRC-300, PCR-300RC

has been developed, designed and manufactured in accordance with the

EC Standards listed above.

The f

ollowing harmonized Standards have been applied:

EN 50081-1 (1991)

Part 1 for the trades sector, emitted interference

EN 50081-2 (1993)

Part 1 for the industrial sector, emitted interference

EN 50082-1 (1991)

Part 1 for the trades sector, immunity to interference

EN 60335-1 (1993-03-09)

IEC 335-1 (1976) ed 2

Electrical safety, part 1: general requirements

EN 60730-1 (1992-12-09)

IEC 730-1 (1986) ed 1

Automatic electronic controls

Full technical documentation is available.

Operating instructions for the device are provided.

Mosbach, March 22

nd

, 1999 Honeywell Flica

Honeywell AG

Hardhofweg

D-74821 Mosbach

i.V. Dr. Osthues

R + D / Production Manager

Page 20

Automation and Control Solutions

Manufactured for and on behalf of the

Environment and Combustion Controls

Division of Honeywell Technologies Sàrl,

Ecublens, Route du Bois 37, Switzerland

by its autorised representative Honeywell GmbH

Honeywell GmbH

Hardhofweg • 74821 Mosbach / Germany

Phone: +49 (0) 62 61 / 81-475

Fax: +49 (0) 62 61 / 81-461

E-Mail: Cooling.Mosbach@honeywell.com

www.honeywell-cooling.com

Loading...

Loading...