Page 1

N05010/N10010

NON-SPRING RETURN DIRECT-COUPLED DAMPER ACTUATORS FOR

MODULATING AND FLOATING / 2-POSITION CONTROL

PRODUCT DATA

SPECIFICATIONS

Supply voltage 24 Vac/dc -15%/+20%, 50/60 Hz

Nominal voltage 24 Vac/dc, 50/60 Hz

All values stated hereinafter apply to operation under

nominal voltage conditions.

Power consumption

N05010 5 VA / 2 W

N10010 5 VA / 2 W

Control signal

Modulating 0...10 V

Floating/2-Position 24 Vac/dc

Ambient limits

Ambient operating limits -20...+60 °C (-5...+140 °F)

Ambient storage limits -30...+80 °C (-22...+176 °F)

Relative humidity 5...95%, non-condensing

Safety

GENERAL

This non-spring return direct-coupled damper actuator

provides modulating and floating/2-position control for:

• air dampers,

• VAV units,

• air handlers,

• ventilation flaps,

• louvers, and

• reliable control for air damper applications with up to 1 m

/ (5 Nm) and 2 m

friction-dependent).

2

(10 Nm) (seal-less damper blades; air

FEATURES

• Declutch for manual adjustment

• Adjustable mechanical end limits

• Removable access cover for direct wiring

• Mountable in any orientation

• Function selection switch for selecting modulating or

floating/2-position control

Protection standard IP54

Protection class II as per EN 60730-1

Overvoltage category II

Lifetime

Full strokes 60000

Repositions 1.5 million

Mounting

Round damper shaft 8...16 mm

Square damper shaft 6...13 mm; 45° steps

Shaft length min. 41 mm

2

End switches (when included)

Rating 5 A (resistive), 3 A (inductive)

Triggering points 5° / 85°

Torque rating 5 Nm / 10 Nm

Runtime for 90°

mod. (dc / 50/60 Hz ac) 90 sec

floating (dc / 60 Hz ac) 90 sec

floating (50 Hz ac) 110 sec

Rotation stroke 95° ± 3°

Dimensions see "Dimensions" on page 8

Weight (without cables) 450 g

Noise rating 35 dB(A) max. at 1 m

® U.S. Registered Trademark EN0B-0478GE51 R0408

Copyright © 2008 Honeywell Inc. • All rights reserved

Page 2

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

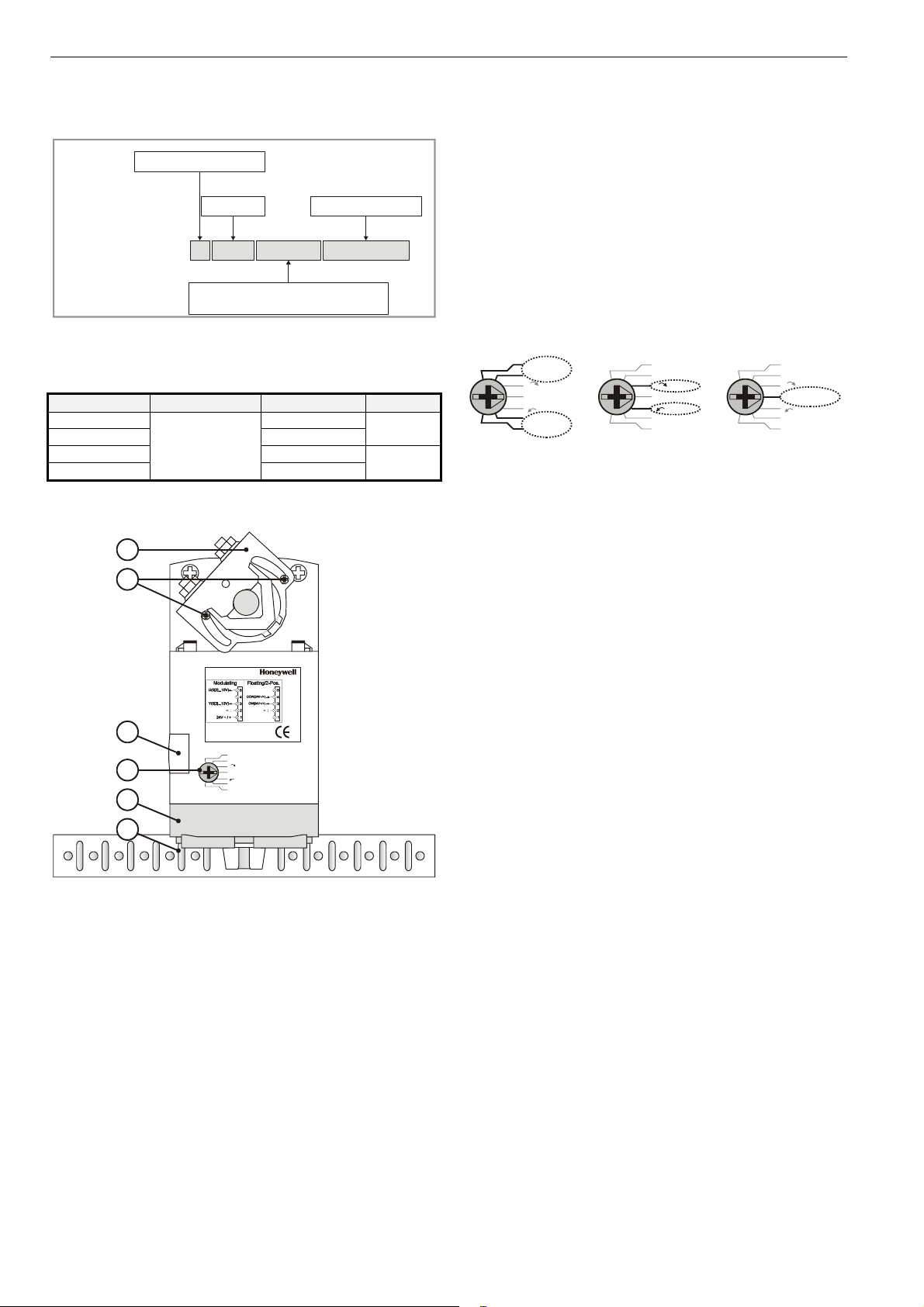

PRODUCT IDENTIFICATION SYSTEM

Contents of Package

The delivery package includes the actuator, parts 1 through 6

N = non-spring return

S = spring return

(see Fig. 2), plus two cable grommets and a spare cable

grommet.

05 = 5 Nm

10 = 10 Nm

equipped with two

end switches

RUN MODES

The function selection switch (see Fig. 3) can be used to

W

SmartAct

N

5

0

0-0

010 = modulating + floating

24 = 24 V floating + ON/OFF

230 = 230 V ON/OFF

S

+ ON/OFF

21

Fig. 1. Product Identification System

place the actuator into any one of three different modes:

• Service/Off;

• the floating/2-position run mode ("Dir" for CCW-closing

dampers or "Rev" for CW-closing dampers); and

• the modulating run mode.

modulating

MODELS

order no. supply voltage end switches torque

N05010 -N05010-SW2 2

N10010 -N10010-SW2

24 Vac/dc

2

BASIC FEATURES

1

2

N05010

3

2...10 V

0...10 V

Dir

4

5

6

Fig. 2. Setting units and control elements

Legend for Fig. 2:

1) Universal shaft adapter

2) Mechanical end limits

3) Declutch button

4) Function selection switch

5) Removable access cover

6) Anti-rotation bracket

Service/Off

Rev

10...0 V

10...2 V

5 Nm

10 Nm

Power-Off Behavior

If power is removed, the shaft adapter remains in position.

Service/Off

If the function selection switch is set to the "Service/Off"

position, then all rotary movement is cancelled, and all control

signals are ignored, thus allowing the actuator to be manually

operated safely.

Floating/2-Position Run Mode

Without Feedback Signal

If, however, the function selection switch has been set to one

of the two floating/2-position control settings – but the

actuator has not been wired for a feedback signal (see Fig. 12

and Fig. 13) – then as soon as operating power is applied, the

shaft adapter will run according to the control signals applied.

With Feedback Signal

If the function selection switch has been set to one of the two

floating/2-position control settings – and if the actuator has

been wired for a feedback signal (see Fig. 12 and Fig. 13) –

then as soon as operating power is applied, the shaft adapter

will likewise run first completely counterclockwise and then

completely clockwise (see also section "Adaption"), after

which it will run according to the control signals applied.

Modulating Run Mode

If the function selection switch has been set to one of the four

modulating control settings – and if the actuator is wired

correspondingly (see Fig. 11) – then as soon as operating

power is applied, the shaft adapter will run first completely

counterclockwise and then completely clockwise (see also

section "Adaption"), after which it will run according to the

control signals applied.

floating/2-position

2...10 V

0...10 V

Dir

Service/Off

Rev

10...0 V

10...2 V

2...10 V

0...10 V

Dir

Service/Off

Rev

10...0 V

10...2 V

Fig. 3. Function selection switch

Service/Off

2...10 V

0...10 V

Service/Off

Rev

10...0 V

10...2 V

Dir

EN0B-0478GE51 R0408

2

Page 3

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

Table 1 describes, for the floating mode, the shaft adapter

behavior ("stops," rotates "CCW," or rotates "CW") in

dependence upon the control signals applied to terminals 3

and 4 and upon the function selection switch setting.

Table 2 describes, for the 2-position mode, the shaft adapter

behavior ("stops," rotates "CCW," or rotates "CW") in

dependence upon the control signals applied to terminals 3

and 4 and upon the function selection switch setting.

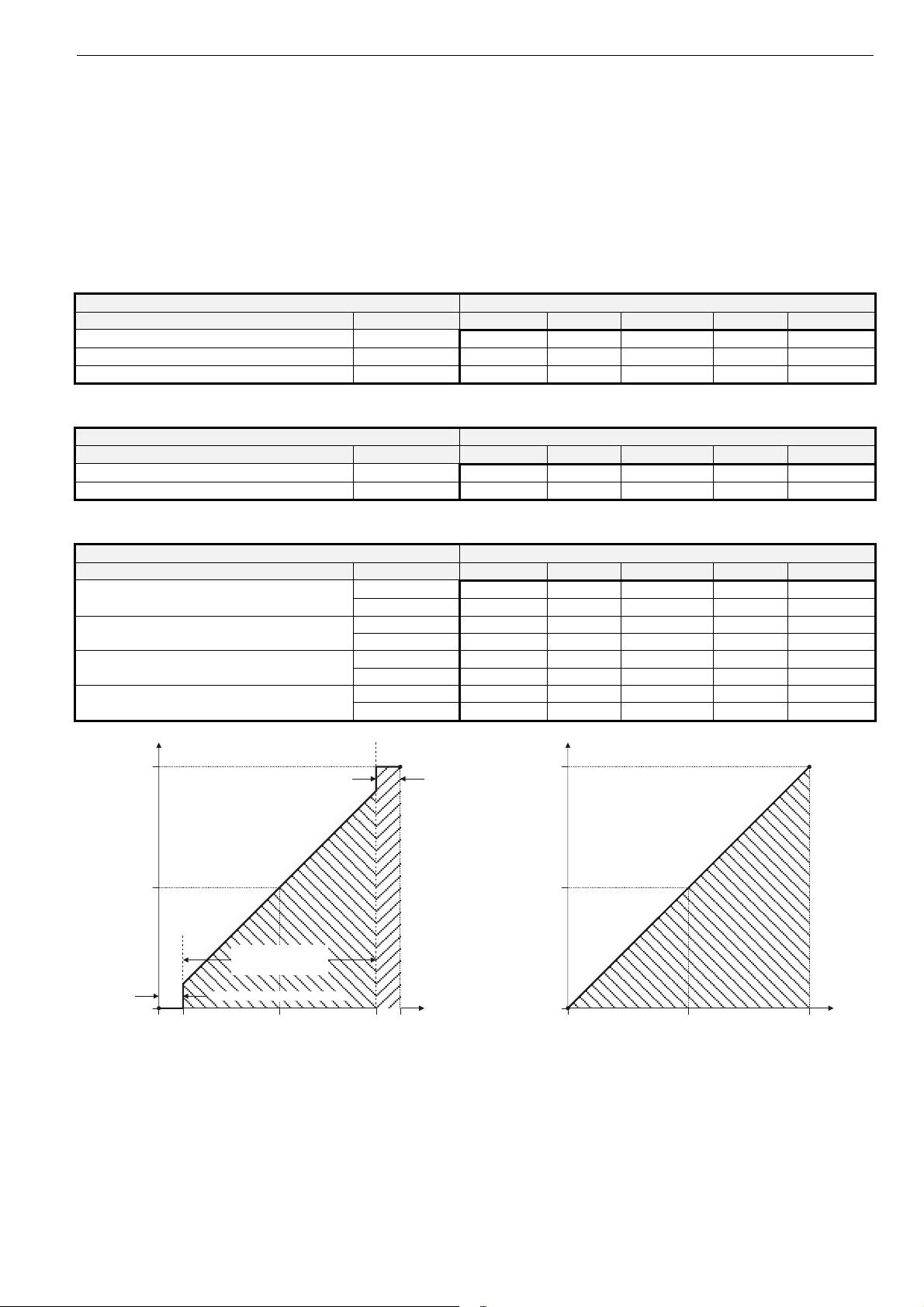

Table 1. Shaft adapter behavior in the floating mode

control signal at switch settings

terminal 3 terminal 4 0[2]...10 V Dir Service / Off Rev 10...0[2] V

open open

open 24 Vac/dc

24 Vac open

Table 2. Shaft adapter behavior in the 2-position mode

control signal at switch settings

terminal 3 terminal 4 0[2]...10 V Dir Service / Off Rev 10...0[2] V

24 Vac open

24 Vac 24 Vac/dc

Table 3. Shaft adapter behavior in the modulating mode

control signal at switch settings

terminal 3 terminal 4 0[2]...10 V Dir Service / Off Rev 10...0[2] V

open

< min. control signal plus 0.24 V

between min. control signal plus 0.24 V

and max. control signal minus 0.24 V

> max. control signal minus 0.24 V

open

24 Vac/dc

open

24 Vac/dc

open

24 Vac/dc

open

24 Vac/dc

Table 3 describes, for the modulating mode, the shaft adapter

behavior ("stops," rotates "totally CCW," rotates "totally CW,"

runs to "proportional" position, or runs to "50%" of max.

stroke) in dependence upon the control signals applied to

terminals 3 and 4 and upon the function selection switch

setting.

-- stops stops stops --

-- CCW stops CW --

-- CW stops CCW --

-- CW stops CCW --

-- CCW stops CW --

totally CCW -- stop -- totally CCW

50% -- stop -- 50%

totally CCW -- stop -- totally CW

50% -- stop -- 50%

proportional -- stop -- proportional

50% -- stop -- 50%

totally CW -- stop -- totally CCW

50% -- stop -- 50%

final position of shaft adapter (% of max. stroke)

100

50

0

upper dead band (9.76 to 10.0 V)

range of proportional

actuator movement

(0.24 to 9.76 V)

lower dead band (0 to 0.24 V)

00.24

control signal (V)

5.0 10.09.76

Fig. 4. Final shaft adapter position in dependence upon

control signal (example function selection switch setting

of 0...10 V)

100

50

0

0

current position of shaft adapter (% of max. stroke)

feedback signal (V)

510

Fig. 5. Feedback signal in dependence upon current

position of shaft adapter (example function selection

switch setting of 0...10 V)

3 EN0B-0478GE51 R0408

Page 4

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

Adaption

Adaption is a function in which the actuator re-maps its feedback signal and control signal in accordance with repositioned

mechanical end limits (see also Fig. 6) and thus recognizes

their new positions.

100

(before)

100

(after)

final position of

0

(after)

0

(before)

a

r

e

t

f

a

actuator (% of max.)

e

or

f

be

010.0

new position of UPPER

mechanical end limit

n

o

i

t

p

a

d

on

i

pt

new position of LOWER

da

a

mechanical end limit

control signal (volts)

95

final position of actuator (degrees)

0

Fig. 6. Adaption (function selection switch set to

"0...10 V")

Adaption will be carried out whenever the actuator is in the

modulating mode or the floating plus feedback mode or the 2position plus feedback mode and

• the user powers up (from a totally powerless condition) the

actuator; or

• the user sets the function selection switch to the

"Service/Off" setting for at least 2 sec and then back to its

previous setting; or

• the control signal's value rises up into the upper dead

band (i.e. to more than the max. control signal minus

0.24 V) or drops down into the lower dead band (i.e. to

less than the min. control signal plus 0.24 V), after which

the shaft adapter must then remain at the respective

(upper or lower) mechanical end limit for at least 3 sec.

However, in this case, the actuator will then recognize the

position of only the respective (upper or lower) mechanical

end limit.

Accuracy

To achieve very exact positioning or synchronicity from

several actuators running in parallel, ensure that the actuator

does one synchronization run per day (i.e. drive the actuator

into the upper dead band, hold for min. 3 sec, then drive the

actuator into the lower dead band, and then hold for min. 3

sec.) See section "Adaption" for exact voltage levels.

Overriding

An override is a condition in which a 24 V signal is applied to

terminal 4 of an actuator in the modulating mode, thus

causing the actuator to ignore the control signal at terminal 3,

whereupon it will instead move to a position of 50% of its

max. stroke (see Table 3).

Feedback

If correspondingly wired (see Fig. 11, Fig. 12, and Fig. 13),

the actuator provides, via terminal 5, a feedback signal proportional to the actual position of the shaft adapter.

MANUAL ADJUSTMENT

IMPORTANT

To prevent equipment damage, you must remove

power or set the function selection switch to the

"Service/Off" position before manual adjustment.

After removing power or setting the function selection switch

to the "Service/Off" position, the gear train can be disengaged

using the declutch button, permitting the shaft adapter to be

manually rotated to any position. If you have wired the

actuator for feedback signal, then, after adaption, the

feedback signal will follow the new position.

Limitation of Rotation Stroke

Two adjustable mechanical end limits are provided to limit the

angle of rotation as desired (see Fig. 7). The mechanical end

limits must be securely fastened in place.

Fig. 7. Mechanical end limits

To ensure tight closing of the dampers, the shaft adapter has

a total rotation stroke of 95°.

After adjusting the mechanical end limits, the user should

trigger adaption (see section "Adaption").

INTERNAL END SWITCHES

NOTE: Only those actuators for which "-SW2" has been

specified when ordering (e.g.: "N05010-SW2")

feature internal end switches.

The internal end switches "A" and "B" are changeover

switches which are activated when the shaft adapter moves

past a position of 5° and 85°, respectively (see also Table 5).

changeover switch A activated

when shaft adapter moves past 5°

-2.5° 92.5°5° 10° 15°0° 90°85°80°75°

Fig. 8. Internal end switch triggering points

changeover switch B activated

when shaft adapter moves past 85°

EN0B-0478GE51 R0408 4

Page 5

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

INSTALLATION

CAUTION

To avoid personal injury (electrical shock) and to

prevent equipment damage, before installation,

you must remove power.

These actuators are designed for single-point mounting.

Mounting Instructions

All information and steps are included in the Installation

Instructions (Product Literature No.: MU1B-0276GE51)

supplied with each actuator.

Mounting Position

The actuators can be mounted in any position (IP54 is

dependent upon orientation; see Fig. 9). Choose a mounting

position permitting easy access to cables and controls.

IP54 IP54IP54 IP54

WIRING

CAUTION

To avoid personal injury (electrical shock) and to

prevent equipment damage, before wiring, you

must remove power.

Connecting to the Power Supply

In order to comply with protection class II, the power source of

24 V actuators must be reliably separated from the network

power supply circuits as per DIN VDE 0106, part 101.

Access Cover

IMPORTANT

Once the access cover has been removed, please

take care to avoid damaging any of the parts now

accessible.

The access cover can be unscrewed and removed in order to

gain access to the terminal block(s) and perform wiring.

Fig. 9. Mounting for IP54

NOTE: Further, in order to guarantee IP54, only original

Honeywell grommets may be used.

Anti-Rotation Bracket and Screws

If the actuator is to be mounted directly on a damper shaft,

use the anti-rotation bracket and screws included in the

delivery package. The min. distance between the center of

the damper shaft and the middle of the anti-rotation bracket is

85 mm; a max. of 108 mm is allowed (see also Fig. 15).

Depending upon the specifics of your mounting site, the

actuator may shift in position slightly while tightening the

screws at the top of the shaft adapter. The anti-rotation

bracket features a T-piece with a 5-mm-long shank to

accommodate for this movement. It is important to ensure

that this play is not impeded.

Universal Shaft Adapter

The universal shaft adapter can be used for shafts of various

diameters and shapes (round: 8...16 mm and square:

6...13 mm).

1

5

4

3

5

2

4

1

3

2

1

1

S

2

S

3

S

5

S

6

S

1

S

2

S

3

S

5

S

6

S

2

removable access cover

Fig. 10. Access cover

5 EN0B-0478GE51 R0408

Page 6

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

A

Wiring Diagrams

Modulating: 0[2]...10V, 10...0[2]V

24V~/=

END SWITCHES

(max. 230 V, 5 A)

24V~/+

1

GND/-

2

0[2]...10V

0[2]...10V

!

Fig. 11. N05010/N10010 (modulating mode)

Floating: Dir

24V~/=

0[2]...10V

!

Fig. 12. N05010/N10010 (floating mode)

= feedback option

Y in

3

POS 50%

4

POS out

5

= override option

24V~/+

1

GND/-

2

CW

3

CCW

4

POS out

5

NOTE: Both of the internal end switches must be connected

Table 4 and Table 5 summarize the information presented in

the preceding wiring diagrams.

minal

1

2

3

4

5

2-Position: Dir

NOTE: All cables connected to these terminals must be

24V~/=

24V~/+

1

GND/-

2

CW

3

CCW

4

0[2]...10V

!

Fig. 13. N05010/N10010 (2-position mode)

= feedback option

5

POS out

terminal type of switch

S2, S3

S5, S6

A,B: C

A: NC

A: NO

B: NC

B: NO

Fig. 14. End switches (Nxx-SW2)

to the same power source.

Table 4. Signals at terminals

modulating floating 2-position

24 V ~/+

(power)

common ~/- common ~/- common ~/-

0[2]...10 V

(control)

24 V ~/+

(override)

0[2]...10 V

(feedback)

equipped with spark suppression.

Table 5. Internal end switches (Nxx-SW2)

S1

common lead for switches A and B

change-over switch A (S1/S2 opens and S1/S3

closes when shaft adapter moves CW past 5°;

reverts to original state when shaft adapter

moves CCW past 5°).

change-over switch B (S1/S5 opens and S1/S6

closes when shaft adapter moves CW past 85°;

reverts to original state when shaft adapter

moves CCW past 85°).

S1

S2

S3

S5

S6

mode ter-

unused or

(with feedback)

24 V ~/+ (power)

24 V ~/+

(control signal)

24 V ~/+

(control signal)

unused or

(with feedback)

0...10 V

(with feedback)

24 V ~/+ (power)

(control signal)

(control signal)

(with feedback)

B

unused or

24 V ~/+

24 V ~/+

unused or

0...10 V

EN0B-0478GE51 R0408

6

Page 7

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

SPARE PARTS

Anti-Rotation Bracket Kit

Order no.: A7211.2073

Contains:

• 10 anti-rotation brackets

• 20 screws

Spare Parts Kit

Order no.: A7211.2071

Contains:

• 1 anti-rotation bracket + screws

• 2 universal terminal blocks

• 2 strain-relief clamps

• 2 grommets*

• 2 adjustable end stops

*In order to guarantee IP54, only original Honeywell

grommets may be used.

7 EN0B-0478GE51 R0408

Page 8

N05010/N10010 DAMPER ACTUATORS FOR MODULATING AND FLOATING/2-POSITION CONTROL

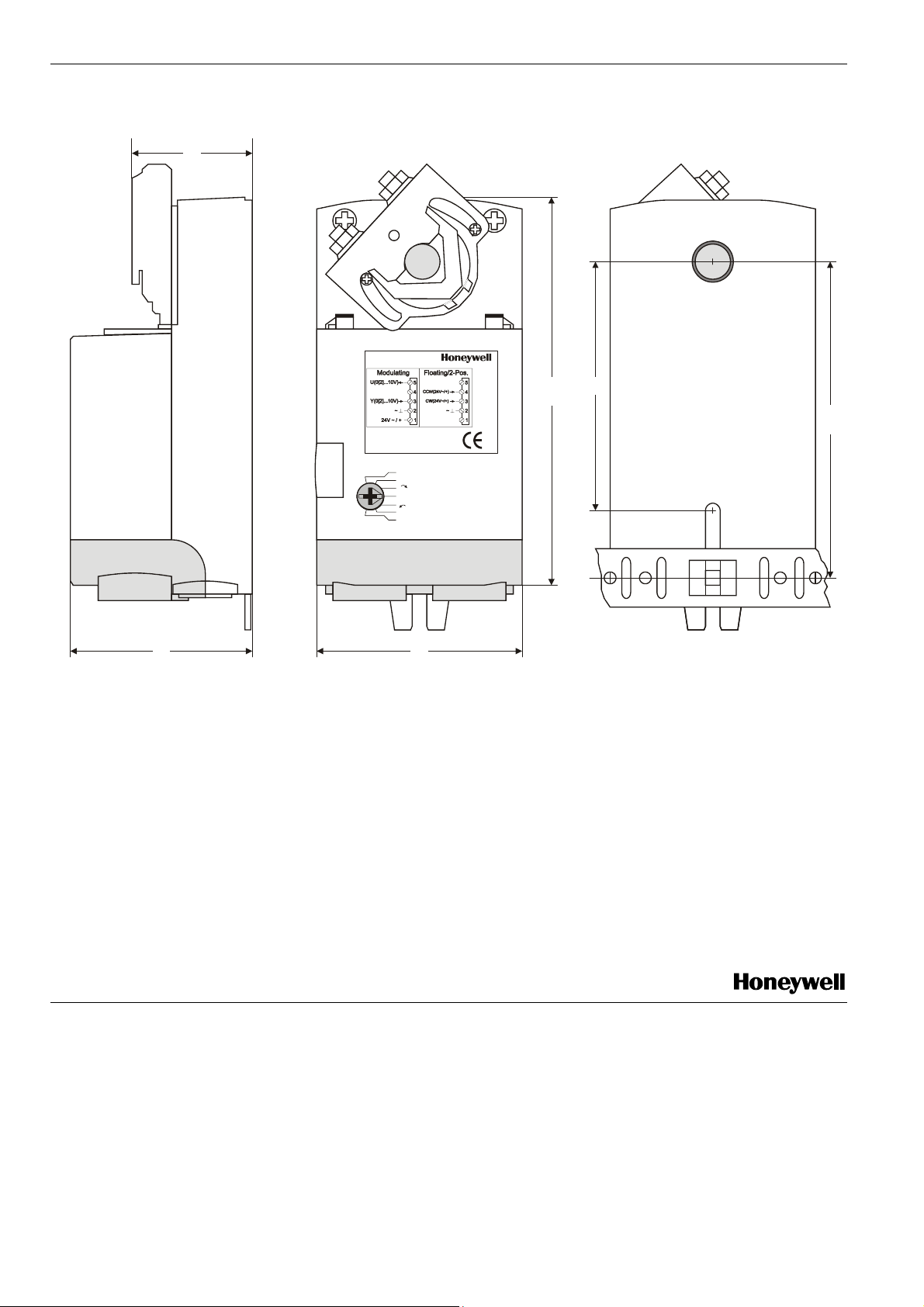

DIMENSIONS

41

N05010

85

134

2...10 V

0...10 V

Dir

Service/Off

Rev

10...0 V

10...2 V

108

6662

Fig. 15. Dimensions (in mm)

Manufactured for and on behalf of the Environmental and Combustion Controls Division of Honeywell Technologies Sàrl, Ecublens, Route du Bois 37, Switzerland by its Authorized Representative:

Automation and Control Solutions

Honeywell GmbH

Böblinger Strasse 17

71101 Schönaich

Germany

Phone: (49) 7031 63701

Fax: (49) 7031 637493

http://ecc.emea.honeywell.com

Subject to change without notice. Printed in Germany

EN0B-0478GE51 R0408

Loading...

Loading...