Page 1

MTA06 / MTA06H

Installation instructions

EB-MTA06 Rev. C

Pressure Reducing Valve Combination

Page 2

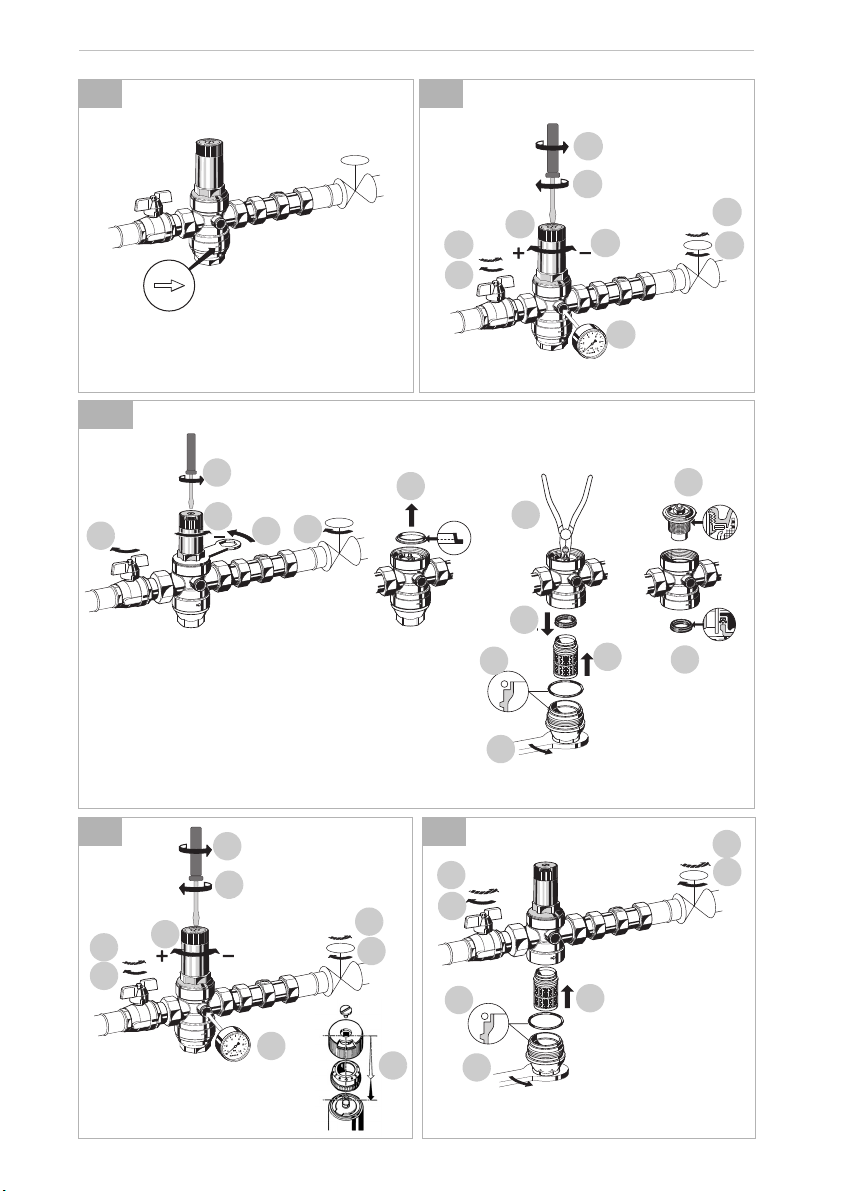

7.2

9.2.1

8.1

9.

5.

8.

7.

1.

6.

4.

10.

3.

1.

9.3

4.

5.

9.

5.

6.

1.

7.

3.

6.

4.

10.

7.

8.

10.

13.

9.

12.

9.4

8.

1.

3.

6.

8.

4.

5.

11.

11.

9.

3.

MU1H-1037GE23 R1208 Honeywell GmbH

Page 3

GB

1. Safety Guidelines

1. Follow the installation instructions.

2. Use the appliance

• according to its intended use

• in good condition

• with due regard to safety and risk of danger.

3. Note that the appliance is exclusively for use in the applications detailed in these installation instructions. Any other

use will not be considered to comply with requirements

and would invalidate the warranty.

4. Please take note that any assembly, commissioning,

servicing and adjustment work may only be carried out by

authorized persons.

5. Immediately rectify any malfunctions which may influence

safety.

2. Functional description

The pressure reducing combination combines a shutoff valve,

a pressure reducing valve and a check valve in one appliance.

Spring loaded pressure reducing valves operate by means of

a force equalising system. The force of a diaphragm operates

against the force of an adjustment spring. If the outlet pressure and therefore diaphragm force fall because water is

drawn, the then greater force of the spring causes the valve

to open. The outlet pressure then increases until the forces

between the diaphragm and the spring are equal again.

The inlet pressure has no influence in either opening or

closing of the valve. Because of this, inlet pressure fluctuation

does not influence the outlet pressure, thus providing inlet

pressure balancing.

Check valves have a moving seal disc which is lifted off the

seat by a greater or lesser amount depending on the flow rate

through the valve. If the flow falls towards zero, then the

spring pushes the disc back onto the seat and seals the

waterway.

3. Application

Medium Water, compressed air* and nitrogen* in

consideration of valid standards (e.g. DIN

EN 12502)

Inlet pressure max. 16 bar (MTA06-B)

max. 25 bar (MTA06-H)

Outlet pressure 1.5-6 bar (preset 3bar) (MTA06-B)

*

As part of an installation being approved according to PED require-

ments, this product must also be certified.

1.5-12 bar (preset 5bar) (MTA06-H)

5. Scope of delivery

The pressure reducing valve combination comprises:

• Housing with pressure gauge connections on both sides

• Shutoff valve on inlet

• Double check valve on outlet

• Valve insert complete with diaphragm and valve seat

• Fine filter with 0.16 mm mesh

• Spring bonnet with adjustment knob and setting scale

(setting scale with MTA06-B only)

•Filter bowl

• Adjustment spring

• Pressure gauge not included (see accessories)

6. Options

MTA06-... B = With threaded connections (inlet male,

outlet female thread)

MTA06-... H = With threaded connections (inlet male,

outlet female thread, brass filter bowl up to

70°C)

7. Assembly

7.1 Installations Guidelines

Ensure that both connections to the PRV are tightened prior

to filling and pressurization

• Install in horizontal pipework with filter bowl downwards.

• The installation location should be protected against frost

and be easily accessible

o Pressure gauge can be read off easily

o Simplified maintenance and cleaning

• For residential applications where maximum protection

against dirt is required, install a fine filter upstream of the

pressure reducing valve

• Provide a straight section of pipework of at least five times

the nominal valve si ze after the pressure reducing valve (in

accordance with DIN 1988, Part 5)

7.2 Assembly instructions

1. Thoroughly flush pipework

2. Install pressure reducing valve combination

o Note flow direction

o Install without tension or bending stresses

4. Technical data

Operating temperature max. 40°C (MTA06-B)

Minimum pressure drop 1 bar

Connection size

Honeywell GmbH 3 MU1H-1037GE23 R1208

max. 70°C (MTA06-H)

(WRAS for cold water use only)

3

/4" and 1"

Page 4

GB

8. Commissioning

8.1 Setting outlet pressure

Set outlet pressure min. 1 bar under inlet pressure.

1. Close shutoff valve on inlet

2. Release pressure on outlet side (e.g. through water tap)

3. Fit manometer

4. Close shutoff valve on outlet

5. Loosen slotted screw

o Do not remove slotted screw

6. Slacken tension in compression spring

o Turn control handle to the left (-) until it does not move

any more

7. Slowly open shutoff valve on inlet

8. Turn adjuster knob until the manometer shows the desired

value.

9. Retighten slotted screw

10.Slowly open shutoff valve on outlet

9. Maintenance

We recommend a planned maintenance contract with

an installation company

In accordance with DIN 1988, part 8, the following measures

must be taken:

9.1 Inspection

9.1.1 Pressure reducing valve

Interval: once a year

1. Close shut off valve on outlet

2. Check back pressure using a pressure meter when there

is zero through-flow

o If the pressure is increasing slowly, the valve may be

dirty or defective. In this instance, carry out servicing and

cleaning

3. Slowly open shutoff valve on outlet

9.1.2 Check valve

Interval: once a year

1. Close shut off valve on outlet

2. Open check valve

o Until the pressure is released, some water will flow out of

the check valve. After a short period of time the water

flow should stop. If the water continues to drip or run,

then the backflow preventer must be replaced - see

servicing of backflow preventer

3. Close check valve again

4. Open shut-off valve again

9.2 Maintenance

9.2.1 Pressure reducing valve

Frequency: every 1-3 years (depending on local

operating conditions)

To be carried out by an installation company

1. Close shutoff valve on inlet

2. Release pressure on outlet side (e.g. through water tap)

3. Close shutoff valve on outlet

4. Loosen slotted screw

o Do not remove slotted screw

Caution !

There is a spring in the spring bonnet. It may cause

injuries if the spring is derailing.

• Make sure tension in compression spring is slakkened!

5. Slacken tension in compression spring

o Turn control handle to the left (-) until it does not move

any more

6. Unscrew spring bonnet

o Use double ring wrench ZR06K

7. Remove slip ring

8. Remove valve insert with a pair of pliers

9. Unscrew filter bowl

o Use double ring wrench ZR06K

10.Remove slotted ring

11.Check that sealing ring, edge of nozzle and slotted ring are

in good condition, and if necessary replace the entire valve

insert

12.Remove filter, clean and reinsert

13.Place O-ring onto filter bowl

14.Reassemble in reverse order

Press in diaphragm with finger before inserting slip ring

Screw in filter cup hand-tight (without tools)

15.Adjust setting scale and set outlet pressure

9.2.2 Check valve

To be carried out by an installation company

1. Close shutoff valve on inlet

2. Release pressure on outlet side (e.g. through water tap)

3. Close shutoff valve on outlet

4. Replace check valve

MU1H-1037GE23 R1208 4 Honeywell GmbH

Page 5

GB

9.3 Adjusting the setting scale (MTA06-B only)

If the adjustment knob is removed, this setting is lost. A new

setting can be achieved using a pressure gauge.

1. Close shutoff valve on inlet

2. Release pressure on outlet side (e.g. through water tap)

3. Close shutoff valve on outlet

4. Fit manometer

5. Loosen slotted screw

o Do not remove slotted screw

6. Slowly open shutoff valve on inlet

7. Set desired outlet pressure (e.g. 4 bar)

8. Align scale (e.g. 4) in middle of viewing window

9. Retighten slotted screw

10.Slowly open shutoff valve on outlet

9.4 Cleaning

Caution !

Do not use any cleaning agents containing solvents

and/or alcohol to clean the plastic parts!

If necessary, the filter bowl and the filter can be cleaned.

To be carried out by an installation company or the

operator.

Detergents must not be allowed to enter the environment or the sewerage system!

1. Close shutoff valve on inlet

2. Release pressure on outlet side (e.g. through water tap)

3. Close shutoff valve on outlet

4. Unscrew filter bowl

o Use double ring wrench ZR06K

5. Remove filter, clean and reinsert

6. Place O-ring onto filter bowl

7. Screw in filter cup hand-tight (without tools)

8. Slowly open shutoff valve on inlet

9. Slowly open shutoff valve on outlet

10. Disposal

The pressure reducing valve comprises:

• Stainless steel

•Steel

• Plastic

Observe the local requirements regarding correct

waste recycling/disposal!

11. Troubleshooting

Problem Cause Remedy

Beating sounds Pressure reducing valve is too

large

Water is escaping from the spring

bonnet

Too little or no water pressure Shutoff valves up- or downstream of the

The outlet pressure set does not

remain constant

Check valve not sealing tightly in the

inlet side

Diaphragm in valve insert is faulty Replace valve insert

pressure reducing valve are not fully open

Pressure reducing valve is not set to the

desired outlet pressure

Filter in pressure reducing valve is contaminated

Pressure reducing valve is not fitted in flow

direction

Filter in pressure reducing valve is contaminated or worn

Valve insert, sealing ring or edge of nozzle

is contaminated or worn

Rising pressure on outlet (e.g. in boiler) Check check valve, safety group etc.

Pressure increases in the inlet side Replace check valve

Sealing surfaces soiled or worn Replace check valve

Call our Technical Customer Services

Open the shutoff valves fully

Set outlet pressure

Clean or replace filter

Fit pressure reducing valve in flow direction

(note direction of arrow on housing)

Clean or replace filter

Replace valve insert

Honeywell GmbH 5 MU1H-1037GE23 R1208

Page 6

GB

12. Spare Parts

Pressure Reducing Valve Combination MTA06-B High Pressure Reducing Valve Combination MTA06-H

1

5

2

4

2

3

No. Description Dimension Part No.

1 Spring bonnet

complete

2 Valve insert

complete

(without filter)

3 Shutoff valve

4 Union seal washer

(10 pcs.)

5 Blanking plug

with O-ring R

(5 pcs.)

6 Replacement filter

insert

7 O-ring set (10 pcs.)

8 Filter bowl with O-

ring

6

7

3

/4" 0901515

1" 0901517

3

/4" D06FA-1/2

1" D06FA-1B

3

/4" 2193100

1" 2193200

3

/4" 0901444

1" 0901445

1

/4"

3

/4" ES06F-1/2A

1" ES06F-1B

3

/4" 0901246

1" 0901499

3

/4" SK06ZH-1/2

1" SK06ZH-1

8

S06K-1/4

1

5

2

4

2

3

6

7

No. Description Dimension Part No.

9 Spring bonnet

complete

10 Valve insert

complete

(without filter) 1" D06FA-1A

11 Shutoff valve

12 Union seal washer

(10 pcs.) 1" 0901445

13 Blanking plug

with O-ring R

(5 pcs.)

14 Replacement filter

insert

15 O-ring

(10 pcs.) 1" 0901247

16 Brass filter bowl with

O-ring 1" SM06T-1A

3

1" 0900228

3

3

1" 2193200

3

1

/4"

3

1" ES06F-1A

3

3

8

/4" 0900227

/4" D06FA-1/2

/4" 2193100

/4" 0901444

S06K-1/4

/4" ES06F-1/2A

/4" 0901246

/4"SM06T-1/2

MU1H-1037GE23 R1208 6 Honeywell GmbH

Page 7

13. Accessories

6

4

8

2

r

ba

0

10

M07M

M07M Pressure gauge

Housing diameter 63 mm, rear connection thread

1

G

/4". Ranges: 0 - 4, 0 - 10, 0 - 16 or 0 - 25 bar.

Please indicate upper value of pressure range

when ordering

ZR06K Double ring wrench

For removal of spring bonnet and filter bowl

GB

ZR06K

Honeywell GmbH 7 MU1H-1037GE23 R1208

Page 8

Automation and Control Solutions

Honeywell GmbH

Hardhofweg

D-74821 Mosbach

Phone: (49) 6261 810

Fax: (49) 6261 81309

http://europe.hbc.honeywell.com

www.honeywell.com

Manufactured for and on behalf of the

Environmental and Combustion Controls Division of

Honeywell Technologies Sàrl, Rolle, Z.A. La Pièce

16, Switzerland by its Authorised Representative Honeywell GmbH

MU1H-1037GE23 R1208

Subject to change

© 2008 Honeywell GmbH

Loading...

Loading...