Page 1

MSXX10, MSXX20 Series

88 AND 175 LB-IN (10 AND 20 NM) SPRING RETURN DIRECT COUPLED

ACTUATORS

PRODUCT DATA

FEATURES

• Brushless DC submotor with electronic stall

protection for floating/modulating models.

• Floating/Modulating models can provide twoposition (SPST) control.

• Brush DC submotor with electronic stall protection

for two-position models.

• Self-centering shaft adapter (shaft coupling) for

wide range of shaft sizes.

• Access cover to facilitate connectivity.

• Metal housing with built-in mechanical end limits.

• Spring return direction field-selectable.

• Shaft position indicator and scale.

• Manual winding capability with locking function.

• UL (cUL) listed.

• All Models are plenum-rated per UL2043.

APPLICATION

MS31XX, MS41XX, MS71XX, MS75XX, MS81XX Spring

Return Direct Coupled Actuators (DCA) are used within

heating, ventilating, and air-conditioning (HVAC) systems.

They can drive a variety of quarter-turn, final control

elements requiring spring return fail-safe operation.

• Models available with 3-foot, 18 AWG color-coded

cable.

• Sylk-enabled models available.

• Features shown in Table 1.

Applications include:

• Volume control dampers, mounted directly to the drive

shaft or remotely (with the use of accessory hardware).

• Quarter-turn rotary valves, such as ball or butterfly

valves mounted directly to the drive shaft.

• Linear stroke globe or cage valves mounted with

linkages to provide linear actuation.

Contents

Application ..................................................................................... 1

Features .......................................................................................... 1

Specifications ............................................................................... 2

Wiring .............................................................................................. 8

Operation ....................................................................................... 15

Checkout ........................................................................................ 16

63-2607-26

Page 2

MSXX10, MSXX20 SERIES

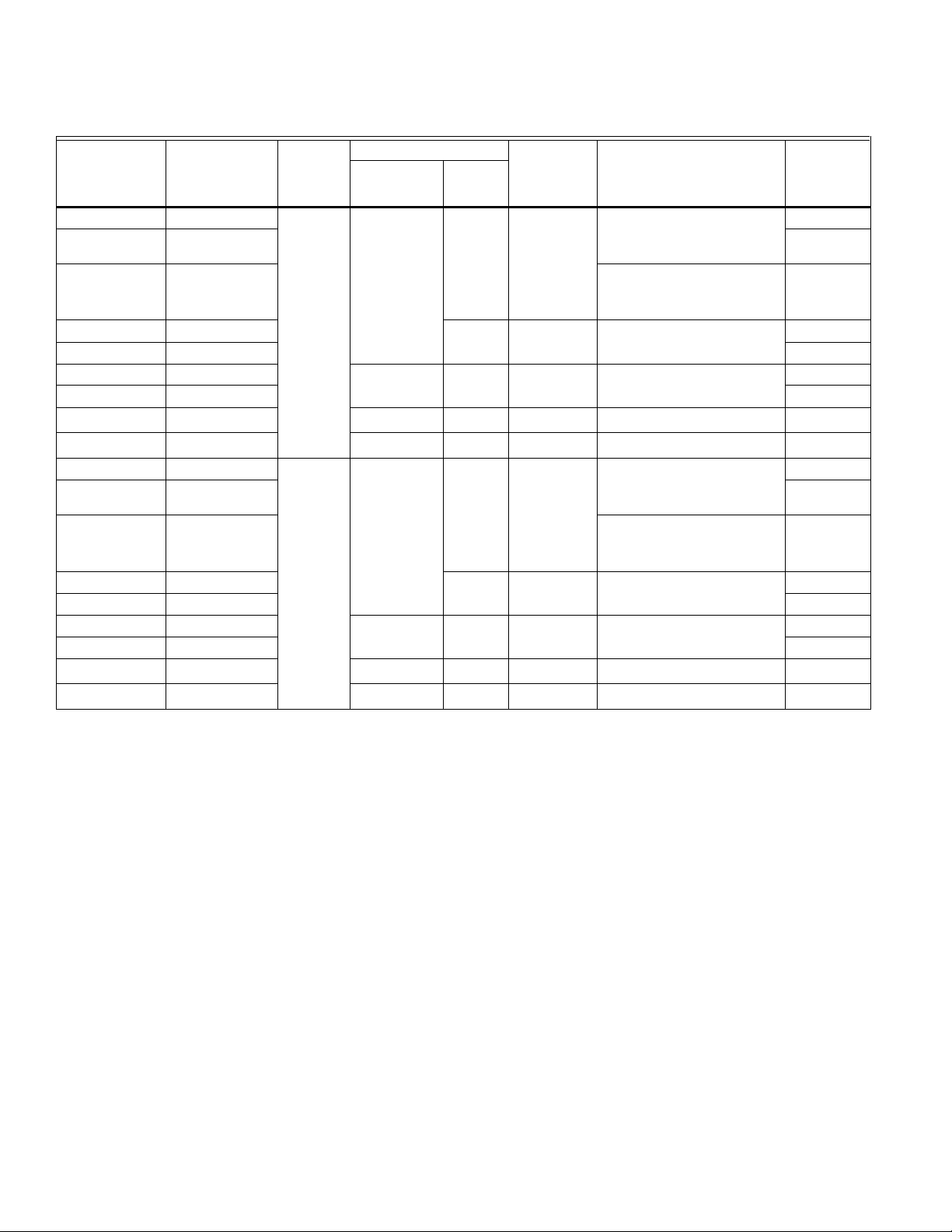

Table 1. Features

Model

Model

Number

Number

(including 3

Tor que

ft. whip)

MS7510A2008 MS7510W2008

MS7510A2206 MS7510W2206 2

MS7510H2209

Power Supply

Voltage

24 Vac/dc

VA

Driving

1

14 90

Drive

2

(sec)

Control Input/Output

Description

Floating, Modulating3,

Two-Position (SPST),

Feedback

Floating, Modulating3,

Feedback, Two-Position

SPDT Aux

Switch

(SPST), Adj. Zero & Span

MS8110A1008 MS8110W1008

MS8110A1206 MS8110W1206 2

MS4110A1002

MS4110A1200 2

MS3110J1008 24 Vac/dc

MS3110J1206 24 Vac/dc

MS7520A2007 MS7520W2007

MS7520A2205 MS7520W2205 2

MS7520H2208

88 lb-in

(10 Nm)

30 45 Two-Position (SPST)

100-250 Vac 45 45 Two-Position (SPST)

14

14

4

4

90 Sylk Enabled 0

90 Sylk Enabled 2

Floating, Modulating

Two-Position (SPST),

16 90

24 Vac/dc

Feedback

Floating, Modulating

Two-Position (SPST),

3

,

3

,

Feedback, Adj. Zero & Span

MS8120A1007 MS8120W1007

MS8120A1205 MS8120W1205 2

MS4120A1001

MS4120A1209 2

MS3120J1007 24 Vac/dc

MS3120J1205 24 Vac/dc

1

Number represents range

2

All spring return actuators have <25 second spring return time

3

0/2-10 Vdc

4

45 second drive has 15 VA for MSxx10 and 22 VA driving for MSxx20

175 lb-in

(20 Nm)

40 45 Two-Position (SPST)

100-250 Vac 60 45 Two-Position (SPST)

16

16

4

4

90 Sylk Enabled 0

90 Sylk Enabled 2

0

2

0

0

0

2

0

0

SPECIFICATIONS

Models: See Tables 2 and 4.

NOTE: This document also covers the MS7110K and

MS7106K.

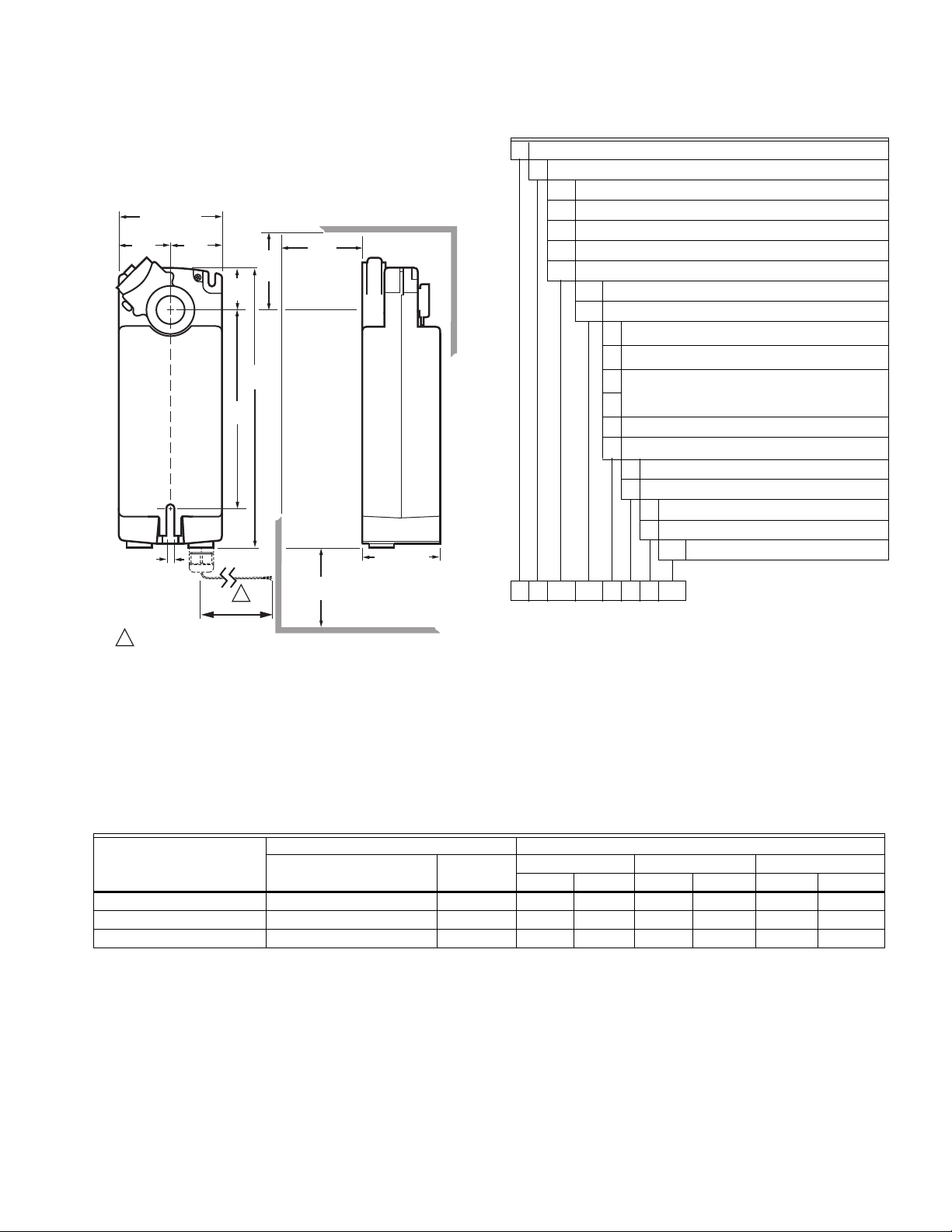

Dimensions: See Fig. 1.

Device Weight: 6 lb (2.7 kg).

Temperature Ratings:

Ambient: -40°F to 140°F (-40°C to 60°C).

Shipping and Storage: -40°F to 158°F (-40°C to 70°C).

Humidity Ratings: 5% to 95% RH noncondensing.

Electrical Connections:

Field wiring 14 to 22 AWG (2.0 to 0.344 mm sq) to screw

terminals, located under the removable access cover.

Electrical Ratings: See Table 3.

63-2607—26 2

End Switches (Two SPDT):

Dry Contact

Settings (fixed): 7° nominal stroke, 85° nominal stroke.

Ratings (maximum load): 250 Vac, 5A resistive.

Mounting: Self-centering shaft adapter (shaft coupling).

Round Damper Shafts: 0.375 to 1.06 in. (10 to 27 mm).

Square Damper Shafts: 1/2 to 3/4 in. (13 to 19 mm).

Actuator can be mounted with shaft in any position.

NOTE: For 175 lb-in. (20 Nm) models: 3/4 in. or greater

shaft diameter recommended.

Minimum Damper Shaft Length: 1 in. (25 mm); 3 in.

(76 mm) recommended.

Cable Specification:

300 V, 75° C, Plenum Rated, 3 ft length from end of access

cover, 18 AWG

Page 3

Timing (At Rated Torque and Voltage):

9-3/4

(247)

1-9/16

(40)

2-1/2

(64)

MIN.

3 (76)

MIN.

3 (76)

MIN.

FROM

SHAFT

END

6-1/8

(156)

1-9/16

(40)

1-9/16

(40)

3-15/16 (100)

2-15/16 (75)

1/4 (6)

M28939

144 (3658)

1

1

CABLE AND STRAIN RELIEF

ON SELECT MODELS ONLY.

Table 2. Model Selection.

a

Model manufactured for sale in the United States.

b

Model manufactured for sale in Europe.

c

Cables available on 75 and 81 Series only.

M Electrical Motor

S Fail Safe Function (Spring Return)

31 24 Vac communicating (Sylk Enabled)

41 120 Vac Two-Position Control; Reversible Mount

71 24 Vac Modulating Control; Reversible Mount

75 24 Vac Modulating and Floating Control; Reversible Mount

81 24 Vac Two-Position Control; Reversible Mount

10 88 lb-in. (10 Nm)

20 175 lb-in. (20 Nm)

A

a

Standard U.S. Model

B

b

Standard European Model

E

b

Selectable control signal; Adjustable zero and span;

Includes service and auto-adapt modes

H

a

J Sylk Enabled

W

c

Standard U.S. Model with Cable

1 No Feedback

2 Voltage Feedback Signal

0 No End Switches

2 Two End Switches

XX System Controlled Numbers

M S 75 20 A 2 0 XX

Drive Open (typical):

Floating, Modulating Models: 90 seconds.

Floating, Modulating Models: 60 seconds.

Two-Position Models: 40 seconds ±10 seconds.

Spring Close: <25 seconds.

MSXX10, MSXX20 SERIES

Fig. 1. Dimensional drawing of actuator in in. (mm).

* Floating/Modulating 60 sec models

Stroke: 95° ±3°, mechanically limited. Approvals: See Table 4.

Floating, Modulating 24 Vac ±20% (Class 2), 24 Vdc 50/60 Hz. 13 5 14 5 16 5

Two-Position, Low-voltage 24 Vac ±20% (Class 2), 24 Vdc 50/60 Hz. 25 8 30 8 40 8

Two-Position, Line-voltage 100-250 Vac 50/60 Hz. 45 13 45 13 60 13

88 lb-in. (10 Nm) 18 VA Driving

175 lb-in. (20 Nm) 22 VA Driving

24 VAC +- 20%

Model(s)

60 second models:

MS7510A2016

MS7510A2214

MS7520A2015

MS7520A2213

Table 3. Electrical Ratings*.

Power Input Power Consumption (VA)

44 lb-in. (5 Nm) 88 lb-in. (10 Nm) 175 lb-in. (20 Nm)

Voltage Frequency

Driving Holding Driving Holding Driving Holding

3 63-2607—26

Page 4

MSXX10, MSXX20 SERIES

TRTDAD×=

N

T

R

TASF×

-------------------=

Design Life (at Rated Voltage):

a

Two-position models: 50,000 full stroke cycles;

50,000 full stroke spring returns.

Floating and Modulating models: 60,000 full stroke cycles;

1,500,000 repositions.

Input Impedance: 95K ohms minimum.

Feedback Signal: 0/2-10 Vdc;

Driving current is 3 mA minimum.

Torque Ratings:

Typical Holding, Driving, Spring Return:

MSXX10: 88 lb-in. (10 Nm).

MSXX20: 175 lb-in. (20 Nm).

Stall Maximum (fully open at 75°F):

MSXX10: 175 lb-in (20 Nm)

MSXX20: 350 lb-in. (39.6 Nm).

Noise Rating at 1m (Maximum):

Holding: 20 dBA (no audible noise).

Two-position models:

Driving: 50 dBA.

Spring Return: 65 dBA.

Floating/Modulating models:

Driving: 40 dBA.

Spring Return: 50 dBA.

Sylk Enabled models:

Driving: < 50 dBA

Spring Return: < 60 dBA

Vibration:

Not suitable for high vibration applications (Example

installation environment: Truck Trailers or Railroad Cars)

Acceptable Vibration Levels 0.6g at 30 to 300 Hz.

Table 4. Approvals.

MS31XX,

MS41XX,

MS75XX,

MS81XX,

MS7110,

MS7106,

UL/cUL X X

UL2043 Plenum Rating,

File No. E4436; Guide No.

XX

XAPX.

Environmental Protection Ratings:

NEMA2 (US Models) or IP54 (European Models) when

mounted on a horizontal shaft with access cover below

the shaft.

Safety:

Protection Class IP54

Overvoltage Category II

a

Floating/Modulating 60 sec models

20,000 full stroke cycles

100,000 repositions

Accessories:

27518 Balljoint (5/16 in.).

103598 Balljoint (1/4 in.).

205860 Electronic Minimum Position Potentiometer.

27520A-E,G,H-L,Q Pushrod (5/16 in. diameter).

32000085-001 Water-tight Cable Gland/Strain-relief Fit-

ting (10 pack).

32003036-001 Weather Enclosure.

32004254-002 Self-Centering Shaft Adapter (supplied

with actuator).

50001194-001 Foot Mount Kit.

50005859-001 NEMA4/4X Enclosure.

50006427-001 Anti-Rotation Bracket (supplied with actu-

ator).

SW2-US Auxiliary Switch Package.

See also Form 63-2620.

Sylk™ Bus:

Sylk is a two-wire, polarity insensitive bus that provides

communications between a Sylk-enabled actuator and a

Sylk-enabled controller. For wiring, the Sylk-enabled

actuator may be mounted up to 200 ft. (61m) from the

controller; twisted pair wire is recommended for wire

runs longer than 100 ft. (30.5m). Using Sylk-enabled

actuators saves I/O on the controller and is faster and

cheaper to install since the bus is polarity insensitive.

Sizing

Required Torque

In lieu of data from a Specification Engineer or

Manufacturer, required torque for a given damper load can

be determined using the following method:

Where:

—T

= Required torque for the damper load.

R

—T

= Damper torque rating from the manufacturer,

D

expressed in either (lb-in.)/(sq ft) or (Nm)/(sq m). the

damper load.

—A

= Damper area expressed in either sq ft or sq m.

D

Actuators Required

In lieu of data from a Specification Engineer or

Manufacturer, the number of required actuators for a given

damper load can be determined using the following

method:

Where:

— N = Number of actuators.

—T

= Required torque for the damper load. (See above.)

R

—T

= Actuator torque rating.

A

— SF = Safety factor.

NOTE: The safety factor accounts for variables such as

misalignments, aging of the damper, etc. 0.8 is a

typical safety factor.

63-2607—26 4

Page 5

INSTALLATION

CAUTION

CAUTION

CAUTION

MSXX10, MSXX20 SERIES

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electrical Shock or Equipment Damage Hazard.

Low voltage can shock individuals or short

equipment circuitry.

Disconnect power supply before installation.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

Location

These actuators are designed to mount directly to a

damper external drive shaft. The shaft coupling fastens to

the drive shaft. The actuator housing includes slots which,

along with an anti-rotation bracket, secure the actuator to

the damper frame or duct work (see Fig. 9).

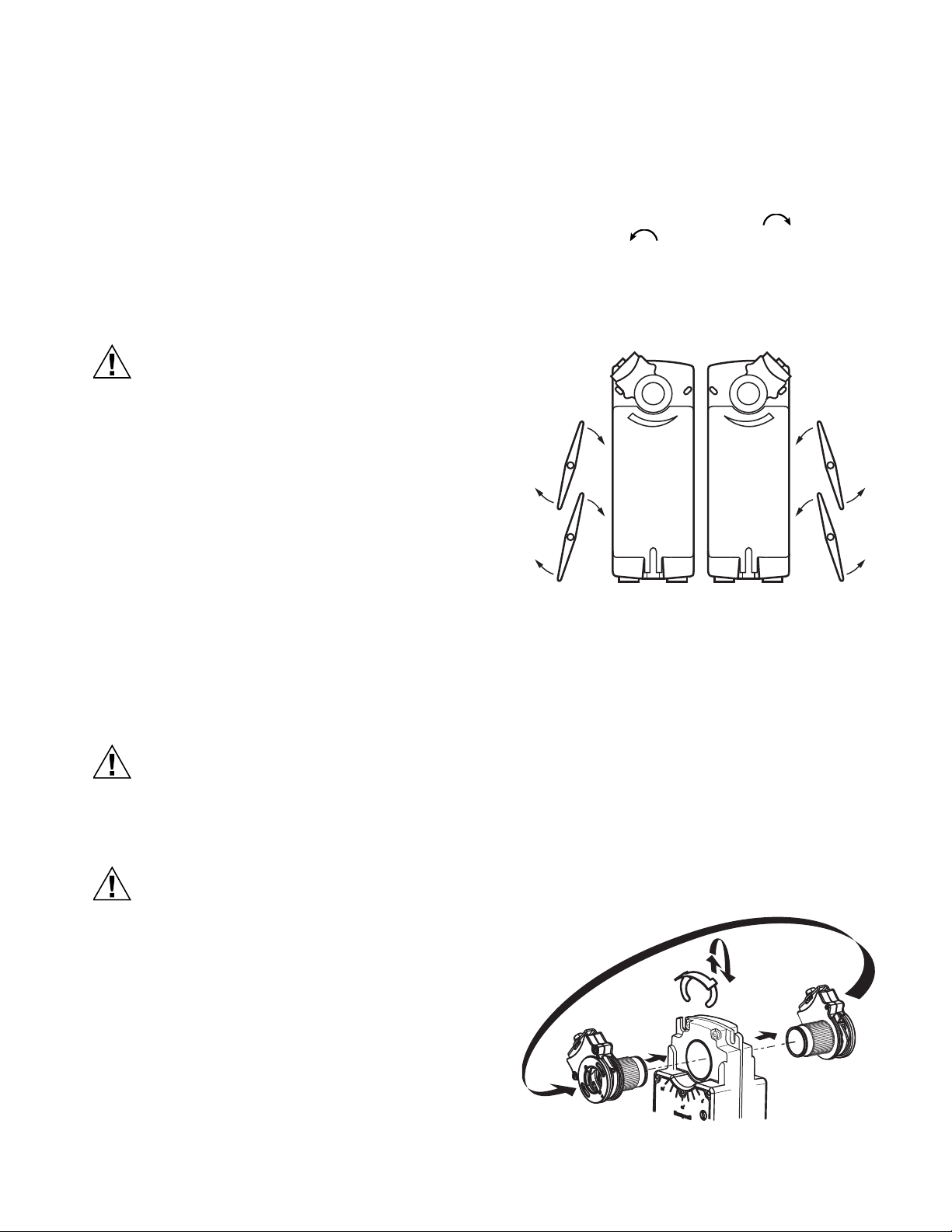

Determine Appropriate Mounting

Orientation

The actuators are designed to open a damper by driving

the damper shaft in either a clockwise or

counterclockwise direction (see Fig. 2).

NOTES:

— Actuators are shipped in the fully closed (spring

return) position.

— An arrow molded into the hub points to tick

marks on the label to indicate the hub rotary

position.

CCW TO CLOSE

(FAIL-SAFE

POSITION)

CW TO OPEN

Fig. 2. Spring Return DCA mounting orientation.

CW TO CLOSE

(FAIL-SAFE

POSITION)

CCW TO OPEN

M20953

NOTES:

— When mounted correctly, these slots allow the

actuator to float without rotating relative to the

damper shaft.

— Using other brackets or linkages, the actuator

can be foot-mounted or tandem-mounted.

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

Equipment Damage Hazard.

Tightly securing actuator to damper housing can

damage actuator.

Mount actuator to allow it to float along its vertical

axis.

Preparation

Before mounting the actuator onto the damper shaft,

determine the:

— Damper/valve opening direction for correct spring

return rotation. The actuator can be mounted to provide

clockwise or counterclockwise spring return.

— Damper shaft size (see the Specifications section).

Measure Damper/Valve Shaft Length

If the shaft is less than three inches in length, the shaft

coupling must be located between the damper/valve and

actuator housing. If the shaft length is more than three

inches, the shaft coupling may be located on either side of

the actuator housing.

If the coupling must be moved from one side of the

actuator to the reverse, follow these instructions (see

Fig. 3):

1. Remove the retainer clip from the shaft coupling and

set it aside for later use.

2. Remove shaft coupling from one side of the actuator.

3. Replace the shaft coupling on the opposite side of

the actuator aligning it based on the stroke labelling.

4. Replace the retainer clip on the shaft coupling using

the groove of the coupling.

M19579

Fig. 3. Mounting shaft coupling to actuator opposite

side.

5 63-2607—26

Page 6

MSXX10, MSXX20 SERIES

32007163-011 Rev. C

Modulating, Forward

Modulating, Reverse

Floating, Forward

Floating, Reverse

Service

Auto Adapt

Start

0V

10V

2V

32V

Span

M20954A

ZERO

LOCKING PIN

SPAN

MODE SELECT

1

1

1

SPAN AND ZERO EXIST ONLY

ON MODELS MS75XXE,H.

M34296A

LOCKING PIN

SYLK ADDRESS

SELECTION

RANGE/DIRECTION

CONTROL SELECTOR

Select Actuator Control Signal

MS41XX, MS71XX, MS75XX, MS81XX

These actuators are available in two control types:

— Standard: includes mode selection dial to select the

desired input signal.

— Enhanced: includes different mode selection dial to

select the desired input signal. Also includes dials for

adjusting the input signal zero and span.

NOTE: Selections are made using a dial that appears on

both the front and back of the actuator (see Fig. 4).

For available options, see Table 5.

To select the control signal simply turn the mode selection

dial to the desired control signal (as indicated on the device

label).

MS31XX

These actuators are available with Sylk address selection

pot and Range/Direct control selector pot. The Range pot

has 3 ranges that cause the actuator to be direct acting

and 3 ranges to cause the actuator to be reverse acting.

NOTE: When Direct range pot called out, a 0 to 100%

command would associate 0% with full spring

return and 100% with position farthest from

spring return. When Reverse range pot called out,

a 0 to 100% command would associate 100%

with full spring return and 0% farthest from spring

return.

There are 15 effective Sylk addresses that you can choose

from. For example, to select Sylk address 11 move the

range pot to Direct control selection and Sylk address pot

to G.

Fig. 4. Dials for control signal and zero/span.

Fig. 5. Dials for control signal.

Table 5. Actuator Control Signal Selections.

Mode Options Standard Enhanced Details

Floating: forward

Floating: reverse

Modulating: 0-10 Vdc

Modulating: 10-0 Vdc

Modulating: 2-10 Vdc

Modulating: 10-2 Vdc

a

X

b

X

c

X

c

X

c

X

c

X

a

X

b

X

Series 60 control. Power to terminal 4 drives toward spring return position.

Series 60 control. Power to terminal 3 drives toward spring return position.

Series 70 control. 0 Vdc signal drives toward spring return position.

Series 70 control. 10 Vdc signal drives toward spring return position.

Series 70 control. 2 Vdc signal drives toward spring return position.

Series 70 control. 10 Vdc signal drives toward spring return position.

Modulating: forward X Voltage input with adjustable zero and span. Minimum signal drives toward

spring return position.

Modulating: reverse X Voltage input with adjustable zero and span. Maximum signal drives toward

spring return position.

Service X Actuator hub stops in place and ignores control signal changes.

Auto-adapt X For setup only. Rescales to allow full input signal over mechanically limited

stroke.

a

Feedback: MS75XXA,H and U.S. S… models are 2-10 Vdc, MS75XXB,E and European S… models are 0-10 Vdc.

b

Feedback: MS75XXA,H and U.S. S… models are 10-2 Vdc, MS75XXB,E and European S… models are 10-0 Vdc.

c

When operating in Modulating mode, the feedback signal matches the control signal.

Non-Standard Stroke

Mechanical Stroke Limit Reduction

For applications requiring a span less than 95 degrees, a

simple adjustment can be made. When the rotational

mounting of the shaft coupling is changed, the actuator

drives less than the full 95 degrees stroke.

The stroke is adjustable in 5 degree increments. Once

adjusted, the actuator drives until the shaft coupling

reaches the mechanical stop (part of the housing). The

stop causes the motor to discontinue driving and the shaft

coupling drives no farther. When the actuator returns, it

stops at the fail-safe position.

63-2607—26 6

Page 7

MSXX10, MSXX20 SERIES

M32268

ROTATING

95

To set the fail-safe position, proceed as follows:

1. Remove the retainer clip from the shaft coupling and

set it aside for later use.

2. Remove shaft coupling from the actuator.

3. Rotate the coupling to the desired fail-safe position,

aligning it based on the stroke labelling. See Fig. 6.

NOTE: The shaft coupling location determines the

travel span.

EXAMPLE:Setting shaft coupling to an approximate

fail-safe position of 35 degrees (as indicated on the housing) limits stroke to 60

degrees. (See Fig. 6)

4. Install the shaft coupling at this position.

5. Replace the retainer clip on the shaft coupling using

the groove of the coupling.

6. If necessary, replace the holder and position indicator

on the shaft coupling.

90

45

D

R

I

S

P

R

I

N

G

R

9

0

S

T

0

E

V

N

R

U

T

E

E

K

O

R

90

45

D

S

R

I

V

P

E

R

I

N

G

R

E

6

T

U

R

0

S

T

R

O

K

E

0

N

M22065

Fig. 6. Stroke reduction.

Auto-Adapt

When using these actuators for standard stroke

applications, this function can be ignored. When it is

desirable to use a mechanically limited stroke (see

Mechanical Stroke Limit Adjustment section), it is possible

to use the Auto-Adapt feature to rescale the input signal

over the new limited stroke.

1. Rotate actuator control signal dial to Auto-Adapt.

NOTE: The actuator will drive open, then closed to

establish the new open and closed positions.

2. Return the actuator control signal dial to the desired

input signal position.

Manual Positioning

The actuator can be operated with no power present. Use

this feature during installation or to move and lock the

damper or valve shaft position when there is no power.

To operate the manual positioning:

1. If the power is on, turn it off.

2. Insert supplied hex wrench (key) as shown in Fig. 7.

3. Rotate key in the direction indicated on the cover.

4. Once the desired position is reached, hold the key to

prevent the spring return from moving the actuator.

5. With the key held in place, use a screwdriver to turn

the gear train lock pin in the indicated direction until

the detent is reached.

NOTE: At the detent, the pin resists further rotation.

6. Remove the key without rotating it further.

Adjustable Zero and Span

(Enhanced Modulating Models only)

These actuators have the capability of adjustable zero and

span. Fig. 4 shows the dials. These dials are present only on

the Enhanced Modulating models. A basic description of

these dials follows:

— Zero: Sets input voltage to define the 0% angle of

rotation. It is factory set to 0 Vdc, and can be adjusted up

to 10 Vdc.

— Span: Adjusts motor response to travel full stroke

through the selected input span. It is factory set to 10

Vdc, and is adjustable from 2 to 32 Vdc.

SET ADJUSTABLE ZERO AND SPAN

1. Apply 24 Vac to the actuator.

2. Turn the zero dial (see Fig. 4) past the desired start

point.

3. Using either a controller or signal generator, apply an

input signal equal to the start point signal.

4. Slowly adjust zero toward the minimum setting until

the actuator hub begins to move.

5. Turn the span dial (see Fig. 4) to the

minimum setting (2 Vdc).

6. Using either a controller or signal generator, apply an

input signal equal to the desired end point signal.

7. Allow the actuator to open fully.

8. Slowly adjust span toward the maximum setting until

the actuator hub moves slightly from fully open.

9. Carefully adjust span knob toward minimum until the

actuator hub returns to fully open.

To release the manual positioning with no power present:

1. Insert supplied key.

2. Turn key 1/4 turn in the direction indicated on the

cover.

3. Remove key without engaging the gear train lock pin.

4. The spring will return actuator to the fail-safe posi-

tion.

NOTE: Once power is restored, the actuator will

return to normal automated control.

Fig. 7. Manual positioning.

7 63-2607—26

Page 8

MSXX10, MSXX20 SERIES

CAUTION

CAUTION

CAUTION

CAUTION

M20956

ENSURE THAT MOUNTING ASSEMBLY PREVENTS ACTUATOR

ROTATION AND ALLOWS ACTUATOR TO FLOAT ALONG

INDICATED AXIS. WHEN TOO TIGHT, THE RESULTING BINDING

CAN DAMAGE THE ACTUATOR OR REDUCE TORQUE OUTPUT.

THE BRACKET CAN BE BENT TO ALLOW MOUNTING THE

ACTUATOR PARALLEL TO THE MOUNTING SURFACE.

1

PART NO. 5006427-001

1

2

2

Mounting

Device Malfunction Hazard.

Improper shaft coupling tightening causes device

malfunction.

Tighten shaft coupling with proper torque to

prevent damper shaft slippage.

Actuator Damage Hazard.

Using actuator as shaft bearing causes device

damage.

Use actuator only to supply rotational torque. Avoid

any side loads to actuator output coupling bearings.

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a

wrench.

Forcibly turning the motor shaft can damage the

gear train.

To mount the actuator to an external drive shaft of a

damper, proceed as follows:

1. Place actuator over damper shaft; and hold mounting

bracket in place. See Fig. 9.

2. Mark screw holes on damper housing.

3. Remove actuator and mounting bracket.

4. Drill or center-punch holes for mounting screws (or

use no.10 self-tapping sheet metal screws).

5. Turn damper blades to desired normal (closed) position.

6. Place actuator and mounting bracket back into position and secure bracket to damper box with sheet

metal screws.

7. Using 10 mm wrench, tighten shaft coupling securely

onto damper shaft using minimum 120 lb-in. (13.6

Nm), maximum 180 lb-in. (20.3 Nm) torque.

NOTE: See Fig. 8 for proper mounting to a square

damper shaft.

Fig. 8. Proper mounting to square damper shaft.

M21007

DAMPER SHAFT

Fig. 9. Mounting actuator to damper housing.

WIRING

Electrical Shock or Equipment Damage Hazard.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than

one disconnect.

IMPORTANT

All wiring must comply with local electrical codes,

ordinances and regulations.

63-2607—26 8

Page 9

Access Cover Removal (Fig. 10)

CAUTION

M20957

Equipment Damage Hazard.

Improper cover removal can damage electric

connections.

Pull the cover along the axis of the actuator.

The cover contains contact sockets that must

connect to actuator contact pins.

Bending these pins can permanently damage the

device.

NOTE: This cover can be removed before or after actuator

mounting.

In order to wire the device, the access cover must be

removed as follows:

1. Remove the screw from the center of the cover, set

the screw aside.

2. Pull the cover along the long axis of the actuator.

3. If the actuator is not yet mounted, set it aside.

4. Remove conduit dust covers as necessary.

5. Thread wire through conduit holes.

6. Connect wires as appropriate to the terminal block(s).

(See Fig. 11 and 12.)

MSXX10, MSXX20 SERIES

NOTE: With US Models, use 1/2 in. NPS strain relief

gland or 1/2 in. conduit adapters. Recommend using flex conduit.

With European Models, use M16 strain relief

gland.

Fig. 10. Removing access cover.

WIRING

See Fig. 11 through 28 for typical wiring details for

actuators without cables (whips). See Fig. 29 through 31

for wiring actuators with cables (whips).

34

5

5

S1 S2

S3 S4

2

1

234

S5

S6

1

M20958

Fig. 11. Terminal block details.

9 63-2607—26

Page 10

MSXX10, MSXX20 SERIES

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

2

V

OR

+

OR

N/A

FEEDBACK

ACTUATOR

1

2

5

4

3

1

7° 85°

S1 S2

S3

S4

S5 S6

2

M33486

ACTUATOR

SPST

24 VAC

1

1

2

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

V

1

2

M35094

3

3

NOTES: AFTER TRANSFORMER SELV–SAFETY EXTRA LOW VOLTAGE FOR

INTERNAL CIRCUIT AND MOTOR.

Fig. 12. Terminal block details.

Terminal Floating Modulating

1 power power power power power Red

2 common common common neutral common Black

3 cw input — — s-bus White

Table 6. Wiring details.

Two-Position

120 Vac

24 Vac

240 Vac Sylk-enabled

Color

a

4 ccw — — — s-bus —

5 feedback feedback — — Brown

a

Only applies to models with wires.

Typical Wiring Without Cables

Fig. 13. Wiring for low-voltage two-position control.

63-2607—26 10

1

1 LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

SPST

1

2

V

2

ACTUATOR

M22289A

Fig. 14. Wiring for line-voltage two-position control.

Page 11

Fig. 15. Wiring for SPDT on/off control.

SPDT

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

M35122

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

ACTUATOR

SPST

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M35123

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

ACTUATOR

SPST

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M35124

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

5

A JUMPER WIRE IS NOT REQUIRED BETWEEN

PIN 1 AND PIN 3 IF SWITCH IS SET TO 10-2 VDC.

5

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M35095

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

NOTES: AFTER TRANSFORMER SELV–SAFETY EXTRA LOW VOLTAGE

FOR INTERNAL CIRCUIT AND MOTOR.

ACTUATOR

4 TO 20 mA

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

490 TO 510

OHMS,

1/2 W

MINIMUM

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M35096

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

NOTES: AFTER TRANSFORMER SELV–SAFETY EXTRA LOW VOLTAGE

FOR INTERNAL CIRCUIT AND MOTOR.

MSXX10, MSXX20 SERIES

1

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

1

2

3

4

24 VAC

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO FLOATING.

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

Fig. 18. Wiring for floating control.

1

2

3

4

5

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M35125

Fig. 16. Wiring for SPST on/off control.

Fig. 17. Wiring for two-wire SPST on/off control.

Fig. 19. Wiring for 0/2-10 Vdc modulating controllers.

Fig. 20. Wiring for 4-20 mA modulating controllers.

11 63-2607—26

Page 12

MSXX10, MSXX20 SERIES

ACTUATOR

CONTROLLER

24 VAC

1

1

2

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

SET SWITCH TO FLOATING.

V

OR +

OR N/A

FEEDBACK

HOT

COM

5

4

3

1

2

M35126

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

2

3

3

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

NOTES: AFTER TRANSFORMER SELV–SAFETY EXTRA LOW VOLTAGE

FOR INTERNAL CIRCUIT AND MOTOR.

Fig. 21. Wiring for high side (triac source) floating

control.

1

CONTROLLER

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

24 VAC

HOT

COM

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT

1

MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

SET SWITCH TO FLOATING.

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

3

3

Fig. 22. Wiring for low side (triac sink) floating control.

63-2607—26 12

1

2

3

4

5

2

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M35127

1

1

CONTROLLER

NOTES: AFTER TRANSFORMER SELV–SAFETY EXTRA LOW VOLTAGE

FOR INTERNAL CIRCUIT AND MOTOR.

24 VAC

HOT

COM

LINE VOLTAGE POWER SUPPLY. PROVIDE DISCONNECT

1

MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

SET SWITCH TO FLOATING.

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

3

24 VAC

ACTUATOR

1

2

3

4

5

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M35128

3

2

Fig. 23. Wiring for low side (triac sink) floating control

using separate transformers.

ACTUATOR

1

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

FEEDBACK

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

1

2

3

4

24 VAC

2

–

+

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS

REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

1

4

2

3

4

5

3

1

2

3

4

5

3

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

ACTUATOR

V

OR +

OR N/A

FEEDBACK

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

M35097

Fig. 24. Wiring for 0/2-10 Vdc modulating controller

operating multiple actuators.

Page 13

Fig. 25. Wiring for Sylk BUS, MS31 series.

S-BUS

LINE VOLTAGE POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

M35129

1

2

1

2

S-BUS

24 VAC

ACTUATOR

1

2

3

4

5

S-BUS

S-BUS

V

S1 S2

S3

S4 S5

S6

85º

7º

NOTES: AFTER TRANSFORMER SELV–SAFETY EXTRA LOW

VOLTAGE FOR INTERNAL CIRCUIT AND MOTOR.

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

4

4

2

LINE VOLTAGE POWER SUPPLY. PROVIDE

DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

LOCATE RESISTOR AT THE LAST ACTUATOR.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M35098

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

500

OHMS

5

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

5

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M35099

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

4

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

MSXX10, MSXX20 SERIES

Fig. 26. Wiring for 4-20 mA modulating controller

operating multiple actuators.

Fig. 27. Wiring for 0/2-10 Vdc modulating controller

operating multiple actuators as master/drone.

13 63-2607—26

Page 14

MSXX10, MSXX20 SERIES

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

M35100

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

ACTUATOR

V

OR +

OR N/A

FEEDBACK

5

4

3

1

2

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

24 VAC

1

24 VAC

1

2

24 VAC

1

HOT

COM

–

+

4

ENSURE PROPER GROUNDING OF ACTUATOR CASE.

NOTES: AFTER TRANSFORMER SELV–SAFETY

EXTRA LOW VOLTAGE FOR INTERNAL

CIRCUIT AND MOTOR.

M28934

ACTUATOR

BLU

BRN

WHT

BLK

RED

5

4

3

1

2

Dir

Service/Off

Rev

2... 10 V

0... 10 V

10... 0 V

10... 2 V

V

OR +

FEEDBACK

POS 50%

M28935

ACTUATOR

BLK

RED

5

4

3

1

2

Dir

Service/Off

Rev

2... 10 V

0... 10 V

10... 0 V

10... 2 V

V

M28936

ACTUATOR

GRY

PPL

YEL

ORG

4

3

1

2

PNK5

TAN6

Fig. 29. MS7510W2008/2206; MS7520W2007/2205

Floating Modulating.

Fig. 28. Wiring for 0/2-10 Vdc modulating controller

operating multiple actuators with separate

transformers.

Typical Wiring With Cables

See Fig. 29 through 31 for wiring actuators with cables

(whips). See Fig. 11 through 28 for typical wiring details for

actuators without cables (whips).

63-2607—26 14

Fig. 30. MS8110W1008/1206; MS81200W1007/1205

Two Position Low.

Fig. 31. Switch only models.

Page 15

OPERATION

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19576A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPDT

ACTUATOR

0/2 TO 10 VDC

PROPORTIONING

CONTROLLER

24 VAC

1

1

2

3

2

LINE VOLTAGE POWER SUPPLY.

PROVIDE DISCONNECT MEANS AND

OVERLOAD PROTECTION AS REQUIRED.

24 VDC SUPPLY ACCEPTABLE.

SET SWITCH TO MODULATING.

V

OR +

OR N/A

FEEDBACK

–

+

FEEDBACK

5

4

3

1

2

M19577A

2-10 VDC

10-2 VDC

0-10 VDC

10-0 VDC

Fltg, fwd

Fltg, rev

3

SPST

M19578

95

SWITCH CONNECTIONS

ACTUATOR POSITION

85

7

3

0

S4S1

S6

S5

S3

S2

CONTACT OPEN

CONTACT MADE

+

-

3

+

-

The actuator is designed to be used in ventilating and air

conditioning installations to operate valves, dampers,

ventilation flaps and louvers requiring torque up to the

rating. (For ratings, see the Specifications section.) If the

power fails, the actuator will spring return to the start

position.

The actuator is operated by a proportional controller. When

using a proportional controller, the actuator drives toward

its fully open position when the input signal increases; the

actuator drives toward the fully closed position when the

input signal decreases. The actuator stops when the input

signal reaches the desired proportional control point.

IMPORTANT

The actuator is designed to respond to DDC

Controller instantaneous contact closures. Take

care not to short cycle the actuator. Unstable

damper control can cause premature actuator failure.

MSXX10, MSXX20 SERIES

Actuator Override

To override the control signal (for freeze protection or

similar applications):

1. Override to full open:

a. Disconnect the input signal (from terminal 3).

b. Apply 24 Vac to terminal 3.

c. See Fig. 32.

2. Override to full closed:

a. Disconnect the input signal (from terminal 3).

b. See Fig. 33.

Fig. 33. Override to full close.

End Switches

Some models include end switches (see Table 2). For wiring

details, see Fig. 12.

SPDT Switches (Fig. 34)

For SPDT end switch wiring, see Fig. 12.

Fig. 32. Override to full open.

Fig. 34. SPDT End Switch Operation.

15 63-2607—26

Page 16

MSXX10, MSXX20 SERIES

CHECKOUT

Modulating/Floating Operation

1. Mount actuator for required application (either

clockwise or counterclockwise rotation to

open the damper).

2. Connect power to terminals 1 and 2. (See Fig. 12 and

Tab le 6 .)

3. Set “Mode Select” dial to desired control signal.

(See Fig. 4 and Table 5.)

4. Apply control signal for actuator 100% position.

(See Fig. 12 and Table 6.)

a. (0)2-10 Vdc: apply 10 Vdc signal to terminal 3.

b. 10-(0)2 Vdc: apply (0)2 Vdc signal to terminal 3.

c. (0)4-20 mA: apply 20 mA signal to terminal 3.

d. 20-(0)4mA: apply (0)4 mA signal to terminal 3.

e. Floating: apply 24 Vac to appropriate CW (3) or

5. Actuator drives to 100% position.

6. Apply control signal for actuator 0% position.

7. Actuator drives to 0% position.

Spring Return Operation

1. Mount actuator for required application (either

2. Connect power to terminals 1 and 2. (See Fig. 12 and

3. Set “Mode Select” dial to desired control signal.

4. Apply control signal for actuator 50% position.

5. Allow the actuator to drive to 50% position.

6. Disconnect wire from terminal 1.

7. Actuator spring returns to 0% position.

8. Re-connect wire to terminal 1, actuator drives

Feedback Operation

1.

2. Apply the same signal as in step 4 of Modulating

CCW (4) terminal.

(See Fig. 12 and Table 6.)

a. (0)2-10 Vdc: apply (0)2 Vdc signal to terminal 3.

b. 10-(0)2 Vdc: apply 10 Vdc signal to terminal 3.

c. (0)4-20 mA: apply (0)4 mA signal to terminal 3.

d. 20-(0)4mA: apply 20 mA signal to terminal 3.

e. Floating: apply 24 Vac to appropriate CW (3) or

CCW (4) terminal.

clockwise or counterclockwise rotation to

open the damper).

Tab le 6 .)

NOTE: For two-position models skip to step 5.

(See Fig. 4 and Table 5.)

(See Fig. 12 and Table 6.)

a. Vdc Input Signal: apply 5-6 Vdc signal to terminal 3.

b. mA Input Signal: apply 10-12 mA signal to termi-

nal 3.

c. Floating: apply 24 Vac to appropriate CW (3) or

CCW (4) terminal.

towards 100% position.

Connect a multi-meter, set for Vdc, to terminals 2 and 5.

Operation.

3.

The multi-meter reading increases to match the input

signal as actuator drives towards 100% position.

4. Apply the same signal as in step 6 of Modulating

Operation.

5. The multi-meter reading decreases to match the

input signal as actuator drives towards 0% position.

Direct Checkout

1. Mount actuator for required application (either

clockwise or counterclockwise rotation to

open the damper).

2.

Check damper position and make sure that 24 Vac is

present at the appropriate connections. (See Fig. 11.)

3. Apply control signal to the appropriate connections

to move the damper to the opposite position. The

actuator should drive the damper.

4. If actuator does not run, verify that the actuator is

properly installed for either clockwise or counterclockwise rotation.

5. If actuator is correctly installed and still does not

run, replace the actuator.

Two-Position Checkout

1. Mount actuator for required application (either

clockwise or counterclockwise rotation to

open the damper).

2. Check damper position and make sure that power is

present at terminals 1 and 2.

3. Actuator drives to 100% position.

4. Disconnect power from terminals 1 and 2.

5. Actuator spring-returns to 0% position.

6. If actuator is correctly installed and does not run,

replace the actuator.

Sylk-enabled (S-BUS) Checkout

1. Mount actuator for required application (either

clockwise or counterclockwise rotation to open the

damper).

2. Connect Sylk-enabled (S-BUS) controller to terminals 3 and 4.

3. Connect power to terminals 1 and 2.

4. Select the proper letters on the A-F and G-L dials to

correspond with the address you wish to use (as

seen in the table next to the dials). Be sure to select

“Direct” or “Reverse” as is needed for your application.

5. Apply S-BUS command via the connected Sylkenabled controller for actuator full open or full

closed position. Local test mode may be selected by

utilizing the “L” field on the G-L dial. Remember to

reset the dials to the appropriate settings for your

address of choice after the test has been completed.

Honeywell Building Technologies

In the U.S.:

Honeywell

715 Peachtree Street NE

Atlanta, GA 30308

customer.honeywell.com

® U.S. Registered Trademark

© 2019 Honeywell International Inc.

63-2607—26 M.S. Rev. 10-19

Printed in United States

Loading...

Loading...