Page 1

Series 61 and Series 62

Modutrol IV™ Motors

FEATURES

• Replaces M644, M944B,E,G,H,J,K,R,S and

• Integral junction box provides NEMA 3 weather

• Integral spring return returns motor to normal position

• Motor and circuitry operate from 24 Vac. Models

• Quick-connect terminals are standard—screw terminal

• Adapter bracket for matching shaft height of older

• Motors have field adjustable stroke (90° to 160°).

• Die-cast aluminum housing.

• Integral auxiliary switches are available factory

APPLICATION

The Series 61 and Series 62 Modutrol IV™ Motors are

three-wire spring return and non-spring return floating control

motors. Use these motors with controllers that provide a

switched spdt or floating output to operate dampers or valves.

The Series 62 motors have an internal electrically isolated

feedback potentiometer that provides indication of the motor

shaft position and can be used for slaving Series 90 Motors or

rebalancing an external control circuit.

• Nominal timing standard of 30 seconds (90° stroke),

• Spring return motors can operate valve linkages from

• All models have dual shafts (slotted and tapped on

• All models have auxiliary switch cams.

• Fixed torque throughout the entire voltage range.

• Motors are designed for either normally open or

• Series 62 models include electrically isolated feedback

• Series 62 TRADELINE models have linear feedback,

PRODUCT DATA

M945B,C,G,K,L,AD Motors.

protection.

when power is interrupted.

available with factory installed transformer, or a field

added internal transformer.

adapter is available.

motors is available.

mounted, or can be field added.

and 60 seconds (160° stroke). Other timings available.

power end or auxiliary end shafts for normally closed

or normally open valve applications.

both ends).

normally closed valves and dampers.

potentiometer that provides shaft position indication.

configurable for slaving Series 90 Motors.

Contents

Application ........................................................................ 1

Features ........................................................................... 1

Specifications ................................................................... 2

Ordering Information ........................................................ 2

Installation ........................................................................ 4

Settings and Adjustments ................................................. 7

Operation .......................................................................... 10

Checkout .......................................................................... 10

Replacement .................................................................... 10

63-2629—2

Page 2

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

SPECIFICATIONS

Models: TRADELINE models are selected and packaged to

provide ease of stocking, ease of handling and maximum

replacement value. TRADELINE model specifications are the

same as those of standard models unless specified otherwise.

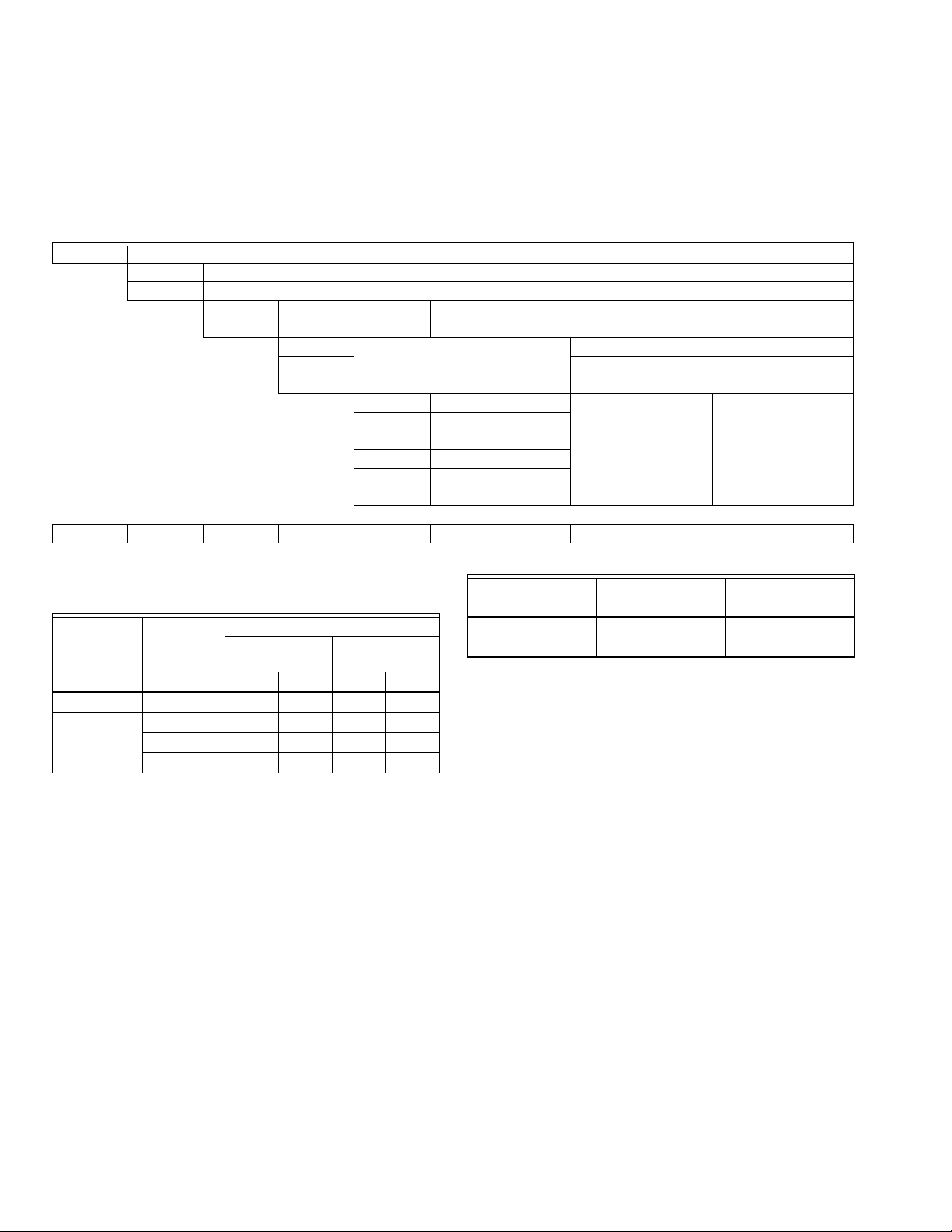

Table 1. Modutrol IV Series 2 Version Order Number Guide.

M Motor

61 Floating Control

62 Floating Control with feedback

8 60 lb-in. Spring Return 150 lb-in. Non-Spring Return

9 — 300 lb-in. Non-Spring Return

2 Dual-ended shaft Normally Closed Spring Return

4 Non-Spring Return

5 Normally Closed Spring Return

A 0 Auxiliary Switches Adjustable Stroke

B 1 Auxiliary Switch

C 2 Auxiliary Switches

D 0 Auxiliary Switch

E 1 Auxiliary Switch

F 2 Auxiliary Switches

M 61 8 4 A XXXX See Catalog for Complete O.S. Number

Electrical Ratings: See Table 2.

Table 2. Series 61 and 62 Modutrol IV Motor

Power Consumption Ratings.

Power Consumption

Non-Spring

Internal

Transformer

No 24 13 6 19 9

Yes 24 1 3 6 19 9

Auxiliary Switch Ratings: See Table 3.

Control Inputs:

Floating three-wire (Series 60): drive open, hold, drive closed.

Series 62 models include an internal, electrically isolated feed-

back potentiometer that provides shaft position

indication.

Voltage at

50/60 Hz

120 13 6 19 9

230 13 6 19 9

Return Spring Return

(VA) (W) (VA) (W)

Modutrol IV Order Number Guide: See Table 1.

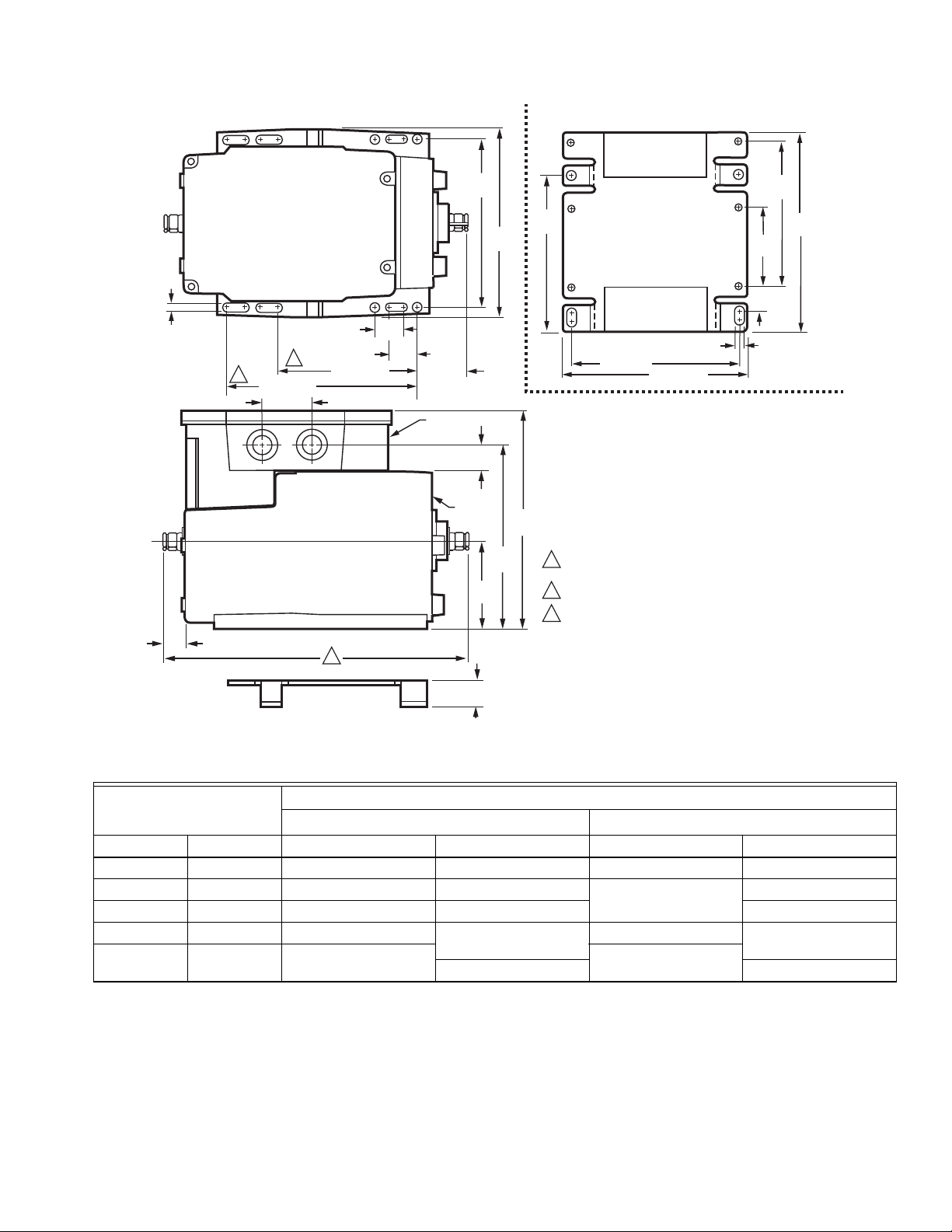

Dimensions: See Fig. 1.

Normally Closed

Table 3. Auxiliary Switch Ratings.

Single Contact

Full Load 7.2 3.6

Locked Rotor 43.2 21.6

a

40 VA pilot duty, 120/240 Vac on opposite contact.

Ambient Temperature Ratings:

Maximum: 150°F (66°C) at 25% duty cycle.

Minimum: -40°F (-40°C).

Dead Weight Load On Shaft:

Power or Auxiliary End: 200 lb (90.8 kg) maximum.

Maximum Combined Load: 300 lb (136 kg).

Crankshaft: 3/8 in. (9.5 mm) square.

Stroke: Adjustable Stroke Models: Available field-adjustable

from 90° to 160°. (See Stroke Setting procedure.)

Timing And Torque: See Table 4.

Rating

a

120V (in Amps) 240V (in Amps)

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Scarborough, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

63-2629—2 2

Page 3

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

M18998B

4-7/8

(124)

5-1/2

(140)

13/16

(20)

4-1/16 (103)

1/4

(7)

1-1/2 (37)

4-1/16 (103)

JUNCTION

BOX

MOTOR

AUXILARY

END

POWER

END

ADAPTER

BRACKET

2-9/16

(66)

5-3/8

(137)

6-7/16

(164)

9/16 (15)

3/4

(19)

TOP VIEW OF BRACKET TOP VIEW

4-5/8

(116)

4-1/4

(107)

2-5/16

(58)

11/16

(17)

4-7/8 (124)

5-9/16 (141)

1/4 (7)

5-13/16

(148)

1

POWER END

2

3

1-1/2 (37)

3/4

(19)

SPRING RETURN MODEL SHOWN

FOR 60 LB-IN. SPRING RETURN MODELS 8-3/4 (222).

FOR NON-SPRING RETUIRN MODELS 7-5/16 (185).

FOR 60 LB-IN. SPRING RETURN MODELS (SHOWN).

FOR NON-SPRING RETURN MODELS.

1

2

3

13/16

(20)

Fig. 1. Series 61 and 62 Modutrol IV Motor mounting dimensions in inches (mm).

Table 4. Series 61 and 62 Modutrol IV Motor Timing and Torque Ratings.

Rated Torque in lb-in. (N•m)

Nominal Timing

90° Stroke 160° Stroke Spring Return Non-Spring Return Spring Return Non-Spring Return

15 30 — 75 (8.5) — 150 (17.0)

30 60 60 (6.8) 35 (4.0) 120 (13.6) 70 (7.9)

60 120 300 (34.0) 600 (68.0)

120 240 —

a

Timings apply to all TRADELINE models. Some OEM models are available with non-standard timing/torque.

b

Torque ratings for dual-ended shaft motors are the sum of the shaft torques (power-end torque plus auxiliary-end torque).

c

Breakaway torque is the maximum torque available to overcome occasional large loads such as a seized damper or valve.

a

in sec

Normal Running Torque Breakaway Torque

150 (17.0) 300 (34.0)

150 (17.0) 300 (34.0)

—

b

NOTE: Torque designation corresponds to torque rating at

standard timing (nominally 60 seconds for 160° and

30 seconds for 90° except for 300 lb-in. motors that

have timings of 2 or 4 minutes).

IMPORTANT

Never use motor continuously at the Breakaway

Torque rating.

Feedback Potentiometer (Series 62 Models Only):

TRADELINE Models (Can be shunted for slaving a

Series 90 Motor).

3 63-2629—2

c

Page 4

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

CAUTION

CAUTION

Approvals:

Underwriters Laboratories Inc. Listed: File No. E4436, Guide

No. XAPX.

Canadian Standards Association Certified: General Listed File

No. LR1620, Guide No. 400-E.

U.S. Patents: pending

Accessories:

220736A Internal Auxiliary Switch Kit; one switch, can be field-

installed.

220736B Internal Auxiliary Switch Kit; two switches, can be

field-installed.

220738A Adapter Bracket raises motor shaft height by 3/4 inch

(19 mm) to match that of previous Modutrol Motor models.

220741A Screw Terminal Adapter converts the standard quick-

connect terminals to screw terminals.

221455A Infinitely Adjustable Crank Arm, can rotate through

downward position and clear motor base without requiring

an adapter bracket.

220738A Adapter Bracket for Modutrol IV Motor to match shaft

height of Modutrol III Motor

4074ERU Weatherproofing Kit provides NEMA 3 rating for

Modutrol IV Motors mounted in position other than upright.

50017460-001 Internal Transformer; 24/120/230 Vac 50/60 Hz

primary, 24 Vac secondary, quick connect terminals.

50017460-003 Internal Transformer; 120 Vac 50/60 Hz

primary, 24 Vac secondary, quick connect terminals.

7617ADW Crank Arm, can rotate through downward position

and clear motor base without requiring an adapter bracket.

Q100 Linkage connects Modutrol Motor to V51 Butterfly Valve.

Requires the 220738A Adapter Bracket.

Q181 Auxiliary Potentiometer for sequence or unison control of

1 to 4 additional modulating (Series 90) motors.

Q5001 Bracket and Linkage Assembly connects Modutrol IV

Motor to water or steam valve.

Q605 Damper Linkage connects motor to damper. Includes

motor crank arm.

Q607 External Auxiliary Switch controls auxiliary equipment as

a function of motor position.

ES650-117 Explosion-Proof Housing encloses motor for use in

explosive atmospheres. Not for use with Q5001 (or any

other valve linkages). Order separately from Nelson Enclosures. To order, contact: Nelson Enclosures and Controls,

(281) 449-6271; or write to:

Nelson Enclosures and Controls

P.O. Box 471650

Tulsa, OK 74147-1650

Requires Honeywell 7617DM Coupling.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow them

could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear train

and stroke limit contacts.

IMPORTANT

Always conduct a thorough checkout when

installation is complete.

Location

Allow enough clearance for accessory installation and motor

servicing when selecting a location (see Fig. 1). If located

outdoors, use liquid-tight conduit connectors with the junction

box to provide NEMA 3 weather protection. If mounted

outdoors in a position other than upright, install a 4074ERU

Weatherproofing Kit and liquid-tight connectors to provide

NEMA 3 protection.

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

In excessive salt environments, mounting base and screws

should be zinc or cadmium plated, not stainless steel or brass.

Use the 220738A Adapter Bracket for mounting on these

surfaces.

Mounting

Use the following guidelines for proper motor mounting:

• Always install motors with the crankshaft horizontal.

• Mounting flanges extending from motor housing base are

drilled for 1/4 inch (6.4 mm) machine screws or bolts.

• Non-Spring Return Motors are shipped from the factory in

the closed position (at the limit of counterclockwise rotation,

as viewed from the power end of the motor).

• Spring Return Motors are shipped from the factory in their

normal position.

• Normally closed models are shipped at the limit of

counterclockwise rotation, as viewed from the power end of

the motor.

NOTE: Refer to Fig. 2 for graphical representation of

fully-open and fully-closed positions.

63-2629—2 4

Page 5

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

M18999

EQUIPMENT

BASE

ADAPTER BRACKET

STANDARD

BOLTS (4)

MOTOR

BOLTS

PROVIDED (4)

WIRING

BOX

NON-SPRING RETURN

SPRING RETURN

1 #12 OR 1/4" ZINC PLATED

MACHINE SCREWS OR BOLTS

1

POWER

END

POWER END

POWER END

VERTICAL

REFERENCE

10

90 DEGREE STROKE

35, 60, AND 75 lb-in. TORQUE

VERTICAL

REFERENCE

90 DEGREE STROKE

150 AND 300 lb-in. TORQUE

FULLY

CLOSED

45

90

FULLY

OPEN

FULLY

CLOSED

90

FULLY

OPEN

VERTICAL

REFERENCE

10

160 DEGREE STROKE

FULLY

CLOSED

FULLY

OPEN

M17090A

160

Adapter Bracket

The 220738A Adapter Bracket, positioned between the motor

and the equipment, raises motor shaft height by 0.75 in.

(19 mm) to match that of previous Modutrol Motor models.

The following applications require this bracket:

• Q607 External Auxiliary Switch.

• Damper linkage applications require added clearance to

allow:

— Crank arm rotation through the downward position.

— Sufficient damper linkage to reach the motor shaft.

• All valve linkages except the Q5001.

NOTE: When the bracket is not used in a replacement

application, the damper linkage requires adjustment

for the new shaft position.

To mount the motor with the bracket:

1. Mount the bracket to the equipment with existing or standard bolts.

2. Using the provided bolts, mount the motor to the bracket

threaded holes. See Fig. 3.

For valve linkage applications (other than the Q5001):

1. Mount the bracket to the linkage.

2. Position the motor on the bracket to align the motor shaft

with the linkage.

3. Attach the motor to the bracket with the four bolts

provided. See Fig. 4.

Fig. 2. Motor shaft positions at stroke limits

(viewed from power end of motor).

Fig. 3. Mounting the motor with an adapter bracket.

5 63-2629—2

Page 6

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

CAUTION

JUNCTION BOX

Q5001

VALV E

LINKAGE

POWER

END OF

MOTOR

VALV E

MOTOR

1/4-20 UNC

1 in. LONG

MOUNTING

BOLTS

M18994

Fig. 4. Mounting the motor on a Q5001 Valve Linkage.

Damper Linkages

The motor does not include a crank arm. Order the crank arm

separately (see Accessories in the Specifications section). For

detailed instructions on the assembly of specific linkages, refer

to the Installation Instructions packed with the linkage.

Wiring

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

Disconnect all power supplies before installation.

Motors with auxiliary switches can have more than one

disconnect.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

1. Ensure that the voltage and frequency stamped on the

motor correspond with the power supply characteristics.

2. When connecting several motors in parallel, ensure that

the power supply VA rating is large enough to provide

power to all motors used without overloading.

3. Fig. 5 shows that motor terminals are quick-connects

located on top of the printed circuit board.

4. To access the wiring compartment:

a. Remove the four screws from the junction box top.

b. Lift off the cover.

5. Refer to Fig. 6 for typical wiring, and Fig. 9 for internal

auxiliary switch connections.

NOTE: Reverse motor rotation by switching wires at either

the motor or panel. Reverse rotation on Series 61

models by reversing wires at terminals W and B.

Reverse rotation on Series 62 models by reversing

wires at terminals 1 and 2 (to correct motor rotation)

and reverse wires at terminals Y and G (to maintain a

feedback signal that corresponds with shaft rotation),

Equipment Damage Hazard. Stalling a motor can

damage the drive shaft.

Ensure installation of motors and linkages allows the

motor to drive through full stroke without obstruction.

Valve Linkages

The Q100 Linkage requires a 220738A Adapter Bracket for all

valve applications. Applications with the Q5001 Valve Linkage

do not require the 220738A Adapter Bracket (see Fig. 4).

Junction Box

When used with liquid-tight conduit connectors, the junction

box provides NEMA 3 weather protection for the motor. The

junction box, standard with replacement motors, encloses the

terminals and provides knockouts for wiring conduits. Housing

an internal transformer or internal auxiliary switches requires

using a junction box.

SENSITIVITY POTENTIOMETER

(ON SOME SERIES 62 MODELS, SEE TABLE 5)

Y

1

G

T

2

1

R

4

3

ADJUSTABLE STROKE

POTENTIOMETER

SERIES 62 TERMINAL DESIGNATIONS SHOWN.

1

NOTE: NOT ALL FEATURES AVAILABLE ON ALL MODELS.

Fig. 5. Terminals and adjustments.

INNER AUXILIARY

SWITCH

INNER AUXILIARY

SWITCH CAM (BLUE)

POWER

END

OUTER AUXILIARY

SWITCH CAM (RED)

OUTER AUXILIARY

SWITCH

M13600B

63-2629—2 6

Page 7

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

R

B

W

R

1

2

T

G

Y

4

3

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

TRANSFORMER MAY BE INTERNAL OR EXTERNAL

TO MOTOR.

FEEDBACK POTENTIOMETER.

M17096

SERIES 60

CONTROLLER

SERIES 62

MOTOR

1

2

3

1

2

3

W

R

B

G

Y

T

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

CONNECTION REQUIRED ONLY FOR SPRING RETURN MOTORS.

M17098

SERIES 90

CONTROLLER

R927C OR R9107A RELAY

160 STROKE SERIES 62 MOTOR

Q181A

2

1

T

1

2

2

L1

(HOT)

L2

1

R

W

Y

T

G

2

B

R

W

B

1

4

3

SERIES 60

CONTROLLER

R

B

W

1

L1

(HOT)

L2

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

2

TRANSFORMER MAY BE INTERNAL OR EXTERNAL

TO MOTOR.

2

SERIES 61

MOTOR

R

W

B

Fig. 6. Series 61 motor wiring.

T2

T1

M17095A

NOTE: Vibration does not affect Modutrol IV Motor

performance (as it did in earlier Modutrol Motors).

When replacing a motor that was connected to an

R927C or R9107A Relay, Honeywell recommends

performing a retrofit to remove the relay and the old

motor. Replace both with one Series 90 Modutrol IV

motor (that is, do not replace the relay).

2

2

BLUE LEAD

RED LEAD

USE NEC CLASS 1 WIRING UNLESS POWER SUPPLY

1

MEETS CLASS 2 REQUIREMENTS. TAPE UNUSED LEADS.

ENSURE THE CURRENT DRAW OF THE EXTERNAL CIRCUIT

IS LESS THAN SWITCH CONTACT RATING.

2

ON TWO-SWITCH MOTORS, SECOND SWITCH HAS BLACK

LEADS WITH BLUE, YELLOW, AND RED TRACERS.

3

SOME AUXILIARY SWITCH ASSEMBLIES INCLUDE ONLY

RED AND YELLOW LEADS. SOME OTHERS DO NOT INCLUDE

THE YELLOW LEAD.

YELLOW LEAD

1

1

2

3

M17099

Fig. 9. Auxiliary switch schematic.

Fig. 7. Series 62 motor wiring.

Fig. 8. Connections to R927C or R9107A Relay.

SETTINGS AND ADJUSTMENTS

Before Setting Stroke

1. Remove the top cover from the motor.

2. Disconnect the controller from the motor.

3. For models with an internal transformer (line voltage

motors), ensure that power (and nothing else) remains

connected to the motor.

IMPORTANT

Detach linkage from motor before adjusting stroke.

Adjustable Stroke

Series 61 Adjustable Stroke

When viewing from the power end of the motor, the stroke

potentiometer is to the far left. To set the stroke to 160°

(maximum position) turn the potentiometer fully clockwise

, using a 1/8 in. straight-blade screwdriver. To set the

stroke at 90° (minimum position) turn the potentiometer fully

counter-clockwise . Setting the potentiometer anywhere

between fully clockwise and fully counter-clockwise will set the

stroke between 160° and 90°.

Series 62 Adjustable Stroke

When viewing from the power end of the motor, the stroke

potentiometer is to the far left. The sensitivity potentiometer is

to the far right. To set the stroke to 160° (maximum position)

turn both potentiometers fully clockwise , using a 1/8

inch straight-blade screwdriver. To set the stroke at 90°

(minimum position) turn both potentiometers fully counter-

clockwise . Setting the potentiometer anywhere between

fully clockwise and fully counter-clockwise will set the stroke

between 160° and 90°.

7 63-2629—2

Page 8

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

CAUTION

CAUTION

3

4

R

1

2

G

Y

M652

Careless Installation Hazard.

Use of excessive force while adjusting cams

damages the motor.

To avoid damaging motor end switches, set cams by

moving only the screwdriver top.

ADJUSTABLE

STROKE

POTENTIOMETER

SENSITIVITY

POTENTIOMETER

(ON SOME SERIES 62

MODELS, SEE TABLE 5)

Equipment Damage Hazard.

Can damage the motor beyond repair.

Never turn the motor shaft by hand or with a wrench.

Forcibly turning the motor shaft damages the gear train

POWER END

OF MOTOR

AUXILIARY

SWITCH CAMS

M13601

and stroke limit contacts.

Fig. 10. Stroke adjustments setup.

Feedback Potentiometer Configuration (Series 62 TRADELINE® Motors Only)

Table 5. Series 62 Feedback Characteristics

Feedback

OS Number

M6284D1000, D1026, D4004, F1070,

Resistance

600 Ohms No Yes No 187 Ohm

M6285A1005, A1054, A4009

M6284F1070 10 K Ohms No No Yes Not Available

M6284A1071, A1089, C1028 196/346 Ohms Yes Yes No 274 Ohm

M6284A1030, A1055, A1097, B1004,

119/224 Ohms Yes Yes No Not Necessary

C1010, C1044, F1013, F1039,

M6285A1039, A1047, C1001,

M6294B1036, D1008

M6284F1062 1800 Ohms No Yes No Not Available

Select and install a shunt resistors to obtain the appropriate

feedback characteristic for your application. See the

Specifications section for details on feedback resistance

without a shunt resistor.

• Linear feedback provides linear indication of shaft position

with no shunt resistor.

• Slaving a Series 90 Motor requires full-stroke feedback

resistance of 142 ohms. Select and attach the proper shunt

resistor across terminals Y and G (see Table 5 and Fig. 11).

Sensitivity

Adjustment Internal Shunted

Linear

Feedback

Series 90 Slaving

Shunt Resistor

Auxiliary Switches

Adjustable cams actuate the auxiliary switches. These cams

can be set to actuate the switches at any angle within the

motor stroke. Select switch differential of 1° or 10°.

Motors with factory-added auxiliary switches are shipped in the

closed position (fully counterclockwise, as viewed from the

power end). Auxiliary cam default actuates the switches 30°

from fully open with a 1° differential. With the motor in the

closed (fully counterclockwise) position, the auxiliary switch

breaks contacts R-B. See Fig. 9 (or the auxiliary switch

Installation Instructions) for auxiliary switch wiring.

Fig. 11. Attaching a shunt resistor to TRADELINE motors.

63-2629—2 8

NOTE: Series 2 Motors are shipped with auxiliary switch

cams that permit acceptance of 220736A,B Internal

Auxiliary Switch Kits. Refer to Form no. 63-2228 for

220736A,B Installation Instructions.

Page 9

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

RIGHT/INNER

AUXILIARY

SWITCH

FAST RISE

PORTION

(APPROX.

1 DIFF.)

SLOW RISE

PORTION

(APPROX.

10 DIFF.)

INNER

AUXILIARY

CAM

(BLUE)

NOTE: CAMS ARE OFFSET VERTICALLY TO

PROVIDE BETTER VIEW OF BACK CAM.

FAST RISE

PORTION

(APPROX.

1 DIFF.)

SLOW RISE

PORTION

(APPROX.

10 DIFF.)

MOTOR

OPEN

MOTOR

CLOSE

POWER

END

OUTER

AUXILIARY

CAM

(RED)

LEFT/OUTER

AUXILIARY

SWITCH

M13700

POWER END

OF MOTOR

OUTER AUXILIARY

CAM (RED)

INNER AUXILIARY

CAM (BLUE)

RIGHT/INNER

AUXILIARY SWITCH

LEFT/OUTER

AUXILIARY

SWITCH

MOVE SCREWDRIVER AT

TOP ONLY TO ADJUST CAM.

1/8 INCH

STRAIGHT-BLADE

SCREWDRIVER

Auxiliary Switch Adjustment

IMPORTANT

When adjusting the auxiliary switch cams use the

following procedure:

1.Insert 1/8 in. screwdriver blade into a slot on cam

and move the screwdriver top as far as possible in

the required direction. See Fig. 12.

2.Repeat step 1 in successive cam slots until the cam

is in the required position.

Use the following procedure to obtain the desired auxiliary

switch settings:

1. Remove the top cover from the motor to gain access to

the motor terminals and auxiliary cams.

2. Disconnect the controller from the motor.

3. Drive the motor to the position where the auxiliary equip-

ment is to be switched as follows:

a. For Non-Spring Return models without a transformer,

connect 24 Vac to terminals 2 and 3 to drive motor

open (clockwise as viewed from the power end), or to

terminals 1 and 3 to drive motor closed

(counterclockwise).

b. For Non-Spring Return models with a transformer,

jumper across terminals R and 2 to drive motor open

(clockwise as viewed from the power end), or across

terminals R and 1 to drive motor closed (counterclockwise).

c. For Spring Return models, connect a jumper across

terminals 2 and 4 to drive the motor open, or across

terminals 1 and 4 to drive the motor closed.

4. Once motor reaches correct position, disconnect the

jumper.

5. For a switch differential of 1°, check continuity of auxiliary

switch contacts R-B and rotate the cam as follows:

a. If the contacts are open, rotate the cam clockwise

until the R-B contacts close.

b. If the contacts are closed, rotate the cam

counterclockwise until the R-B contacts open.

6. For a switch differential of 10°:

a. For Spring Return models, rotate the cam

approximately 180° so the slow-rise portion of the

cam actuates the switch. Then check continuity of

the auxiliary switch contacts R-B.

b. For Non-Spring Return models, check continuity of

the auxiliary switch contacts R-B.

7. Rotate the cam as follows:

a. If the contacts are open, rotate the cam

counterclockwise until the R-B contacts close.

b. If the contacts are closed, rotate the cam clockwise

until the R-B contacts open.

8. Check for the proper differential and switching of the

auxiliary equipment by driving the motor though the full

stroke in both directions.

9. Disconnect the jumper, reconnect the controller, and

replace the top cover on the motor.

NOTE: Changing the differential from 1° to 10° reverses the

switching action. For example, with a 10° differential,

switch contacts R-B make and R-W break on a

counterclockwise (closed) rotation. With a 1°

differential, switch contacts R-W make and R-B break

on a counterclockwise (closed) rotation.

Fig. 12. Auxiliary switch adjustment.

9 63-2629—2

Page 10

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

OPERATION

Use Series 61 and 62 Modutrol IV Motors for standard Series

60 operation (drive open, hold, drive closed). Series 62 motors

can also be used with the feedback potentiometer as an input

to the controller.

See Table 6 for details on motor response to controller signals.

NOTE: Reverse the wires at either the motor or controller.

To reverse the rotation direction of a non-spring return motor:

• Reverse the wires at terminals W and B.

Table 6. Modutrol IV Motor Operation.

Terminal Connection

Motor Type

Non-Spring Return

or Spring Return

Non-Spring Return None None stops (none)

Spring Return - None spring return

R-W 4-1 ccw (closed)

R-B 4-2 cw (open)

Resulting

ActionSeries 61 Series 62

(closed)

CHECKOUT

After the installation and linkage adjustment, check the entire

motor and control hookup. Proper checkout ensures that:

• The motor operates the load (damper or valve) properly.

• The motor responds properly to the controller as the input

varies. See Table 6.

• The auxiliary switch, if used, operates at the desired point of

motor rotation.

1. Inspect motor, linkage, and valve or damper to ensure all

mechanical connections are correct and secure.

REPLACEMENT

Damper Application

1. Turn off power and remove wiring from the old motor.

2. Remove the crank arm from the shaft of the old motor

and remove the old motor.

3. Determine mounting bracket necessity. If the linkage can

reach the new motor shaft position and the crank arm

has clearance for the necessary rotation, the bracket is

not required. Use the 220738A Adapter Bracket or the

221455A Crank Arm if the crank arm must rotate through

the bottom plane of the motor.

a. If no bracket is required, mount the new motor

directly to the equipment and refer to the

Installation, Settings and Adjustments, and the Operation and Checkout sections.

b. If the bracket is required, refer to the Adapter Bracket

section and Fig. 3 in addition to the

Installation, Settings and Adjustments, and the Operation and Checkout sections.

4. Use No. 12 or 1/4 inch machine screws or bolts to mount

the new motor.

5. Mount damper crank arm and linkage to the new motor

shaft.

6. Use the Checkout procedures to test the crank arm and

linkage adjustment.

Valve Application

When replacing a motor in a valve application, the linkage type

determines the necessity for the 220738A Adapter Bracket.

With Q100, Q601 or Q618 Linkages, it is necessary to use the

220738A to raise the motor shaft to the appropriate height.

Valve applications with a Q5001 Linkage do not require the

220738A Adapter Bracket. To operate Honeywell V5011 Twoway or V5013 Three-way Valves through full stroke, use a 160°

stroke motor.

NOTE: In damper installations, the pushrod should not

extend more than a few inches past the ball

joints.

2. Ensure that there is adequate clearance for the linkage

throughout the entire motor stroke without binding or

striking other objects.

3. Drive the motor fully open and fully closed. See Table 6.

NOTE: Refer to controller or system instructions for

additional checkout procedures.

4. For spring return motors, ensure that the valve or

damper returns to its normal position when power is

interrupted.

5. Return controller to the desired setting before leaving the

job.

63-2629—2 10

Page 11

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

11 63-2629—2

Page 12

SERIES 61 AND SERIES 62 MODUTROL IV™ MOTORS

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2006 Honeywell International Inc.

63-2629—2 C.H. Rev. 11-06

Loading...

Loading...