Page 1

X4 Series

Operating Instructions and

Maintenance Manual

Page 2

Alternative language versions are available for download from the Honeywell

Analytics website www.honeywellanalytics.com

Alternatieve talen versies zijn electronisch beschikbaar via onze web pagina van

Honeywell Analytics: www.honeywellanalytics.com

Les versions alternatives de langue sont disponibles pour le téléchargement du

website www.honeywellanalytics.com de Honeywell Analytics

Las versions alternativas de la lengua están disponibles para la transferencia

directa del website www.honeywellanalytics.com de Honeywell Analytics

Versioni in alter lingue, incluso l'italiano, sono disponibili e possono essere

scaricate dal sito web della Honeywell Analytics

www.honeywellanalytics.com

Zusätzliche Sprachen stehen zum Download auf folgender Webseite zur Verfügung. www.honeywellanalytics.com

X4 Series2

Page 3

Important Notice

System configurations of the detector are available with 4, 3, 2, and 1 gas sensor(s)

installed in order to provide specific protection for most major industrial applications

and compliance requirements. Though this operating manual is provided for the

detector with 4 gas sensors installed, the information in the manual also applies to

other system configurations of the detector with 3, 2, and 1 gas sensor(s) installed

as well (See Section 8 System Configurations Options).

To ensure proper functioning of this product, do not use it until you read and

completely understand this operating manual. It contains operating and maintenance

procedures to ensure proper detector function. For your safety, it is required to

calibrate the detector periodically (See Section 4 Calibration).

Honeywell Analytics can take no responsibility for use of its equipment if it is not

used in accordance with the instructions stated in the relevant manual. If further

details are required but not provided in this manual, contact Honeywell Analytics

or their agent.

Honeywell Analytics shall not be liable for any incidental or consequential damages

in connection with any modifications, errors or omissions in this manual.

While every effort has been made to ensure accuracy in this publication, no

responsibility can be accepted for errors or omissions. This publication is not intended

to form the basis of a contract, and the company reserves the right to amend the

design and specifications of the detectors without notice. Note too that data may

change as well as legislation, and you are advised to obtain copies of the most

recently issued regulations, standards and guidelines.

WARNINGS AND CAUTIONS

•

Substitution of any components may impair intrinsic safety.

Use only approved memory cards, part # 2566-0435, which are available

•

from Honeywell Analytics. Use of any other manufacturer or type will violate

intrinsic safety requirements.

Activation of the detector after the date on the packaging means less usable

•

life and shorter warranty period.

Use only approved ‘AA’ Alkaline Batteries, Energizer

•

only approved 'AA' NiMH recharchable cells. Quest 1500mAh, order part

number 2566-0454 (Quest part number HL-AAC1500). Use of any other

manufacturer or type will violate intrinsic safety requirements.

•

Use only two new batteries of the same type, when replacing the batteries.

•

The optional NiMH rechargeable batteries must be in fully charged condition

and replaced as a new pair. Do not attempt to charge the optional NiMH cells

in potentially hazardous areas

•

Replace batteries as soon as the detector emits a low battery alarm.

•

Battery life will be reduced at low temperatures.

•

Replace batteries only in an area known to be NON-HAZARDOUS.

•

Instrument contains no user serviceable parts. Contact Honeywell Analytics for any

servicing

X4 Series 3

requirements.

®

E91 or EN91: or use

(cont’d)

Page 4

Perform a Self-Test prior to each day’s use (See Section 3-1 Performing a

•

Self-Test).

Periodically test the sensors’ response to gas by exposing the monitor to a target gas

•

concentration that exceeds the alarm set points. Verify proper operation of audible,

visual and vibrating alarms during this test.

Use only factory supplied calibration gas for calibration. Accurate calibration

•

can be achieved only if specific concentrations of the correct gases are

used.

Calibration should be carried out in a well-ventilated area to avoid

•

contaminants.

Calibration cannot be carried out when the detector emits a low battery

•

alarm.

Do not use the detector in oxygen-enriched atmospheres.

•

The flammable sensor’s sensitivity can be adversely affected by exposure

•

to certain substances called “poisons”. Sulfur compounds, phosphorus

containing compounds, halogens, silicone or lead containing compounds

are examples of such poisons. Every effor t should be made to avoid

exposure to these substances. When the detector is exposed to such

substances, a gas test should be performed on the flammable sensor

to verify its accuracy and a calibration performed if necessary.

Extended exposure of the detector to certain high concentrations of flammable

•

gases and air may stress the flammable detector element, which can

seriously affect its performance. If an alarm occurs due to high concentration

of flammable gases, recalibration should be performed, or if needed, the

sensor replaced.

Do not use solvents, soap, polishes or any product containing silicon

•

compounds to clean the detector as these can cause damage to the

sensors.

•

Do not expose the detector to electrical shock and/or severe mechanical

shock. When the detector is exposed to such shocks, a check should be

performed on the sensors to verify its accuracy and a calibration performed

if necessary.

•

Disabling one or more installed sensors configures the detector to a 1, 2,

or 3-gas unit. No protection is provided for the gas targeted by the disabled

sensor(s).

Do not install or remove the memory card in the detector or attempt to read,

•

download or write to the memory card using a memory card reader and/or

computer in potentially hazardous atmospheres.

Do not remove the batteries from the detector while the power is on. This can

•

cause fatal damage to the optional memory card if installed.

No gas will be detected while in the set-up mode or the gas exposure status

•

review mode.

The desktop USB memory card reader and data logging kit are not

•

certified intrinsically safe and must not be used in potentially hazardous

atmospheres.

X4 Series4

Page 5

Contacting Honeywell Analytics Customer Business Centers

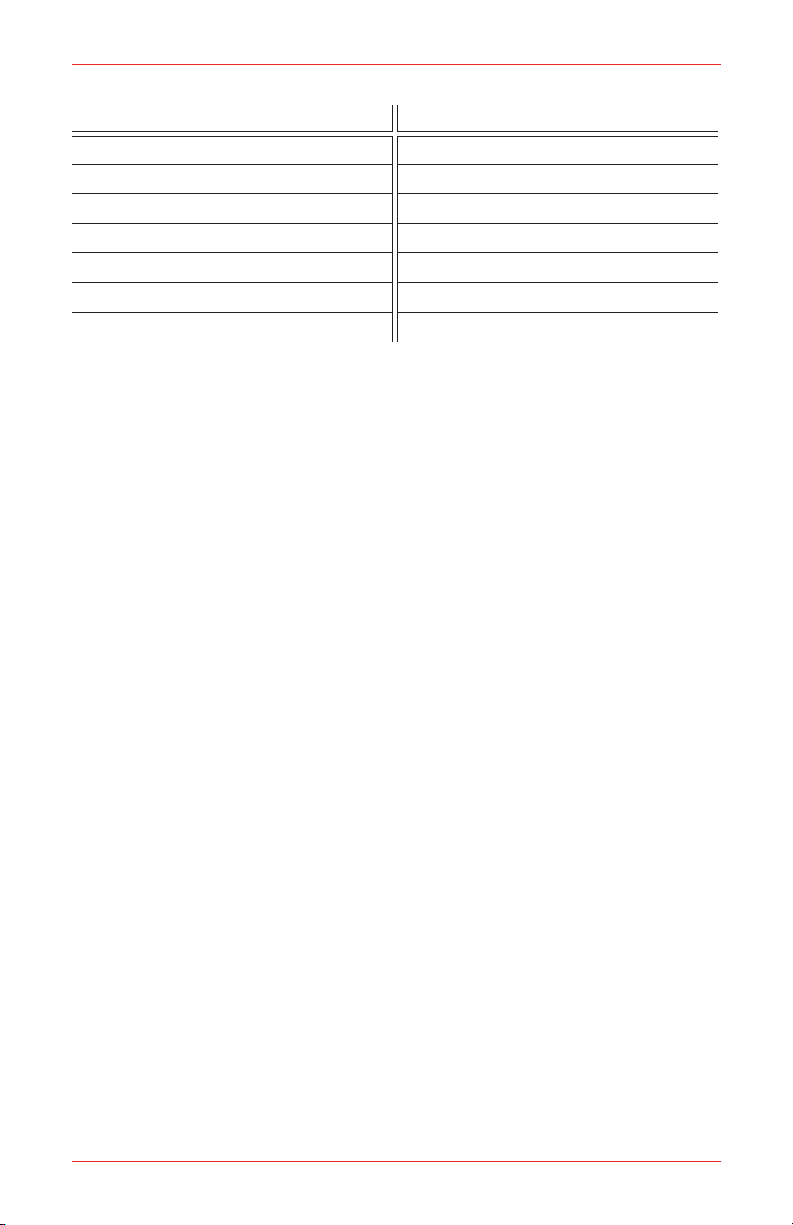

Americas (Minimax4 series) Europe and ROW (ImpulseX4 series)

400 Sawgrass Corporate Parkway Wilstrasse 11-U11

Suite 100 Ch-8610 Uster

Sunrise, Florida 33325 Switzerland

Tel: +1 954 514 2700 Tel: +41 (0)1 943 4300

Toll free: +1 800 538 0363

Fax: +1 954 514 2784 Fax: +41 (0) 1 943 4398

sales@honeywellanalytics.com sales@honeywellanalytics.co.uk

Or visit our web site at www.honeywellanalytics.com

X4 Series 5

Page 6

Additional Warnings and Cautions for Canadian Certification

and Other Global Certification Bodies

WARNING

Substitution of any components may impair intrinsic safety.

AVERTISSEMENT

La substitution de composants peut compromettre la sécurité intrinsèque.

CAUTION

For safety reasons this equipment must be operated and serviced by qualified

personnel

operating or servicing.

Pour des raisons de sécurité, cet équipement doit être utilisé, entretenu et réparé

uniquement par un personnel qualifié. Étudier le manuel d’instructions en

entier avant d’utiliser, ’entretenir ou de réparer l’équipement.

High off-scale reading may indicate explosive concentration.

Des lectures supérieures à l’échellepeuvent indiquer des concentrations

explosives.

only. Read and understand instruction manual completely before

ATTENTION

CAUTION

ATTENTION

CAUTION

Before each day’s usage sensitivity must be tested on a known concentration of

methane equivalent to 25-50%LEL. Accuracy must be within +/-20% of actual

concentration. Accuracy may be corrected by performing proper calibration on

the detector.

ATTENTION

Chaque jour, avant toute utilisation, tester la sensibilité sur une concentration

connue de méthane équivalente à 25-50% LEL. La précision doit être comprise

dans une plage de +/-20% de concentration réelle. A précision peut être

corrigée en effectuant un étalonnage approprié du détecteur.

X4 Series6

Page 7

WARNING

Under proper calibration procedures, repetitive calibration failures could indicate

that the sensor is either approaching its end of life, or it has been seriously

contaminated, or both.

AVERTISSEMENT

Si Les Procédures D’étalonnage Sont Bien Respectées, Des Défauts D’étalonnage

Répétitifs Peuvent Indiquer Que Le Capteur Arrive En Fin De Vie Ou Qu’il A

Été Sérieusement Contaminé, Ou Les Deux.

WARNING

The detector must not be removed from its rubber boot during transportation or

use, and if the rubber boot is removed for servicing or any other reason, it must

be replaced before the instrument is placed back in service.

AVERTISSEMENT

Le support en caoutchouc du détecteur ne doit jamais être retiré pendant

son utilisation ou son transport. Si pour un quelconque motif, d’entretien ou

autre, cette protection a été retirée, elle doit toujours être remise en place avant

d’utiliser l’instrument.

Only the combustible gas detection portion of this instrument has been assessed

for performance.

S e u l l e f o n c t i o n n e m e n t d e la p a r t i e d é t e c t i o n d e g a z

combustible de cet instrument a été évalué

The csa symbol, “exia”, represents intrinsically safe, or in french, sécurité

intrinsèque.

Le symbole csa “exia” signifie “sécurité intrinsèque”

WARNING

Use only the approved Honeywell Analytics charger (part number 2566-0484)

when charging the sealed rechargeable battery pack (part number 2566-0482 for

Minimax4 series and part number 2566-0462 for Impulse X4 series). Use of any

other charger will void the intrinsic safety certification of the instrument.

AVERTISSEMENT

Utiliser uniquement le chargeur Honeywell Analytics homologué (référence 2566-

0484) lors de la mise en charge du kit batterie étanche rechargeable (référence

2566-0482 pour la série Minimax4 et référence 2566-0462 pour la série Impulse X4).

En cas d’utilisation de tout autre chargeur, la certification de sécurité intrinsèque de

l’instrument sera nulle et non avenue.

X4 Series 7

Page 8

WARNING

Use only the Honeywell Analytics supplied ac adapter (part number 2566-0483)

to connect to the cradle charger (part number 2566-0484).

AVERTISSEMENT

Utiliser uniquement l’adaptateur à courant alternatif Honeywell Analytics

fourni (référence 2566-0483) pour

(référence 2566-0484).

connecter l’instrument au chargeur socle

WARNING

The charger units contain no user serviceable parts. No attempt should be

made to alter or repair the charger.

AVERTISSEMENT

Les chargeurs ne comportent pas de pièces d’entretien sur lesquelles

l’utilisateur peut intervenir. Ne pas essayer de modifier ni de réparer le

chargeur.

X4 Series8

Page 9

Table of Contents

1. Introduction .......................................................................11

1-1. Product Overview ...................................................11

1-2. Basic Button Operation ..........................................12

1-3. LCD Display .............................................................12

1-4. Standard Accessories ............................................13

2. Turning the Detector On and Off ......................................13

2-1. Turning the Detector On .........................................13

2-1-1. Displaying the Firmware Version

2-1-2. Clearing the STEL and TWA Values

2-1-3. Checking the Memory Card

2-1-4. Power-Up Self-Test

.........................................15

2-1-5. Checking the Calibration Due Date

....................13

...............14

............................14

................15

2-2. Turning the Detector Off .........................................15

3. Operation ...........................................................................16

3-1. Performing a Self-Test ............................................16

3-2. Measuring Mode......................................................17

3-2-1. Flipping the Display

........................................18

3-3. Testing Sensors and Alarms (Bump Testing) .......18

3-4. Gas Alarms ..............................................................18

3-4-1. Gas Alarms for the Minimax4 series

3-4-2. Gas Alarms for the ImpulseX4 series

...............19

.............19

3-5. Gas Exposure Status Review ................................21

3-6. Confidence Flash/Beep ..........................................22

3-7. Low Battery .............................................................22

3-8. Data Logging ...........................................................22

4. Calibration..........................................................................24

4-1. Calibration Prompt ..................................................24

4-2. Zero Calibration (Span Calibration for Oxygen) ..24

4-3. Span Calibration (for Flammable and Toxic

Sensors Only) ..........................................................25

4-3-1. Pass Code Input

4-3-2. Span Gas Information

4-3-3. Span Gas Setting

4-3-4. Gas Search and Countdown

4-3-5. Span Calibration Result

.............................................26

.....................................26

...........................................27

..........................27

..................................28

5. Set-Up Mode ......................................................................29

5-1. Entering the Set-Up Mode ......................................30

5-2. Changing the Detector Set-Up ...............................31

5-3. Exiting the Set-Up Mode.........................................31

X4 Series 9

Page 10

6. Maintenance.......................................................................32

6-1. Replacing the Batteries ..........................................32

6-2. Installing or Removing the Memory Card .............33

6-4. Replacing the Expired Sensor ...............................34

7. Optional Accessories........................................................35

8. System Configuration Options ........................................36

8-1. System Configurations for the Minimax4 series ..36

8-2. System Configurations for the ImpulseX4 series 36

Appendix A ............................................................................37

A-1. Calibration Mode Menu Structure 1/2 ...................37

A-2. Calibration Mode Menu Structure 2/2 ...................38

A-3. Set-up Mode Menu Structure 1/4 ..........................39

A-4. Set-up Mode Menu Structure 2/4 ..........................40

A-5. Set-up Mode Menu Structure 3/4 ..........................41

A-6. Set-up Mode Menu Structure 4/4 ..........................42

Appendix B ............................................................................43

B-1. Sensor Cross-Sensitivity .......................................43

B-1-1. H2S and CO SureCell Cross-Sensitivity .........43

B-1-2. O

B-1-3. Flammable Cross-Sensitivity

Cross-Sensitivity .......................................43

2

..........................44

B-2. Flammable Lower Explosive Limit ........................45

Appendix C ............................................................................46

C-1. Warranty ..................................................................46

C-2. Accuracy Statement ...............................................47

C-3. Declaration ..............................................................48

C-3-1. Declaration for the Minimax4 series

C-3-2. Declaration for the ImpulseX4 series

...............48

.............49

Appendix D ............................................................................50

D-1. Specifications .........................................................50

D-1-1. Specifications for the Minimax4 series ...........50

D-1-2. Specifications for the ImpulseX4 series

.........51

X4 Series10

Page 11

1. Introduction

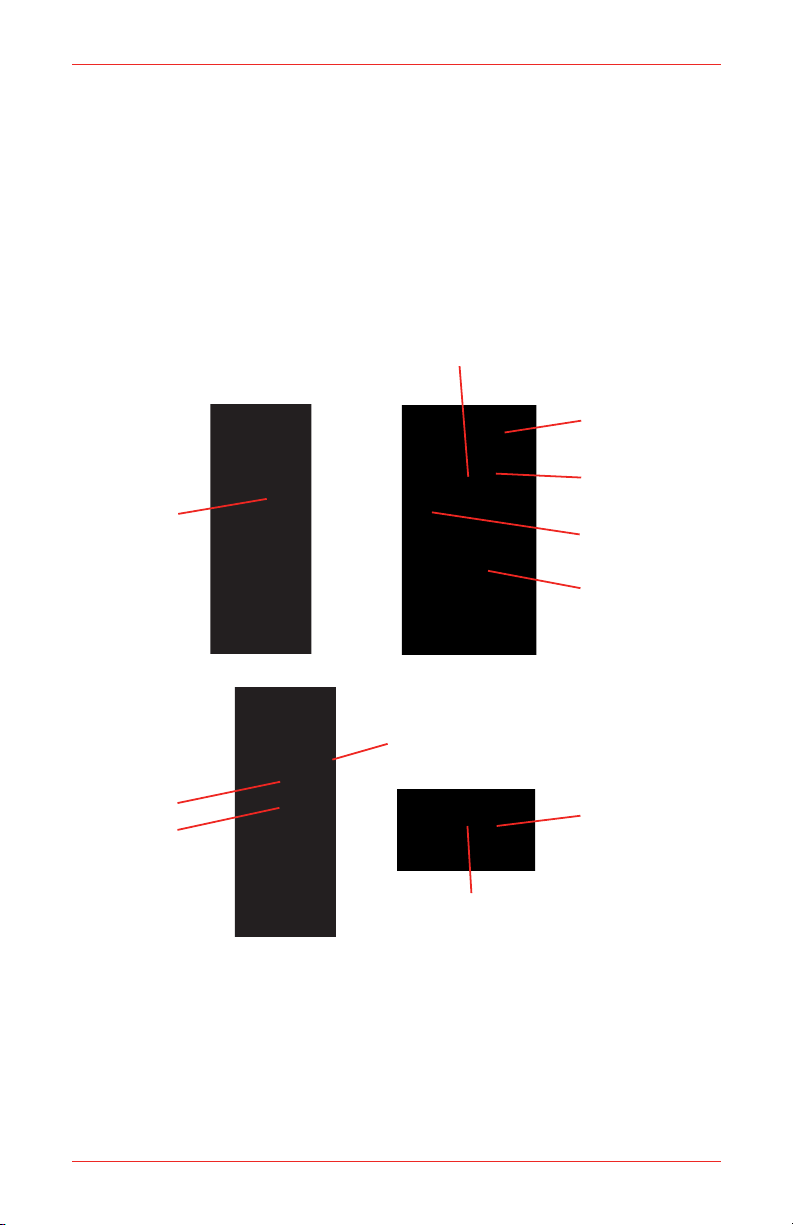

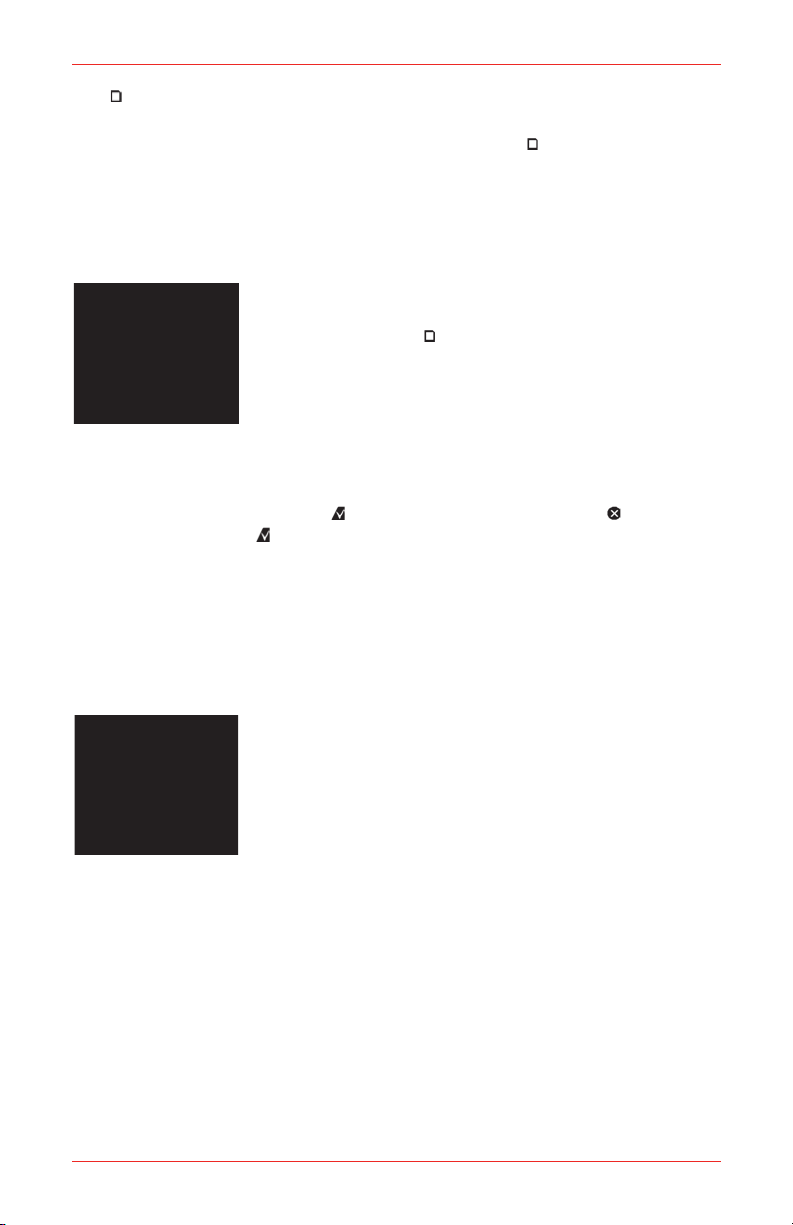

Visual Alarm

Sensor Grille

Audible Alarm

LCD Display

Locking Tab

Crocodile Clip

Battery Holder

UP Button

DOWN Button

ON/OFF Button

Threaded Hole for

Flow Adaptor

Left

Right

Front

Bottom

The X4 series is an easy to use personal gas detector, designed for monitoring

the atmosphere for potentially hazardous levels of flammables, oxygen, carbon

monoxide, and hydrogen sulfide. It uses a front-mounted LCD display to show

readings of the gases being measured and other useful information. A loud audible

alarm and bright visual alarm are used to warn users when the concentrations of

measured gases exceed the alarm set points. It has built-in cell decay compensation,

thermal shock protection, and Reflex™, a patented cell check technique, for

maximum reliability.

1-1. Product Overview

X4 Series 11

Page 12

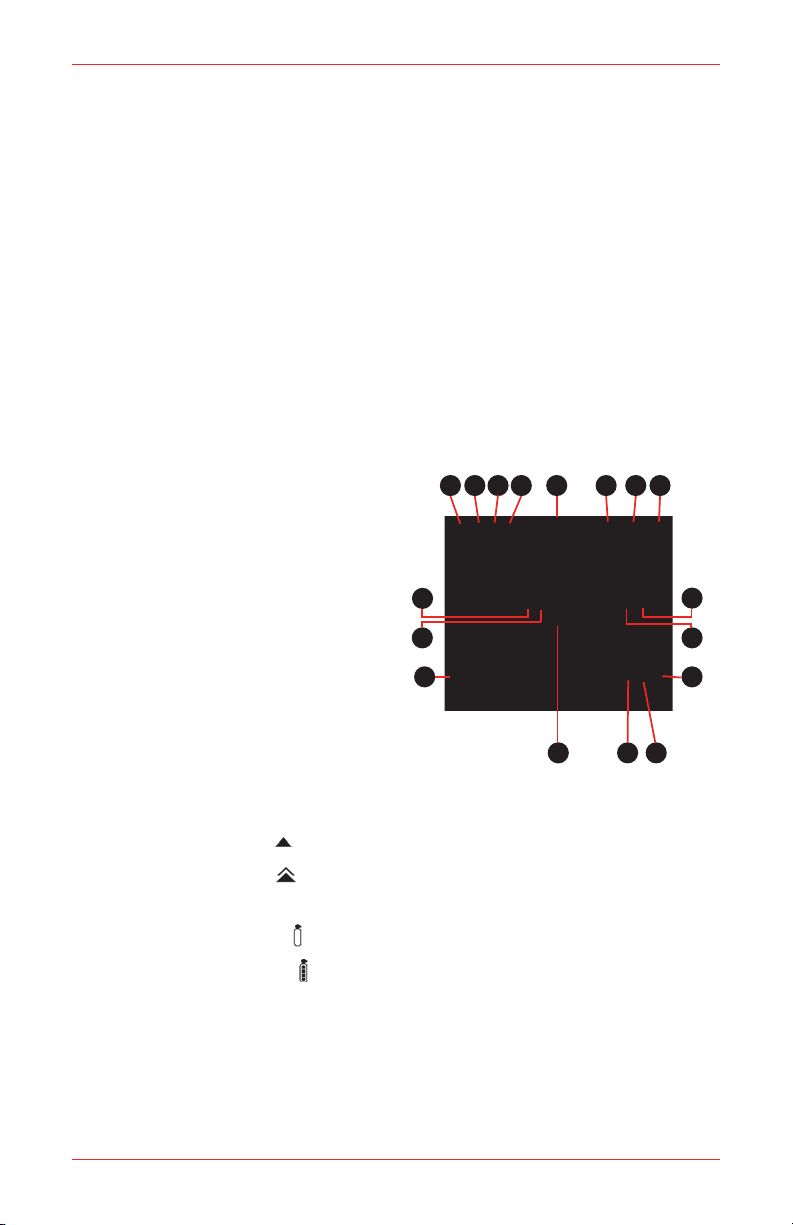

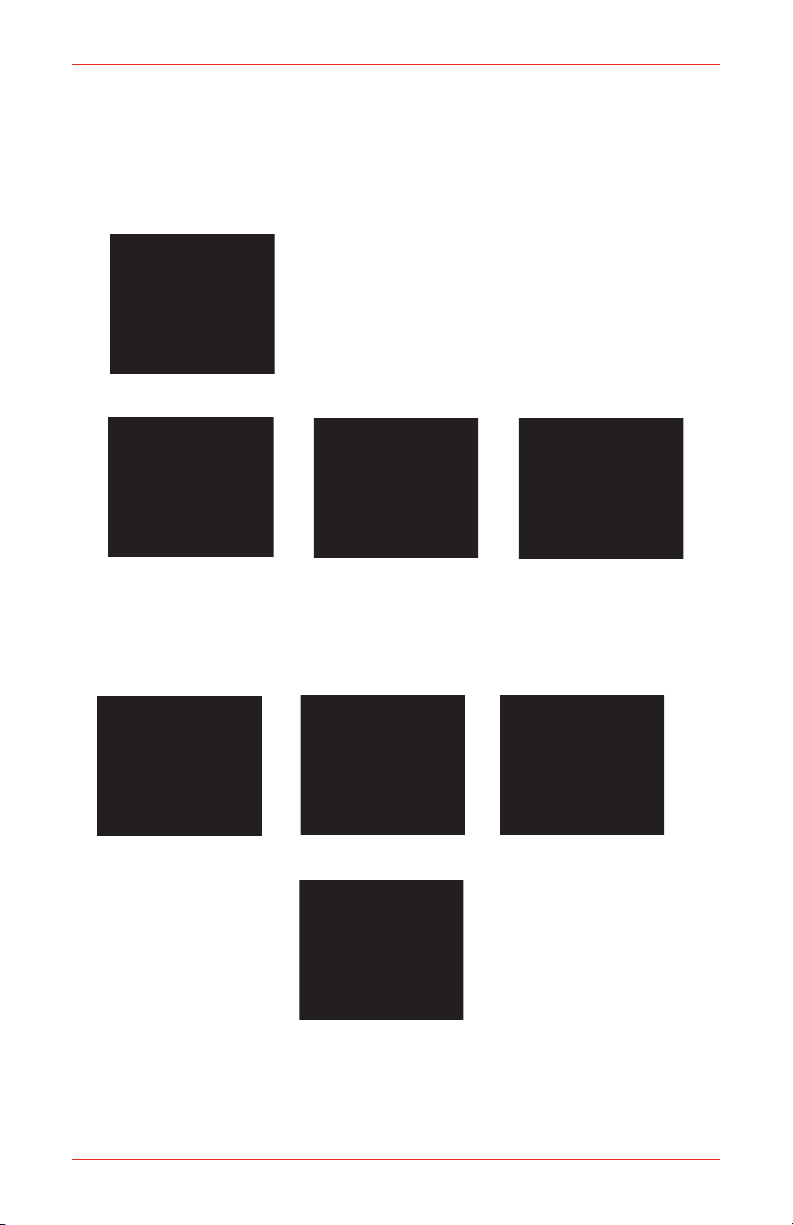

1

2 3 4

5 6

7

8

9

10

11

1213

14

15

16

17

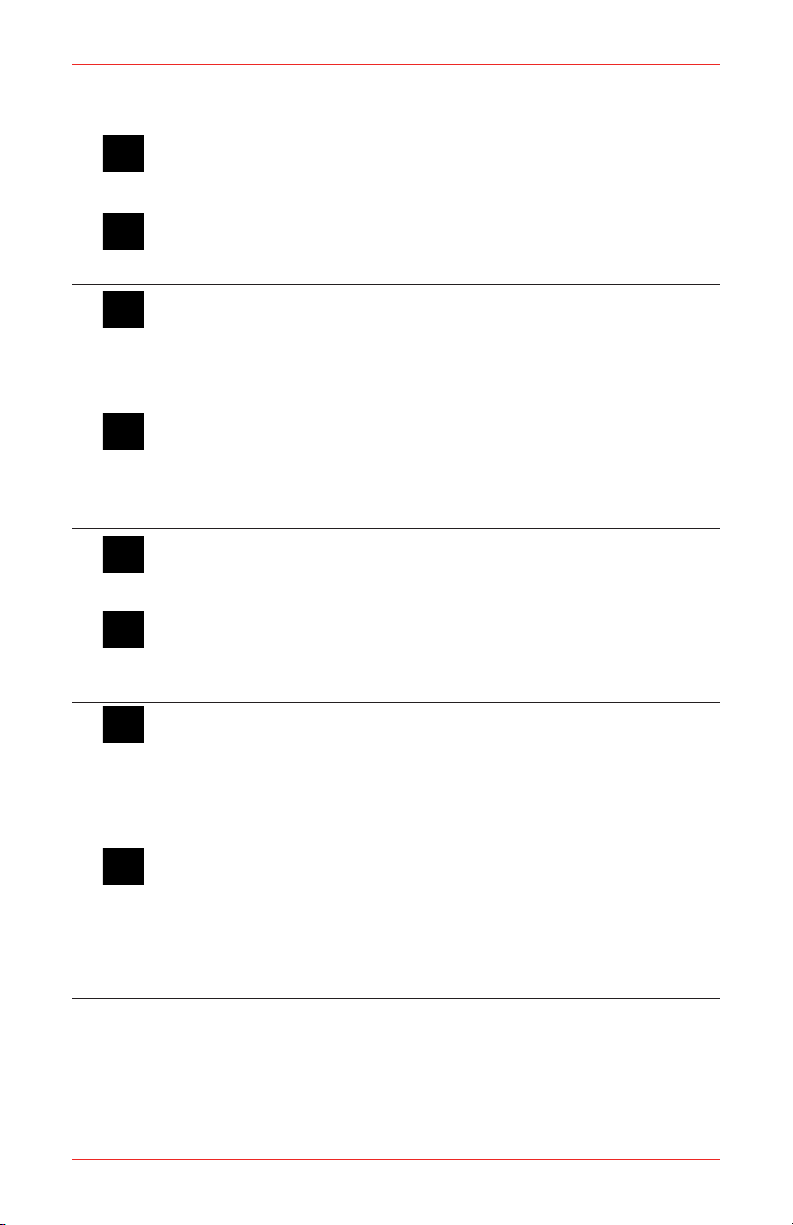

1-2. Basic Button Operation

ON/OFF button

Turn on the detector

•

Turn off the detector

•

Self-Test

•

ZERO calibration

•

SPAN calibration

•

Accept a user set-up change

•

Latched Alarm acknowledgement

•

1-3. LCD Display

Test Pass Icon

1.

Test Fail Icon

2.

High Peak Icon

3.

Low Peak Icon (for O2 only)

4.

Alarm Icon

5.

Data Logging Icon

6.

Battery Icon

7.

Pass Code Protection Icon

8.

%Vol Unit Icon

9.

%LEL Unit Icon

10.

STEL Icon

11.

TWA Icon

12.

Alarm Level 1 Icon

13.

Alarm Level 2 Icon

(for flammable and toxic)

Zero Calibration Icon

14.

Span Calibration Icon

Gas Label Icon

15.

O2 Deficiency Alarm Icon

16.

O2 Excess Alarm Icon

17.

UP button

Scroll through status or menu

•

options

Increase value

•

Ac t i v a t e / d ea c t i v a t e fl i p p e d

•

display

Activate backlight

•

DOWN button

Scroll through status or menu

•

options

Decrease value

•

Activate backlight

•

The LCD display has a backlight that

will operate automatically whenever

an alarm occurs, and also whenever

any button is pressed. To turn on the

backlight while staying in the measuring

mode in a low light area, press the UP

or DOWN button once.

X4 Series12

Page 13

1-4. Standard Accessories

The items listed below are included with the X4 series. For damaged or missing

parts, contact Honeywell Analytics or their agent.

Part No. Description Qty

2566-0424 Calibration Certicate 1

2566-0422 Quick Start Guide 1

2566-0433 Alkaline Batteries (1.5V AA), Energizer® E91 or EN91 2

2566-0426N Flow Adaptor (Neotronics) 1

2566-0426L Flow Adaptor (Lumidor) 1

2566-0480 Protective Rubber Boot (Neotronics) 1

2566-0445 Protective Rubber Boot (Lumidor) 1

2566-0443 Tubing (45 cm/18”) 1

2566K0130 Crocodile Clip Kit 1

2566-0420 Manual 1

2. Turning the Detector On and Off

Before turning the detector on for the first time, you will need to install two “AA”

alkaline (Energizer® E91 or EN91) batteries (See Section 6-1 Replacing the

Batteries).

A sealed rechargeable battery pack (part number 2566-0482 for the Minimax,

and 2566-0462 for the Impulse) is also available (See Section 7 Optional

Accessories)

If you plan on logging data and have a memory card, now is also a good time to

install the card (See Section 6-2 Installing or Removing the Memory Card).

2-1. Turning the Detector On

Press and hold the ON/OFF button for 2 seconds and the detector will turn on.

2-1-1. Displaying the Firmware Version

The detector will display the version of the firmware.

X4 Series 13

Page 14

2-1-2. Clearing the STEL and TWA Values

When the non-zero STEL and/or TWA values are carried over from the previous

measurement, a “Delete no” prompt will be displayed with the gas labels and the STEL

and TWA icons. (When the STEL and TWA values are zero, the “Delete no” prompt

will not be displayed.)

Press the UP or DOWN buttons to scroll

to “no” or “YES” and press the ON/OFF

button to select.

or

When “no” is selected, the recorded STEL and TWA values will be used as initial

STEL and TWA values for the current session. When “YES” is selected, the STEL

and TWA values will be cleared.

2-1-3. CHECKING THE MEMORY CARD

The detector will check the memory card in the memory card slot. When a properly

formatted FAT16 memory card with a data full condition is detected, a “Data Fu” message

will be displayed followed by a “Delete no” prompt. (When a properly formatted FAT16

memory card is not full of data, the “Data Fu” message and the “Delete no” prompt will

not be displayed).

Press the UP or DOWN buttons to scroll to “no” or “YES” and press the ON/OFF

button to select.

or

X4 Series14

Page 15

When “no” is selected, the detector keeps the current data file and the Data Logging

icon will not be displayed in the measuring mode which indicates that no data is

being logged. When “Yes” is selected, the detector deletes the current data file and

creates a new file for data logging. The Data Logging icon will be displayed in the

measuring mode which indicates that data is being logged.

The detector does not support either FAT32 or NTFS format for the memory card.

When a memory card with non-FAT16 format is detected, a “Card Er” message will

be displayed with a single beep. (When a properly formatted FAT16 memory card

is detected, a “Card Er” message will not be displayed.)

The Data Logging icon will not be displayed in the measuring

mode which indicates that no data is being logged.

2-1-4. Power-Up Self-Test

The detector will beep and perform a power-up Self-Test. If the detector passes

the Self-Test, the Test Pass icon is displayed. If the Test Fail icon is displayed

and the Test Pass icon blinks with 1 beep and 1 flash every 5 seconds, then the

detector has failed the Self-Test (See Section 3-1 Performing a Self-Test).

2-1-5. Checking the Calibration Due Date

The detector checks the calibration due date stored in the detector after the Power-Up

Self-Test. When the number of days remaining until calibration is due reaches zero,

a "CAL dUE dAY 0" message will be displayed to remind the user that a calibration

needs to be performed.

To perform the calibration, see Section 4 Calibration.

2-2. Turning the Detector Off

To turn off the detector, press and hold the ON/OFF button while in the measuring mode.

A countdown will be displayed for 5 seconds, and then the detector will beep and

turn off.

X4 Series 15

Page 16

3. Operation

3-1. Performing a Self-Test

When the ON/OFF button is pressed, the detector checks the sensor, circuit, batteries,

and audible, visual, and vibrating alarms.

The detector will do the following:

= Turn on all the display elements

= Test the audible, visual, and vibrating alarms

= Check the battery, electronic circuit and sensors

a a

Display the level 1 (flammable and toxic low, O2 excess) and level 2 (flammable

•

and toxic high, O2 deficiency) alarm set points

Display the STEL and TWA alarm set points (for CO & H2S only).

•

a a a

Level 1 Level 2 STEL

TWA

*Examples shown for default settings of each gas for the Minimax4 series.

X4 Series16

Page 17

Display the result of the Self-Test as follows:

•

Test Pass Test Fail

Self-Test

Result

Pass None None

Fail

Additionally, the detector will periodically check its batteries, electronic circuit and

sensors.

If it passes, the Test Pass icon will be displayed. If it fails, the Test Fail icon

will be displayed and the Test Pass icon will blink with 1 beep and 1 flash every

5 seconds.

Note

If the Self-Test has failed, repeat the Self-Test. If a second failure occurs, contact

Honeywell Analytics or their agent

Display Audible Alarm Visual Alarm

1 beep every 5

sec

1 flash every 5

sec

3-2. Measuring Mode

The detector may be used as either a “diffusion” or “sample-draw” type monitoring

device. In normal operation, the detector is worn on the belt or held by hand. Once

turned on, the detector monitors continuously. The atmosphere being measured

reaches the sensor by diffusion through the vents of the grille cover. Normal air

movements are enough to carry the sample to the sensors, which react to the

concentrations of the gases being measured. This type of “diffusion” operation

monitors only the atmosphere that immediately surrounds the detector. It is possible

to use the detector to sample locations that are remote from the detector by using

a flow adaptor and an optional hand aspirator. When using the flow adaptor, ensure

that the sample flow direction matches the arrow mark.

The gas types and concentration values for each sensor are displayed. If fewer than

four sensors are installed, the unused sensor position(s) will be blank.

Normal Display

X4 Series 17

Page 18

3-2-1. Flipping the Display

The LCD display can be flipped upside down by pressing and holding the UP button

for 2 seconds. This allows easy reading when the detector is clipped to a waist belt

or chest pocket.

Flipped Display

3-3. Testing Sensors and Alarms (Bump Testing)

To maintain optimal accuracy, the detector should be periodically supplied with

a known concentration test gas (bump test) and if the readings are outside of

15% of the applied gas concentration, a span calibration should be performed,

under conditions of standard temperature (15°C to 25°C), humidity and pressure.

Follow local regulations and/or your company’s policy on the frequency of bump

testing. For more information on test gas, contact your local Honeywell Analytics

representative.

3-4. Gas Alarms

The detector has two levels of instantaneous gas alarms, of which the level 2

(flammable and toxic high, O2 deficiency) alarm is more urgent than the level 1

(flammable and toxic low, O2 excess) alarm for flammable and toxic. The O2 excess

and deficiency alarms are equally important. It also has a 15-minute STEL alarm

and an 8-hour TWA alarm for the carbon monoxide and hydrogen sulfide sensors.

Note

STEL (Short Term Exposure Limit) and TWA (Time-Weighted Average)

comply with relevant agency standards.

TWA is an 8-hour time-weighted average, so if the work shift exceeds 8 hours,

the readings will still be logged but averaged over the 8-hour period.

The user can set up the level 1 alarm point, level 2 alarm point, STEL alarm point,

TWA alarm point and alarm latch mode in the set-up mode. (See Section 5 Set-Up

Mode).

X4 Series18

Page 19

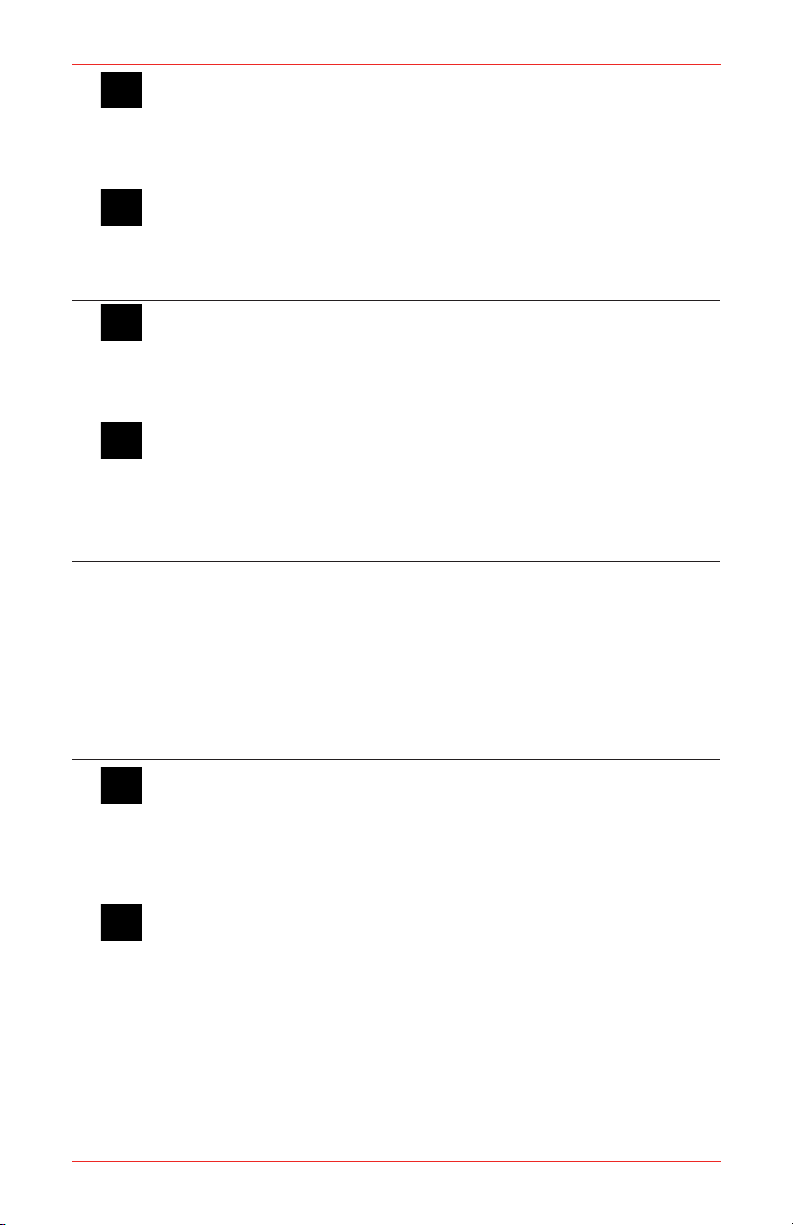

3-4-1. Gas Alarms for the Minimax4 series

The Minimax4 series is supplied with the following alarm increments, alarm ranges,

and default alarm set points:

Level 1 (Flammable

All

or

and Toxic Low, O2

Excess) Alarm

21.5~30%

Vol

2~60%

LEL

or

0.10~ 3%

Vol

5-999

ppm

3-250

ppm

Alarms

Gas Type Increment Range Default Range Default Range Default Range Default

Oxygen (O2) 0.1% Vol

Flammable

(Exp)

Carbon

Monoxide

(CO)

Hydrogen

Sulde (H2S)

1% LEL

0.01% Vol

1 ppm

1 ppm

23.5%

Vol

10%

LEL

or

0.50%

Vol

35 ppm

10 ppm

Level 2 (Flammable

and Toxic High, O2

Deciency) Alarm

1-20.5%

2~60%

0.10~3%

5~999

3~250

Vol

LEL

Vol

ppm

ppm

19.5%

Vol

20%

LEL

or

or

1%

Vol

100 ppm

15 ppm

STEL Alarm TWA Alarm

N/A N/A N/A N/A

N/A N/A N/A N/A

5~999

ppm

3~250

ppm

100 ppm

15 ppm

5~999

ppm

3~250

ppm

35 ppm

10 ppm

3-4-2. Gas Alarms for the ImpulseX4 series

The ImpulseX4 series is supplied with the following alarm increments, alarm ranges,

and default alarm set points:

Level 1 (Flammable and

All

or

Toxic Low, O2 Excess)

Alarm

21.5~30%

2~60% LEL

0.10~ 2.64%

23% Vol 1-20.5% Vol 19% Vol N/A N/A N/A N/A

Vol

or

Vol

0.44%

Alarms

Gas Type Increment Range Default Range Default Range Default Range Default

Oxygen (O2) 0.1% Vol

Flammable

(Exp)

Carbon

Monoxide

(CO)

Hydrogen

Sulde (H2S)

1% LEL

0.01% Vol

1 ppm 5-999 ppm 35 ppm 5~999 ppm 400 ppm

1 ppm 3-250 ppm 10 ppm 3~250 ppm 40 ppm

10%

LEL

or

Vol

Level 2 (Flammable

and Toxic High, O2

Deciency) Alarm

2~60% LEL

or

0.10~2.64%

Vol

20%

LEL

or

0.88%

Vol

STEL Alarm TWA Alarm

N/A N/A N/A N/A

5~999

ppm

3~250

ppm

200 ppm

10 ppm

5~999

ppm

3~250

ppm

30 ppm

5 ppm

Note

For flammable, carbon monoxide, and hydrogen sulfide, level 1 alarm can

only be set to less than or equal to the level 2 alarm. When level 1 and

level 2 alarms are set to the same value, the level 2 alarm action overrides

the level 1 alarm.

The maximum value of the level 2 alarm in %Vol for flammable gas varies

depending on the gas. (See Appendix B-2 Flammable Lower Explosive

Limit.)

X4 Series 19

Page 20

If an alarm occurs, the icons blink and relevant alarm level icons, s (Level 1 for

flammable and toxic, and O2 excess), (Level 2 for flammable and toxic), t (O2 deficiency),

(STEL), or (TWA) will be displayed according to the alarm level for the gas

type in question.

Alarm Type Display* Audible Alarm Visual Alarm Vibrating Alarm

Level 1 Alarm

Level 2 Alarm

STEL Alarm

TWA Alarm

3 Tones/ 2 Beeps

per 1 second

5 Tones/ 4 Beeps

per 1 second

5 Tones/ 4 Beeps

per 1 second

5 Tones/ 4 Beeps

per 1 second

2 Flashes

per 1 second

4 Flashes

per 1 second

4 Flashes

per 1 second

4 Flashes

per 1 second

once every 2

seconds

once every 1

second

once every 1

second

once every 1

second

* Examples shown for default settings of each gas for the Minimax4 series.

Note

In latching alarm mode, once an alarm occurs, the audible, visual and

vibrating alarms continue to operate even after the atmospheric hazard

has cleared. By pressing the ON/OFF button, the alarm will be cleared

(after the atmospheric hazard has cleared). Any subsequent alarm will

reactivate the audible, visual and vibrating alarms.

In non-latching alarm mode, should the gas alarm occur the detector

would enter alarm condition. When the reading returns to a normal level,

the audible, visual and vibrating alarms will stop.

If the measured reading exceeds the range of the sensor, the full-scale

value will blink.

See Section 5 Set-up Mode for more information on Latching/NonLatching Alarms

X4 Series20

Page 21

3-5. Gas Exposure Status Review

CAUTION

No gas will be detected while in the gas exposure status review mode.

The detector records the maximum readings, minimum readings (for oxygen only),

STEL and TWA values (for toxic only). While in measuring mode, these can be viewed

by pressing the UP or DOWN button. The first press of the UP or DOWN button turns on

the backlight if it is not already on. The exposure status can be scrolled through in the

order of High Peak ( ), Low Peak ( ), STEL ( ), and TWA ( ), followed by Calibration

Due Date, Current Date, and Current Time by pressing the UP button or in reverse order

by pressing the DOWN button.

Note

If no button is pressed within 10 seconds, the detector will revert back to

the measuring mode.

Gas Exposure

Status

High Peak

Low Peak

STEL

TWA

Calibration Due

Date

Current Date

Display Description

Maximum gas exposure levels encountered during work shift.

Note: To clear the high peak values, press the ON/OFF button

while the values are

displayed.

Minimum oxygen level encountered during work shift.

Note: To clear the low peak value, press the ON/OFF button while

the value is displayed.

Short-term exposure limit based on a 15-minute period. Note:

The STEL value can be cleared manually when the power is

turned on or will be cleared automatically if the power is kept

turned off for more than 15 minutes.

Time-weighted average based on an 8-hour workday. Note: The

TWA value can be cleared manually when the power is turned on

or will be cleared automatically if the power is kept turned off for

more than 8 hours.

Remaining days until next SPAN calibration

Current date in MM DD - YY format (US) or DD MM - YY format

(EU)

Current Time

Current time in HH:MM:SS format (24 hour format)

* Examples shown for the status review for the Minimax4 series

X4 Series 21

Page 22

3-6. Confidence Flash/Beep

If selected, the detector will emit a flash and a beep once every 30 seconds to indicate that

the detector is operating. The user can select whether this feature is activated or

not, and whether it is an audible signal, visual signal or both (See Section 5 SetUp Mode). If any error or fault is detected, the confidence flash/beep will stop. The

factory default is no confidence flash/beep.

3-7. Low Battery

When the detector’s battery level reaches a preset level, it will warn the user that the battery

is low and needs replacing by generating a beep and flashing the alarm LED once

every 5 seconds. Also, the Test Fail icon will be displayed and the Low Battery icon

and Test Pass icon will blink alternately. When the battery is finally exhausted,

the Test Fail icon and Low Battery icon will blink simultaneously with seven

beeps and “bAttEry oFF” will be displayed. Pressing the ON/OFF button will turn

the detector off completely.

After a low battery alarm, the batteries should be replaced as shown in Section 6-1

Replacing the Batteries.

3-8. Data Logging

WARNING

Do not install or remove the memory card in the detector or attempt to read,

download or write to the memory card using a memory card reader and/or

computer in potentially hazardous atmospheres.

Do not remove the batteries from the detector while the power is on. This can

cause fatal damage to the optional memory card if installed.

Before you can begin data logging, you will need to purchase a memory card and a card

reader. You will also need PC software, which you can either download from our web site

(www.honeywellanalytics.com), or you can purchase it on CD. (See Section 7

Optional Accessories.)

WARNING

Use only approved memory cards, part # 2566-0435, which are available

from Honeywell Analytics. Use of any other manufacturer or type will

violate intrinsic safety requirements.

Do not use a memory card containing non-X4 data. The detector or card

reader will either erase non-X4 data or reformat the memory card.

Memory card readers can be purchased from Honeywell Analytics or from a

local source of your choice. Card Readers must be able to read both MMC

(MultiMediaCard) and SD (SecureDigital) cards.

When the detector is turned on, it will check the memory card in the memory card slot

if card is installed. When a properly formatted blank memory card is detected, the Data

Logging icon will be displayed in the measuring mode which indicates that data

is being logged.

X4 Series22

Page 23

Note

The detector only supports FAT16 format for the memory card.

The detector will start data logging automatically and save

the gas readings at a user-configurable interval. The factory

default interval is 60 seconds. (See Section 5 Set-Up

Mode.)

Note

Should an alarm be activated while in the data logging mode, varied alarm

sound may be generated, as the detector periodically writes data to the

memory card.

W h e n t h e m e m o r y c a r d b e c o me s fu l l i n th e me a s u r i n g m o d e ,

the detector will stop data logging and the Data Logging icon will blink which

indicates that no data is being logged.

Note

The detector cannot format the memory card.

WARNING

The detector ignores the write-protect feature of the SD memory card.

When the Data Logging icon is either blinking or not displayed, it

indicates that no data is being logged.

To install or remove the memory card, see Section 6-2 Installing or Removing the

Memory Card.

X4 Series 23

Page 24

4. Calibration

Note

Calibration should be carried out with fresh batteries.

WARNING

Calibration cannot be carried out when the detector emits a low battery

alarm.

The calibration mode menu structure is shown in Appendix A (A-1 and A-2).

4-1. Calibration Prompt

To enter calibration mode while in measuring mode, press the ON/OFF button 2

times.

A “CAL no” prompt will be displayed.

Press the UP or DOWN buttons to alternate between “no”

or “YES” and press the ON/OFF button to select.

or

When “no” is selected, the calibration will be aborted. When “YES” is selected, the

calibration will be performed.

4-2. Zero Calibration (Span Calibration for Oxygen)

ZERO calibration must be performed in a clean atmosphere. It is recommended that

a ZERO calibration be performed daily or after any gas alarm.

The detector will initiate a ZERO calibration showing a blinking ZERO

•

Calibration icon and a countdown from ‘020’ to ‘000’.

a

Countdown

When the ZERO calibration has been completed successfully for all sensors,

•

the Test Pass icon will blink for 5 seconds.

X4 Series24

Page 25

If the ZERO calibration fails for one or more sensors, the detector will give a

•

single beep and a single flash and both the Test Pass icon and Test Fail

icon will blink for 5 seconds.

If the ZERO calibration fails for all sensors, the detector will give a single beep

•

and a single flash and only the Test Fail icon will blink for 5 seconds.

All Pass Some Pass/Fail All Fail

Note

If any sensor has failed, repeat the ZERO calibration ensuring that the

detector is in fresh air. If a second failure occurs, contact Honeywell

Analytics or their agent.

WARNING

Under proper calibration procedures, repetitive calibration failures could

indicate that the sensor is either approaching its end of life, or it has been

seriously contaminated, or both.

4-3. Span Calibration (for Flammable and Toxic Sensors Only)

Calibrate the detector at least every 6 months (CH4, CO, H2S), depending on use and

exposure to contaminants. User can perform the SPAN calibration with 3 gases at the

same time or with a single gas. When SPAN calibration is performed with a single gas,

the detector detects the supplying gas automatically.

To carry out the SPAN calibration, the user needs the following accessories, which

are available from Honeywell Analytics (See Section 7 Optional Accessories):

Calibration gas cylinder of known concentration (multi-gas mix) as follows:

•

Gas

CH

Recommended

Calibration Gas

Concentration

4

50% LEL 20 ~ 50% LEL

Concentration Range

Calibration Gas

CO 50 ppm 50 ~ 200 ppm

H2S 25 ppm 20 ~ 50 ppm

• A flow regulator supplying the gas at 300 mL/min flow rate

• Tubing for use between the regulator and the flow adaptor

X4 Series 25

Page 26

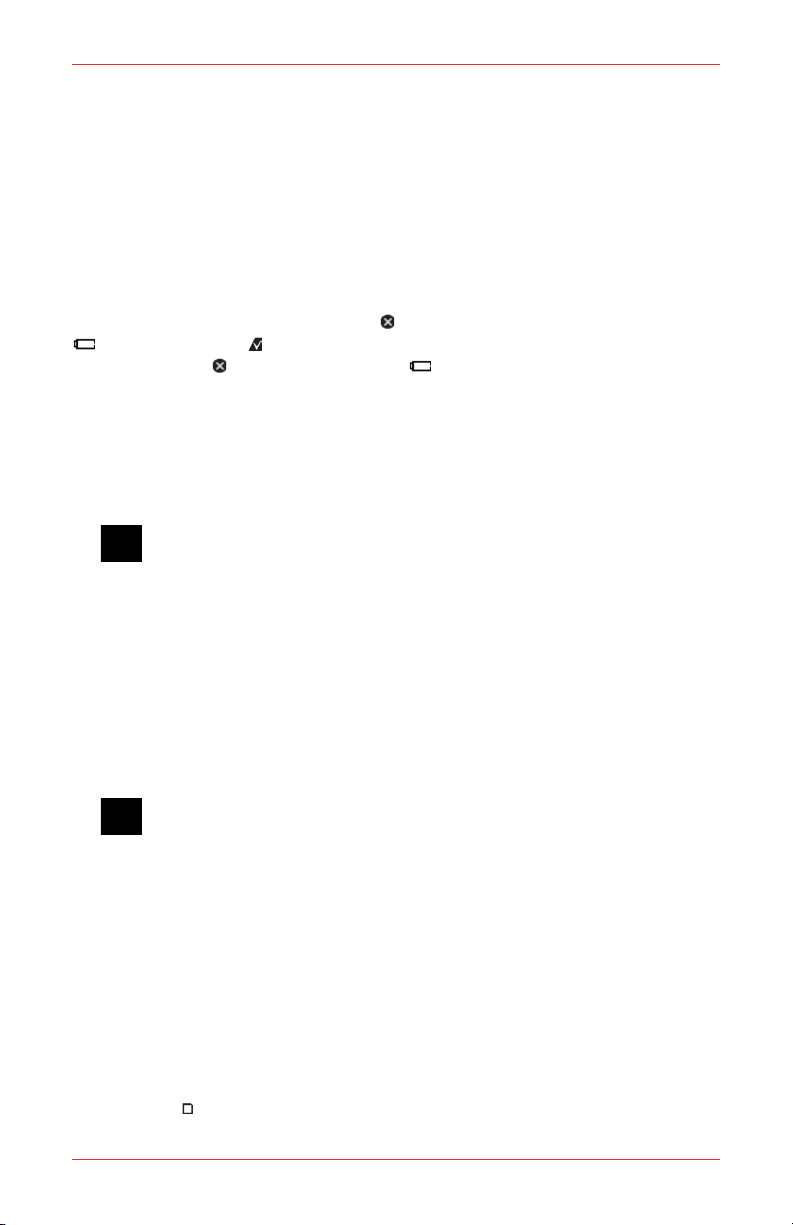

Flow Regulator

Pressure Gauge

Gas Cylinder

ON/OFF Valve

Gas Tube

Flow Adaptor

To ventilated area

Carry out the ZERO calibration procedure as described in Section 4-2 Zero Calibration

(Span Calibration for Oxygen).

Only if the ZERO calibration is successful can a SPAN calibration be

•

performed.

At the end of the ZERO calibration procedure, the ON/OFF button must be

•

pressed and held continuously for 5 seconds in order to proceed to SPAN

calibration while the Test Pass icon is still blinking. If pass code protection

is activated proceed to Section 4-3-1 Pass Code Input, otherwise proceed to

Section 4-3-2 Span Gas Information.

If no actions are performed at the end of the zero calibration the detector will

•

return to measuring mode.

4-3-1. Pass Code Input

If the Pass Code Protection feature has been activated, the detector prompts the

user to enter the pass code.

Press the UP or DOWN buttons to scroll to the current pass code. For fast scrolling, press

and hold the UP or DOWN buttons. When the current pass code is displayed, press

the ON/OFF button to enter the pass code.

NOTE

If the user fails to input the correct pass code 3 times consecutively, the

detector will return to measuring mode.

NOTE

For lost pass code, contact Honeywell Analytics or their agent.

4-3-2. Span Gas Information

The SPAN gas information will be displayed.

Only the gas label and SPAN gas concentration of the flammable and/or toxic

sensor(s) that passed the ZERO calibration will be shown on the LCD display.

X4 Series26

Page 27

4-3-3. Span Gas Setting

The SPAN gas information will be displayed.

• The span gas concentration can be changed by pressing the ON/OFF button within

10 seconds during the display of the span gas information.

•

The user can adjust the value with the UP or DOWN buttons and accept it by pressing the

ON/OFF button.

• To scroll to a gas sensor without altering current values, press the ON/OFF button without pressing

the UP or DOWN buttons.

a a

Select Exp Gas Change Concentration

from 50% to 40% LEL

4-3-4. Gas Search and Countdown

For SPAN calibration, apply the gas to the detector when the SPAN Calibration icon blinks.

The detector will monitor sensor signals for supplied gas.

Gas Searching

If the detector detects one or more gases, it displays the expected concentration for

the detected gas(es) and starts a 60 second countdown for SPAN calibration.

a

Countdown

The detector detects gas and executes SPAN calibration

Note

If no gas is detected within 30 seconds, the detector will give a single beep

and a single flash, indicate an error “Err” for all gases on the LCD display,

blink the Test Fail icon for 5 seconds, and then exit calibration mode.

X4 Series 27

Page 28

No Gas Detected

4-3-5. Span Calibration Result

If one or more gases are detected, the detector will display the SPAN calibration

results after the countdown.

When the SPAN calibration has been completed successfully for all sensors,

•

the Test Pass icon will blink for 5 seconds.

If the SPAN calibration has failed for some sensor(s), the detector will give a

•

single beep and a single flash and indicate an error “Err” for the gas type in

question on the LCD display. Both the Test Pass icon and the Test Fail icon

will blink for 5 seconds.

If the SPAN calibration has failed for all sensors, the detector will give a single

•

beep and a single flash and indicate an error “Err” for all gases on the LCD

display. The Test Fail icon will blink for 5 seconds.

Note

If the span calibration fails, the calibration of failed sensor(s) will

remain as it was before the span calibration was attempted. Repeat the

SPAN calibration ensuring that the calibration gas used is of the correct

concentration, there is sufficient gas in the cylinder and the flow rate is

correct. If a second failure occurs, contact Honeywell Analytics or their

agent.

a a

All Pass Some Pass/Fail All Fail

After SPAN calibration, the detector saves the successful SPAN calibration value(s)

and exits SPAN calibration mode unless the ON/OFF button is pressed and held

within 5 seconds. If the ON/OFF button is pressed and held for 5 seconds while the

Test Pass icon and/or Test Fail icon are still blinking (depending on the

calibration result), the detector will save successful SPAN calibration value(s) and

repeat the SPAN calibration procedure.

X4 Series28

Page 29

5. Set-Up Mode

CAUTION

No gas will be detected while in the set-up mode.

The detector is provided with a means for the user to configure the following aspects

of its operation:

Latching/Non-latching alarms

•

The X4 has both latching and non-latching mode selections. When latching

mode is selected, both level 1 and level 2 alarms for all enabled gas

channels are of the latching type. When non-latching mode is selected,

both level 1 and level 2 alarms for oxygen and toxic gas channels are of the

non-latching type. For the flammable gas channel, only the level 1 alarm is

of the non-latching type. The level 2 alarm is designed to be a fixed latching

type according to certification requirement.

Note

•

•

•

•

•

•

Note

X4 Series 29

For a latching type alarm, the audible and visual alarms continue until

the user acknowledges the alarm. For a non-latching type of alarm, the

audible and visual alarms stop when the gas concentration comes down

to the level below the alarm set points (or in the case of Oxygen, the gas

concentration comes up to the level above the level 2 alarm ).

For the flammable channel only, once the gas concentration level exceeds

the alarm range, it remains latched until the On/Off button is pressed and

the over range condition is gone.

Alarm 1 set point

Adjusts the level 1 (flammable and toxic low, O2 excess) gas alarm set

point. A gas concentration at or above this point generates an alarm

instantly.

Alarm 2 set point

Adjusts the level 2 (flammable and toxic high, O2 deficiency) gas alarm set

point. A gas concentration at or below this point (for oxygen) or at or above

this point (for flammable and toxic) generates an alarm instantly.

STEL alarm set points

Adjusts the short term exposure limit alarm set points.

TWA alarm set points

Adjusts the time-weighted average alarm set points.

Confidence signals

Sets the confidence signal as a beep (“b--”), flash (“--F”), beep and flash

(“b-F”), or none (“---”). (Factory default is “---” for disabling the confidence

signals.)

Pass code protection

Enables or disables the pass code protection and changes the current

pass code as required. (Factory default pass code protection setting is

“oFF”. The factory default pass code is “000”.)

To proceed, the detector prompts the user to enter the current valid pass

code.

Page 30

Data logging interval

•

Sets the data logging interval to 5, 10, 30, 60, 120, or 180 seconds.

(Factory default is “60”.)

Current date

•

Sets the current date. (Factory default is US format for Minimax4 series

and EU format for ImpulseX4 series.)

Note

The order is month, day, then year in the US format. The order is day,

month, then year in the EU format.

Current time

•

Sets the current time in the order of hours, minutes, then seconds.

Note

Hour is expressed in a 24-hour format (eg. 3:42 PM = 15:42).

%LEL / %Vol (for flammable)

•

Measure the flammable gas concentration in the unit of %LEL or %Vol.

(Factory default is “%LEL”.)

Correction factor (for flammable)

•

Sets the %Vol concentration equivalent to the 100% LEL of the target gas

(Refer to Appendix B-2 for more information). (Factory default is “5.00” for

Minimax4 series and “4.40” for ImpulseX4 series.)

Calibration due date

•

Sets the interval (30 ~ 180 days) between span calibrations. (Factory

default is “180”.)

User ID number

•

Sets the user ID number (001 ~ 999). (Factory default is “001”.)

Sensor enable (on) / disable (off)

•

Enables or disables installed sensors.

Note

Disabling one or more installed sensors configures the detector to a 1,

2, or 3-gas unit. No protection is provided for the gas targeted by the

disabled sensor(s).

5-1. Entering the Set-Up Mode

While in measuring mode, press and hold both the UP and DOWN buttons

simultaneously for 3 seconds to enter the set-up mode. The detector will generate

a single beep, display the icon, generate a beep, and then enter the set-up mode.

If the Pass Code Protection feature has been activated, the detector prompts the

user to enter the pass code. (See Section 4-3-1 Pass Code Input.)

X4 Series30

Page 31

Note

If the user fails to input the correct pass code 3 times consecutively, the

detector will return to measuring mode

5-2. Changing the Detector Set-Up

The set-up mode menu structure is shown in Appendix A (A-3, A-4, A-5, and A-

6).

In set-up mode, pressing the UP or DOWN buttons scrolls to a function and pressing

the ON/OFF button selects the function, so that the displayed value or status may

be changed.

For each value/status, pressing the UP button increases the displayed value or

scrolls through the status, pressing the DOWN button decreases the displayed value

or scrolls through the status. Pressing the ON/OFF button accepts the displayed

value or status.

Note

The previous value or status can be restored by pressing the UP and DOWN

buttons together instead of pressing the ON/OFF button.

Once the displayed value or status has been changed and accepted, the new value

or status is stored within the detector.

5-3. Exiting the Set-Up Mode

In set-up mode, if no button is pressed within 20 seconds, or both the UP and DOWN

buttons are pressed together and held for 2 seconds, the detector will revert back to the

measuring mode.

X4 Series 31

Page 32

6. Maintenance

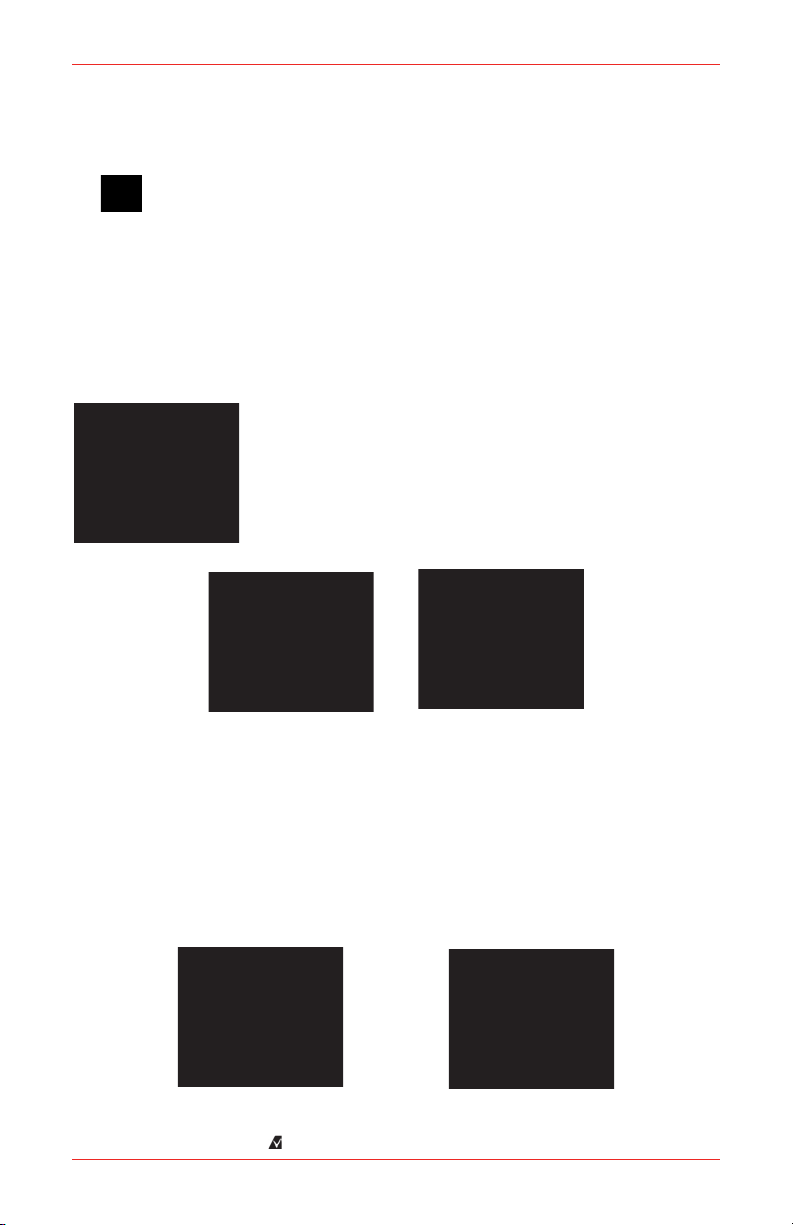

Lift

Turn 90º

Pull

6-1. Replacing the Batteries

WARNING

Substitution of components may impair intrinsic safety.

AVERTISSEMENT

La substitution de composants peut compromettre la sécurité intrinsèque.

WARNING

Use only approved ‘AA’ Alkaline Batteries, Energizer® E91 or EN91; or use

only approved ‘AA’ NiMH rechargeable cells, Quest 1500mAh, order part

number 2566-0454 (Quest part number HL-AAC1500). Use of any other

manufacturer or type will violate intrinsic safety requirements. The optional

NiMH rechargeable cells must be in a fully charged condition.

Use only two new batteries of the same type, when replacing the batteries.

Replace batteries as soon as the detector emits a low battery alarm.

Do not attempt to charge these cells in potentially hazardous atmospheres.

Do not remove the batteries from the detector while the power is on. This can

cause

fatal damage to the optional memory card if installed.

If the rubber boot is removed for servicing or any other reason, it must be

replaced before the instrument is placed back in service.

Turn the detector off.

•

Li ft the locking tab on th e bott om of th e d etect or and turn it 90°

•

counterclockwise.

Pull the battery holder with locking tab out of the detector.

•

Remove the old batteries and insert new batteries ensuring correct orientation

as indicated on the molding. Ensure they are of the correct type to comply with

the intrinsic safety requirements.

Note

Dispose of batteries according to local or national regulations.

Insert battery holder into the detector, turn the locking tab 90° clockwise, and

•

return the locking tab to its original position.

X4 Series32

Page 33

An optional sealed rechargeable NiMH battery is also available with an AC powered

cradle charger. Turn the X4 detector off. Remove the original (alkaline) battery holder

from the detector. Insert the sealed rechargeable NiMH battery pack, turn the locking

tab 90° clockwise and return the locking tab to its original position.

To charge the X4 in the cradle charger, first turn the X4 detector off. Ensure the

cradle charger POWER light is illuminated (orange LED).

Gently push the X4 gas detector (including the supplied rubber boot) into the open

bay of the recharger cradle. The front of the X4 should be visible from the front of

the cradle charger

illuminate (RED for charging

CHARGING light changes color to GREEN. Pull the X4 vertically out of the cradle

charger. The X4 detector is now charged and can be switched on.

Once correctly inserted the cradle charger CHARGING light will

mode). Leave the X4 unit in the cradle charger until the

WARNING

Use only the approved Honeywell Analytics charger (part number 2566-

0484) when charging the sealed rechargeable battery pack (part number

2566-0482 for Minimax4 Series and part number 2566-0462 for Impulse X4

Series). Use of any other charger will void the intrinsic safety certification of

the instrument. Use only the Honeywell Analytics supplied AC adaptor (part

number 2566-0483) to connect to the charger (part number 2566-0484).

The battery charger units contain no user serviceable parts; no attempt

should be made to alter or repair the cradle charger.

Note

Periodically inspect the battery holder terminal contacts for build up of

dirt. Remove any debris using soft cloth and industrial alcohol.

6-2. Installing or Removing the Memory Card

WARNING

Do not install or remove the memory card in the detector or attempt to read,

download or write to the memory card using a memory card reader and/or

computer in potentially hazardous atmospheres.

Use only approved memory cards, part # 2566-0435, which are available

from Honeywell Analytics. Use of any other manufacturer or type will

violate intrinsic safety requirements.

Turn the detector off.

•

Remove the battery holder from the detector. (See Section 6-1 Replacing

•

the Batteries.)

To remove the memory card from the detector, press on its edge until a ‘click’

•

sound is heard, which indicates the memory card has been released. The

memory card can now be pulled out from the detector.

To install the memory card, insert it into the card slot and press on its edge

•

until a ‘click’ sound is heard, which indicates that it is secured in the card slot.

Pay attention to the memory card direction (see diagram below).

Insert the battery holder into the detector. (See

•

Batteries.)

X4 Series 33

Section 6-1 Replacing the

Page 34

Memory Card

Card Slot

Data Contacts Face Up

6-3. Cleaning

WARNING

Do not use solvents, soap, polishes and any product containing silicon

compounds to clean the detector as these can cause damage to the sensors.

Clean the exterior of the detector with a clean damp cloth.

•

Clean the sensor grilles with a soft brush.

•

6-4. Replacing the Expired Sensor

If the sensor reaches the end of its recommended life, contact Honeywell Analytics

or their agent to arrange sensor replacement service.

X4 Series34

Page 35

7. Optional Accessories

WARNING

Do not install or remove the memory card in the detector or attempt to read,

download or write to the memory card using a memory card reader and/or

computer in potentially hazardous atmospheres.

Part No. Description

2566-0429 Field case

2655-0428 Belt clip

2566-0446 Hand aspirator kit with in-line lter and 10 m sample tube

2302B0828 10 m (30’) sample tube with in-line lter

2303B0845 In-line lter pack of 10

2303B0846 Ball oat

402-190-120 Tubing (2 m/6’)

2302B0847 1 m (3’) sample probe

2566-0427 10 m (30’) sample tubing with ball oat

GFV243 Calibration gas (CH4 50% LEL/CO 50 ppm/H2S 25 ppm/Balanced Air) 34 Liter

235-285-085 0.3 L/min ow regulator

2566-0435 Spare memory card for data logging

2566-0436 (*) Desktop USB memory card reader

2566-0482 Rechargeable battery pack (Minimax4)

2566-0462 Rechargeable battery pack (Impulse X4)

2566-0484 Battery Charger for Battery Packs 2566-0482 and 2566-0462

2566-0483 AC Adapter for 2566-0484 Battery Charger

2566-0437 Data log graphing and reporting software (CD)

2566K0438 (*) Data logging kit includes memor y card, memory card reader and

data log graphing and reporting software CD

2566-0442 Interactive training guide software / X4 simulator (CD)

2566K0440 Conned space kit for bump test with carrying case

2566K0441 Calibration kit (MAX-KIT#1-MINI) includes 34L cylinder (50% LEL, CH4, 50ppm

CO, 25ppm H2S, balance air)

Test-1A Bump gas cylinder (O2, LEL, CO, H2S, Bal. N2)

WARNING

The items indicated above with an asterisk (*) are not certified intrinsically

safe and must not be used in potentially hazardous atmospheres.

See Section 1-4 Standard Accessories for the part numbers of the standard

(included) items.

For inquiry see the Contacting Honeywell Analytics section on page 5.

X4 Series 35

Page 36

8. System Configuration Options

8-1. System Configurations for the Minimax4 series

Variant Description Part Number

4 gas Minimax4 with O2,

1

Flammable, CO, H2S sensors

2 3 gas Minimax4 with O2, Flammable, CO sensors MiniMAX-3-OFCX

3 3 gas Minimax4 with O2, Flammable, H2S sensors MiniMAX-3-OFXH

4 2 gas Minimax4 with O2, Flammable sensors MiniMAX-2-OFXX

5 1 gas Minimax4 with Flammable sensor MiniMAX-1-XFXX

6 1 gas Minimax4 with O2 sensor MiniMAX-1-OXXX

MiniMAX-4-OFCH

8-2. System Configurations for the ImpulseX4 series

Variant Description Part Number

4 gas Impulse X4 with O2,

1

Flammable, CO, H2S sensors

2 3 gas Impulse X4 with O2, Flammable, CO sensors ImpulseX-3-OFCX

3 3 gas Impulse X4 with O2, Flammable, H2S sensors ImpulseX-3-OFXH

4 2 gas Impulse X4 with O2, Flammable sensors ImpulseX-2-OFXX

5 1 gas Impulse X4 with Flammable sensor ImpulseX-1-XFXX

6 1 gas Impulse X4 with O2 sensor ImpulseX-1-OXXX

For inquiry see the Contacting Honeywell Analytics section on page 5.

ImpulseX-4-OFCH

X4 Series36

Page 37

Appendix A

< UP >

to increase

or

< DOWN >

to decrease

the value

--------------------< ON/OFF >

to save the value

and

scroll to the next gas

(Exp / CO / H2S)

Zero Cal.

Fail (all)

Zero Cal.

Fail (some)

Zero Cal.

Success (all)

< ON/OFF >

within 10 seconds to

activate the function

for setting span gas

concentration

< ON/OFF >

to save H2S value

Set Span Gas

Concentration

Span Gas

Information

Span Gas

Search

Span

Calibration

20 seconds countdown

with zero calibration icon blinking

wait for 10 seconds

< ON/OFF > for 5 seconds

while " " is blinking for 5 seconds

span gas search

for up to 30 seconds

60 seconds countdown

with span calibration icon blinking

Zero

Calibration

No Gas

Found

CH

4

CO

H2S

balance

O2/N

2

< 3 Gas Calibration >

Zero Cal.

Fail

No gas

found

A-1. Calibration Mode Menu Structure 1/2

X4 Series 37

Page 38

A-2. Calibration Mode Menu Structure 2/2

Span Cal.

Fail (all)

Span Cal.

Fail (some)

Span Cal.

Success (all)

60 seconds countdown

with span calibration icon blinking

Span Gas

Search

Span

Calibration

span gas search

for up to 30 seconds

60 seconds countdown

with span calibration icon blinking

No Gas

Detected

Span Cal.

Fail

Span Cal.

Success

< 1 Gas Calibration >

CO

balance

O2/N

2

< Continued from Span

Gas Information>

Span Cal.

Fail

No gas

detected

Span Cal.

Fail

X4 Series38

Page 39

A-3. Set-up Mode Menu Structure 1/4

< ON/OFF >

to activate the function

on

oFF

---------------------< UP > or

< DOWN >

to scroll

Alarm Latch

Setting

< ON/OFF >

to activate the function

< ON/OFF >

to save the new selection

O

2

Excess/

Alarm 1 Setting

Set

O

2

Excess/

Alarm 1

< ON/OFF >

to activate the function

Set

O

2

Defi-

ciency/Alarm 2

O

2

Deficiency/

Alarm 2 Setting

< ON/OFF >

to activate the function

Set

STEL Alarm

STEL Alarm

Setting

< ON/OFF >

to activate the function

TWA Alarm

Setting

Set

TWA Alarm

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< UP >

to increase

or

< DOWN >

to decrease

the value

--------------------< ON/OFF >

to save the value

and

scroll to the next gas

(O2 / Exp / CO / H2S)

< ON/OFF >

to save H2S value

< ON/OFF >

to save H2S value

< UP >

to increase

or

< DOWN >

to decrease

the value

--------------------< ON/OFF >

to save the value

and

scroll to the next gas

(CO / H2S)

< UP >

to increase

or

< DOWN >

to decrease

the value

--------------------< ON/OFF >

to save the value

and

scroll to the next gas

(O2 / Exp / CO / H2S)

< UP >

to increase

or

< DOWN >

to decrease

the value

--------------------< ON/OFF >

to save the value

and

scroll to the next gas

(CO / H2S)

< ON/OFF >

to save H2S value

< ON/OFF >

to save H2S value

X4 Series 39

Page 40

A-4. Set-up Mode Menu Structure 2/4

< ON/OFF >

to activate the function

< ON/OFF >

to save the new selection

< ON/OFF >

to activate the function

< ON/OFF >

to activate the function

< ON/OFF >

to save the new interval

< ON/OFF >

to activate the function

New

Pass Code

000 ~ 999

---------------------< UP >

to increase

or

< DOWN >

to decrease

5 / 10 / 30

60 / 120 / 180

----------------------

< UP > or

< DOWN >

to scroll

Enable/Disable

Pass Code

Protection

on

oFF

---------------------< UP > or

< DOWN >

to scroll

Pass Code

Setting

Data Logging

Interval

Date Setting

Confidence

Signals

- - -

b - -

- - F

b - F

---------------------< UP > or

< DOWN >

to scroll

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

Current

Pass Code

000 ~ 999

--------------------< UP >

to increase

or

< DOWN >

to decrease

< ON/OFF >

to enter current pass code

< ON/OFF >

to save Year data

MM DD - YY

US

----------------------

< UP > or < DOWN >

to adjust

while blinking

< ON / OFF >

to save and scroll to

the next setting

(US / MM / DD / YY)

DD MM - YY

EU

----------------------

< UP > or < DOWN >

to adjust

while blinking

< ON / OFF >

to save and scroll to

the next setting

(EU / DD / MM / YY)

Date Setting

to save the new pass code

< ON/OFF >

< ON/OFF >

to save the new selection

X4 Series40

Page 41

A-5. Set-up Mode Menu Structure 3/4

001 ~ 999

---------------------< UP >

to increase

or

< DOWN >

to decrease

< ON/OFF >

to activate the function

< ON/OFF >

to save the new days

< ON/OFF >

to activate the function

< ON/OFF >

to save the new number

30 ~ 180

---------------------< UP >

to increase

or

< DOWN >

to decrease

User ID No

Setting

Cal Due Date

Setting

< UP > or < DOWN >

< UP > or < DOWN >

< UP > or < DOWN >

< ON/OFF >

to activate the function

HH : MM : SS

----------------------

< UP > or < DOWN >

to adjust

while blinking

< ON/OFF >

to save and scroll to

the next setting

Time Setting

< ON/OFF >

to save Second data

< UP > or < DOWN >

< ON/OFF >

to activate the function

< ON/OFF >

to save the new selection

LEL

Vol

----------------------

< UP > or

< DOWN >

to scroll

LEL / Vol

Setting

< UP > or < DOWN >

< ON/OFF >

to activate the function

1.00 ~ 6.00

----------------------

< UP > or

< DOWN >

to adjust

while blinking

Correction

Factor Setting

< ON/OFF >

to save new value

< UP > or < DOWN >

X4 Series 41

Page 42

A-6. Set-up Mode Menu Structure 4/4

< ON/OFF >

to activate the function

Set Sensors

(on / off)

Sensors

(on / off)

< UP > or < DOWN >

< UP > or < DOWN >

< ON/OFF >

to save H2S status

< UP > or

< DOWN >

to toggle On/Off

--------------------< ON/OFF >

to save the status

and

scroll to the next gas

(O2 / Exp / CO /

H2S)

X4 Series42

Page 43

Appendix B

B-1. Sensor Cross-Sensitivity

B-1-1. H2S and CO SureCell Cross-Sensitivity

The H2S and CO sensors are designed to be gas specific, minimizing the effects of

common cross-interfering gases. The table below summarizes the effect of various

gases on the carbon monoxide and hydrogen sulfide sensors.

Gas Applied

Acetone (1000 ppm) 0 0

Acetylene (40 ppm) 0 80

Ammonia (50 ppm) 0 0

Carbon Monoxide (50 ppm) 0 50

Carbon Dioxide (5000 ppm) 0 0

Chlorine (0.5 ppm) 0 0

Ethanol (2000 ppm) 0 3

Ethylene (100 ppm) 0 85

Hydrogen (100 ppm) 0 20

Hydrogen Sulde (10 ppm) 10 0

Iso-Propanol (200 ppm) 0 0

Nitric Oxide (25 ppm) 0 4

Nitrogen Dioxide (3 ppm) 0 0.5

Sulfur Dioxide (2 ppm) 0 0

B-1-2. O2 Cross-Sensitivity

Gas Applied

Hydrogen (100% vol) -9

Methane (100% vol) 0

Nitrogen Dioxide (25

ppm)

H2S Response

(ppm)

Response

CO Response

(ppm)

O2

(% Vol)

0

X4 Series 43

Page 44

B-1-3. Flammable Cross-Sensitivity

Note

The flammable sensor requires O2 to properly operate. Display

concentration will drop with low levels of O2.

There is variability in sensor cross-sensitivity between methane and other

•

flammable compounds. Therefore, if the detector is calibrated to methane,

the reading when other flammable gases are detected will be subject to

variation.

For more accurate detection of non-methane gases, the detector should be

•

calibrated to the targeted gas desired. In this instance, the reading obtained

when methane is detected may be subject to inaccuracy.

WARNING

The flammable sensor’s sensitivity can be adversely affected by exposure

to certain substances called “poisons”. Sulfur compounds, phosphorus

containing compounds, halogens, silicone or lead containing compounds are

example of such poisons. Every effort should be made to avoid exposure to

these substances. When the detector is exposed to such substances, a check

should be performed on the flammable sensor to verify its accuracy and a

calibration performed if necessary.

Extended exposure of the detector to certain high concentrations of

flammable gases stress the flammable detector element, which can seriously

affect its performance. If an alarm occurs due to high concentration of

flammable gases, recalibration should be performed, or if needed, the sensor

replaced.

Do not expose the detector to electrical shock and/or severe mechanical

shock. When the detector is exposed to such shocks, a check should be

performed on the sensors to verify accuracy (and a calibration performed if

necessary).

X4 Series44

Page 45

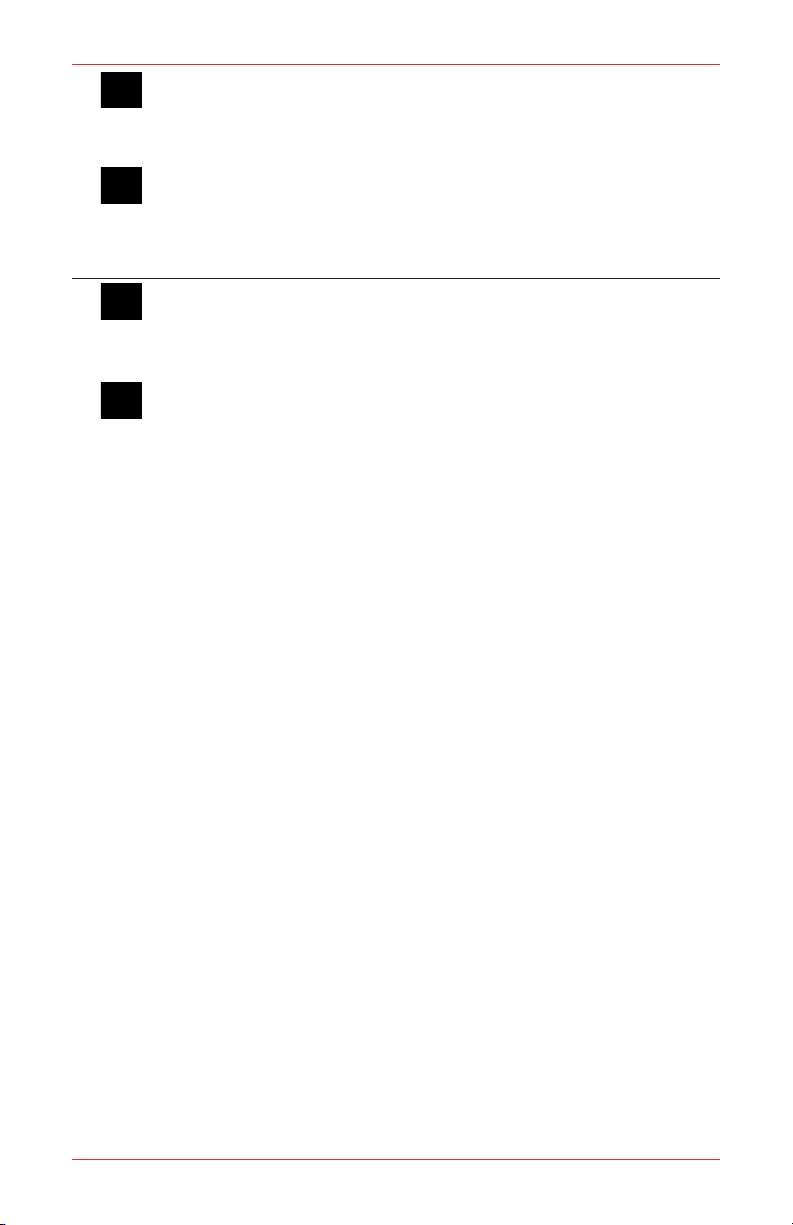

B-2. Flammable Lower Explosive Limit

Note

Gas Type

Hydrogen 4.00 4.00

Methane 5.00 4.40

Methanol 5.50 5.50

Ethane 3.00 2.50

Ethanol 3.30 3.10

Propane 2.10 1.70

Butane 1.80 1.40

Pentane 1.50 1.40

Octane 1.00 0.80

Factory default values of the Correction Factor are set to 5.00% Vol for

100% LEL methane for Minimax4 series and 4.40% Vol for 100% LEL

methane for ImpulseX4 series, assuming that the detector is calibrated

by methane with relevant concentrations suitable for each standard and

going to measure methane gas.

For measuring other gases listed in the table, the detector should be

calibrated with the target gas at relevant concentration and the proper

Correction Factor needs to be set depending on the standard to be used.

%Vol for 100% LEL

(Ref. - NIOSH: 2002)

%Vol for 100% LEL

(Ref. - IEC 7920)

X4 Series 45

Page 46

Appendix C

C-1. Warranty

All products are designed and manufactured to the latest internationally recognized

standards by Honeywell Analytics under a Quality Management system that is

certified to ISO 9001:2000.

Device Warranty Terms

24 months from date of switch on / installation

X4 Series

Service Warranty Terms

A. Replacement with new product within the rst

90 days of the original warranty period.

B. Repair (or replacement with new or

reconditioned product at HA discretion) after the

rst 90 days of the original warranty period.

Components replaced under original product

warranty.

Repair or Replacement outside of original warranty

period

Product Refurbishment Program (Minimax4 four

gas monitor only)

Warranty conditions

1.

The HA Limited Product Warranty only extends to the sale of new and unused products to the original buyer

where purchased from a HA authorized distributor or service center.

2.

Not covered are:

•

consumable items such as dry-cell batteries, lters and fuses or routine replacement parts due to the

normal wear and tear of the product;

•

any product which in HA’s opinion has been altered, neglected, misused or damaged by accident or

abnormal conditions of operation, handling, use or severe sensor poisoning; or failure to maintain and

calibrate the product as prescribed in the product documentation;

•

defects attributable to improper installation, repair by an unauthorized person or the use of unauthorized

accessories/parts on the product;

3.

Any claim under the HA Product Warranty must be made within the warranty period and as soon as reasonably

possible after a defect is discovered.

4.

If a Warranty claim is being sought it is the responsibility of the buyer to return the product to the distributor or

HA authorized service center along with a full description of the fault. If no description of the fault is provided,

HA reserves the right to charge an investigation fee.

A warranty claim will only be accepted if a proof of purchase is submitted and all conditions contained within

5.

this Warranty are met. When, in the opinion of HA, a warranty claim is valid, HA will repair or replace the

defective product according to the terms herein. Where repair or replacement provides signicant upgrade,

enhancement or modication of the instrument, HA reserve the right to charge a reasonable fee in respect

of such.

6.

In the course of the investigation it may be determined that recalibration of the instrument is required. In

provided this takes place prior to the ‘Activate Before’

/ install by date. Pro rata after ‘Activate Before’ /

install by date.

Full warranty period as specied in Warranty Terms

above.

Pro-rata warranty realized as balance of original

warranty specied in Warranty Terms above, or

equivalent discounted price on a new, fully warranted

instrument or component.

Warranted against same fault for 3 months from

date of repair

12 months from date of refurbishment

X4 Series46

Page 47

such cases, calibration charges may apply.

Please note that if, in the opinion of HA the warranty claim is not valid, HA reserves the right to charge for

7.

an investigation, any repair work carried out and for any attendance by its service engineer at the usual

rates in force at the time the claim was received.

In no event shall HA’s liability exceed the original purchase price paid by the buyer for the product.

8.

After the effective date, this warranty supersedes all existing warranty statements and HA makes no other

9.

warranty expressed or implied except as stated above.

C-2. Accuracy Statement

To achieve optimal accuracy, the detector should be periodically supplied with a

known concentration test gas, and if the readings are outside of 15% of the applied

gas concentration, a span calibration should be performed, under conditions of

standard temperature (15°C to 25°C), humidity and pressure.

X4 Series 47

Page 48

C-3. Declaration