Page 1

Honeywell

L404A

Pressuretrol@

L604

IA04

and

li7J

evoltage

ating

reset

300

psi

I

I

i

i

I

Ii

Can

or

ment

Stainless

cm2

monia

IA04B

ing

Models

ing

control

limit

21

be

fluids

2068 kPa

medium

and

pressure

protection

1

used

non

steel

oxygen

is

are

in

Dustproof

els

except

Automatic

differential

free

Trip

that

sures

defeated

by

PressuretrofFJ

controllers

automatic

for

with

steam

corrosive

diaphragm

models

distilled

pressure

available

of

which

models

except

function

jamming

or

with

operating

free

L604M

kglcm2

recommended

variety

trouble

lA04F

reset

mechanism

limit

limit

protection

pressure

2068

air

the

to

except

also

water

for

oil

spst

mercury

has

have

on

manual

of

reset

lever

kpa

non

pressure

supervision

burner

snap

adjustable

controller

trollers

Con

thatprovide

systems

combustible

300

psi

use

allows

and

similar

systems

or

spdt

ranges

switches

acting

reset

are

oper

ormanual

of

up

gases

sensing

21

1

with

media

of

atomiz

switch

dpst

mod

all

switch

subtractive

models

cannot

to

ele

kg

as

be

D

F

Screw

Scaleplates

cm2

kg

lA04F

British

scaleplates

Clear

plastic

and

tings

Leveling

Hexagonal

for

direct

loop

Surface

holes

knockouts

Controllers

on

marked

available

cover

is

made

Pipe

in

on

action

visible

with

available

in

in

English

with

Threads

kglcm2

case

418NPT

1

to

14026 Steam

case

adjustments

units

models

Standard

marked

switch

indicator

fitting

mounting

mount

L604A

L

of

top

ground

and

to

observe

through

using

backing

case

psi

Euro

pean

either

cover

internal

screws

M

and

enclosure

screw

psi

pressure

Trap

Metric

and

or

kPa

set

eads

SIphon

through

CONTENTS

Specifications

Ordering1nformation

Installation

I

L

Z

Rev395

@Honeywelllnc

1995

Setting

Service

and

Information

Checkout

11111111111111111

2

2

5

8

10

II

Page 2

DFL604ALM

04A

JECIFICATIONS

ORDERING

INFORMATION

Specitications

TRADELINE@

TRADELINE@

provide

replacement

trols

noted

TRADELINE@

L604A

ADDmONAL

ease

are

the

below

Pressuretrol@

10to150

50

103

kPa

cm2

69

to

2068

cross

kPa

reference

value

same

4

STANDARD

MODELS

trollers

IA04A

See

MODELS

models

of

stocking

Specifications

as

MODELS

and

35

to

1034

kPa

FEATURES

label

MODELS

DFandL604A

Table

are

ease

those

of

A

V

Controllers

20

to

300

cm2

kg

and

1

A

14026 Steam

selected

of

standard

All

ABLE

and

handling

of

and

TRADELlNE@

models

Available

14to11

psi

34

to

345

kPa

14to21

0

kg

TRAnELINE@

L

MPressuretrol@Con

Trap

packaged

maximum

except

in

2

to

15

cm2

kg

7to10

cm2

138

pack

siphon

con

5

14to

6

kg

with

loop

available

is

to

trap

is

necessary

SWITCHESMercury

2068

minus

4

which

SENSING

brass

kPa

models

AMBIENTTEMPERA11JRE

AMBIENT

370C

section

are

marked

CONNECTIONS

in

ofcase

side

MEANS

18

NPT

trap

siphon

screws

IA04F

as

PRESSURE

phragm

MAXIMUM

to

to

MINlMUM

Mounting

ADJUSTMENT

Scales

ELECfRICAL

hole

MOUNTING

1

steariJ

using

case

exCept

for

hasaMicro

bellows

also

MEANS

in

internal

loop

through

where

noted

boiler

installations

switch

es

Switch

ELEMENT

in

TEMPERATURE

refertothe

Screws

and

kPa

psi

for12in

Hexagonal

threads

two

for

Also

holes

in

in

all models

snap

300

note

on

top

Internal

conduit

fitting

mounting

can

be

knockouts

Table

acting

Stainless

21

psi

1500F

in

the

of

controller

screw

on

diaphragm

surface

1

The

except

swit9h

steel

1

Minus

Location

tenninals

on

a

mounted

in

kg

660C

pipe

back

steam

the

dia

cm2

350F

and

case

has

or

of

When

Catalog

1

2

3

4

5

6

If

you

1

2

purchasing

or

price

number

Order

Operating

Model

without

Optional

specifications

Replacement

Accessories

have

additional

local

Your

Home

and

Honeywell

Minneapolis

In

Cmlada

Officesinall

Service

Netherlands

replacement

sheets

for

TRADELINE4D

see

range

steam

parts

if

desired

questions

Home

and

Building

Inc

1885

Minnesota

Honeywell

Spain

and

modernization

comple

Table

if

Control

1

if

trap

if

desired

desired

need

Building

Customer

Douglas

ordering

modelifdesired

desired

further

Control

Drive

55422

4386

LimitedIHoneywell

principal

Taiwan

cities

United

number

and

see

fable

infonnation

Sales

Logistics

North

612

of

the

Kingdom

products

available

1

Office

951

Limitee

world

from

or

specify

see

Table

would

or

please

1000

740

ManufacturinginAustralia

U

SA

TRADELlNE@

your

I

Note

like

to

check

Ellesmere

Ordering

wholesal

b

on

conunent

the

Road

white

our

of

pages

Scarborough

Canada

products

your

phone

Ontario

Finland

Information

or

r

distributor

or

services

directory

M1P2V9

France

refertothe

please

International

Germany

write

Japan

Tradeline

or

phone

Sales and

Mexico

Page 3

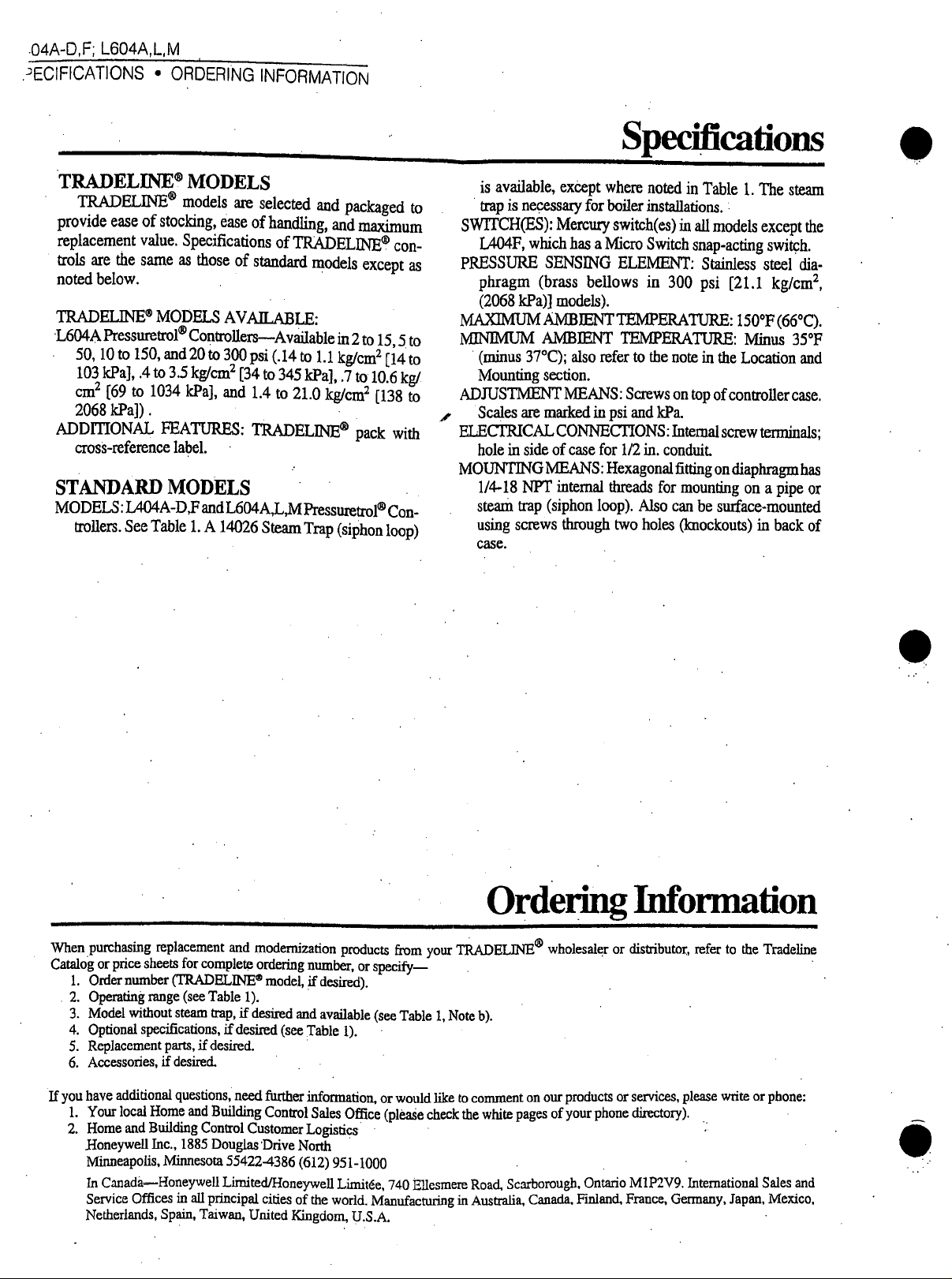

Model

L404A

i

8

I

A04

I

A04C

lA04D

lA04F

L604A

L604L

L604M

a

Scaleplates

b

Model

C

L404A

d

Brass

bellows

e

Model

0

035

f

Model

g

L404C

function

minimum

h

L404F

Model

J

switches

Spst

k

Also

recommended

a

L404F

b

L6

4A

ratmg

Switching

Action

Pressure

to

spst

spst

spst

spst

spdt

switch

W

R

isolated

2

circuits

spdt

W

spdt

makes

breaks

spdt

makesR

breaksRB

are

available

B

and L604A

available

kglcm2

available

D

and

as

an

value

only

available

Model

L404A

L604A

L604M

snap

andLhave

of98

on

Rise

Setpoint

breaks

circuit

makes

circuit

breaks

circuit

makes

circuit

acting

snaR

makes

breaks

R B

spst

1 5

or

R1

makes

breaks

R2

circuit

R

W

R B

circuit

W

markedinboth

with

special

models

replaces

with

minimum

345kPa

or

with

special

L604L

models

automatic

of

the

other

with

operate

models

sealed

in

for

all

Lb

acting

also

load

Afull

psi

2to

5to50

10

to

20

to

2

to

15d

5to50

10

to

20

to

2to15

5to50

10to150

to

20

2to15

10to150

2to15

5

10to150

20

to

to15C

2

10

B

20

to

2

10to150

psi

fixed

are

stainless

steel

operating

fixed

are

designated

reset

device

adjustable

have

bell

unison

spdt

supervision

does

not

been

tested

plus

Operating

15b

c

150b

300d

c

e

f

150e

b

300d

300d

to

50i

300d

to

50

150

to

300d

15

to

and

kglcm2

low

differential

available

diaphragm

pressure

low

differential

when

differential

mercury

crank

adjustment

action

of

atomizing

SWITCH

Load

Full

Load

Locked

Norimductiv

Full

Load

Locked

Noninductive

Load

Full

have

non

and

360

VA

TABLE

Ranges

kglem2

14to1

0

35to3 5

66to10

14to21

14to11

35to35

66to10

14to21

1

14 to

35to35

66to10

1

4to21

14 to

1

66to10 69

14 to10

35to

3 5

66to10

14

to21

14 to10

35to3 5

66to10

1

4

to21

14to1

66to10

Switch

with

1

to

Not

of

Switch

as

Manual

manual

the

of

the

L404A

switches

when

jumper

medium

CONTACT

Rotor

Rotor

inductive

listed

by

ignition

MODELS

1

a

14to103

34to345

6 69

138

0

14

24to345

69to1034

6

138

0

14to103

0

34to345

69

6

138

0

0

14

14to103

34to345

69to1034

138

0

14

34

69to1034

138to2068

0

0

14

69to1034

1

rated

6

midscale

psi

suitable

1

25

psi

rated

Reset

reset

for

is

pressure

or

dc

Underwriters

250

plus

kPa

to

1034

to

2068

to

103

to

2068

1034

to

to

2068

to

103

to

1068

2068

to

103

to

to

345

to

103

for

subtractive

for

use

009

kglcm2

for

0

2

controllers

is

held

lever

each

corresponding

installed

air

RATING

120

Vae

0

8

48

0

10

0

0 5

8

48

0

10

0

1

0

ratings

Laboratories

VA

pilot

V

A

I

Midscale

2to6

4

8

15to40

2to6

4

8

15

6

10

20

8to16

15

O

5A

with

5A

between

or

in

duty

All

ABLE

psi

to

12

16

to

12

to

16

to

40

to

fixed

fixed

2to6

14

to

22 69

to

50

to

2to6

to

12

40 1

to

fixed

at

120

ammonia

or

at

120

the

trip

the

in

Rl

steam

amperes

Subtractive

Adjustable

kgfcm2

to

41

14

82

28

to

1

10

56

to

276103

1

04

to

14to41

28to82

56to1

10

04to2

76

1

reset

manual

subtractive

manual

reset

subtractive

14 to

41

97 41to97

41

to

15

to

3

1

4

to

to

41 14to41

14

28to82 27

56to1

10

04

to

2

manual

reset

subtractive

fixed

3 5

psi

Vac

differential

8

62

Vac

reset

and

inanoil

at

120

in

oxygen

and

kPa

free

reset

position

operating

R2

burner

at

50 60

240

Vac

51

30

6

50

1

30

6

50 80

05 1

Inc

and

Vac

Differential

kPa

14to4

to

127

55to110 225

to

14to41

27to83

55to110 225

103to276 500

differential

g

differential

14to41

2

60to152

5 138

76

241kPa

2

minimum

to

to

55to110 225

103to276 500

g 25

differential

to

15

psi

other

corrosivematerials

or

mechanism

The

subtractive

range

system

Hz

120Vde

24

20

breaking

L404A

I

a

Maximum

Pressure

psi

kglem2

83

85

276

500

85

85 6

225

500

225

85

225

345 500

25

83

85

225

models

subtractive

does

4

0

5

0

20

0

0

not

differential

not

permit

differentialisfixedatthe

I

making

a

L604ALM

D

F

SPECIFICATIONS

I

Surge

kPa

35

6

15 8

35

35

6

15

35

35

15

35

35

15 8 1550

35

60

15 8

35

15 8 1550

35

15 8

the

load

0

2

0

8

2

0

8

2

2

1

8

6

0

2

1

8

of

controller

240Vde

2

1

0

12

20

10

10

0

4

0

05

with

345

586

1550

3445

345

586

1550

3445

345

586

1550

3445

345

345

586

1550

3445

172

586

3445

172

1550

0

a

5

total

psi

to

I

1

flO215010

Page 4

404A

DFL604A

JPECIFICA

nONS

L

M

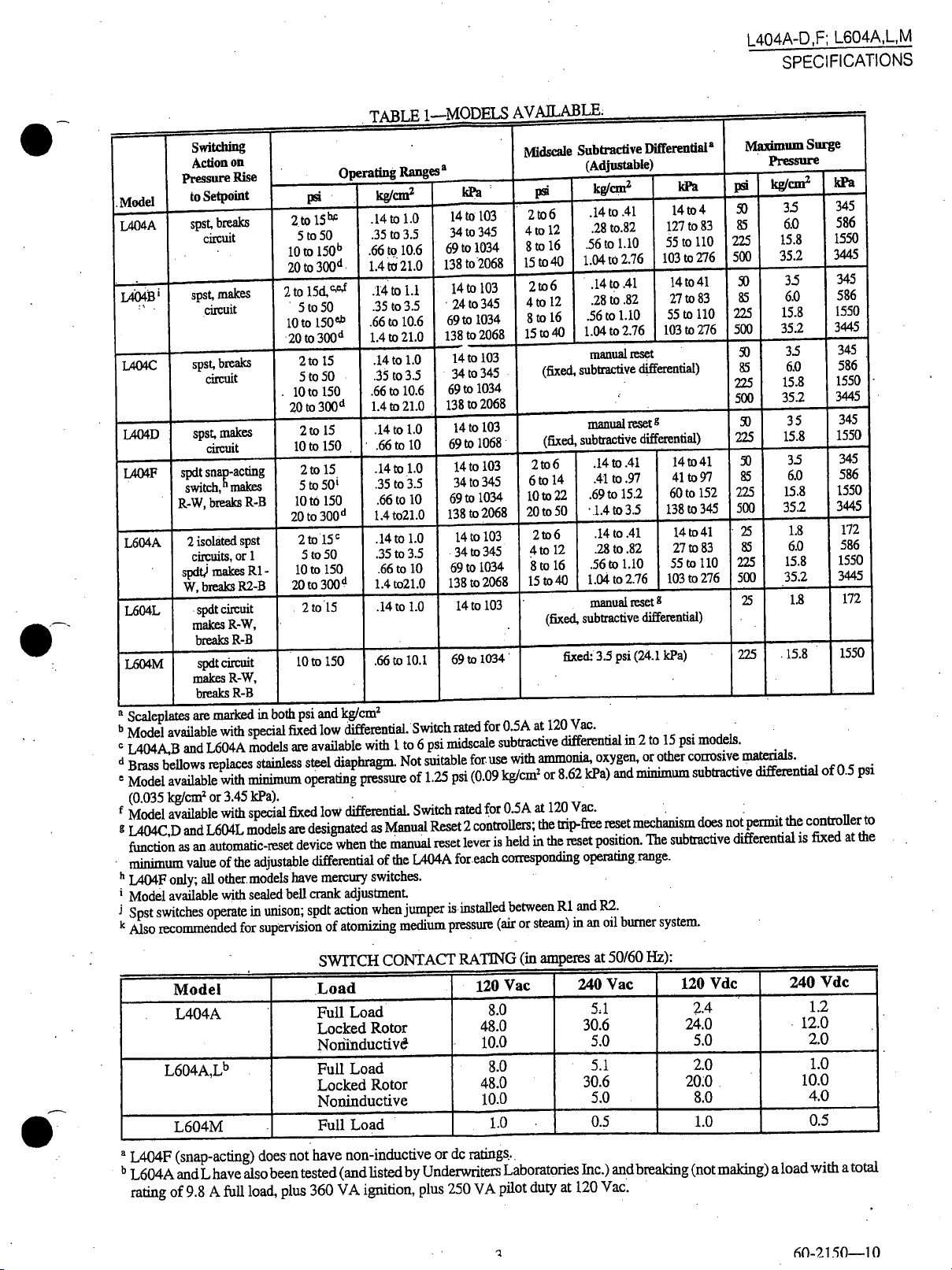

DIMENSIONS

trap

siphon

WEIGHT

FINISH

Gray

APPROVALS

Underwriters

no

Canadian

L604A

I

Scale

psi

oto15

2

to

5to50

5to150

10to150

20to300

2

me

L604A

L

MBPR

Standards

L

Plate

15

See

Fig

loop

0

91

kg

Laboratories

M

only

Association

file

only

Operating

kglcm2

14

3to3

3

7to10

1

1

See

file

no

OtolO

to1

to

4to20

Fig

Inc

no

certified

LR1620

Range

Equivalent

0

5

10

3

3

7

2

for

listed

MP466

guide

TABLE

mounting

A

IA04

v01

l0

LA04A

B

noAOO

2

kPa

o

to

14

34

34

to

69

to

138

s

BCD

F

guide

CD

F

E

O

ONVERSION

103

to

103

to

345

1034

1034

to

2068

REPLACEMENT

129178

14026

Thermoplastic

Steam

Trap

Necessary

ACCESSORlES

33312B

Knurled

on

main

scale

4074BWJLimitStop

TABLE

Scale

ineludes

Screw

Plate

psi

and

to

129564

kPa

Subtractive

psi

1to6

2to

6

4to

12

5to14

16

8

to

10to22

40

15

to

20to50

PARTS

siphon

for

boiler

Adjustment

pressure

Range

23466

Wrench

kglcm2

07to4

14

3to8

4to1

6to11

7to1

1

0to28

1

4

to

Cover

loop

installations

Knob

adjusting

Assembly

to

Stop

DitTerential

Equivalent

to

4

0

5

35

l

4inblack

with

screw

limit

107194

55

69to152

103

138to345

setscrew

set

point

Range

kPa

7to41

14to41

28

to

41to97

to

110

to

276

83

iron

pipe

fits

ranges

Stop

Flg

1

Mountlng

LA04A

dimensions

FjI604ALM

1

1S16

3G16

1

32

29A

41

l

1143COVER

4

1132

49

2

81

0

1r

110

3

of

the

L404A

B

CASE

Hl1164

C DFand

49

6

L604ALM

pressuretroP

2

at4

69

9

Controllers

in in

mm

j

1

I

1

1M6

48

0

J

Me

4

KNOCKOl1T

3 76

lI8

4

X

21164

6

63

2

3

2332

94

5

43132

126

2

L

1

1f

1

RESET

LEVERONMANUAL

iHISOIMENSION

AND534

N

l48

AMM

ONLY

ON

Ui04MOOasWITHA2TO

hO

1

1

RESET

MOOas

ONLY

IS

27132IN

t23

0MM

ON

t

eo4MOOas

ONlJi04MOOasWITHA21O

WlTHA2010

15

PSI

141010

300

kgIan2

PSI14TO2A7

103

14

10

1SPSl

kPo

iqycm2

OPEAAllNG

14

TO

1

1410103

2068JdaOPERATING

kPa

13810

0kg

an

RANGE

38

OPERATINGRANae

RANGE

n

Page 5

WHEN

them

INSTALLING

1

Read

could

condition

2

Check

ct

prod

to

application

3

Installer

control

guard

After

4

operation

as

TIllS

these instructions

ratings

must

sure

be

the

given

the

a

tramed

damage

the

make

technician

installation

provided

is

in

PRODUCT

carefully

product

in

the

product

complete

instructions

these

Failure

or

cause

instructions

is

suitable

expenenced

check

to

hazardous

a

andonthe

for

flame

out

product

follow

your

safe

Fig

trap

sions

2

Rlght

siphon

in in

and

loop

mm

wrong

with

l404A

D

F

INSTALLATION

Installation

a

steam

mounting

approximate

of

dimen

l604A

M

l

ffi

CAUTION

1

2

IMPORTANT

1

Locate

will

2

Use

hole

not

Do

3

4

Accurately

LOCATION

For

NOTE

to

installations

200P

minus290C

temperatUre

cause

mercury

When

above

troller

loop

siphon

troller

and

corrosive

the

steam

on

of

controller

the

expansion

causes

the

The

controller

sure

gauge

manufacturer

vibration

cutoff

Disconnect power

stallation

age

When

install

header

can

not

pipe

in

tighten

most

used

the

vapors

or

switch

or

the

the

trap

contraction

2

to

electrical

or

using

a

dampening

or

surge

damage

controller

exceed

1500F

compound

or

pipe

the

the

level

AND

MOUNTING

accurate

where

falls

below

in

the

with

steam

water

the

must

always

boiler

from

must

If

the

to

operate

can

in

a

fitting

3

ataremote

4

in

a

controllerbyhand

Never

Fig

be

before

supply

prevent

the

possible

shock

controller

the

suchasaneed1e

device

to

tank

controllerorreduceits

where

dampen

the

ambient

660C

sparingly

diaphragm

controller

operation

the

temperature

minus

switch

boilers

line in

be

2

attacking

always

loop

of

the

to

fitting

for

proper

add

the

locate

350P

freezesatthis

always

the

boiler

connected

to

prevent

the

diaphragm

be

perpendicular

is

parallel

tips

loop

inaccurately

mounted

on

special

boiler

the

location

mounting

1

beginning

equipment

with

a

compressor

pulsations

life

temperature

avoid

clogging

the

holding

by

operation

supplemental

below minus

falls

controller

minus

where

370C

temperature

mount

the

A

steam

between

to

the

alongside

boiler

the

controller

the

scale and

The

to

controller

the

provided

case of

in

excesSIve

low

on

a

the

in

dam

valve

that

case

heat

con

trap

con

loop

face

pres

by

water

the

the

be

and

e

Make

standards

seal

the

the

small

operating

Toavoid

wrench

the

controller

LeveUng

A

controller

leveled

indicator

over

the

controller

loop

Mounting

To

mount

2

Fig

siphon

nipples

endsofthe

1

4

BLACK

IN

TRHEADSON

SIPHON

Use

pipe

connections

only

all

connection

holeinthe

properly

leaks

the

controller

on

hand

by

with

for

proper

11

Fig

mark

index

bycarefu11y

Alongside

the

remove

loop

moUnt

tee

the

with

the

Level

IRON

PIPE

ENDS

BOTH

LOOPTOLEVEL

a

small

Excess

joints

fitting

and

damage

s

hexagonal

by

holding

a

mercury

operation

hangs

inside

bending

a

Pressure

controller

gauge

a

tee

on

controller

controller

the

WITH14

THE

in

accordance

amount

and

prevent

to

switch

Itislevel

freely

the

backofthe

alongside

In

its

top

and

18

STEAM

THE

BEf

lD

CONTROLLER

of

pipe

pipe

compound

the

the

case

fitting

the

case

must

with

its

the

steam

Gauge

install

place

Using

pressure gau

after

NPT

EXTERNAL

with

compound

controller

use

a

Donot

be

when

pointer

case

a

pressure

elbows

installattOn

TRAP

M8934

approved

can

clog

from

parallelJaw

tig

accurately

the

leveling

directly

Level

trap

siphon

gauge

a

steam

and

pIpe

e

on

to

ten

the

ap

the

I

11

Page 6

D

L404A

F

INSTALLATION

Mounting

If

it

the

pressure

fitting

fitting

the

boiler

steam

Mounting

If

there

adversely

controller

must

be

properly

boiler

tween

controller

on

is

not

gauge

provided

mount

manufacturer

and

trap

at

is

affect

ataremote

suitable

pitched

A

steam

the

remote

after

M

L604A

L

a

Boiler

convenient

install

the

by

the

steam

level

a

Remote

excessive

the

operation

and

solidly

to

trap

piping

installation

to

a

boiler

trap

Screw

the

controller

Location

vibration at

location

drain

siphon

mount

steam

manufactUrer

at

a

location

the

of

the

All

mounted

all

condensation

loop

and

the

the

controller

trap

siphon

controller

the

controller

piping

The

must

controller

alongside

loop

If

there

recommended

directly

boiler

that

mount

from

the

must

piping

backtothe

be

mounted

Level

in

is

to

can

the

boiler

be

the

the

no

by

the

be

3

Fig

schematics

L404A

BREAKS

ON

PRESSURE

TO

SETPOINT

L404

C

RISE

terminal

blocks

RISE

L404B

MAKE ON

PRESSURE

TO

SETPOINT

and

internal

RISE

B

D

RISE

L404F

SNAP ACTING

BREAKSRa

MAKESRWON

PRESSURE

TO

SETPOINT

RISE

M8941

SupervisionofAtomizing

Air

or

When

oil

burner

bodies

opening

sure

is

atomizing

The

makesacircuit

breaks

differential

WlRING

1

to

preventelectrical

2

Assume

co

ordinances

voltage

3

Fornormalinstallations

wire

sUitable

the

controller

least

1940F

control

4

For

tant

No

maximum

All

5

3

and4anda7 8in22

condui

tIi

e

screw

ing

6

Refer

the

burnerorboiler

vided

7

Make

Ratings

8

Replace

Steam

L404B

air

or

steam

system

and

codes

the

main

oil

present

andtoshut

pressure

L404B

is

when

when

the

pressure

10

Fig

t

the

DiscoDDe

all

wiring

wiring

foratleast

withaflame

900C

high

temperature

14

wire

selected

operating

have

models

cableorwires

the

at

to

Fig

the

sure

the

in

Specifications

front

the

is used

authorities

often

valve

falls

recommended

the

power

shock

and

regulations

when

temperature

a

bottom

5

through

manufacturer

loads

cover

Medium

require

until

too

low

pressure

falls

supply

or

equipment

complies

1670

1

safeguard

using

installations

for

a

terminal

2

mm

Remove

of

9

do

not

section

when

as

the

Pressure

an

atomizing

jurisdiction

having

a

low

limit

sufficient

down

the

system

for

this

to

rises

the

to

set

the

point

before

beginning

damage

with

applicable

Use

NEC

use

moisture

when

750C

primary

it

with

a

use

temperature

block

hole

the

main

for

typical

s

exceed the

inside

in

one

front

scale

wiring

wiring

rating

cover

hookups

diagram

Switch

is

medium

in

approval

to

prevent

atomizing

pres

when

application

set

point

minus

wiring

electrical

Class 1

resistant

you

control

are

line

No

using

or

programming

moisture

the

side

completed

above

cover

for12

loosen

by

Follow

if

Contact

resis

Fig

pro

the

and

the

the

in

4

L404

an

schematic

Fig

terminal

block

and

Internal

It

L604A

MAKES

BREAKSR28

ON

SPDT

OTHERWISE

W

Rl

PRESSURE RISETOSETPOINT

SWITCH

ACTION

TWO

WITH

ISOLATED

JUMPER

SPST SWITCHES

INSTALLED

L604L

M

M8935

14

at

Fig

controller

POWER

SUPPLY

PROVIDE

AS

HIGH

TO

LOW

MINUS

OPERATING

TO

SETPOINT

Ll

U

HOT

1

Lll

DISCONNECT

REQUIRED

l

404A

UMIT

SETPOINT

UMIT

t

DIFFERENTIAL

SETPOINT AND

MINUS

4048

L404 used

S

SPST

CONTROLLER

MEANS

C

OR

BREAKS WHEN

MAKES

DIFFERENTIAL

as

a

AND

BREAKS

404A

CONTROLLER

t

AGAIN WHEN

limit

OVERLOAD

WHEN

PRESSURE

BREAKS

orasan

PROTECTION

PRESSURE

FALLSTOSETPOINT

WHEN

PRESSURE

operating

FlAME

SAFEGUARD

CONTROL

MOTOR

OTHER

RISES

PRESSURE

FALLS

OR

LOAD

RISES

TO

M8936

Page 7

L404A

D

F

L604A

L

INSTALLATION

M

6

Fig

VOLT

24

THERMOSTAT

PROVIDE

AS

7

Fig

as

a

high

Ll

HOT

POWER

SUP

PLY

12

l404

LOW

DISCONNECT

REQUIRED

l404F

limit

PROVIDe

AS

REQUIRED

BREAKSRTO

FALLS

TO

withalow

VOLTAGE

l604A

with

SPOT

CONTROUER

LOW

UMfT

DISCONNEct

W

AND

SETPOINT

voltage relay

RELAY

MEANS

Oump

an

alarm

MEANS

RTOB

MAKES

MINUS

DIFFERENTIAL

LOAD

AND

AND

OVERLOAD

r

installed

circuit

OVERLOAD

WHEN

PRESSURE

POWER

SUPPLY

PROTECTION

used

FlAME

SAFEGUARD

CONTROL

MOTOR

OTHER

PROTECTION

MB937

OR

LOAD

8

Fig

l604M

l404F l604A

used

as

with

limit

jumper

with

a

low

an

installed

alarm

or

circuit

SPOT

Lb

PROVIDE

AS

REQUIRED

BREAKS

RISES

L404F

W

ill

DISCONNECT

RTOB

CONTROUER

HIGH

ALARM

DISCONNECT

RTOB

TO

SETPOINT

an

AND

UMIT

MEANB

AND

MAKESRTOWWHEN

or

L604

M644B

motor

WHITE

BLACK

BLACK

MeANS

MAKES

R

TOWWHEN

AND

wlth

AND

OVERLOAD

jumper

UNEVOLTAGE

lWO

POsmON

CLOSED

LOW

OPEN

HIGH

OVERLOAD

PRESSURE

PROTECTION

PRESSURE

installed

MOTOR

ARE

FIRE

PROTECTION

FlAME

SAFEGUARD

CONTROl

MOTOR

OR

OTHER

LOAD

M8938

MB44B

M8939

L1

HOT

1

a

L2

Ll

HOT

POWER

SUPPLY

12

M8940

9

Fig

controlling

SPOT

CONTROLLER

Ll

HOT

POWER

SUPPLY

L2

PROVIDE

AS

REQUIRED

BREAKS

RISESTOSETPOINT

Page 8

04A

ETTING

D

F

AND

L604A

L

M

CHECKOUT

SETIING

all

In

scale

main

mined

by

ing

point

differential

installed

shown

are

Fig

L404A

L404B

L404F

L604A

models

set

main

the

is

determined

setting

L

M

in

Fig

L404

1o

C

PRESSURE

RISE

D

L604

M

D

lA04C

DIFFERENTIAL

TO

FALLS

l

604M

HAS

W

the

point

have

10

and

I

PRESSURE

RISE

I

PRESSURE

RISE

I

PRESSURE

RISE

AND

l604L

THE

MAIN

A

differential

The

scale

The

spdt

MANUAL

THEY

CAN

SCALE

AXED

SMALl

upper

set

point

main

the

by

L404F

switching

L604

operating

SUBTRACTIVE

DIFFERENTIAL

SUBTRACTIVE

DIFFERENTIAL

SUBTRACTIVE

DIFFERENTIAL

MAKE

SUBTRACTIVE

DIFFERENTIAL

RESET

MANUALLY

BE

SETPOINT

DIFFEAENTlAL

is

subtractive

operating

while

and

action

point

lower

the

scale

setting

L604A

with

Operating points

points

MAIN SCALE

DIFFERENTIAL

MAIN

DIFFERENTIAL

MAIN

BREAKSRBMAKESRW

MAKESRBBREAKS

BREAKS

SETPOINT

BREAKS

SWITCH

SETTING

MAKES

SWITCH

SETPOINT

SCALE

SWITCH

MAKES

SETTING

SWITCH

BREAKS

SETPOINT

SCALE

Rl

MeDB

S

RESET

Rl W

OF

SETTING

W

BREAKSR28

SETTING

MAKESR28

HAVE

A

SMALL

WHEN

THE

DIFFERENTlAL

PSI025

3 5

DIFFERENTIAL

MAIN SCALESETPOINT

DIFFERENTIAL

MINUS

THE

R

kgIcm2

W

from

is

deter

operat

less

jumper

4

ill

4

ill

a

AXED

PRESSURE

the

the

Setting

scale

main

fonner

their

until

wait

differential

and

11

Fig

release

you

from

troller

is

lever

stuck

11

Fig

ADJUSTABLE

150

AND

TRIP

MODELS

PSI

setpoint

positions

the

pressure

Fig

release

the

becoming

held

Setting

0

34

MODELS

L604A

MANUAL

FREe

ONLY

They

10

Then

it

manual

in

a

DIAPHRAGM

ASSEMBLY

DIFFERENTIAL

103

TO

kglcm2

ONLY

RESET LEVER

and

will

To

falls

The

reset

an

automatic

or

tied

Checkout

not

one

reset

depress

controller

lever

ON

TO

34

to

down

Press

Jretrollli

THE

134

ON

the

L404A

of

set

the

will

This

reset

kPal

THE

B

L404CDAND

automatic

illy

these

point

manual

not

be

prevents

device

Controller

INDICATOR

F

L404L

OPERATING

return

controllers

minus

reset

lever

until

reset

the

reset

if

the

TO

WITHA5

RANGE

L604L

MIlIl43

to

the

con

Adjust

pressure

the

on

the

is

at

3

to

L604A

ferential

setting

L604L

The

L604M

marked

Trip

The

makes

the

by

of

top

desired

10

3

kg

adjust

adjusting

indicator

are

psi

Free

L404C

D

L404C

R

W

main

turning

the

value

cm

the

manual

has

arid

kg

Manual

and

L604Lonly

breaks

and

scale

the

case

2

34

differential

screw

is at

reset

a

fixed

cm2

Reset

breaks

main

until

On

to

set

an

1034

the

models

the

R

for

point

scale

adjusting

the main

L404A

scale

B F

kPa

settingbyturning

11

Fig

desired value

see

differential

Feature

L404D

B

when

makes

the

desired

the

screw

setting

witha5to150

operating

until

the

the

next

The

scaleplates

and

pressure

operating

Fig

indicator

range

differential

L404C

paragraph

the

risestothe

the

D

L604L

11

psi

or

an

dif

and

are

CHECKOUT

After

the

with

the

system

and

the

lowered

Also

do

they

necessary

Use

the

Then

setpoint

check

gauge

accurate

controller

stabilize

raising

when

is

If

pressure

be

out

controllers

controller

observe

lowering

the

not

agree

a

pressure

are

carefully

has

in

operation

its

raised

is

make

with

slight

not

Do

is installed

First

the

operation

setpoint

decrease

and

break

and

a

separate

adjusnnent

testing

on

rely

calibrated

of

Pressure

points

of

equipment

inexpensive

at

and

wired

allow

the

the

controller

should

when

of

the

accurately

the

scaleplate

when

the

factory

set

system

the

controller

calibrated

gauges

test

to

while

increase

set

point

s

may

checking

The

it

Page 9

Boiler

Installation

If

the

as

follows

1

Note

gauge

a

pressure

scale

2

Turn

m

rlnscale

b9iler

3

TheL404A

controller

the

range

the

setting

pressure

it

sure

have

main

th

automatically

or

slightly

circumstances

break

The

R2 B

4Ifthe

scale

indicator

The

L404BorD

The

L404F

theRB

L604A

circuit

adjusting

is at

exceeds

controller

boiler

To

perform

main

when

circuit

should

under

screw

the

is

being

pressure

reading

scale

indicator

gauge

or

C

the

the

should

under

the

Fig

desired

used

this

near

adjusting

on

readiri

should

boiler

controller

make

should

L604L

M

the

make

same

is

operating

11

set

on

a

boiler

by

checking

testproperly

the

middle

screw

the

controller

g

the

break

pressure

gauge

setting

the

circliit

inake

theRW

same

circumstances

theRIW

circumstances

point

until

circuit

properly

the

installation

the

boiler

the

boiler

the

controller

of

11

Fig

corresponds

control

reading

under

circuit

and

turn

main

scale

until

circuit

the

break

the

test

pres

should

the

equals

same

and

the

main

setting

L404A

SETTING

ffi

s

CAUTION

Do

not

the

system

put

satisfactorily

scribedinthis

sectionofthe

safeguard

burner

and

completed

Checkout

applicable

control

boiler

into

service

all

section

instructions

and

any

others

manufacturers

applicable

AND

until

in

the

Checkout

for

the

required

D

F

L604ALM

CHECKOUT

have

you

tests

de

flame

tlie

by

to

s

Fig

an

12

ohmmeter

Checking

controller

MAIN

SCALE

ADJUSTlNG

SCREW

operation

using

If

a

Controller

If

may

1

cover

2

3

4

pressure

tial

The

the

modelofthe

L404B

RBand

make

breaks

5

pressure

tial

The

action

reset

models

NOTE

observing

change

6Ifthe

7

the

wirestothe

the

cover

the

controller

be

further

Disconnect

screw

DisconneCt

Connect

Lower

increase

switch

or

D

should

make

RI

W

the

ohmmeter

Raise

decrease

switch

in

step

An

approximation

from

controller

When

the

screw

and

the

R

If

the

should

4

the

terminal

Seems

is

checked

all

remove

the

an

ohmmeter

set

through

should

controller

make

W

it

makes

set

through

except

change

zero

to

controller

and

reconnect

to

Operate

suspected

as

power

the

wires

point

a

either

AnL404A

an

and

an

reads

of

point

a

break

for

the

of

in

set

infinity

operates

is

block

Improperly

of

operating

follows

to

cover

from

between

of

the

range

make

the

the

Fig

controller

controller

the

controller

greater

or

break

12

switch

than

orC

IA04F

L604A

the

should

ohmmeter

infinity

the

controller

greater

just

D

and

required

than

the

range

or

make

L404C

the

differential

point

improperly replace

operating

replace

the

power

properly

the

cover

iniproperly

loosen

terminals

simulating

the

differen

depending

should

break

should

L604L

M

breakR2

reads

zero

simulating

the

differen

opposite

L604L

manual

can

be

made

foraresistance

it

reconnect

and

tighten

break

B

and

if

of

by

the

on

its

it

MAIN

SCALE

SETllNG

INDICATOR

a

an

00

INPUT

OUTPUT

it

a

o

280

ADJ

ANl604

WITH

L404F

JUMPER

OPERATES

ONLY

TWO

AND

FAfl

ENOUGH

AN

OR0HAS

ORCBREAKS

DECREASED

INSTALLED

SIMIlJRLY

TERMINALS

L404BOR0

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

BElWEEN

SPOT

SPST SWITCHING

MAKES

ro

ZERO

OHMS

INANITY

SWITCHING

WHEN

SETPOINT

DEqREASE

WHEN

R

Rl

ANDRIS SHOWN

AN

L404A

AN

THE

SETPOINT

B

BREAKS

L404A

B C

IS

M8944

Page 10

Q4A

RVICE

D

F

L604A

INFORMATION

L

M

CALmRATION

The

controller

and

errors

be

over

indicator

be

over

carefully

should

are

level

the

the

within

switches

turing

tion

should

directly

leveling

may

be

operating

case

controller

was

not

caused

when

index

may

index

bend

carefully

require

by

improper

the

pointer

mark

not

be

mark

tolerance

the

the

steam

properly

calibrated

recalibration

leveling

on

the

11

Fig

accurate

but

the

of

trap

leveling

In

enough

controller

its

scale

siphon

during

Most

The

some

setting

loop

manufac

calibra

controller

indicator

cases

The

still

may

until

is

the

pointer

not

this

In

the

Service

MAINTENANCE

The

to

protect

physical

occasional

accumulated

controller

the

the

entire

of

cover

the

damage

inspection

dirt

system

the

internal

and

at

all

during

controller

Routine

and

dust

times

Information

in

be

should

components

maintenance

blowing

To

ensure

perform

routine

maintenance

place

from

dirt

should

or

brushing

proper

an

operational

times

at

all

dust

consist

away

functioning

check

checks

and

of

any

of

of

Loading...

Loading...