Page 1

INSTALLATION MANUAL

(Preliminary)

KXP 2290

MODE S

TRANSPONDER

MANUAL NUMBER 006-10689-0000

REVISION 0 JUNE, 2006

Page 2

THIS PUBLICATION MAY BE CONTROLLED BY THE U.S. DEPARTMENT OF STATE INTERNATIONAL TRAFFIC IN ARMS REGULATIONS (ITAR) 22 CFR 120-130 OR THE U.S.

DEPARTMENT OF COMMERCE EXPORT ADMINISTRATION REGULATIONS (EAR), AND

MAY NOT BE EXPORTED OUT OF THE UNITED STATE OR BE PROVIDED TO FOREIGN

PERSONS (AS DEFINED BY THE ITAR) LOCATED WITHIN THE UNITED STATES, WITHOUT

THE APPROPRIATE PRIOR AUTHORIZATIONS FROM THE U.S. GOVERNMENT. DIVERSION CONTRARY TO U.S. EXPORT LAWS AND REGULATIONS IS PROHIBITED.

COPYRIGHT NOTICE

©2006 Honeywell International Inc.

REPRODUCTION OF THIS PUBLICATION OR ANY PORTION THEREOF BY ANY

MEANS WITHOUT THE EXPRESS WRITTEN PERMISSION OF HONEYWELL IS PROHIBITED, EXCEPT TO THE EXTENT REQUIRED FOR INSTALLATION OR MAINTENANCE OF THE RECIPIENT'S EQUIPMENT. FOR FURTHER INFORMATION

CONTACT THE MANAGER, TECHNICAL PUBLICATIONS, HONEYWELL, ONE TECHNOLOGY CENTER, 23500 WEST 105th STREET OLATHE KS 66061 TELEPHONE:

(913) 782-0400.

Page 3

n KXP 2290

REVISION HISTORY

KXP 2290

KXP 2290 Installation Manual

Part Number: 006-10689-XXXX

For each revision, add, delete, or replace as indicated.

Rev. 0c, June/2006 Preliminary 05/24/06

ITEM ACTION

New manual No previous manual revision exists.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page RH-1

Page 4

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page RH-2

Page 5

n KXP 2290

TABLE OF CONTENTS

ITEM PAG E

SECTION I

GENERAL INFORMATION

1.1 INTRODUCTION............................................................................................................ 1-1

1.2 EQUIPMENT DESCRIPTION ........................................................................................ 1-1

1.3 TECHNICAL CHARACTERISTICS ............................................................................... 1-2

1.3.1 KXP 2290 TECHNICAL CHARACTERISTICS............................................................... 1-2

1.3.2 ANTENNA ...................................................................................................................... 1-2

1.4 UNITS AND ACCESSORIES SUPPLIED ..................................................................... 1-3

1.4.1 CONFIGURATIONS AVAILABLE .................................................................................. 1-3

1.4.2 KXP 2290 INSTALLATION KIT......................................................................................1-3

1.5 ACCESSORIES REQUIRED, BUT NOT SUPPLIED .................................................... 1-4

1.6 LICENSING REQUIREMENTS...................................................................................... 1-5

1.7 CONTINUED AIRWORTHINESS INSTRUCTIONS ...................................................... 1-5

1.7.1 EQUIPMENT..................................................................................................................1-5

1.7.2 WIRES/COAX CABLES ................................................................................................. 1-5

SECTION II

INSTALLATION

2.1 GENERAL INFORMATION ........................................................................................... 2-1

2.2 UNPACKING AND INSPECTING EQUIPMENT ........................................................... 2-1

2.3 EQUIPMENT INSTALLATION ...................................................................................... 2-1

2.3.1 GENERAL ...................................................................................................................... 2-1

2.3.2 KXP 2290 INTERCONNECTION AND CABLE HARNESS FABRICATION .................. 2-2

2.3.3 EQUIPMENT LOCATION .............................................................................................. 2-4

2.3.4 KXP 2290 INSTALLATION ............................................................................................ 2-5

2.3.5 CRIMP TOOL INFORMATION....................................................................................... 2-7

2.4 POST-INSTALLATION CHECKS................................................................................ 2-37

2.4.1 TRANSPONDER SYSTEM CHECKOUT..................................................................... 2-37

SECTION III

OPERATION

3.1 GENERAL......................................................................................................................3-1

ENVIRONMENTAL QUALIFICATIONS APPENDIX

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TC-1

Page 6

n KXP 2290

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TC-2

Page 7

n KXP 2290

ITEM

FIGURE 2-1 MAIN CONNECTOR - JKXP2290-1............................................................. 2-9

FIGURE 2-2 KXP 2290 INSTALLATION DRAWING ...................................................... 2-11

FIGURE 2-3 KXP 2290 BAR CLAMP ASSEMBLY DRAWING....................................... 2-19

FIGURE 2-4 KA 61 INSTALLATION DRAWING............................................................. 2-21

FIGURE 2-5 KXP 2290 INTERCONNECTION DRAWING............................................. 2-25

FIGURE 2-6 KXP 2290 INTERCONNECTION DRAWING............................................. 2-27

FIGURE 2-7 RF CONNECTOR DRAWING .................................................................... 2-29

FIGURE 2-8 RG-400 CABLE CONNECTIONS DRAWING ............................................ 2-31

FIGURE 2-9 ECS/ECS-RG-400 CABLE CONNECTIONS DRAWING ........................... 2-32

FIGURE 2-10 CABLE CONNECTOR DRAWING ............................................................. 2-33

FIGURE 2-11 TYPE “N” AND “C” CONNECTOR ASSEMBLY DRAWING...................... 2-34

FIGURE 2-12 BNC CONNECTOR ASSEMBLY DRAWING............................................. 2-35

PAG E

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TC-3

Page 8

n KXP 2290

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TC-4

Page 9

n KXP 2290

ITEM

TABLE 2-1 SIZE 22 HIGH DENSITY D-SUB CONTACT TOOLS .................................. 2-7

TABLE 2-2 JKXP2290-1 PIN FUNCTION LIST ............................................................. 2-9

TABLE 2-3 ANTENNA CONNECTORS AND DESCRIPTIONS ................................... 2-10

TABLE 2-4 INSPECTION/CHECK PROCEDURE........................................................ 2-37

PAG E

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TC-5

Page 10

n KXP 2290

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TC-6

Page 11

n KXP 2290

SECTION I

GENERAL INFORMATION

1.1 INTRODUCTION

This manual contains information relative to the physical, mechanical, and electrical characteristics of the Honeywell KXP 2290 Mode S Transponder. Installation and check out procedures are

also included. Information relative to the maintenance, alignment, and procurement of the replacement parts may be found in the KXP 2290 Maintenance/Overhaul Manual, P/N 006-15689XXXX. The only current KXP 2290 installation option is as a part of the APEX system. The KXP

2290 is blind-mounted and shares a mounting rack with the KMC 2210 APEX controller. For additional information relating to the APEX system, refer to the APEX System Manual 006-10667XXXX.

1.2 EQUIPMENT DESCRIPTION

The KXP 2290 is a Mode S Transponder that is capable of non-diversity or diversity operation.

The KXP 2290 Mode S Transponder is designed to meet TSO-C112, ETSO-2C112a for a Class

2A ATCRBS/Mode Select Airborne Transponder System. It replies to ATCRBS Mode A and C,

Intermode, and Mode S interrogations.

Since the KXP 2290 is a Class 2A transponder, it can handle Comm A & Comm B Mode S data

link protocols. The KXP 2290 is compliant with TSO-C112 Class 2A and ETSO-2C112a requirements. The EUROCAE ED-73B transponder functionality is Level 2 (Surveillance and Comm A/

B) and the marking is level 2s. Additionally the ED-73B defined class is "CLASS 1". The KXP

2290 is also designed to meet the Enhanced Surveillance mandated in Europe.

The KXP 2290 has the ability to receive an 8-digit alphanumeric Flight ID code. The flight crew

enters the Flight ID information via the APEX control panel.

The KXP 2290 uses ARINC 735A TCAS interface protocol to interface with TCAS II. As a peripheral to the TCAS II processor, the transponder receives and replies to short and long Air-to-Air

surveillance and TCAS Coordination interrogations. Also, it receives and replies to Ground-to-Air

surveillance and Comm-A interrogations directed to TCAS.

Top and bottom antennas provide the diversity option that allow compatibility with TCAS. The diversity option allows selection of signal receptions from either the top or the bottom antenna based

on the characteristics of the received interrogation signals. This improves air-to-air surveillance

and communication. An Optional top-mounted omnidirectional antenna is required for diversity.

The KXP 2290 contains BITE (Built In Test Equipment) so the operational health of the unit is constantly monitored. When a critical fault is detected, the unit will notify the APEX system. The unit

stores detected failures in non-volatile memory for later review. The unit also has a temperature

sensor and a timer so that faults can be time stamped and temperature data can be collected and

stored.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 1-1

Page 12

n KXP 2290

1.3 TECHNICAL CHARACTERISTICS

1.3.1 KXP 2290 TECHNICAL CHARACTERISTICS

TSO COMPLIANCE: TSO-C112, ETSO-2C112a

SOFTWARE CERTIFICATION

CATEGORY:

ENVIRONMENTAL

CATEGORIES:

PHYSICAL DIMENSIONS: SEE FIGURE 2-2 KXP 2290 INSTALLATION DRAWING

WEIGHT: SEE FIGURE 2-2 KXP 2290 INSTALLATION DRAWING

MOUNTING: BLIND-MOUNT (SHARES RACK WITH KMC 2210)

TEMPERATURE: SEE ENVIRONMENTAL QUALIFICATIONS APPENDIX

ALTITUDE: SEE ENVIRONMENTAL QUALIFICATIONS APPENDIX

COOLING: NO FORCED-AIR COOLING REQUIRED.

POWER INPUT: 18-32 VOLTS, 30 WATTS

1.3.2 ANTENNA

The KXP 2290 will work with any conventional ATCRBS blade or quarter-wave monopole type antenna provided it is certified to TSO-C112/ETSO-2C112a A representative type is the Honeywell

KA 61 antenna, P/N 071-00221-0010 (BNC) or 071-00221-0020 (TNC). Refer to FIGURE 2-4 KA

61 INSTALLATION DRAWING for KA 61 technical characteristics, installation, and certification

information.

RTCA/DO-178B SOFTWARE LEVEL “B”

SEE ENVIRONMENTAL QUALIFICATIONS APPENDIX

NOTE:

Two antennas (top and bottom) are required for diversity operation.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 1-2

Page 13

n KXP 2290

1.4 UNITS AND ACCESSORIES SUPPLIED

1.4.1 CONFIGURATIONS AVAILABLE

P/N 066-01198-0101 is the only version of the KXP 2290 that is currently available.

1.4.2 KXP 2290 INSTALLATION KIT

The KXP 2290 Transponder shares a mounting rack with the KMC 2210 APEX controller; therefore, installation kits P/N 050-03683-0000 and P/N 050-03670-0000 are both required to install the

KXP 2290. Installation kit P/N 050-03683-0000 contains the following parts:

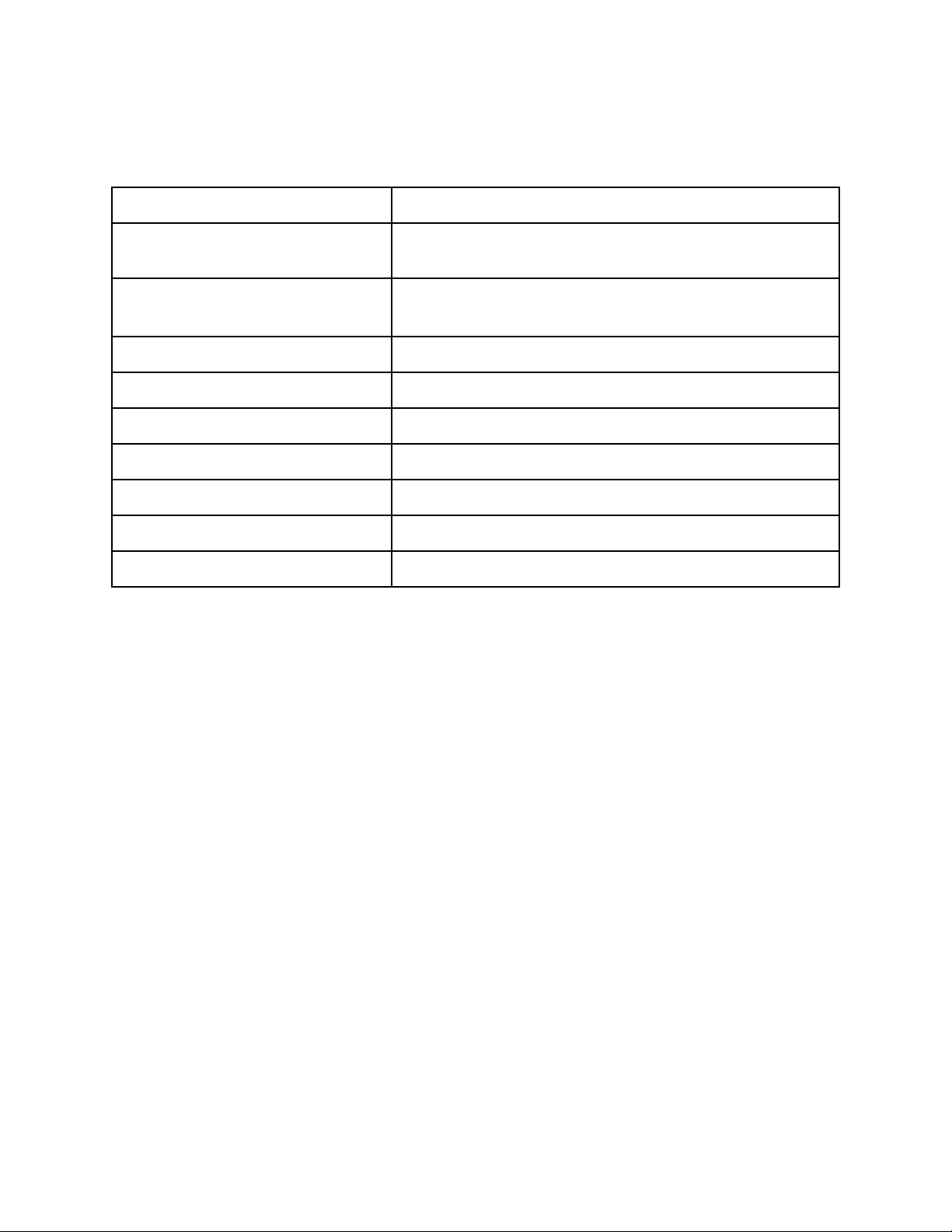

PN DESCRIPTION REV

----------------------------------------------------------------------050-03683-0000 KXP 2290 INSTALLATION KIT D

------------------------------------------------------------------------------------------------SYMBOL PART NUMBER FIND NO DESCRIPTION UM -0000

------------------------------------------------------------------------------------------------J1 030-03296-0000 HI DENSITY SUBD44P EA 1.00

J2 030-00101-0002 PANEL MOUNT PLUG EA 1.00

J3 030-00101-0002 PANEL MOUNT PLUG EA 1.00

001-01299-0000 INSTRUCTION FOR HARNESS ASSEMBLY PARTS RF .00

030-01466-0001 CONN, D-SUB, CONTACT, 22AWG, CRIMP, FEMALE EA 44.00

047-11179-0002 STRAIN RELIEF CLAMP MED EA 1.00

057-05944-0060 KIT TSO LABEL, KXP 2290 EA 1.00

073-01076-0004 BACK PLATE W/HARDWARE EA 1.00

073-01120-0002 SUB-D25 BACKSHELL W/FINISH EA 1.00

073-01121-0002 SUB-D25 BACKSHELL COVER W/FINISH EA 1.00

076-03189-0001 SCREW 100DEG FHP 2-56 X 3/8 SPECIAL EA 4.00

089-05903-0004 SCR PHP 4-40X1/4 EA 2.00

089-06008-0004 SCR FHP 4-40X1/4 EA 2.00

089-08303-0000 WASHER EA 2.00

090-00019-0007 RING RTNR .438 EA 2.00

155-01786-0000 INSTALLATION DRAWING KMC 2210/KXP2290 RF .00

200-10452-0000 BAR CLAMP ASSEMBLY -25 EA 1.00

Installation kit P/N 050-03670-0000 contains the following parts:

PN DESCRIPTION REV

----------------------------------------------------------------------050-03670-0000 KMC 2210 INSTALLATION KIT C

------------------------------------------------------------------------------------------------SYMBOL PART NUMBER FIND NO DESCRIPTION UM -0000

------------------------------------------------------------------------------------------------J1 030-03296-0006 CONN, D-SUB, RECPT, HSNG, SN PLATE, 26 POS EA 1.00

001-01299-0000 INSTRUCTION FOR HARNESS ASSEMBLY PARTS RF .00

030-01466-0001 CONN, D-SUB, CONTACT, 22AWG, CRIMP, FEMALE EA 26.00

047-11179-0002 STRAIN RELIEF CLAMP MED EA 1.00

047-12880-0006 RACK WITH HARDWARE EA 1.00

057-05944-0054 TSO LABEL KMC 2210 EA 1.00

073-01118-0002 SUB-D15 BACKSHELL W/FINISH EA 1.00

073-01119-0002 SUB-D15 BACKSHELL COVER W/FINISH EA 1.00

076-03189-0001 SCREW 100DEG FHP 2-56 X 3/8 SPECIAL EA 4.00

076-03192-0001 SCREW, 100DEG FHP 4-40 X 3/8 EA 2.00

076-03193-0001 SPACER, W/FINISH EA 2.00

155-01786-0000 INSTALLATION DRAWING KMC 2210/KXP2290 RF .00

200-10452-0001 BAR CLAMP ASSEMBLY -15 EA 1.00

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 1-3

Page 14

n KXP 2290

Shield braids must be clamped to the connector backshell using bar clamp assembly P/N 20010452-0000 which contains the following parts. See FIGURE 2-2 KXP 2290 INSTALLATION

DRAWING and FIGURE 2-3 KXP 2290 BAR CLAMP ASSEMBLY DRAWING for additional infor-

mation.

PN DESCRIPTION REV

----------------------------------------------------------------------200-10452-0000 BAR CLAMP ASSEMBLY -25 -

------------------------------------------------------------------------------------------------SYMBOL PART NUMBER FIND NO DESCRIPTION UM -0000

------------------------------------------------------------------------------------------------REF1 300-10452-0000 BAR CLAMP ASSEMBLY KMC 2220 RF .00

047-11178-0001 BACKSHELL BAR CLAMP LONG EA 1.00

076-03190-0001 SCREW PHP 4-40 X 7/16 SPECIAL EA 2.00

187-01943-0001 BACKSHELL GASKET LONG EA 1.00

1.5 ACCESSORIES REQUIRED, BUT NOT SUPPLIED

Each antenna will require a connector and a length of coaxial cable to connect it to the KXP 2290

transponder.

NOTE:

Connector 030-00101-0002, which accommodates

RG-400 cable, is included in the installation kit. Connector P/N 030-00102-0001 is for larger diameter

cables i.e. P/N 024-00072-0000 and is not included.

NOTE:

The transmission line loss design value for the KXP

2290 is 0.5 to 2.0 dB. Total line loss between the unit

and the antenna must be within this specification.

The following are three antenna cable connection

options for the KXP 2290; however, they may not

have line loss specifications within tolerance in all installations. Refer to (8) Antenna Transmission Line

Loss Considerations in SECTION II INSTALLATION

for specific cabling information and to ensure a proper line loss value.

Use the following parts for installations using FIGURE 2-8 RG-400 CABLE CONNECTIONS

DRAWING.

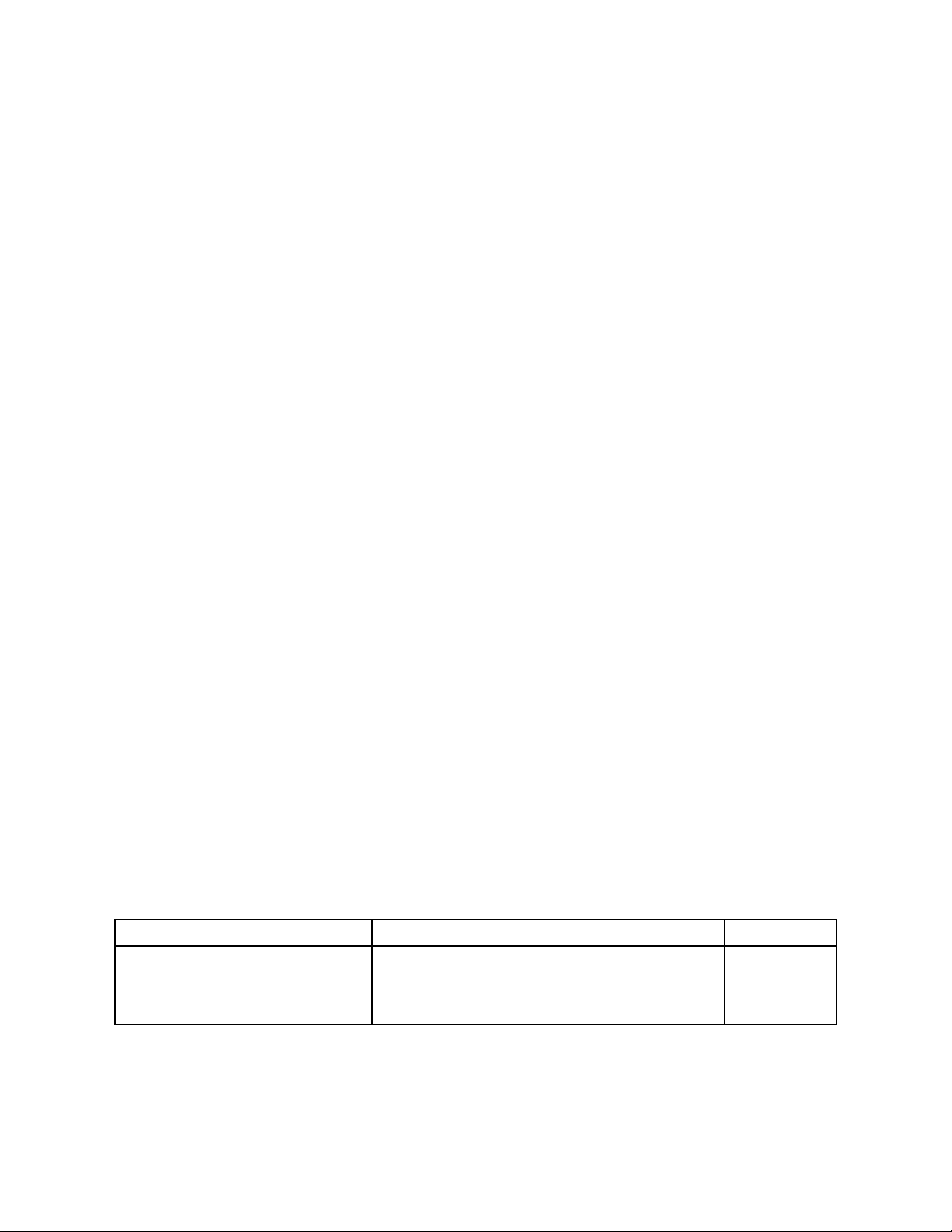

HONEYWELL PART NUMBER DESCRIPTION QUANTITY

030-00101-0002 Connector, Coax 1

024-00051-0060 Cable,Coax 11 ft.

030-00005-0000 Connector, Coax Mod Type BNC 1

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 1-4

Page 15

n KXP 2290

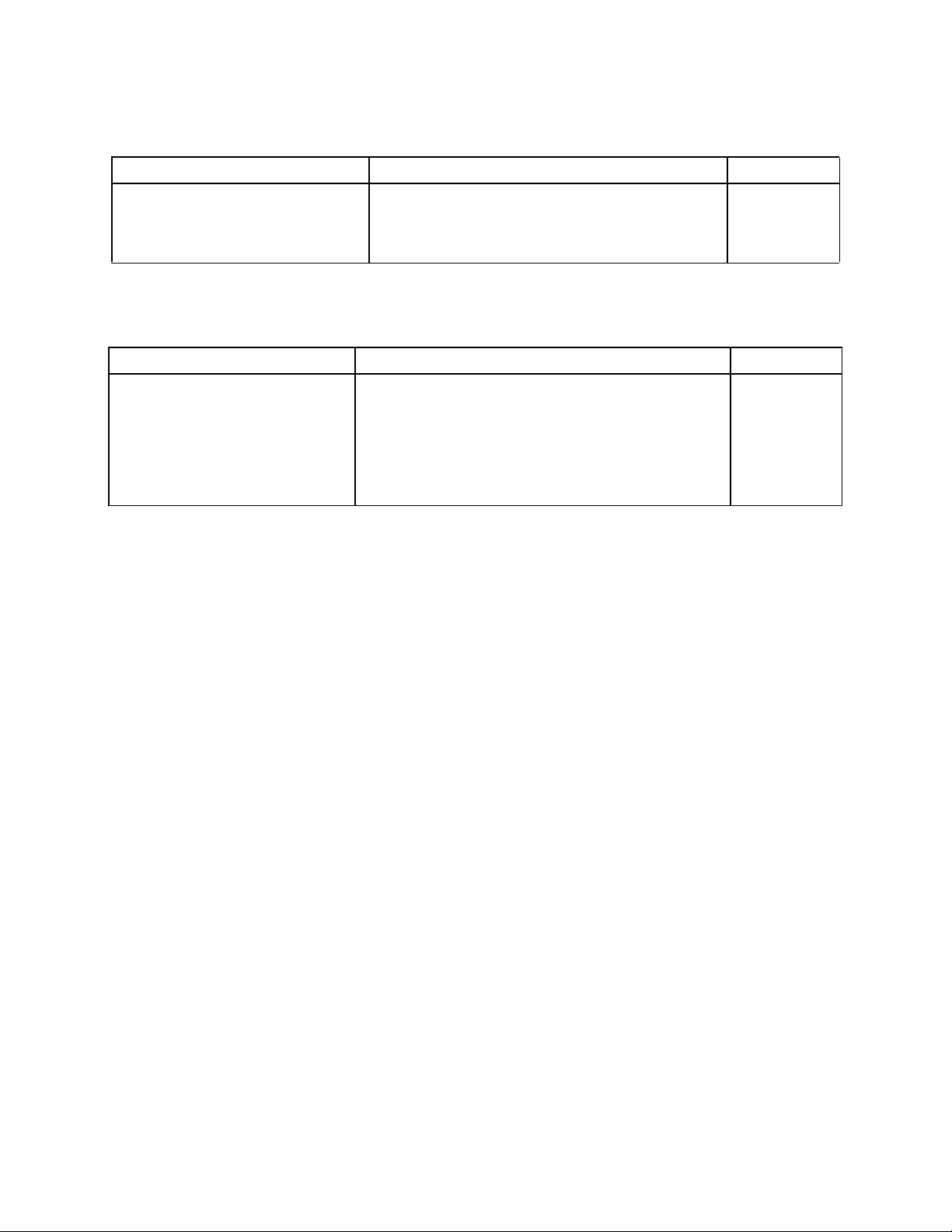

Use the following parts for installations using FIGURE 2-9 ECS/ECS-RG-400 CABLE CONNEC-

TIONS DRAWING. (ECS cable only)

HONEYWELL PART NUMBER DESCRIPTION QUANTITY

030-00102-0001 Connector, Type Unit 1

024-00072-0000 Cable,Coax 25 ft.

030-00435-0000 Connector, Antenna 1

Use the following parts for installations using FIGURE 2-9 ECS/ECS-RG-400 CABLE CONNEC-

TIONS DRAWING. (ECS cable with RG-400 cable).

HONEYWELL PART NUMBER DESCRIPTION QUANTITY

030-00101-0002 Connector Type Unit 1

024-00051-0060 Cable, Coax 6 in.

024-00071-0000 Cable, Coax 32.5 ft.

030-00138-0000 Connector, Unit extension to antenna connector 6 in.

030-00434-0000 Connector, Antenna 2

1.6 LICENSING REQUIREMENTS

This equipment has been type accepted by the FCC and entered on the type accepted equipment

list, as FCC ID: ASYKXP2290??.

For non-US registered aircraft, follow applicable licensing requirements as required.

1.7 CONTINUED AIRWORTHINESS INSTRUCTIONS

1.7.1 EQUIPMENT

FAA requires that transponders, including the KXP 2290, be tested and inspected and found to

comply with Federal Aviation Regulation (FAR) Appendix F of Part 43 of chapter 91.413, ATC transponder tests and inspections This requirement is applicable previous to or at the time of installation of a new unit and again at two year intervals for any unit.

Other than the FAR noted above, there are no periodic service requirements necessary to maintain continued airworthiness. No maintenance is required until the equipment does not properly

perform its intended function. When service is required, a complete performance test should be

accomplished following any repair action. Consult the appropriate unit Maintenance/Overhaul

Manual for complete performance test information.

1.7.2 WIRES/COAX CABLES

During on-condition or regularly scheduled maintenance, inspect the wires and coax cables following the guidelines listed in AC 43,13-1 Chapter 15 as necessary.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 1-5

Page 16

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 1-6

Page 17

n KXP 2290

SECTION II

INSTALLATION

2.1 GENERAL INFORMATION

This section contains suggestions and factors to consider before installing the KXP 2290 Mode S

Transponder. Close adherence to these suggestions will assure a more satisfactory performance

from the equipment.

The conditions and test required for the TSO and MOPS approval of this article are minimum performance standards. It is the responsibility of those installing this article either on or with a specified type or class of aircraft to determine that the aircraft installation conditions are within the TSO

and MOPS standards. These articles must have separate approval for installation in an aircraft.

Any features in this equipment outside the requirements of this applicable TSO and MOPS must

be evaluated and approved as part of the installation approval. The article may be installed only

if performed under 14 CFR part 43 or the applicable airworthiness requirements.

2.2 UNPACKING AND INSPECTING EQUIPMENT

Exercise extreme caution when unpacking the unit. Make a visual inspection of the unit for evidence of damage incurred during shipment. If a claim for a damage is to be made, save the shipping container to substantiate the claim. When all equipment is removed, place all packing materials in the shipping container for future storage or reshipment of the unit.

2.3 EQUIPMENT INSTALLATION

2.3.1 GENERAL

The following paragraphs contain information pertaining to the initial installation of the KXP 2290

Mode S Transponder, including instructions concerning the location and mounting of the supporting antenna(s).

The equipment should be installed in the aircraft in a manner consistent with acceptable workmanship and engineering practices and in accordance with the instructions set forth in this publication.

To ensure that the system has been properly and safely installed in the aircraft, the installer should

make a through visual inspection and conduct an overall operational check of the system on the

ground prior to flight.

CAUTION:

AFTER INSTALLATION OF THE CABLING

AND BEFORE INSTALLATION OF THE

EQUIPMENT, A CHECK SHOULD BE MADE

WITH THE AIRCRAFT PRIMARY POWER

SUPPLIED TO THE MOUNTING CONNECTOR TO ENSURE THAT POWER IS APPLIED

ONLY TO THE PINS SPECIFIED IN THE INTERCONNECTION DRAWING, FIGURE 2-5

KXP 2290 INTERCONNECTION DRAWING.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-1

Page 18

n KXP 2290

The installation should be installed in accordance with standards established by the customer’s

installing agency and existing conditions as to unit location and type of installation. However, the

following suggestions should be considered before installing the system. Close adherence to

these suggestions will assure a more satisfactory performance from the equipment.

The installing agency will supply and fabricate all external cables. The connectors required are

supplied by Honeywell.

NOTE:

The TSO identifies the minimum performance standards, tests, and other conditions applicable for issuance of design and production approval of the article. The TSO applicant is responsible for documenting all limitations and conditions suitable for installation of the article. An applicant requesting approval

for installation of the article within a specific type or

class of product is responsible for determining environmental and functional compatibility.

2.3.2 KXP 2290 INTERCONNECTION AND CABLE HARNESS FABRICATION

2.3.2.1 General

The KXP 2290 Mode S Transponder receives primary power from the aircraft power source. Power connections, voltage requirements, and circuit breaker requirements are shown on the interconnect diagrams (FIGURE 2-5 KXP 2290 INTERCONNECTION DRAWING).

The length of the wires to parallel pins should be approximately the same length, so that the best

distribution of current can be effected. Honeywell recommends that all wires, including spares as

shown on the interconnect diagram be included in the fabrication of the wiring harness. However;

if full wiring is not desired, the installer should ensure that the minimum wiring requirements for

the features and functions to be used have been incorporated.

When cables are installed in the aircraft, they must be supported firmly enough to prevent movement and should be carefully protected against chaffing. Additional protection should also be provided in all locations where the cable may be subjected to abuse.

In wire bundles, the cabling should not be tied tightly together as this tends to increase the possibility of noise pickup and similar interference. When routing cables through the aircraft the cables

should cross high level rf lines at right angles.

Prior to installing any equipment, make a continuity check of all wires and cables associated with

the system. Then apply power and check for proper voltages at system connectors, and then remove power before completing the installation.

Please note the following guidelines:

(1) The installing facility will supply and fabricate all external cables. The required con-

nectors are supplied as part of the installation kit (P/N 050-03451-0000).

(2) The KXP 2290 must be kept a minimum of three feet from the antenna(s). Addition-

ally, the antenna coax cable(s) should not be bundled with the other wiring harnesses to the KXP 2290.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-2

Page 19

n KXP 2290

(3) The length and routing of the external cables must be carefully planned before at-

tempting the actual installation. Avoid sharp bends or locating the cable near aircraft

control cables. The cables should be of a length to allow for a “maintenance loop”.

That is, the length should be adequate to access and extend the connectors aft of

the panel for future maintenance purposes. Excess cabling should be secured and

stowed by tie-wrapping until such maintenance is required.

(4) The cables should be supported firmly enough to prevent movement. They should

be carefully protected wherever one may chafe against another or against some other object. Extra protection should be provided in all locations where the cables may

be subject to abuse. Shields on shielded wires should be grounded as shown on

the system interconnection diagrams.

(5) Shields should be carried through any obstruction via a thru-bulkhead connector. If

shielding cannot be carried through by use of a bulkhead/connector pin, precautions

should be taken to ensure each segment of the shielded lead be grounded at only

one point. A ground connection of not more than two inches in length should be

used. The preceding discussion does not apply to coaxial and quadraxial cable.

(6) Avoid routing cabling near high noise and high power sources.

(7) Do not route the transponder antenna coax(s) near ADF sense or loop antenna ca-

bles.

(8) Antenna Transmission Line Loss Considerations

NOTE:

The total losses in the coaxial cable run and interconnects between the antenna(s) and the KXP 2290

transponder must not be less than 0.5 dB and must

not be more than 2.0 dB at 1030MHz.

NOTE:

The antenna cabling information noted in this section, in particular by FIGURE 2-8 RG-400 CABLE

CONNECTIONS DRAWING, FIGURE 2-9 ECS/

ECS-RG-400 CABLE CONNECTIONS DRAWING,

FIGURE 2-10 CABLE CONNECTOR DRAWING,

FIGURE 2-11 TYPE “N” AND “C” CONNECTOR ASSEMBLY DRAWING, and FIGURE 2-12 BNC CONNECTOR ASSEMBLY DRAWING, is provided as

possible antenna connection solutions and is provided for reference only. While the options noted in the

figures will be applicable to many installations, adherence to the following sub-sections will ensure that

the total cable/interconnection losses are within

specification.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-3

Page 20

n KXP 2290

(a) Consult manufacturer’s coaxial cable data sheet specifications. Using the

length of the top and/or bottom antenna cables and the manufacturer specified dB loss per foot of cable type, select a particular type or types of cable

that meet the top and bottom cable loss limitations. In anticipation of aging

factors, it is advisable to select a cable type that has an insertion loss that

when combined with interconnect losses will equal a dB loss significantly lower than 2 dB.

(b) In diversity installations, it is conceivable that the type of cable selected to

meet the dB loss requirements of the top antenna cable will be different than

the type of cable selection required to meet the dB loss requirements of the

bottom antenna. For example: if the antenna run to one antenna is relatively

lengthy, and the antenna run to the other antenna is relatively short, the longer

run may require low loss antenna cable to meet the less than 2 dB antenna

cable/interconnect requirement while the short run may require a relatively

higher loss cable to exceed the 0.5 dB antenna cable/interconnect loss requirement

NOTE:

For installations with diversity transponder antennas

(top and bottom) the cable lengths must be within 10

feet of each other.

(c) Consult manufacturer’s data sheets to determine the nanosecond delay per

foot (at 1030 MHz) for the type or types of cable selected.

2.3.2.2 Primary Power and Circuit Breaker Requirements and Wiring

The KXP 2290 transponder receives primary power from the aircraft power circuit breakers. The

KXP 2290 is designed to operate over the range of 18-32V dc. Power connections, wire sizes,

and circuit breaker requirements are shown on the interconnection diagrams FIGURE 2-5 KXP

2290 INTERCONNECTION DRAWING.

2.3.3 EQUIPMENT LOCATION

Care should be exercised to avoid mounting components near equipment operating with high

pulse current or high power outputs such as radar and satellite communications equipment. In

general, the equipment should be installed in a location convenient for operation, inspection, and

maintenance, and in an area consistent with the TSO environmental limits.

Refer to the mechanical installation drawing (FIGURE 2-2 KXP 2290 INSTALLATION DRAWING),

cable and connector assembly diagrams (FIGURE 2-7 RF CONNECTOR DRAWING, FIGURE 2-

8 RG-400 CABLE CONNECTIONS DRAWING, FIGURE 2-9 ECS/ECS-RG-400 CABLE CONNECTIONS DRAWING, FIGURE 2-10 CABLE CONNECTOR DRAWING, FIGURE 2-11 TYPE

“N” AND “C” CONNECTOR ASSEMBLY DRAWING, FIGURE 2-12 BNC CONNECTOR ASSEMBLY DRAWING), interconnection drawing(s) (FIGURE 2-5 KXP 2290 INTERCONNECTION

DRAWING), and connector pin assignments diagrams (FIGURE 2-1 MAIN CONNECTOR JKXP2290-1, TABLE 2-2 JKXP2290-1 PIN FUNCTION LIST) as required. Determine the mount-

ing location for system components following the guidelines below.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-4

Page 21

n KXP 2290

2.3.3.1 Transponder And Mounting Tray Locations

The KXP 2290 Mode S Transponder shares a mounting tray with the Honeywell APEX KMC 2210

controller and is part of the APEX cockpit panel configuration.

Except for antenna cables the lengths of the cables from the KXP 2290 transponder mounting tray

connector to other system units are not critical because unit interfaces are designed with high impedance inputs, low impedance outputs, and low noise susceptibility characteristics.

2.3.3.2 Antenna(s)

The antenna(s) should be well removed from other antenna projections, the engine(s), and propeller(s). It should also be well removed from landing gear doors, access doors, or other openings

which will break the ground plane for the antenna(s). The surface directly beneath the antenna(s)

should be a flat plane over as large an area as possible.

A back-up plate for each antenna should be used for added strength on thin-skinned aircraft.

The antenna(s) need to be within 5 degrees of the centerline

To prevent rf interference, the antenna(s) must be physically mounted a minimum distance of

three feet from the KXP 2290 and the wiring harness.

The transponder antenna(s) should be mounted a minimum of 30 inches away from the TCAS or

DME antennas and four feet from the ADF sense antenna.

Where practical, plan the antenna location(s) to keep cable lengths as short as possible and avoid

sharp bends in the cable to minimize the VSWR.

Avoid running other cables or wires near the antenna cable(s).

On pressurized aircraft, the antenna(s) should be sealed using an approved sealant, such as RTV

No. 3145 (P/N 016-01082-0000) or equivalent, around the connector and mounting hardware.

The antenna mounting(s) should be sealed from the outside for moisture protection using RTV or

equivalent.

Mount the antenna(s) in as clean as environment as possible, away from exhaust gases and oils.

The antenna(s) should be kept clean. If left dirty (oil covered), the range of the transponder may

be affected.

For installations with diversity transponder antennas (top and bottom) the distance between the

top and bottom antennas on the horizontal plane of the aircraft fuselage must not exceed 25 feet

(7.62m).

2.3.4 KXP 2290 INSTALLATION

2.3.4.1 General

The mounting tray for the transponder/control unit should be mounted using the dimensions specified in the outline and mounting drawing, FIGURE 2-2 KXP 2290 INSTALLATION DRAWING.

KXP 2290 wiring should be per the system interconnect diagram, FIGURE 2-5 KXP 2290 INTER-

CONNECTION DRAWING.

2.3.4.2 Transponder

(1) Slide the transponder into the tray until the front lobe touches the mounting tray.

(2) Turn the Allen wrench clockwise until the rear lobe engages the mounting tray slot.

Continue turning the wrench clockwise until tight.

CAUTION:

DO NOT OVERTIGHTEN THE LOCKING FASTENER

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-5

Page 22

n KXP 2290

(3) For removal, turn the 3-32 inch Allen wrench counter-clockwise until the unit disen-

gages from the mounting tray slot. If all connectors are removed, the unit can be

pulled completely out of the rack.

For additional KXP 2290 installation information, refer to FIGURE 2-2 KXP 2290 INSTALLATION

DRAWING as required

2.3.4.3 Aircraft Address Programming Options

The Mode S aircraft address and maximum airspeed data must be programmed for use for the

KXP 2290. This information is received from the APEX system via the ARINC 429 bus.

NOTE:

THE AIRCRAFT MODE S ADDRESS MUST BE OBTAINED FROM FAA AND PROGRAMMED INTO

THE KXP 2290. FOR US REGISTERED AIRCRAFT, THE ICAO AIRCRAFT ADDRESS CODE

CAN BE FOUND ON THE AIRCRAFT REGISTRATION.

AIRCRAFT MODE S ADDRESSES MAY BE OBTAINED BY CALLING THE FAA AIRMAN AND AIRCRAFT REGISTRY DIVISION AT (405)-954-3116.

IF THREE (3) OR MORE ADDRESSES ARE NEEDED, WRITE TO AIRCRAFT REGISTRATION

BRANCH, ANV-450, P.O. BOX 25082, OKLAHOMA

CITY, OK 73125.

2.3.4.4 Antenna

For KA 61 antenna installation information, refer to FIGURE 2-4 KA 61 INSTALLATION DRAW-

ING. For other L-band blade antenna outline drawings, installation procedures, and mounting di-

mensions, refer to the manufacturer’s instructions.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-6

Page 23

n KXP 2290

2.3.5 CRIMP TOOL INFORMATION

The following is a listing of crimp tools and accessories for use with the KXP 2290.

SOURCE * CRIMP TOOL POSITIONER 22-30 AWG ** INSERTION/EXTRACTION TOOL

HONEYWELL 005-02012-0034 Not Available Not Available

MIL-SPEC M22520/2-01 M22520/2-06 M81969/1-04 ***

DANIELS MFG. AFM8 (M22520/2-01) K41 (M22520/2-06)

POSITRONICS 9507-0-0 9502-3 (K41)

ASTRO (BUCHANAN) 615717 (M22520/2-01) 615722 (M22520/2-06)

* All source tools and positioners are to Mil-Spec Standard and are interchangeable.

** Positioner wire gauge (AWG) refers to barrel only.

*** SUPERCEDES MIL SPEC P/N M24308/18-1. ORDER FROM POSITRONICS, DANIELS, OR ASTRO

BY MIL SPEC P/N.

NOTE: Selections in parentheses denote optional ordering number from source.

Vendor Ordering Information:

Astro Tool Company

21615 SW TV Hwy, Beaverton, OR 97006

(503) 642-9853 * Fax: 503-591-7766 * Email: sales@astrotool.com

Daniels Manufacturing Company (DMC)

526 Thorpe Road, Orlando, FL 32824-8133 USA

Tel: 407-855-6161 * Fax: 407-855-6884 * Email: dmc@dmctools.com

Positronics Industries, Inc.

423 N. Campbell Ave P.O. Box 8247, Springfield, MO 65801

Tel: 800-641-4054 * Fax: 417-866-4115 * Email: info@connectpositronics.com

TABLE 2-1 SIZE 22 HIGH DENSITY D-SUB CONTACT TOOLS

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-7

Page 24

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-8

Page 25

n KXP 2290

FIGURE 2-1 MAIN CONNECTOR - JKXP2290-1

Front View

Pin # I/O Description Specification

1 I +28 Vdc Power In Aircraft Power +18 to +32 Vdc

2 I Ext Standby ~ Discrete input. GND (< 10 ohms-to-ground) on this

pin forces the unit to Standby. Resistance-toground > 100K on this pin keeps the present mode.

3 I TCAS 429 RX - A TCAS II compatibility

4 I Spare 1 429 RX - A Reserved

5 I Spare 2 429 RX - A Reserved

6 I Spare 3 429 RX - A Reserved

7 I XPDR 1/2 Reserved

8 I Serial Data In Reserved

9 O Serial Clk Reserved

10 I Conc 429 RX - A Concentrated A429 input bus

11 I Spare 4 429 RX - A Reserved

12 I GPS 1 429 RX - A GPS ARINC 429 input

13 I GPS 2 429 RX - A GPS ARINC 429 input

14 O GP 2 429 TX - B Reserved

15 O GP 2 429 TX - A Reserved

16 I +28 Vdc Power Return Aircraft Ground

17 I +28 Vdc Power In Aircraft Power +18 to +32 Vdc

18 I TCAS 429 RX - B TCAS II compatibility

19 I Spare 1 429 RX - B Reserved

20 I Spare 2 429 RX - B Reserved

21 I Spare 3 429 RX - B Reserved

22 I RS232 Return Reserved

TABLE 2-2 JKXP2290-1 PIN FUNCTION LIST

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-9

Page 26

n KXP 2290

Pin # I/O Description Specification

23 I Ext Ident Reserved

24 I Ext Air/Gnd Reserved

25 I Conc 429 RX - B Concentrated A429 input bus

26 I Spare 4 429 RX - B Reserved

27 I GPS 1 429 RX - B GPS ARINC 429 input

28 I GPS 2 429 RX - B GPS ARINC 429 input

29 O GP 1 429 TX - B General Purpose A429 output bus

30 O GP 1 429 TX - A General Purpose A429 output bus

31 I +28 Vdc Power Return Aircraft Ground

32 I GPS Mark 1 - A GPS Time Mark for precision ADS-B

33 I GPS Mark 1 - B GPS Time Mark for precision ADS-B

34 I GPS Mark 2 - A GPS Time Mark for precision ADS-B

35 O Serial Data Out Reserved

36 I GPS Mark 2 - B GPS Time Mark for precision ADS-B

37 I XPDR 1/2 Parity Reserved

38 O + 3.3 Vdc Reserved

39 O EXT EEPROM CS Reserved

40 I RS232 Diag - RX Diagnosis Input

41 O RS232 Diag - TX Diagnosis Output

42 I/O ARINC Supr I-O As an input: voltage >= 18 V and <= 70 V will

cause suppression. A steady state voltage >= 18

V will cause the suppression to cease.

As an output: this pin will go >= 18 V when the

transponder transmits. This line conforms to

ARINC 718A Attachment 6.

43 O TCAS 429 TX - A TCAS II compatibility

44 O TCAS 429 TX - B TCAS II compatibility

TABLE 2-2 JKXP2290-1 PIN FUNCTION LIST

NOTE: Do not connect to pins marked “Reserved” as the functionality is for future application.

Connector Pin I/O Description

JKXP2290-2 J2 I/O RX/TX Port - Bottom Antenna (BNC)

JKXP2290-3 J3 I/O RX/TX Port - Top Antenna (BNC)

TABLE 2-3 ANTENNA CONNECTORS AND DESCRIPTIONS

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-10

Page 27

n KXP 2290

FIGURE 2-2 KXP 2290 INSTALLATION DRAWING

(Dwg. 155-01786-0000 Rev. B, Sheet 1 of 4)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-11

Page 28

Page 29

n KXP 2290

FIGURE 2-2 KXP 2290 INSTALLATION DRAWING

(Dwg. 155-01786-0000 Rev. B, Sheet 2 of 4)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-13

Page 30

Page 31

n KXP 2290

FIGURE 2-2 KXP 2290 INSTALLATION DRAWING

(Dwg. 155-01786-0000 Rev. B, Sheet 3 of 4)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-15

Page 32

Page 33

n KXP 2290

FIGURE 2-2 KXP 2290 INSTALLATION DRAWING

(Dwg. 155-01786-0000 Rev. B, Sheet 4 of 4)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-17

Page 34

Page 35

n KXP 2290

FIGURE 2-3 KXP 2290 BAR CLAMP ASSEMBLY DRAWING

(300-10452-0000, Rev. -)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-19

Page 36

Page 37

n KXP 2290

FIGURE 2-4 KA 61 INSTALLATION DRAWING

(Sheet 1 of 2)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-21

Page 38

Page 39

n KXP 2290

FIGURE 2-4 KA 61 INSTALLATION DRAWING

(Sheet 2 of 2)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-23

Page 40

Page 41

n KXP 2290

FIGURE 2-5 KXP 2290 INTERCONNECTION DRAWING

(Dwg. 155-0xxxx-000x Rev. -, Sheet 1 of 2)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-25

Page 42

Page 43

n KXP 2290

FIGURE 2-6 KXP 2290 INTERCONNECTION DRAWING

(Dwg. 155-0xxxx-000x Rev. -, Sheet 2 of 2)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-27

Page 44

Page 45

n KXP 2290

FIGURE 2-7 RF CONNECTOR DRAWING

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-29

Page 46

Page 47

n KXP 2290

FIGURE 2-8 RG-400 CABLE CONNECTIONS DRAWING

(Option For Short Antenna Cable Lengths)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-31

Page 48

n KXP 2290

FIGURE 2-9 ECS/ECS-RG-400 CABLE CONNECTIONS DRAWING

(Options For Longer Antenna Cable Lengths)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-32

Page 49

n KXP 2290

FIGURE 2-10 CABLE CONNECTOR DRAWING

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-33

Page 50

n KXP 2290

PART NUMBER SIZE DIMENSION

RG/U CABLE A B C D

024-00075-0000 393 9/32 1/8 5/32 3/64

024-00051-0060 400 9/32 1/8 5/32 3/64

FIGURE 2-11 TYPE “N” AND “C” CONNECTOR ASSEMBLY DRAWING

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-34

Page 51

n KXP 2290

FIGURE 2-12 BNC CONNECTOR ASSEMBLY DRAWING

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-35

Page 52

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-36

Page 53

n KXP 2290

2.4 POST-INSTALLATION CHECKS

2.4.1 TRANSPONDER SYSTEM CHECKOUT

The post-installation test is used to apply power and functionally checkout the system. Successful

completion of the post-installation test verifies the proper operation of the KXP 2290 Mode S Transponder System.

TABLE 2-4 INSPECTION/CHECK PROCEDURE is a visual inspection/check procedure that

should be performed after system installation as part of a system checkout. A post-installation test

per paragraph 2.4.1.2 Post-Installation Checkout/Operation should be performed. In addition, the

procedure should be used as a periodic maintenance inspection check.

EQUIPMENT INSPECTION/CHECK PROCEDURE

KXP 2290 Mode S A. Inspect external surface for damage.

Transponder

Antennas A. Inspect external surfaces for damage.

2.4.1.1 Inspection

Perform the following inspection on the overall system:

(1) Check that cables do not interfere with aircraft controls or other equipment.

(2) Check cabling for proper routing and check security of tie-down points. Inspect and

adjust cable runs to ensure that cables are not strained, kinked, or severely twisted

and are not exposed to rough or sharp surfaces.

B. Check that the unit is securely installed and that retaining

mechanism is securely tightened.

C. Ensure that all connections in the mounting tray are properly

mounted and secure.

B. Check that antenna is properly mounted and mounting screws

are tight.

C. Ensure that antenna coaxial cable connectors are properly mated

and secure.

TABLE 2-4 INSPECTION/CHECK PROCEDURE

2.4.1.2 Post-Installation Checkout/Operation

(1) General

Installation of the transponder system requires three stages of testing to ensure the

proper operation of the Mode S transponder. Initially, prior to the installation of the

transponder and antenna, a system interwiring check should be performed. This

check verifies that the aircraft and all transponder interconnections are correct, before power is applied. After the units are installed a visual inspection of the equipment and connections is made. Finally, a post-Installation test is performed.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-37

Page 54

n KXP 2290

(2) System Interwiring Check

To check the aircraft and transponder system interconnections proceed as follows:

(a) Check that all cables and interwiring are installed in accordance with the In-

terwiring and Cable Harness Fabrication instructions (paragraph 2.3.2 KXP

2290 INTERCONNECTION AND CABLE HARNESS FABRICATION).

(b) Using the interconnect diagram (see FIGURE 2-5 KXP 2290 INTERCON-

NECTION DRAWING), check wiring for proper destination, opens, and

shorts.

(c) Check rf cables for insertion loss and VSWR.

(3) Visual Inspection

In conjunction with system installation, perform the inspection/check procedure (TA-

BLE 2-4 INSPECTION/CHECK PROCEDURE).

(4) Post-Installation Test

Perform the ATC transponder tests and inspections noted in section 1.7.1 EQUIP-

MENT (per Federal Aviation Regulation Part 43).

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 2-38

Page 55

n KXP 2290

SECTION III

OPERATION

3.1 GENERAL

The only current operational function of the KXP 2290 is as a part of the Honeywell APEX system.

Consult the applicable APEX system operation handbook(s) as required.

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 3-1

Page 56

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page 3-2

Page 57

n KXP 2290

ENVIRONMENTAL QUALIFICATIONS APPENDIX

ENVIRONMENTAL QUALIFICATION FORM(S)

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TSO-1

Page 58

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TSO-2

Page 59

n KXP 2290

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TSO-3

Page 60

n KXP 2290

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TSO-4

Page 61

n KXP 2290

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TSO-5

Page 62

n KXP 2290

THIS PAGE IS RESERVED

Rev. 0c, June/2006 Preliminary 05/24/06 10689I00.JA Page TSO-6

Loading...

Loading...