Page 1

Draft

Honeywell International Inc.

Draft as of 10/15/2012

23500 West 105th Street

Olathe, Kansas 66061-8425

U.S.A.

CAGE: 22373

Telephone: (800) 601-3099 (Toll Free U.S.A./Canada)

Telephone: (602) 365-3099 (International Direct)

Telephone: 00-800-601-30999 (EMEA Toll Free)

Telephone: 420-234-625-500 (EMEA Direct)

Website: www.myaerospace.com

System Installation Manual

KSN 765/770 Safety Navigator

Part Number CAGE

066-01204-0101 22373

066-01204-1101 22373

066-01213-0101 22373

066-01213-1101 22373

Legal Notice

Export Control

This document contains technical data and is subject to U.S. export regulations. These commodities,

technology, or software were exported from the United States in accordance with the export administration

regulations. Diversion contrary to U.S. law is prohibited.

ECCN: 7E994, NLR Eligible.

Publication Number 006-10716-0000, Revision 0 Initial 6 Dec 2012

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page T-1

Page 2

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Proprietary Information

Honeywell – Confidential

THIS COPYRIGHTED WORK AND ALL INFORMATION ARE THE PROPERTY OF HONEYWELL

INTERNATIONAL INC., CONTAIN TRADE SECRETS AND MAY NOT, IN WHOLE OR IN PART, BE USED,

DUPLICATED, OR DISCLOSED FOR ANY PURPOSE WITHOUT PRIOR WRITTEN PERMISSION OF

HONEYWELL INTERNATIONAL INC. ALL RIGHTS RESERVED.

Honeywell Materials License Agreement

The documents and information contained herein (“the Materials”) are the proprietary data of Honeywell

International Inc. and Honeywell Intellectual Properties Inc. (collectively “Honeywell”). These Materials are

provided for the exclusive use of Honeywell Service Centers; Honeywell-authorized repair facilities; operators

of Honeywell aerospace products subject to an applicable product support agreement, their wholly

owned-subsidiaries or a formally designated third party service provider; and direct recipients of Materials from

Honeywell’s Aerospace T echnical Publication Distribution. The terms and conditions of this License Agreement

govern your use of these Materials, except to the extent that any terms and conditions of another applicable

agreement with Honeywell regarding the operation, maintenance, or repair of Honeywell aerospace products

conflict with the terms and conditions of this License Agreement, in which case the terms and conditions of the

other agreement will govern. However, this License Agreement will govern in the event of a conflict between its

terms and conditions and those of a purchase order or acknowledgement.

1. License Grant - If you are a party to an applicable pr oduct sup po rt agree men t, a Ho ne ywell Se rvice Cente r

agreement, or an authorized repair facility agreement, Honeywell hereby grants you a limited, non-exclusive

license to use these Materials to operate, maintain , or repair Honeywell aerospace product s only in accordance

with that agreement.

If you are a direct recipient of these Materials from Honeywell’s Aerospace Technical Publication Distribution

and are not a party to an agreement related to the operation, maintenance or repair of Honeywell aerosp ace

products, Honeywell hereby grants you a limited, non- excl usive license to use these Materials to maintain or

repair the subject Honeywell aerospace products only at the facility to which these Materials have been shipped

("the Licensed Facility"). Transfer of the Materials to another facility owned by you is permitted only if the original

Licensed Facility retains no copies of the Materials and you provide prior written notice to Honeywell.

2. Rights In Materials - Honeywell retains all rights in these Materials and in any copies thereof that are not

expressly granted to you, including all rights in patents, copyrig hts, trademarks, and trade secrets. No license

to use any Honeywell trademarks or patents is granted under this License Agreement.

3. Confidentiality - Y ou acknowledge that these Materials contain information that is confidential and proprietary

to Honeywell. You agree to take all reasonable efforts to maintain the confidentiality of these Materials.

4. Assignment And Transfer - This License Agreement may be assigned to a formally designated service

designee or transferred to a subsequent owner or operator of an aircraft containing the subject Honeywell

aerospace products. However, the recipient of any such assignment or transfer must assume all of your

obligations under this License Agreement. No assignment or transfer shall relieve any party of any obligation

that such party then has hereunder.

5. Copies of Materials - Unless you have the express written permission of Honeywell, you may not make or

permit making of copies of the Materials. Notwithst anding the foregoing, you may make copies of only portions

of the Material for your internal use. Y ou a gree to return the Materials and any copies thereof to Honeywe ll upon

the request of Honeywell.

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page T-2

6 Dec 2012

Page 3

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

6. Term - This License Agreement is effective until terminated as set forth herein. This License Agreement will

terminate immediately, without notice from Honeywell, if you fail to comply with any provision of this License

Agreement or will terminate simultaneously with the termination or expiration of your applicable product support

agreement, authorized repair facility agreement, or your formal designation as a third party service provider.

Upon termination of this License Agreement, you will return these Materials to Honeywell without retaining any

copies and will have one of your authorized officers certify that all Materials have been returned with no copies

retained.

7. Remedies - Honeywell reserves the right to pursue all available remedies and damages resulting from a

breach of this License Agreement.

8. Limitation of Liability - Honeywell does not make any representation regarding the use or sufficiency of the

Materials. THERE ARE NO OTHER WARRANTIES, WHETHER WRITTEN OR ORAL, EXPRESS, IMPLIED

OR STATUTORY, INCLUDING, BUT NOT LIMITED TO, (i) WARRANTIES ARISING FROM COURSE OF

PERFORMANCE, DEALING , USAGE, OR TRADE, WHICH ARE HEREBY EXPRESSL Y DISCLAIMED, OR (ii)

WARRANTIES AGAINST INFRINGEMENT OF INTELLECTUAL PROPERTY RIGHTS OF THIRD PARTIES,

EVEN IF HONEYWELL HAS BEEN ADVISED OF ANY SUCH INFRINGEMENT. IN NO EVENT WILL

HONEYWELL BE LIABLE FOR ANY INCIDENTAL DAMAGES, CONSEQUENTIAL DAMAGES, SPECIAL

DAMAGES, INDIRECT DAMAGES, LOSS OF PROFITS, LOSS OF REVENUES, OR LOSS OF USE, EVEN IF

INFORMED OF THE POSSIBILITY OF SUCH DAMAGES. TO THE EXTENT PERMITTED BY APPLICABLE

LAW, THESE LIMITATIONS AND EXCLUSIONS WILL APPLY REGARDLESS OF WHETHER LIABILITY

ARISES FROM BREACH OF CONTRACT, WARRANTY, TORT (INCLUDING BUT NOT LIMITED TO

NEGLIGENCE), BY OPERATION OF LAW , OR OTHERWISE.

9. Controlling Law - This License shall be governed and construed in accordance with the laws of the State of

New Y ork without regard to the conflict s of laws provisions thereof. This license set s forth the entire agreeme nt

between you and Honeywell and may only be modifie d by a writing duly executed by the duly authorized

representatives of the parties.

Safety Advisory

WARNING: BEFORE THE MATERIALS CALLED OUT IN THIS PUBLICATION ARE USED, KNOW THE

HANDLING, STORAGE AND DISPOSAL PRECAUTIONS RECOMMENDED BY THE MANUFACTURER OR

SUPPLIER. FAILURE TO OBEY THE MANUFACTURERS’ OR SUPPLIERS’ RECOMMENDATIONS CAN

RESULT IN PERSONAL INJURY OR DISEASE.

This publication describes physical and chemical processes which can make it necessary to use chemicals,

solvents, paints, and other commercially available materials. The user of this publication must get the Material

Safety Data Sheets (OSHA Form 174 or e quiva lent) from th e manufacturers or sup pliers of the materi als to be

used. The user must know the manufacturer/ supplier data and obey the procedures, recommendations,

warnings and cautions set forth for the safe use, handling, storage, and disposal of the materials.

Warranty/Liability Advisory

WARNING: HONEYWELL ASSUMES NO RESPONSIBILITY FOR ANY HONEYWELL EQUIPMENT WHICH

IS NOT MAINTAINED AND/OR REPAIRED IN ACCORDANCE WITH HONEYWELL’S PUBLISHED

INSTRUCTIONS AND/OR HONEYWELL’S FAA/SFAR 36 REPAIR AUTHORIZATION. NEITHER DOES

HONEYWELL ASSUME RESPONSIBILITY FOR SPECIAL TOOLS AND TEST EQUIPMENT F ABRICATED BY

COMPANIES OTHER THAN HONEYWELL.

WARNING: INCORRECTLY REPAIRED COMPONENTS CAN AFFECT AIRWORTHINESS OR DECREASE

THE LIFE OF THE COMPONENTS. INCORRECTLY FABRICATED SPECIAL TOOLING OR TEST

EQUIPMENT CAN RESUL T IN DAMAGE TO THE PRODUCT COMPONENTS OR GIVE UNSATISFACTORY

RESULTS.

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page T-3

6 Dec 2012

Page 4

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Copyright - Notice

Copyright 2012 Honeywell International Inc. All rights reserved.

Honeywell is a registered trademark of Honeywell International Inc.

All other marks are owned by their respective companies.

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page T-4

6 Dec 2012

Page 5

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

TRANSMITTAL INFORMATION

THIS IS AN INITIAL RELEASE OF THE KSN 765/770 SAFETY NAVIGATOR SIM PUB. NO. 006-10716-0000

AND IS ISSUED FOR USE IN SUPPORT OF THE FOLLOWING:

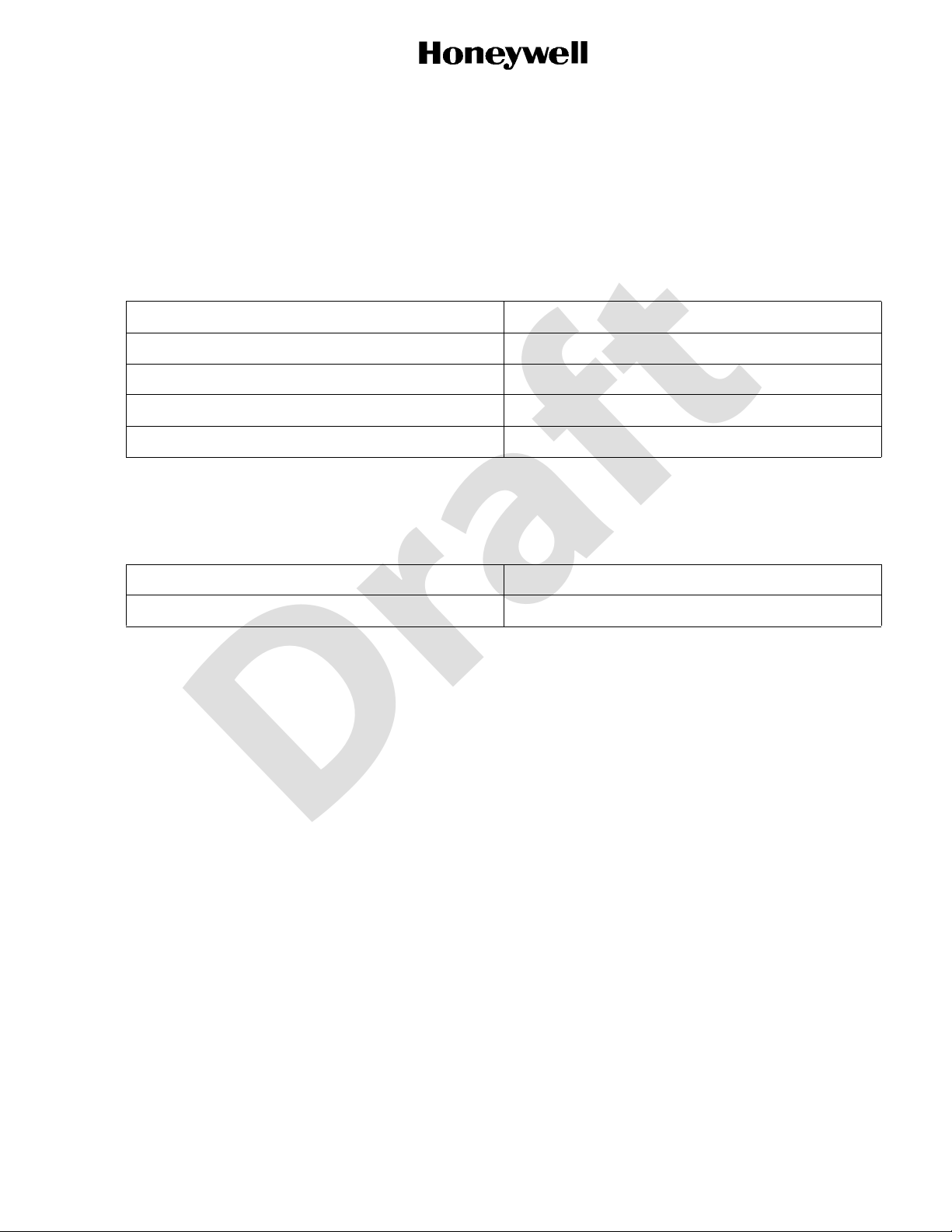

Table TI-1 shows the applicable components.

Table TI-1. Applicable Components

Component PN Nomenclature

066-01204-0101 KSN 770 Safety Navigator

066-01204-1101 KSN 770 Safety Navigator

066-01213-0101 KSN 765 Safety Navigator

066-01213-1101 KSN 765 Safety Navigator

Revision History

Table TI-2 shows the revision history of this SIM.

Table TI-2. Revision History

Revision Number Revision Date

0 6 Dec 2012

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page TI-1

6 Dec 2012

Page 6

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page TI-2

6 Dec 2012

Page 7

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

RECORD OF REVISIONS

For each revision, write the revision number, revision date, date put in the manual, and your initials in the

applicable column.

NOTE:

Revision

Number

Refer to the Revision History in the TRANSMITTAL INFORMATION section for revision data.

Revision

Date

Date Put

In Manual By

Revision

Number

Revision

Date

Date Put

In Manual By

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page RR-1

6 Dec 2012

Page 8

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page RR-2

6 Dec 2012

Page 9

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

RECORD OF TEMPORARY REVISIONS

Instructions on each page of a temporary revision tell you where to put the pages in your manual. Remove

temporary revision pages only when discard instructions are given. For each temporary revision, put the

applicable data in the record columns on this page.

Definition of Status column: TR may be active, cancelled, or incorporated. If TR is incorporated list the revision

number. For example enter: INC Rev 7. If TR is replaced by another TR then put “Cancelled”. For example:

Cancelled by TR NN-NN. “Active” is entered by the holder of manual.

Temporary

Revision

Number Status

Page

Number

Issue

Date

Date Put in

Manual By

Date

Removed

From Manual By

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page RTR-1

6 Dec 2012

Page 10

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page RTR-2

6 Dec 2012

Page 11

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

SERVICE BULLETIN LIST

Service Bulletin/

Revision Number Title Modification

Date Put in

Manual

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page SBL-1

6 Dec 2012

Page 12

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page SBL-2

6 Dec 2012

Page 13

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

LIST OF EFFECTIVE PAGES

Subheading and Page Date Subheading and Page Date

Title

T-1 6 Dec 2012

T-2 6 Dec 2012

T-3 6 Dec 2012

T-4 6 Dec 2012

T-4 6 Dec 2012

Transmittal Information

TI-1 6 Dec 2012

TI-2 6 Dec 2012

Record of Revisions

RR-1 6 Dec 2012

RR-2 6 Dec 2012

Record of Temporary Revisions

RTR-1 6 Dec 2012

RTR-2 6 Dec 2012

Service Bulletin List

SBL-1 6 Dec 2012

SBL-2 6 Dec 2012

List of Effective Pages

LEP-1 6 Dec 2012

LEP-2 6 Dec 2012

LEP-3 6 Dec 2012

LEP-4 6 Dec 2012

Table of Contents

TC-1 6 Dec 2012

TC-2 6 Dec 2012

TC-3 6 Dec 2012

TC-4 6 Dec 2012

TC-5 6 Dec 2012

TC-6 6 Dec 2012

TC-7 6 Dec 2012

TC-8 6 Dec 2012

TC-9 6 Dec 2012

TC-10 6 Dec 2012

Introduction

INTRO-1 6 Dec 2012

INTRO-2 6 Dec 2012

INTRO-3 6 Dec 2012

INTRO-4 6 Dec 2012

INTRO-5 6 Dec 2012

INTRO-6 6 Dec 2012

INTRO-7 6 Dec 2012

INTRO-8 6 Dec 2012

Section I

General Information

1-1 6 Dec 2012

1-2 6 Dec 2012

1-3 6 Dec 2012

1-4 6 Dec 2012

1-5 6 Dec 2012

1-6 6 Dec 2012

Section II

Installation

2-1 6 Dec 2012

2-2 6 Dec 2012

2-3 6 Dec 2012

2-4 6 Dec 2012

2-5 6 Dec 2012

2-6 6 Dec 2012

2-7 6 Dec 2012

2-8 6 Dec 2012

2-9 6 Dec 2012

2-10 6 Dec 2012

2-11 6 Dec 2012

2-12 6 Dec 2012

F 2-13 6 Dec 2012

F 2-14 6 Dec 2012

F 2-15 6 Dec 2012

F 2-16 6 Dec 2012

F 2-17 6 Dec 2012

F 2-18 6 Dec 2012

F 2-19 6 Dec 2012

F 2-20 6 Dec 2012

2-21 6 Dec 2012

2-22 6 Dec 2012

2-23 6 Dec 2012

2-24 6 Dec 2012

2-25 6 Dec 2012

2-26 6 Dec 2012

2-27 6 Dec 2012

2-28 6 Dec 2012

2-29 6 Dec 2012

2-30 6 Dec 2012

2-31 6 Dec 2012

2-32 6 Dec 2012

2-33 6 Dec 2012

2-34 6 Dec 2012

F 2-35 6 Dec 2012

* indicates a changed or added page.

F indicates a foldout page.

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page LEP-1

6 Dec 2012

Page 14

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Subheading and Page Date Subheading and Page Date

F 2-36 6 Dec 2012

F 2-37 6 Dec 2012

F 2-38 6 Dec 2012

F 2-39 6 Dec 2012

F 2-40 6 Dec 2012

F 2-41 6 Dec 2012

F 2-42 6 Dec 2012

F 2-43 6 Dec 2012

F 2-44 6 Dec 2012

2-45 6 Dec 2012

2-46 6 Dec 2012

F 2-47 6 Dec 2012

F 2-48 6 Dec 2012

2-49 6 Dec 2012

2-50 6 Dec 2012

Section III

System Interconnects

3-1 6 Dec 2012

3-2 6 Dec 2012

3-3 6 Dec 2012

3-4 6 Dec 2012

F 3-5 6 Dec 2012

F 3-6 6 Dec 2012

3-7 6 Dec 2012

3-8 6 Dec 2012

F 3-9 6 Dec 2012

F 3-10 6 Dec 2012

3-11 6 Dec 2012

3-12 6 Dec 2012

F 3-13 6 Dec 2012

F 3-14 6 Dec 2012

F 3-15 6 Dec 2012

F 3-16 6 Dec 2012

3-17 6 Dec 2012

3-18 6 Dec 2012

3-19 6 Dec 2012

3-20 6 Dec 2012

3-21 6 Dec 2012

3-22 6 Dec 2012

F 3-23 6 Dec 2012

F 3-24 6 Dec 2012

F 3-25 6 Dec 2012

F 3-26 6 Dec 2012

3-27 6 Dec 2012

3-28 6 Dec 2012

3-29 6 Dec 2012

3-30 6 Dec 2012

F 3-31 6 Dec 2012

F 3-32 6 Dec 2012

3-33 6 Dec 2012

3-34 6 Dec 2012

3-35 6 Dec 2012

3-36 6 Dec 2012

F 3-37 6 Dec 2012

F 3-38 6 Dec 2012

F 3-39 6 Dec 2012

F 3-40 6 Dec 2012

F 3-41 6 Dec 2012

F 3-42 6 Dec 2012

3-43 6 Dec 2012

3-44 6 Dec 2012

3-45 6 Dec 2012

3-46 6 Dec 2012

3-47 6 Dec 2012

3-48 6 Dec 2012

3-49 6 Dec 2012

3-50 6 Dec 2012

F 3-51 6 Dec 2012

F 3-52 6 Dec 2012

F 3-53 6 Dec 2012

F 3-54 6 Dec 2012

F 3-55 6 Dec 2012

F 3-56 6 Dec 2012

F 3-57 6 Dec 2012

F 3-58 6 Dec 2012

3-59 6 Dec 2012

3-60 6 Dec 2012

3-61 6 Dec 2012

3-62 6 Dec 2012

3-63 6 Dec 2012

3-64 6 Dec 2012

F 3-65 6 Dec 2012

F 3-66 6 Dec 2012

F 3-67 6 Dec 2012

F 3-68 6 Dec 2012

F 3-69 6 Dec 2012

F 3-70 6 Dec 2012

F 3-71 6 Dec 2012

F 3-72 6 Dec 2012

3-73 6 Dec 2012

3-74 6 Dec 2012

F 3-75 6 Dec 2012

F 3-76 6 Dec 2012

F 3-77 6 Dec 2012

F 3-78 6 Dec 2012

© Honeywell International Inc. Do not copy without express permission of Honeywell.

* indicates a changed or added page.

F indicates a foldout page.

34-70-06

Page LEP-2

6 Dec 2012

Page 15

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Subheading and Page Date Subheading and Page Date

F 3-79 6 Dec 2012

F 3-80 6 Dec 2012

3-81 6 Dec 2012

3-82 6 Dec 2012

3-83 6 Dec 2012

3-84 6 Dec 2012

3-85 6 Dec 2012

3-86 6 Dec 2012

3-87 6 Dec 2012

3-88 6 Dec 2012

F 3-89 6 Dec 2012

F 3-90 6 Dec 2012

F 3-91 6 Dec 2012

F 3-92 6 Dec 2012

F 3-93 6 Dec 2012

F 3-94 6 Dec 2012

F 3-95 6 Dec 2012

F 3-96 6 Dec 2012

F 3-97 6 Dec 2012

F 3-98 6 Dec 2012

F 3-99 6 Dec 2012

F 3-100 6 Dec 2012

3-101 6 Dec 2012

3-102 6 Dec 2012

F 3-103 6 Dec 2012

F 3-104 6 Dec 2012

3-105 6 Dec 2012

3-106 6 Dec 2012

F 3-107 6 Dec 2012

F 3-108 6 Dec 2012

3-109 6 Dec 2012

3-1 10 6 Dec 2012

F 3-111 6 Dec 2012

F 3-112 6 Dec 2012

F 3-113 6 Dec 2012

F 3-114 6 Dec 2012

3-1 15 6 Dec 2012

3-1 16 6 Dec 2012

3-1 17 6 Dec 2012

3-1 18 6 Dec 2012

F 3-119 6 Dec 2012

F 3-120 6 Dec 2012

F 3-121 6 Dec 2012

F 3-122 6 Dec 2012

3-123 6 Dec 2012

3-124 6 Dec 2012

F 3-125 6 Dec 2012

F 3-126 6 Dec 2012

F 3-127 6 Dec 2012

F 3-128 6 Dec 2012

3-129 6 Dec 2012

3-130 6 Dec 2012

F 3-131 6 Dec 2012

F 3-132 6 Dec 2012

3-133 6 Dec 2012

3-134 6 Dec 2012

3-135 6 Dec 2012

3-136 6 Dec 2012

F 3-137 6 Dec 2012

F 3-138 6 Dec 2012

3-139 6 Dec 2012

3-140 6 Dec 2012

F 3-141 6 Dec 2012

F 3-142 6 Dec 2012

3-143 6 Dec 2012

3-144 6 Dec 2012

3-145 6 Dec 2012

3-146 6 Dec 2012

F 3-147 6 Dec 2012

F 3-148 6 Dec 2012

F 3-149 6 Dec 2012

F 3-150 6 Dec 2012

F 3-151 6 Dec 2012

F 3-152 6 Dec 2012

F 3-153 6 Dec 2012

F 3-154 6 Dec 2012

3-155 6 Dec 2012

3-156 6 Dec 2012

Section IV

TBD

4-1 6 Dec 2012

4-2 6 Dec 2012

* indicates a changed or added page.

F indicates a foldout page.

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page LEP-3

6 Dec 2012

Page 16

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page LEP-4

6 Dec 2012

Page 17

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

TABLE OF CONTENTS

Title Page

INTRODUCTION

1. How to Use This Manual .......................................................................................................INTRO-1

A. General ..................................... ....................... ................... ....................... ..................INTRO-1

B. Observance of Manual Instructions ....................... .................................................... ..INTRO-1

C. Symbols ........................................................... ................... .................... ..................... INTRO-1

D. Units of Measure ................................... ... .... ... ... ... .... ...................................... ... .... ... .. INTRO-2

E. Standard Practices Manual ......................................................................................... INTRO-2

F. Electrostatic Discharge ................................................................................................INTRO-2

2. Customer Support .................................................................................................................INTRO-2

A. Honeywell Aerospace Online Technical Publications Website ................................... INTRO-2

B. Global Customer Care Center ..................................................................................... INTRO-2

3. References ............................ ....................................... ....................................... ................. INTRO-3

A. Honeywell/Vendor Publications ................................................................................... INTRO-3

B. Other Publications ................................. ... .... ... ... ....................................... ... ... ... .... ... .. INTRO-3

4. Acronyms and Abbreviations ............................................................................................... INTRO-3

A. General ..................................... ....................... ................... ....................... ..................INTRO-3

5. Process Verification .............................................................................................................. INTRO-7

A. Verification Data .......................................................................................................... INTRO-7

6. Software History ................................................................................................................... INTRO-7

A. Software Data .............. .... ...................................... .... ... ... ... ... .... .................................. INTRO-7

7. History of Changes ............................................................................................................... INTRO-7

A. Modification/Configuration History ............................................................................... INTRO-7

B. Change History for Parts List ...................................................................................... INTRO-7

SECTION I - GENERAL INFORMATION

1.1 Introduction ....................................................................................................................................1-1

1.2 Applicability of the Installation Manual ...................... ...... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ..............1-1

1.3 Description of the Equipment .........................................................................................................1-1

1.3.1 KSN 7xx Safety Navigator ..................................................................................................1-1

1.3.2 GPS Antenna .....................................................................................................................1-2

1.3.3 KCM 200 Configuration Module ................. ... ... ... .... ... ... ... ... .... ... ...... .... ... ... ... ... .... ... ... ... .... . 1-2

1.4 Technical Characteristics ...............................................................................................................1-2

1.5 Units Supplied ................................................................................................................................1-4

1.5.1 KSN 7xx Safety Navigator ..................................................................................................1-4

1.5.2 GPS Antennas ................................................................................................................... 1-4

1.6 License Requirements ...................................................................................................................1-4

1.7 Recommendations for IFR Approval ..............................................................................................1-4

A. Aircraft Logbook Entry ..................... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... ..... 1-4

B. Aircraft Installation Requirements ................... ..................................................................... 1-4

C. Approved Airplane Flight Manual Supplement ..................................................................... 1-5

D. Pilot’s Guide ......................................................................................................................... 1-5

Page TC-1

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

6 Dec 2012

Page 18

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

TABLE OF CONTENTS (CONT)

Title Page

SECTION II - INSTALLATION

2.1 Overview ........................................................................................................................................2-1

2.2 Unpacking and Inspecting Equipment ............................................................................................2-1

2.3 KSN 7xx Installation ........................ ....................................... ... ... .... ... ... ... ..................................... 2-1

2.3.1 General ..............................................................................................................................2-1

2.3.2 Minimum System Configuration ......................................................................................... 2-2

2.3.3 Installation Materials ..... ... ... ... .... ... ... ... ....................................... ... ... .... ... ... ... .....................2-2

2.3.4 KSN 7xx Installation Considerations .................................................................................. 2-7

2.3.5 KSN 7xx Cooling Requirements ...................................................................................... 2-11

2.3.6 KSN Pinouts ..................................................................................................................... 2-21

2.3.7 KSN Wiring and Cable Harness Fabrication .................................................................... 2-32

2.3.8 KSN Power Distribution ...................................................................................................2-45

2.3.9 Placards and Labels ........................................................................................................2-45

2.3.10 Weight and Balance ......................................................................................................... 2-45

2.4 Antenna Installation ........................... .... ... ... ... ... .... ...................................... .... ... ... ... .... ............... 2-46

2.4.1 GPS/WAAS Antenna Location Considerations ................................................................ 2-46

2.4.2 COM and NAV Antenna Installation Considerations ........................ ....................... ......... 2-49

2.5 Optional Accessory Installation ........................................... ......................................................... 2-50

2.5.1 External Annunciators ......................................................................................................2-50

2.5.2 External Switches ............................................................................................................2-50

2.6 Magnetic Compass Recalibration ................................................................................................2-50

SECTION III - SYSTEM INTERCONNECT

3.1 Introduction ....................................................................................................................................3-1

3.2 Standard Interface Definitions ........................................................................................................ 3-1

3.2.1 Discrete Input .....................................................................................................................3-1

3.2.2 Discrete Output ..................................................................................................................3-1

3.2.3 EIA Standard Serial Interfaces ........................................................................................... 3-2

3.2.4 ARINC 429 Standard Serial Interfaces .............................................................................. 3-2

3.2.5 ARINC 453 Interface ........................... ... .... ... ... ....................................... ... ... .... ... ... ... ........3-2

3.3 Power System Interface ................................................................................................................. 3-3

3.3.1 General ..............................................................................................................................3-3

3.3.2 Electrical Characteristics ....................................................................................................3-3

3.3.3 Panel Lighting Inputs ......................................................................................................... 3-4

3.3.4 Interconnect Diagram .........................................................................................................3-4

3.4 Position Interface ......... ... ....................................... ... ... ... .... ... ... .....................................................3-7

3.4.1 Applicable Part Numbers ...................................................................................................3-7

3.4.2 Function .............................................................................................................................3-7

3.4.3 Requirements and Limitations ........................................................................................... 3-7

3.4.4 Electrical Characteristics ....................................................................................................3-7

3.4.5 Interconnect Diagram .........................................................................................................3-7

3.5 WX RDR Interface .......................... ... .... ... ... ....................................... ... ... ... .... ... ... ...................... 3-11

3.5.1 Applicable Part Numbers ................................................................................................. 3-11

Page TC-2

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

6 Dec 2012

Page 19

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

TABLE OF CONTENTS (CONT)

Title Page

3.5.2 Function ...........................................................................................................................3-11

3.5.3 Requirements and Limitations ..........................................................................................3-11

3.5.4 Electrical Characteristics ..................................................................................................3-11

3.5.5 Interconnect Diagram .......................................................................................................3-11

3.6 EGPWS Interface .........................................................................................................................3-17

3.6.1 Applicable Part Numbers .................................... .... ... ... ... ....................................... ... ... ... 3-17

3.6.2 Function ...........................................................................................................................3-18

3.6.3 Requirements and Limitations ..........................................................................................3-18

3.6.4 Electrical Characteristics ..................................................................................................3-18

3.6.5 Interconnect Diagram .......................................................................................................3-21

3.7 Traffic Interface .................. ... .... ... ... ... ... .... ...................................... .... ... ... ... .... ... .........................3-27

3.7.1 Applicable Part Numbers .................................... .... ... ... ... ....................................... ... ... ... 3-27

3.7.2 Function ...........................................................................................................................3-27

3.7.3 Requirements and Limitations ..........................................................................................3-27

3.7.4 Electrical Characteristics ..................................................................................................3-28

3.7.5 Interconnect Diagram .......................................................................................................3-29

3.8 Heading/AHRS Interface ................................. ... .... ... ....................................... ... ... ... ... .... ............ 3-33

3.8.1 Applicable Part Numbers .................................... .... ... ... ... ....................................... ... ... ... 3-33

3.8.2 Function ...........................................................................................................................3-33

3.8.3 Requirements and Limitations ..........................................................................................3-34

3.8.4 Electrical Characteristics ..................................................................................................3-34

3.8.5 Interconnect Diagram .......................................................................................................3-35

3.9 Altitude/Airdata/Fuel Interface ......................................... .... ... ... ... ... .... ...... ... .... ... ... ... ... .... .. ..........3-43

3.9.1 Applicable Part Numbers .................................... .... ... ... ... ....................................... ... ... ... 3-43

3.9.2 Functions ................................ ....... ...... ....... ...... ... ....... ...... ....... ...... ....... ...... ...... .... ............3-43

3.9.3 Requirements and Limitations ..........................................................................................3-45

3.9.4 Electrical Characteristics ..................................................................................................3-46

3.9.5 Interconnect Diagrams .....................................................................................................3-49

3.10 Flight Control Interface ................................................................................................................. 3-59

3.10.1 Applicable Part Numbers ................................. ... .... ... ... ... ... .... ...................................... ...3-59

3.10.2 Function ...........................................................................................................................3-59

3.10.3 Requirements and Limitations .......................................................................................... 3-59

3.10.4 Electrical Characteristics ..................................................................................................3-61

3.10.5 Interconnect Diagram ....................................................................................................... 3-64

3.11 DME Interface .............................................................................................................................. 3-73

3.11.1 Applicable Part Numbers ................................. ... .... ... ... ... ... .... ...................................... ...3-73

3.11.2 Function ...........................................................................................................................3-73

3.11.3 Requirements and Limitations .......................................................................................... 3-73

3.11.4 Electrical Characteristics ..................................................................................................3-73

3.11.5 Interconnect Diagram ....................................................................................................... 3-74

3.12 NAV Indicator Interface ................................................................................................................3-81

3.12.1 Applicable Part Numbers ................................. ... .... ... ... ... ... .... ...................................... ...3-81

3.12.2 Function ...........................................................................................................................3-81

3.12.3 Requirements and Limitations .......................................................................................... 3-

81

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page TC-3

6 Dec 2012

Page 20

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

TABLE OF CONTENTS (CONT)

Title Page

3.12.4 Electrical Characteristics .................................................................................................. 3-82

3.12.5 Interconnect Diagram ....................................................................................................... 3-85

3.13 RMI/OBI Interface ...................................................................................................................... 3-101

3.13.1 Applicable Part Numbers ............................................................................................... 3-101

3.13.2 Function .........................................................................................................................3-101

3.13.3 Requirements and Limitations ....................................................................................... 3-101

3.13.4 Electrical Characteristics ................................................................................................3-101

3.13.5 Interconnect Diagram .....................................................................................................3-101

3.14 Dual System Interface (Cross-Fill) ............................................................................................. 3-105

3.14.1 Applicable Part Numbers ............................................................................................... 3-105

3.14.2 Function .........................................................................................................................3-105

3.14.3 Requirements and Limitations ....................................................................................... 3-105

3.14.4 Electrical Characteristics ................................................................................................3-105

3.14.5 Interconnect Diagram .....................................................................................................3-105

3.15 Audio Interface ........................................................................................................................... 3-109

3.15.1 Applicable Part Numbers ............................................................................................... 3-109

3.15.2 Function .........................................................................................................................3-109

3.15.3 Requirements and Limitations ....................................................................................... 3-109

3.15.4 Electrical Characteristics ................................................................................................3-109

3.15.5 Interconnect Diagram .....................................................................................................3-109

3.16 Annunciations - Suspend/Dead Reckoning/NAV Interface .................................................. ...... . 3-115

3.16.1 Applicable Part Numbers ............................................................................................... 3-115

3.16.2 Function .........................................................................................................................3-115

3.16.3 Requirements and Limitations ....................................................................................... 3-116

3.16.4 Electrical Characteristics ................................................................................................3-118

3.16.5 Interconnect Diagram .....................................................................................................3-118

3.17 Miscellaneous Interface ..... ... .... ... ... ... .... ... ....................................... ... ... ... ... .... ... ....................... 3-123

3.17.1 Applicable Part Numbers ............................................................................................... 3-123

3.17.2 Function .........................................................................................................................3-123

3.17.3 Requirements and Limitations ....................................................................................... 3-123

3.17.4 Electrical Characteristics ................................................................................................3-124

3.17.5 Interconnect Diagram .....................................................................................................3-124

3.18 XM Receiver Interface ...............................................................................................................3-129

3.18.1 Applicable Part Numbers ............................................................................................... 3-129

3.18.2 Function .........................................................................................................................3-129

3.18.3 Requirements and Limitations ....................................................................................... 3-129

3.18.4 Electrical Characteristics ................................................................................................3-129

3.18.5 Interconnect Diagram .....................................................................................................3-129

3.19 Maintenance Interface ...............................................................................................................3-133

3.19.1 Applicable Part Numbers ............................................................................................... 3-133

3.19.2 Function .........................................................................................................................3-133

3.19.3 Requirements and Limitations ....................................................................................... 3-133

3.19.4 Electrical Characteristics ................................................................................................3-134

3.19.5 Interconnect Diagram .....................................................................................................3-135

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page TC-4

6 Dec 2012

Page 21

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

TABLE OF CONTENTS (CONT)

Title Page

3.20 Stormscope Interface (WX-500) ................................................................................................. 3-139

3.20.1 Applicable Part Numbers ................................. ... .... ... ... ... ... .... ...................................... . 3-139

3.20.2 Function .........................................................................................................................3-139

3.20.3 Requirements and Limitations ........................................................................................3-139

3.20.4 Electrical Characteristics ................................................................................................3-139

3.20.5 Interconnect Diagram .....................................................................................................3-139

3.21 NAV/COM Interface (KSN 7x0 Only) .......................................................................................... 3-143

3.21.1 Applicable Part Numbers ................................. ... .... ... ... ... ... .... ...................................... . 3-143

3.21.2 Function .........................................................................................................................3-143

3.21.3 Requirements and Limitations ........................................................................................3-143

3.21.4 Electrical Characteristics ................................................................................................3-144

3.21.5 Interconnect Diagram .....................................................................................................3-146

3.22 Data Bus Information ................................................................................................................. 3-155

SECTION IV - TBD

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page TC-5

6 Dec 2012

Page 22

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page TC-6

6 Dec 2012

Page 23

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

LIST OF FIGURES

Figure Page

INTRO-1 Symbols ............................................................................................................................. INTRO-2

2-1 Field of View - CDI Source Selection .......................................................................................... 2-9

2-2 Field of View - GPS Annunciation ............................................................................................. 2-10

2-3 Field of View - TAWS ................................................................................................................ 2-11

2-4 KSN 7xx Safety Navigator Outline Drawing .............................................................................. 2-13

2-5 KSN 7xx Back Panel ................................................................................................................. 2-21

2-6 Coaxial Right Angle Connector Instruction Sheet ..................................................................... 2-35

2-7 TNC Antenna Coax with Straight Connector ... .... ... ....................................... ... ... ... ... .... ... ... ...... 2-37

2-8 Quadraxial Cable Preparation ................................................................................................... 2-39

3-1 Power System Interface Interconnect Diagram .......................................................................... 3-5

3-2 Position Interface Interconnect Diagram ............................................................. ... ... .... ... ... ... .....3-9

3-3 WX RDR Interface Interconnect Diagram ................................................................................. 3-15

3-4 EGPWS Interface - Internal (Growth) Interconnect Diagram .................................................... 3-23

3-5 EGPWS Interface - External Interconnect Diagram .................................................................. 3-25

3-6 Traffic Interface Interconnect Diagram ......................................................................................3-31

3-7 Heading Interface - XYZ Interconnect Diagram ........................................... ............................ 3-37

3-8 AHRS Interface Interconnect Diagram ............................................... ... ... .... ... ... ... ................... 3-41

3-9 Altitude Interface Interconnect Diagram ............. ... ... ... .... ... ... ....................................... ... ... ... ... 3-51

3-10 Airdata/OAT Interface Interconnect Diagram ..................................... ... ... .... ... ... ... ................... 3-53

3-11 Fuel Flow/Airdata Interface Interconnect Diagram ................................................................... 3-55

3-12 Flight Control Interface - Roll Composite Steering Interconnect Diagram ................................ 3-65

3-13 Flight Control Interface - Deviation/Course Datum Interconnect Diagram ................................ 3-67

3-14 Flight Control Interface - DC Interconnect Diagram (Sheet 1 of 1) ........................................... 3-69

3-15 Flight Control Interface - ARINC 429 Interconnect Diagram .................................................... 3-71

3-16 DME Interface - Remote Interconnect Diagram .............................................. ... ... ....... ... ... ... ... 3-75

3-17 DME Interface - Panel Mount Interconnect Diagram ............................... .... ... ... ... ....... ... ... ... ... 3-77

3-18 DME Interface - ARINC 429 Interconnect Diagram ........................................ ... ... ... ....... ... ... ... 3-79

3-19 NAV Indicator Interface - OBS 1 Interconnect Diagram ........................................................... 3-89

3-20 NAV Indicator Interface - OBS 2 Interconnect Diagram ........................................................... 3-91

3-21 NAV Indicator Interface - Deviation and Flag Interconnect Diagram ....... ................................ 3-93

3-22 NAV Indicator Interface - ARINC 429 Interconnect Diagram .................................................... 3-95

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page TC-7

6 Dec 2012

Page 24

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

LIST OF FIGURES (CONT)

Figure Page

3-23 NAV Indicator Interface - Composite Interconnect Diagram (KSN 7x0 Models Only) ............... 3-99

3-24 RMI/OBI Interface Interconnect Diagram ............................................................................... 3-103

3-25 Dual System Interface Interconnect Diagram ......................................................................... 3-107

3-26 Audio Interface 1 Interconnect Diagram ................................................................................ 3-111

3-27 Audio Interface 2 Interconnect Diagram ................................................................................ 3-113

3-28 Annunciations - Suspend/Dead Reckoning Interconnect Diagram ........................................ 3-119

3-29 Annunciations - NAV Interface Interconnect Diagram ............................................................. 3-121

3-30 Miscellaneous Interface 1 Interconnect Diagram ................................................................... 3-125

3-31 Miscellaneous Interface 2 Interconnect Diagram ................................................................... 3-127

3-32 XM Receiver Interface Interconnect Diagram .......................... .... ... ... ... ... .... ... ... ... ....... ... ... ... . 3-131

3-33 Maintenance Interface Interconnect Diagram ........................................................................ 3-137

3-34 Stormscope Interface (WX-500) Interconnect Diagram .......................................................... 3-141

3-35 COM Interface Interconnect Diagram ..................................................................................... 3-147

3-36 NAV Interface Interconnect Diagram ..................................................................................... 3-149

3-37 NAV Interface - Remote DME Channeling Interconnect Diagram ......................................... 3-151

3-38 NAV Interface - Panel Mount DME Channeling Interconnect Diagram .................................. 3-153

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page TC-8

6 Dec 2012

Page 25

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

LIST OF TABLES

Table Page

INTRO-1 Verification Data .............. .... ... ... ... ... .... ... ....................................... ... ... ... .... ... ... ...............INTRO-7

1-1 Installation Manual Applicability ............................................................................................... 1-1

1-2 KSN 765 Safety Navigator Leading Particulars ....................................................................... 1-2

1-3 KSN 770 Safety Navigator Leading Particulars ....................................................................... 1-3

2-1 KSN 765 Safety Navigator Installation Kit, PN PL050-03727-0000 ......................................... 2-2

2-2 KSN 770 Safety Navigator Installation Kit, PN PL050-03727-0001 ......................................... 2-3

2-3 Accessories Required But Not Supplied .................................................................................. 2-4

2-4 Accessories Required But Not Supplied .................................................................................. 2-5

2-5 Operational Software ...... .... ...................................... .... ... ... ... ... .... ........................................... 2-6

2-6 Americas Database .................................................................................................................. 2-6

2-7 Atlantic Database ..................................................................................................................... 2-6

2-8 Pacific Database ...................................................................................................................... 2-7

2-9 Special Tools Required ............................. ... .... ... ... ....................................... ... ... ... .... ... ... ........ 2 -7

2-10 Connector List ........................................................................................................................ 2-21

2-11 Signals Assigned to the I/O 1 Connector (J1) ........................................................................ 2-22

2-12 Signals Assigned to the I/O 2 Connector (J2) ........................................................................ 2-25

2-13 Signals Assigned to the Power Supply Interface Connector (J3) .......................................... 2-28

2-14 Signals Assigned to the Main Processor Board Interface Connector (J4) ....... ... ... .... ... ... ... ... 2-28

2-15 Signals Assigned to the GPS Antenna Connector (J5) .......................................................... 2-30

2-16 Signals Assigned to the Video Connector (J6) ...................................................................... 2-30

2-17 Signals Assigned to the Rear Panel USB Connector (J8) .................. ... .... ... ... ... ... .... ... ... ... ... 2-30

2-18 Signals Assigned to XM WX Datalink Antenna Connector (J10) ........................................... 2-31

2-19 Signals Assigned to the VHF Transceiver Antenna Connector (J11) (KSN 7x0 Only) .......... 2-31

2-20 Signals Assigned to the Navigation Radio (VOR/LOC) Antenna

Connector (J12) (KSN 7x0 Only) ........................................................................................... 2-31

2-21 Signals Assigned to the Navigation Radio (GS) Antenna

Connector (J13) (KSN 7x0 Only) ........................................................................................... 2-31

2-22 Signals Assigned to the WX RDR/EGPWS Connector (J14) ................................................. 2-31

2-23 Component Weights .............................................................................................................. 2-45

2-24 GPS Antenna Cable Information ............................................................................................ 2-47

2-25 Cable Vendor Contact Information ......................................................................................... 2-47

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page TC-9

6 Dec 2012

Page 26

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

LIST OF TABLES (CONT)

Table Page

3-1 Discrete Input States ...... .... ... ... ....................................... ... ... .... ... ... ... ..................................... 3-1

3-2 High Current Discrete Output States ....................................................................................... 3-1

3-3 Superflag Output States .................. ... ... ... ....................................... ... ... .... ... ... ... ..................... 3-2

3-4 TBD .............................. .......................... ....................... ......................... .................................. 3-3

3-5 TBD .............................. .......................... ....................... ......................... .................................. 3-4

3-6 WX RDR Requirements and Limitations ................................................................................ 3-13

3-7 ARINC 429 Label 017 Control Function Availability in EGPWS Units ................................... 3-20

3-8 AHRS Labels ......................................................................................................................... 3-34

3-9 ARINC 429 Serial Airdata Labels .......................................................................................... 3-47

3-10 ARINC 429 Serial Airdata Labels .......................................................................................... 3-48

3-11 ARINC 429 Label ................................................................................................................... 3-74

3-12 TBD......................................................................................................................................... 3-82

3-13 ARINC 429 Labels ................................................................................................................. 3-85

3-14 NAV Annunciators by Installation Type ............................................................................... 3-117

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page TC-10

6 Dec 2012

Page 27

Draft

1. How to Use This Manual

Draft as of 10/15/2012

A. General

(1) This publication gives maintenance instructions for the equipment shown on the Title page.

(2) St andard maintenance procedures that technicians must know are not given in this manual.

(3) This publication is written in agreement with the ATA Specification.

(4) Warnings, cautions, and notes in this manual give the data that follows:

• A WARNING gives a condition or tells personnel what part of an operation or

maintenance procedure, which if not obeyed, can cause injury or death

• A CAUTION gives a condition or tells personnel what p art of an operation or maintenan ce

procedure, which if not obeyed, can cause damage to the equipment

• A NOTE gives data, not commands. The NOTE helps personnel when they do the related

instruction.

(5) Warnings and cautions go before the applicable paragraph or step. Notes follow the

applicable paragraph or step.

SYSTEM INSTALLATION MANUAL

066-01204 / 066-01213

INTRODUCTION

B. Observance of Manual Instructions

(1) Make sure that you carefully obey all safety, quality, operation, and shop procedures for the

unit.

(2) All personnel who operate equipment and do maintenance specified in this manual must

know and obey the safety precautions.

C. Symbols

(1) The symbols and special characters are in agreement with IEEE Publication 260 and IEC

Publication 27. Special characters in text are spelled out.

(2) The signal mnemonics, unit control designators, and test designators are shown in capital

letters.

(3) The signal names followed by an “*” show an active low signal.

(4) The symbols in Figure INTRO-1 show ESDS and moisture sensitive devices.

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page INTRO-1

6 Dec 2012

Page 28

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Figure INTRO-1. Symbols (Sheet 1 of 1)

D. Units of Measure

(1) Measurements, weights, temperatures, dimen sions, and other values are expressed in the

USMS followed by the appropriate SI metric units in parentheses. Some standard tools or

parts such as drills, taps, bolts, nuts, etc. do not have an equivalent.

E. Standard Practices Manual

(1) St andard cleaning, check, repair, and assembly procedures applicable to multiple models

can be found in a standard practices manual. Refer to Paragraph 3, References.

F. Electrostatic Discharge

(1) Touch the items susceptible to electrostatic discharge in accordance with MI L- HDBK- 2 63.

Refer to MIL-STD-1686 for definition of the standards and conditions.

2. Customer Support

A. Honeywell Aerospace Online Technical Publications Website

(1) Go to the Honeywell Online Technical Publications Website at (www.myaerospace.com).

• To download or see publications online

• To order a publication

• To tell Honeywell of a possible data error in a publication.

B. Global Customer Care Center

(1) If you do not have access to the Ho neywell Technical Publications Website, or if you need to

speak to personnel about non-Technical Publication matters, the Honeywell Aerospace

Global Customer Care Center gives 24/7 customer service to Air Transport & Regional,

Business & General Aviation, and Defense & Space customers around the globe.

• Telephone: 800-601-3099 (Toll Free U.S.A./Canada)

• Telephone: 602-365-3099 (International)

• Telephone: 00-800-601-30999 (EMEA Toll Free)

• Telephone: 420-234-625-500 (EMEA Direct).

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page INTRO-2

6 Dec 2012

Page 29

Draft

3. References

Draft as of 10/15/2012

A. Honeywell/Vendor Publications

(1) Related Honeywell publications in this manual are shown in the list that follows:

• ATA No. 34-70-07 (Pub. No. 006-15716-0000), CMM, KSN 765/770 Safety Navigator

• Pub. No. A09-1100-004, Standard Repair Pro cedur es for Hon eywe ll Avionics Equipment

Instruction Manual.

B. Other Publications

(1) These publications are standard references. Check for latest version of publication.

• The United States GPO Style Manual 2000 (available at

http://www.gpoaccess.gov/stylemanual/browse.html)

• IEEE Std 260, Standard Letter Symbols for Units of Measurement (available from the

American National Standards Institute, New York, NY)

• ASME Y14.38, Abbreviations for Use on Drawings and in Text (available from the

American National Standards Institute, New York, NY)

SYSTEM INSTALLATION MANUAL

066-01204 / 066-01213

• ANSI/IEEE St d 91, Graphic Symbols for Logic Functions (available from the American

National Standards Institute, New York, NY)

• H4/H8 CAGE Codes (available at http://www.logisticsinformationservice.dla.mil)

• IEEE 315/ANSI Y32.2, Graphic Symbols for Electrical and Electronics Diagrams

(available from the American National Standards Institute, New York, NY)

• MIL-HDBK-263, Electrostatic Discharge Control Handbook for Protection of Electrical

and Electronic Parts, Assemblies and Equipment (Excluding Electrically Initiated

Explosive Devices) (Metric) (available from any military standards database)

• MIL-STD-1686, Electrostatic Discharge Control Program for Protection of Electrical and

Electronic Parts, Assemblies and Equipment (Excluding Electrically Initiated Explosive

Devices) (Metric) (available from any military standards database).

4. Acronyms and Abbreviations

A. General

(1) The abbreviations are used in agreement with ASME Y14.38.

(2) Acronyms and non-standard abbreviations used in this publication are as follows:

List of Acronyms and Abbreviations

Term Full Term

AC alternating current

AHRS attitude heading reference system

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page INTRO-3

6 Dec 2012

Page 30

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

List of Acronyms and Abbreviations (Cont)

Term Full Term

AMP ampere

ANSI American National Standards Institute

ARTCC air route traffic control center

ARINC Aeronautical Radio, Incorporated

ASME American Society of Mechanical Engineers

ATA Air Transport Association

AWG American wire gauge

C celsius

CAGE commercial and government entity

CDI course deviation indicator

COM communication

cm centimeter

CMM component maintenance manual

dB decibel

DC direct current

DME distance measuring equipment

DPL detailed parts list

EB engineering bulletin

EGPWS enhanced ground proximity warning system

EIA Electronic Industries Association

ELT emergency locator transmitter

EMEA Europe, the Middle East, and Africa

ESDS electrostatic discharge sensitive

EZ electrically zeroed

F fahrenheit

FMS flight manual supplement

FSS flight service station

GND ground

GPO Government Printing Office

GPS ground positioning satellite

HSI horizontal situation indicator

Hz Hertz

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page INTRO-4

6 Dec 2012

Page 31

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

List of Acronyms and Abbreviations (Cont)

Term Full Term

ICAO International Civil Aviation Organization

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronics Engineers

IFIS electronic flight information system

IFR instrument flight rule

I/O input/output

INS inertial navigation system

IRU inertial reference unit

kg kilogram

KRC King Radio Company

LCD liquid crystal display

LPV localizer performance with vertical guidance

LOC localizer

mA milliampere

MAX maximum

MFD multifunction display

MOD modification

mm millimeter

MMDS multimode digital sensor

mW milliwatt

N/A not applicable

NAV navigation

NAVAID navigational aid

NBD n on -dire c t ion al be a co n

nm nautical mile

No. number

OBS omni-bearing selector

ORZ o mn i-r a ng e ze ro ed

PN part number

Pub. publication

RAIM receiver autonomous integrated monitor

RDR radar

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page INTRO-5

6 Dec 2012

Page 32

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

List of Acronyms and Abbreviations (Cont)

Term Full Term

REF reference

RF rad io fr eq ue n cy

RX receive

SB service bulletin

SBAS satellite based augmentation system

SID standard instrument departure

SIM system installation manual

SSM sign status matrix

STAR standard terminal arrival route

STC supplemental type certificate

SUA special-use airspace

TAS traffic awareness system

TAWS terrain awareness and warning system

TCAS traffic collision avoidance system

THD TBD BY ENGINEERING

TIS traffic information service

TR temporary revision

TSO Technical Standard Order

TX transmit

VHF very high frequency

VOR very high frequency omnidirectional range

USB universal serial bus

USMS United States Measurement System

VAC volt, alternating current

VDC volt, direct current

VLOC very high frequency omni-range localizer

VNAV vertical navigation

VOR very high frequency omni-range

WAAS wide area augmentation system

WOW weight on wheels

Vrms volt, root-mean-square

WX weather

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page INTRO-6

6 Dec 2012

Page 33

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

List of Acronyms and Abbreviations (Cont)

Term Full Term

XM satellite based flight information services weather source

5. Process Verification

A. Verification Data

(1) Honeywell does a verification of these technical instructions by performance or by simulation

of the necessary procedures. Performance shows that the pr ocedure s were che cked by the

use of the manual. Simulation shows that the applicable personnel looked at the procedure

in the manual and that the procedure is technically correct. The dates of verification for this

manual are given in Table INTRO-1.

Table INTRO-1. Verification Data

Section Method Date

TBD TBD TBD

TBD TBD TBD

TBD TBD TBD

6. Software History

A. Software Data

(1) Not applicable.

7. History of Changes

A. Modification/Configuration History

(1) Not applicable.

B. Change History for Parts List

(1) Not applicable.

34-70-06

© Honeywell International Inc. Do not copy without express permission of Honeywell.

Page INTRO-7

6 Dec 2012

Page 34

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

066-01204 / 066-01213

Blank Page

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page INTRO-8

6 Dec 2012

Page 35

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

765/770 - would prefer to see this throughout the manual

066-01204 / 066-01213

SECTION I - GENERAL INFORMATION

1.1 Introduction

This manual contains information relative to the physical, mechanical, and electrical characteristics of the

KSN 7xx Safety Navigator. Installation and operating procedures are also included.

Operating instructions are provided in KSN 7xx Pilot’s Manual, Pub. No. 006-18324-0000. Information

relative to the maintenance, alignment, and procurement of th e replacement parts can be found in the A T A

No. 34-70-07 (Pub. No. 006-15716-0000), CMM, KSN 765/770 Safety Navigator.

1.2 Applicability of the Installation Manual

This manual is applicable only to the KSN 7xx integrated avionics systems with the part numbers as

shown in Table 1-1.

Table 1-1. Installation Manual Applicability

System PN Description

KSN 765 300-10940-0000 Top level assembly

066-01213-0101 Safety Navigator

066-01213-1101 Safety Navigator with RDR/EGPWS Support

KSN 770 300-10694-0000 Top level assembly

066-01204-0101 Safety Navigator NAV/COM

066-01204-1101 Safety Navigator NAV/COM with RDR/EGPWS

Support

1.3 Description of the Equipement

1.3.1 KSN 7xx Safety Navigator

The KSN 7xx product family feature is a full featured WAAS, integrated GPS navigator capable of LPV

approaches. Some of the system features include:

A. A TSO, GPS based, long range airborne database driven navigation. The primary purpose of the

KSN 7xx is to provide the pilot with present position information, to display guidance information

with respect to a flight plan defined by the pilot, and to provide communications functions to the

pilot. Flight plan information is entered by the pilot via the concentric knobs and button s on the front

panel.

B. A front loading pilot updateable database using a USB 2.0 thumb drive. Databases contain

worldwide information on NAVAID, intersections, low altitude airways, terrain, obstructions and

minimum safe altitudes. Database also includes public use and military airports with runways at

least 3000 feet (914.4 meters) in length, airport communication frequencies, runway information,

air route traffic control center data, flight service station frequencies, and SUA. SID and STAR

waypoints and approaches are also included. The information can be selected by airport and

procedure name.

© Honeywell International Inc. Do not copy without express permission of Honeywell.

34-70-06

Page 1-1

6 Dec 2012

Page 36

Draft

SYSTEM INSTALLATION MANUAL

Draft as of 10/15/2012

C. Information on the KSN 7xx is displayed on a large, easy-to-read color LCD. Pilot information is

input to the unit via flexible combination of touchscreen and graphics interf ace combined with

cursor control and by the 16 push buttons on the front panel.

D. An optional NAV receiver and COM transceiver that will allow integrated navigation and

communications on KSN 7xx units so equipped.

The KSN 7xx can use its present position information to determine crosstrack error,

distance-to-waypoint, ground speed, track an gle , time - to- wa yp oin t an d be a ring to wayp oin t.

The KSN 7xx can provide navigation data to external disp lays and autopilots. Some of this data is output

to external devices.

The internal database of the KSN 7xx contains information concerning airports, VOR, NDB, SUAs,

airport runways and frequency location information, and nearest FSS and ARTCC names and

frequencies. Waypoints are stored in the database by their ICAO identifiers. The ICAO identifiers are

(in most cases) taken directly from Jeppesen or government aeronautical charts.

1.3.2 GPS Antenna

The KA 96 GPS antenna, PN 071-01620-0001 or equ ivalent is the designated antenna for the KSN 7xx.

1.3.3 KCM 200 Configuration Module

066-01204 / 066-01213

The configuration module is used to store some installation specific information, which is used by the