Page 1

IFS-2600

8/05/08

Rev:

3.01

Fire Indicator Panel

TECHNICAL, PROGRAMMING

& INSTALLATION MANUAL

P/N 10069 ECN08-0066

Page 2

Page 3

Installation Precautions

Adherence to the following will aid in

problem-free installation with long-term

reliability:

WARNING - Several different sources of power

can be connected to the fire alarm control

panel. Disconnect all sources of power before

servicing. Control unit and associated equipment

may be damaged by removing and/or inserting

cards, modules, or interconnecting cables while the

unit is energized. Do not attempt to install, service,

or operate this unit until manuals are read and

understood.

Verify that wire sizes are adequate for all

initiating and indicating device loops. Most devices

cannot tolerate more than a 10% I.R. drop from the

specified device voltage.

Like all solid state electronic devices, this

system may operate erratically or can be damaged

when subjected to lightning induced transients.

Although no system is completely immune from

lightning transients and interference, proper

grounding will reduce susceptibility. Overhead or

outside aerial wiring is not recommended, due to

an increased susceptibility to nearby lightning

strikes. Consult with the Technical Services

Department if any problems are anticipated or

encountered.

Disconnect AC power and batteries prior to

removing or inserting circuit boards. Failure to do

so can damage circuits.

Remove all electronic assemblies prior to any

drilling, filing, reaming, or punching of the

enclosure. When possible, make all cable entries

from the sides or rear. Before making

modifications, verify that they will not interfere with

battery, transformer, or printed circuit board

location.

Do not over tighten screw terminals. Over

tightening may damage threads, resulting in

reduced terminal contact pressure and difficulty

with screw terminal removal.

This system contains static-sensitive

components. Always ground yourself with a

proper wrist strap before handling any circuits so

that static charges are removed from the body.

Use static suppressive packaging to protect

electronic assemblies removed from the unit.

Follow the instructions in the installation,

operating, and programming manuals. These

instructions must be followed to avoid damage to

the control panel and associated equipment.

FACP operation and reliability depend upon proper

installation.

This equipment must be correctly programmed

and installed to suit the specific application.

Please ensure correct operational parameters are

set prior to commissioning. If further details on

programming options are required, please consult

the programming manual or contact our helpful

technical support personnel.

EMC WARNING:

This equipment may radiate radio frequency energy. It may also be affected by radio frequency energy and, if

not installed and operated in accordance with the manufacturers instructions, may cause interference to radio

communications. It has been tested and found to comply with the Class A radiated and conducted EMI

requirements of AS/NZ 3548:1995 (including Amendments 1 & 2) as well as the EMI susceptibility

requirements of Clause C3.5 in AS4428.0:1997.

Radio communication devices should not be used in the vicinity of fire panels or associated ancillary devices

and systems.

Page 4

Documentation Feedback

Your feedback helps us keep our documentation up to date and accurate. If you have any comments or suggestions about

our printed manuals you can email us.

Please include the following information:

Product name and version number (if applicable)

Manual part number and revision (found on the front cover)

Page number

Brief description of the content you think should be improved or corrected

Your suggestion for how to correct/improve documentation

Send email messages to:

techpubs@notifier.com.au

Please note this email address is for documentation feedback only. If you have any technical issues, please contact

you nearest branch for technical support.

Page 5

IFS-2600 Installation & Programming Manual Page 1

TABLE OF CONTENTS

COMPATIBLE DETECTORS................................................................................................5

OVERVIEW...........................................................................................................................6

CAUTION ........................................................................................................................................................................... 6

SPECIFICATION...................................................................................................................7

APPROVALS...................................................................................................................................................................... 7

ENVIRONMENTAL LIMITS........................................................................................................................................... 7

POWER SUPPLY RATINGS AND SETTINGS ............................................................................................................. 9

INTERNAL 24 VDC (nom) 3.0A MAIN POWER SUPPLY .......................................................................................... 9

INTERNAL 27.3V DC 1.5A BATTERY CHARGER..................................................................................................... 9

Internal 5VDC 2A Power Supply ..................................................................................................................................... 9

EXTERNAL 27VDC POWER SUPPLY ....................................................................................................................... 10

BATTERY TYPE AND CAPACITIES .......................................................................................................................... 10

TECHNICAL DESCRIPTION..............................................................................................11

GENERAL ........................................................................................................................................................................ 11

TRANSIENT SUPPRESSION......................................................................................................................................... 11

CURRENT CONSUMPTION ......................................................................................................................................... 11

AZF DESCRIPTION........................................................................................................................................................ 12

AZF SUPERVISORY CURRENT .................................................................................................................................. 12

OVERLOAD PROTECTION.......................................................................................................................................... 12

ZONE OVERLOAD SELF RESET ................................................................................................................................ 12

PRINTER OUTPUT......................................................................................................................................................... 13

CABLE CONNECTION.................................................................................................................................................. 13

PROGRAMMING BY COMPUTER............................................................................................................................. 13

ALIGNMENT AND ADJUSTMENT.....................................................................................14

PCB2006 POWER SUPPLY BOARD ............................................................................................................................ 14

INTERNAL 24VDC (nom) POWER SUPPLY.............................................................................................................. 14

INTERNAL 27.3 VDC BATTERY CHARGER............................................................................................................ 14

EXTERNAL 24VDC (nom) POWER SUPPLY (if fitted)............................................................................................. 14

P/N 10069 ECN08-0066

Page 6

Page 2 IFS-2600 Installation & Programming Manual

PCB2005 TERMINATION BOARD...............................................................................................................................14

INTERNAL 5VDC POWER SUPPLY TP8...................................................................................................................14

POWER SUPPLY COMPARATOR REFERENCE VOLTAGE TP10 ......................................................................... 14

NON ADJUSTABLE TEST POINTS..............................................................................................................................14

ALARM THRESHOLD COMPARATOR TP7.............................................................................................................15

FAULT THRESHOLD COMPARATOR TP6 ..............................................................................................................15

CONFIGURATION JUMPERS......................................................................................................................................16

IFS2004 - JP3 DEFAULT .............................................................................................................................................16

IFS2004 - JP4 PROGRAM DISABLE ..........................................................................................................................16

IFS2004 - JP5 CPU RESET...........................................................................................................................................16

IFS2005 – JP2 DOOR HOLDER BYPASS...................................................................................................................16

IFS2006 – JP1 EXTERNAL PS MONITORING..........................................................................................................16

IFS804 - JP1-7 ZONE BOARD ADDRESSING...........................................................................................................16

PLACING INTO OPERATION............................................................................................ 17

EQUIPMENT AS FITTED..............................................................................................................................................17

INITIAL CHECKLIST....................................................................................................................................................17

POWER UP CHECKLIST...............................................................................................................................................18

FUNCTIONAL TESTING...............................................................................................................................................18

FAULT RECORD.............................................................................................................................................................19

INSTRUCTIONS TO OPERATORS....................................................................................20

INDICATORS...................................................................................................................................................................20

SUGGESTED ALARM PROCEDURE.......................................................................................................................... 21

OPERATOR INSTRUCTIONS.......................................................................................................................................21

FIREFIGHTER FUNCTIONS........................................................................................................................................21

GLOBAL FUNCTIONS.................................................................................................................................................22

ZONE FUNCTIONS.......................................................................................................................................................24

PROGRAMMING................................................................................................................27

GLOBAL OPTIONS.........................................................................................................................................................27

ZONE OPTIONS ..............................................................................................................................................................27

OUTPUT RELAY OPTIONS ..........................................................................................................................................28

DEFAULT SETTINGS.....................................................................................................................................................28

PROGRAM MODE..........................................................................................................................................................29

PROGRAMMING MODE..............................................................................................................................................29

PROGRAMMING HIERARCHY..................................................................................................................................29

ZONES............................................................................................................................................................................29

RELAYS.........................................................................................................................................................................30

GLOBAL ........................................................................................................................................................................ 30

PRINT.............................................................................................................................................................................30

P/N 10069 ECN08-0066

Page 7

IFS-2600 Installation & Programming Manual Page 3

MAIN MENU.................................................................................................................................................................... 30

EXIT PROGRAMMING MODE................................................................................................................................... 31

ZONE PROGRAMMING................................................................................................................................................ 31

SELECT ZONE #........................................................................................................................................................... 31

ZONE SELECTED......................................................................................................................................................... 31

ZONE TYPE .................................................................................................................................................................. 31

ZONE OUTPUT CONFIGURATION ........................................................................................................................... 32

RELAY PROGRAMMING MODE................................................................................................................................ 32

SELECT RELAY # ........................................................................................................................................................ 32

RELAY SELECTED...................................................................................................................................................... 32

RELAY TYPE................................................................................................................................................................ 33

RELAY MAPPING........................................................................................................................................................ 33

GLOBAL PROGRAMMING.......................................................................................................................................... 33

ACF OUTPUT................................................................................................................................................................ 34

AVF................................................................................................................................................................................ 34

RELAY (GLOBAL RELAY UNITY MAP) .................................................................................................................. 34

PRINT PROGRAMMING DATA.................................................................................................................................. 35

TIME (DATE & TIME)................................................................................................................................................... 35

APPENDIX A ......................................................................................................................36

DESCRIPTION OF ALARM ZONE TYPES................................................................................................................ 36

LATCHING TYPE......................................................................................................................................................... 36

NON LATCHING TYPE ............................................................................................................................................... 36

TIME DELAY AZF........................................................................................................................................................ 37

APPENDIX B ......................................................................................................................38

ZONE OUTPUT CONFIGURATIONS.......................................................................................................................... 38

APPENDIX C ......................................................................................................................39

ALARM VERIFICATION FACILITY (AVF).............................................................................................................. 39

GLOBAL PROGRAMMABLE OPTIONS.................................................................................................................... 39

APPENDIX D ......................................................................................................................40

ANCILLARY TRIP (ACF).............................................................................................................................................. 40

GLOBAL PROGRAMMABLE OPTIONS.................................................................................................................... 40

APPENDIX E.......................................................................................................................41

RELAY OUTPUT MAPPING......................................................................................................................................... 41

AND MAPPING ............................................................................................................................................................... 41

OR MAPPING.................................................................................................................................................................. 41

FAULT MAPPING........................................................................................................................................................... 41

FAULT/ISOLATE MAPPING........................................................................................................................................ 42

ISOLATE MAPPING ...................................................................................................................................................... 42

P/N 10069 ECN08-0066

Page 8

Page 4 IFS-2600 Installation & Programming Manual

APPENDIX F ......................................................................................................................43

GLOSSARY OF TERMS.................................................................................................................................................43

APPENDIX G...................................................................................................................... 44

SUMMARY OF TERMINATIONS AND CAUTIONS.................................................................................................44

MCP LOOP..................................................................................................................................................................... 44

DETECTION ZONES ....................................................................................................................................................44

RELAY OUTPUTS ........................................................................................................................................................44

BELL OUTPUTS ...........................................................................................................................................................44

ACF OUTPUTS..............................................................................................................................................................44

WARNING SYSTEM.....................................................................................................................................................44

DOOR HOLDER OUTPUTS.........................................................................................................................................44

AUXILIARY POWER & MIMIC POWER ................................................................................................................... 44

MAF ISOL & TRANSPONDER 0V ..............................................................................................................................44

MIMIC DATA & CLOCK..............................................................................................................................................44

AC INPUT......................................................................................................................................................................44

BATTERY......................................................................................................................................................................45

DOOR HOLDER AC INPUT.........................................................................................................................................45

OUTPUT RELAYS ........................................................................................................................................................45

APPENDIX H...................................................................................................................... 46

IFS-2600 PROGRAMMED OPTIONS...........................................................................................................................46

APPENDIX I........................................................................................................................ 53

TECHNICAL DRAWINGS.............................................................................................................................................53

MAIN KEYPAD AND DISPLAY..................................................................................................................................53

EXPANSION DISPLAY ................................................................................................................................................ 53

Block Connection Diagram.............................................................................................................................................54

System Sensor Conventional Detector Connection Diagram.......................................................................................... 54

System Sensor Conventional Detector Connection Diagram.......................................................................................... 55

Hochiki Conventional Detector Connection Diagram.....................................................................................................55

Hochiki Conventional Detector Connection Diagram.....................................................................................................56

Ancillary Connection Diagram........................................................................................................................................57

ASE Connection Diagram...............................................................................................................................................58

Auto Changeover Dual Sounder Connection Diagram....................................................................................................59

Auto Change Over Dual Sounder Connection Diagram.................................................................................................. 60

MIMIC Connection Diagram..........................................................................................................................................61

Single Fan Connection Diagram .....................................................................................................................................62

Dual Fan Connection Diagram........................................................................................................................................63

Exhaust Fan Connection Diagram...................................................................................................................................64

Supply Fan Connection Diagram ....................................................................................................................................65

Smoke Spill Fan Connection Diagram............................................................................................................................66

10W EVAC Connection Diagram...................................................................................................................................67

10W EVAC Slave Connection Diagram.........................................................................................................................68

30W EVAC Connection Diagram...................................................................................................................................69

30W EVAC Slave Connection Diagram.........................................................................................................................70

50W EVAC Connection Diagram...................................................................................................................................71

50W EVAC Slave Connection Diagram.........................................................................................................................72

P/N 10069 ECN08-0066

Page 9

IFS-2600 Installation & Programming Manual Page 5

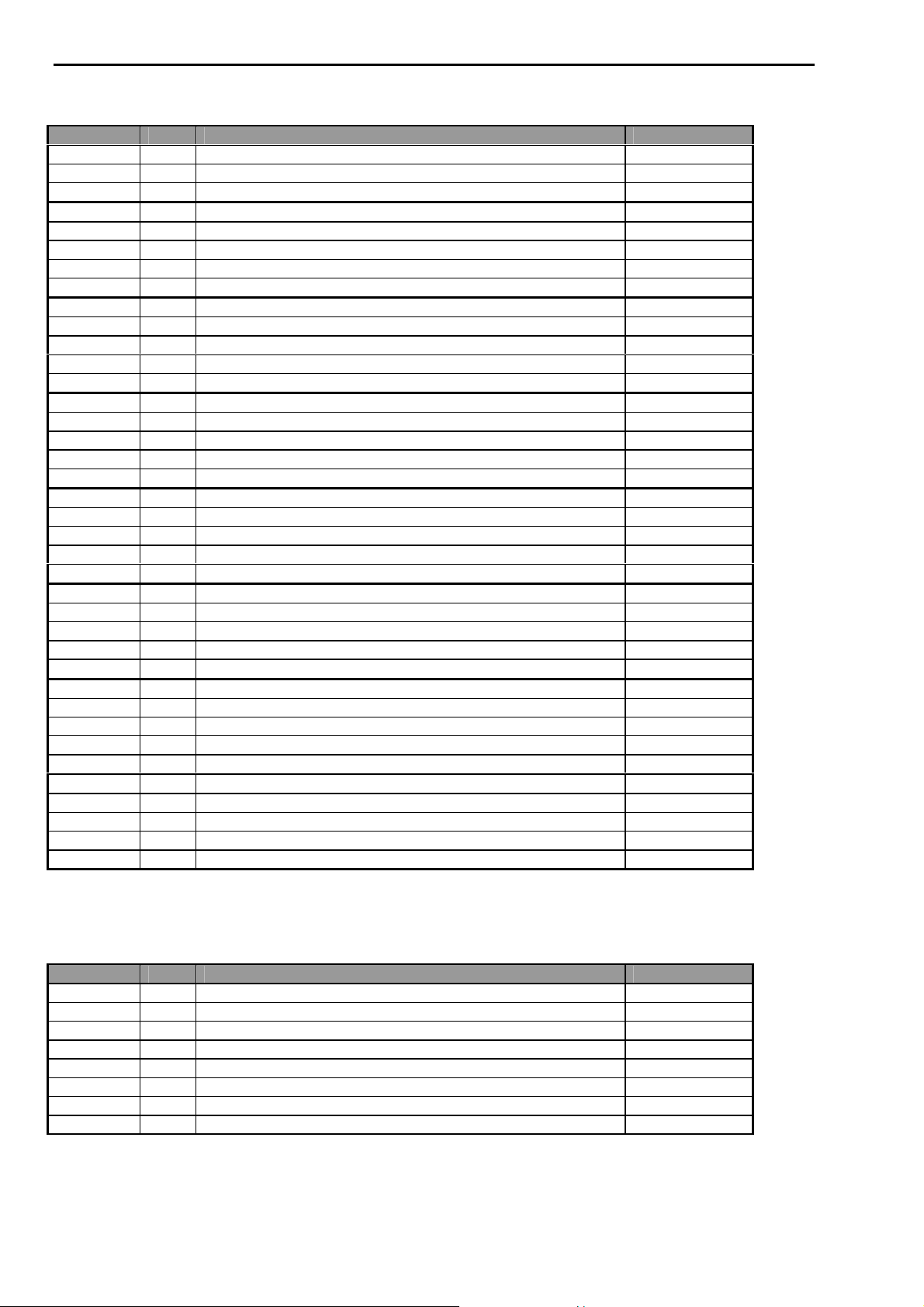

COMPATIBLE DETECTORS

Make Model Type Model Number

System Sensor Thermal Type A 5451 AUS

System Sensor Thermal Type A 51A51

System Sensor Thermal Type B 4451 AUS

System Sensor Thermal Type B 51B51

System Sensor Thermal Type B Sealed 51B51S

System Sensor Thermal Type C 51C51

System Sensor Thermal Type D 51D51

System Sensor Smoke Photo-Optical 2151 AUS

System Sensor Smoke Photo-Optical 2151B AUS

System Sensor Smoke Ionisation 1151 AUS

System Sensor Thermal Type D 51D51

System Sensor Smoke Beam BEAM1224

System Sensor Smoke Duct DHP-100

Apollo Thermal Type A Series 60

Apollo Thermal Type B Series 60

Apollo Thermal Type C Series 60

Apollo Thermal Type D Series 60

Apollo Smoke Ionisation Series 60

Apollo Smoke Photo Optical Series 60

Hochiki Thermal Type A DCA-B-60R MkV

Hochiki Thermal Type A DCC-A

Hochiki Thermal Type A DCD-A

Hochiki Thermal Type B DFE-60B

Hochiki Thermal Type B DFJ-60B

Hochiki Thermal Type C DCA-B-90R Mk1

Hochiki Thermal Type C DCC-C

Hochiki Thermal Type C DCD-C

Hochiki Thermal Type D DFE-90D

Hochiki Thermal Type D FDJ-90D

Hochiki Thermal Cool Room Type B sealed DFG-60BLKJ

Hochiki Smoke Ionisation SIH-AM

Hochiki Smoke Ionisation SIJ-ASN

Hochiki Smoke Photo Optical SLK-A

Hochiki Smoke Photo Optical SLR-AS

Olsen Thermal Type A T56B-T6A

Olsen Thermal Type B T56B-T6B

Olsen Thermal Type C T56B-T6C

Olsen Thermal Type D T56B-T6D

Olsen Smoke Ionisation C24B

Olsen Smoke Photo Optical P24B

Panelect Thermal Type A PFS-A

Panelect Thermal Type B PFS-B

Panelect Thermal Type C PFS-C

Panelect Thermal Type D PFS-D

Panelect Smoke Ionisation PFS-I

Panelect Smoke Ionisation PFS-I , MkII

Panelect Smoke Photo Optical PFS-P

Panelect Smoke Photo Optical PFS-P, MkII

IEI VESDA E700, E70D CONTACT DEVICE

Please contact NOTIFIER INERTIA for any additional detectors.

P/N 10069 ECN08-0066

Page 10

Page 6 IFS-2600 Installation & Programming Manual

OVERVIEW

IFS-2600 Fire Indicator Panel (FIP) is designed to provide simplicity to the end user. The FIP uses both a liquid crystal

display and conventional LED displays for fast and accurate display of system status and changing events.

A custom designed membrane keypad is used together with the liquid crystal display and LED indicators to provide fast,

efficient and simple modes of operation. The keypad also provides the required flexibility for the programming of the

many user configurable options of this FIP. The FIP can be configured on-site without the need of expensive

programmers or components.

A serial printer can also be connected if required. The printer can be used to output programming information for ease of

modification, for safekeeping and to assist in the commissioning of the installation.

IFS-2600 uses serial chain mimic outputs which significantly saves time and costs of cabling to mimic panels.

A door holder power supply (using optional transformer) is incorporated into the system for the release of smoke and fire

doors on alarm.

IFS-2600 is available in a standard 8-zone configuration and can be expandable to its fully expanded state as required.

The IFS-2600 in its fully expanded state can;

• Monitor 64 detection zones

• Control 64 optional "mapped" relay outputs

• Output to a serial printer

• Output serially to a mimic panel

• Control to door holders

• Interface as required to any Australian Fire Brigade

IFS-2600 has been designed to be functional, flexible and reliable whilst maintaining a user-friendly interface.

CAUTION

IFS-2600 FIP has been tested and approved to AS4428.1 and meets the requirements of AS1670 and AS1668 Parts 1 &

2.

However, the equipment must be correctly programmed and installed to suit the specific application. Please ensure

correct operational parameters are set prior to commissioning. If further details on programming options are required,

please consult the programming manual or contact our helpful technical support personnel.

WARNING:

This equipment may radiate radio frequency energy. It may also be affected by radio frequency energy and, if

not installed and operated in accordance with the manufacturers instructions, may cause interference to radio

communications. It has been tested and found to comply with the Class A radiated and conducted EMI

requirements of AS/NZ 3548:1995 (including Amendments 1 & 2) as well as the EMI susceptibility

requirements of Clause C3.5 in AS4428.0:1997

CAUTION: Radio communication devices should not be used in the vicinity of fire panels or associated

ancillary devices and systems

P/N 10069 ECN08-0066

Page 11

IFS-2600 Installation & Programming Manual Page 7

SPECIFICATION

Cabinet Zinc Sealed Steel 1.6mm

Powder Coated

Hinged Inner Door

Hinged Outer Door

Outside Dimensions 2608 (8 zones) 394mm H x 390mm W x 180mm D*

2624 (24 zones) 750mm H x 390mm W x 180mm D*

2600 (32 to 64 zones) 18U, 28U & 40U Cabinets

Battery Box

*Note: the depth quoted is including the door and break glass.

The internal cabinet depth not including he door and break glass

is 140mm.

AC Operational Voltage 240 VAC 50Hz + 10%

Internal Power Supplies Battery Charger 27.3 VDC 1.5AMP

Panel Supply 24 VDC(nom) 3.0AMP

Logic Supply 5 VDC 2.0AMP

Microprocessor 80C52

Memory Type Non-volatile E2ROM

Liquid Crystal Display 2 Lines x 16 Characters LED Backlit

Fuses F1: Panel Supply M205 5A

F2: Battery Charger M205 3A

F3: Battery Protection Polyfuse 3A

F4: External Supply M205 7A

F5: Door Holder M205 3A

F6: Aux Power Output M205 1A Slow Blow

F7: Bell M205 1A

F8: Warning System M205 1A

F9: ACF M205 1A

E.O.L Resistor On AZFs, monitored

outputs, Bells, Warning system, ACF

4K7 Ohms

APPROVALS

Australian Standard AS4428.1 1998

SSL Approval No AFP-1553

C-Tick Approval No. N1336

ENVIRONMENTAL LIMITS

-10 Deg. C to +55 Deg. C Dry heat.

+40 Deg. C @ 93% Relative Humidity.

P/N 10069 ECN08-0066

Page 12

Page 8 IFS-2600 Installation & Programming Manual

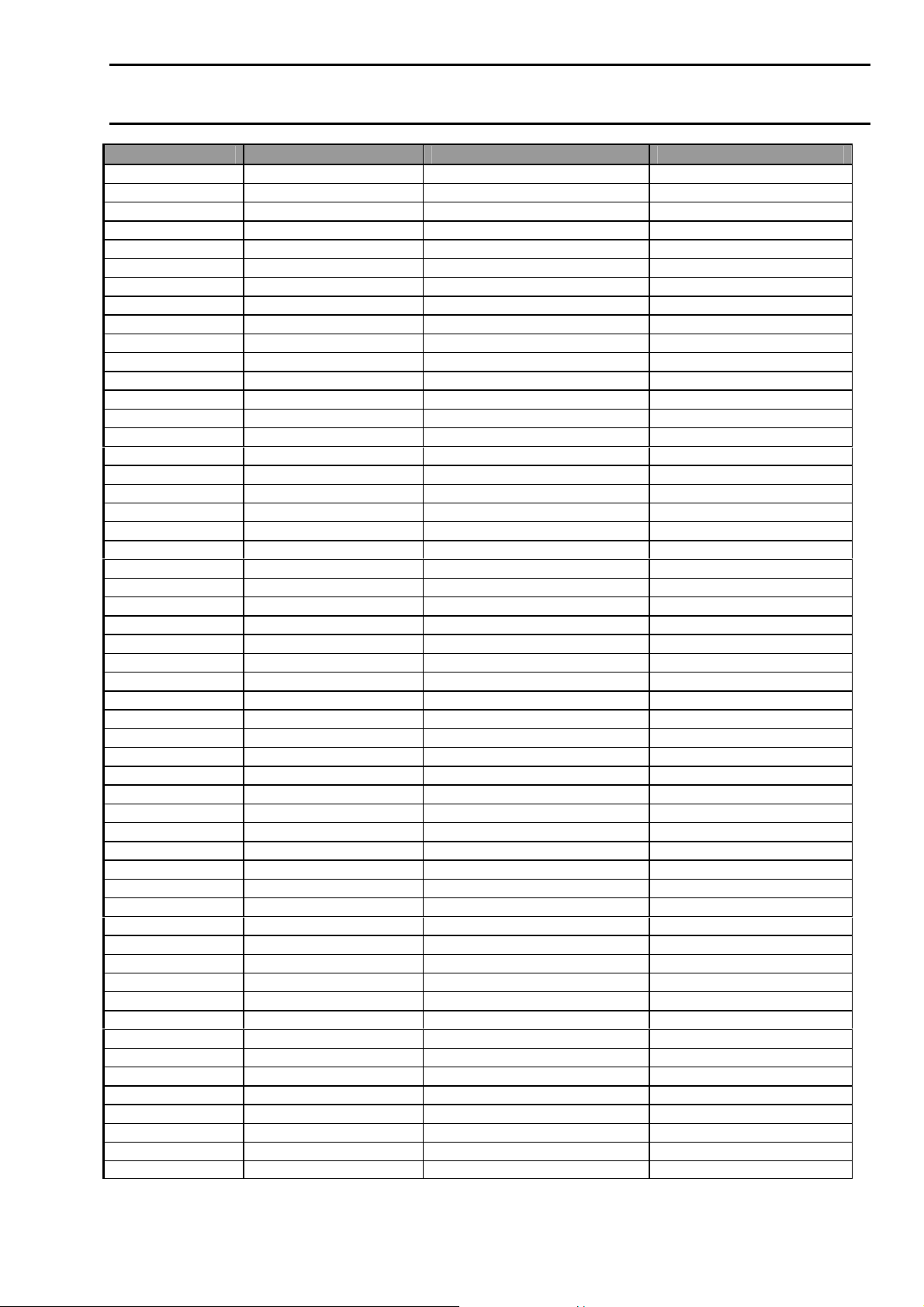

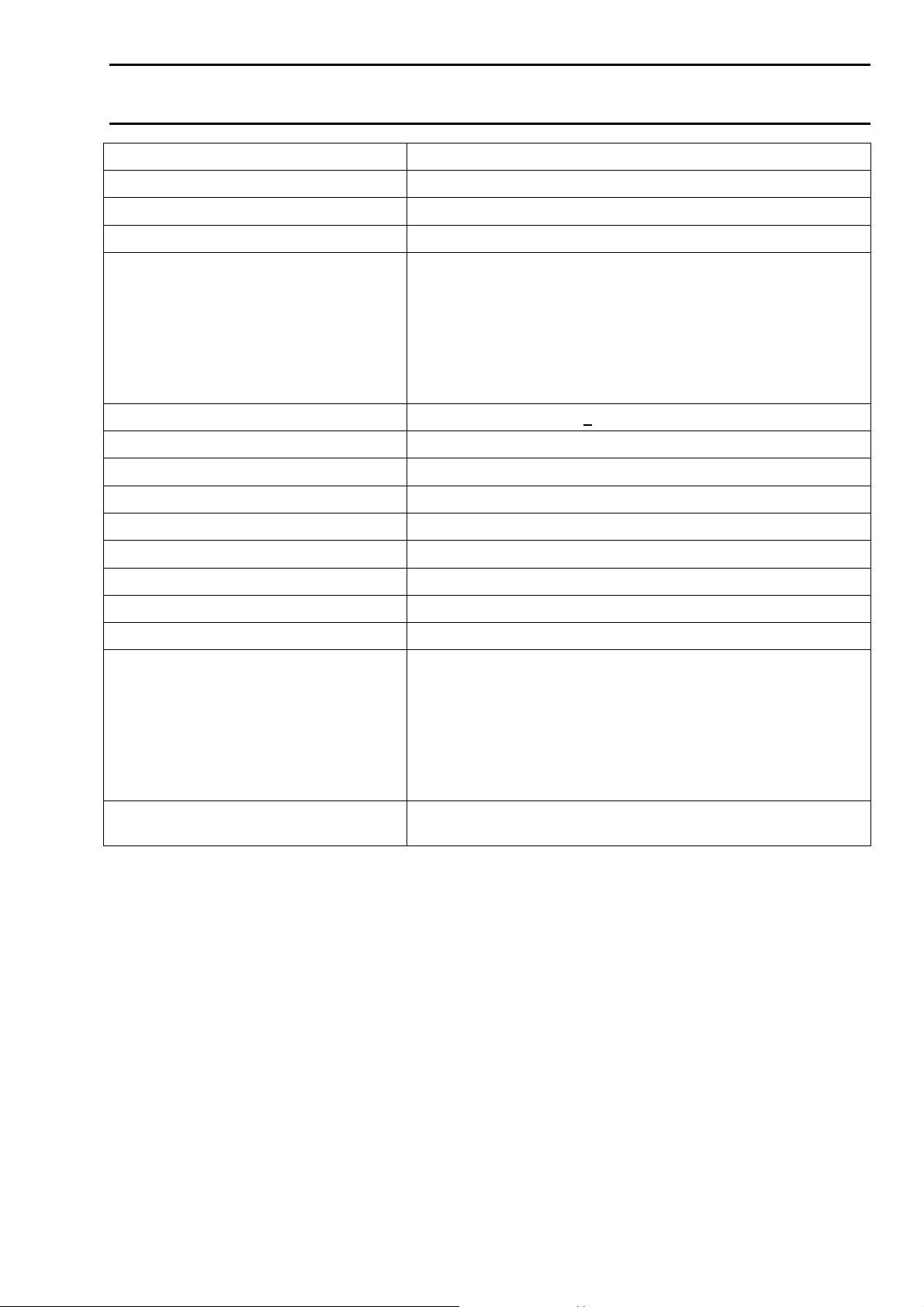

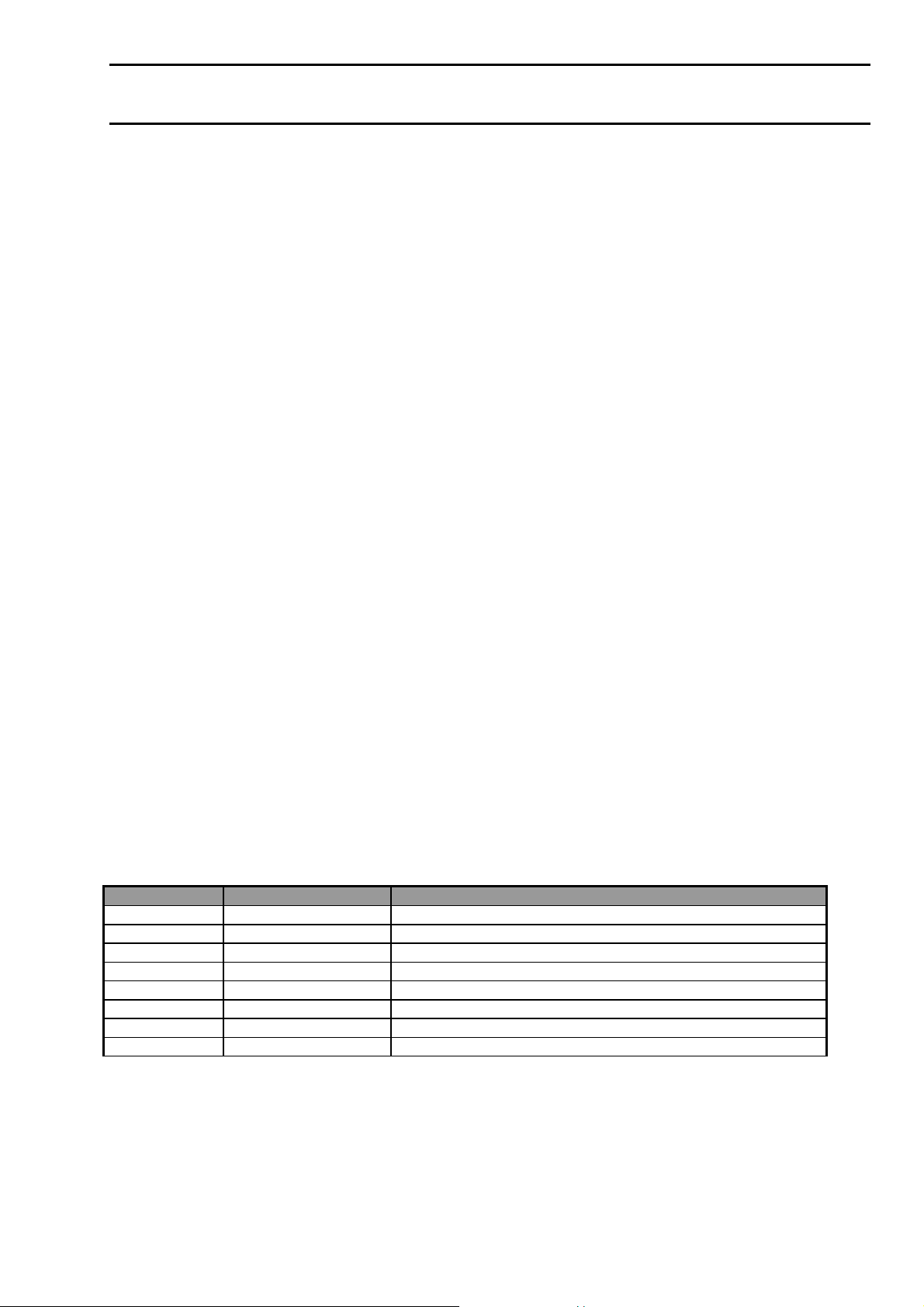

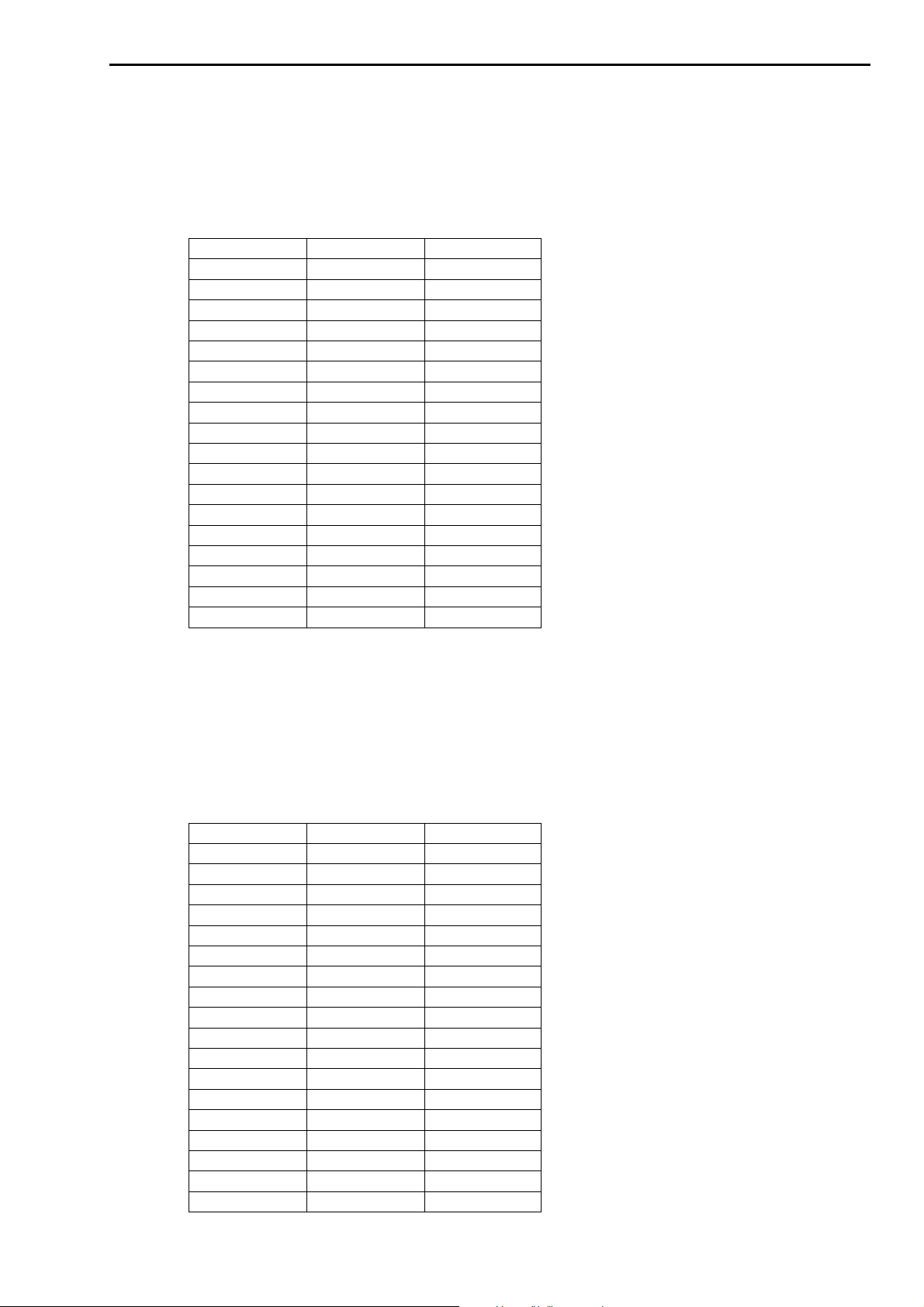

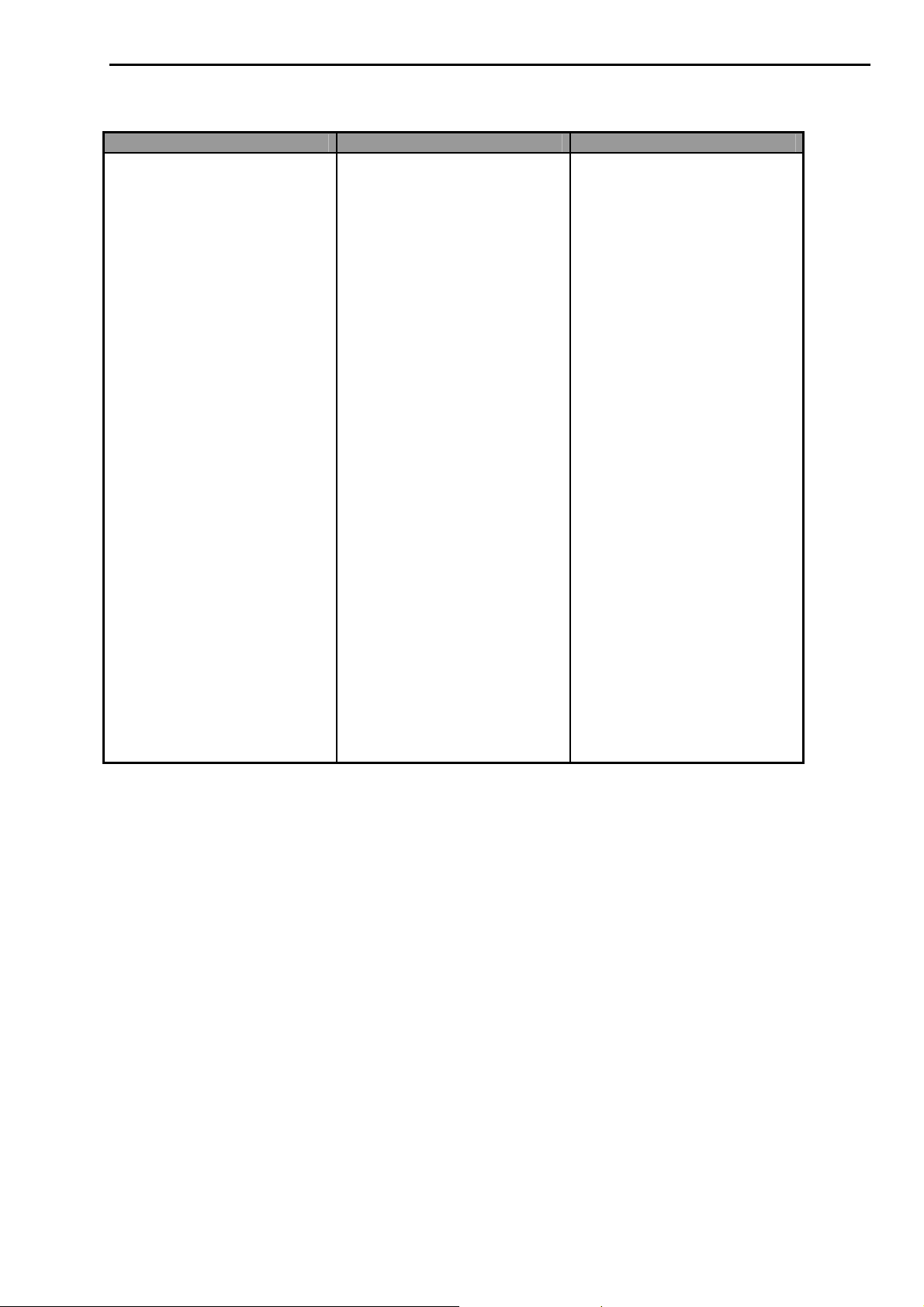

SYSTEM EXPANSION

Zones Qty Hardware Required Product Code

8 1 Main Control Board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

16 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

1 8 Zone Expansion board PCB-804G3

1 16 Zone Indicator board PCB-816

24 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

2 8 Zone Expansion board PCB-804G3

1 16 Zone Indicator board PCB-816

32 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

3 8 Zone Expansion board PCB-804G3

2 16 Zone Indicator board PCB-816

40 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

4 8 Zone Expansion board PCB-804G3

2 16 Zone Indicator board PCB-816

48 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

5 8 Zone Expansion board PCB-804G3

3 16 Zone Indicator board PCB-816

56 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

6 8 Zone Expansion board PCB-804G3

3 16 Zone Indicator board PCB-816

64 1 Main Control board PCB-2004

1 Main Termination board PCB-2005

1 Power Supply board PCB-2006

7 8 Zone Expansion board PCB-804G3

4 16 Zone Indicator board PCB-816

Additional relay outputs:

Relays Qty Hardware Required Product Code

8 1 Relay board containing 8 relays 24VDC 1A IFS-717

16 2 Relay board containing 8 relays 24VDC 1A IFS-717

24 3 Relay board containing 8 relays 24VDC 1A IFS-717

32 4 Relay board containing 8 relays 24VDC 1A IFS-717

40 5 Relay board containing 8 relays 24VDC 1A IFS-717

48 6 Relay board containing 8 relays 24VDC 1A IFS-717

56 7 Relay board containing 8 relays 24VDC 1A IFS-717

64 8 Relay board containing 8 relays 24VDC 1A IFS-717

P/N 10069 ECN08-0066

Page 13

IFS-2600 Installation & Programming Manual Page 9

POWER SUPPLY RATINGS AND SETTINGS

INTERNAL 24 VDC (nom) 3.0A MAIN POWER SUPPLY

This supply's primary function is to power panel logic and all external operations of the FIP, i.e.: detection

circuits, ancillary circuits, etc. This supply meets the requirements of AS4428.5.

AC Input 30 VAC +10% - 15%

Output Current 3.0 AMPS

Output Voltage 26.5 VDC

Current Limit 3.0 AMPS

Output Ripple 50 mV

INTERNAL 27.3V DC 1.5A BATTERY CHARGER

Its primary function is to charge the batteries. This supply meets the requirements of AS4428.5.

AC Input 30 VAC +10% -15%

Output Current 1.5 AMPS

Output Voltage 27.3 VDC

Current Limit 1.5 AMPS

Output Ripple 200 mV

Important Note:

After a power failure, the battery will only reconnect to the charger if the battery voltage is above approximately

20V +/- 2V.

A battery fault will be generated in the event that the battery does not automatically reconnect. This is to ensure

that a faulty or dead flat battery (due to an extended power failure) does not bring the entire system down.

In order to reconnect a flat battery, it is necessary to disconnect the battery from the panel and charge it

externally. The battery should be thoroughly tested before returning it to service.

In the event that an external charger is not available, the battery may be trickle charged above 22V via a 30

ohm, 5W resistor connected between the 24v Aux Output and the battery positive terminal. A 1N4004 Diode

(Notifier part number #286) or similar should also be fitted in series with the resistor to stop the battery from

pulling down the main panel voltage. Trickle charging the battery by this method may take several hours to

bring it up to the minimum level.

The battery can then be reconnected to the panel for charging via the internal battery charger. It is important

that the voltage on the battery be monitored to ensure that it is charging. The battery should then be left for 24

hours and then fully tested to ensure that no damage has occurred due to the deep discharge.

Internal 5VDC 2A Power Supply

This supply's primary function is to power all internal operations of the FIP, i.e.: Microprocessor, liquid crystal

display, LED's keypad etc.

AC Input 30 VAC +15% or 27.6VDC+15%

Output Current 2.0 AMPS

Output Voltage 5.0 VDC

Current Limit 2.0 AMPS

Output Ripple 150 mV

P/N 10069 ECN08-0066

Page 14

Page 10 IFS-2600 Installation & Programming Manual

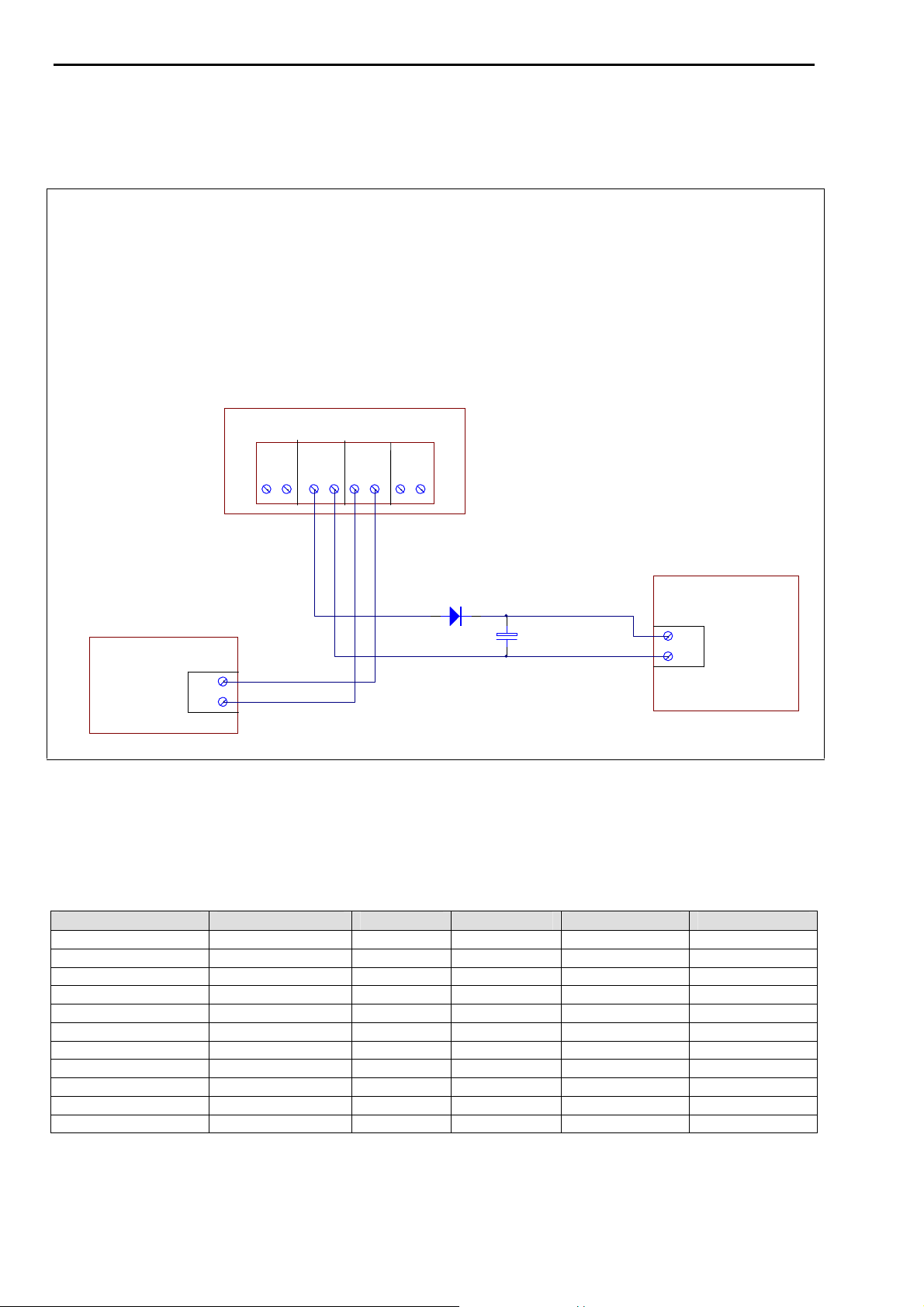

INPUT

INPUT

24V0V

IFS-2600 TERMINATION BOARD

EXTERNAL 27VDC POWER SUPPLY

This supply is used in addition to the internal power supply for large systems. Its primary function is to power

any additional ancillary loads of the FIP up to 7 amps. This supply meets the requirements of AS4428.5

Important Notes:

When using external power supply, JP1 link on IFS2006E must be fitted to enable external PSU monitoring.

If this supply is used to power a NI-2008 gas module, the following additional components are required to

ensure a break free change over from the mains supply to the panel battery in case of mains fail condition.

1. A 6A4 or P600G rectifier diode (Notifier part number #266) is to be installed in series with the

external +27V output of the IFS-2600 termination board.

2. A 3300µF 50V Electrolytic Capacitor (Notifier part number #1248) should be installed across the

+27V and 0V of the ancillary device.

AC

REMOTE

REMOTE

OUTPUT

24V 0V-+24V 0V

BATT

INPUT

EXTERNAL

POWER

SUPPLY

OUTPUT

0V

24V

6A4

+

3300uF

POWER IN

NI-2008 GAS

SUPPRESSION

MODULE

BATTERY TYPE AND CAPACITIES

In general, any Sealed Lead Acid Battery, or Wet Lead Acid Battery designed for stationary use is compatible

with the IFS-2600 Fire Indicator Panel. Automotive batteries must not be used. The use of Nickel Cadmium

batteries is not recommended.

Manufacturer Type Number Voltage Capacity (Ah) Qty Required

Best and Best Sealed LA BP17-12 12 17 2

Best and Best Sealed LA BP24-12 12 24 2

Best and Best Sealed LA BP40-12 12 40 2

Olympic Batteries Sealed LA CJ12-7 12 7 2

Olympic Batteries Sealed LA CJ12-12 12 12 2

Olympic Batteries Sealed LA CJ12-18 12 18 2

Olympic Batteries Sealed LA CJ12-26 12 26 2

Olympic Batteries Sealed LA CJ12-33 12 33 2

Olympic Batteries Sealed LA CJ12-40 12 40 2

Olympic Batteries Sealed LA CJ12-88 12 88 2

Olympic Batteries Sealed LA CJ12-100 12 100 2

P/N 10069 ECN08-0066

Page 15

IFS-2600 Installation & Programming Manual Page 11

TECHNICAL DESCRIPTION

GENERAL

The IFS-2600 in its most basic form comprises of three boards, the main control board, the main termination

board and the power supply board.

The main control board contains the Microprocessor, EPROM, RAM and E2ROM. The main control board also

has the liquid crystal display and keypad attached. All of the "delicate" electronics have been placed on this

board. The main control board complete with the inner door is easily removed during installation to avoid

damage and allow greater access to the field terminals.

The main termination board contains the one power supply for 5V logic, and connectors for a Power Supply

and Battery Charger daughter board, the first eight zones, all common outputs and the printer interface. All

charger settings, fuses etc are located on this board. The Power Supply and Battery Charger board contains

two switch mode regulators, 26.5V for the panel power, 27.3V for the battery charger.

Up to seven (7) zone expansion boards can be added to the system to increase its detection capability. These

boards contain the same electronics as on the main termination board for zone scanning. Addressing is by a

jumper that selects which group of eight zones the board refers to.

Up to four (4) zone indicator boards can also be added. These boards will display the status of the zone

expansion boards fitted.

Up to eight (8) relay boards can be added. These boards contain 8 change-over relay contacts, each rated at

1 amp. These boards require no addressing, as they work on a serial data chain. Output 1 is the closest

output to the main board.

NOTE This product utilises state of the art components and materials and therefore boards must be returned

to our factory for proper troubleshooting, repair and retesting. Field component level repairs are not

recommended and would void all warranties on the product.

TRANSIENT SUPPRESSION

The IFS-2600's superior transient protection comprises of Dual Transorb input traps, inductive paths on

incoming PCB tracks, circuit board planes and metal oxide varistors on outputs. These devices are all selfresetting.

CURRENT CONSUMPTION

Zones Fitted Quiescent Current Quiescent + 2 AZF'S in alarm +1A of Bell +1 Amp ACF

8 150 mA 2.23 AMPS

16 250 mA 2.33 AMPS

24 350 mA 2.43 AMPS

32 450 mA 2.53 AMPS

40 550 mA 2.63 AMPS

48 650 mA 2.73 AMPS

56 750 mA 2.83 AMPS

64 850 mA 2.93 AMPS

Note:

1: Each installation would require individual battery calculations to be performed for load capacity and

power supply capacity.

2: Each IFS-717 relay board, can add 370 mA (in alarm and quiescent) current per board.

P/N 10069 ECN08-0066

Page 16

Page 12 IFS-2600 Installation & Programming Manual

AZF DESCRIPTION

The AZF's on the IFS-2600 are monitored and scanned by custom thick film hybrids. These hybrid IC's

significantly reduce the possibility of false alarms and improve product efficiency and reliability.

The total Alarm Zone loop resistance is the sum of the end of line resistor (EOLR 4K7) plus all the parallel

connected detector loads.

AZF SUPERVISORY CURRENT

The supervisory current flows through the external terminal AZF+, through the field cable and to the end of line

resistor (EOLR), returning to the panel at AZF- terminal. Parallel connected, across the 2-wire pair field cable,

are a number of the previously listed detectors. During the quiescent state there is essentially an open circuit

across the + and - terminals of the detector base. The maximum number of detectors that can be installed on

each AZF is dependant on the type of detector and is listed in the IFS-2600 ActivFire®listing.

In an alarm state, a 560-ohm resistor is connected across the detector base causing additional loop current to

flow. This is sensed by the AZF to produce an alarm output. Removal of the E.O.L. resistor (in a non alarm

state) or the interruption of the supervisory current will produce a fault signal in the AZF.

As described above, the level of current is used to define the status of the alarm zone: -

I = 3.5 mA and below FAULT

I = 4.0 - 5.0mA at 24V QUIESCENT

I = 16 mA to 40 mA (current limited) ALARM

The zone current is used by the hybrid IC to determine the condition of the zone as above. This information is

then transferred to the microprocessor for processing.

OVERLOAD PROTECTION

Panel Supply Fuse F1 M205 5A

Battery Charger Fuse F2 M205 3A

Battery Protection Fuse F3 Polyfuse 3A

External Supply Fuse F4 M205 7A

Door Holder Fuse F5 M205 3A

Aux Power Output Fuse F6 M205 1A Slow Blow

Bell Fuse F7 M205 1A

Warning System Fuse F8 M205 1A

ACF Fuse F9 M205 1A

AZF Circuits Current Limited 40mA

ZONE OVERLOAD SELF RESET

If a zone is overloaded by an accidental short to earth on an AZF circuit, the zone will automatically shut down

and produce a fault. Once this happens the panel will automatically recheck the zone every 60 seconds and

once the overload is removed, restore power and the fault will clear.

P/N 10069 ECN08-0066

Page 17

IFS-2600 Installation & Programming Manual Page 13

PRINTER OUTPUT

The printer port is designed to be used during testing and commissioning of the panel. The serial printer will

report alarms and faults together with the date and time of the event. The printer can also be used during

“walk test” mode to produce a history of the test and can also be used to print current programming

configuration.

A DB9 plug male is provided at the top of the main termination board. This communication port will

communicate with an IBM compatible serial printer (ASCII printer) with the following settings.

Baud Rate 1200 bps

Data Bits 8

Stop Bits 1

Parity None

Handshaking DTR

CABLE CONNECTION

Cabling to the printer requires a 4-core telephone style cable with a maximum length of 10 metres. A DB9

socket is required at the panel end. The printer end is dependent on the type of printer used but is usually a

male DB25. Connection is as follows. A 5-core cable can be used for both comms and printer functions

IFS-2600 END PRINTER END

DB9 FEMALE DB25 MALE DB9 MALE

2 RX (only for programming) 2 3

3 TX 3 2

5 GND 7 5

7 RTS ( do not use) (5) (8)

8 CTS ( only for printer) 4 7

PROGRAMMING BY COMPUTER

Programming of the zones, relays, global functions and time can by set with the DOS based program

“2600/SW” using the printer port. (Cannot be used with Windows XP)

After the cable is installed, the program can be run and the menu will prompt for the available functions.

2600

P/N 10069 ECN08-0066

Page 18

Page 14 IFS-2600 Installation & Programming Manual

ALIGNMENT AND ADJUSTMENT

PCB2006 POWER SUPPLY BOARD

INTERNAL 24VDC (nom) POWER SUPPLY

With batteries disconnected and no alarms present, measure voltage across the 0V and MAIN test

points on the 2006 power supply board and, if necessary, adjust the multi-turn potentiometer VR2 until

voltage is 26.5V 0.05V (26.45V – 26.55V).

Current limiting is fixed and field adjustment is not possible.

INTERNAL 27.3 VDC BATTERY CHARGER

With batteries disconnected and no alarms present, measure voltage across the 0V and CHARG test

points on the 2006 power supply board and, if necessary, adjust the multi-turn potentiometer VR1 until

voltage is 27.3V 0.05V (27.25V – 27.35V).

Current limiting is factory preset and field adjustment is not required.

EXTERNAL 24VDC (nom) POWER SUPPLY (if fitted)

With batteries disconnected and no alarms present, measure voltage across Remote Input terminals

on PCB2005 and adjust the voltage on the external power supply until the voltage is 26.5V 0.5V

(26.0V – 27.0V). Note: This voltage is not critical for the operation of the IFS-2600 panel, but the

voltage must not go outside the limits as specified for the field ancillaries that it powers.

PCB2005 TERMINATION BOARD

INTERNAL 5VDC POWER SUPPLY TP8

All parameters are fixed and field adjustment is not possible.

POWER SUPPLY COMPARATOR REFERENCE VOLTAGE TP10

With the panel in the quiescent mode, measure voltage between system 0V and TP10. Adjust multiturn potentiometer VR3 until voltage is 7.0V 1% (6.93V – 7.07V)

NON ADJUSTABLE TEST POINTS

TP8 = 5.0 VDC 5% 5VDC POWER SUPPLY

TP5 = 12.0 VDC 5% 12VDC POWER SUPPLY

(If these test point voltages are not correct, please return the main termination board to the factory for

repair.)

P/N 10069 ECN08-0066

Page 19

IFS-2600 Installation & Programming Manual Page 15

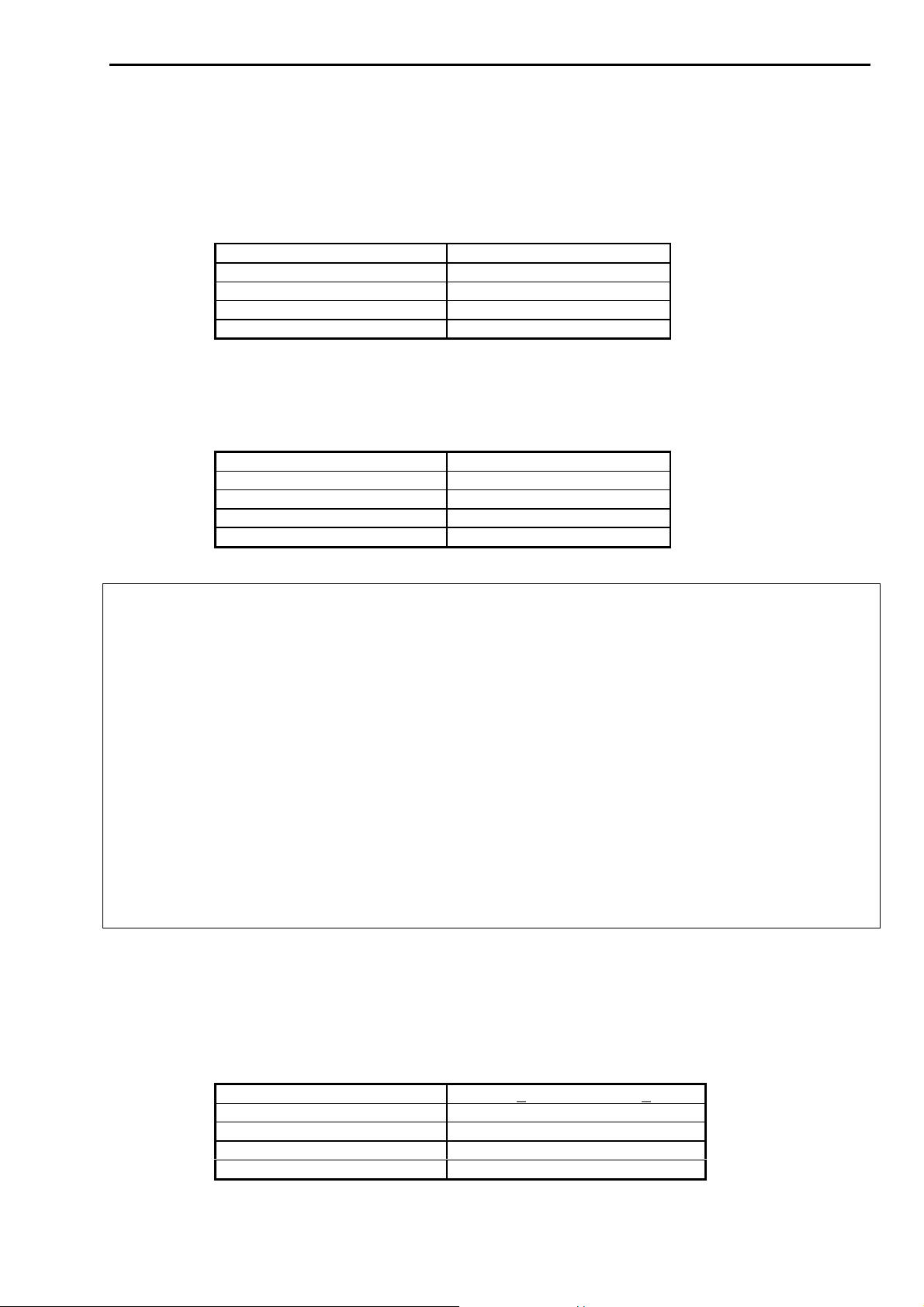

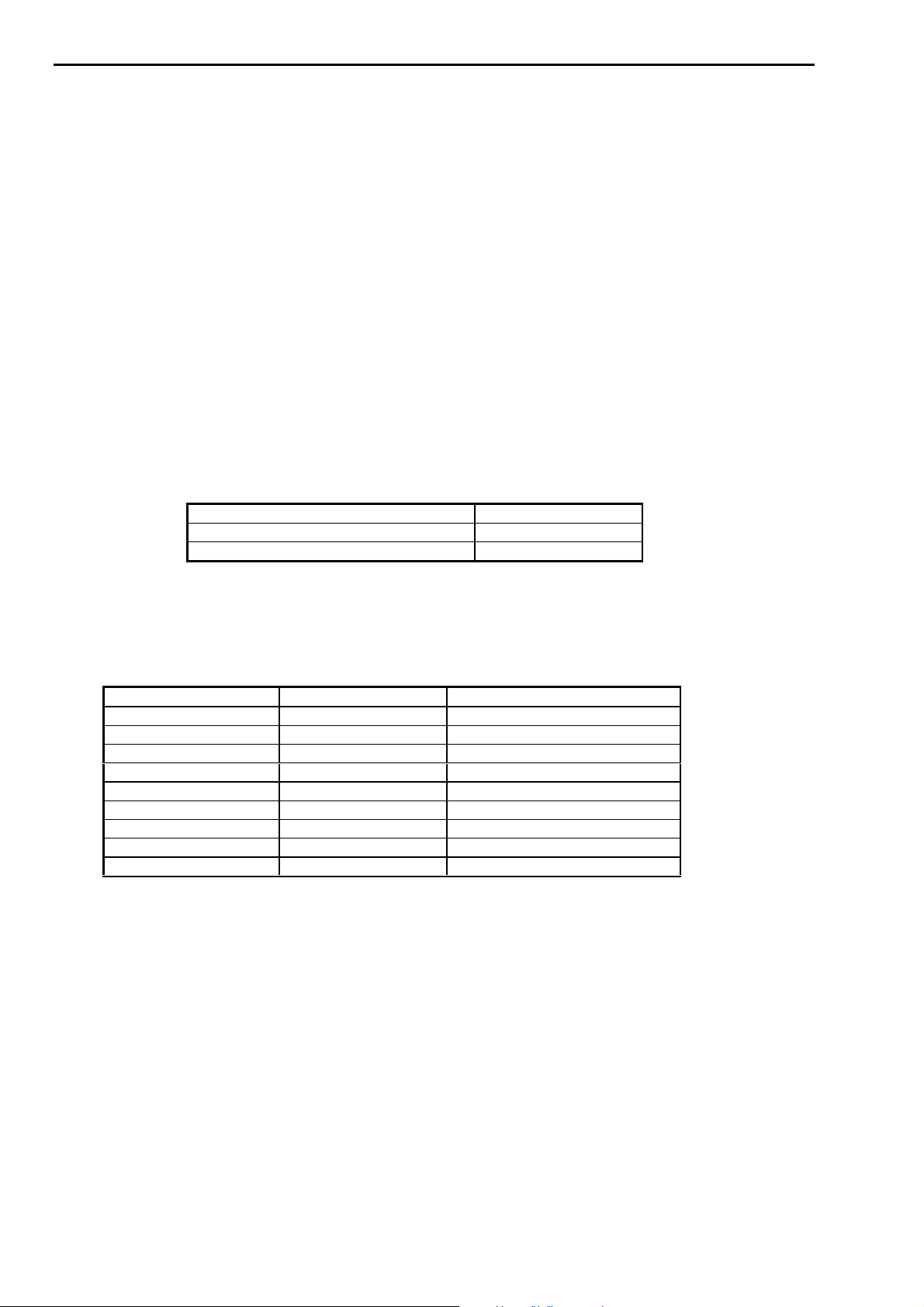

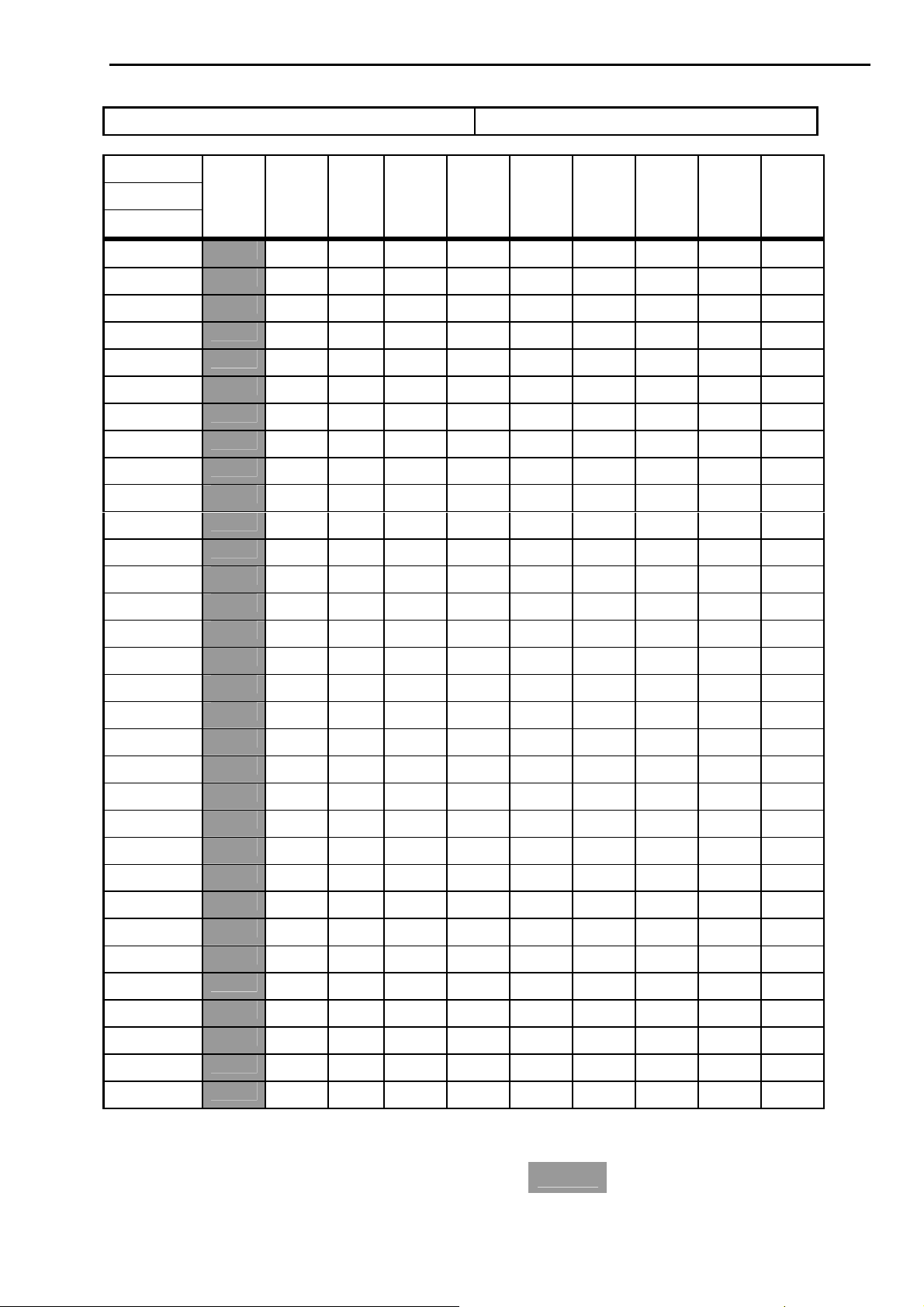

ALARM THRESHOLD COMPARATOR TP7

With the panel in the quiescent mode, measure and take note of the INTERNAL 24V DC POWER

SUPPLY as above.

Measure voltage between system 0V and TP7. Adjust multi-turn potentiometer VR4, and adjust until

the voltage is as per the following table.

Rail Voltage 3.3V Setting Range

20.6 2.833 2.80 to 2.86

21.0 2.888 2.86 to 2.92

21.5 2.956 2.93 to 2.99

22.0 3.025 2.99 to 3.06

22.5 3.094 3.06 to 3.12

23.0 3.163 3.13 to 3.19

23.5 3.231 3.20 to 3.26

24.0 3.300 3.27 to 3.33

24.5 3.369 3.34 to 3.40

25.0 3.438 3.40 to 3.47

25.5 3.506 3.47 to 3.54

26.0 3.575 3.54 to 3.61

26.5 3.644 3.61 to 3.68

27.0 3.713 3.68 to 3.75

27.5 3.781 3.74 to 3.82

27.6 3.795 3.76 to 3.83

28.0 3.850 3.81 to 3.89

FAULT THRESHOLD COMPARATOR TP6

With the panel in the quiescent mode, measure and take note of the INTERNAL 24V DC POWER

SUPPLY as above.

Measure the voltage between system 0V and TP6. Adjust multi-turn potentiometer VR1, and adjust

until the voltage is as per the following table.

Rail Voltage 0.6V Setting Range

20.6 0.600 0.59 to 0.61

21.0 0.612 0.61 to 0.62

21.5 0.626 0.62 to 0.63

22.0 0.641 0.63 to 0.65

22.5 0.655 0.65 to 0.66

23.0 0.670 0.66 to 0.68

23.5 0.684 0.68 to 0.69

24.0 0.699 0.69 to 0.71

24.5 0.714 0.71 to 0.72

25.0 0.728 0.72 to 0.74

25.5 0.743 0.74 to 0.75

26.0 0.757 0.75 to 0.76

26.5 0.772 0.76 to 0.78

27.0 0.786 0.78 to 0.79

27.5 0.801 0.79 to 0.81

27.6 0.804 0.80 to 0.81

28.0 0.816 0.81 to 0.82

P/N 10069 ECN08-0066

Page 20

Page 16 IFS-2600 Installation & Programming Manual

CONFIGURATION JUMPERS

IFS2004 - JP3 DEFAULT

Holding a short across these pins for 5 seconds during start-up causes the panel to reset to standard

factory defaults. The panel will give 4 beeps after reset, to acknowledge default on start-up.

IFS2004 - JP4 PROGRAM DISABLE

When fitted, jumper between these pins to inhibit program changes.

IFS2004 - JP5 CPU RESET

With panel operating, a momentary short across these pins will cause a CPU restart.

IFS2005 – JP2 DOOR HOLDER BYPASS

If zoned door holder outputs are required and is to be done external to the main termination board,

then the main door holder release needs to be disabled. Fitting a link across JP2 on IFS2005 PCB

does this.

Note: Door holder output is only enabled if optional door holder transformer is fitted. SW1 must be

linked on PCB2004 CPU board prior to Version 6 Firmware.

IFS2006 – JP1 EXTERNAL PS MONITORING

When using external power supply, JP1 link on IFS2006E must be fitted to enable external PSU

monitoring.

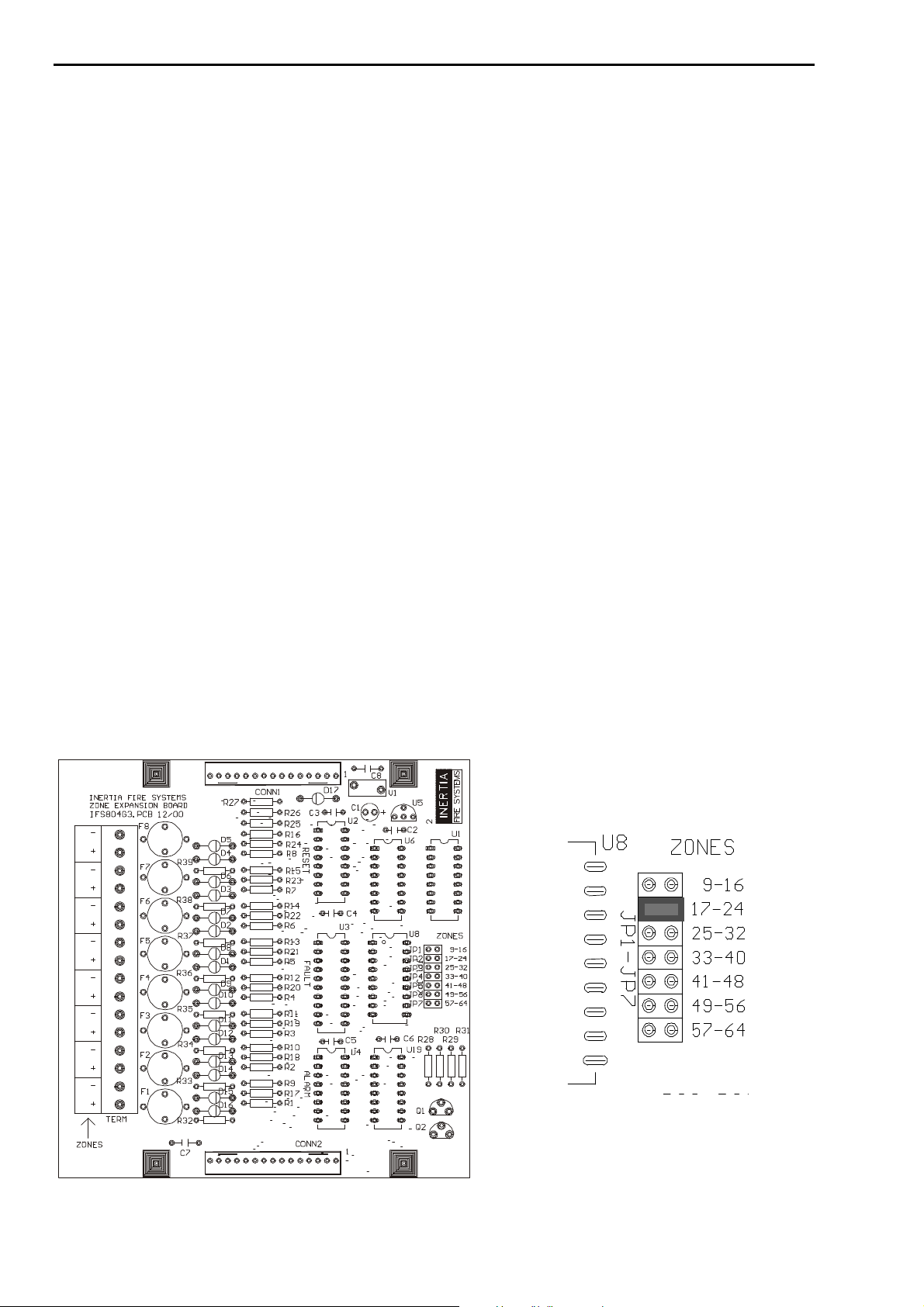

IFS804 - JP1-7 ZONE BOARD ADDRESSING

Jumper JP1 to JP7 on zone expansion board IFS-804 selects the addressing for the zones.

Place jumper in link position for the appropriate 8 zones to which the expansion board applies.

P/N 10069 ECN08-0066

Page 21

IFS-2600 Installation & Programming Manual Page 17

PLACING INTO OPERATION

Suitably qualified technicians must install the panel. The following check procedures are recommended after

every installation and prior to initial power-up.

A thorough visual inspection should be made to every aspect of the fire panel. This includes loose wire, metal

filings, loose circuit boards, loose cabling, damage in transit etc.

All problems must be rectified immediately as they could cause incorrect operation or permanent damage to

the equipment.

EQUIPMENT AS FITTED

QTY Description Code

1 MAIN CONTROL BOARD IFS -2004

1 MAIN TERMINATION BOARD IFS -2005

1 MAIN POWER SUPPLY IFS -2006

8 ZONE EXPANSION BOARD IFS -804

16 ZONE INDICATOR BOARD IFS -816

ADD ON, 8 WAY RELAY BOARD IFS-717

EXTERNAL POWER SUPPLY BOOSTER PS244, PS249, NPS-3,

3A DOOR HOLDER P/SUPPLY TRANSFORMER 2600/DHTX

INITIAL CHECKLIST

System general appearance good

Cabinet colour and condition good

Cabinet keyed 003

All circuit boards firmly fastened

Manual call point fitted & functional

Viewing window clear and firmly secured

Cable entries adequately sealed

240VAC mains cabling is correctly terminated

All earthing secured

Transformer securely mounted

Transformer correctly wired

All ribbon cables firmly secured

All operational zones adequately identified

All fuses correct value and fitted properly

All other modules securely fitted

Manufacturing label affixed

NPS-5, NPS-11

You are now ready to power up the IFS-2600 Fire Indicator Panel.

P/N 10069 ECN08-0066

Page 22

Page 18 IFS-2600 Installation & Programming Manual

POWER UP CHECKLIST

Ensure batteries are disconnected.

Turn mains switch to "on"

The "mains on" led should light.

Allow 15 seconds for the panel to perform its start up tests.

Connect batteries

FUNCTIONAL TESTING

Primary ac supply voltage: 200 or 220 or 240vac +10% as required

Charger output voltage without batteries: 27.3v dc

Keypad functional

Perform auto test

Led’s all functional

LCD backlighting functional

Liquid crystal display functional

Zone fault detection

Zone alarm detection

Internal sounder operating

MCP loop wired to zone number ______ (if applicable)

Test auxiliary power output

Test bell output

Test warning system output

Test ACF output

Test door holder output (optional)

Test bell output supervision

Test warning system output supervision

Test ACF output supervision

Test brigade alarm relay #1

Test brigade alarm relay #2

Test standby relay (normally energised)

Test fault relay (normally energised)

Test mains fail relay

Test isolate relay

Test general alarm relays (2)

Test relay boards (if fitted)

Test open collector output boards (if fitted)

Press "battery test" once

If batteries are flat, allow 24hrs to charge and then re-test.

P/N 10069 ECN08-0066

Page 23

IFS-2600 Installation & Programming Manual Page 19

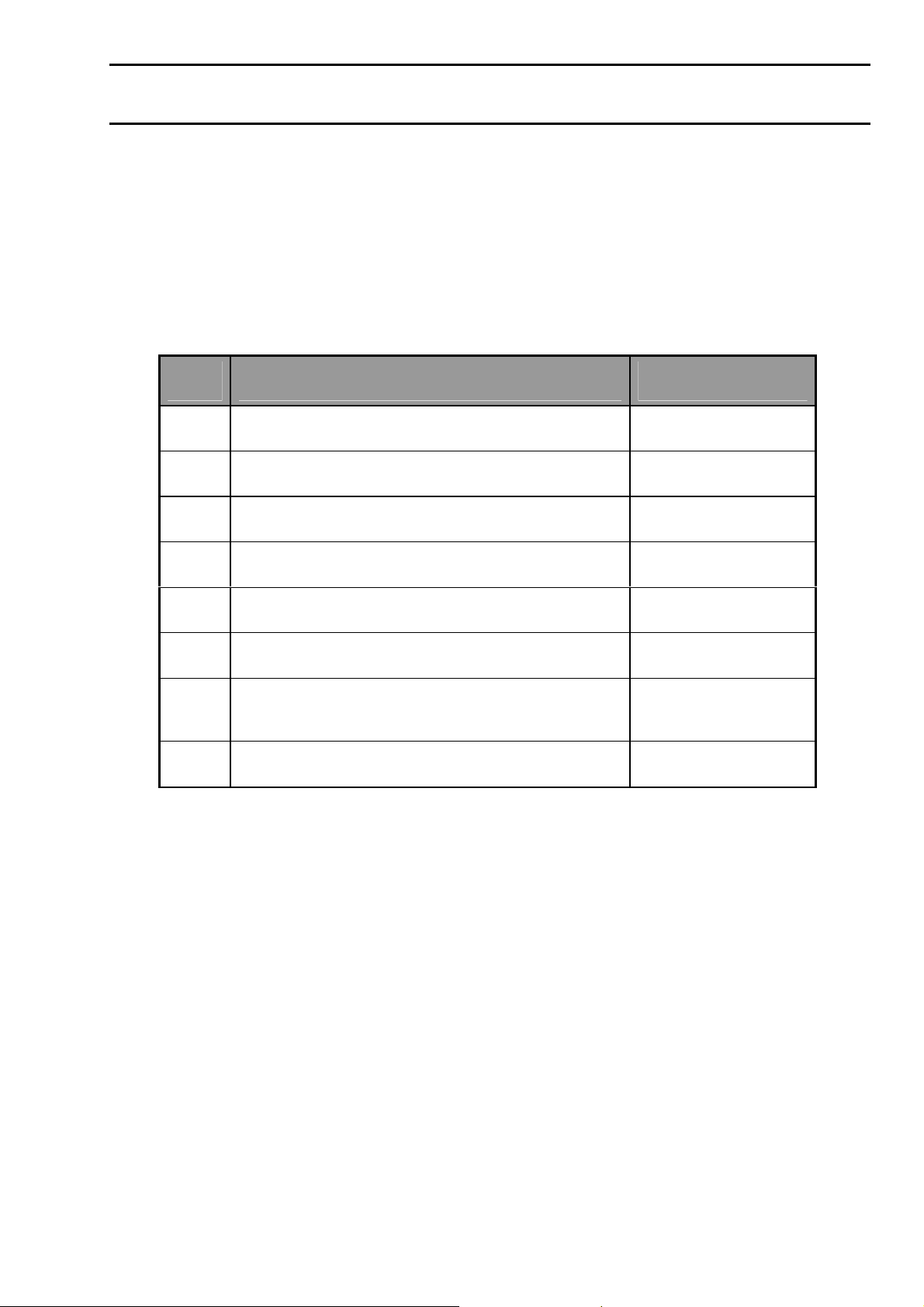

FAULT RECORD

FAULT CORRECTION DATE

TESTS SATISFACTORILY COMPLETED.

TESTED BY _______________________________

SIGNATURE _______________________________

DATE OF TEST ____________________________

If all faults have been rectified and all tests are completed satisfactorily, the 2600 fire indicator panel is now

ready for operation.

P/N 10069 ECN08-0066

Page 24

Page 20 IFS-2600 Installation & Programming Manual

INSTRUCTIONS TO OPERATORS

INDICATORS

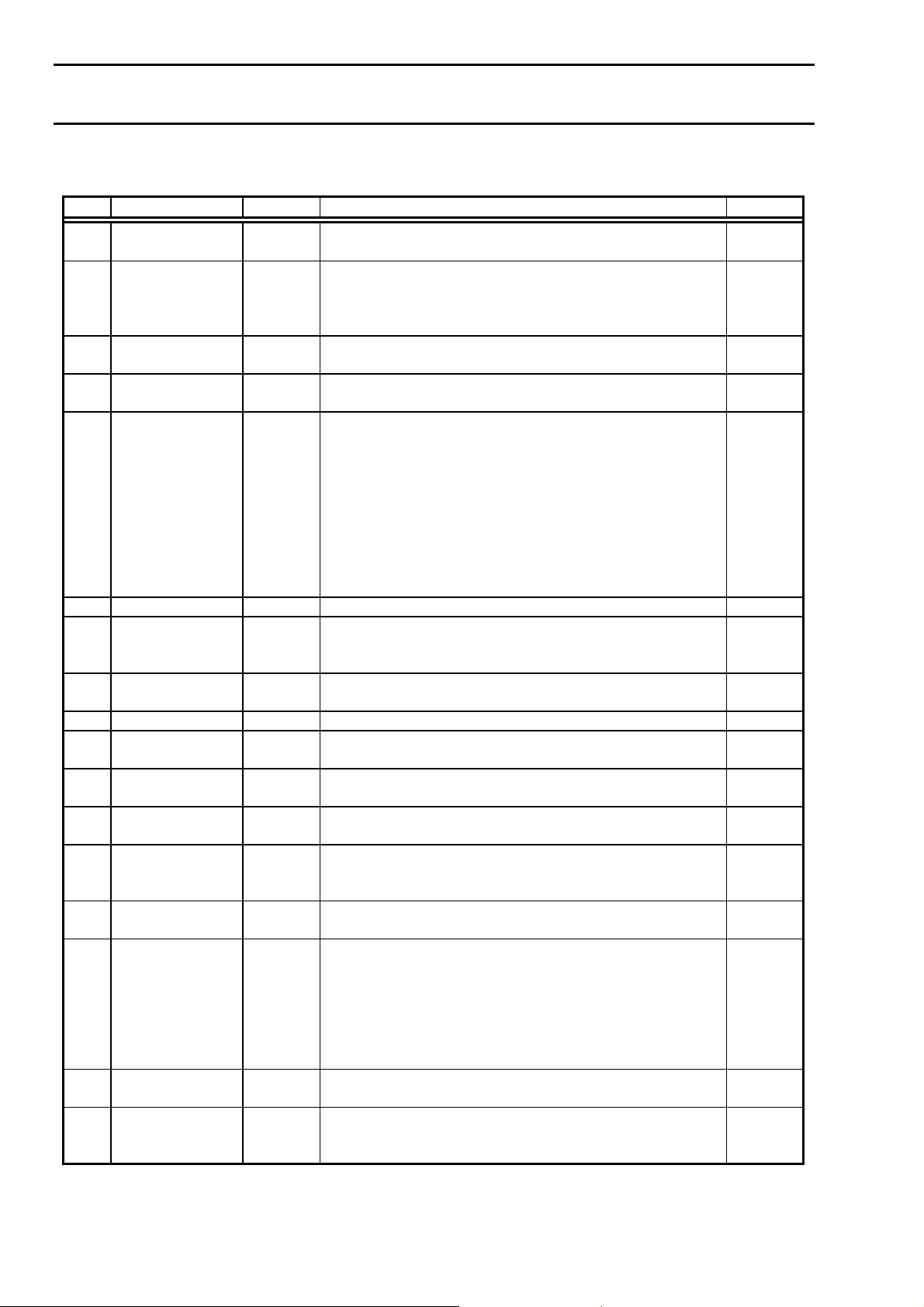

Qty Descriptor Colour Function Buzzer

1 MAINS ON Green Illuminates when there is 200/220/240 VAC supply to

the panel.

1 BATTERY

FAULT

1 PSU FAULT Yellow Illuminates if the power supply is outside the

1 CHARGER

LOW

1 COMMON

FAULT

1 ACF ACT Red Illuminates if the ACF output has been activated.

1 ACF FLT Yellow Illuminates if the ancillary circuit is open or short

1 ACF ISO Yellow Illuminates if the ancillary output has been manually

1 Bell ACT Red Illuminates when the bell output has been energised.

1 Bell FLT Yellow Illuminates if the bell circuit is open or short circuit.

1 Bell ISO Yellow Illuminates if the bell output has been manually

1 Warning

System ACT

1 Warning

System FLT

1 Warning

System ISO

8 ALARM LEDS Red This LED will flash if it's corresponding zone goes

8 FAULT LEDS Yellow This LED illuminates if it's corresponding zone goes

8 ISOLATE LEDS Yellow This LED illuminates if its corresponding zone is

Yellow Illuminates if the battery fails a battery test.

Illuminates if batteries are disconnected >30

seconds.

Illuminates if batteries are short circuit >30 seconds.

manufacturers range.

Yellow Illuminates if the battery charger is outside the

recommended float charge voltage.

Yellow Illuminates if;

Any un-isolated zone goes into fault.

ACF output is open or short circuit

Bell output is open or short circuit

Warning System output is open or short circuit

Battery Fault

Charger Fault

Power Supply Fault

MAF Isolate Input is Open Circuit

Configuration Fault

circuit. The LED will extinguish when the load is

restored.

isolated.

The LED will extinguish when the load is restored.

isolated.

Red Illuminates if the Warning System output has been

energised.

Yellow Illuminates if the Warning System circuit is open or

short circuit. The LED will extinguish if the load is

restored.

Yellow Illuminates if the Warning System has been manually

isolated.

into alarm. It will remain flashing until it is

Acknowledged at which time it will go steady and

remain on until the alarm is reset. If the zone is

programmed as a time delay type, a steady LED

indicates the “pre-alarm” condition. If the zone is

isolated and in alarm it will also be steady.

into fault. It will remain on until the fault is removed.

isolated. It will remain on until the zone is deisolated.

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

P/N 10069 ECN08-0066

Page 25

IFS-2600 Installation & Programming Manual Page 21

SUGGESTED ALARM PROCEDURE

The following is a suggested alarm procedure for use by building fire officers or duty wardens. The fire

indicator panel is designed for use by qualified fire fighters and it is strongly recommended that the fire panel

not be operated in an emergency situation by anyone other than suitably qualified fire fighters.

Do not open fire indicator panel door or press any buttons until fire officers arrives.

Determine location of the fire by inspecting the label beside any lit red zone alarm LEDs on the panel.

Visually inspect area at a safe distance for actual fire or false alarm.

Notify fire-monitoring station of either result.

Perform evacuation and extinguishing operations as required.

IF a FIRE, direct fire fighters to the fire indicator panel and cause of alarm as they arrive.

IF a FALSE ALARM, advise maintenance technicians to determine and rectify cause.

Record all events in logbook.

NOTE A suitably qualified fire officer should perform the above procedure. These are suggested procedures

only, and if specific fire procedures are available or issued, they MUST prevail.

OPERATOR INSTRUCTIONS

The functions of the IFS-2600 are divided into three (3) categories

Fire Fighter Functions

Global Functions

Zone Functions

FIREFIGHTER FUNCTIONS

Fire Fighter Functions are those specifically used by the Fire Brigade on attendance. Following is an

explanation of their operation and the keystrokes required to perform the function required. These keys are

located at the top of the keypad marked FIREFIGHTER’S FACILITY and bordered in red.

ACKNOWLEDGE

The purpose of the internal buzzer is to alert persons of a new event on the panel, and a new potential fire

danger. Once the fire's location has been determined, the fire-fighter may wish to silence the internal buzzer

without having to totally reset the alarm.

When the buzzer is operating, pressing the "ACK" key once will silence it, however the External Alarm Bell will

continue to sound. If a subsequent alarm arises, the buzzer will be reactivated and a second ACK operation

will be required to silence it.

When an alarm is acknowledged, the Alarm LED will stop flashing and light continuously.

ACK

RESET

The reset function momentarily disconnects power, and resets all alarm parameters for the zone(s) that have

been acknowledged. This returns the zone back to its "normal" state. The reset key only operates on zones

with acknowledged alarms.

ISOLATE

The isolate function prevents the transmission of alarms or faults from the zones to the master alarm facility.

The isolate key only operates on zones with acknowledged alarms.

P/N 10069 ECN08-0066

RESET

ISOLATE

Page 26

Page 22 IFS-2600 Installation & Programming Manual

EXT BELL

BELL ISOLATE

Depressing the "EXT BELL ISOLATE" key will isolate the bells. The "Ext Bells Isolate" LED will illuminate and

the bells will not sound until the bells are de-isolated. Pressing "EXT BELL ISOLATE" a second time will deisolate the bell.

WARN SYS ISOLATE

ISOL

WARN SYS

ISOL

Depressing the "WARN SYS ISOLATE" key will isolate the warning system. The "Warn Sys Isolate" LED will

illuminate and the warning system will not operate in the event of an alarm. Pressing "WARN SYS ISOLATE"

a second time will de-isolate the warning system.

GLOBAL FUNCTIONS

Global functions are those relating to the overall system and are not specific to particular zones. Following is

an explanation of their operation and the keystrokes required to perform the function.

BATTERY TEST BATT

TEST

This function tests the performance of the batteries fitted to the system. Pressing this button will initiate a

battery test as specified in AS4428. The test will temporarily disconnect the batteries from the panel and apply

load on the batteries for 15 seconds.

The result of the test will be displayed on the LED's. If the "Battery Fault" LED is on, only a successful battery

test will turn the LED off. The pressing of any key during the test period will abort the battery test and return

the system back to normal mode.

Battery test function is disabled when the panel is in alarm condition.

AUTO

AUTO TEST MODE

This function will perform a fixed automatic test procedure to the panel. This mode cannot be selected if any

zone(s) is in alarm. Auto test will perform the following test functions;

Turn on ALL LEDs for 0.5 seconds

Test LCD backlighting

Test panel memory (E2ROM & RAM)

Test LCD

Isolate all alarm zones

Fault test all alarm zones

Alarm test all alarm zones

Test buzzer

TEST

The pressing of any key during "AUTO TEST" will abort the tests and return the system back to normal mode

once the current test is complete.

Note During "AUTO TEST", all zones are treated as zone type #1 (standard latching type with 2 second

delay). Once AUTO TEST has finished, all zones will be reset and returned back to their previously

configured types.

P/N 10069 ECN08-0066

Page 27

IFS-2600 Installation & Programming Manual Page 23

WALK TEST MODE

WALK

TEST

This function will place the panel into "walk test" mode. Walk test mode is used for the on-site testing of

detector zones. This mode cannot be selected if any zone(s) is in alarm. Entry to walk test mode will be

acknowledged by three beeps and the LCD will display "WALK TEST MODE".

For the duration of walk test mode, all zones are changed to output configuration #2 (indicate and ring bells

only) and all zones are set to type #1 (standard latching, 2 second).

If the bells are not required to ring during walk test, simply press the "EXT BELL ISOLATE" key once. The EXT

BELL ISOLATE LED will illuminate to verify that the bells have been isolated.

Any alarm signal from detectors etc. will be received by the panel on its appropriate zone. The panel will beep

to acknowledge receipt of the alarm and indicate the alarm by illuminating the appropriate alarm LED for 4

seconds (the bells will also ring for a 3 second period unless previously isolated).

The zone and detector will then be automatically reset for 15 seconds

If the optional printer is connected, the alarm will be printed out as it is received. This can eliminate the need

for a second serviceman to record zone numbers during walk test and the printout can be retained for

verification at a later date.

Pressing any key will terminate the walk test mode and return the panel back to normal operation, restoring all

zone types and output configurations also ensuring that bell and ancillary outputs are de-isolated. The bells will

give three pulses of 1 second each to warn any testers still in the building that walk test mode has been

terminated.

Failure to receive any alarms or keystrokes within a 15 minutes period will result in the panel automatically

exiting walk test mode and returning back to normal as follows:

Bell outputs to be de-isolated.

Ancillary outputs to be de-isolated.

Bell will sound 3 times, each of 1-second duration.

Exit from walk test mode.

Zone types and output configurations restored

ACF ISOLATE

ACF

ISOL

Depressing the "ACF ISOLATE" key will isolate the ACF (Ancillary output) and the Door Holder Output. The

ACF isolated LED will illuminate and the output will not operate until de-isolated. Pressing "ACF ISOLATE" for

a second time will de-isolate the output.

If the ancillary output has already been tripped and is programmed as latching, isolating the ACF will not affect

the existing ancillary output. If the ACF is isolated prior to the alarm, it will prevent the ancillary output from

tripping. This does not apply to the Door Holder output.

ACF RESET

ACF

RESET

Resetting of the ancillary output (ACF) is only required if the ancillary output was programmed as latching.

The ancillary alarm will remain latched until manually reset. Pressing the "ACF RESET" button will extinguish

the 'ACF Activated' LED and de-energise the ancillary output. Pressing "ACF RESET" when the ACF is not

tripped will have no effect.

P/N 10069 ECN08-0066

Page 28

Page 24 IFS-2600 Installation & Programming Manual

ZONE FUNCTIONS

Zone functions are those relating specifically to the detection zones. Following is an explanation of their

operation and the keystrokes required to perform the function required.

ALARM TEST

The alarm test function momentarily disconnects the detector lines of the zone(s) under test and simulates a

detector going into alarm, therefore testing the zone(s) alarm detection capability.

A resistive load equal to worst case alarm condition is placed on the zone for a period of 120 seconds and

then removed, if the zone being tested is not a latching type, the alarm will reset automatically once the load is

removed. Acknowledging and resetting the alarm will terminate an alarm test.

Once the zone has alarmed, all outputs are initiated (as programmed) similar to a real alarm.

The zone may be isolated prior to an alarm test if desired; this will prevent any outputs from operating.

‘#’ in the above key sequence is the zone number.

If only one zone is to be tested, use the appropriate number. Alternatively the "ALL" button can be used to

simultaneously test all zones.

To perform an alarm test:

1. Press the "ALARM TEST" button once; the buzzer will give 2 short beeps to indicate that alarm test mode

has been entered.

2. The LCD display will read "ALARM TEST MODE, ENTER ZONE No.".

ALARM TEST # ENT

3. Now enter the zone number ("#") 1-64 or “all”

4. Press "ENT"

If a correct entry is made, alarm testing on the zone commences immediately. However remember there is a 2

second transient delay on all zones. It will therefore take approximately 2 seconds before the zone registers an

alarm (this could be longer, depending on zone type).

A long beep will signify an incorrect entry and will revert back to normal operating mode. The "ALARM TEST"

button will need to be depressed again to re-enter alarm test mode.

P/N 10069 ECN08-0066

Page 29

IFS-2600 Installation & Programming Manual Page 25

FAULT TEST

The fault test function momentarily disconnects the detection zone(s) under test and simulates the worst-case

condition for fault.

A resistor load equal to worst case fault is placed on the zone continuously for 5 seconds then the zone is

returned back to its normal condition.

If several zones are being tested consecutively and are being entered at a rate faster than the 5-second fault

timer, the fault timeout will occur 5 seconds after the last entry was completed.

Once the zone has registered a fault, all outputs relating to that zone are initiated similar to a real fault.

The zone may be isolated prior to a fault test if desired. This will prevent any outputs from operating.

‘#’ in the above key sequence is the zone number.

If only one zone is to be tested, use the appropriate zone number. Alternatively the "ALL" button can be used

to simultaneously test all zones.

To perform a fault test on a particular zone or on all zones:

1. Press the "FAULT TEST" button once.

The buzzer will give 2 short beeps to indicate that fault test mode has been entered.

FAULT TEST # ENTER

2. The LCD display will read "FAULT TEST MODE, ENTER ZONE No.".

3. Enter the zone number ("#") 1-64 or “all”.

4. Press "ENTER".

A long beep will signify an incorrect entry and the panel will revert back to normal operating mode. The

"FAULT TEST" button will need to be pressed again to re-enter fault test mode.

If a correct entry is made, fault testing on the zone commences and the fault LED will illuminate.

P/N 10069 ECN08-0066

Page 30

Page 26 IFS-2600 Installation & Programming Manual

ISOLATE

The isolate function prevents the transmission of alarms or faults from the zones, to the master alarm facility.

‘#’ in the above key sequence is the zone number.

If only one zone is to be isolated, use the appropriate zone number. Alternatively the "ALL" button can be used

to simultaneously isolate all zones.

To isolate a particular zone or all zones:

1. Press the "ISOLATE" button.

The buzzer will give 2 short beeps to indicate that isolate mode has been entered.

2. The LCD display will read "ALARM ISOL. MODE, ENTER ZONE No.".

3. Enter the zone number ("#")1-64 or “all”.

4. Press "ENTER".

A long beep will signify an incorrect entry and will revert back to normal operating mode. The "ISOLATE"

button will need to be depressed again to re-enter isolate mode.

If a correct entry is made, the zone is immediately isolated. If the zone is already in alarm, all of its alarm

outputs are isolated and indicators remain visible.

ISOLATE # ENTER

If the "ALL" function is performed, all zones will be isolated, regardless of their previous state. Performing the

"ALL" function for a second time will de-isolate all zones.

RESET

The reset function momentarily disconnects power, and resets all alarm parameters for the zone(s) being

reset. This returns the zone back to its "normal" state.

‘#’ in the above key sequence is the zone number.

If only one zone is to be reset, type in the zone number. Alternatively the "ALL" button can be used to

simultaneously reset all zones.

To perform a reset on a particular zone or on all zones:

1. Press the "RESET" button.

The buzzer will give 2 short beeps to indicate that reset mode has been entered.

2. The LCD display will read "ALARM RESET MODE, ENTER ZONE NO".

3. Enter the zone number ("#") 1-64 or “all”.

4. Press "ENTER".

RESET # ENTER

A long beep will signify an incorrect entry and will revert back to normal operating mode. The "RESET" button

will need to be depressed again to re-enter reset mode.

If a correct entry is made, resetting of the zone begins immediately. Any alarm indication will be removed

immediately; also resetting the zone(s) programmed outputs.

P/N 10069 ECN08-0066

Page 31

IFS-2600 Installation & Programming Manual Page 27

PROGRAMMING

GLOBAL OPTIONS

ANCILLARY TRIP

1 LATCHING NORMALLY DE-ENERGISED

2 NON-LATCHING NORMALLYDE-ENERGISED

3 LATCHING NORMALLY ENERGISED

4 NON-LATCHING NORMALLY ENERGISED

ALARM VERIFICATION

1 DISABLED

2 2 MINUTES

3 3 MINUTES

4 4 MINUTES

5 5 MINUTES

ZONE OPTIONS

1 Standard Latching 2 seconds

2 Standard Latching 2 seconds with AVF

3 Non Latching 2 seconds

4 Non Latching 20 seconds

5 Time Delay 10 seconds

6 Time Delay 20 seconds

7 Time Delay 30 seconds

8 Time Delay 40 seconds

9 Time Delay 50 seconds

10 Time Delay 60 seconds

TIME

(DD) / (MM) / (YY)

(HH) : (MM)

DESCRIPTION INPUT DELAY

Type Output Description

1 Indicate Only

2 Indicate, Bell

3 Indicate, Bell, General Alarm

4 Indicate, Bell, General Alarm, Ancillary

5 Indicate, Bell, General Alarm, Ancillary, Brigade Relay #1

6 Indicate, Bell, General Alarm, Ancillary Brigade Relay #2

7 Indicate, Bell, General Alarm, Ancillary, Brigade Relay #1, & Brigade Relay #2

P/N 10069 ECN08-0066

Page 32

Page 28 IFS-2600 Installation & Programming Manual

OUTPUT RELAY OPTIONS

Optional Relays can be programmed to simulate: -

Isolate Relay

ACF Output

Brigade Relay #1

Brigade Relay #2

Fault Relay

Mains Fail Relay

General Alarm Relay

Bell Output

Door Holder Relay

Door Switch

Reset

Or Can Be Used To:

"MAP AND" Up to 5 Zones in Alarm

"MAP OR" Up to 5 Zones in Alarm

“MAP FAULT” Up to 5 Zones in Fault

“MAP ISOLATE” Up to 5 Zones in Isolate

“MAP ISO/FAULT” Up to 5 Zones in Isolate/Fault

DEFAULT SETTINGS

ACF OUTPUT NON-LATCHING, NORMALLY DE-ENERGISED

ALARM VERIFICATION (AVF) 3 MINUTES

TIME 1/1/11 11:11

ZONE TYPES STANDARD LATCH 2S

ZONE OUTPUT CONFIG I-B-G-A-BR1 & BR2

RELAY MAPPING MAP-OR-, MAPPING = 1 TO 1

The 2600 PANEL is self-configuring on power-up therefore it is not necessary to program the number

of relay boards.

Zone expansion boards fitted must have the correct jumper selected.

IE: RELAY 1 = ZONE 1, RELAY 2 = ZONE 2.............

P/N 10069 ECN08-0066

Page 33

IFS-2600 Installation & Programming Manual Page 29

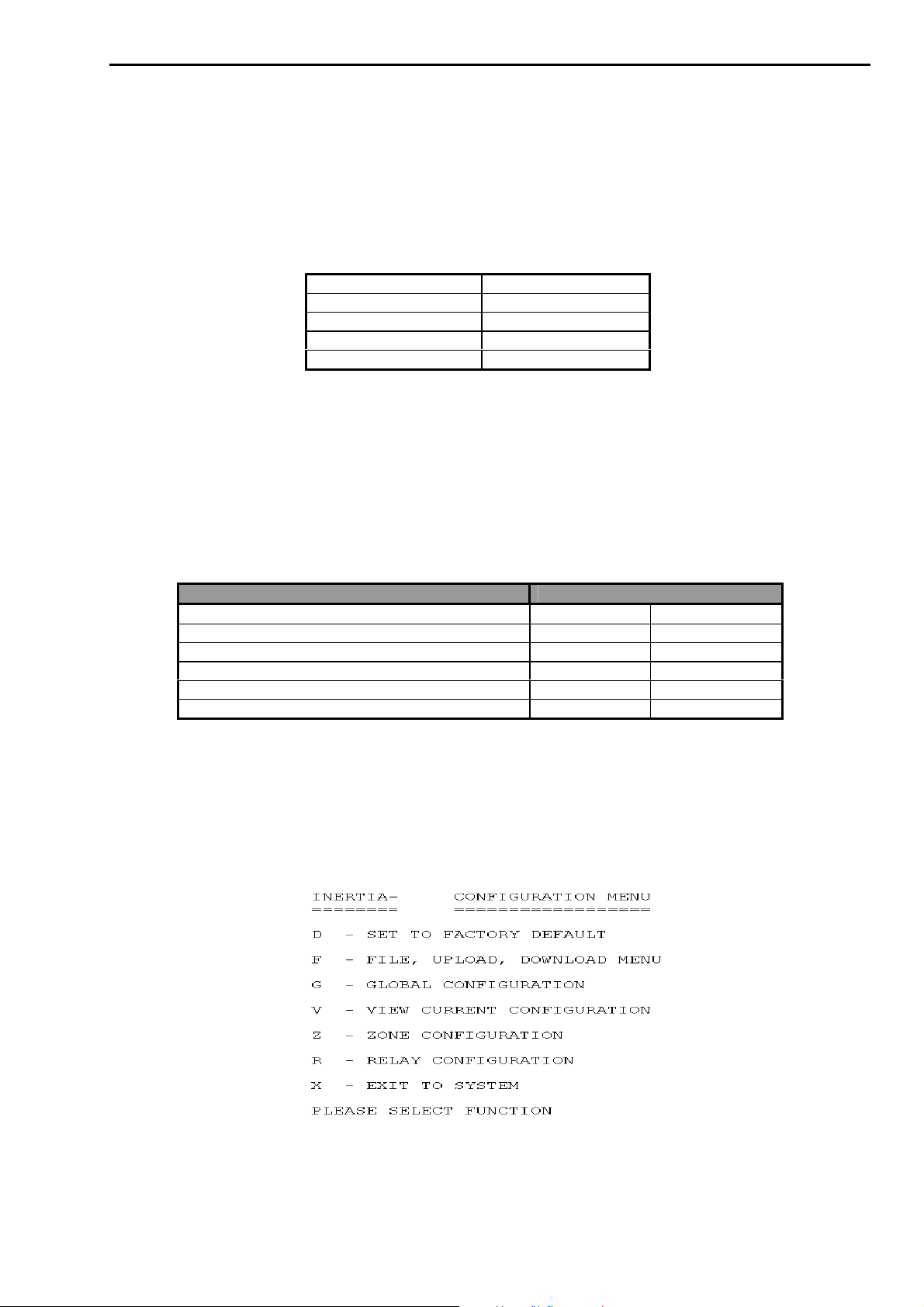

PROGRAM MODE

Press the following buttons in order shown to enter programming mode.

PREVIOUS

→

NEXT

→

SELECT

→

EXIT

→

ENTER

PROGRAMMING MODE

The liquid crystal display will display all messages and prompts required to program the 2600.