Page 1

Copyright © 2004 Honeywell Control Systems Ltd.

All Rights Reserved EN2B-0004UK07 R0304

ICON-343C / ICON-363C

REFRIGERATION CONTROLLER

USER GUIDE

Page 2

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 1

Trademark Information Genus® is a registered trademark of Honeywell Control Systems Ltd.

Page 3

ICON 343C / 363C USE R GUIDE

2 EN2B-0004UK07 R0304

1. CONTENTS

1. CONTENTS.....................................................................................................................................................................2

2. SAFETY INSTRUCTIONS............................................................................................................................................3

3. GENERAL DESCRIPTI ON...........................................................................................................................................4

4. OPERATOR MODES ....................................................................................................................................................4

5. TECHNICAL SPECIFICATIONS.................................................................................................................................5

6. INSTALLATION .............................................................................................................................................................6

6.1. First Things .............................................................................................................................................................6

6.2. Probes......................................................................................................................................................................6

6.3. Electrical Wiring......................................................................................................................................................6

6.4. Fitting.......................................................................................................................................................................8

6.5. Probe Self Detect...................................................................................................................................................9

7. ICON FRONT PANEL .................................................................................................................................................10

7.1. Functions of the Front Panel..............................................................................................................................10

7.2. Controller front panel LEDs................................................................................................................................10

7.3. Controller front panel keys..................................................................................................................................11

7.4. Functions Of The Keys........................................................................................................................................11

7.5. LED Functions......................................................................................................................................................14

8. CONFIG URATION PARAMETERS..........................................................................................................................15

8.1. Parameter Configuration of the Icon 343C & 363C Controller.....................................................................16

9. REAL TIME CLOCK AND DEFROST SETUP .......................................................................................................23

9.1. Setting and Displaying the Real Time Clock...................................................................................................23

9.2. Setting the Daily Defrost Cycles on the Real Time Clock.............................................................................23

10. CONNECTING TO HONEYWELL GENUS NETWOR K.....................................................................................24

10.1. Icon Controller Identification on Genus® Network........................................................................................24

10.2. Network Logging-On Procedure ......................................................................................................................24

10.3. Network Logging-Off Procedure ......................................................................................................................24

11. PROGRAMMABLE HOTKEY.................................................................................................................................25

11.1. HotKey Uploading Procedure..........................................................................................................................25

11.2. HotKey Downloading Procedure.....................................................................................................................25

12. TROUBLESHOOTING..............................................................................................................................................26

12.1. Alarm Messages ................................................................................................................................................26

12.2. Warning Messages............................................................................................................................................27

13. MAIN TENANCE.........................................................................................................................................................27

14. ABOUT THE OPERATING INSTRUCTIONS .......................................................................................................27

15. NOTES.........................................................................................................................................................................28

Page 4

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 3

2. SAFETY INSTRUCTIONS

A. Keep this instruction booklet where it can always be easily consulted by

the operator or by maintenance personnel.

B. Before making an intervention or connection of any kind, make sure that

the mains are disconnected both from the instrument and from any

device connected to it.

C. Warning: hot components may be inside the plastic housing of the

controller.

D. No user-serviceable parts are inside the plastic housing of the controller.

E. The controller and any device connected to it must be installed in

compliance with the safety regulations in force. If these regulations are

not complied with during installation, and if our product is not installed in

compliance with the indications given in this instruction booklet, then this

may result in the safety of the controller being comprimised. In

particular, the ambient operating conditions for the controller given in our

technical data must be complied with. Absolutely avoid: water

condensation or excessive humidity, exposure to steam, corrosive or

toxic gases, contact with any type of liquid, and exposure to shocks or

extreme vibrations. Not complying with the above indications could

cause malfunctions and entail unpredictable consequences.

F. This controller is guaranteed by Honeywell to have a specific immunity

level, in compliance with CE regulations, against irradiated and

conducted electromagnetic disturbances. By irradiated electromagnetic

disturbances we recommend to screen the controller with a metal screen

connected to ground. To eliminate, or at least reduce conducted

disturbances, which not only could propagate through the mains but also

through the probes or the connected loads, carry out the electrical wiring

according to the indications given in this instruction booklet. If

necessary, use filters with suitable characteristics for specific

applications and for the detected type of disturbance.

G. If the type of probe to be used will directly touch foodstuffs, make sure

that it is in compliance with the local sanitary and health regulations.

H. The controller has no type of protection for the connected loads, so

these must be protected against short circuits, over-current or overvoltage, excessive temperature, etc., by suitable protective means (such

as fuses, suitable thermo-magnetic circuit breakers, thermal protections,

etc.). At any rate, the electrical power lines that supply both the

controller and any other device connected to it, either directly or through

a transformer, must be manufactured in compliance with the regulations

in force.

I. When the controller is used in appliances where any malfunction of said

controller could cause a form of risk to persons, animals or objects, it is

ABSOLUTELY MANDATORY to provide a suitable protective/safety

device, in addition to the controller, which independently starts to

operate in case of a failure.

J. The controller cannot be used as critical component in life-support

devices or systems without a written approval expressly issued by the

legal representative of Honeywell.

CAUTION

Disconnect the power supply before you begin installing the Icon controller.

Do not reconnect the power supply until you have completed installation.

Page 5

ICON 343C / 363C USE R GUIDE

4 EN2B-0004UK07 R0304

3. GENERAL DESCRIPTION

The Honeywell Icon 300 Series is a microprocessor controlled thermostat,

powered by AC 230 V, 50/60 Hz, and operates with up to three NTC or PT1000

probes (air-on, air-off and evaporator probes), and has up to six relay outputs

(alarm, auxiliary, light, compressor, defrost and fan), and two digital inputs

(doorswitch and auxiliary). Icon 300 series has a RS485 serial line connection

to enable the controller to interface to Honeywell Genus® network.

The Icon 300 series comes in two variants:

Icon 343 (Part Number: ICON-343C)

Icon 363 (Part Number: ICON-363C)

The Icon 300 series can be applied both in cooling and refrigeration

applications and has the following features:

• satisfy the most diverse plant requirements for cooling/refrigeration with its

42 configurable parameters, that can be set very easily and quickly through

the instrument keyboard.

• display the conditioned ambient temperature as well as the alarm messages

that refer to faulty cooling/refrigeration plant functions.

• control the conditioned ambient temperature through weighted average of

the air-on / air-off probes in order to maintain it under a set limit value (main

set point + differential), by activating the compressor to lower said

temperature every time it exceeds the main set point + differential value.

• control the defrost cycles of the cooling/refrigeration plant manually, through

the network or through the programmed mode; in the latter mode it is

possible to set the starting times of up to six daily defrost cycles.

• control the defrost cycle time as well as the successive startup of the

cooling/refrigeration plant fan through the evaporator probe.

• select the Low Humidity mode (with a specific key) which keeps the fan of

the cooling/refrigeration plant running.

4. OPERATOR MODES

The ICON 343C / 363C controller has three operating modes:

A. Stand-by: The controller is not active and OFF is displayed.

B. Programming: In this mode it is possible to set the configurable

parameter values of the thermostat.

C. Normal: In this mode the conditioned ambient temperature is displayed

and the digital outputs, the defrost cycles, and any case / coldroom alarms

are monitored.

Page 6

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 5

5. TECHNICAL SPECIFICATIONS

Icon 343C / 363C

Power Supply AC 230Vac 50/60 Hz

Transformer on board AC 230 – 12 V, 50/60 Hz

Door switch input

operates according to customer

requirements. (not on ICON-343C).

Networking Connection RS485 (Honeywell Genus®)

Air-On, air-off and evaporator

probe range

- 55 … + 85 °C / - 67 … + 185 °F

Compressor output SPST relay, AC 240 V 15A (resist.)

Defrost output SPST relay, AC 250 V 8A (resist.)

Fan output SPST relay, AC 250 V 6A (resist.)

Alarm output:

SPDT relay, AC 250 V 4A (resist.) (not

on ICON-343)

ON/OFF (Auxiliary) output

SPST relay, AC 250 V 4A (resist.) (not

on ICON-343)

Light output SPST relay, AC 250 V 6A (resist.)

Internal alarm buzzer

Back-up battery for internal clock 3 V, lithium (non-replaceable)

Display:

four-digit, 14.2 mm high, green LEDs and

four decimal points

Front panel

Keyboard with 8 keys, 1 red signaling

LEDs and 4 green signaling LEDs

Resolution 0.1 or 1 unit

Network Honeywell Genus®

Electrical connections of the inputs

(probes, digital inputs)

through 3-mm screw terminals for 14

AWG, 2.5 mm2 wires

Electrical connections of the

outputs (relays)

Fast-on shrouded spades

Controller dimensions (height x

width x depth)

46mm x 188mm x 68mm

Installation panel mount

Panel cutout dimension 149.5 x 31.5 mm

Housing in self -extinguishing PC/ABS plastic.

Front Panel IP Class IP52

Operating ambient temperature 0…+ 50 °C / 32… 122 °F

Operating ambient R.H. 30…85 % non-condensing

Storage temperature - 20…+ 80 °C / - 4…176 °F

Table 1. Technical Specifications

Honeywell reserves all rights to modify the technical features of its instruments as

well as to discontinue the production of any model without previous notification.

Page 7

ICON 343C / 363C USE R GUIDE

6 EN2B-0004UK07 R0304

6. INSTALLATION

6.1. First Things

The controller must be installed in a place where it is protected from extreme

vibration, impact, water, corrosive gases, steam, etc., and where temperature

and humidity do not exceed the values given in the technical data sheet.

6.2. Probes

We recommend the use of probes such as Honeywell 2k ohm NTC thermistor

temperature probes (Part Number: TP002K).

Both the air-on and air-off probe is to be installed inside the coldroom or

refrigerated display case where it is protected from direct air flow (i.e., far from

fans or doors) so that the average ambient temperature can be measured.

The evaporator probe must be installed in the coldest area between the

evaporator fins, i.e., where the greatest amount of ice will form and far from the

resistances or the area that warms up first during defrosting, in order to avoid

anticipating termination of said defrost cycle.

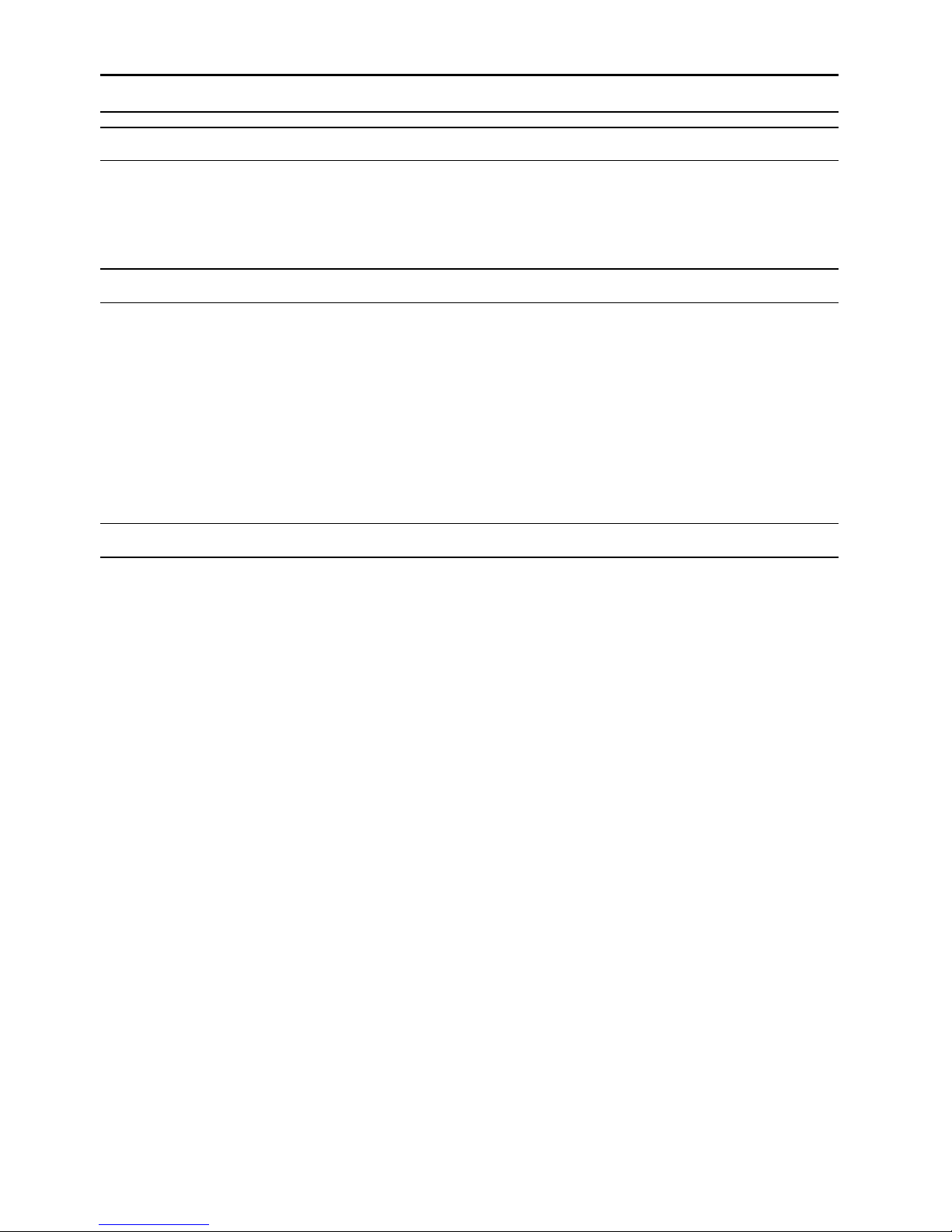

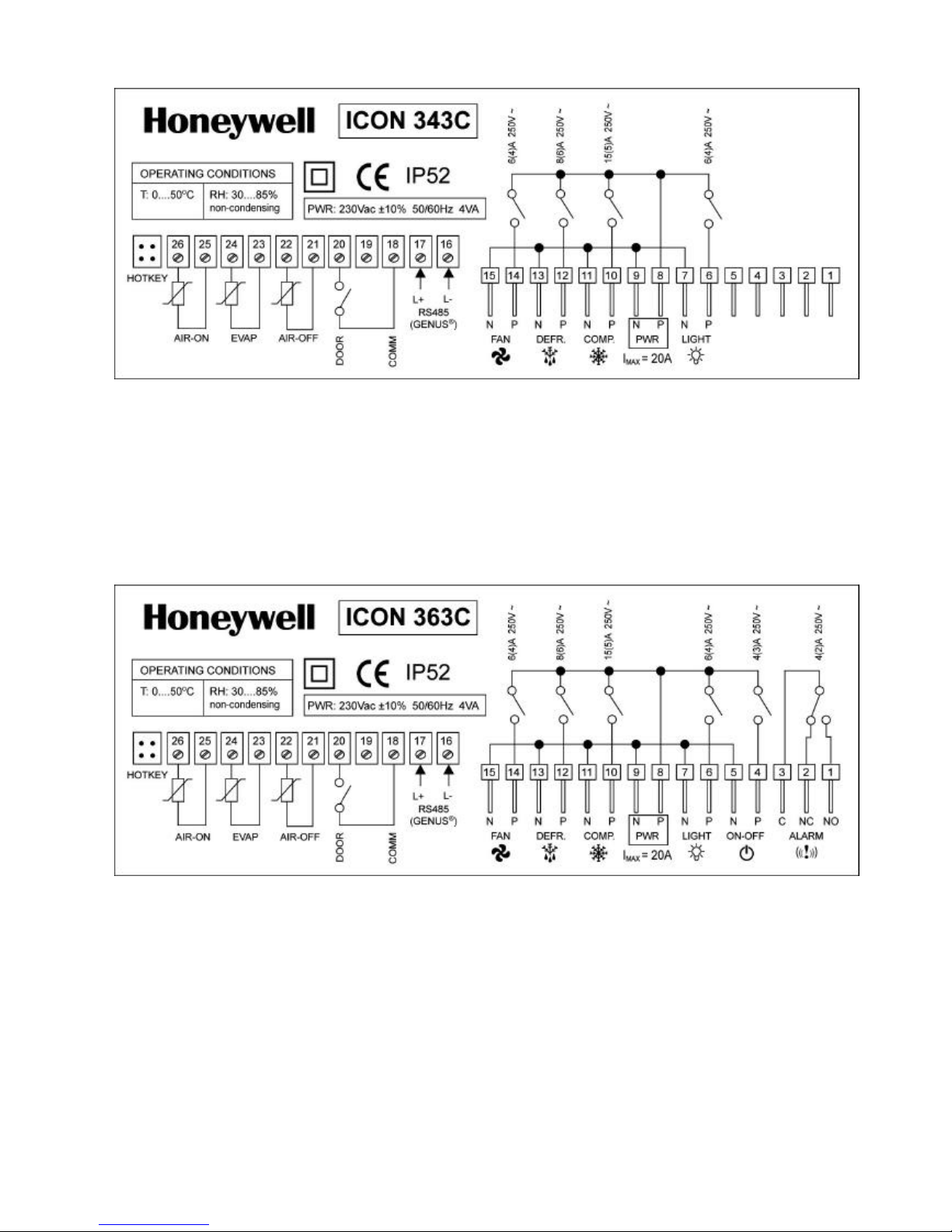

6.3. Electrical Wiring

The wiring diagram of the ICON 343C / 363C controller is shown in Figs.1. & 2.

We recommend the protection of the controllers power supply from

electromagnetic disturbances, voltage peaks, etc., especially applications in

particularly critical industrial environments.

This can be done while carrying out the electrical wiring by keeping the

following points in mind:

A. Keep the power output cable s for the compressor, motors, etc. separate

from those for the control part;

B. Keep the probe cables, the controller power cables and the attached load

power supply cables separate and far enough from each other, so they do

not cross or form spirals;

C. Use mains filters to reduce disturbances at the controller power supply, as

well as filters for the loads in order to attenuate disturbances at the

controller relay outputs;

D. If strong radio disturbances are present, screen the entire device with a

metal screen and connect it to ground.

E. Use correct wire gauges to avoid damaging the screw connectors.

Page 8

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 7

Fig. 1. – Electrical wiring diagram of the ICON 343C controller

6,7:

8,9:

10,11:

12,13:

14,15:

16,17:

light output

controller power supply

compressor output

defrost output

fan output

RS485 serial line input

18:

19:

20:

21,22:

23,24:

25,26:

comms contact input

not used

door contact input

air-off probe input

evaporator probe input

air-on probe input

Fig. 2. – Electrical wiring diagram of the ICON 363C controller

1,2,3:

4,5:

6,7:

8,9:

10,11:

12,13:

14,15:

alarm output

ON / OFF output

light output

controller power supply

compressor output

defrost output

fan output

16,17:

18:

19:

20:

21,22:

23,24:

25,26:

RS485 serial line input

comms contact input

not used

door contact input

air-off probe input

evaporator probe input

air-on probe input

Page 9

ICON 343C / 363C USE R GUIDE

8 EN2B-0004UK07 R0304

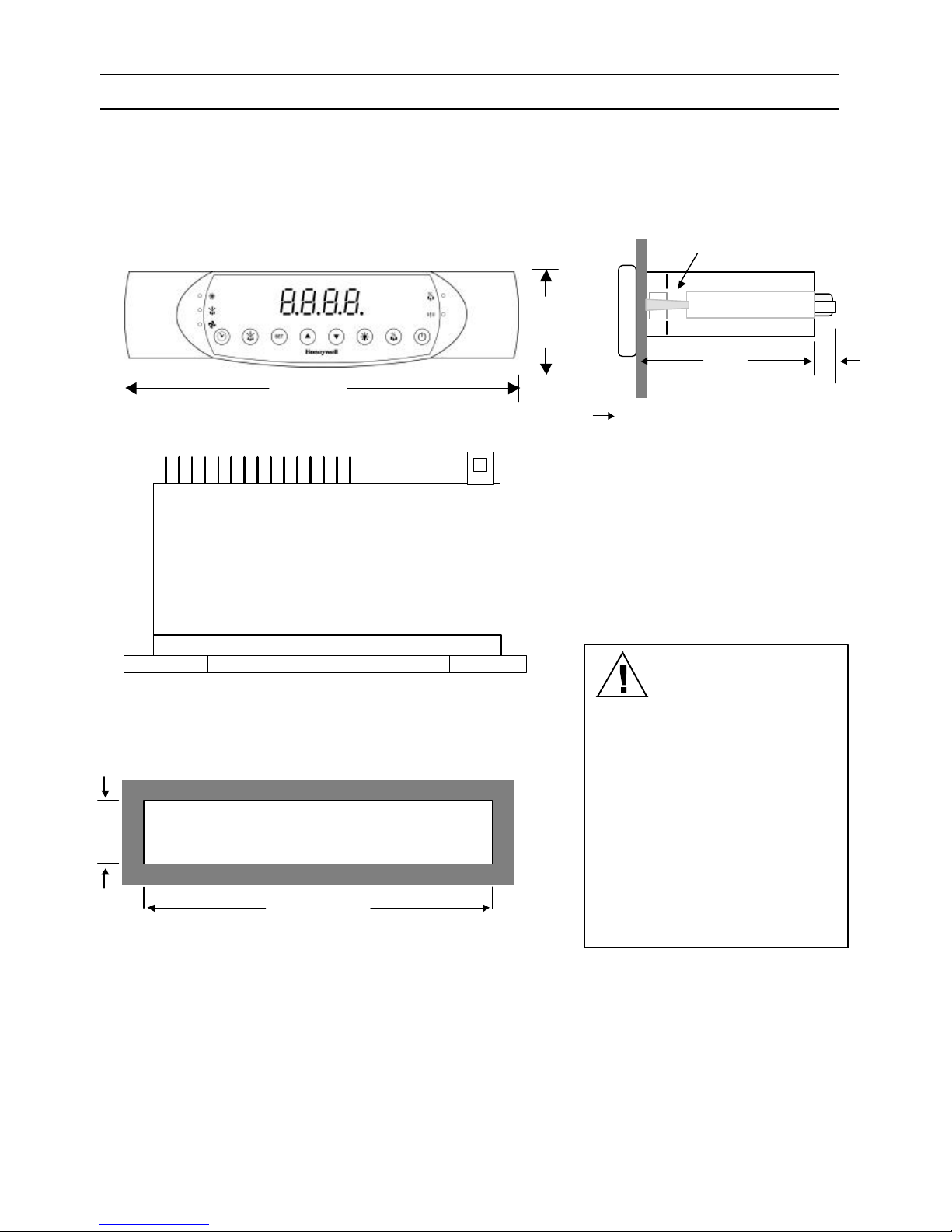

6.4. Fitting

When fitting the controller, leave enough room at the rear to avoid compressing

or excessively bending the cables. The overall instrument dimensions and

panel cut out are given in Figure 3. below.

149.5

31.5

PANEL CUTOUT

188

46

Fig. 3.

– Controller

–

Pane

l-mount

(all dimensions are expressed in mm)

12 8

68

SCREW FIXTURE

Note:

In order to access the screw

fixture (x2) please remove the front

facia, screw controller onto panel

and replace front facia.

WARNING

Disconnect the power supply before you

begin installing the Icon controller. Do

not reconnect the power supply until you

have completed installation.

Please be aware that the relay outputs

are live when controller is powered up.

The contacts are NOT volt free.

Disconnect the power supply before you

begin any maintenance on the Icon

controller.

Page 10

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 9

6.5. Probe Self Detect

The Icon 300 series has a feature that allows only the AIR-OFF

probe to be fitted. If this function is used then the controller will not

alarm on any probes that are missing.

Again, this applies to the AIR OFF probe if this is the only probe

that is fitted, and therefore the weighting parameter pair must be

set to 0%.

This function only applies from initial power up of the controller. If

both the AIR -ON and AIR-OFF probes are fitted and the AIR-ON

probe becomes faulty, then the controller will continue to function

using the AIR-OFF probe, and the power to the controller would

have to be cycled off and then on again.

Page 11

ICON 343C / 363C USE R GUIDE

10 EN2B-0004UK07 R0304

7. ICON FRONT PANEL

7.1. Functions of the Front Panel

The front panel of the ICON 343C / 363C controller is shown in Fig. 4. The

front panel includes a four-digit display and four decimal points, a keyboard

with eight keys, and has one red and four green LED alerts.

Fig. 4 Controller Front Panel and Remote Control

With reference to Fig. 3, in Table 1 the LEDs of the front panel are indicated

together with their denomination. In Table 2 the symbols of the front panel keys

are indicated with their denomination.

7.2. Controller Front Panel LEDs

References to Fig. 3

Symbols Description

1

ALARM

2

LOW HUMIDITY

3, 4, 5, 6

•

DECIMAL POINTS 1, 2, 3, 4

7, 8, 9, 10

DIGITS 1, 2, 3, 4

11

COMPRESSOR

12

DEFROST

13

FAN

Table 2. Controller LED’s

Page 12

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 11

7.3. Controller Front Panel Keys

References

To Fig. 4.

Symbols Description

14

REAL TIME CLOCK

15

LOW HUMIDITY

16

SET

SET

17

UP

18

DOWN

19

LIGHT

20

DEFROSTING

21

ON/OFF

Table 3. Controller Keys

7.4. Functions of the Keys

The function of the individual keys and combinations thereof are listed below.

Please note that the use of the keys in a combined manner is only possible on

the controller front panel.

DEFROST KEY

• When depressed for 5 seconds, during normal controller functioning,

starts a manual defrost cycle, provided that the temperature measured by

the evaporator probe is below the defrost -end temperature value,

parameter 11 (dFEt). During the manual defrost cycle the DEFROST LED

is switched on.

SET KEY

• When depressed and released, during the normal controller function,

displays SEtP and the main set point value for 5 seconds; it also allows to

you change this value.

• When depressed for 15 seconds, during the normal controller function,

allows you to access the parameter configuration menu (see Section 8.)

and change the parameter settings.

• When depressed and released after having changed the main set point or

a parameter value, enters the new setting.

SET

Page 13

ICON 343C / 363C USE R GUIDE

12 EN2B-0004UK07 R0304

UP KEY

• When depressed while selecting the main set point or parameter settings,

increases the numerical value shown on the display.

DOWN KEY

• When depressed while selecting the main set point or parameter settings,

decreases the numerical value shown on the display.

• When de pressed for 5 seconds when in an alarm state, the acoustic alarm

signal is switched off as well as the alarm signal on the display (provided

the reason for the alarm has been cleared).

LIGHT KEY

• When depressed for 1 second activates or deactivates the light output and

switches the LIGHT KEY LED on or off, if the door of the coldroom is

closed. If the door of the coldroom is open, the LIGHT KEY has no effect

on the ON/OFF function of the coldroom light.

• In “OFF” mode and when the key is depressed for 15 seconds the

controller displays “DEFAULT”, at which time the controller will return to

the factory default settings.

LOW HUMIDITY KEY

• When depressed for 3 seconds, switches the low humidity function on or

off and simultaneously switches the LOW HUMIDITY LED and the LOW

HUMIDITY KEY LED on or off.

• During the low humidity function the fan is always switched on, or is

switched off during defrosting, provided in parameter 20 (FanO), either

option CoF or OnOF have been selected.

• If the low humidity function is switched off, and according to how parameter

20 was set, the fan runs parallel with the compressor or always remains

switched on, except during the defrost and drain-down cycle and until the

evaporator temperature reaches the value set in para meter 18.

ON/OFF KEY

• When depressed for 3 seconds switches the controller on or off. When the

controller is switched off, OFF is displayed.

CLOCK KEY

• When depressed the current time is displayed. As long as this key is

depressed, the display first shows tiME, then the current time, then t1,

followed by the air-on temperature value, then t2, followed by the

evaporator probe temperature value, then t3 followed by the air-off

temperature value then the current time, and so on until the key is

released.

Page 14

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 13

UP and SET KEYS

?? When depressed simultaneously during the normal controller operation,

the temperature of the air-off probe (t1) is displayed The display first

shows t1 and then the air-off temperature value until the both keys are

released.

DOWN and SET KEYS

• When depressed simultaneously during the normal controller operation,

the temperature of the evaporator probe (t2) is displayed The display first

shows t2 and then the evaporator temperature value until the both keys

are released.

LIGHT and SET

• When depressed simultaneously during the normal controller operation,

the temperature of the air-on probe (t3) is displayed The display first

shows t3 and then the air-on temperature value until the both keys are

released.

UP and LIGHT KEYS

• When depressed simultaneously for 5 seconds, allows the controller to

log onto the Honeywell Genus® network and communicate.

DOWN and LIGHT KEYS

• When depressed simultaneously for 5 seconds, allows the controller to

log off the Honeywell Genus® network.

UP and DOWN KEYS

• When depressed simultaneously for 10 seconds, locks the keypad.

Display will show ‘access disabled’ in scrolling format. Repeat process to

unclock keypad. Display will then ahow ‘access enabled’.

+ SET

+ + SET

+

+

+ SET

+

Page 15

ICON 343C / 363C USE R GUIDE

14 EN2B-0004UK07 R0304

7.5. LED Functions

ALARM LED

• When switched on, this indicates the presence of an alarm situation. The

alarm situations are accompanied by an intermittent bleeping sound and

are shown with a message on the display.

LOW HUMIDITY LED

• This indicates that the low humidity function is switched on. The fan output

is always switched on, depending on the selection made on parameter 20).

DISPLAY LEDs

• These LEDs show the temperature value of the current time, the values or

the parameter configuration options, the alarm messages or alarm si gnals.

COMPRESSOR LED

• When switched on, but not blinking, indicates that the compressor output is

activated.

• When blinking, indicates that the compressor in anti-short cycle mode

DEFROST LED

• When switched on, but not blinking, indicates that a programmed or

manual defrost cycle is running (the defrost output is activated).

• When switched on, and blinking, indicates that the evaporator is in the

drain-down phase.

FAN LED

• When switched on indicates that the fan output is activated.

COMPRESSOR, DEFROST AND FAN LEDs

?? When flashing in sequence indicates that the controller is in the

programming mode.

+ +

Page 16

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 15

8. CONFIGURATION PARAM ETERS

The configuration parameters, their description, and their respective limits or

options as well as their default values are given in Table 4 (page 17).

When the controller is in the normal operating mode it is possible to change

parameter configuration by proceeding the following way:

• Depress the SET key for 15 seconds until the three front panel

COMPRESSOR, DEFROST and FAN LEDs switch on and off in

sequence and SEtP is displayed (this procedure enters the parameter

configuration menu).

• Release the SET key, and when the display shows the previously set

value of the SEtP parameter, change said value by using the UP or

DOWN keys (the change must be carried out within 15 seconds after the

SET key has been released, otherwise the controller returns to the

normal function mode.

• Confirm the newly selected value by depressing the SET key (this must

be done within 15 seconds after changing the SEtP parameter value,

otherwise the controller exits the parameter configuration menu without

changing said value. Once the new parameter value is confirmed it blinks

for 2 seconds, to confirm that the value was accepted and saved by the

controller. After the value is stored the next parameter code is displayed

and, after 2 seconds, its value).

• Change the displayed value of the second parameter and save the new

data by repeating the procedure described in the above two points.

Proceed this way with all the other parameters (once the last parameter

has been saved, the code of the first parameter will again be displayed

and, after 2 seconds, its value. After 15 seconds the controller returns to

the normal function mode.

Please note th at in order to leave a configured parameter value unchanged

during the configuration procedure, depress the SET key when, after having

stored the changed value of the previous parameter, the controller displays

the code or the value of the parameter one wi shes to leave unchanged. In this

manner the controller proceeds and displays the code and then the value of

the next parameter.

The changes made related to time values are only effective after the currently

timed cycles end, while changes regarding other variables are immediately

effective.

Should it be necessary to only change the main set point (parameter SEtP)

during the normal controller function, then this can be done without entering

the parameter configuration menu by proceeding the following way:

• Depress and then release the SET key (SEtP will be displayed and then

current the main set point value).

• Change the displayed main set point value by using the UP or the DOWN

key (the change must be made within 5 seconds after the set point value is

displayed, otherwise the controller returns to the normal function mode

and displays the current message without changing the main set point

value; it is possible to select a main set point value only within the upper

and lower limits, set respectively in para meters 3 and 4).

• Confirm the new value by depressing and then releasing the SET key (this

must be done within 10 seconds after completing the previous operation,

otherwise the controller will return to the normal functioning mode without

changing the main set point value; once the new set point value is

confirmed it blinks for 2 seconds, to validate that it was accepted and

saved by the controller, after which it is replaced on the display by the

current message).

Page 17

ICON 343C / 363C USE R GUIDE

16 EN2B-0004UK07 R0304

8.1. Parameter Configuration of the Icon 343C & 363C Controller

No. Code

Limits/options

[default values]

Resolution

Description

1 SEtP

LSPL…HSPL

[0]

1/0.1 °C (°F)

Main set point: when the compressor is

switched on to reduce the conditioned ambient

temperature, this parameter sets the

temperature value of said conditioned ambient,

which, once it is reached, will switch off the

compressor.

2 HySt

0.1…20.0 °C

0.1…68.0 °F

[2]

1/0.1 °C (°F)

Differential or Hysteresis: when the

compressor is switched off and the conditioned

ambient temperature rises , this parameter sets

the maximum temperature increase with

respect to the main set point, which, once it is

exceeded, will switch on the compressor to

reduce the temperature.

3 LSPL

-55…HSPL °C

-67…HSPL °F

[-40]

1/0.1 °C (°F)

Lower set point limit : this parameter fixes the

lower set point limit value.

4 HSPL

LSPL…+50 °C

LSPL…+122 °F

[50]

1/0.1 °C (°F)

Upper set point limit: this parameter fixes the

upper set point limit value.

5 ACyt

0…999 s

[120]

1 s

Anti cycling time: this parameter fixes the

time interval which starts when the compressor

is switched off and during which it is not

possible to switch it on, in order to allow the

internal refrigeration circuit pressures to

stabilize.

6 HtAd

0…50 °C

0…122 °F

[10]

1/0.1 °C (°F)

High temperature alarm differential: this

parameter fixes the temperature increase of the

conditioned ambient temperature with respect

to the main set point (1), which, when

exceeded, causes the controller, after ALdy

minutes (8), to activate the alarm output, the

intermittent acoustic alarm signal, and displays

the ALHt alarm message, which alternates with

the conditioned ambient temperature value,

provided that during time interval ALdy (8), the

ambient temperature always remains above

SEtP+HtAd

7 LtAd

0…50 °C

0…122 °F

[10]

1/0.1 °C (°F)

Low temperature alarm differential: this

parameter fixes the temperature decrease of

the conditioned ambient temperature with

respect to the main set point (1), which, when

exceeded, causes the controller, after ALdy

minutes (8), to activate the alarm output, the

intermittent acoustic alarm signal, and displays

the ALLt alarm message, which alternates with

the conditioned ambient temperature value,

provided that during time interval ALdy, the

ambient temperature always remains below

SEtP-LtAd.

Table 4. Parameters

Page 18

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 17

Parameter Configuration of the Icon 343C / 363C Controller (continued)

No Code

Limits/options

[default

values]

Resolution Description

8 ALdy

0…99 min

[10]

1 min

Low and high temperature alarm delay: this

parameter fixes the time interval in minutes

between the moment in which the conditioned

ambient temperature exceeds the value

SEtP+HtAd (1, 6) and the moment the ALHt

alarm signal is given, provided that during this

time interval, the ambient temperature always

remains above SEtP+HtAd.

Likewise it fixes the time interval in minutes

between the moment in which the conditioned

ambient temperature drops below the value

SEtP-LtAd (1, 7) and the moment the ALLt alarm

signal is given, provided that during this time

interval, the ambient temperature always remains

below SEtP-LtAd.

9

dCSt

1…999 h

[4]

1 h

Time interval between defrost cycles: this

parameter fixes the time interval between the

beginning of a defrost cycle and the beginning of

the next one.

When the defrost cycle is regulated by this

parameter (dCSt), counting of the time interval

between defrost cycles restarts from zero, every

time a defrost cycle is started manually.

During the defrost cycle the settings in parameter

dIdF (22) are displayed.

Please remember that the value set in this

parameter must be greater than the maximum set

interval between two defrost cycles start times set

in parameters tIN1…tIN6.

10 dFCt

1…999 min

[30]

1 min

Maximum defrost cycle time: this parameter

fixes the maximum defrost cycle time, provided

the evaporator defrost-end temperature is not

reached, which is set in parameter dFEt (11), or

an evaporator probe failure occurs.

11 dFEt

-55…+50 °C

-67…+122 °F

[10]

1/0.1 °C (°F)

Defrost-end temperature: this parameter fixes

the evaporator temperature, which, when

reached, ends the defrost cycle. For security

purposes, defrosting ends after the time set in

parameter dFct (10) ends.

12 dFdL

0…99 min

[10]

1 min

Delay of real defrost-end temperature display

:

this parameter fixes the tim e interval, that starts

at the end of a defrost cycle (including draindown time), and during which the controller

displays the last temperature value shown before

the current defrost cycle started, provided the real

temperature value of the conditioned am bient is

higher than said value.

If not, and in any case at the end of the above

mentioned time interval, the controller will again

display the real ambient temperature.

Page 19

ICON 343C / 363C USE R GUIDE

18 EN2B-0004UK07 R0304

Parameter Configuration of the Icon 343C / 363C Controller (continued)

No. Code

Limits/options

[default values]

Resolution Description

13 OFP1

-20…+20 °C (°F)

[0]

1/0.1 °C (°F)

Air-off probe offset: this parameter

fixes the positive or negative correction

to be made of the value measured by

the air-off probe in order to

compensate for measurement errors.

14 OFP2

-20…+20 °C (°F)

[0]

1/0.1 °C (°F)

Evaporator probe offset: this

parameter fixes the positive or

negative correction to be made of the

value measured by the evaporator

probe in order to compensate

measurement errors.

15 OFP3

-20…+20 °C (°F)

[0]

1/0.1 °C (°F)

Air-on probe offset: this parameter

fixes the positive or negative correction

to be made of the value measured by

the air-on probe in order to

compensate for measurement errors.

16 PAir

0…100%

[50]

1%

Control Temperature Weighting:

This parameter fixes the value of the

wighted average of the air-on and airoff probes. Set to zero (0) for 100%

Air-off or set to 100 for 100% Air-on.

17 SErC

0…9999 h

[0]

1 h

Filter maintenance interval time

(service): This parameter indicates

the number of working hours of the fan

which, when reached, will generate the

MSEr message on the display,

accompanied by the sound of the

buzzer, three consecutive times. This

message means maintenance of the

fan filter is required.

This message is repeated in 1-minute

intervals until deactivated by setting

parameter SerC to 0. When the filter

maintenance intervention is terminated

one can set a new interval time for the

following maintenance intervention.

18 FAnt

-55…+50 °C

-67…+122 °F

[0]

1/0.1

Fan startup temperature at

controller start-up and after defrost

cycle: this parameter determines the

evaporator temperature value

measured by the evaporator probe.

Below this value the fan is switched on

after delay time in parameter Fand

(19).

The Fand parameter is de-activated

while the controller operates in low

humidity mode. The fan is always

switched on, except during defrosting

(see parameter 20, FanO).

Page 20

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 19

Parameter Configuration of the Icon 343C / 363C Controller (continued)

No. Code

Limits/options

[default values]

Resolution Description

19 FAnd

0…99 min

[2]

1

Fan start delay at controller startup

and after defrost cycle : this parameter

fixes the time interval that starts at

controller start-up or at the end of a

defrost cycle (including drain-down

time), during which the fan must remain

switched off in order to not introduce

warm and humid air into the conditioned

ambient air.

At the end of said time interval, the fan

will be switched on either immediately, if

the evaporator probe is defective, or

when the evaporator temperature drops

and reaches the value set in parameter

18 (Fant).

The Fand parameter is de-activated

while the controller operates in the low

humidity mode. The fan is always

switched on, except during defrosting

(see parameter 20, FanO).

20 FAnO

Con, CoF, OnOn

OnOF

[OnOn]

Fan operating mode: this parameter

fixes the type of fan operating mode.

If the Con option is selected, then the

fan operating mode is linked to that of

the compressor, provided the system is

not operating in the low humidity mode.

The fan is always switched on when the

system is operating in the low humidity

mode.

If the CoF option is selected, then the

fan operating mode is linked to that of

the compressor, provided the system is

not operating in the low humidity mode.

The fan is always switched on, except

during the defrost cycle, when the

system is operating in the low humidity

mode.

If the OnOn option is selected, then the

fan is always switched on, except during

the defrost cycle and thereafter for the

time set in parameter 19 (Fand), until the

temperature has reached the value set

in parameter 18 (Fant), provided the

system is not operating in the low

humidity mode. The fan is always

switched on when the system is

operating in the low hu midity mode.

If the OnOF option is selected, then the

fan is always switched on, except during

the defrost cycle and thereafter for the

time set in parameter 19 (Fand). Until

the temperature has reached the value

set in parameter 18 (Fant), provided the

system is not operating in the low

humidity mode. The fan is always

switched on, except during the defrost

cycle, when the system is operating in

the low humidity mode.

Page 21

ICON 343C / 363C USE R GUIDE

20 EN2B-0004UK07 R0304

Parameter Configuration of the Icon 343C / 363C Controller (continued)

No. Code

Limits/options

[default values]

Resolution Description

21 CodF

OFF, On

[OFF]

Compressor operating mode during the

defrost cycle: this parameter determines

the compressor function mode during a

defrost cycle, i.e., always switched off when

the OFF option is selected, or always

switched on when the On option is selected.

22 DIdF

REAL, dEF, LAST

[dEF]

Displayed message during a defrost

cycle: this parameter indicates the

message to be displayed during a defrost

cycle (including the drain-down time), i.e.,

the real conditioned ambient temperature if

option REAL is selected, dEF if option dEF

is selected, or the last conditioned ambient

temperature measured before the defrost

cycle if option LAST is selected.

23 drIP

0…99 min

[2]

1 min

Drain-down time: this parameter fixes the

time interval, which starts when a defrost

cycle ends, and during which the

compressor is switched off to allow for

optimized drying of the evaporator.

24 Ptyp

NTC, RTD

[NTC]

This parameter determines the type of

probe connected to the controller; option

NTC (default) is for NTC 2K probes,

whereas option RTD is for PT1000 probe.

25 RESo

Int, Dec

[Int]

Resolution: this parameter determines with

which resolution the temperature value is to

be displayed, i.e., 1 if option Int is selected,

or 0,1 if option Dec is selected.

26 UnIt

CELS, FAHr

[CELS]

Unit of measure: This parameter sets the

unit of measure of the temperature, i.e., °C

if the option CELS is selected, or °F if the

option FAHr is selected.

27 COPF

OFF, ON, CYC

[CYC]

Compres

sor function during probe

failure: this parameter fixes the compressor

operating mode during a conditioned

ambient temperature probe failure.

If option OFF is selected, the compressor is

switched off and remains like that until the

failure has been repaired; if option ON is

selected, the compressor is switched on

and remains like that until the probe failure

has been repaired; if option CYC is

selected, the compressor – as soon as the

failure occurs – alternates the time interval

set in parameter 28 (CoOF), during which it

remains switched off, with the time interval

set in parameter 27 (CoOn), during which it

remains switched on, and so on until the

failure has been repaired.

Page 22

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 21

Parameter Configuration of the Icon 343C / 363C Controller (continued)

No. Code

Limits/options

[default values]

Resolution Description

28 COOn

1...99 min

[2]

1 min

Compressor on-time during probe

failure: this parameter fixes the time

interval that alternates with the time set in

parameter 28 (CoOF), during which the

compressor must remain switched on during

a probe failure, provided option CYC is

selected in parameter 26 (CoPF).

29 COOF

1…99 min

[5]

1 min

Compressor off-time during probe failure

:

this parameter fixes the time interval that

alternates with the time set in parameter 27

(CoOn), during which the compressor must

remain switched off during a probe failure,

provided option CYC is selected in parameter

26 (CoPF).

30 dOrS

nO, nC

[nO]

Door switch: this parameter determines the

position of the door switch, that corresponds

with when the door is closed. If dorS = nO, the

door is closed when the switch is normally

open. If dorS = nC, the door is closed when

the switch is normally closed.

31 dSFU

nOCy, FAOF,

COOF, FCOF

[FAOF]

Controller functions when door is open:

this parameter determines the controller

function when the door is open.

If the option nOCY is selected the controller

continues to function normally.

If the option FAOF is selected then the

controller switches off the fan two seconds

after the door has been opened and for as long

as the door remains open.

If the option COOF is selected then the

controller switches off the compressor one

minute after the door has been opened and for

as long as the door remains open.

If the option FCOF is selected then the

controller switches off the fan two seconds

after the door has been opened, and the

compressor one minute after the door has

been opened, and both for as long as the door

remains open.

Whichever option is selected, as long as the

door remains open the controller displays the

message “door” that alternates with the current

message.

32 rHPb

EnAb

dISA

[dISA]

Low humidity push -button

activation/deactivation:

This parameter enables or disables the High

Humidity key, according to the option that

was selected, i.e., EnAb or dISA.

33 tINE

00.00…23.59

[12.00]

1 min

Real time: this parameter allows to set the

current time in the HH:MM format.

Page 23

ICON 343C / 363C USE R GUIDE

22 EN2B-0004UK07 R0304

Parameter Configuration of the Icon 343C / 363C Controller (continued)

No. Code

Limits/options

[default values]

Resolution Description

34 tIN1

35 tIN2

36 tIN3

37 tIN4

38 tIN5

39 tIN6

00.01…23.59

- - - -

- - - -

- - - -

- - - -

- - - -

- - - 1 min

1st, 2nd,…,6th defrost cycle starting

times: in this parameter up to six defrost

cycle starting times can be set, or the

same can be disabled (option - - - - ).

A given defrost cycle not only doesn’t

occur when disabled, but is also

deactivated, should its starting time be

during another enabled defrost cycle

(manual defrosting), or during a time alarm

(ALti).

If the various defrost cycle start times are

not set in the increasing order of the

parameters (e.g., TIM1=18.30,

TIM2=09.27), then the execution of the

defrost cycles will not respect the order of

said parameters, but will respect the

increasing order of real time.

Every selected defrost cycle ends when

the evaporator reaches the temperature

value set in parameter 11 (dFEt), or when

the time set in parameter 10 (dFct) ends.

During the defrost cycle the display shows

the settings made in parameter 22 (dIdF).

40 DFst

DFSt = rEM

(remote)

DFS t= Loc (local)

Local or Remote Defrost Start Modes

DFSt for defrost start mode that defines

the selection between Local or Remote

defrost operation; if DFSt= rEM the

defrost is initiated only when a net work

command is issued by the Supervisor (or

Genus® Front -End system); if DFSt= Loc

the defrost is controlled by the local

timing set by the parameters

TIN1….TIN6

41 StUb

0...99

[0]

Stub Number

Number given to identify refrigeration

stub from 0…99 when connected to, and

viewed from, a Genus® network

42 CASE

0...9, A,B,C,D, E,

F,G,H,I,L,P,T,U,Y

[0]

Case number

Number given to identify refrigeration

case from 0…9…A…Y when connected

to, and viewed from, Genus® network.

Page 24

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 23

9. REAL TIME CLOCK AND DEFROST SETUP

9.1. Setting and Displaying the Real Time Clock

The Real Time Clock (RTC) operates on a 24 hour cycle (00:00…23:59)

The current time set in the RTC can be displayed by depressing and holding the

CLOCK key. The display will show the standard format (24 hours) of: HH.MM

(hours. minutes)

Procedure:

1. To set the Real-Time clock press and hold the SET Key for 15 seconds until

the three front panel COMPRESSOR, DEFROST and FAN LEDs switch on

and off in sequence and SEtP is displayed (with this procedure one enters

the parameter configuration menu).

2. Repeatedly press the SET key until ‘tINE’ is displayed followed by current

time value. Use the UP and DOWN arrows to set clock as required.

3. Press SET to confirm new value.

9.2. Setting the Daily Defrost Cycles on the Real Time Clock

It is possible to set -up 6 defrost cycles per day on Icon models: ICON-343C &

ICON-363C.

The time parameters regarding this function are: tIN1, tIN2, tIN3, tIN4, tIN5 & tIN6

Notes:

1. In order to activate a defrost cycle it is necessary to set the defrost cycle

starting time in at least one of the parameters (tIN1, tIN2, tIN3, tIN4, tIN5 or

tIN6)

2. To be recognized as valid the time must be set in the format of HH.MM, (24

hours)

3. If parameters tIN1…tIN6 are set to - - . - - then function is DISABLED.

Procedure:

1. To set the timed defrost press and hold the SET Key for 15 seconds until

the three front panel COMPRESSOR, DEFROST and FAN LEDs switch on

and off in sequence and SEtP is displayed (with this procedure one enters

the parameter configur ation menu).

2. Repeatedly press the SET key until ‘tIN1’ is displayed followed by current

value. Use the UP and DOWN arrows to set defrost start time as required.

3. Press SET to confirm new value.

4. Repeat steps 1 to 3 for tIN2…tIN6.

Important:

With regard to parameter dCSt, (time interval between defrost cycles), please

remember that the value set in said parameter (dCSt) must be greater than the

maximum set interval between two defrost cycles start times set in parameters

tIN1…tIN6.

Example: tIN1 = 05.00 tIN2 = 11.30

TIN3 = 15.30 tIN4 = 23.50

TIN5 = - -.- - tIN6 = - -.- -

Therefore: dCSt > 18 hours 50 mins.

Page 25

ICON 343C / 363C USE R GUIDE

24 EN2B-0004UK07 R0304

10. CONNECTING TO HONEYWELL GENUS NETWORK

10.1. Icon Controller Identification on Genus® Network

Icon has to be given a name (alias) in order to log onto the Genus® network. The

following naming convention is required for Genus network identification and

defrost capabilities.

The Icon controller name is displayed as ‘ICXX-Y’ on Genus network. Where ‘XX’

is the StUB number and ‘Y’ is the CASE number.

A stub number ‘XX’ represents the refrigeration section where the Icon controller

is situated within the supermarket. A case number ‘Y’ represents the case within

the stub.

10.2. Network Logging-On Procedure

1. Disconnect or ensure that the controller is not logged on the network by

depressing the buttons LIGHT+DOWN for 5 sec: the controller will display

OFFLINE

2. Connect Genus® network cable to Genus® socket at rear end of the Icon

controller. OBSERVE POLARITY

3. Set the StUb parameter between 0..99

4. Set the CASE parameter between 0…9,A,B,C,D,E,F,G,H,I,L,P,T,U,Y

5. Enable the controller to communicate on the network by depressing the

buttons LIGHT+UP for 5 sec: the controller will display ONLINE

10.3. Network Logging-Off Procedure

1. To log off from the Genus network depress the buttons LIGHT+DOWN for

5 seconds, the controller will display OFFLINE

Page 26

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 25

11. PROGRAMMABLE HOTKE Y

The Icon controller has an optional programmable HotKey (Part Number: ICONKEY3) When the controller is in OFF mode i.e. when it is non-activated and displays

the message “OFF”, it is possible to upload the parameter configurations of the

controller to the HotKey, or vice-versa, to download parameter configurations from

the HotKey to the controller.

11.1. HotKey Uploading Procedure

To upload the parameter configuration from the controller to the HotKey, proceed in

the following manner.

1. Connect the HotKey to the HotKey connector on the rear of the controller (Note:

the HotKey is orientated where the Hotkey main body is vertically inserted with

the keyring hole below the main body of the Icon controller. Failure to observe

this orientation instruction will result in controller malfunction)

2. Press the DEFROST key for 15 seconds until the ”PrOG” message appears on

the display.

3. Press the UP key until the “n-SA” message appears on the display.

4. Press the SET key for at least 5 seconds until the “yES” message, the “-rST”

message (meaning the data is being uploaded) and after that the “OFF” message

appears on the display.

5. The HotKey can now be removed.

11.2. HotKey Downloading Procedure

To download the parameter configuration from the HotKey to the controller, proceed

in the following manner.

1. Connect the HotKey to the HotKey connector on the rear of the controller. (Note:

the HotKey is orientated where the Hotkey main body is vertically inserted with

the keyring hole below the main body of the Icon controller Failure to observe

this orientation instruction will result in controller malfunction)

2. Press the DEFROST key for 15 seconds until the ”PrOG” message appears on

the display.

3. Press the DOWN key until the “n-rd” message appears on the display.

4. Press the SET key for at least 5 seconds until the “yES” message, the “-rST”

message (meaning the data is being downloaded) and after that the “OFF”

message appears on the display.

5. The HotKey can now be removed.

6. If for any reason the download procedure from the HotKey to the controller does

not work correctly, or is not possible because the HotKey is not enabled, after

pressing the SET key the “Err” message will appear on the display (indicating

that the data was not transferred) and will be followed by “-rST” and “OFF”.

7. If the Icon is connected to the Honeywell Genus® network, manually re-configure

controller parameters StUb and CASE to reflect new address. Also manually reconfigure DFst (see note below).

Note: Parameters DFst (local or remote defrost) will be automatically set to ‘LOC’

(local) , StUb (stub number), CASE (case number) are automatically set to ‘0’

(default) when Hotkey download to new controller is complet e. This ensures that

there is no conflict with 2 or more controllers having the same network address.

Reconfigure these parameters to create new address for controller as well as

network logging status. E.g. StUb = 14, CASE = 5.

Page 27

ICON 343C / 363C USE R GUIDE

26 EN2B-0004UK07 R0304

12. TROUBLESHOOTING

The ICON controller is able to recognize and to signal seven types of alarm

situation. Each alarm type has a corresponding alarm message and actions

that are made by the controller (see Table 5).

The alarm messages are displayed and alternate with the current di splayed

value; they are also accompanied by an intermittent audible signal (buzzer).

Once the cause for the alarm has been eliminated, the corresponding alarm

message continues to be displayed and is accompanied by the buzzer.

In case of an ‘Alti’ alarm, once the cause has been eliminated, it is necessary to

reset both the current time and the various defrost cycle starting times

(parameter 38 – tINE…. tIN1, tIN2,.., tIN6).

When DOWN key is depressed for 5 seconds when in an alarm state, the

acoustic al arm signal is switched off as well as the alarm signal on the display

(provided the reason for the alarm has been cleared).

12.1. Alarm Messages

Alarm

message

Cause Controller intervention

ALP1

Interruption or short circuit of the

AIR-OFF probe.

Alarm output active

Compressor output according to parameters

COPF, COOn & COOF (26, 27, 28)

Other outputs not modified

ALP2

Interruption or short circuit of the

evaporator probe.

Alarm output active

Defrost output as set in parameter 10 (dFCt)

Fan start delay as set in parameter 19

(Fand)

Other outputs not modified

ALP3 Interruption or short circuit of the

AIR-ON probe.

Alarm output active

Other outputs not modified

ALHt The temperature of the conditioned

ambient exceeds SEtP+HtAd (1, 6)

and therefore remains above

SEtP+HtAd for the time set in

parameter 8 (ALdy)

Alarm output active

Other outputs not modified

ALLt The temperature of the conditioned

ambient drops below SEtP-LtAd (1,

7) and therefore remains below

SEtP-HtAd for the time set in

parameter 8 (ALdy)

Alarm output active

Other outputs not modified

ALti Internal clock failure or clock back-up

battery exhausted or defective.

Alarm output active

Defrost output as set in parameters 9,11,10

(dCSt, dFEt or dFCt)

ALEE Loss of EEPROM data Alarm output active. The instrument

functions with the default parameters given

in Table 4

Table 5. Alarm Messages

Page 28

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 27

12.2. Warning Messages

As well as the alarm signals, the ICON controller can also display four warning

messages as given in the table below.

Warning Messages Meaning

dEF Defrost cycle activated

door Coldroom door is open

FiLt Filter requires maintenance

OFF Controller is in the stand-by mode

Table 6. Warning Messages

13. MAINTENANCE

Clean the instrument front panel with a soft cloth, dampen ed with soapy water.

We recommend not to use abrasive detergents or detergents that contain

solvents, since they could damage the instrument; also, do not splash water or

any other liquid directly on the instrument.

All repairs on the controller must be carried out by authorized personnel.

Opening the instrument housing or tampering with the controller automatically

voids the warranty.

14. ABOUT THE OPERATING INSTRUCTIONS

These operating instructions are to be considered part of our product and are

therefore to be kept with proper care until the product itself is disposed of.

The user can directly request new operating instructions from Honeywell,

should those supplied have been damaged or lost.

Honeywell reserves the right to modify product features and/or to up-date the

operating instructions at any time, without giving prior notice and without the

obligation to up-date previously issued versions.

The user can request possible up-dates or integrations directly from Honeywell;

he/she may also request further information about the product and in turn make

proposals on how to improve these operating instructions.

The information included in these operating instructions shall serve to illustrate

the use of the product as foreseen in the application, to list its technical

features, to supply information about its installation and regulation, to prescribe

maintenance procedures, to list residual risks, etc.

Honeywell therefore assumes no responsibility deriving from the improper use

of its product or use by incompetent personnel, incorrect installation, faulty

power supply, serious lack of prescribed maintenance, non-authorized

modifications or interventions, the use of spare parts that are either not original

or not specific for this model or not fully complying with the operating

instructions.

Page 29

ICON 343C / 363C USE R GUIDE

28 EN2B-0004UK07 R0304

15. NOTES

Page 30

ICON 343C / 363C US ER GUIDE

EN2B-0004UK07 R0304 29

Page 31

ICON 343C / 363C USE R GUIDE

30 EN2B-0004UK07 R0304

Page 32

Automation & Control Solutions

Cooling & Refrigeration

Newhouse Industrial Estate

Motherwell

Lanarkshire ML1 5SB

Phone: (44) 01698 481698

Fax: (44) 01698 481699

www.honeywell.com/cooling

Subject to change without notice. Printed in United Kingdom

EN2B-0004UK07 R0304

Loading...

Loading...