Page 1

Military & Space Products

32K x 8 ROM—SOI HX6656

FEATURES

RADIATION

• Fabricated with RICMOS™ IV Silicon on Insulator

(SOI) 0.75 µm Process (L

= 0.6 µm)

eff

• Total Dose Hardness through 1x106rad(SiO2)

• Dynamic and Static Transient Upset

Hardness through 1x109 rad(Si)/s

• Dose Rate Survivability through 1x1011 rad(Si)/s

14

-2

• Neutron Hardness through 1x10

cm

• SEU Immune

• Latchup Free

OTHER

• Read Cycle Times

< 17 ns (Typical)

≤ 25 ns (-55 to 125°C)

• Typical Operating Power <15 mW/MHz

• Asynchronous Operation

• CMOS or TTL Compatible I/O

• Single 5 V ± 10% Power Supply

• Packaging Options

- 28-Lead Flat Pack (0.500 in. x 0.720 in.)

- 28-Lead DIP, MIL-STD-1835, CDIP2-T28

- 36-Lead Flat Pack (0.630 in. x 0.650 in.)

GENERAL DESCRIPTION

The 32K x 8 Radiation Hardened ROM is a high performance 32,768 word x 8-bit read only memory with industrystandard functionality. It is fabricated with Honeywell’s

radiation hardened technology, and is designed for use in

systems operating in radiation environments. The ROM

operates over the full military temperature range and requires only a single 5 V ± 10% power supply. The ROM is

available with either TTL or CMOS compatible I/O. Power

consumption is typically less than 15 mW/MHz in operation,

and less than 5 mW when de-selected. The ROM operation

is fully asynchronous, with an associated typical access

time of 14 ns.

Honeywell’s enhanced SOI RICMOS™IV (Radiation Insensitive CMOS) technology is radiation hardened through the

use of advanced and proprietary design, layout, and process hardening techniques. The RICMOS™ IV process is a

5-volt, SIMOX CMOS technology with a 150 Å gate oxide

and a minimum drawn feature size of 0.75 µm (0.6 µm

effective gate length—L

tungsten via plugs, Honeywell’s proprietary SHARP planarization process, and a lightly doped drain (LDD) structure for improved short channel reliability.

). Additional features include

eff

Page 2

HX6656

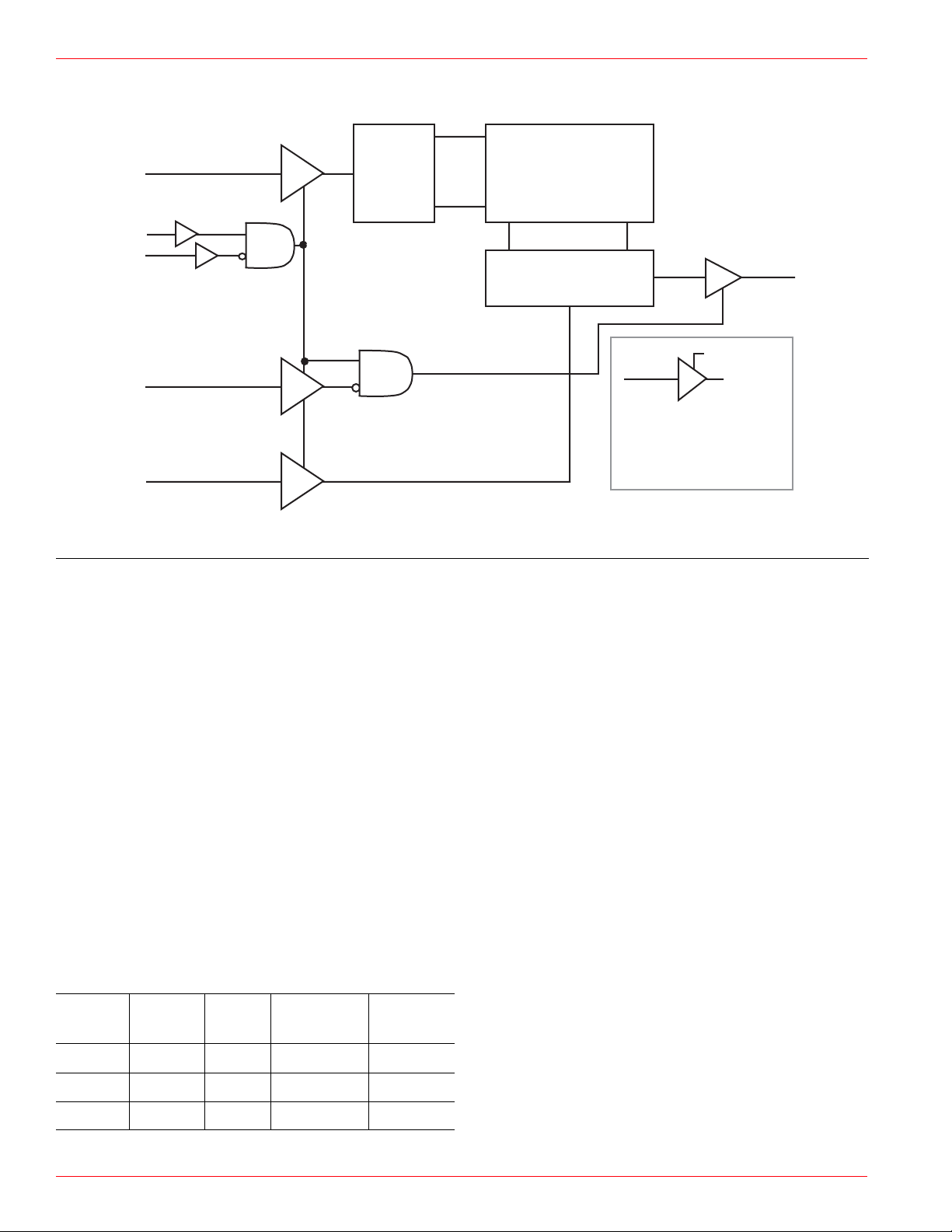

FUNCTIONAL DIAGRAM

A:0-8,12-13

CE

NCS

NOE

A:9-11,14

11

Ro w

Decoder

•

•

•

CS • CE • OE

(0 = high Z)

32, 768 x 8

Memory

Array

• • •

Column Decoder

Data Output

Signal

8

1 = enab l ed

#

Q:0-7

Signal

All controls must b e

enabled for a signal to

pass. (#: numbe r of

4

buffers, default = 1)

SIGNAL DEFINITIONS

A: 0-14 Address input pins which select a particular eight-bit word within the memory array.

Q: 0-7 Data Output Pins.

NCS Negative chip select, when at a low level allows normal read operation. When at a high level NCS forces the

ROM to a precharge condition, holds the data output drivers in a high impedance state and disables all input

buffers except CE. If this signal is not used it must be connected to VSS.

NOE Negative output enable, when at a high level holds the data output drivers in a high impedance state. When

at a low level, the data output driver state is defined by NCS and CE. If this signal is not used it must be

connected to VSS.

CE* Chip enable, when at a high level allows normal operation. When at a low level CE forces the ROM to a

precharge condition, holds the data output drivers in a high impedance state and disables all the input buffers

except the NCS input buffer. If this signal is not used it must be connected to VDD.

TRUTH TABLE

NCS CE* NOE MODE Q

L H L Read Data Out

H X XX Deselected High Z

X L XX Disabled High Z

Notes:

X: VI=VIH or VIL

XX: VSS≤VI≤VDD

NOE=H: High Z output state maintained

for NCS=X, CE=X

*Not Available in 28-lead DIP or 28-Lead Flat Pack

2

Page 3

RADIATION CHARACTERISTICS

Total Ionizing Radiation Dose

HX6656

The ROM will meet all stated functional and electrical

specifications over the entire operating temperature range

after the specified total ionizing radiation dose. All electrical

and timing performance parameters will remain within

specifications after rebound at VDD = 5.5 V and T =125°C

extrapolated to ten years of operation. Total dose hardness

is assured by wafer level testing of process monitor transistors and ROM product using 10 keV X-ray and Co60

radiation sources. Transistor gate threshold shift correlations have been made between 10 keV X-rays applied at a

dose rate of 1x105 rad(SiO2)/min at T = 25°C and gamma

rays (Cobalt 60 source) to ensure that wafer level X-ray

testing is consistent with standard military radiation test

environments.

Transient Pulse Ionizing Radiation

The ROM is capable of reading and retaining stored data

during and after exposure to a transient ionizing radiation

pulse of ≤1 µs duration up to 1x109 rad(Si)/s, when applied

under recommended operating conditions. To ensure validity of all specified performance parameters before, during, and after radiation (timing degradation during transient pulse radiation (timing degradation during transient

pulse radiation is ≤10%), it is suggested that stiffening

capacitance be placed on or near the package VDD and

VSS, with a maximum inductance between the package

(chip) and stiffening capacitance of 0.7 nH per part. If

there are no operate-through requirements, typical circuit

board mounted de-coupling capacitors are recommended.

The ROM will meet any functional or electrical specification after exposure to a radiation pulse of ≤50 ns duration

up to 1x1011 rad(Si)/s, when applied under recommended

operating conditions.

Neutron Radiation

The ROM will meet any functional or timing specification

after a total neutron fluence of up to 1x1014 cm-2 applied

under recommended operating or storage conditions. This

assumes an equivalent neutron energy of 1 MeV.

Single Event Phenomena

All storage elements within the ROM are immune to single

event upsets. No access time or other performance degradation will occur for LET 190 MeV/cm/mg

2

.

Latchup

The ROM will not latch up due to any of the above radiation

exposure conditions when applied under recommended

operating conditions. Fabrication with the SIMOX substrate material provides oxide isolation between adjacent

PMOS and NMOS transistors and eliminates any potential

SCR latchup structures. Sufficient transistor body tie connections to the p- and n-channel substrates are made to

ensure no source/drain snapback occurs.

RADIATION HARDNESS RATINGS (1)

Parameter

Total Dose ≥1x10

Transient Dose Rate Upset (3) ≥1x10

Transient Dose Rate Survivability (3) ≥1x10

Neutron Fluence ≥1x10

(1) Device will not latch up due to any of the specified radiation exposure conditions.

(2) Operating conditions (unless otherwise specified): VDD=4.5 V to 5.5 V, TA=-55°C to 125°C.

(3) Not guaranteed with 28–Lead DIP.

Limits (2)

6

9

11

14

3

Units

rad(SiO2)

rad(Si)/s

rad(Si)/s

2

N/cm

Test Conditions

TA=25°C

Pulse width ≤1 µs

Pulse width ≤50 ns, X-ray,

VDD=6.0 V, TA=25°C

1 MeV equivalent energy,

Unbiased, TA=25°C

Page 4

HX6656

ABSOLUTE MAXIMUM RATINGS (1)

Rating

Symbol

VDD Positive Supply Voltage (2) -0.5 7.0 V

VPIN Voltage on Any Pin (2) -0.5 VDD+0.5 V

TSTORE Storage Temperature (Zero Bias) -65 150 °C

TSOLDER Soldering Temperature • Time 270•5 °C•s

PD Total Package Power Dissipation (3) 2.5 W

IOUT DC or Average Output Current 25 mA

VPROT ESD Input Protection Voltage (4) 2000 V

ΘJC

TJ Junction Temperature 175 °C

(1)Stresses in excess of those listed above may result in permanent damage. These are stress ratings only, and operation at these levels is not

implied. Frequent or extended exposure to absolute maximum conditions may affect device reliability.

(2)Voltage referenced to VSS.

(3)ROM power dissipation (IDDSB + IDDOP) plus ROM output driver power dissipation due to external loading must not exceed this specification.

(4)Class 2 electrostatic discharge (ESD) input protection. Tested per MIL-STD-883, Method 3015 by DESC certified lab.

Thermal Resistance (Jct-to-Case)

Parameter

Min

28 FP/36 FP 2

28 DIP 10

Max

Units

°C/W

RECOMMENDED OPERATING CONDITIONS

Symbol

VDD Supply Voltage (referenced to VSS) 4.5 5.0 5.5 V

TA Ambient Temperature -55 25 125 °C

VPIN Voltage on Any Pin (referenced to VSS) -0.3 VDD+0.3 V

Parameter

Min

Description

MaxTyp

CAPACITANCE (1)

Symbol

CI Input Capacitance 7 pF

CO Output Capacitance 9 pF VIO=VDD or VSS, f=1 MHz

Parameter

Typical

(1)

Worst Case

Min

Max

Units

Test Conditions

VI=VDD or VSS, f=1 MHz

Units

(1) This parameter is tested during initial design characterization only.

4

Page 5

DC ELECTRICAL CHARACTERISTICS

HX6656

Symbol Parameter

Typical

(1)

Worst Case

Min

Max

(2)

Units

IDDSB1 Static Supply Current 1.5 mA

IDDSBMF Standby Supply Current - Deselected 1.5 mA

IDDOPR Dynamic Supply Current, Selected 4.0 mA

II Input Leakage Current -1 +1 µA

IOZ Output Leakage Current -1 +1 µA

VIL Low-Level Input Voltage

CMOS 0.3xVDD V

TTL 0.8 V VDD = 4.5V

VIH High-Level Input Voltage

CMOS 0.7xVDD V

TTL 2.2 V VDD = 5.5V

VOL Low-Level Output Voltage

0.4 V VDD = 4.5V, IOL = 10 mA

0.05 V VDD = 4.5V, IOL = 200 µA

VOH High-Level Output Voltage

(1) Typical operating conditions: VDD= 5.0 V,TA=25°C, pre-radiation.

(2) Worst case operating conditions: VDD=4.5 V to 5.5 V, -55°C to +125°C, post total dose at 25°C.

(3) All inputs switching. DC average current.

4.2 V VDD = 4.5V, IOH = -5 mA

VDD-0.05 V VDD = 4.5V, IOH = -200 µA

Test Conditions

VIH=VDD IO=0

VIL=VSS Inputs Stable

NCS=VDD, IO=0,

f=40 MHz

f=1 MHz, IO=0, CE=VIH=VDD

NCS=VIL=VSS

VSS≤VI≤VDD

VSS≤VIO≤VDD

Output=high Z

2.9 V Valid high

249Ω

DUT

output

CL>

50 pF*

*CL = 5 pF for TWLQZ, TSHQZ, TELQZ, and TGHQZ

Tester Equivalent Load Circuit

Vref1

Vref2

+

-

+

-

output

Valid low

output

5

Page 6

HX6656

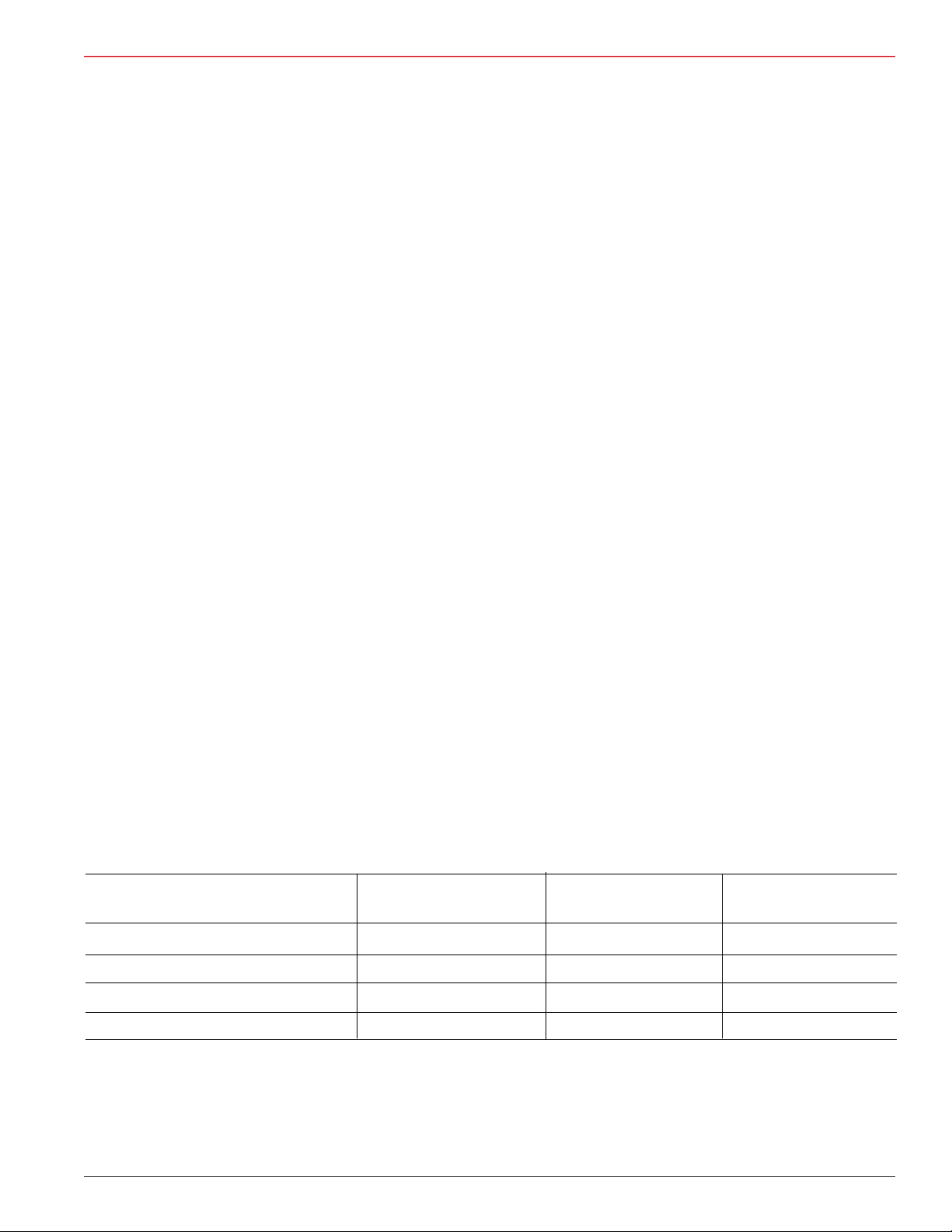

READ CYCLE AC TIMING CHARACTERISTICS (1)

Worst Case (3)

Symbol Parameter Typical -55 to 125°C Units

(2) Min Max

TAVAVR Address Read Cycle Time 25 ns

TAVQV Address Access Time 25 ns

TAXQX Address Change to Output Invalid Time 3 ns

TSLQV Chip Select Access Time 25 ns

TSLQX Chip Select Output Enable Time 5 ns

TSHQZ Chip Select Output Disable Time 10 ns

TEHQV Chip Enable Access Time (4) 25 ns

TEHQX Chip Enable Output Enable Time (4) 5 ns

TELQZ Chip Enable Output Disable Time (4) 10 ns

TGLQV Output Enable Access Time 9 ns

TGLQX Output Enable Output Enable Time 0 ns

TGHQZ Output Enable Output Disable Time 9 ns

(1) Test conditions: input switching levels VIL/VIH=0.5V/VDD-0.5V (CMOS), VIL/VIH=0V/3V (TTL), input rise and fall times <1 ns/V, input and

output timing reference levels shown in the Tester AC Timing Characteristics table, capacitive output loading C

capacitive output loading CL=5 pF for TSHQZ, TELQZ TGHQZ. For CL >50 pF, derate access times by 0.02 ns/pF (typical).

(2) Typical operating conditions: VDD=5.0 V, TA=25°C, pre-radiation.

(3) Worst case operating conditions: VDD=4.5 V to 5.5 V, -55°C to +125°C, post total dose at 25°C.

(4) Chip Enable (CE) pin not available on 28-lead FP or DIP.

T

AVAVR

>50 pF, or equivalent

L

ADDRESS

T

AVQV

T

SLQV

T

AXQX

NCS

T

DATA OUT

HIGH

IMPEDANCE

SLQX

DATA VALID

T

SHQZ

CE

NOE

T

T

EHQX

EHQV

T

GLQX

T

GLQV

T

ELQZ

T

GHQZ

6

Page 7

DYNAMIC ELECTRICAL CHARACTERISTICS

Read Cycle

The ROM is asynchronous in operation, allowing the read

cycle to be controlled by address, chip select (NCS), or chip

enable (CE) (refer to Read Cycle timing diagram). To

perform a valid read operation, both chip select and output

enable (NOE) must be low and chip enable must be high.

The output drivers can be controlled independently by the

NOE signal. Consecutive read cycles can be executed with

NCS held continuously low, and with CE held continuously

high, and toggling the addresses.

For an address activated read cycle, NCS and CE must be

valid prior to or coincident with the activating address edge

transition(s). Any amount of toggling or skew between

address edge transitions is permissible; however, data

outputs will become valid TAVQV time following the latest

occurring address edge transition. The minimum address

activated read cycle time is TAVAV. When the ROM is

operated at the minimum address activated read cycle

time, the data outputs will remain valid on the I/O until

TAXQX time following the next sequential address transition.

HX6656

To control a read cycle with NCS, all addresses and CE

must be valid prior to or coincident with the enabling NCS

edge transition. Address or CE edge transitions can occur

later than the specified setup times to NCS, however, the

valid data access time will be delayed. Any address edge

transition, which occurs during the time when NCS is low,

will initiate a new read access, and data outputs will not

become valid until TAVQV time following the address edge

transition. Data outputs will enter a high impedance state

TSHQZ time following a disabling NCS edge transition.

To control a read cycle with CE, all addresses and NCS

must be valid prior to or coincident with the enabling CE

edge transition. Address or NCS edge transitions can

occur later than the specified setup times to CE; however,

the valid data access time will be delayed. Any address

edge transition which occurs during the time when CE is

high will initiate a new read access, and data outputs will

not become valid until TAVQV time following the address

edge transition. Data outputs will enter a high impedance

state TELQZ time following a disabling CE edge transition.

7

Page 8

HX6656

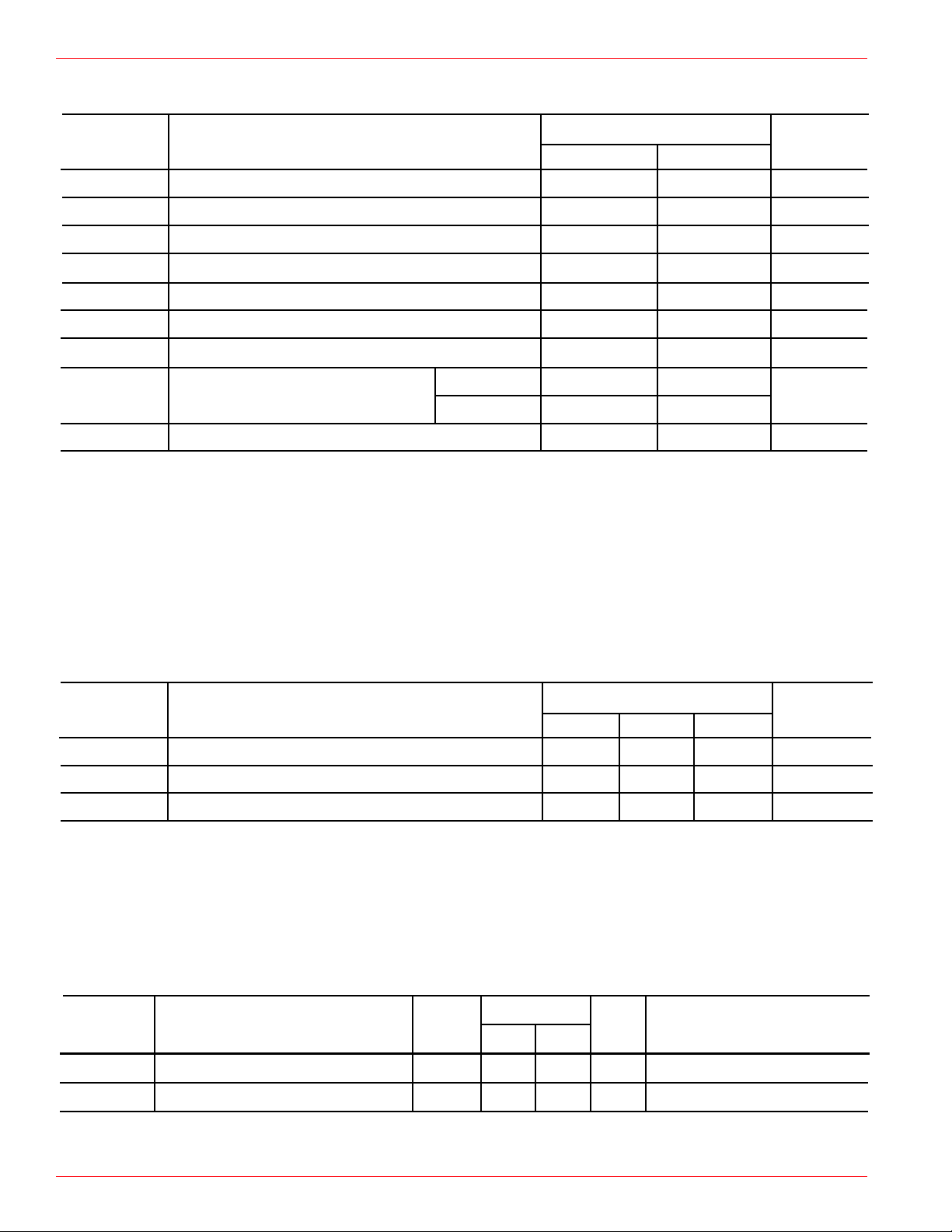

TESTER AC TIMING CHARACTERISTICS

TTL I/O Configuration

3 V

Input

Levels*

0 V

Output

Sense

Levels

High Z

High Z = 2.9V

3.4 V

2.4 V

* Input rise and fall times <1 ns/V

QUALITY AND RADIATION HARDNESS

ASSURANCE

VDD-0.4V

0.4 V

1.5 V

1.5 V

High Z

CMOS I/O Configuration

VDD-0.5 V

0.5 V

VDD/2

High Z

High Z = 2.9V

VDD-0.4V

3.4 V

2.4 V

0.4 V

High Z

VDD/2

Honeywell maintains a high level of product integrity through

process control, utilizing statistical process control, a complete “Total Quality Assurance System,” a computer data

base process performance tracking system, and a radiation-hardness assurance strategy.

The radiation hardness assurance strategy starts with a

technology that is resistant to the effects of radiation.

Radiation hardness is assured on every wafer by irradiating

test structures as well as product die, and then monitoring

key parameters which are sensitive to ionizing radiation.

Conventional MIL-STD-883C TM 5005 Group E testing,

which includes total dose exposure with Cobalt 60, may

also be performed as required. This Total Quality approach

ensures our customers of a reliable product by engineering

in reliability, starting with process development and continuing through product qualification and screening.

SCREENING LEVELS

Honeywell offers several levels of device screening to meet

your system needs. “Engineering Devices” are available

with limited performance and screening for breadboarding

and/or evaluation testing. Hi-Rel Level B and S devices

undergo additional screening per the requirements of MILSTD-883. As a QML supplier, Honeywell also offers QML

Class Q and V devices per MIL-PRF-38535 and are available per the applicable Standard Military Drawing (SMD).

QML devices offer ease of procurement by eliminating the

need to create detailed specifications and offer benefits of

improved quality and cost savings through standardization.

RELIABILITY

Honeywell understands the stringent reliability require

ments for space and defense systems and has extensive

experience in reliability testing on programs of this nature.

This experience is derived from comprehensive testing of

VLSI processes. Reliability attributes of the RICMOS

process were characterized by testing specially designed

irradiated and non-irradiated test structures from which

specific failure mechanisms were evaluated. These specific

mechanisms included, but were not limited to, hot carriers,

electromigration and time dependent dielectric breakdown.

This data was then used to make changes to the design

models and process to ensure more reliable products.

In addition, the reliability of the RICMOS

TM

process and

product in a military environment was monitored by testing

irradiated and non-irradiated circuits in accelerated dynamic life test conditions. Packages are qualified for product use after undergoing Groups B & D testing as outlined

in MIL-STD-883, TM 5005, Class S. The product is qualified

by following a screening and testing flow to meet the

customer’s requirements. Quality conformance testing is

performed as an option on all production lots to ensure the

ongoing reliability of the product.

TM

-

8

Page 9

PACKAGING

VSS

VDD

NWE

CE

A13

A8

A9

A11

NOE

A10

NCS

DQ7

DQ6

DQ5

DQ4

DQ3

VDD

VSS

VSS

VDD

A14

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

NC

VDD

VSS

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

Top

View

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

HX6656

The 32K x 8 ROM is offered in a custom 36-lead flat pack

(FP), 28-Lead FP, or standard 28-lead DIP. Each package

is constructed of multilayer ceramic (Al2O3) and features

internal power and ground planes. The 36-lead FP also

features a non-conductive ceramic tie bar on the lead

frame. The tie bar allows electrical testing of the device,

while preserving the lead integrity during shipping and

handling, up to the point of lead forming and insertion.

28-LEAD FP PINOUT

A14

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

VSS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Top

View

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VDD

NWE

A13

A8

A9

A11

NOE

A10

NCS

DQ7

DQ6

DQ5

DQ4

DQ3

Ceramic chip capacitors can be mounted to the package to

maximize supply noise decoupling and increase board

packing density. These capacitors attach directly to the

internal package power and ground planes. This design

minimizes resistance and inductance of the bond wire and

package. All NC (no connect) pins should be connected

to VSS to prevent charge build up in the radiation

environment.

36-LEAD FP PINOUT

36-LEAD FLAT PACK

E

22018131-001

1

b

Top

D

HGL L

Ceramic

Body

J

I

A

C M

X

VDD

F

1

1

VSS

P

View

Optional

Capacitors

O

T

R

Y

VDD

Kovar

Lid [3]

N

VSS

V

W

U

9

(width)

(pitch)

Non-

Conductive

Tie-Bar

S

e

0.004

All dimensions are in inches

A

0.095 ± 0.014

b

0.008 ± 0.002

C

0.005 to 0.0075

D

0.650 ± 0.010

E

0.630 ± 0.007

e

0.025 ± 0.002 [2]

F

0.425 ± 0.005 [2]

G

0.525 ± 0.005

H

0.135 ± 0.005

I

0.030 ± 0.005

J

0.080 typ.

L

0.285 ± 0.015

[1] Parts delivered with leads unformed

[2] At tie bar

[3] Lid tied to VSS

M

N

O

P

R

S

T

U

V

W

X

Y

[1]

0.008 ± 0.003

0.050 ± 0.010

0.090 ref

0.015 ref

0.075 ref

0.113 ± 0.010

0.050 ref

0.030 ref

0.080 ref

0.005 ref

0.450 ref

0.400 ref

Page 10

HX6656

28-LEAD FLAT PACK (22017842-001)

E

1

TOP

F

L

W

A

G

Q

VIEW

X

Y

Kovar

Lid [4]

E2

28-LEAD DIP (22017785-001)

Capacitor

Pads

Ceramic

Body

E3

C

b

(width)

e

(pitch)

U

Lead

Alloy 42 [3]

Index

D

BOTTOM

VIEW

S

All dimensions in inches

1

[1] BSC – Basic lead spacing between centers

[2] Where lead is brazed to package

[3] Parts delivered with leads unformed

[4] Lid connected to VSS

A

0.105 ± 0.015

b

0.017 ± 0.002

C

0.003 to 0.006

D

0.720 ± 0.008

e

0.050 ± 0.005 [1]

E

0.500 ± 0.007

E2

0.380 ± 0.008

E3

0.060 ref

F

0.650 ± 0.005 [2]

G

0.035 ± 0.004

L

0.295 min [3]

Q

0.026 to 0.045

S

0.045 ± 0.010

U

0.130 ref

W

0.050 ref

X

0.075 ref

Y

0.010 ref

For 28-Lead DIP description, see MIL-STD-1835, Type CDIP2-T28, Config. C, Dimensions D-10

10

Page 11

HX6656

DYNAMIC BURN-IN DIAGRAM*

VDD

1

A14

VSS

R

2

A12

R

3

A7

R

4

A6

R

5

A5

R

6

A4

R

7

A3

R

8

A2

R

9

A1

R

10

A0

R

11

DQ0

R

12

DQ1

R

13

DQ2

R

14

VSS

32K x 8 ROM

F16

F7

F6

F5

F4

F3

F2

F8

F13

F14

F1

F1

F1

VDD = 6.5V, R ≤ 10 KΩ, VIH = VDD, VIL = VSS

Ambient Temperature ≥ 125 °C, F0 ≥ 100 KHz Sq Wave

Frequency of F1 = F0/2, F2 = F0/4, F3 = F0/8, etc.

VDD

NC

A13

A8

A9

A11

NOE

A10

NCS

DQ7

DQ6

DQ5

DQ4

DQ3

28

27

R

26

25

24

23

22

21

20

19

18

17

16

15

F0

F15

R

R

F12

F11

R

R

F10

F17

R

R

F9

R

F17

R

F1

R

F1

R

F1

R

F1

R

F1

STATIC BURN-IN DIAGRAM*

VDD

1

R

R

R

R

R

R

R

R

R

R

R

R

R

VSS

A14

2

A12

3

A7

4

A6

5

A5

6

A4

7

A3

8

A2

9

A1

10

A0

11

DQ0

12

DQ1

13

DQ2

14

VSS

VDD = 5.5V, R ≤ 10 KΩ

Ambient Temperature ≥ 125 °C

28

VDD

27

NC

26

A13

25

A8

24

A9

23

A11

22

NOE

21

A10

20

NCS

19

DQ7

32K x 8 ROM

DQ6

DQ5

DQ4

DQ3

18

17

16

15

VDD

R

R

R

R

R

R

R

R

R

R

R

R

R

R

*36-lead Flat Pack burn-in diagrams have similar connections and are available on request.

ROM CODE

The ROM code can be provided to Honeywell via FTP, E-Mail or a variety of magnetic storage media, including

3.5 inch floppy disc, 4m digital tape and others.

The ROM Code data file should contain the following format:

<address> [/] <data> [;] [Comment]

Where items enclosed in ‘[‘and’]’ are optional.

The address and data must be hex numbers in the form, MSB...LSB. The “/” and the “;” are optional and any

characters after the “#” are comments. For example the following input file, all of the lines are valid:

000 d4

001 / 32

002 1d

003 / 72;

4/5e; # all of these lines are in valid format

11

Page 12

HX6656

ORDERING INFORMATION (1)

H

SOURCE

H=HONEYWELL

(1) Orders may be faxed to 612-954-2051. Please contact our Customer Logistics Department at 612-954-2888 for further information.

(2) Engineering Device description: Parameters are tested from -55 to 125°C, 24 hr burn-in, no radiation guaranteed.

Contact Factory with other needs.

X

PROCESS

X=SOI

6656

PART NUMBER

PACKAGE DESIGNATION

N=28-Lead FP

R=28-Lead DIP

X=36-Lead FP

K=Known Good Die

- = Bare die (No Package)

N

S

SCREEN LEVEL

V=QML Class V

Q=QML Class Q

S=Level S

B=Level B

E=Engr Device (2)

R=1x105 rad(SiO2)

F=3x105 rad(SiO2)

H=1x106 rad(SiO2)

N=No Level Guaranteed

H

TOTAL DOSE

HARDNESS

C

INPUT

BUFFER TYPE

C=CMOS Level

T=TTL Level

To learn more about Honeywell Solid State Electronics Center,

visit our web site at http://www.ssec.honeywell.com

Honeywell reserves the right to make changes to any products or technology herein to improve reliability, function or design. Honeywell does not assume any liability

arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of others.

Helping You Control Your World

900154

2/96

Loading...

Loading...