Honeywell HX6356 User Manual

查询HX6356供应商

Aerospace Electronics

32K x 8 STATIC RAM—SOI HX6356

FEATURES

RADIATION

• Fabricated with RICMOS™ IV Silicon on Insulator (SOI)

0.75 µm Process (L

= 0.6 µm)

eff

• Total Dose Hardness through 1x106rad(SiO2)

• Neutron Hardness through 1x1014 cm

-2

• Dynamic and Static Transient Upset Hardness

through 1x1011 rad(Si)/s

12

• Dose Rate Survivability through 1x10

• Soft Error Rate of <1x10

-10

upsets/bit-day

rad(Si)/s

in Geosynchronous Orbit

• Latchup Free

GENERAL DESCRIPTION

The 32K x 8 Radiation Hardened Static RAM is a high

performance 32,768 word x 8-bit static random access

memory with industry-standard functionality. It is fabricated

with Honeywell’s radiation hardened technology, and is

designed for use in systems operating in harsh, transient

radiation environments. The RAM operates over the full

military temperature range and requires only a single 5 V ±

10% power supply. The RAM is available with either TTL or

CMOS compatible I/O. Power consumption is typically less

than 15 mW/MHz in operation, and less than 5 mW when

de-selected. The RAM read operation is fully asynchronous, with an associated typical access time of 14 ns at 5V.

OTHER

• Listed On SMD# 5962-95845

• Fast Read/Write Cycle Times

≤ 17 ns (Typical)

≤ 25 ns (-55 to 125°C)

• Typical Operating power < 15 mW/MHz

• Asynchronous Operation

• CMOS or TTL Compatible I/O

• Single 5 V ± 10% Power Supply

• Packaging Options

- 36-Lead CFP—Bottom Braze (0.630 in. x 0.650 in.)

- 36-Lead CFP—Top Braze (0.630 in. x 0.650 in.)

Honeywell’s enhanced SOI RICMOS™IV (Radiation Insensitive CMOS) technology is radiation hardened through the

use of advanced and proprietary design, layout and process hardening techniques. The RICMOS™ IV process is a

5-volt, SIMOX CMOS technology with a 150 Å gate oxide

and a minimum drawn feature size of 0.75 µm (0.6 µm

effective gate length—L

). Additional features include

eff

tungsten via plugs, Honeywell’s proprietary SHARP planarization process, and a lightly doped drain (LDD) structure for improved short channel reliability. A 7 transistor

(7T) memory cell is used for superior single event upset

hardening, while three layer metal power bussing and the

low collection volume SIMOX substrate provide improved

dose rate hardening.

HX6356

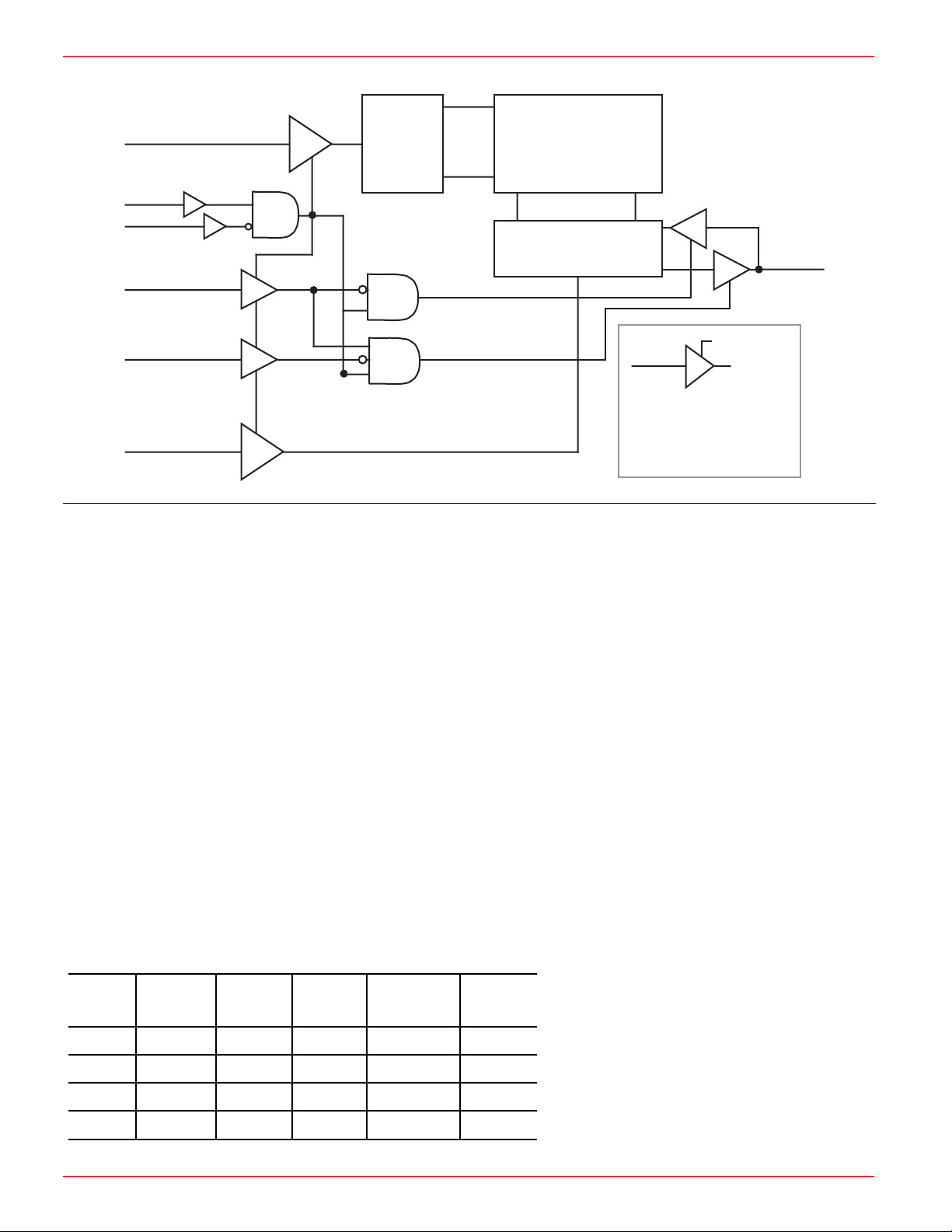

FUNCTIONAL DIAGRAM

A:0-8,12-13

CE

NCS

NWE

NOE

A:9-11, 14

SIGNAL DEFINITIONS

32,768 x 8

Memory

Array

• • •

Column Decoder

Data Input/Output

8

DQ:0-7

11

Row

Decoder

•

•

•

8

WE • CS • CE

NWE • CS • CE • OE

(0 = high Z)

Signal

1 = enabled

Signal

#

All controls must be

enabled for a signal to

4

pass. (#: number of

buffers, default = 1)

A: 0-14 Address input pins which select a particular eight-bit word within the memory array.

DQ: 0-7 Bidirectional data pins which serve as data outputs during a read operation and as data inputs during a write

operation.

NCS Negative chip select, when at a low level allows normal read or write operation. When at a high level NCS

forces the SRAM to a precharge condition, holds the data output drivers in a high impedance state and

disables all input buffers except CE. If this signal is not used it must be connected to VSS.

NWE Negative write enable, when at a low level activates a write operation and holds the data output drivers in a

high impedance state. When at a high level NWE allows normal read operation.

NOE Negative output enable, when at a high level holds the data output drivers in a high impedance state. When

at a low level, the data output driver state is defined by NCS, NWE and CE. If this signal is not used it must

be connected to VSS.

CE Chip enable, when at a high level allows normal operation. When at a low level CE forces the SRAM to a

precharge condition, holds the data output drivers in a high impedance state and disables all the input buffers

except the NCS input buffer. If this signal is not used it must be connected to VDD.

TRUTH TABLE

NCS CE NWE NOE MODE DQ

L H H L Read Data Out

L H L X Write Data In

H X XX XX Deselected High Z

X L XX XX Disabled High Z

Notes:

X: VI=VIH or VIL

XX: VSS≤VI≤VDD

NOE=H: High Z output state maintained for

NCS=X, CE=X, NWE=X

2

RADIATION CHARACTERISTICS

HX6356

Total Ionizing Radiation Dose

The SRAM will meet all stated functional and electrical

specifications over the entire operating temperature range

after the specified total ionizing radiation dose. All electrical

and timing performance parameters will remain within

specifications after rebound at VDD = 5.5 V and T =125°C

extrapolated to ten years of operation. Total dose hardness

is assured by wafer level testing of process monitor transistors and RAM product using 10 keV X-ray and Co60

radiation sources. Transistor gate threshold shift correlations have been made between 10 keV X-rays applied at a

dose rate of 1x105 rad(SiO2)/min at T = 25°C and gamma

rays (Cobalt 60 source) to ensure that wafer level X-ray

testing is consistent with standard military radiation test

environments.

Transient Pulse Ionizing Radiation

The SRAM is capable of writing, reading, and retaining

stored data during and after exposure to a transient

ionizing radiation pulse up to the transient dose rate upset

specification, when applied under recommended operating conditions. To ensure validity of all specified performance parameters before, during, and after radiation

(timing degradation during transient pulse radiation (timing degradation during transient pulse radiation is ≤10%),

it is suggested that stiffening capacitance be placed on or

near the package VDD and VSS, with a maximum inductance between the package (chip) and stiffening capacitance of 0.7 nH per part. If there are no operate-through

or valid stored data requirements, typical circuit board

mounted de-coupling capacitors are recommended.

The SRAM will meet any functional or electrical specification after exposure to a radiation pulse up to the transient

dose rate survivability specification, when applied under

recommended operating conditions. Note that the current

conducted during the pulse by the RAM inputs, outputs,

and power supply may significantly exceed the normal

operating levels. The application design must accommodate these effects.

Neutron Radiation

The SRAM will meet any functional or timing specification

after exposure to the specified neutron fluence under

recommended operating or storage conditions. This assumes an equivalent neutron energy of 1 MeV.

Soft Error Rate

The SRAM has an extremely low Soft Error Rate (SER) as

specified in the table below. This hardness level is defined

by the Adams 90% worst case cosmic ray environment.

The low SER is achieved by the use of a unique 7-transistor

memory cell and the oxide isolation of the SOI substrate.

Latchup

The SRAM will not latch up due to any of the above radiation

exposure conditions when applied under recommended

operating conditions. Fabrication with the SIMOX substrate

material provides oxide isolation between adjacent PMOS

and NMOS transistors and eliminates any potential SCR

latchup structures. Sufficient transistor body tie connections to the p- and n-channel substrates are made to ensure

no source/drain snapback occurs.

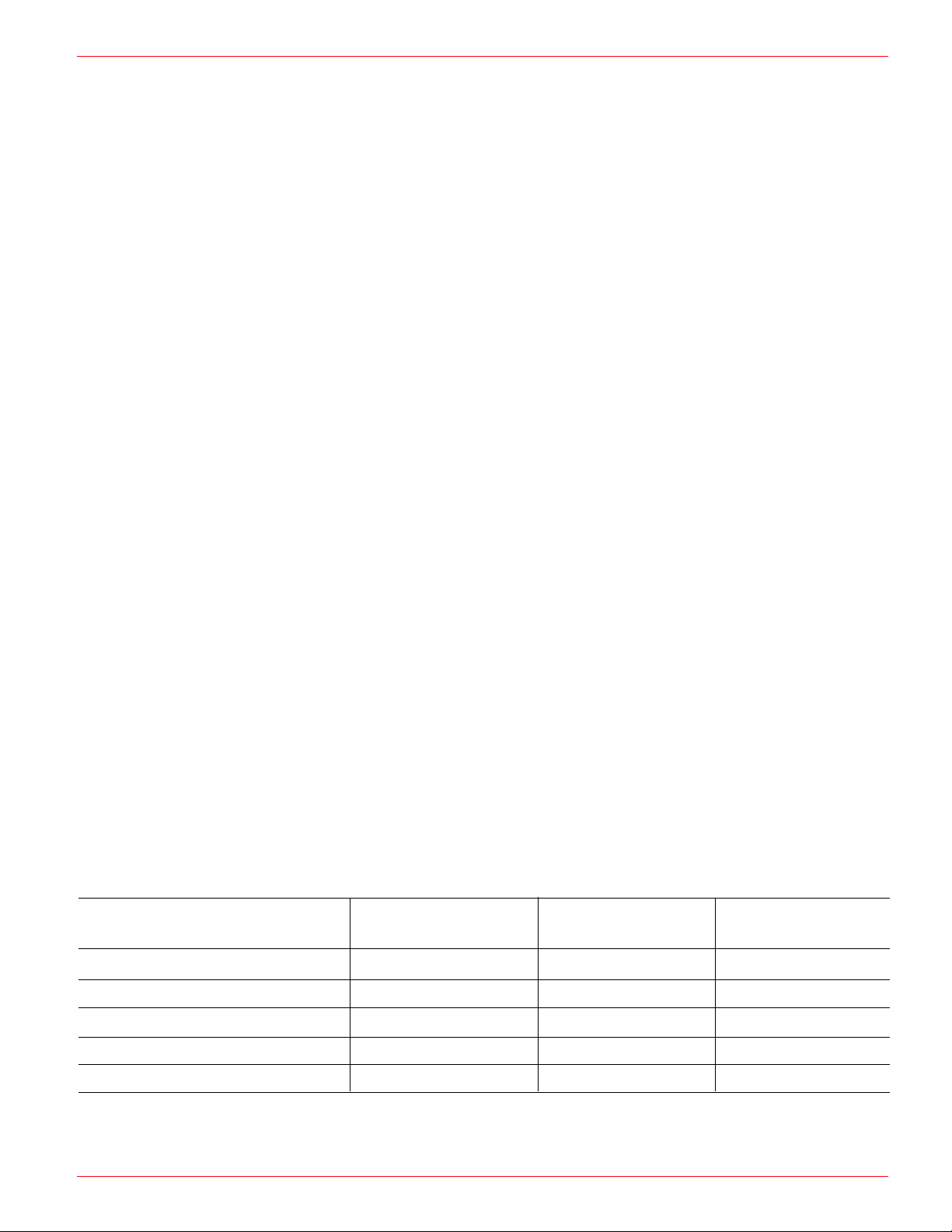

RADIATION HARDNESS RATINGS (1)

Parameter

Total Dose ≥1x10

Transient Dose Rate Upset ≥1x10

Transient Dose Rate Survivability ≥1x10

Soft Error Rate <1x10

Neutron Fluence ≥1x10

(1) Device will not latch up due to any of the specified radiation exposure conditions.

(2) Operating conditions (unless otherwise specified): VDD=4.5 V to 5.5 V, -55°C to 125°C.

Limits (2) Test Conditions

6

11

12

-10

14

3

Units

rad(SiO2)

rad(Si)/s

rad(Si)/s

upsets/bit-day

2

N/cm

TA=25°C

Pulse width ≤1 µs

Pulse width ≤50 ns, X-ray,

VDD=6.0 V, T

TA=125°C, Adams 90%

worst case environment

1 MeV equivalent energy,

Unbiased, T

A=25°C

A=25°C

HX6356

ABSOLUTE MAXIMUM RATINGS (1)

Rating

Symbol

Parameter

Min

Max

Units

VDD Positive Supply Voltage (2) -0.5 6.5 V

VPIN Voltage on Any Pin (2) -0.5 VDD+0.5 V

TSTORE Storage Temperature (Zero Bias) -65 150 °C

TSOLDER Soldering Temperature (5 Seconds) 270 °C

PD Total Package Power Dissipation (3) 2.0 W

IOUT DC or Average Output Current 25 mA

VPROT ESD Input Protection Voltage (4) 2000 V

ΘJC Thermal Resistance (Jct-to-Case) – 36 FP 2 °C/W

TJ Junction Temperature 175 °C

(1) Stresses in excess of those listed above may result in permanent damage. These are stress ratings only, and operation at these levels is not

implied. Frequent or extended exposure to absolute maximum conditions may affect device reliability.

(2) Voltage referenced to VSS.

(3) RAM power dissipation (IDDSB + IDDOP) plus RAM output driver power dissipation due to external loading must not exceed this specification.

(4) Class 2 electrostatic discharge (ESD) input protection. Tested per MIL-STD-883, Method 3015 by DESC certified lab.

RECOMMENDED OPERATING CONDITIONS

Symbol

Parameter

Min

MaxTyp

VDD Supply Voltage (referenced to VSS) 4.5 5.0 5.5 V

TA Ambient Temperature -55 25 125 °C

VPIN Voltage on Any Pin (referenced to VSS) -0.3 VDD+0.3 V

CAPACITANCE (1)

Description

Symbol

Parameter

Typical

(1)

CI Input Capacitance 7 pF VI=VDD or VSS, f=1 MHz

CO Output Capacitance 9 pF VIO=VDD or VSS, f=1 MHz

(1) This parameter is tested during initial design characterization only.

Worst Case

Min

Max

Units

Test Conditions

DATA RETENTION CHARACTERISTICS

Symbol

Parameter

Typical

(1)

Worst Case

Min

VDR Data Retention Voltage 2.5 V

IDR Data Retention Current

(1) Typical operating conditions: TA= 25°C, pre-radiation.

(2) Worst case operating conditions: -55°C to +125°C, post total dose at 25°C.

(2)

Units

Test Conditions

Max

NCS=VDR

VI=VDR or VSS

500 µA NCS=VDD=2.5V, VI=VDD or VSS

330 µA NCS=VDD=3.0V, VI=VDD or VSS

Units

4

Loading...

Loading...