Page 1

H808C

Convertible Dehumidifier Controller

Application

The H808C Dehumidifier Controller provides automatic

low voltage control of dehumidifiers in central heating

systems. The humidity controller has an spst, snap-acting,

dust-proof switch and is designed for wall or surface duct

mounting.

MODELS:

■ H808C1029: Premier White™.

■ H808C1037: Beige.

ELECTRICAL RATING: 50 VA at 24 Vac.

MAXIMUM AMBIENT TEMPERATURE: 125° F [52° C].

SWITCH DIFFERENTIAL: 5 percent RH, nonadjustable.

SET POINT ADJUSTMENT RANGE: 20 to 80 percent

RH; positive ON and OFF positions.

Installation

CAUTION

1. Installer must be a trained, experienced service

technician.

2. Disconnect power supply before beginning

installation.

3. Conduct a thorough checkout before leaving

installation.

WALL MOUNTING

1. Locate the humidity controller about 5 ft [1.5m]

above the floor on an inside wall.

NOTES:

a. Be sure the humidity controller is subject to average

room temperature and average relative humidity.

The maximum temperature at the location selected

must not exceed 125° F [52° C].

b. The humidity controller can be mounted directly on

the wall.

2. Drill a small hole in the wall.

3. Run low voltage wiring to the location and pull about

6 in. [152 mm] of wire through the hole.

NOTE: Plug the opening to prevent drafts from affecting

humidity controller operation.

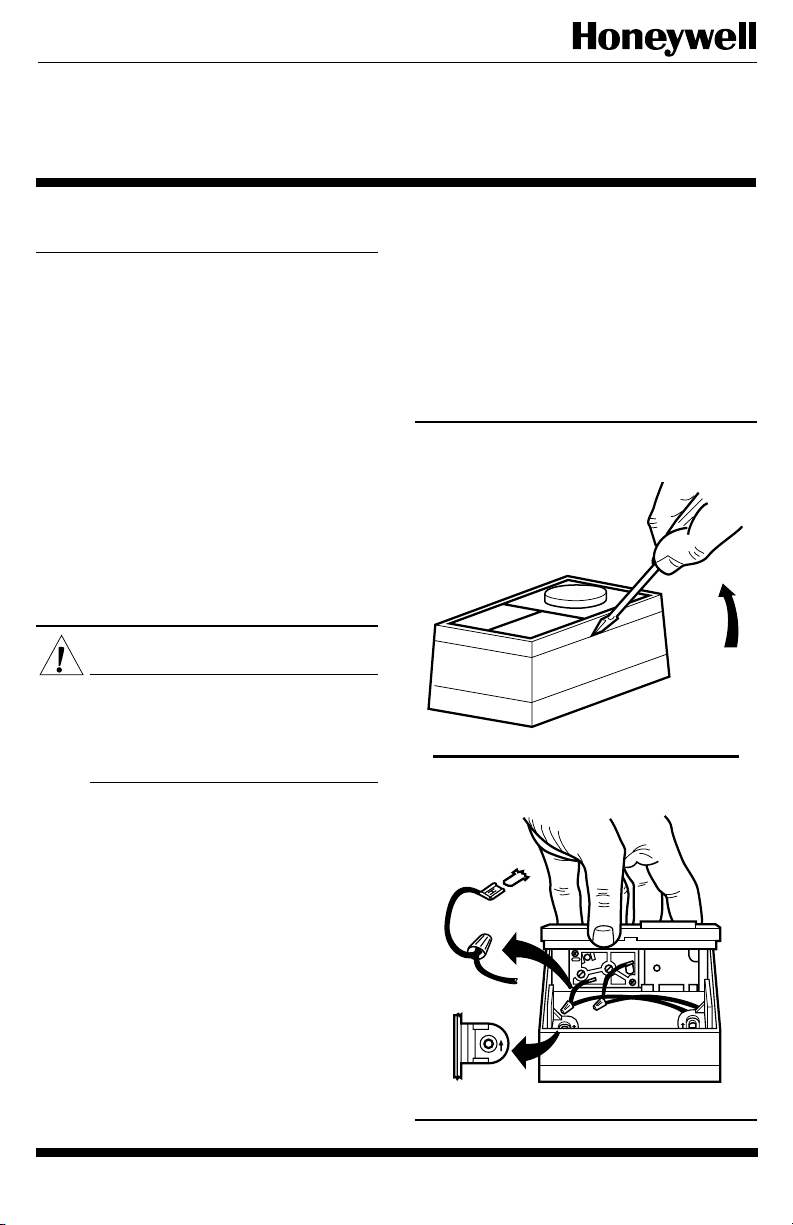

4. Remove the humidity controller assembly by prying

with a screwdriver in the notch on the bottom of the case

(Fig. 1).

5. Position the case horizontally over the wires with the

arrows on the tabs pointing up and secure the case to the

wall using the two screws provided.

6. Connect the wires to the humidity controller assembly using leadwires and wire nuts provided (see Wiring

section and Fig. 2).

7. Tuck the wires into the bottom of the case.

8. Snap the cover assembly into the case (Fig. 2).

Fig. 1—Removing humidity controller assembly

from case.

M9262

Fig. 2—Wiring connections on humidity

controller.

QUICK-CONNECT

WIRE LEAD

UP

MOUNTING

HOLE (2)

COVER

CASE

UP

UP

M9263

WIRE

NUT

HUMIDIFIER

LEADWIRE

1 69-0821

J.F. • 3-94 • ©Honeywell Inc. 1994 • Form Number 69-0821

Page 2

DUCT MOUNTING

1. Locate the humidity controller at least 8 in. [203 mm]

upstream of the humidifier in the return air duct.

NOTE: If mounting near an elbow area, keep the humidity

controller 6 in. [152 mm] upstream of the elbow so the

element will be affected by the normal airflow (Fig. 3)

.

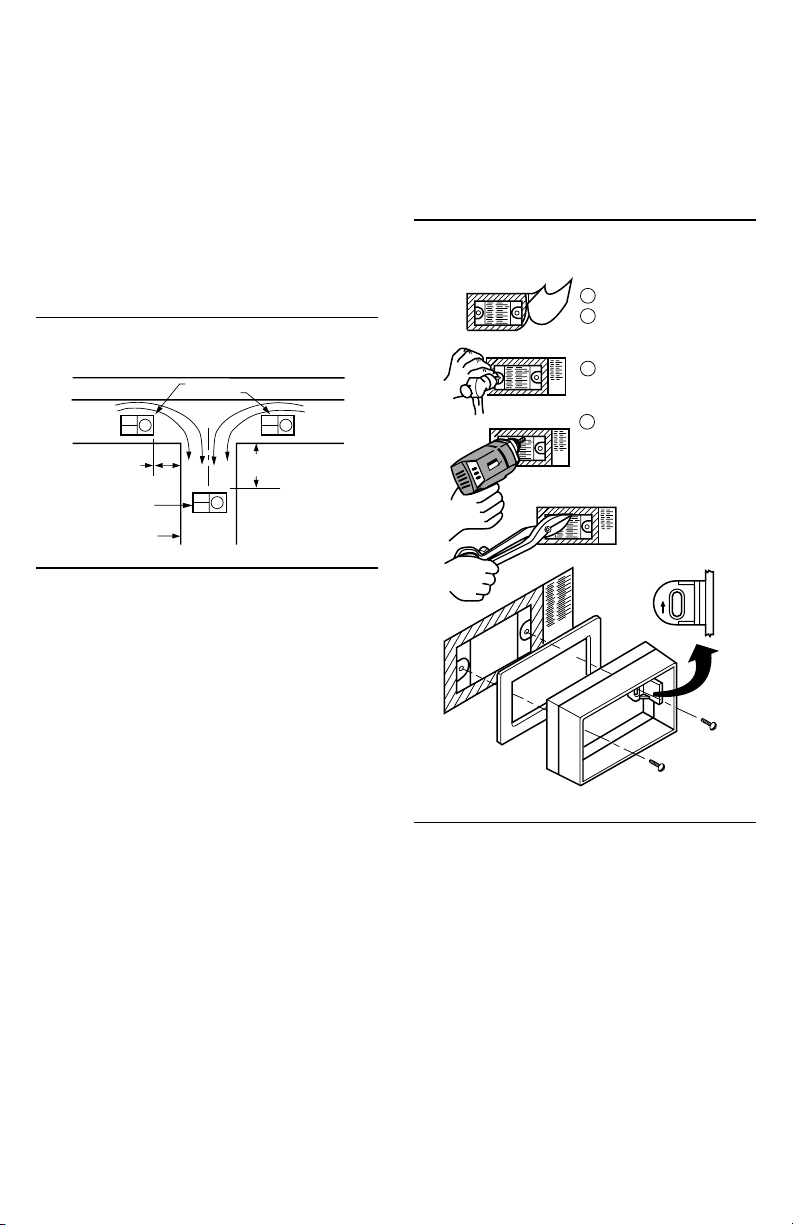

2. Using Fig. 4 and the instructions on the template,

drill two mounting holes (3/32 in. [2.4 mm]) and 12 sensing

holes (1/4 in. [6.4 mm] in diameter) in the duct. (The

sensing holes allow return air to reach the nylon sensing

element and operate the humidity controller.)

NOTE: If desired, cut a square hole in the duct as indicated

on the template in place of the sensing holes.

Fig. 3—Selecting a duct location for the humidity controller.

ALTERNATE

RETURN

AIR

6 in. [152 mm]

MINIMUM

BEST LOCATION

RETURN AIR DUCT

LOCATIONS

15 in. [381 mm]

MINIMUM

RETURN

AIR

M9277

7. While holding wire in place, mount the case on the

duct using the two mounting screws provided.

NOTE: Tighten the screws firmly so the gasket seals the

space between the case and the duct (Fig. 4).

8. Connect the wires to the humidity controller assembly using leadwires and wire nuts supplied (see Wiring

section and Fig. 2).

9. Snap cover assembly into the case.

Fig. 4—Mounting humidity controller on return

air duct.

LOCATE TEMPLATE.

1

2

PEEL BACKING

FROM TEMPLATE

AND APPLY TO DUCT.

3

PUNCH AND DRILL

TWO 3/32 IN. [3 mm]

MOUNTING HOLES.

DRILL MINIMUM

4

OF TWELVE

1/4 IN. [7 mm] HOLES.

OR

DRILL OR PUNCH

CORNER HOLES AND

CUT OUT SQUARE

ON SOLID LINE.

3. Remove the protective backing from the foam gasket

included with each control and apply the foam gasket to the

template in the location indicated.

4. Remove the cover and humidity controller assembly

from the case by prying with a screwdriver in the notch in

the bottom of the case (Fig. 1).

5. Run low voltage wire from the humidity controller to

the template (Figs. 5 and 6).

6. Lay wire over one side of the foam gasket allowing

about 6 in. [152 mm] for connection to the humidity controller. Wire can enter the humidity controller case from

any direction.

NOTE: Do not position wire directly under the two stand-

off projections at the back of the case. If wire is under

these projections, the case will not seat tightly against

the gasket, causing air leakage and possible improper

operation.

CASE

TEMPLATE

GASKET

UP

M9264

69-0821 2

Page 3

Fig. 5—Typical parallel wiring diagram of H808C with T87F/Q539A combination for dehumidification

and mildew control.

H808C

T87F/Q539A INTERNALSCHEMATIC

FILTER

LIGHT

HEAT OFF FANAUTO ONCOOL

3 2

BX O

PROVIDE OVERLOAD PROTECTION AND DISCONNECT MEANS

1

AS REQUIRED.

HEATING DAMPER MOTOR, IF USED.

2

3

CLOGGED FILTER SWITCH OR COOLING PANEL CONNECTION.

Fig. 6—Typical series wiring diagram of H808C with T87F/Q539A combination for dehumidification and

mildew control.

H808C

FILTER

LIGHT

R1

T87F/Q539A INTERNALSCHEMATIC

R1

T87F

TEMPERATURE

FALL

W1 Y1

HEAT OFF COOL

W Y

HEATING

RELAY OR

VALVE COIL

COOLING

CONTACTOR

COIL

T87F

TEMPERATURE

FALL

W1 Y1

FIXED

COOL

ANTICIPATOR

G RHR

FAN RELAY

COIL

FIXED

COOL

ANTICIPATOR

ADJUSTABLE

HEAT

ANTICIPATOR

ADJUSTABLE

HEAT

ANTICIPATOR

1

M18627

HEAT OFF FANAUTO ONCOOL

3 2

BX O

PROVIDE OVERLOAD PROTECTION AND DISCONNECT MEANS

1

AS REQUIRED.

HEATING DAMPER MOTOR, IF USED.

2

3

CLOGGED FILTER SWITCH OR COOLING PANEL CONNECTION.

HEAT OFF COOL

W Y

HEATING

RELAY OR

VALVE COIL

COOLING

CONTACTOR

COIL

G RHR

FAN RELAY

COIL

1

M18626

3 69-0821

Page 4

Fig. 7—Typical wiring diagram for H46C,E.

1

L1

(HOT)

L2

POWER SUPPLY. PROVIDE DISCONNECT MEANS

1

AND OVERLOAD PROTECTION AS REQUIRED.

HUMIDITY

RISE

H46C, E CONTROLLER

DEHUMIDIFIER

EXHAUST FAN

OR AIR

CONDITIONER

M9297

WIRING

All wiring must comply with local codes and ordinances. Make wiring connections according to to dehumidifier instructions if available; otherwise, see typical

wiring diagrams in Figs. 5 and 6.

Settings

HUMIDITY CONTROLLER ADJUSTMENT

The humidity comfort range of a living space is generally between 25 and 50 percent RH. However, as the

outdoor temperature changes, the humidity level on the

humidity controller may need to be reset to assure maximum comfort.

To reduce the relative humidity, reduce the set point approximately three percent RH every 24 hours. To increase

the relative humidity, increase the set point approximately

three percent RH every 24 hours.

WALL MOUNT HUMIDITY CONTROLLER

Set the humidity set point according to the prevailing

outdoor temperature to provide optimum relative humidity

control for most installations. Adjust the humidity level to

a particular structure using the procedure above.

DUCT MOUNT HUMIDITY CONTROLLER

If the temperature at the humidity controller location

on the return air duct is less than 80° F [27° C] ,use the

procedure for wall mounted humidity controllers.

If the air surrounding the humidity controller is greater

than 80° F [27° C], reset the recommended settings to

compensate for the higher ambient temperature. High ambient temperatures will cause the humidity controller to control

at an increased setting. To determine the compensated set

point for surface mounted humidity controllers with high

ambient temperatures, use the following procedure:

1. With a bulb type thermometer, accurately determine

the surrounding duct temperature at the humidity controller

location.

2. Decrease the recommended setting about five percent

for each 5° F [3° C] above 80° F [27° C] at the humidity

controller.

For example, if the humidity controller is set at 25 per-

cent and the temperature at the humidity controller is 90° F

[32° C], the compensated set point should be 15 percent.

(This is the 25 percent setting less 10 percent for the 10° F

[6° C] above ambient temperature.)

Checkout

Place the system in operation and observe through at

least one complete cycle to make certain that all components are functioning properly.

Home and Building Control Home and Building Control Helping You Control Your World

Honeywell Inc. Honeywell Limited—Honeywell Limitée

1985 Douglas Drive North 740 Ellesmere Road

Golden Valley, MN 55422 Scarborough, Ontario

69-0821 4

Printed in U.S.A.

M1P 2V9

QUALITY IS KEY

Loading...

Loading...