Page 1

H7625B; H7635B,C; H7655B

Duct-Mount and Outdoor-Mount

Humidity/Temperature Sensors

INSTALLATION INSTRUCTIONS

APPLICATION

The H7625B, H7635B, H7655B Duct-Mount and H7635C

Outdoor-Mount Humidity/Temperature Sensors are

universal Relative Humidity transmitters that can be

powered with either a +18 to 36 Vdc or 24 Vac supply.

The sensors use a half-wave bridge rectifier to convert

AC power to a usable DC voltage. The device also

includes a 20K ohm temperature sensor for optional use.

The humidity sensors are designed with a fieldselectable 4to20 mA, 0to5Vdc, or 0to10Vdc output

signal equivalent to 0 to 100% RH. All units are shipped

from the factory with a default setting to accept AC power

with three-wire, 0 to 10 Vdc loop-powered output.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check ratings given in instructions and on the

product to ensure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage

Hazard.

Can shock individuals or short equipment

circuitry.

Disconnect power supply before installation.

Mounting

The method of mounting depends on the particular

sensor application. The following procedures include

outdoor and duct applications. Also refer to the

instructions for the electronic control.

Duct Mounting

The H7625B, H7635B and H7655B can be mounted in a

duct to sense humidity and temperature.

IMPORTANT

Select a location to expose sensor to average

duct humidity and temperature. Avoid locations

where stratification can cause sensing errors.

NOTES:

— H7635C is weatherproof for outdoor use.

Knockouts allow 1/2 in. conduit connection.

— To avoid damaging board during installation,

the cover can be detached completely:

1.Carefully remove wire plug from board.

1. Cut a hole in the duct just large enough to accept

2. Open case by rotating the cover counterclockwise.

3. Mount standard 1/2 in. conduit to the case.

4. Use case to mark mounting screw pilot hole

5. Drill the pilot holes and fasten the sensor to the

6. Wire the sensor. See Wiring section.

7. Reattach the wire plug and cover being careful not

2.Set the cover aside.

the sensing element.

locations.

duct.

NOTE: The two free wires are thermistor wiring

connections. When connecting these, use

two wire nuts.

to pinch wires between the cover and case.

CAUTION

Equipment Damage Hazard.

Improper wiring can damage the sensor

beyond repair.

Follow the wiring instructions carefully.

63-2579—3

Page 2

H7625B; H7635B,C; H7655B DUCT-MOUNT AND OUTDOOR-MOUNT HUMIDITY/TEMPERATURE SENSORS

Outdoor Mounting

The H7635C senses outdoor air humidity and

temperature. Mount this control where it can sense

average outdoor air humidity and temperature. Normally,

the north side of a building provides a suitable location.

NOTES:

— H7635C is weatherproof for outdoor use.

Knockouts allow 1/2 in. conduit connection.

— To avoid damaging board during installation,

the cover can be detached completely:

1.Carefully remove wire plug from board.

2.Set the cover aside.

1. Open case by rotating the cover counterclockwise.

NOTE: Orient case so the element points down.

2. Mount standard 1/2 in. conduit to the case.

3. Use case to mark mounting screw pilot hole

locations.

4. Drill pilot holes.

5. Fasten the case to the wall.

6. Wire the sensor. See Wiring section.

NOTE: The two free wires are thermistor wiring

connections. When connecting these, use

two wire nuts.

7. Reattach the wire plug and cover being careful not

to pinch wires between the cover and case.

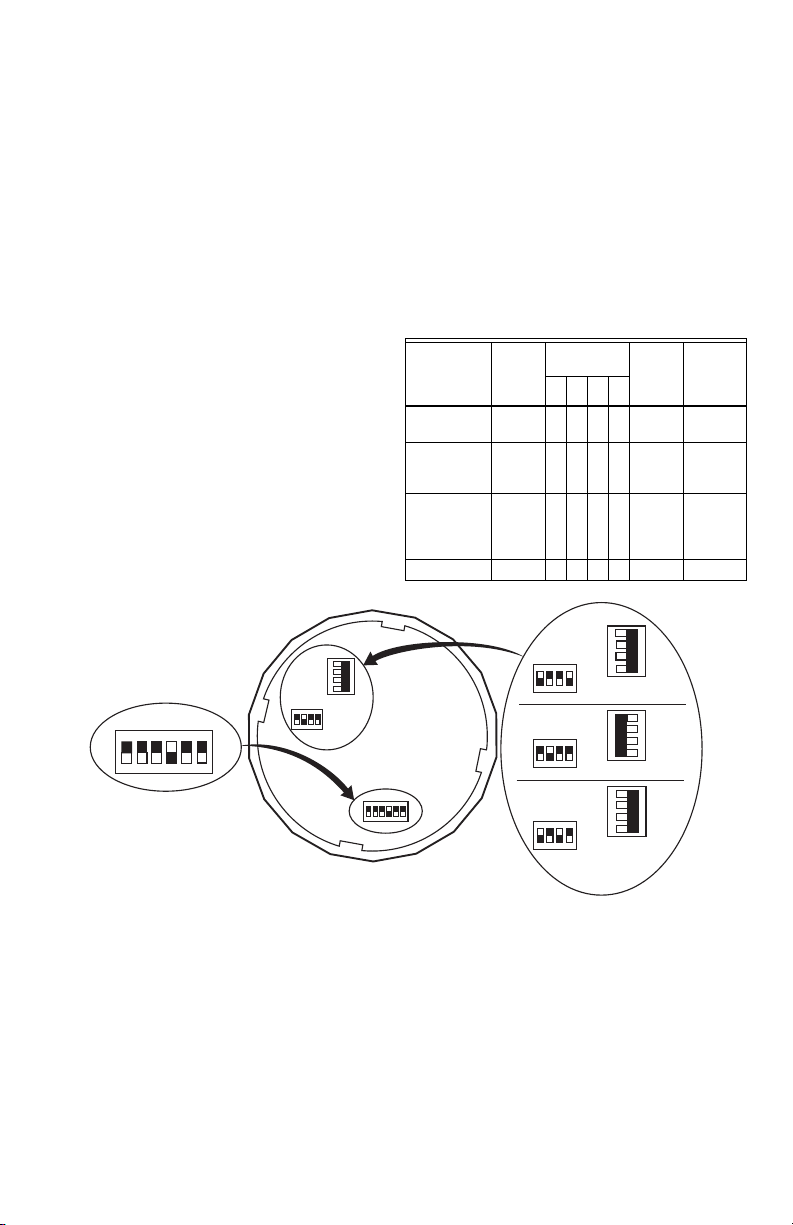

Output Settings (Table 1)

The board has three switch blocks:

— A six DIP switch block.

— A four DIP switch block.

— A white gang switch on a blue block.

1. Adjust the 4-switch block according to Table 1.

NOTE: The 6-switch block normally requires no

adjustment. (See the Appendix.)

2. Set the gang switch (white switch in blue block) to

correspond with the output (mA or Vdc).

NOTE: See Fig. 1 for DIP switch locations.

Table 1. Controller Compatibility

and Output Settings.

Required

4-Switch Block

Controller

W7750, W7760,

W7761

W7750B,C

W7760C,

W7753, W7760

T7350, XL50,

XL100,

XL500 XF

Modules, XFL

Sensor

Output

Setting

4-20 mA — On — — 4-20 mA C7600C

0-10 Vdc

(default)

0-10 Vdc

(default)

Settings

On — — On Vout H7621/31

On — — On Vout n/a

Non-Honeywell 0-5 Vdc On — On — Vout n/a

Blue and

White

Output

Switch

ONSPEC™

L

Setting4321

NORMAL OPERATION

OFF

ON

Fig. 1. DIP switch locations and settings.

63-2579—3 2

OFF

ON

OFF

ON

OFF

ON

0-10 VDC

4-20 MA

0-5 VDC

M22705

Page 3

H7625B; H7635B,C; H7655B DUCT-MOUNT AND OUTDOOR-MOUNT HUMIDITY/TEMPERATURE SENSORS

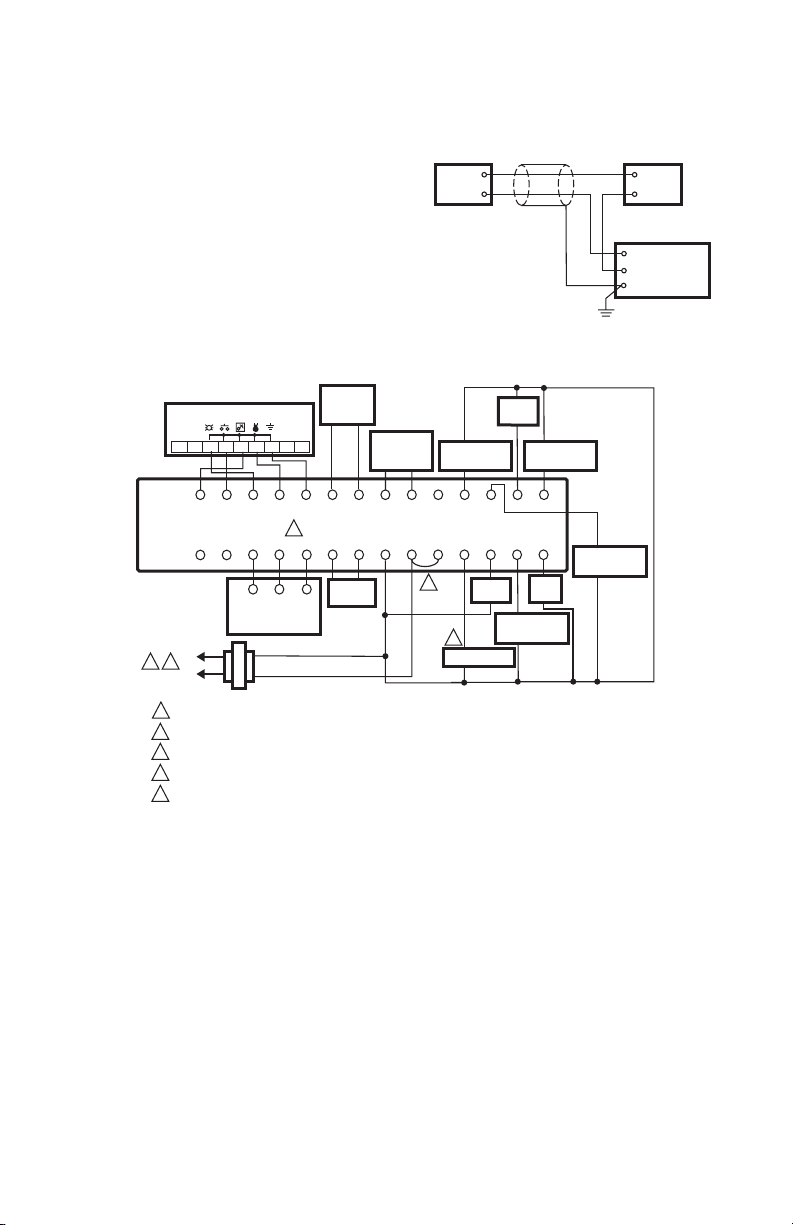

WIRING

For voltage output, shielded cable (16-22 AWG) should

be used.

For current output, either shielded cable or twisted pair

(16-22 AWG) can be used.

NOTE: When using shielded cable, ground the shield

only at the controller end (see Fig. 2). Grounding

both ends can cause a ground loop.

The 20K ohm NTC temperature output is accessed

through the separate blue and green wires (located inside

the enclosure).

OUTDOOR

5

Gnd Vin

(Vac)

AIR

SENSOR

123456789

T3

OSOS ASAS

M

MHC HP

MOTION

SENSOR

T7770 REMOTE SENSOR

T7350

SUBBASE

T5 T6 T7 T4

HS

Vo

(0-10 Vdc)

HUMIDITY SENSOR

L2

2

1

L1

(HOT)

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

ENSURE TRANSFORMER IS SIZED TO HANDLE THE LOAD.

2

3

HEAT/COOL SYSTEMS WITH ONE TRANSFORMER REQUIRE THE FACTORY-INSTALLED JUMPER.

4

USE ECONOMIZER INSTRUCTIONS FOR INSTALLATION DIRECTIONS.

5

HC AND HP PROVIDE 24 VAC TO THE HUMIDITY SENSOR.

Fig. 3. Humidity sensor (0-10 Vdc output) wiring with T7350

(use with RH/Temperature combination T7350 units only).

mA OUTPUT

TRANSDUCER

ONLY

18 TO 36 Vdc

POWER SUPPLY

Vin +

Io –

CONTROLLER, METER

OR RECORDER

INPUT SIGNAL

+

COMMON

–

GROUND

Fig. 2. Typical wiring diagram for transducer with two-

wire mA output and external DC power supply.

HEAT

RELAY 2

DISCHARGE

AIR

SENSOR

COMPRESSOR

CONTACTOR 4

W3/Y4 Y3 W2

RCX

AUXRH

3

4

ECONOMIZER

W1 G

HEAT

RELAY 1

COMPRESSOR

CONTACTOR 1

COMPRESSOR

CONTACTOR 2

Y2

Y1

FAN

RELAY

COMPRESSOR

CONTACTOR 3

M22529

M22528

3 63-2579—3

Page 4

H7625B; H7635B,C; H7655B DUCT-MOUNT AND OUTDOOR-MOUNT HUMIDITY/TEMPERATURE SENSORS

P7640

PWR

+

COM

–

O

OUT

W7760A

OUT1OUT2OUT3OUT4OUT5OUT6OUT7OUT8DI1DI2DI3DI4GND GND

P7640

PWR

+

COM

–

O

OUT

12345 6789101112 14 1615

E

GND

AI1AI

AI3AI

AI

2

GND

17 18 19 20 21 22 23 24 25 26 27 28 29

(HOT)

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

TEMPERATURE SIGNAL CONNECTIONS ARE NOT POLARITY SENSITIVE.

2

Fig. 4. Typical wiring diagram for 5-wire temperature/humidity sensor with Vdc output

(used with the XL15A controller).

Vin (Vac)

+

Gnd

–

Vo (0-10 Vdc)

O

4

GND

L1

L2

AI

H76XX

+

2

–

13

AI5AI6AI7AI

AI

GND

24

24

24

VAC

VAC

VAC24VAC24VAC24VAC24VAC

COM

COM

ANALOG

AI

OUT

8

GND

AO1AO

31 32 33 34 35 36 37 38 39 40 41 42 43

OUT

COM

AO

GND

2

21

VDC

OUT

GND E-BUS E-BUS

44

M18302B

63-2579—3 4

Page 5

H7625B; H7635B,C; H7655B DUCT-MOUNT AND OUTDOOR-MOUNT HUMIDITY/TEMPERATURE SENSORS

CHECKOUT

CAUTION

Converting Output Signal to Percent RH

Equipment Damage Hazard.

Can short electric circuitry.

• Never connect 120 Vac to the transducer.

• Connect only DC voltage to a transducer

intended for DC supply.

NOTE: Use laboratory quality meters and gauges for

applications requiring a high degree of accuracy.

1. Verify the transducer is mounted in the correct position.

2. Verify appropriate input signal and voltage supply.

3. Verify appropriate configuration range.

Table 2. Troubleshooting.

Problem Items to Check

No reading • Verify correct supply voltage at the power terminal blocks.

Erratic readings • Verify all wires are terminated properly.

• Verify correct wiring configuration and DIP switch settings.

• Verify that terminal screws are connected tightly with all wires firmly in place.

• Ensure that there is no condensation on the board.

• Verify clean input power. In areas of high RF interference or noise, shielded cable can be

necessary to stabilize signal.

4 to 20mA Signal

signal [in mA] 4–〈〉

------------------------------------------------- p er ce n t R H=

0.16

Example: 12 mA output signal

(12 - 4)/ 0.16 = 50% RH

0 to 10 Vdc Signal

Example: 8 VDC transmitter signal output

8 Vdc/0.10 = 80% RH

5 63-2579—3

Page 6

H7625B; H7635B,C; H7655B DUCT-MOUNT AND OUTDOOR-MOUNT HUMIDITY/TEMPERATURE SENSORS

APPENDIX

RH Test and Configuration DIP Switch Settings (Table 3)

IMPORTANT

• Only adjust these switches for troubleshooting or

recalibrating the sensor. (Adjustment is not

normally necessary.)

• For normal operation, always keep DIP switch 3

in the ON position. When DIP switch 3 is off, the

RH transmitter cannot read the sensor. This

inability-to-read forces the output to never

change.

Table 3. Test/Calibration Settings (Six-Switch Block).

Setting 654321

Normal Operation (Default) — — — On — —

0% RH Output On—————

50% RH Output —On————

100% RH Output — — On — — —

Increment RH Output — — — — On —

Decrement RH Output —————On

Reset to Original Calibration — — — — On On

0% RH Output (for Testing Only)

Transmitter always outputs a signal of 4 mA or 0 Vdc. The

sensor does not affect the transmitter output.

50% RH Output (for Testing Only)

Transmitter always outputs a signal of 12 mA, 2.5 VDC, or

5 VDC. The sensor does not affect transmitter output.

100% RH Output

Transmitter always outputs a signal of 20 mA, 5 VDC, or

10 VDC. The sensor does not affect the transmitter

output. Sensor doesn’t affect the transmitter output.

Normal Operating Condition

DIP switch 3 must be set in the On position for normal

operation. All other DIP switches must be set Off.

63-2579—3 6

Page 7

H7625B; H7635B,C; H7655B DUCT-MOUNT AND OUTDOOR-MOUNT HUMIDITY/TEMPERATURE SENSORS

CALIBRATION

All transducers are factory calibrated to meet/exceed published

specifications. Field adjustment should not be necessary.

IMPORTANT

• Do not verify comparative RH with a sling

psychrometer. Too many variables exist which

induce errors into this process.

• Recalibration must be done in a controlled

environment. Relative humidity must be held

stable while making any adjustment.

• Verify the device output directly with calibrated

instrumentation and verify RH with calibrated

instrumentation. Never use a controller output.

• With correct power applied, and only a meter

connected to the transducer output, ensure that

the output is proportional to the true RH.

Using Increment/Decrement Switches

Increment RH Output

This DIP switch allows you to calibrate the sensor through

the software. The switch must be toggled from the Off to

the On position and then returned to the Off position for

an increase of 0.5% RH. This means that if your humidity

has drifted 1% lower over a certain time period, you can

toggle the Increment RH Output switch (2 times) in order

to slide the whole curve upward 1%.

Decrement RH Output

This DIP switch allows calibration in the same way as the

Increment RH. The difference is that each toggle results

in a decrease of 0.5% RH.

Using Calibration Trim Potentiometers

IMPORTANT

• Due to sensitive nature of humidity calibration,

adjusting trimmer potentiometers is not highly

recommended.

• Calibrate only in a stable humidity/temperature

chamber of laboratory grade.

Single Point Calibration

IMPORTANT

Use only one of the following two options.

OPTION 1

1. Select a controlled humidity environment between

10 and 40 percent RH. Be sure humidity is stable.

2. Adjust zero trimmer (z).

OPTION 2

1. Select a controlled humidity environment between

40 and 70 percent RH. Be sure humidity is stable.

2. Adjust span trimmer (s).

Two Point Calibration

1. Select a controlled humidity environment between

10 and 40 percent RH. Be sure humidity is stable.

2. Adjust zero trimmer (z).

3. Select a controlled humidity environment between

70 and 75 percent RH. Be sure humidity is stable.

4. Adjust span trimmer (s).

7 63-2579—3

Page 8

LonSpec™ is a trademark of Echelon® Corporation.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Scarborough, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2005 Honeywell International Inc.

63-2579—3 B.B. Rev. 01-05

Loading...

Loading...